dimensions NISSAN LATIO 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 333 of 2771

ASSEMBLY

AT-321

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

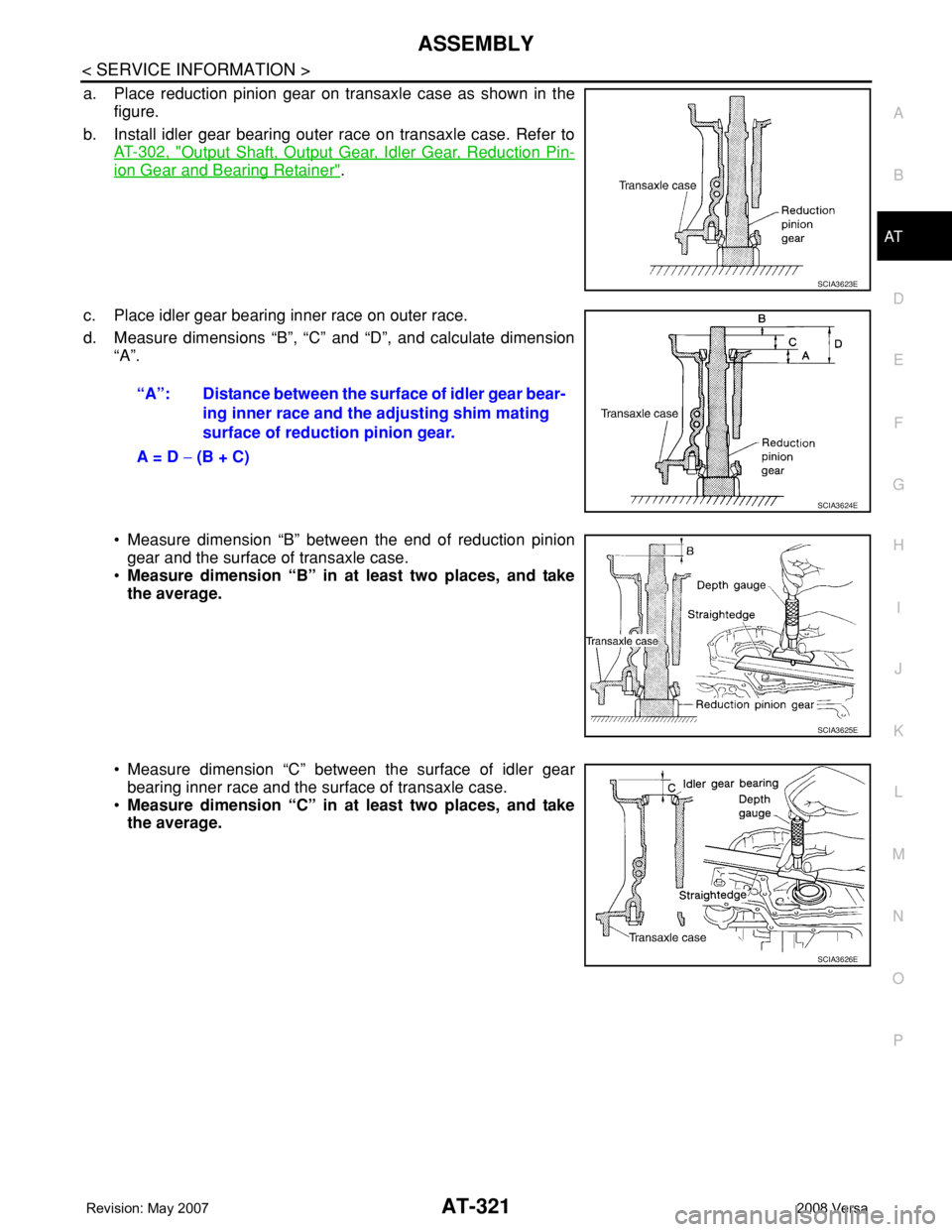

a. Place reduction pinion gear on transaxle case as shown in the

figure.

b. Install idler gear bearing outer race on transaxle case. Refer to

AT-302, "

Output Shaft, Output Gear, Idler Gear, Reduction Pin-

ion Gear and Bearing Retainer".

c. Place idler gear bearing inner race on outer race.

d. Measure dimensions “B”, “C” and “D”, and calculate dimension

“A”.

• Measure dimension “B” between the end of reduction pinion

gear and the surface of transaxle case.

•Measure dimension “B” in at least two places, and take

the average.

• Measure dimension “C” between the surface of idler gear

bearing inner race and the surface of transaxle case.

•Measure dimension “C” in at least two places, and take

the average.

SCIA3623E

“A”: Distance between the surface of idler gear bear-

ing inner race and the adjusting shim mating

surface of reduction pinion gear.

A = D − (B + C)

SCIA3624E

SCIA3625E

SCIA3626E

Page 336 of 2771

AT-324

< SERVICE INFORMATION >

ASSEMBLY

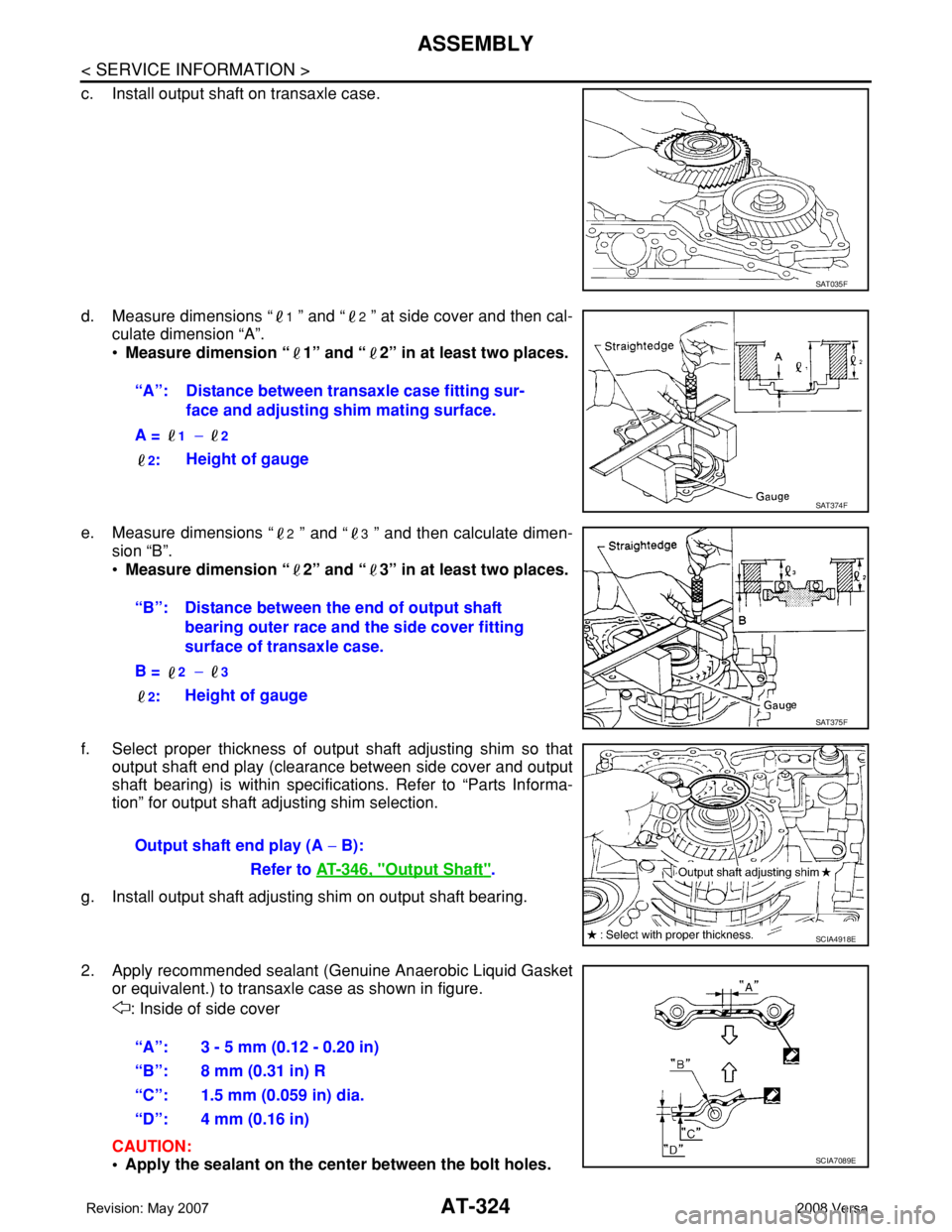

c. Install output shaft on transaxle case.

d. Measure dimensions “

1 ” and “2 ” at side cover and then cal-

culate dimension “A”.

•Measure dimension “ 1” and “ 2” in at least two places.

e. Measure dimensions “

2 ” and “3 ” and then calculate dimen-

sion “B”.

•Measure dimension “ 2” and “ 3” in at least two places.

f. Select proper thickness of output shaft adjusting shim so that

output shaft end play (clearance between side cover and output

shaft bearing) is within specifications. Refer to “Parts Informa-

tion” for output shaft adjusting shim selection.

g. Install output shaft adjusting shim on output shaft bearing.

2. Apply recommended sealant (Genuine Anaerobic Liquid Gasket

or equivalent.) to transaxle case as shown in figure.

: Inside of side cover

CAUTION:

• Apply the sealant on the center between the bolt holes.

SAT035F

“A”: Distance between transaxle case fitting sur-

face and adjusting shim mating surface.

A =

1 − 2

2

:Height of gauge

SAT374F

“B”: Distance between the end of output shaft

bearing outer race and the side cover fitting

surface of transaxle case.

B =

2 − 3

2

:Height of gauge

SAT375F

Output shaft end play (A − B):

Refer to AT-346, "

Output Shaft".

SCIA4918E

“A”: 3 - 5 mm (0.12 - 0.20 in)

“B”: 8 mm (0.31 in) R

“C”: 1.5 mm (0.059 in) dia.

“D”: 4 mm (0.16 in)

SCIA7089E

Page 342 of 2771

AT-330

< SERVICE INFORMATION >

ASSEMBLY

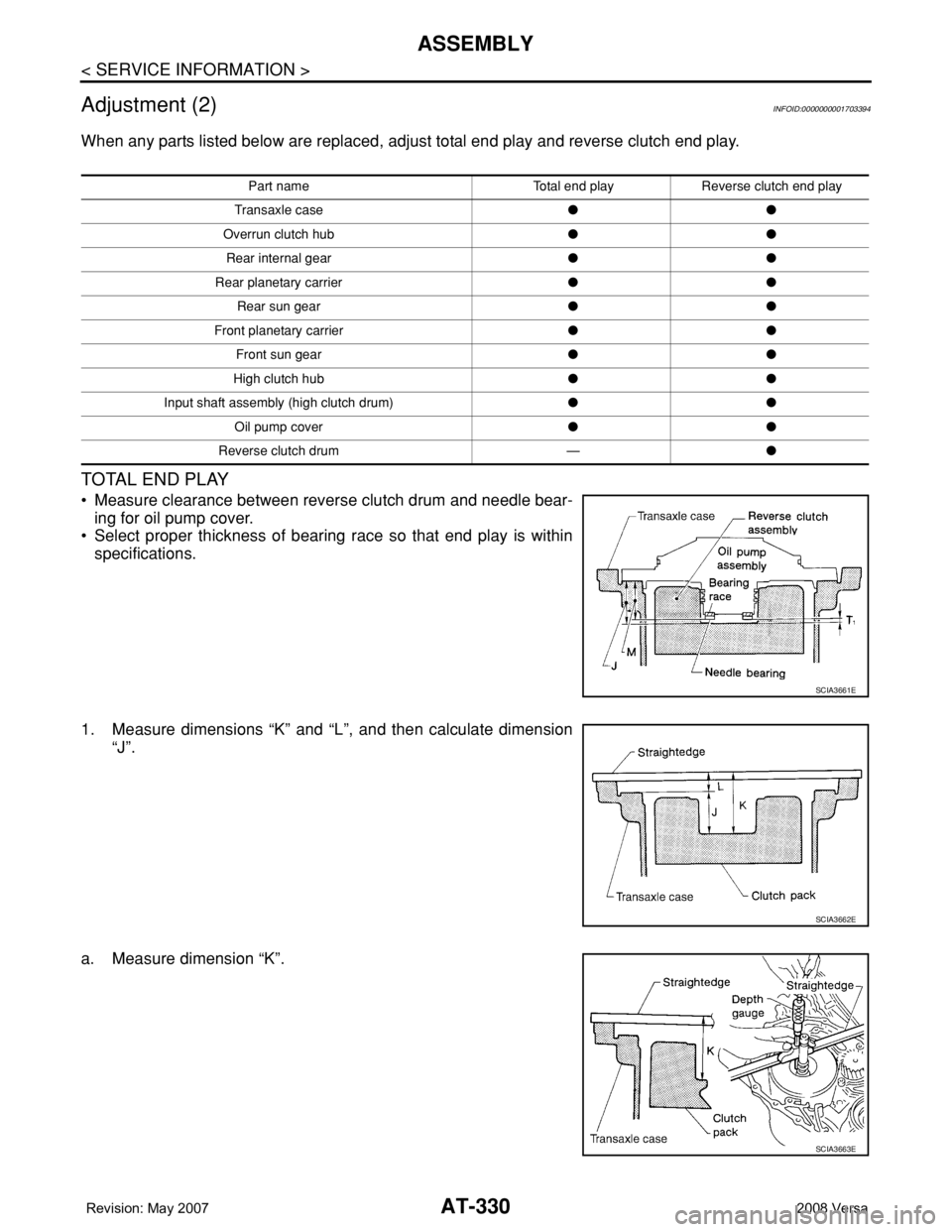

Adjustment (2)

INFOID:0000000001703394

When any parts listed below are replaced, adjust total end play and reverse clutch end play.

TOTAL END PLAY

• Measure clearance between reverse clutch drum and needle bear-

ing for oil pump cover.

• Select proper thickness of bearing race so that end play is within

specifications.

1. Measure dimensions “K” and “L”, and then calculate dimension

“J”.

a. Measure dimension “K”.

Part name Total end play Reverse clutch end play

Transaxle case●●

Overrun clutch hub●●

Rear internal gear●●

Rear planetary carrier●●

Rear sun gear●●

Front planetary carrier●●

Front sun gear●●

High clutch hub●●

Input shaft assembly (high clutch drum)●●

Oil pump cover●●

Reverse clutch drum —●

SCIA3661E

SCIA3662E

SCIA3663E

Page 344 of 2771

AT-332

< SERVICE INFORMATION >

ASSEMBLY

• Measure clearance between oil pump cover and thrust washer for

reverse clutch drum.

• Select proper thickness of thrust washer so that end play is within

specification.

1. Measure dimensions “O” and “P”, and then calculate dimension

“N”.

a. Place thrust washer on reverse clutch drum.

b. Measure dimension “O”.

c. Measure dimension “P”.

d. Calculate dimension “N”.

2. Measure dimensions “R” and “S”, and then calculate dimension

“Q”.

SCIA3665E

SCIA3666E

SCIA3667E

“N”: Distance between oil pump fitting surface of

transaxle case and thrust washer on reverse

clutch drum.

N = O – P

SCIA3668E

SAT384D

Page 682 of 2771

BL-248

< SERVICE INFORMATION >

BODY REPAIR

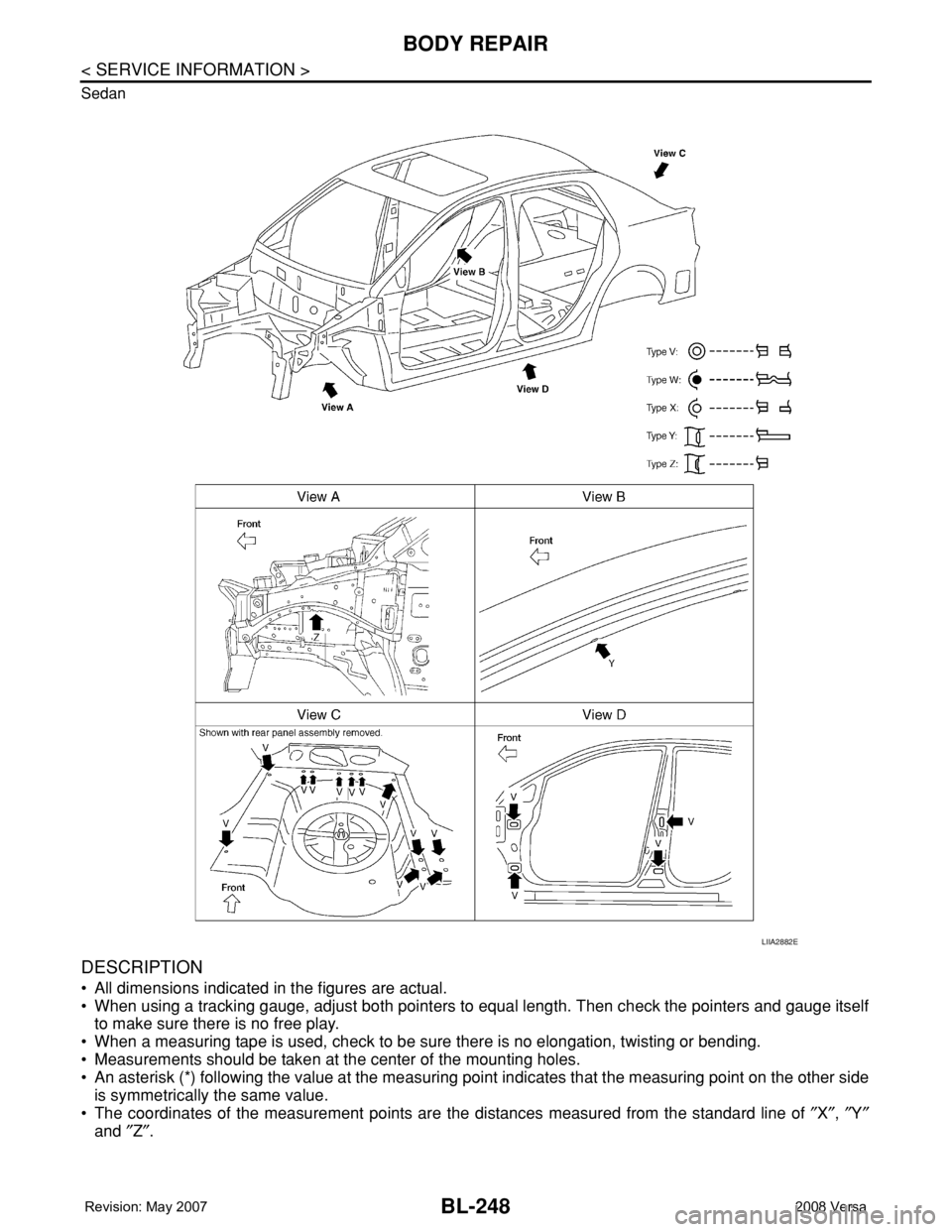

Sedan

DESCRIPTION

• All dimensions indicated in the figures are actual.

• When using a tracking gauge, adjust both pointers to equal length. Then check the pointers and gauge itself

to make sure there is no free play.

• When a measuring tape is used, check to be sure there is no elongation, twisting or bending.

• Measurements should be taken at the center of the mounting holes.

• An asterisk (*) following the value at the measuring point indicates that the measuring point on the other side

is symmetrically the same value.

• The coordinates of the measurement points are the distances measured from the standard line of ″X″, ″Y″

and ″Z″.

LIIA2882E

Page 820 of 2771

PRECAUTIONS

CO-3

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

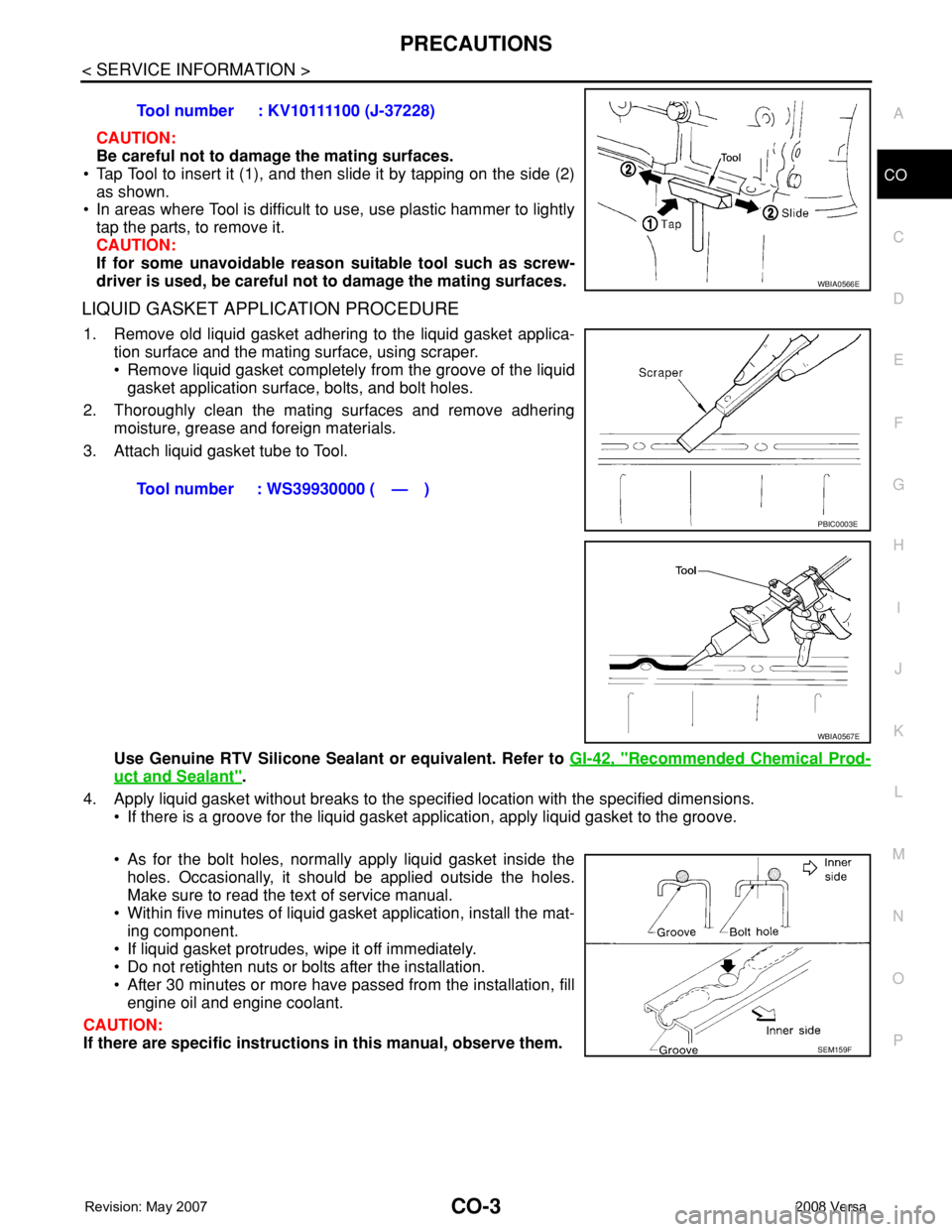

CAUTION:

Be careful not to damage the mating surfaces.

• Tap Tool to insert it (1), and then slide it by tapping on the side (2)

as shown.

• In areas where Tool is difficult to use, use plastic hammer to lightly

tap the parts, to remove it.

CAUTION:

If for some unavoidable reason suitable tool such as screw-

driver is used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

1. Remove old liquid gasket adhering to the liquid gasket applica-

tion surface and the mating surface, using scraper.

• Remove liquid gasket completely from the groove of the liquid

gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering

moisture, grease and foreign materials.

3. Attach liquid gasket tube to Tool.

Use Genuine RTV Silicone Sealant or equivalent. Refer to GI-42, "

Recommended Chemical Prod-

uct and Sealant".

4. Apply liquid gasket without breaks to the specified location with the specified dimensions.

• If there is a groove for the liquid gasket application, apply liquid gasket to the groove.

• As for the bolt holes, normally apply liquid gasket inside the

holes. Occasionally, it should be applied outside the holes.

Make sure to read the text of service manual.

• Within five minutes of liquid gasket application, install the mat-

ing component.

• If liquid gasket protrudes, wipe it off immediately.

• Do not retighten nuts or bolts after the installation.

• After 30 minutes or more have passed from the installation, fill

engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them. Tool number : KV10111100 (J-37228)

WBIA0566E

Tool number : WS39930000 ( — )

PBIC0003E

WBIA0567E

SEM159F

Page 1016 of 2771

DIFFERENTIAL SIDE OIL SEAL

CVT-177

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

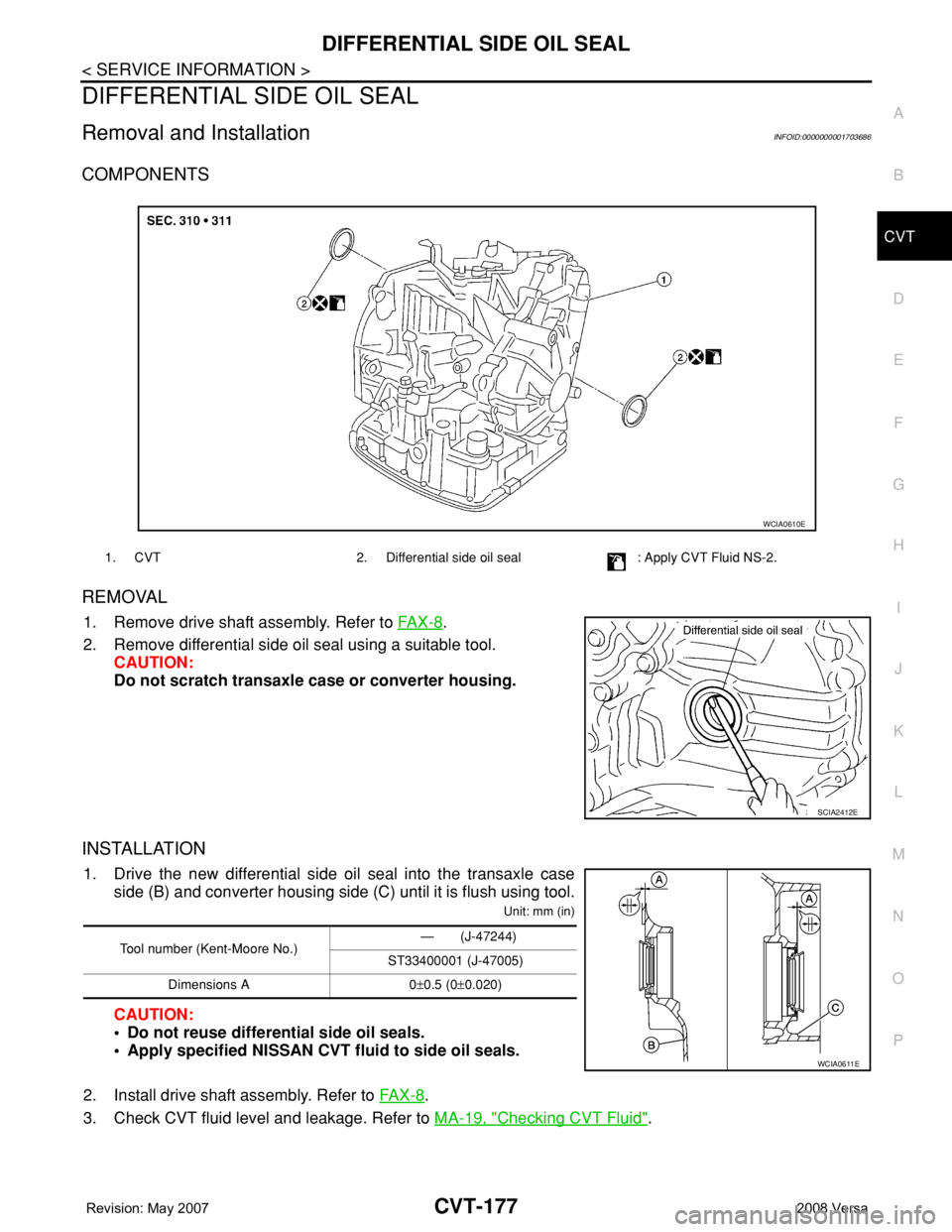

DIFFERENTIAL SIDE OIL SEAL

Removal and InstallationINFOID:0000000001703686

COMPONENTS

REMOVAL

1. Remove drive shaft assembly. Refer to FA X - 8.

2. Remove differential side oil seal using a suitable tool.

CAUTION:

Do not scratch transaxle case or converter housing.

INSTALLATION

1. Drive the new differential side oil seal into the transaxle case

side (B) and converter housing side (C) until it is flush using tool.

Unit: mm (in)

CAUTION:

• Do not reuse differential side oil seals.

• Apply specified NISSAN CVT fluid to side oil seals.

2. Install drive shaft assembly. Refer to FA X - 8

.

3. Check CVT fluid level and leakage. Refer to MA-19, "

Checking CVT Fluid".

1. CVT 2. Differential side oil seal : Apply CVT Fluid NS-2.

WCIA0610E

SCIA2412E

Tool number (Kent-Moore No.)— (J-47244)

ST33400001 (J-47005)

Dimensions A 0±0.5 (0±0.020)

WCIA0611E

Page 1686 of 2771

PREPARATION

EM-9

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

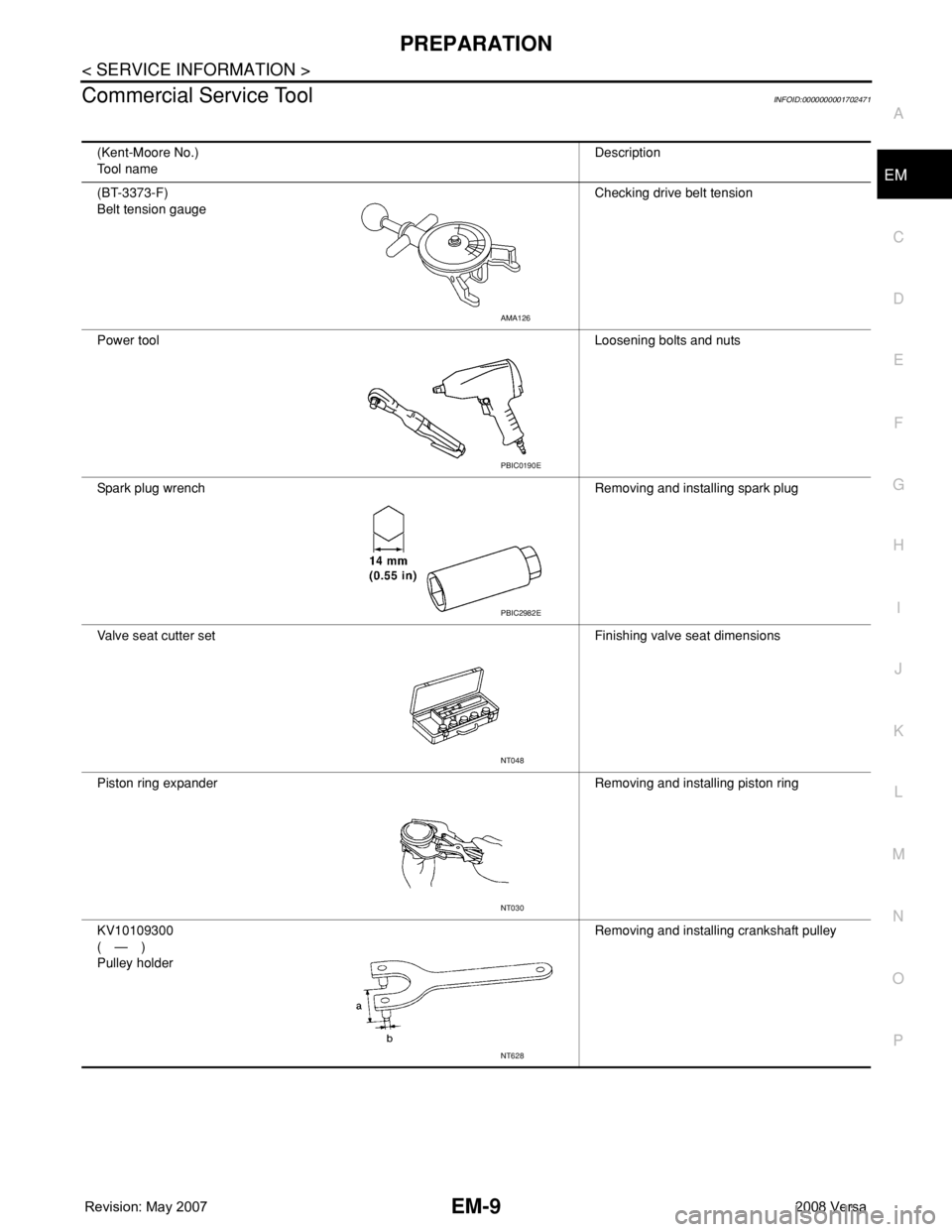

Commercial Service ToolINFOID:0000000001702471

(Kent-Moore No.)

Tool nameDescription

(BT-3373-F)

Belt tension gaugeChecking drive belt tension

Power toolLoosening bolts and nuts

Spark plug wrench Removing and installing spark plug

Valve seat cutter set Finishing valve seat dimensions

Piston ring expander Removing and installing piston ring

KV10109300

(—)

Pulley holderRemoving and installing crankshaft pulley

AMA126

PBIC0190E

PBIC2982E

NT048

NT030

NT628

Page 1705 of 2771

EM-28

< SERVICE INFORMATION >

OIL PAN

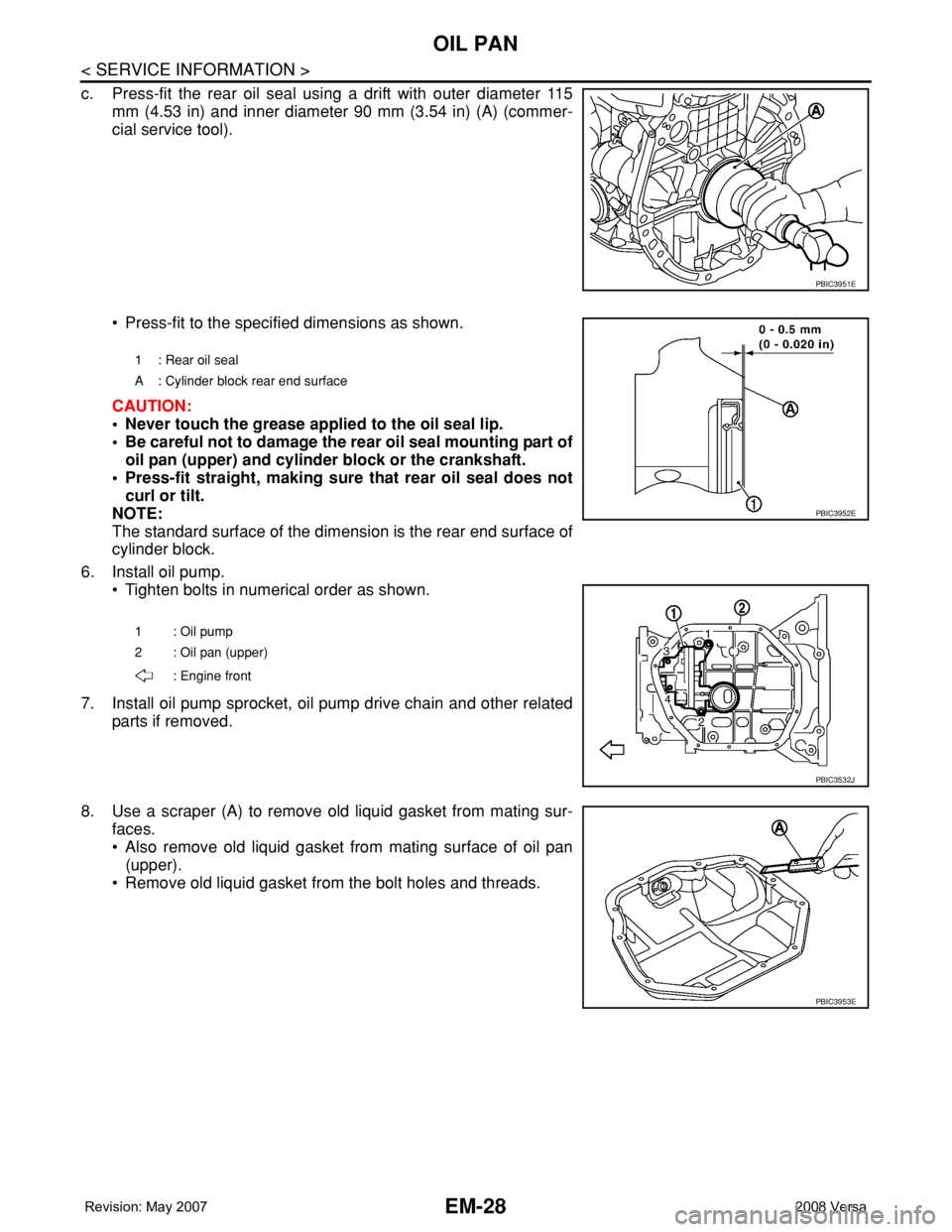

c. Press-fit the rear oil seal using a drift with outer diameter 115

mm (4.53 in) and inner diameter 90 mm (3.54 in) (A) (commer-

cial service tool).

• Press-fit to the specified dimensions as shown.

CAUTION:

• Never touch the grease applied to the oil seal lip.

• Be careful not to damage the rear oil seal mounting part of

oil pan (upper) and cylinder block or the crankshaft.

• Press-fit straight, making sure that rear oil seal does not

curl or tilt.

NOTE:

The standard surface of the dimension is the rear end surface of

cylinder block.

6. Install oil pump.

• Tighten bolts in numerical order as shown.

7. Install oil pump sprocket, oil pump drive chain and other related

parts if removed.

8. Use a scraper (A) to remove old liquid gasket from mating sur-

faces.

• Also remove old liquid gasket from mating surface of oil pan

(upper).

• Remove old liquid gasket from the bolt holes and threads.

PBIC3951E

1 : Rear oil seal

A : Cylinder block rear end surface

1 : Oil pump

2 : Oil pan (upper)

: Engine front

PBIC3952E

PBIC3532J

PBIC3953E

Page 1744 of 2771

CYLINDER HEAD

EM-67

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

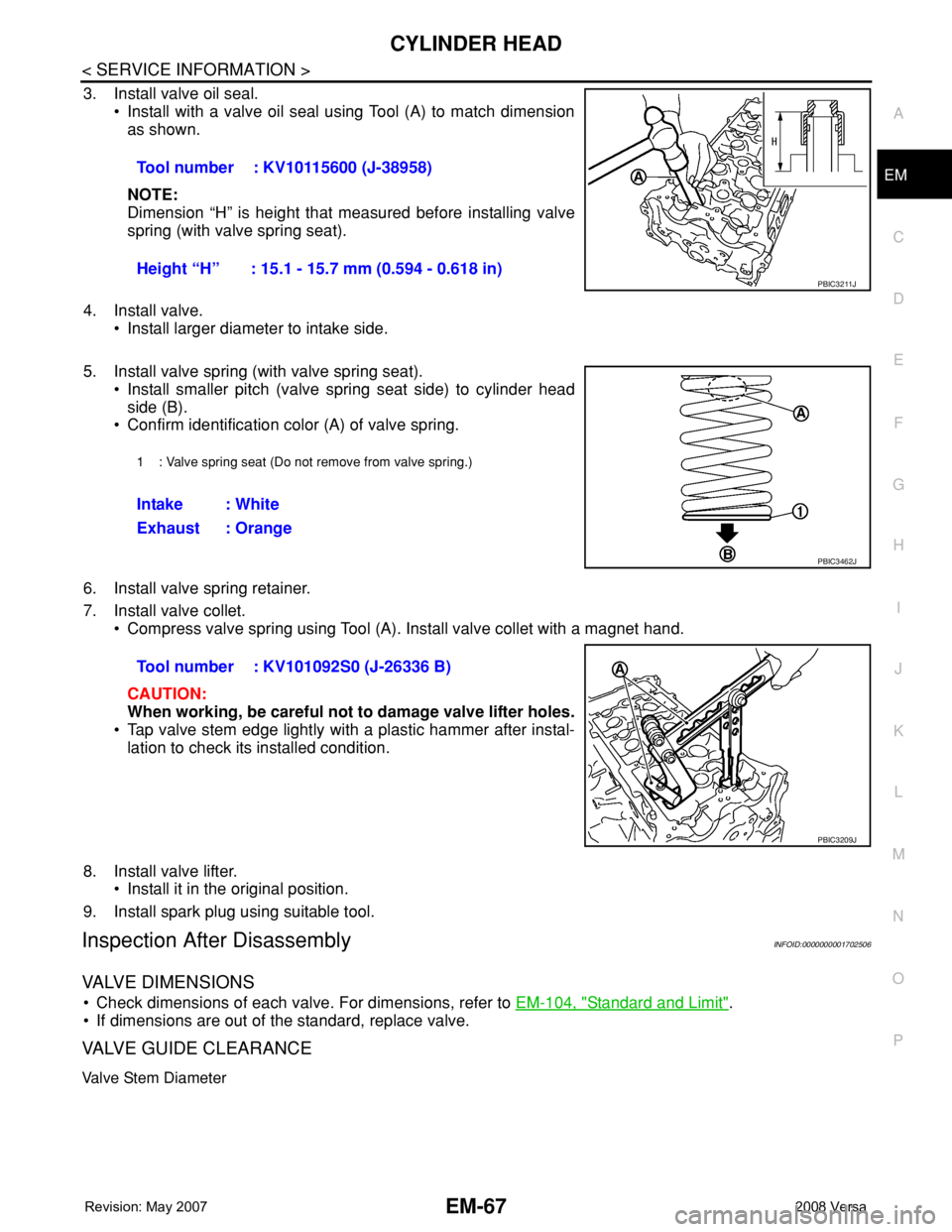

3. Install valve oil seal.

• Install with a valve oil seal using Tool (A) to match dimension

as shown.

NOTE:

Dimension “H” is height that measured before installing valve

spring (with valve spring seat).

4. Install valve.

• Install larger diameter to intake side.

5. Install valve spring (with valve spring seat).

• Install smaller pitch (valve spring seat side) to cylinder head

side (B).

• Confirm identification color (A) of valve spring.

6. Install valve spring retainer.

7. Install valve collet.

• Compress valve spring using Tool (A). Install valve collet with a magnet hand.

CAUTION:

When working, be careful not to damage valve lifter holes.

• Tap valve stem edge lightly with a plastic hammer after instal-

lation to check its installed condition.

8. Install valve lifter.

• Install it in the original position.

9. Install spark plug using suitable tool.

Inspection After DisassemblyINFOID:0000000001702506

VALVE DIMENSIONS

• Check dimensions of each valve. For dimensions, refer to EM-104, "Standard and Limit".

• If dimensions are out of the standard, replace valve.

VALVE GUIDE CLEARANCE

Valve Stem Diameter

Tool number : KV10115600 (J-38958)

Height “H” : 15.1 - 15.7 mm (0.594 - 0.618 in)

PBIC3211J

1 : Valve spring seat (Do not remove from valve spring.)

Intake : White

Exhaust : Orange

PBIC3462J

Tool number : KV101092S0 (J-26336 B)

PBIC3209J