engine NISSAN LATIO 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 2454 of 2771

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-21

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

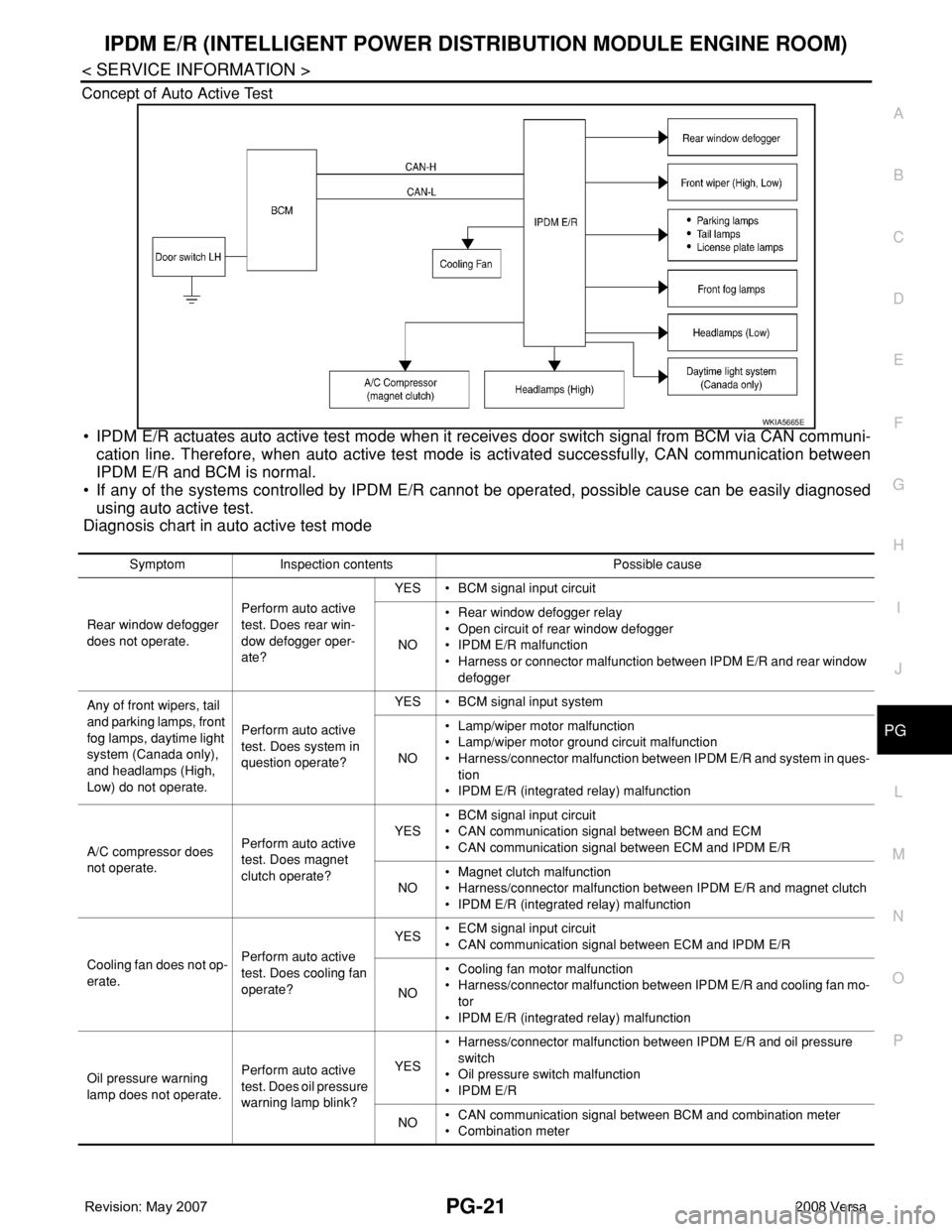

P Concept of Auto Active Test

• IPDM E/R actuates auto active test mode when it receives door switch signal from BCM via CAN communi-

cation line. Therefore, when auto active test mode is activated successfully, CAN communication between

IPDM E/R and BCM is normal.

• If any of the systems controlled by IPDM E/R cannot be operated, possible cause can be easily diagnosed

using auto active test.

Diagnosis chart in auto active test mode

WKIA5665E

Symptom Inspection contents Possible cause

Rear window defogger

does not operate.Perform auto active

test. Does rear win-

dow defogger oper-

ate?YES • BCM signal input circuit

NO• Rear window defogger relay

• Open circuit of rear window defogger

• IPDM E/R malfunction

• Harness or connector malfunction between IPDM E/R and rear window

defogger

Any of front wipers, tail

and parking lamps, front

fog lamps, daytime light

system (Canada only),

and headlamps (High,

Low) do not operate.Perform auto active

test. Does system in

question operate?YES • BCM signal input system

NO• Lamp/wiper motor malfunction

• Lamp/wiper motor ground circuit malfunction

• Harness/connector malfunction between IPDM E/R and system in ques-

tion

• IPDM E/R (integrated relay) malfunction

A/C compressor does

not operate.Perform auto active

test. Does magnet

clutch operate?YES• BCM signal input circuit

• CAN communication signal between BCM and ECM

• CAN communication signal between ECM and IPDM E/R

NO• Magnet clutch malfunction

• Harness/connector malfunction between IPDM E/R and magnet clutch

• IPDM E/R (integrated relay) malfunction

Cooling fan does not op-

erate.Perform auto active

test. Does cooling fan

operate?YES• ECM signal input circuit

• CAN communication signal between ECM and IPDM E/R

NO• Cooling fan motor malfunction

• Harness/connector malfunction between IPDM E/R and cooling fan mo-

tor

• IPDM E/R (integrated relay) malfunction

Oil pressure warning

lamp does not operate.Perform auto active

test. Does oil pressure

warning lamp blink?YES• Harness/connector malfunction between IPDM E/R and oil pressure

switch

• Oil pressure switch malfunction

• IPDM E/R

NO• CAN communication signal between BCM and combination meter

• Combination meter

Page 2455 of 2771

PG-22

< SERVICE INFORMATION >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

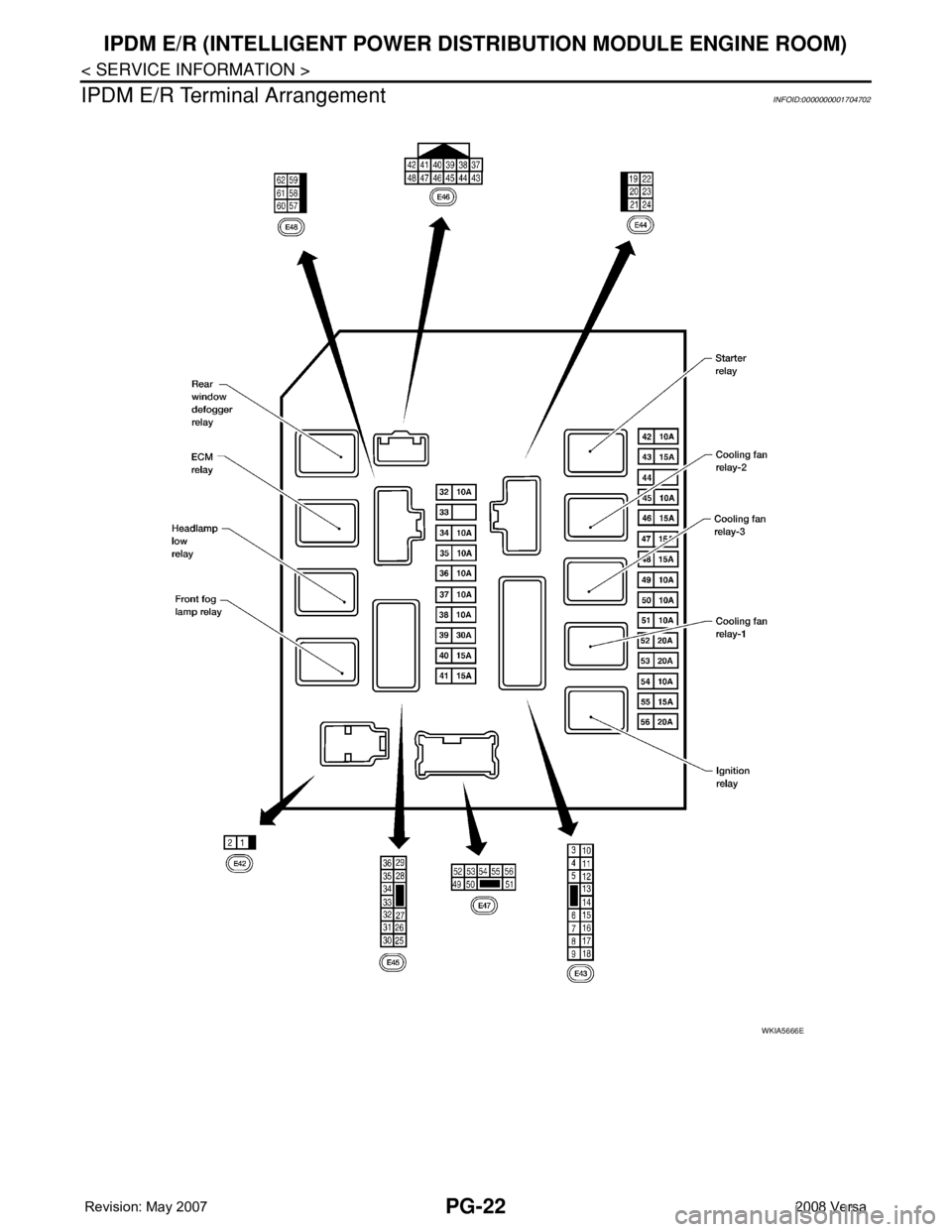

IPDM E/R Terminal Arrangement

INFOID:0000000001704702

WKIA5666E

Page 2456 of 2771

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-23

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

P

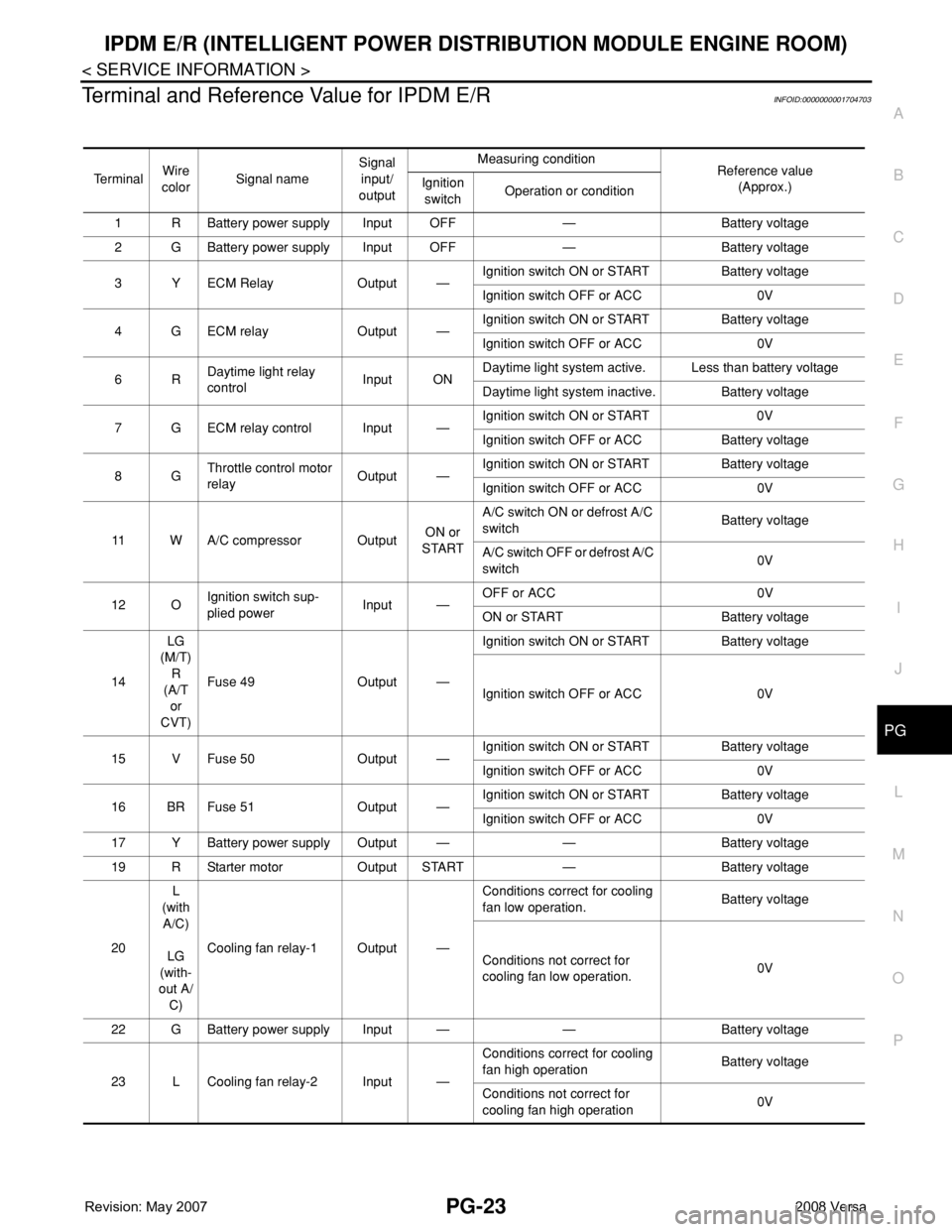

Terminal and Reference Value for IPDM E/RINFOID:0000000001704703

Te r m i n a lWire

colorSignal nameSignal

input/

outputMeasuring condition

Reference value

(Approx.) Ignition

switchOperation or condition

1 R Battery power supply Input OFF — Battery voltage

2 G Battery power supply Input OFF — Battery voltage

3YECM Relay Output—Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

4GECM relay Output—Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

6RDaytime light relay

controlInput ON Daytime light system active. Less than battery voltage

Daytime light system inactive. Battery voltage

7 G ECM relay control Input —Ignition switch ON or START 0V

Ignition switch OFF or ACC Battery voltage

8GThrottle control motor

relayOutput —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

11 W A/C compressor OutputON or

STARTA/C switch ON or defrost A/C

switchBattery voltage

A/C switch OFF or defrost A/C

switch0V

12 OIgnition switch sup-

plied powerInput —OFF or ACC 0V

ON or START Battery voltage

14LG

(M/T)

R

(A/T

or

CVT)Fuse 49 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

15 V Fuse 50 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

16 BR Fuse 51 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

17 Y Battery power supply Output — — Battery voltage

19 R Starter motor Output START — Battery voltage

20L

(with

A/C)

LG

(with-

out A/

C)Cooling fan relay-1 Output —Conditions correct for cooling

fan low operation.Battery voltage

Conditions not correct for

cooling fan low operation.0V

22 G Battery power supply Input — — Battery voltage

23 L Cooling fan relay-2 Input —Conditions correct for cooling

fan high operationBattery voltage

Conditions not correct for

cooling fan high operation0V

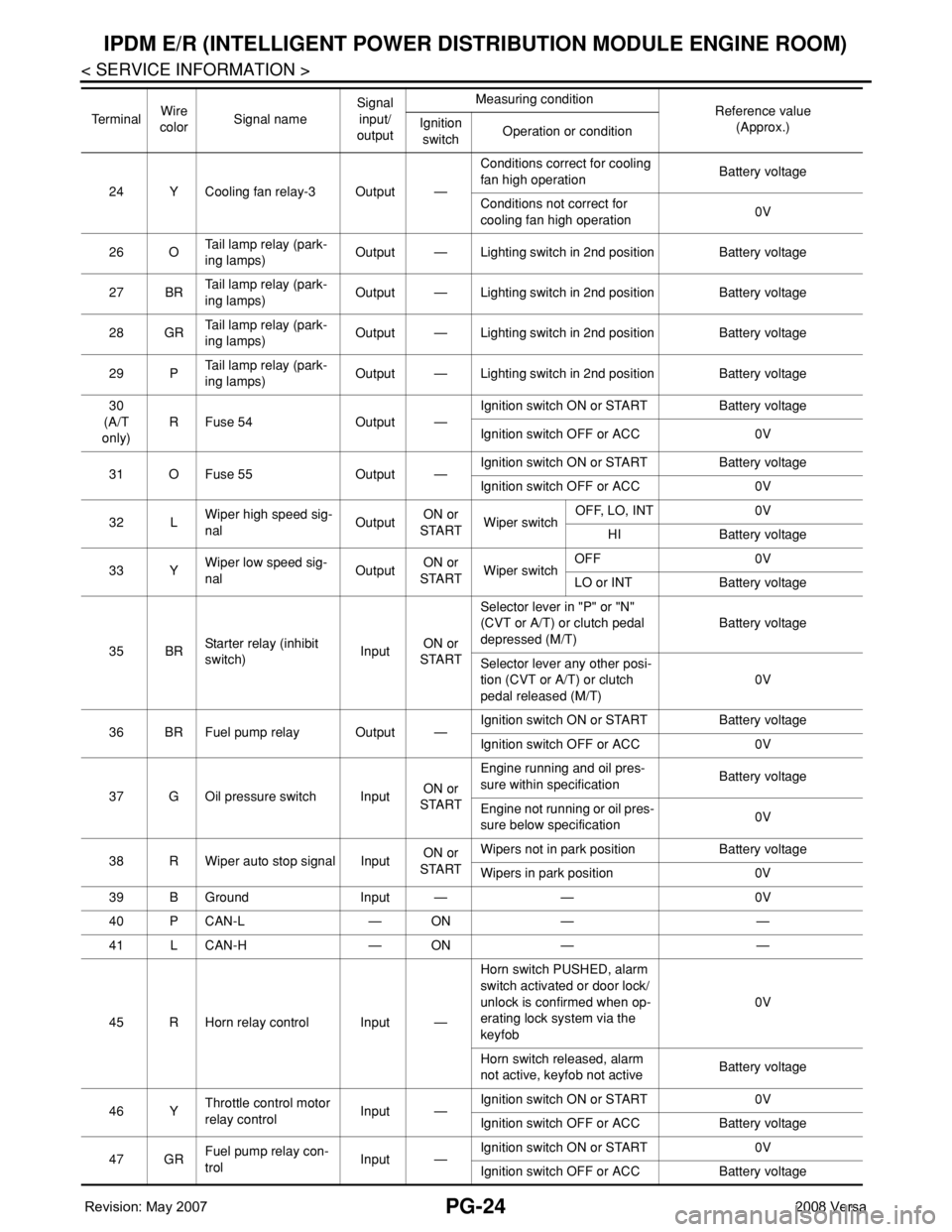

Page 2457 of 2771

PG-24

< SERVICE INFORMATION >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

24 Y Cooling fan relay-3 Output —Conditions correct for cooling

fan high operationBattery voltage

Conditions not correct for

cooling fan high operation0V

26 OTail lamp relay (park-

ing lamps)Output — Lighting switch in 2nd position Battery voltage

27 BRTail lamp relay (park-

ing lamps)Output — Lighting switch in 2nd position Battery voltage

28 GRTail lamp relay (park-

ing lamps)Output — Lighting switch in 2nd position Battery voltage

29 PTail lamp relay (park-

ing lamps)Output — Lighting switch in 2nd position Battery voltage

30

(A/T

only)R Fuse 54 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

31 O Fuse 55 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

32 LWiper high speed sig-

nalOutputON or

STARTWiper switchOFF, LO, INT 0V

HI Battery voltage

33 YWiper low speed sig-

nalOutputON or

STARTWiper switchOFF 0V

LO or INT Battery voltage

35 BRStarter relay (inhibit

switch)InputON or

STARTSelector lever in "P" or "N"

(CVT or A/T) or clutch pedal

depressed (M/T)Battery voltage

Selector lever any other posi-

tion (CVT or A/T) or clutch

pedal released (M/T)0V

36 BR Fuel pump relay Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

37 G Oil pressure switch InputON or

STARTEngine running and oil pres-

sure within specificationBattery voltage

Engine not running or oil pres-

sure below specification0V

38 R Wiper auto stop signal InputON or

STARTWipers not in park position Battery voltage

Wipers in park position 0V

39 B Ground Input — — 0V

40 P CAN-L — ON — —

41 L CAN-H — ON — —

45 R Horn relay control Input —Horn switch PUSHED, alarm

switch activated or door lock/

unlock is confirmed when op-

erating lock system via the

keyfob0V

Horn switch released, alarm

not active, keyfob not activeBattery voltage

46 YThrottle control motor

relay controlInput —Ignition switch ON or START 0V

Ignition switch OFF or ACC Battery voltage

47 GRFuel pump relay con-

trolInput —

Ignition switch ON or START 0V

Ignition switch OFF or ACC Battery voltage Te r m i n a lWire

colorSignal nameSignal

input/

outputMeasuring condition

Reference value

(Approx.) Ignition

switchOperation or condition

Page 2458 of 2771

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-25

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

PIPDM E/R Power/Ground Circuit InspectionINFOID:0000000001704704

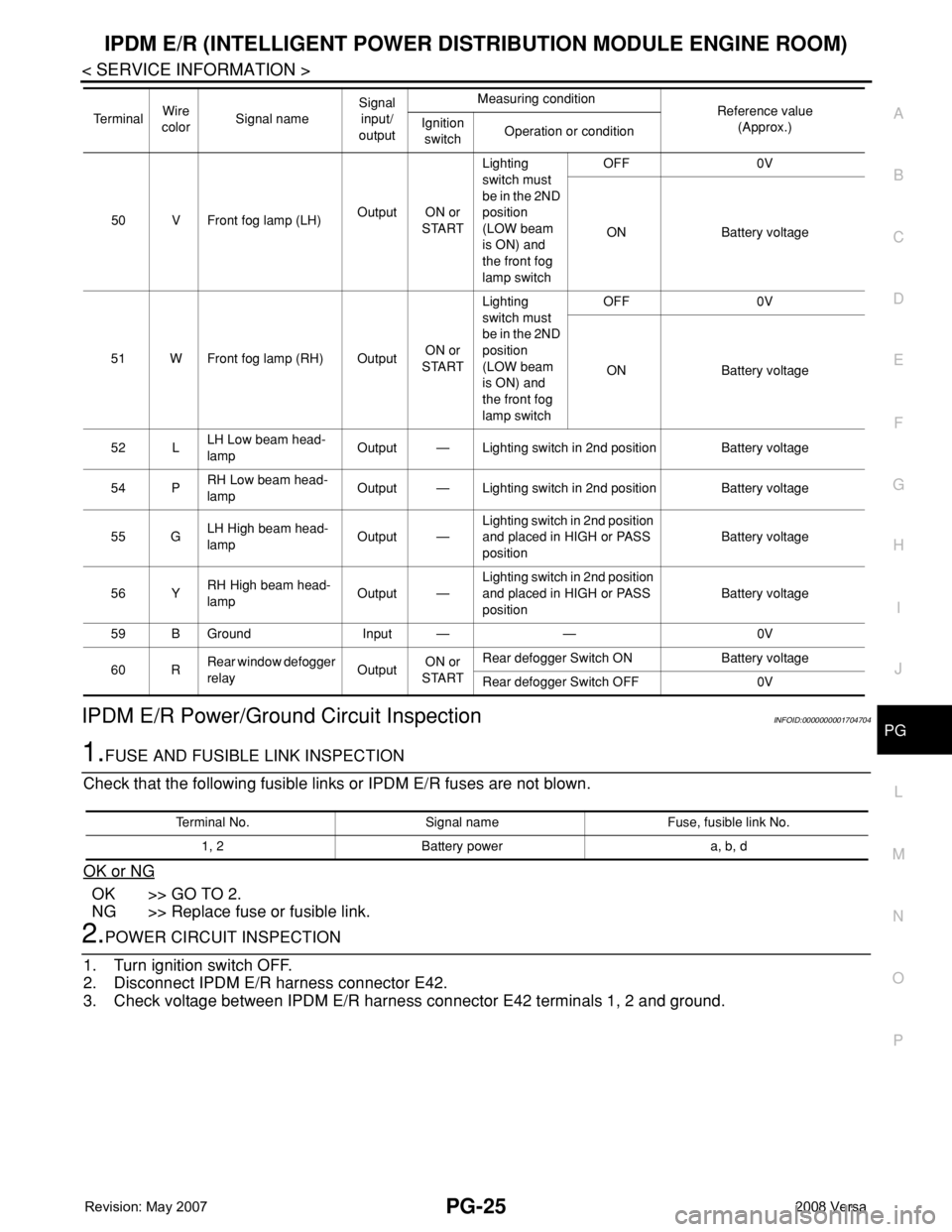

1.FUSE AND FUSIBLE LINK INSPECTION

Check that the following fusible links or IPDM E/R fuses are not blown.

OK or NG

OK >> GO TO 2.

NG >> Replace fuse or fusible link.

2.POWER CIRCUIT INSPECTION

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector E42.

3. Check voltage between IPDM E/R harness connector E42 terminals 1, 2 and ground.

50 V Front fog lamp (LH)Output ON or

STARTLighting

switch must

be in the 2ND

position

(LOW beam

is ON) and

the front fog

lamp switchOFF 0V

ON Battery voltage

51 W Front fog lamp (RH) OutputON or

STARTLighting

switch must

be in the 2ND

position

(LOW beam

is ON) and

the front fog

lamp switchOFF 0V

ON Battery voltage

52 LLH Low beam head-

lampOutput — Lighting switch in 2nd position Battery voltage

54 PRH Low beam head-

lampOutput — Lighting switch in 2nd position Battery voltage

55 GLH High beam head-

lampOutput —Lighting switch in 2nd position

and placed in HIGH or PASS

positionBattery voltage

56 YRH High beam head-

lampOutput —Lighting switch in 2nd position

and placed in HIGH or PASS

positionBattery voltage

59 B Ground Input — — 0V

60 RRear window defogger

relayOutputON or

STARTRear defogger Switch ON Battery voltage

Rear defogger Switch OFF 0V Te r m i n a lWire

colorSignal nameSignal

input/

outputMeasuring condition

Reference value

(Approx.) Ignition

switchOperation or condition

Terminal No. Signal name Fuse, fusible link No.

1, 2 Battery power a, b, d

Page 2459 of 2771

PG-26

< SERVICE INFORMATION >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

OK or NG

OK >> GO TO 3.

NG >> Repair or replace IPDM E/R power circuit harness.

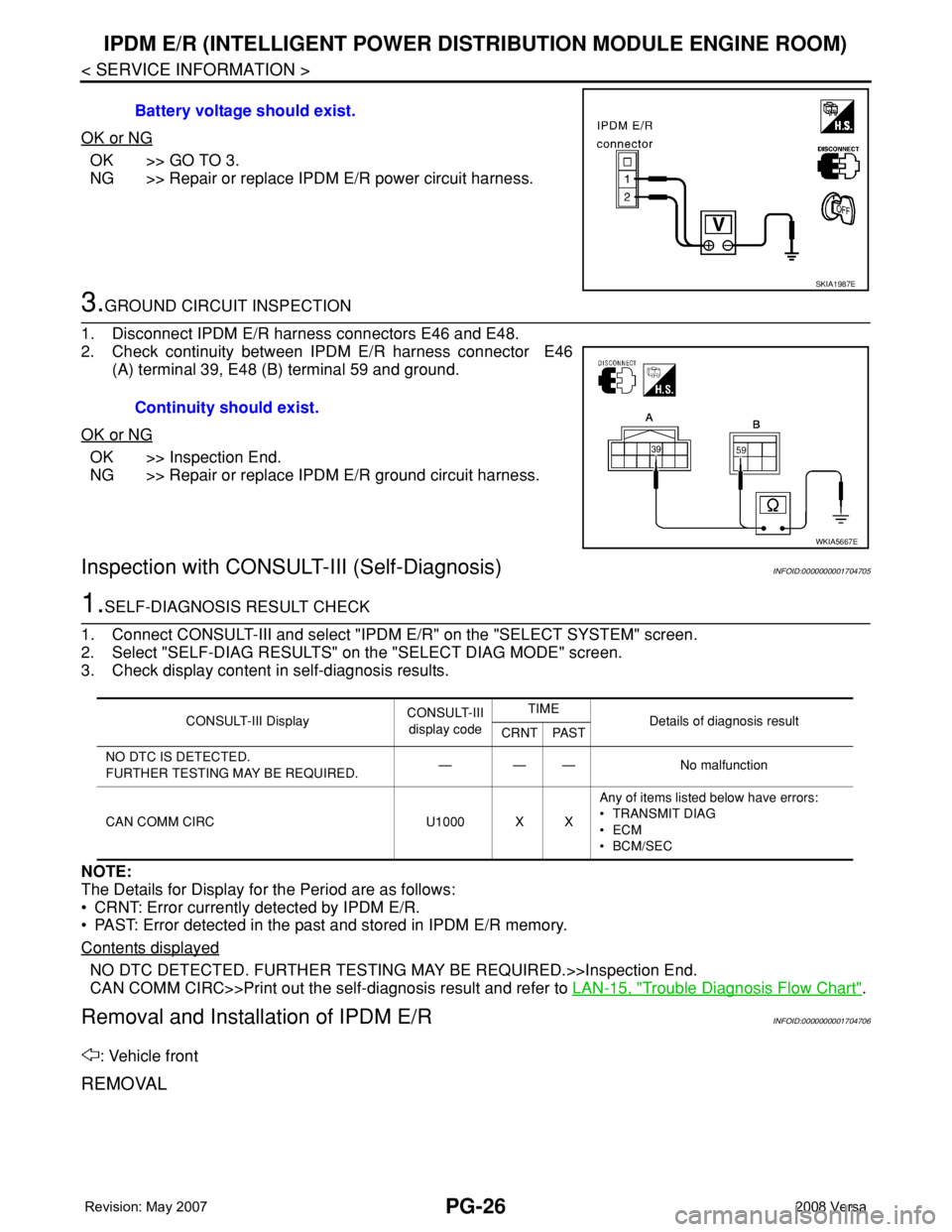

3.GROUND CIRCUIT INSPECTION

1. Disconnect IPDM E/R harness connectors E46 and E48.

2. Check continuity between IPDM E/R harness connector E46

(A) terminal 39, E48 (B) terminal 59 and ground.

OK or NG

OK >> Inspection End.

NG >> Repair or replace IPDM E/R ground circuit harness.

Inspection with CONSULT-III (Self-Diagnosis)INFOID:0000000001704705

1.SELF-DIAGNOSIS RESULT CHECK

1. Connect CONSULT-III and select "IPDM E/R" on the "SELECT SYSTEM" screen.

2. Select "SELF-DIAG RESULTS" on the "SELECT DIAG MODE" screen.

3. Check display content in self-diagnosis results.

NOTE:

The Details for Display for the Period are as follows:

• CRNT: Error currently detected by IPDM E/R.

• PAST: Error detected in the past and stored in IPDM E/R memory.

Contents displayed

NO DTC DETECTED. FURTHER TESTING MAY BE REQUIRED.>>Inspection End.

CAN COMM CIRC>>Print out the self-diagnosis result and refer to LAN-15, "

Trouble Diagnosis Flow Chart".

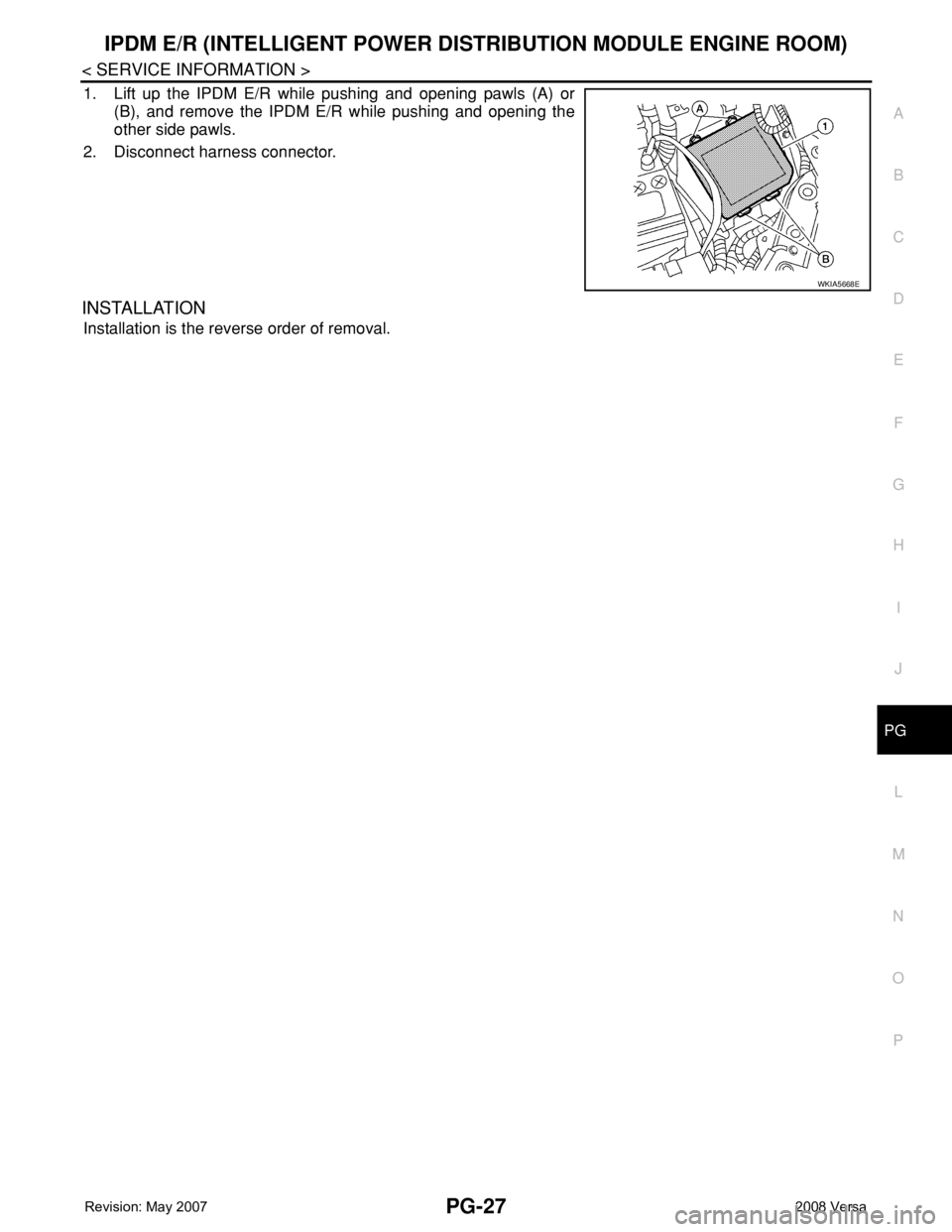

Removal and Installation of IPDM E/RINFOID:0000000001704706

: Vehicle front

REMOVAL

Battery voltage should exist.

SKIA1987E

Continuity should exist.

WKIA5667E

CONSULT-III DisplayCONSULT-III

display codeTIME

Details of diagnosis result

CRNT PAST

NO DTC IS DETECTED.

FURTHER TESTING MAY BE REQUIRED.— — — No malfunction

CAN COMM CIRC U1000 X XAny of items listed below have errors:

• TRANSMIT DIAG

•ECM

• BCM/SEC

Page 2460 of 2771

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-27

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

P

1. Lift up the IPDM E/R while pushing and opening pawls (A) or

(B), and remove the IPDM E/R while pushing and opening the

other side pawls.

2. Disconnect harness connector.

INSTALLATION

Installation is the reverse order of removal.

WKIA5668E

Page 2464 of 2771

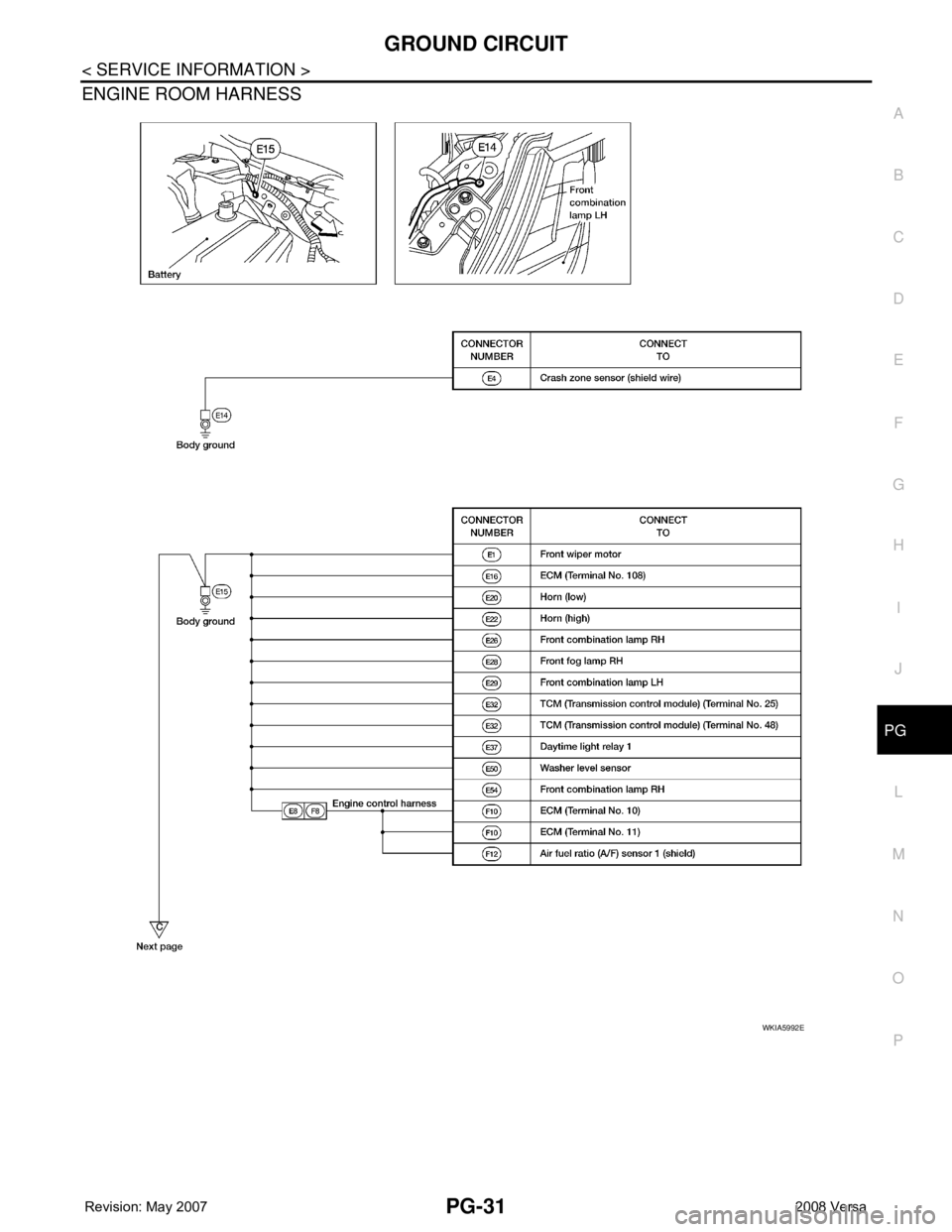

GROUND CIRCUIT

PG-31

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

P

ENGINE ROOM HARNESS

WKIA5992E

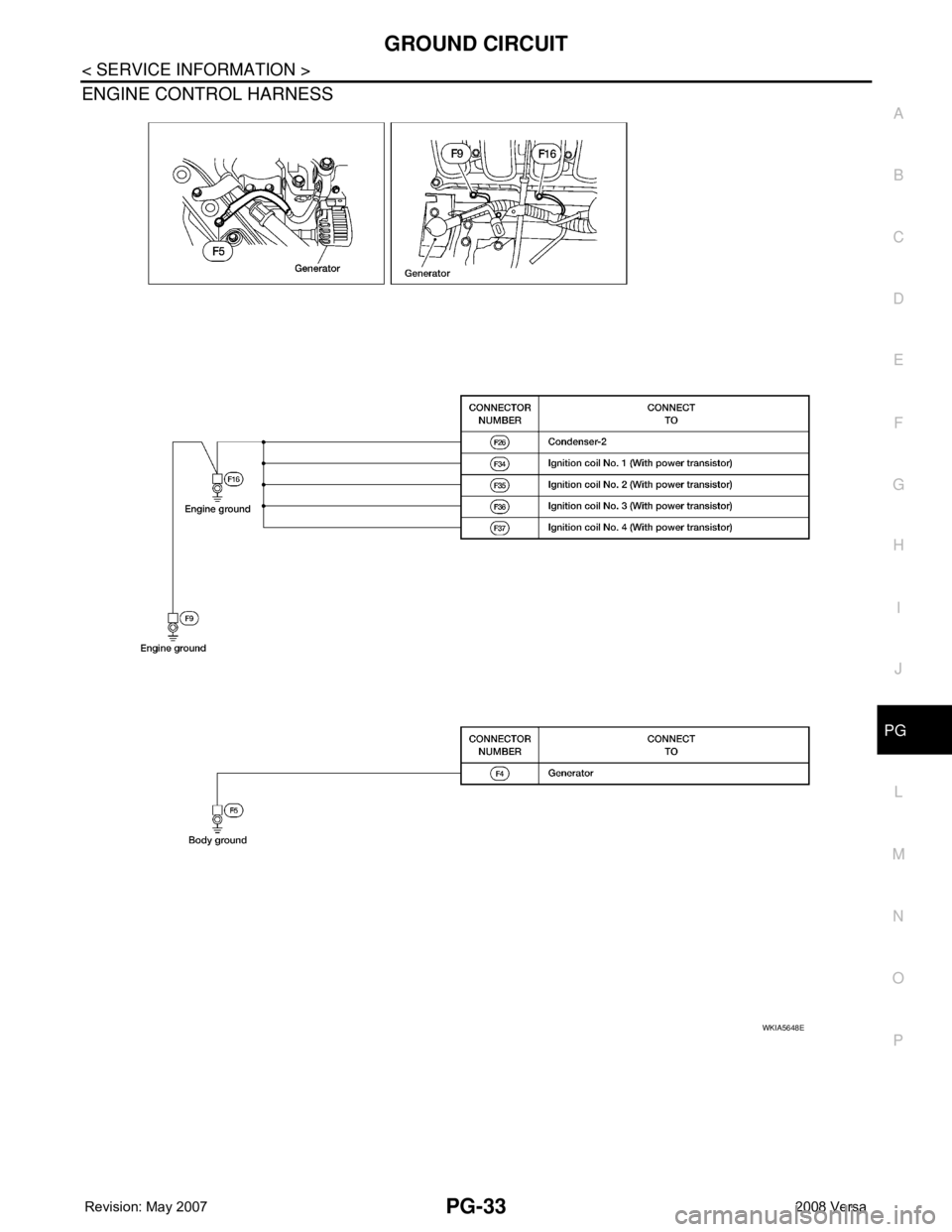

Page 2466 of 2771

GROUND CIRCUIT

PG-33

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

P

ENGINE CONTROL HARNESS

WKIA5648E

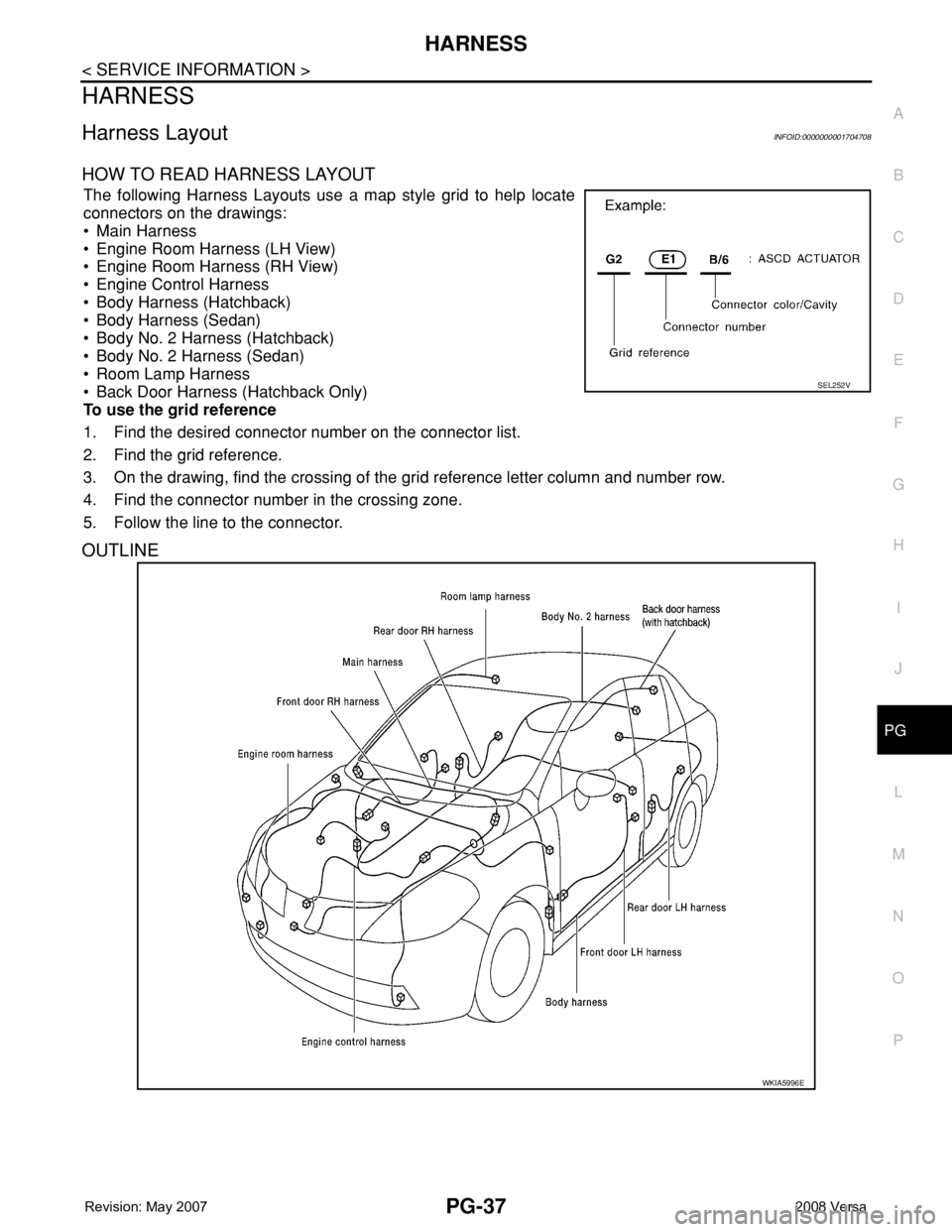

Page 2470 of 2771

HARNESS

PG-37

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

P

HARNESS

Harness LayoutINFOID:0000000001704708

HOW TO READ HARNESS LAYOUT

The following Harness Layouts use a map style grid to help locate

connectors on the drawings:

• Main Harness

• Engine Room Harness (LH View)

• Engine Room Harness (RH View)

• Engine Control Harness

• Body Harness (Hatchback)

• Body Harness (Sedan)

• Body No. 2 Harness (Hatchback)

• Body No. 2 Harness (Sedan)

• Room Lamp Harness

• Back Door Harness (Hatchback Only)

To use the grid reference

1. Find the desired connector number on the connector list.

2. Find the grid reference.

3. On the drawing, find the crossing of the grid reference letter column and number row.

4. Find the connector number in the crossing zone.

5. Follow the line to the connector.

OUTLINE

SEL252V

WKIA5996E