engine NISSAN LATIO 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 2473 of 2771

PG-40

< SERVICE INFORMATION >

HARNESS

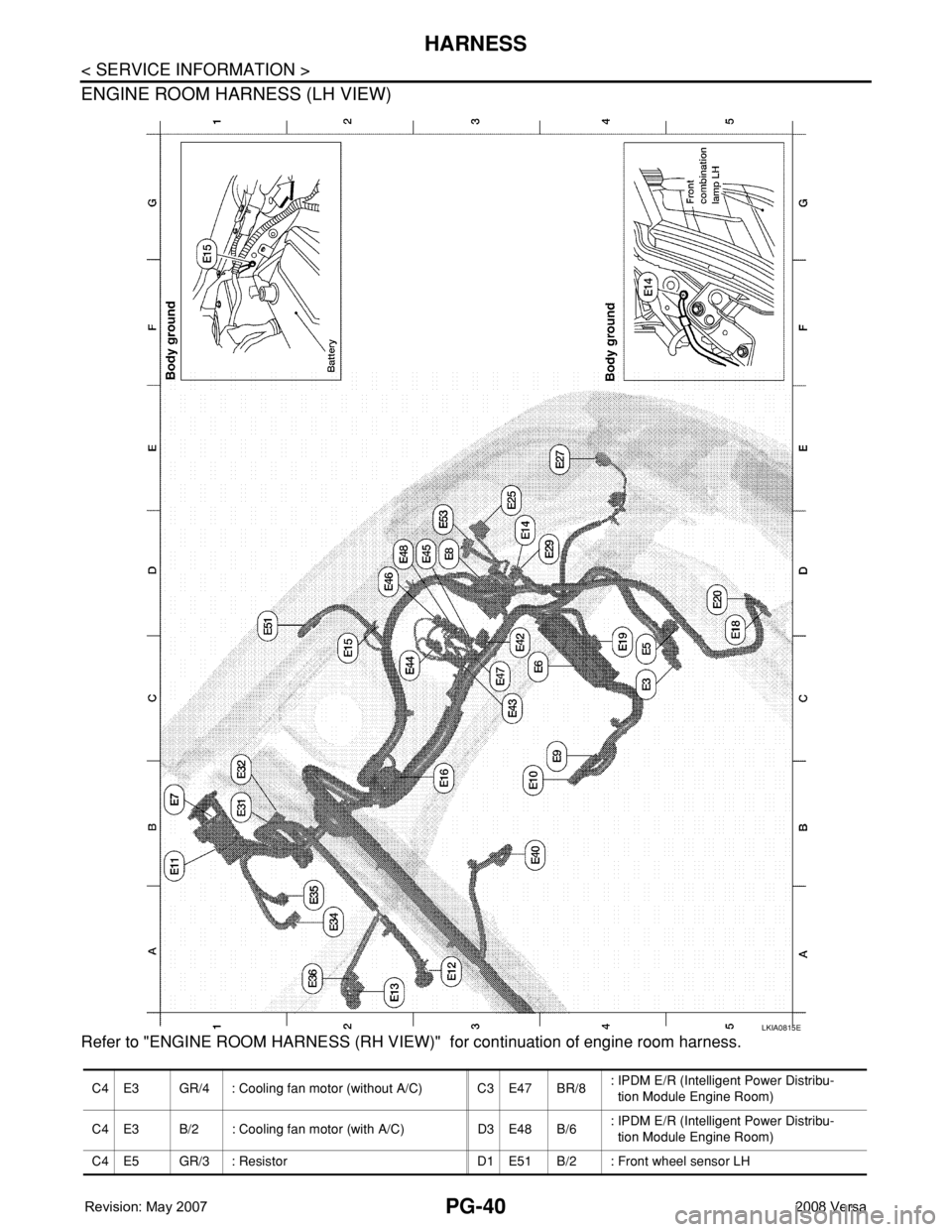

ENGINE ROOM HARNESS (LH VIEW)

Refer to "ENGINE ROOM HARNESS (RH VIEW)" for continuation of engine room harness.

LKIA0815E

C4 E3 GR/4 : Cooling fan motor (without A/C) C3 E47 BR/8: IPDM E/R (Intelligent Power Distribu-

tion Module Engine Room)

C4 E3 B/2 : Cooling fan motor (with A/C) D3 E48 B/6: IPDM E/R (Intelligent Power Distribu-

tion Module Engine Room)

C4 E5 GR/3 : Resistor D1 E51 B/2 : Front wheel sensor LH

Page 2474 of 2771

HARNESS

PG-41

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

P

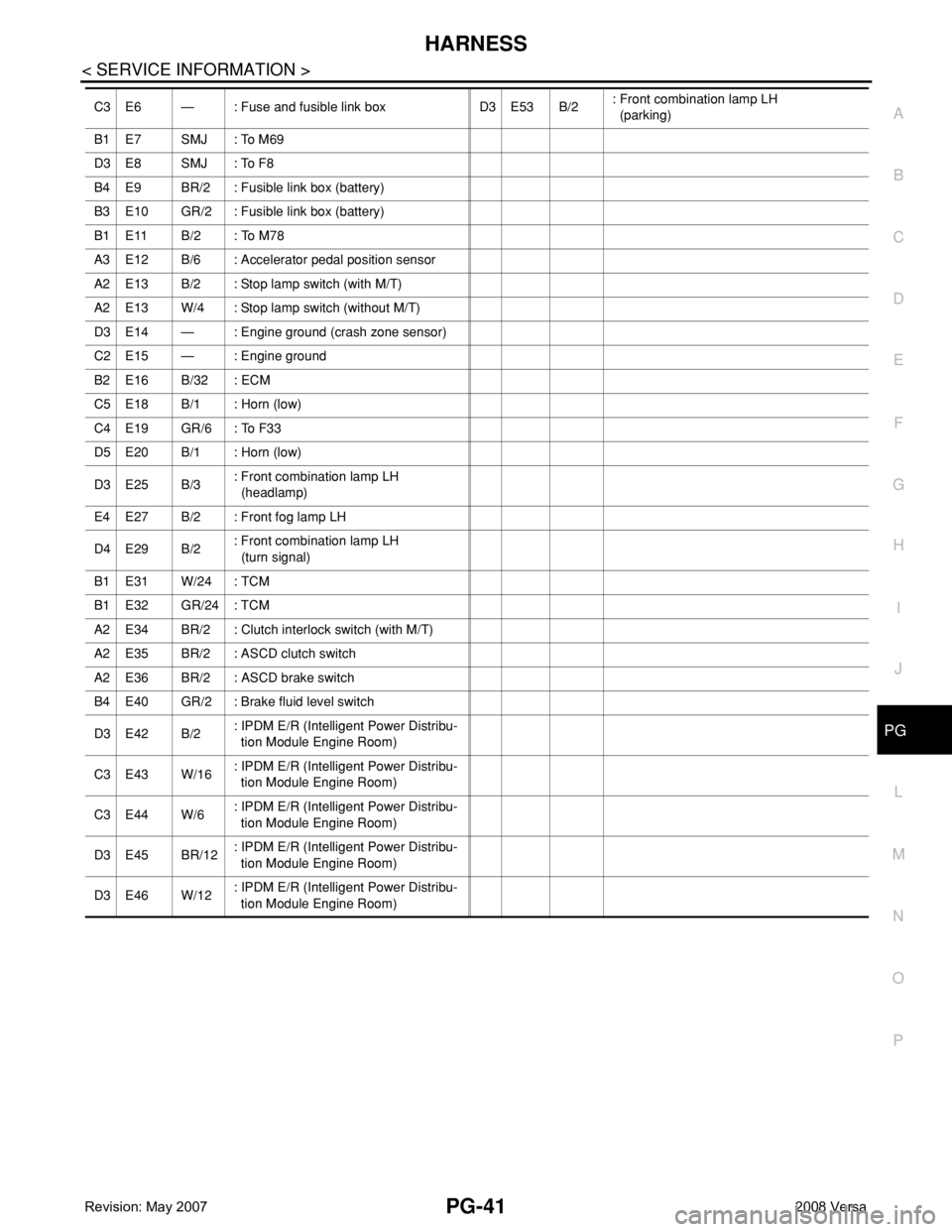

C3 E6 — : Fuse and fusible link box D3 E53 B/2: Front combination lamp LH

(parking)

B1 E7 SMJ : To M69

D3 E8 SMJ : To F8

B4 E9 BR/2 : Fusible link box (battery)

B3 E10 GR/2 : Fusible link box (battery)

B1 E11 B/2 : To M78

A3 E12 B/6 : Accelerator pedal position sensor

A2 E13 B/2 : Stop lamp switch (with M/T)

A2 E13 W/4 : Stop lamp switch (without M/T)

D3 E14 — : Engine ground (crash zone sensor)

C2 E15 — : Engine ground

B2 E16 B/32 : ECM

C5 E18 B/1 : Horn (low)

C4 E19 GR/6 : To F33

D5 E20 B/1 : Horn (low)

D3 E25 B/3: Front combination lamp LH

(headlamp)

E4 E27 B/2 : Front fog lamp LH

D4 E29 B/2: Front combination lamp LH

(turn signal)

B1 E31 W/24 : TCM

B1 E32 GR/24 : TCM

A2 E34 BR/2 : Clutch interlock switch (with M/T)

A2 E35 BR/2 : ASCD clutch switch

A2 E36 BR/2 : ASCD brake switch

B4 E40 GR/2 : Brake fluid level switch

D3 E42 B/2: IPDM E/R (Intelligent Power Distribu-

tion Module Engine Room)

C3 E43 W/16: IPDM E/R (Intelligent Power Distribu-

tion Module Engine Room)

C3 E44 W/6: IPDM E/R (Intelligent Power Distribu-

tion Module Engine Room)

D3 E45 BR/12: IPDM E/R (Intelligent Power Distribu-

tion Module Engine Room)

D3 E46 W/12: IPDM E/R (Intelligent Power Distribu-

tion Module Engine Room)

Page 2475 of 2771

PG-42

< SERVICE INFORMATION >

HARNESS

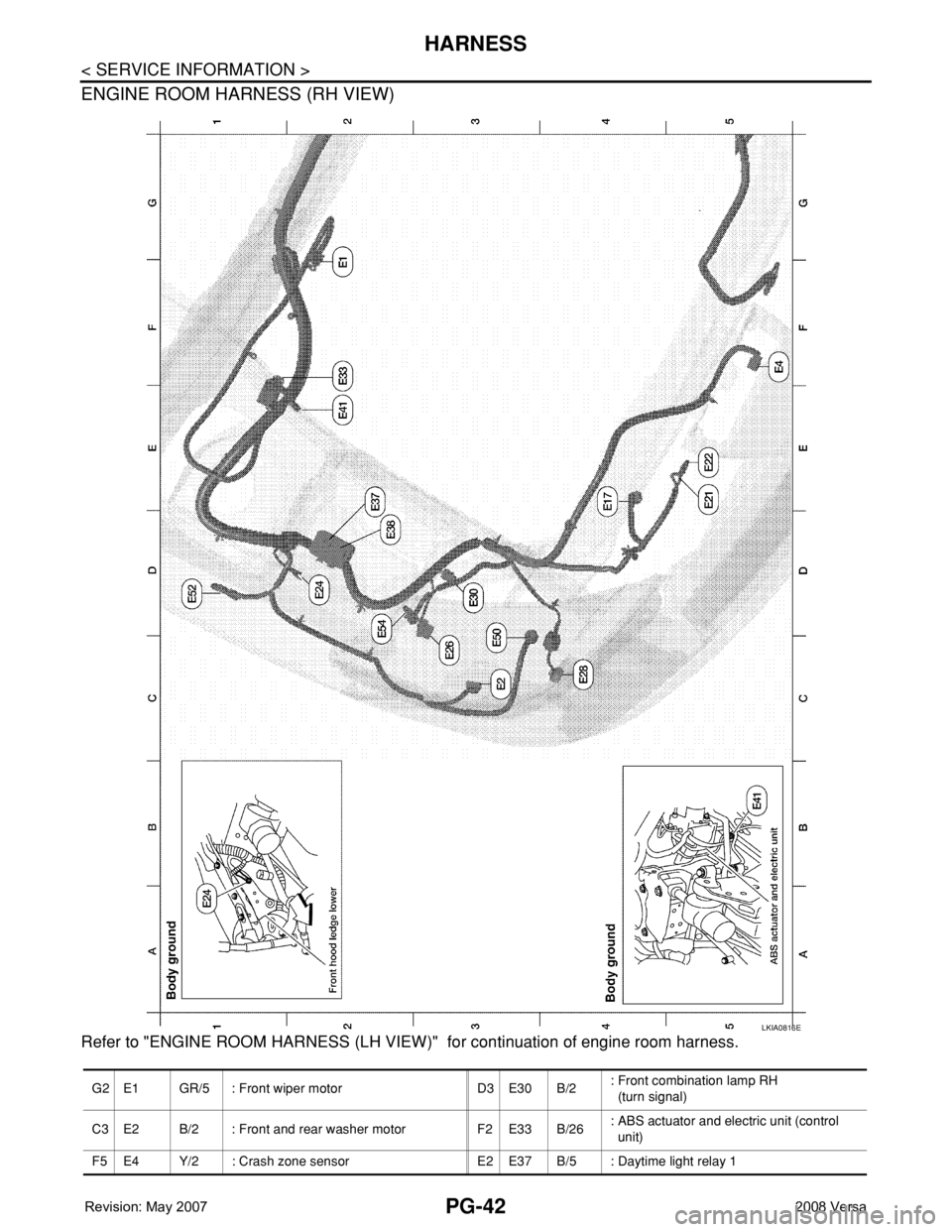

ENGINE ROOM HARNESS (RH VIEW)

Refer to "ENGINE ROOM HARNESS (LH VIEW)" for continuation of engine room harness.

LKIA0816E

G2 E1 GR/5 : Front wiper motor D3 E30 B/2: Front combination lamp RH

(turn signal)

C3 E2 B/2 : Front and rear washer motor F2 E33 B/26: ABS actuator and electric unit (control

unit)

F5 E4 Y/2 : Crash zone sensor E2 E37 B/5 : Daytime light relay 1

Page 2476 of 2771

HARNESS

PG-43

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

P

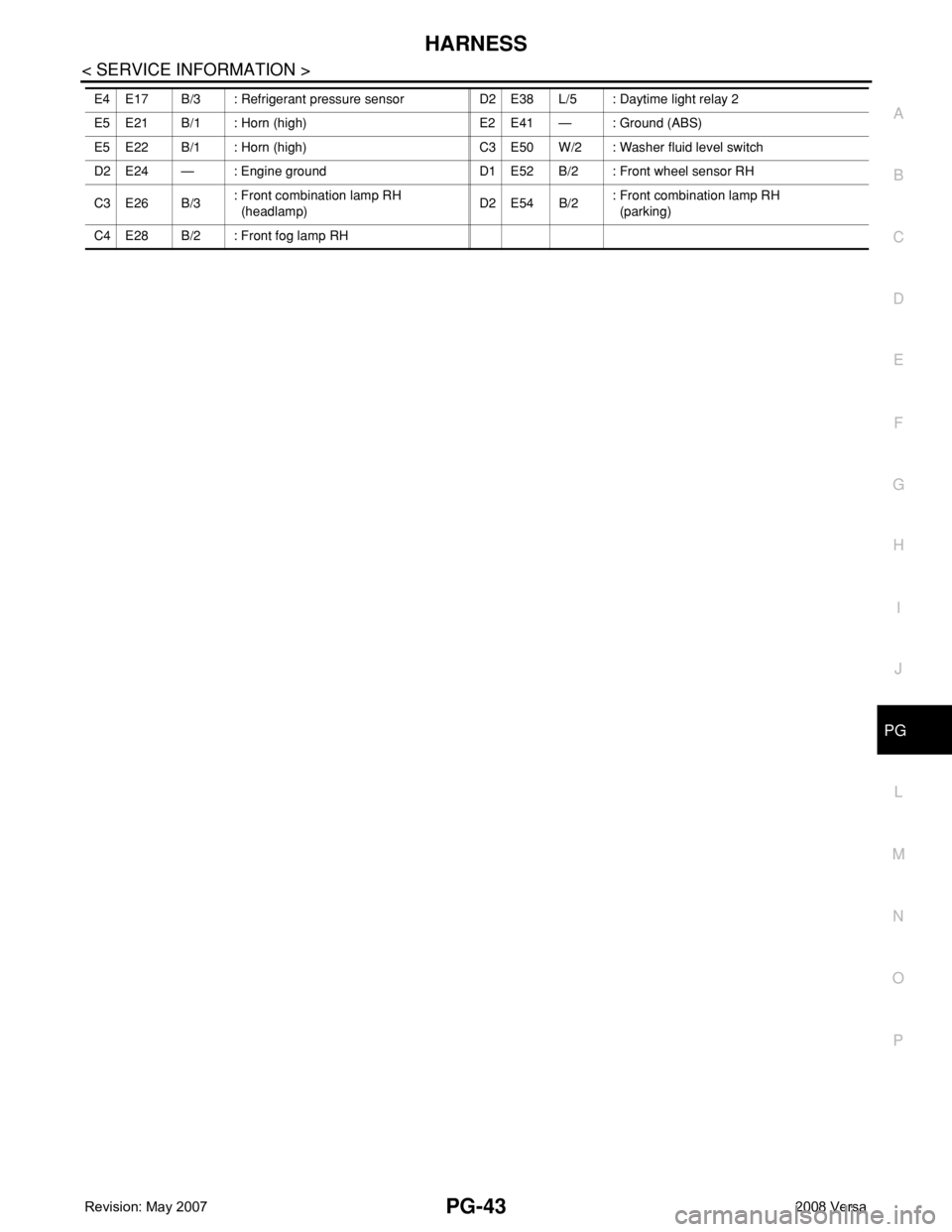

E4 E17 B/3 : Refrigerant pressure sensor D2 E38 L/5 : Daytime light relay 2

E5 E21 B/1 : Horn (high) E2 E41 — : Ground (ABS)

E5 E22 B/1 : Horn (high) C3 E50 W/2 : Washer fluid level switch

D2 E24 — : Engine ground D1 E52 B/2 : Front wheel sensor RH

C3 E26 B/3: Front combination lamp RH

(headlamp)D2 E54 B/2: Front combination lamp RH

(parking)

C4 E28 B/2 : Front fog lamp RH

Page 2477 of 2771

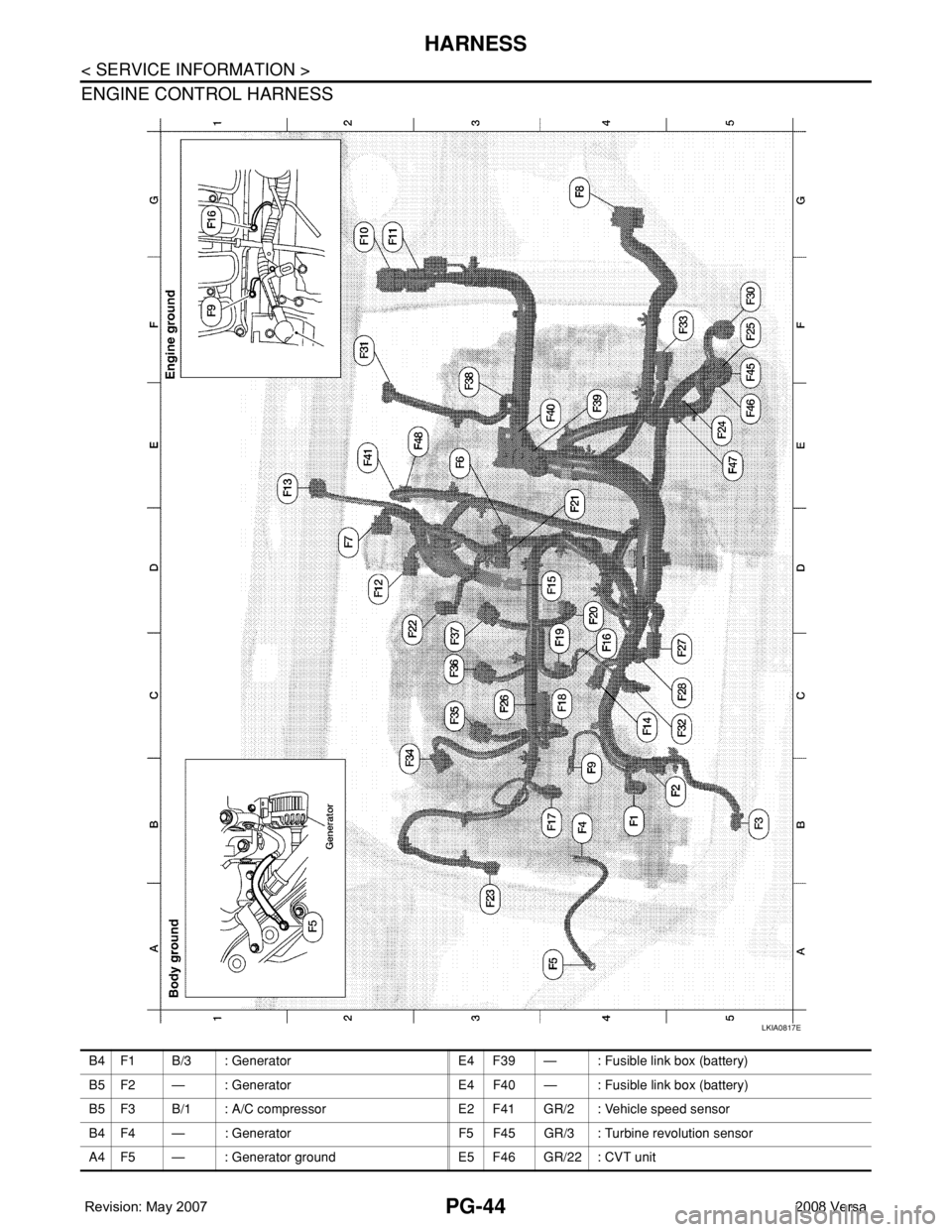

PG-44

< SERVICE INFORMATION >

HARNESS

ENGINE CONTROL HARNESS

LKIA0817E

B4 F1 B/3 : Generator E4 F39 — : Fusible link box (battery)

B5 F2 — : Generator E4 F40 — : Fusible link box (battery)

B5 F3 B/1 : A/C compressor E2 F41 GR/2 : Vehicle speed sensor

B4 F4 — : Generator F5 F45 GR/3 : Turbine revolution sensor

A4 F5 — : Generator ground E5 F46 GR/22 : CVT unit

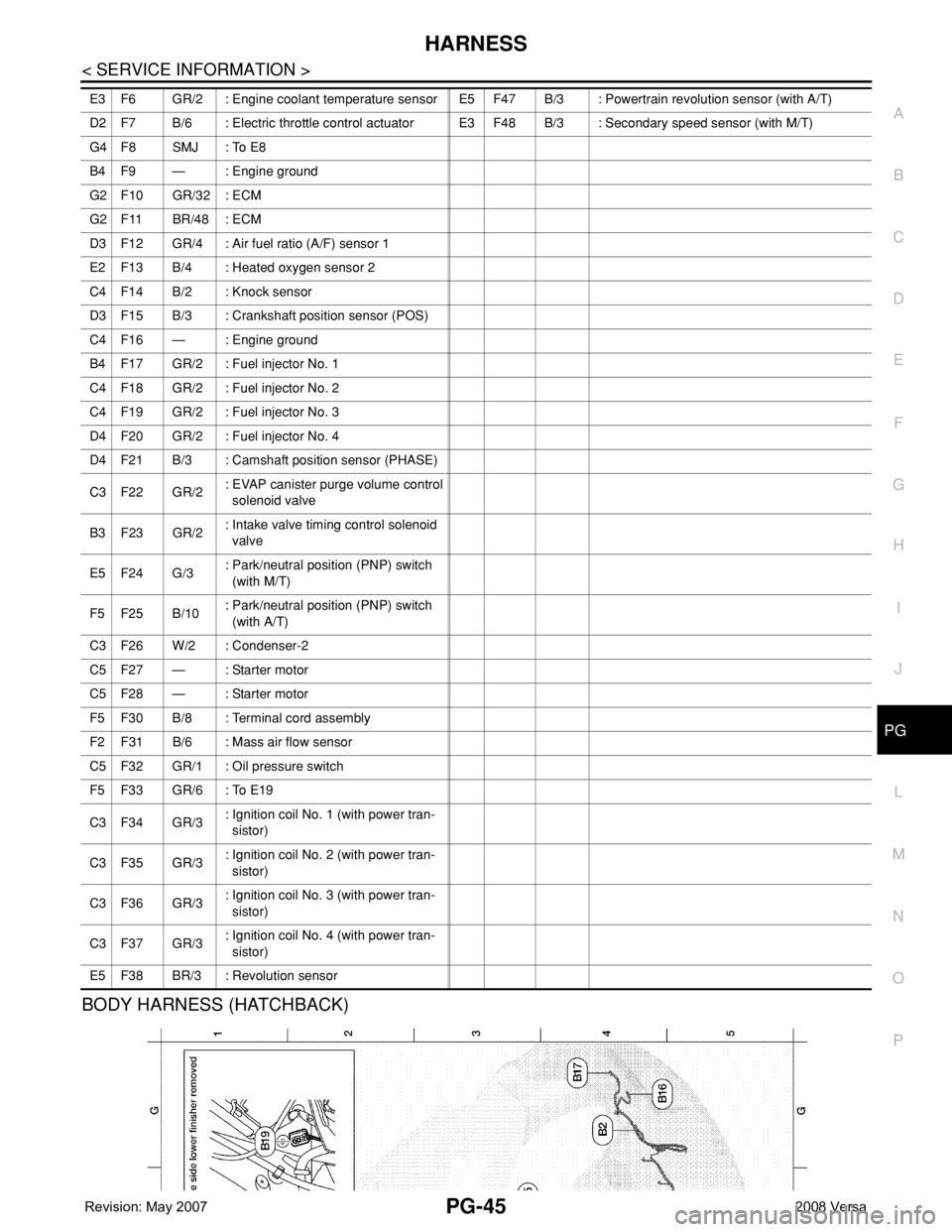

Page 2478 of 2771

HARNESS

PG-45

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

P

BODY HARNESS (HATCHBACK)

E3 F6 GR/2 : Engine coolant temperature sensor E5 F47 B/3 : Powertrain revolution sensor (with A/T)

D2 F7 B/6 : Electric throttle control actuatorE3 F48 B/3 : Secondary speed sensor (with M/T)

G4 F8 SMJ : To E8

B4 F9 — : Engine ground

G2 F10 GR/32 : ECM

G2 F11 BR/48 : ECM

D3 F12 GR/4 : Air fuel ratio (A/F) sensor 1

E2 F13 B/4 : Heated oxygen sensor 2

C4 F14 B/2 : Knock sensor

D3 F15 B/3 : Crankshaft position sensor (POS)

C4 F16 — : Engine ground

B4 F17 GR/2 : Fuel injector No. 1

C4 F18 GR/2 : Fuel injector No. 2

C4 F19 GR/2 : Fuel injector No. 3

D4 F20 GR/2 : Fuel injector No. 4

D4 F21 B/3 : Camshaft position sensor (PHASE)

C3 F22 GR/2: EVAP canister purge volume control

solenoid valve

B3 F23 GR/2: Intake valve timing control solenoid

valve

E5 F24 G/3: Park/neutral position (PNP) switch

(with M/T)

F5 F25 B/10: Park/neutral position (PNP) switch

(with A/T)

C3 F26 W/2 : Condenser-2

C5 F27 — : Starter motor

C5 F28 — : Starter motor

F5 F30 B/8 : Terminal cord assembly

F2 F31 B/6 : Mass air flow sensor

C5 F32 GR/1 : Oil pressure switch

F5 F33 GR/6 : To E19

C3 F34 GR/3: Ignition coil No. 1 (with power tran-

sistor)

C3 F35 GR/3: Ignition coil No. 2 (with power tran-

sistor)

C3 F36 GR/3: Ignition coil No. 3 (with power tran-

sistor)

C3 F37 GR/3: Ignition coil No. 4 (with power tran-

sistor)

E5 F38 BR/3 : Revolution sensor

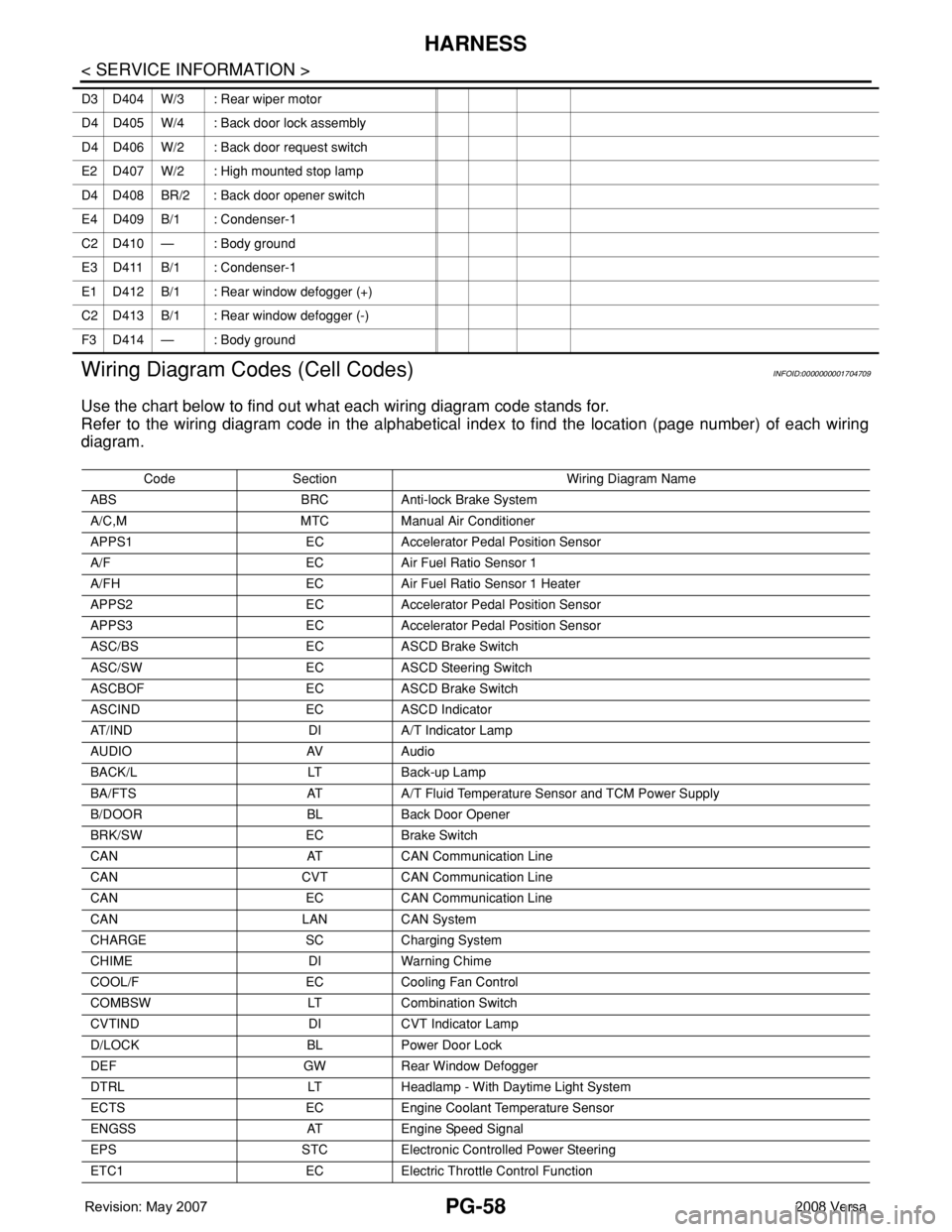

Page 2491 of 2771

PG-58

< SERVICE INFORMATION >

HARNESS

Wiring Diagram Codes (Cell Codes)

INFOID:0000000001704709

Use the chart below to find out what each wiring diagram code stands for.

Refer to the wiring diagram code in the alphabetical index to find the location (page number) of each wiring

diagram.

D3 D404 W/3 : Rear wiper motor

D4 D405 W/4 : Back door lock assembly

D4 D406 W/2 : Back door request switch

E2 D407 W/2 : High mounted stop lamp

D4 D408 BR/2 : Back door opener switch

E4 D409 B/1 : Condenser-1

C2 D410 — : Body ground

E3 D411 B/1 : Condenser-1

E1 D412 B/1 : Rear window defogger (+)

C2 D413 B/1 : Rear window defogger (-)

F3 D414 — : Body ground

Code Section Wiring Diagram Name

ABS BRC Anti-lock Brake System

A/C,M MTC Manual Air Conditioner

APPS1 EC Accelerator Pedal Position Sensor

A/F EC Air Fuel Ratio Sensor 1

A/FH EC Air Fuel Ratio Sensor 1 Heater

APPS2 EC Accelerator Pedal Position Sensor

APPS3 EC Accelerator Pedal Position Sensor

ASC/BS EC ASCD Brake Switch

ASC/SW EC ASCD Steering Switch

ASCBOF EC ASCD Brake Switch

ASCIND EC ASCD Indicator

AT/IND DI A/T Indicator Lamp

AUDIO AV Audio

BACK/L LT Back-up Lamp

BA/FTS AT A/T Fluid Temperature Sensor and TCM Power Supply

B/DOOR BL Back Door Opener

BRK/SW EC Brake Switch

CAN AT CAN Communication Line

CAN CVT CAN Communication Line

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

COOL/F EC Cooling Fan Control

COMBSW LT Combination Switch

CVTIND DI CVT Indicator Lamp

D/LOCK BL Power Door Lock

DEF GW Rear Window Defogger

DTRL LT Headlamp - With Daytime Light System

ECTS EC Engine Coolant Temperature Sensor

ENGSS AT Engine Speed Signal

EPS STC Electronic Controlled Power Steering

ETC1 EC Electric Throttle Control Function

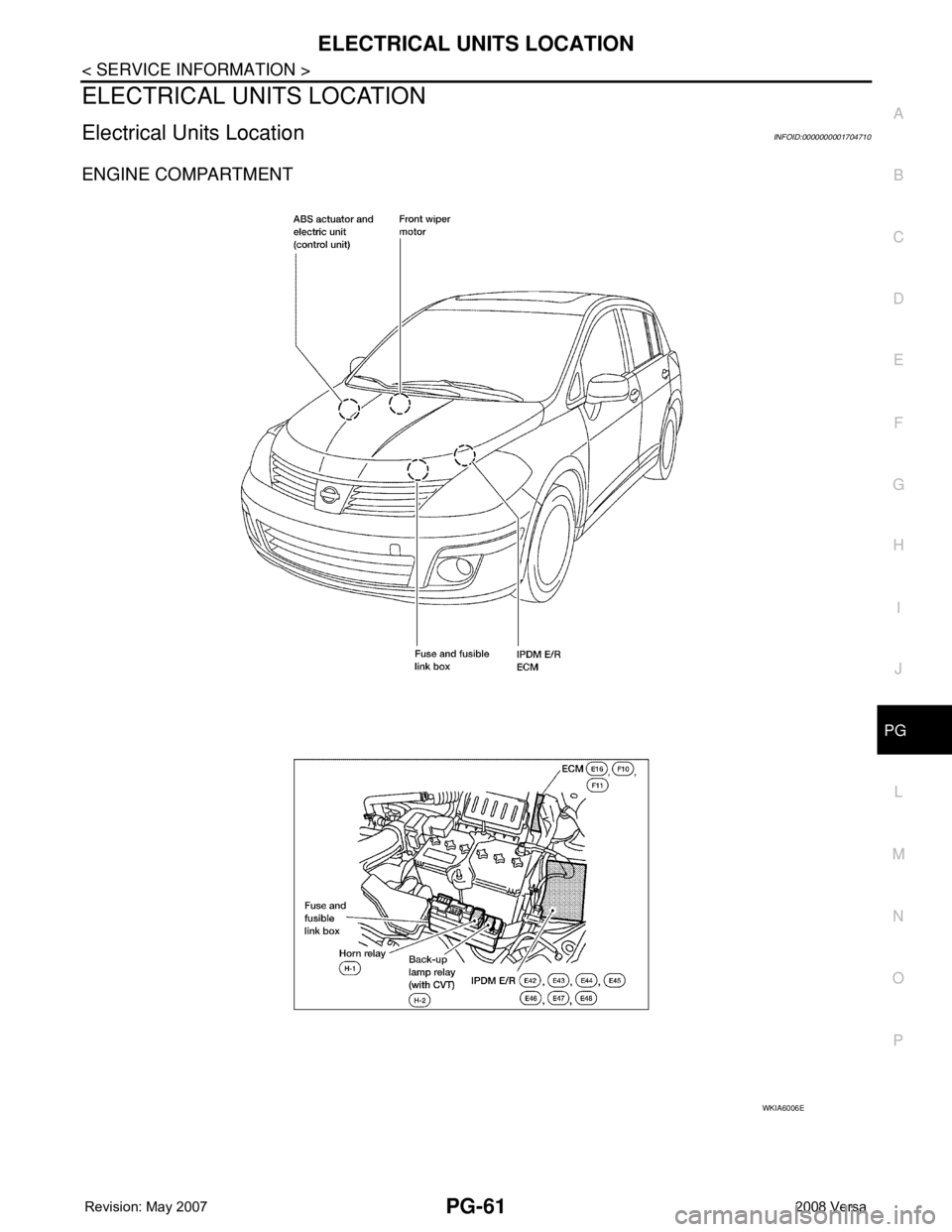

Page 2494 of 2771

ELECTRICAL UNITS LOCATION

PG-61

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

P

ELECTRICAL UNITS LOCATION

Electrical Units LocationINFOID:0000000001704710

ENGINE COMPARTMENT

WKIA6006E

Page 2512 of 2771

PS-6

< SERVICE INFORMATION >

STEERING WHEEL

STEERING WHEEL

On-Vehicle Inspection and ServiceINFOID:0000000001703859

CHECKING CONDITION OF INSTALLATION

• Check installation conditions of steering gear assembly, front suspension assembly, axle and steering col-

umn assembly.

• Check if movement exists when steering wheel is moved up and down, to the left and right and to the axial

direction.

• Check steering gear assembly mounting bolts and nuts for looseness. Refer to PS-12, "

Removal and Instal-

lation" .

CHECKING STEERING WHEEL PLAY

• Turn steering wheel so that front wheels come to the straight-ahead position. Start engine and lightly turn

steering wheel to the left and right until front wheels start to move. Measure steering wheel movement on the

outer circumference.

• When the measurement value is outside the standard value, check backlash for each joint of steering col-

umn assembly and installation condition of steering gear assembly.

CHECKING NEUTRAL POSITION STEERING WHEEL

• Make sure that steering gear assembly, steering column assembly and steering wheel are installed in the

correct position.

• Perform neutral position inspection after wheel alignment. Refer to RSU-2, "

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"" .

• Set vehicle to the straight-ahead position and confirm steering wheel is in the neutral position.

• Loosen outer socket lock nut and turn inner socket to left and right equally to make fine adjustments if steer-

ing wheel is not in the neutral position.

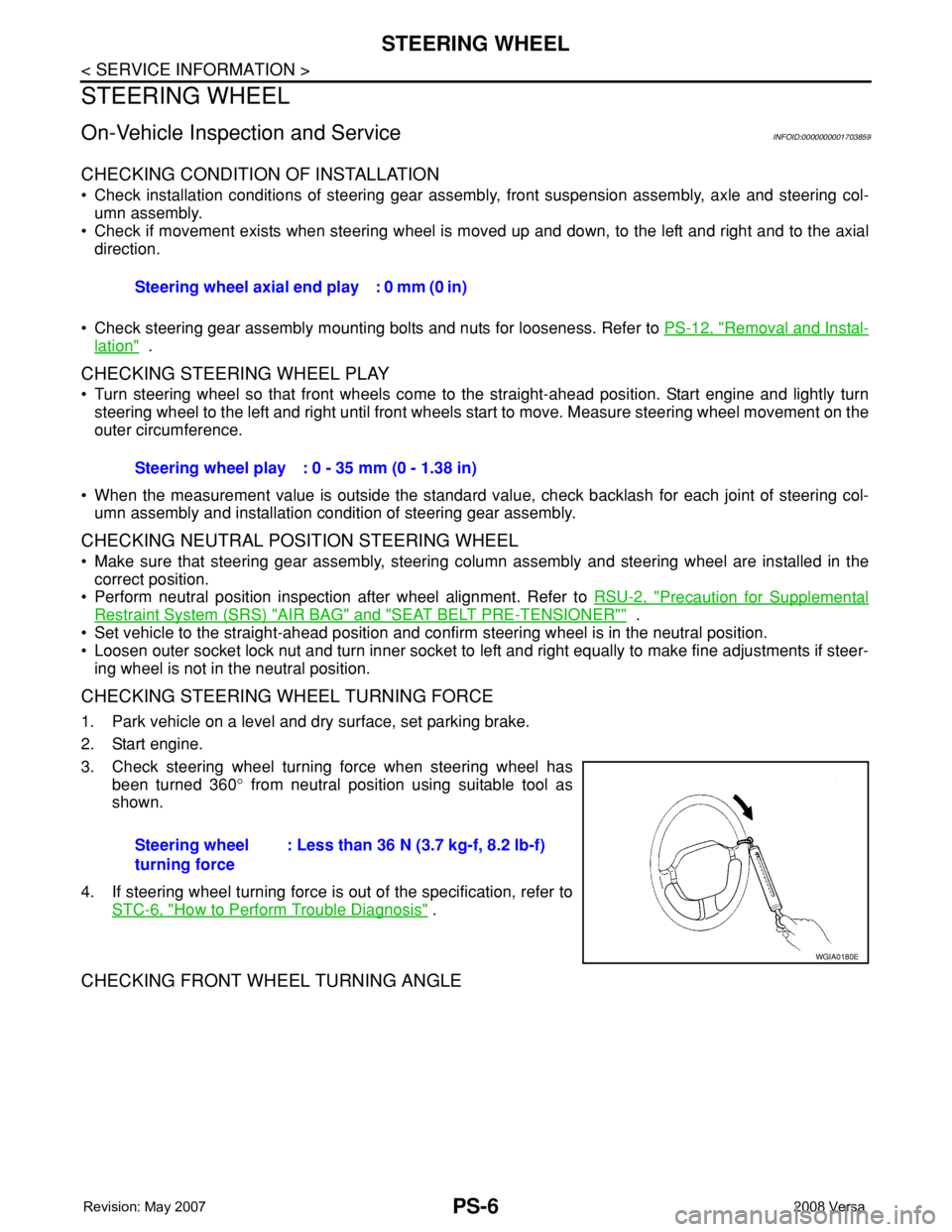

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level and dry surface, set parking brake.

2. Start engine.

3. Check steering wheel turning force when steering wheel has

been turned 360° from neutral position using suitable tool as

shown.

4. If steering wheel turning force is out of the specification, refer to

STC-6, "

How to Perform Trouble Diagnosis" .

CHECKING FRONT WHEEL TURNING ANGLE

Steering wheel axial end play : 0 mm (0 in)

Steering wheel play : 0 - 35 mm (0 - 1.38 in)

Steering wheel

turning force: Less than 36 N (3.7 kg-f, 8.2 lb-f)

WGIA0180E

Page 2513 of 2771

STEERING WHEEL

PS-7

< SERVICE INFORMATION >

C

D

E

F

H

I

J

K

L

MA

B

PS

N

O

P

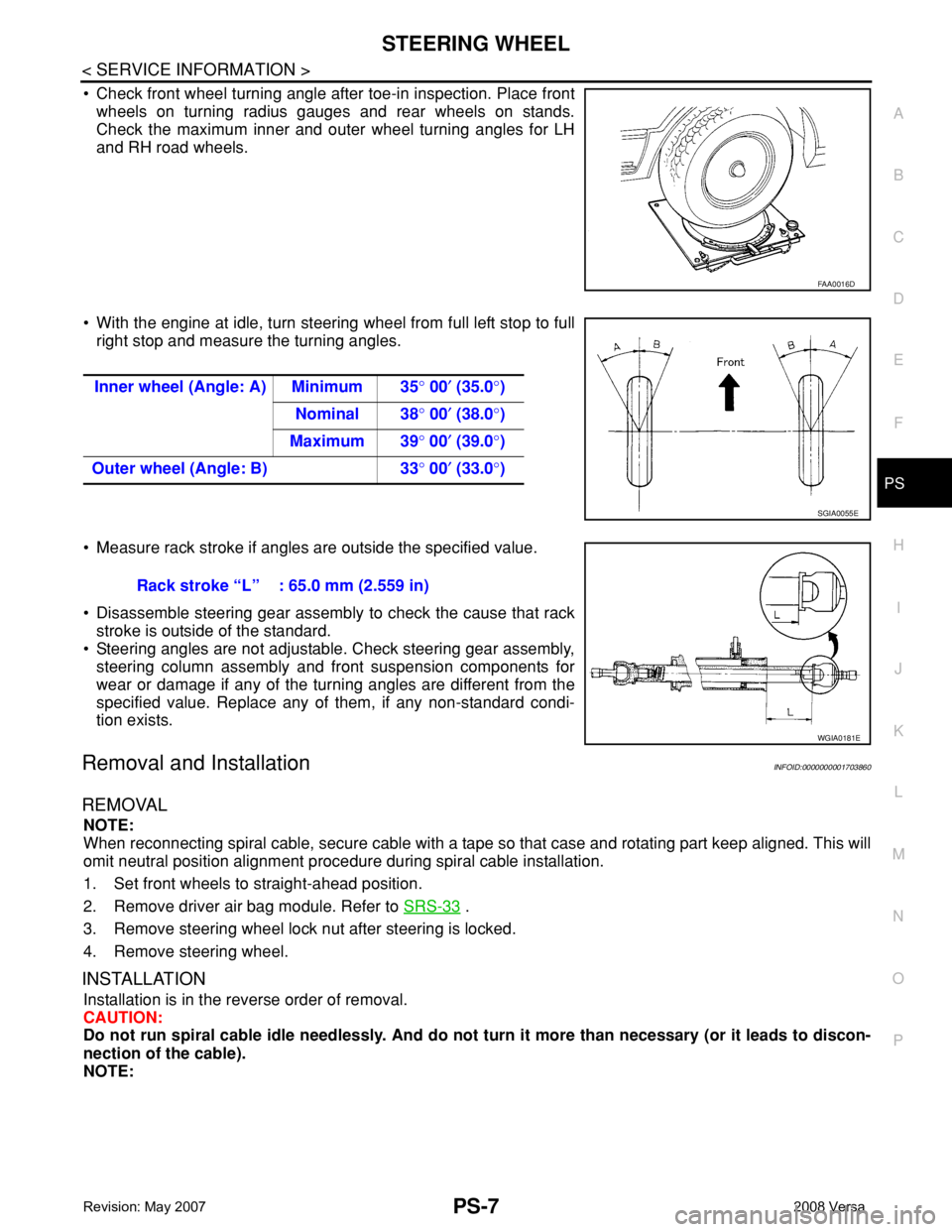

• Check front wheel turning angle after toe-in inspection. Place front

wheels on turning radius gauges and rear wheels on stands.

Check the maximum inner and outer wheel turning angles for LH

and RH road wheels.

• With the engine at idle, turn steering wheel from full left stop to full

right stop and measure the turning angles.

• Measure rack stroke if angles are outside the specified value.

• Disassemble steering gear assembly to check the cause that rack

stroke is outside of the standard.

• Steering angles are not adjustable. Check steering gear assembly,

steering column assembly and front suspension components for

wear or damage if any of the turning angles are different from the

specified value. Replace any of them, if any non-standard condi-

tion exists.

Removal and InstallationINFOID:0000000001703860

REMOVAL

NOTE:

When reconnecting spiral cable, secure cable with a tape so that case and rotating part keep aligned. This will

omit neutral position alignment procedure during spiral cable installation.

1. Set front wheels to straight-ahead position.

2. Remove driver air bag module. Refer to SRS-33

.

3. Remove steering wheel lock nut after steering is locked.

4. Remove steering wheel.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Do not run spiral cable idle needlessly. And do not turn it more than necessary (or it leads to discon-

nection of the cable).

NOTE:

FAA0016D

Inner wheel (Angle: A) Minimum 35° 00′ (35.0°)

Nominal 38° 00′ (38.0°)

Maximum 39° 00′ (39.0°)

Outer wheel (Angle: B) 33° 00′ (33.0°)

SGIA0055E

Rack stroke “L” : 65.0 mm (2.559 in)

WGIA0181E