NISSAN LATIO 2009 Service Repair Manual

LATIO 2009

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57359/w960_57359-0.png

NISSAN LATIO 2009 Service Repair Manual

Trending: oil temperature, tire size, mileage, service indicator, fuel pressure, adding oil, boot

Page 1611 of 4331

![NISSAN LATIO 2009 Service Repair Manual P0300, P0301, P0302,

P0303, P0304 MISFIRE

EC-255

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Listen to each fuel injector operating sound.

Is the inspection result normal? YES NISSAN LATIO 2009 Service Repair Manual P0300, P0301, P0302,

P0303, P0304 MISFIRE

EC-255

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Listen to each fuel injector operating sound.

Is the inspection result normal? YES](/img/5/57359/w960_57359-1610.png)

P0300, P0301, P0302,

P0303, P0304 MISFIRE

EC-255

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Listen to each fuel injector operating sound.

Is the inspection result normal? YES >> GO TO 5.

NO >> Perform trouble diagnosis for FUEL INJECTOR, refer to EC-432, " Component Inspection " .

5.

CHECK FUNCTION OF IGNITION COIL-I

CAUTION:

Do the following procedure in the place where ventilation is good without the combustible.

1. Turn ignition switch OFF.

2. Remove fuel pump fuse in IPDM E/R to release fuel pressure. NOTE:

Do not use CONSULT-III to release fuel pressure, or fuel pressure applies again during the following pro-

cedure.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel pressure.

5. Turn ignition switch OFF.

6. Remove all ignition coil harness connectors to avoid the electrical discharge from the ignition coils.

7. Remove ignition coil and spark plug of the cylinder to be checked.

8. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

9. Connect spark plug and harness connector to ignition coil.

10. Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 -

0.66 in) between the edge of the spark plug and grounded metal

portion as shown in the figure.

11. Crank engine for about 3 seconds, and check whether spark is

generated between the spark plug and the grounded metal por-

tion.

CAUTION:

• During the operation, alw ays stay 0.5 m (19.7 in) away

from the spark plug and the ig nition coil within. Be careful

not to get an electrical sh ock while checking, because the

electrical discharge voltage becomes 20 kV or more.

• It might cause to damage the igni tion coil if the gap of more than 17 mm (0.66 in) is taken.

NOTE:

When the gap is less than 13 mm (0.52 in), the sp ark might be generated even if the coil is mal-

functioning.

Is the inspection result normal? YES >> GO TO 9.

NO >> GO TO 6. 6.

CHECK FUNCTION OF IGNITION COIL-II

1. Turn ignition switch OFF.

2. Disconnect spark plug and connect a known-good spark plug.

3. Crank engine for about 3 seconds, and recheck whether spark is generated between the spark plug and the grounded metal portion.

Is the inspection result normal? YES >> GO TO 7.

NO >> Check ignition coil, power transistor and their circuits. Refer to EC-439, " Component Function

Check " .

Clicking noise should be heard.

PBIB3332E

Spark should be generated.

JMBIA0066GB

Spark should be generated.

Page 1612 of 4331

YES >> Replace spark plug(s) with standard type one(s). For

spark plug type, refer to EM-117, " Spark Plug " .

NO >> Repair or clean spark plug. Then GO TO 8. YES >> INSPECTION END

NO >> Replace spark plug(s) with standard type one(s). For spark plug type, refer to EM-117, " Spark

Plug " .

Inspection " .

Is the inspection result normal? YES >> GO TO 10.

NO >> Check pistons, piston rings, valves, valve seats and cylinder head gaskets. Inspection " .

Is the inspection result normal? YES >> GO TO 12.

NO >> GO TO 11. YES >> Replace “fuel filter and fuel pump assembly”.

NO >> Repair or replace. BASIC INSPECTION : Special Repair Requirement " .

For specification, refer to EC-504, " Ignition Timing " .

Is the inspection result normal? YES >> GO TO 13.

NO >> Follow the EC-26, " BASIC INSPECTION : Special Repair Requirement " .

Page 1613 of 4331

EC

NP

O

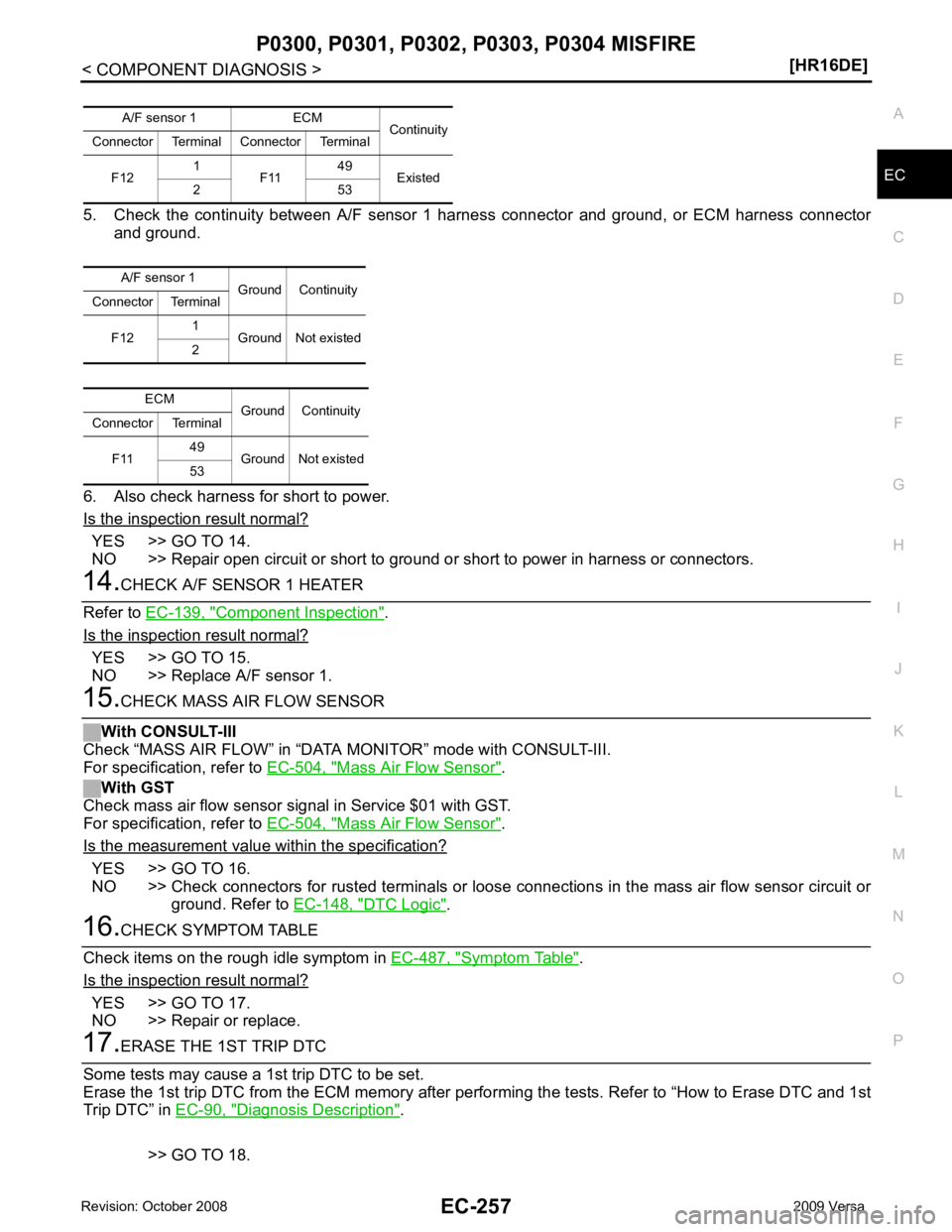

5. Check the continuity between A/F sensor 1

harness connector and ground, or ECM harness connector

and ground.

6. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 14.

NO >> Repair open circuit or short to ground or short to power in harness or connectors. Component Inspection " .

Is the inspection result normal? YES >> GO TO 15.

NO >> Replace A/F sensor 1. Mass Air Flow Sensor " .

With GST

Check mass air flow sensor signal in Service $01 with GST.

For specification, refer to EC-504, " Mass Air Flow Sensor " .

Is the measurement value within the specification?YES >> GO TO 16.

NO >> Check connectors for rusted terminals or loose c onnections in the mass air flow sensor circuit or

ground. Refer to EC-148, " DTC Logic " .

Symptom Table " .

Is the inspection result normal? YES >> GO TO 17.

NO >> Repair or replace. Diagnosis Description " .

>> GO TO 18.

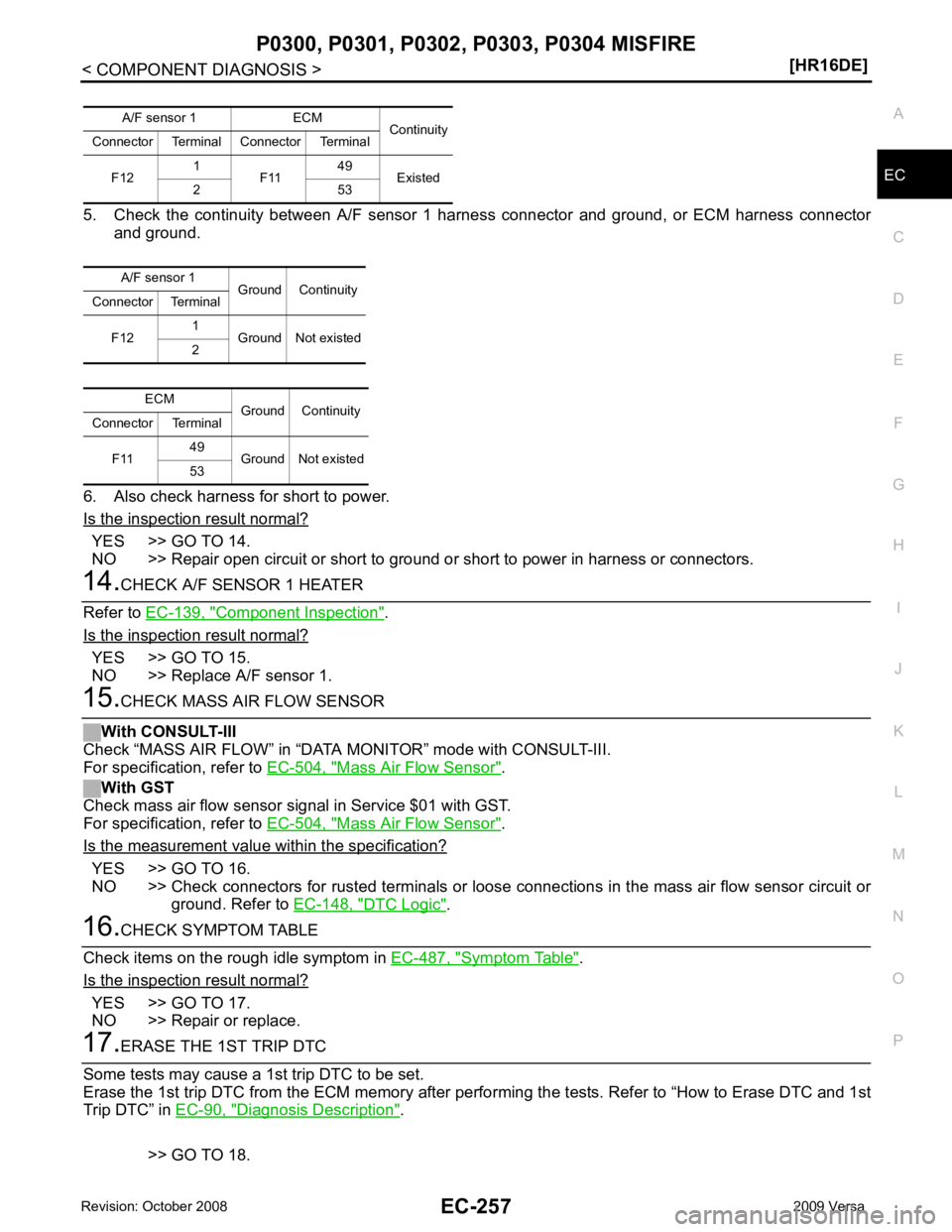

A/F sensor 1 ECM

Continuity

Connector Terminal Connector Terminal

F12 1

F11 49

Existed

2 53

A/F sensor 1 Ground Continuity

Connector Terminal

F12 1

Ground Not existed

2

ECM Ground Continuity

Connector Terminal

F11 49

Ground Not existed

53

Page 1614 of 4331

Diagnosis Procedure " .

>> INSPECTION END

Page 1615 of 4331

EC

NP

O

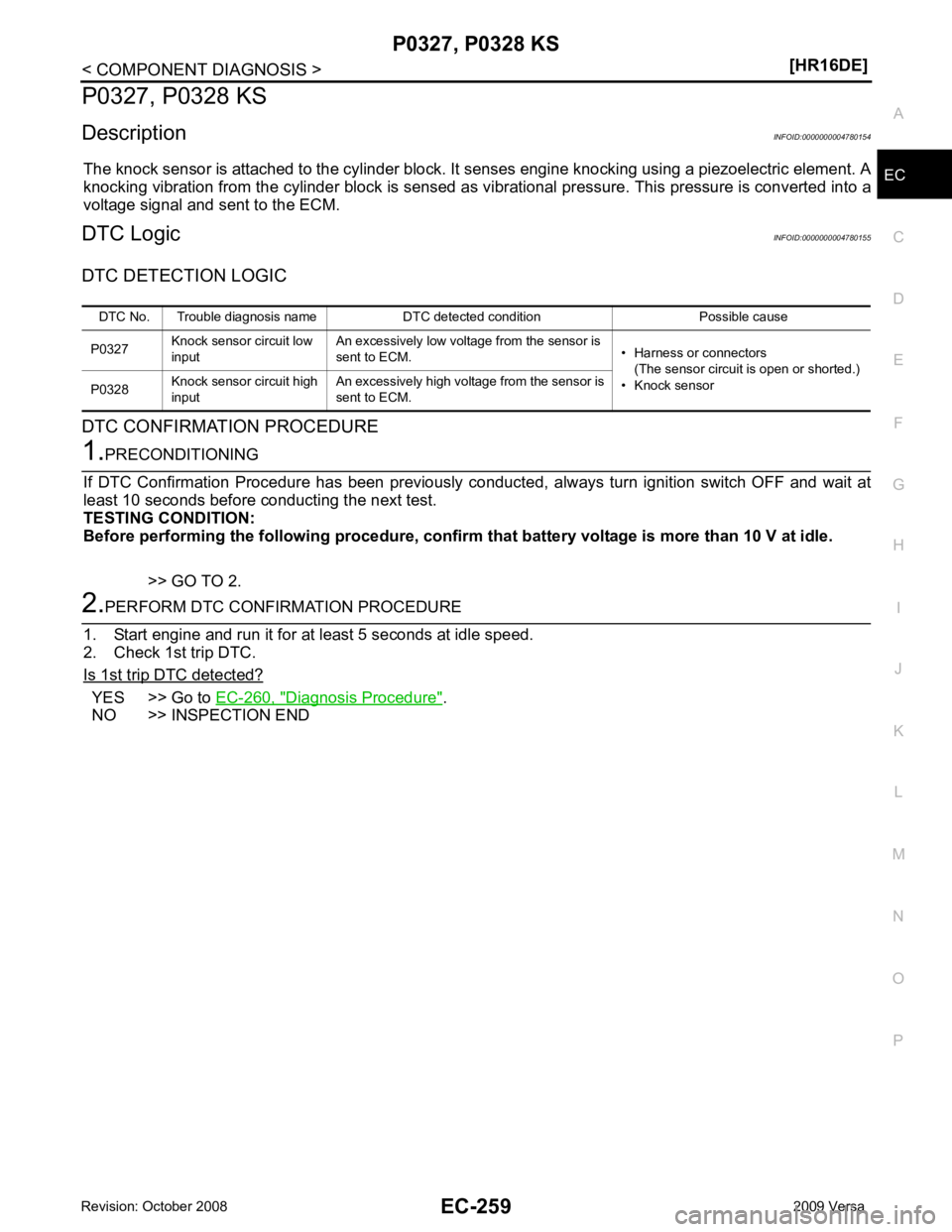

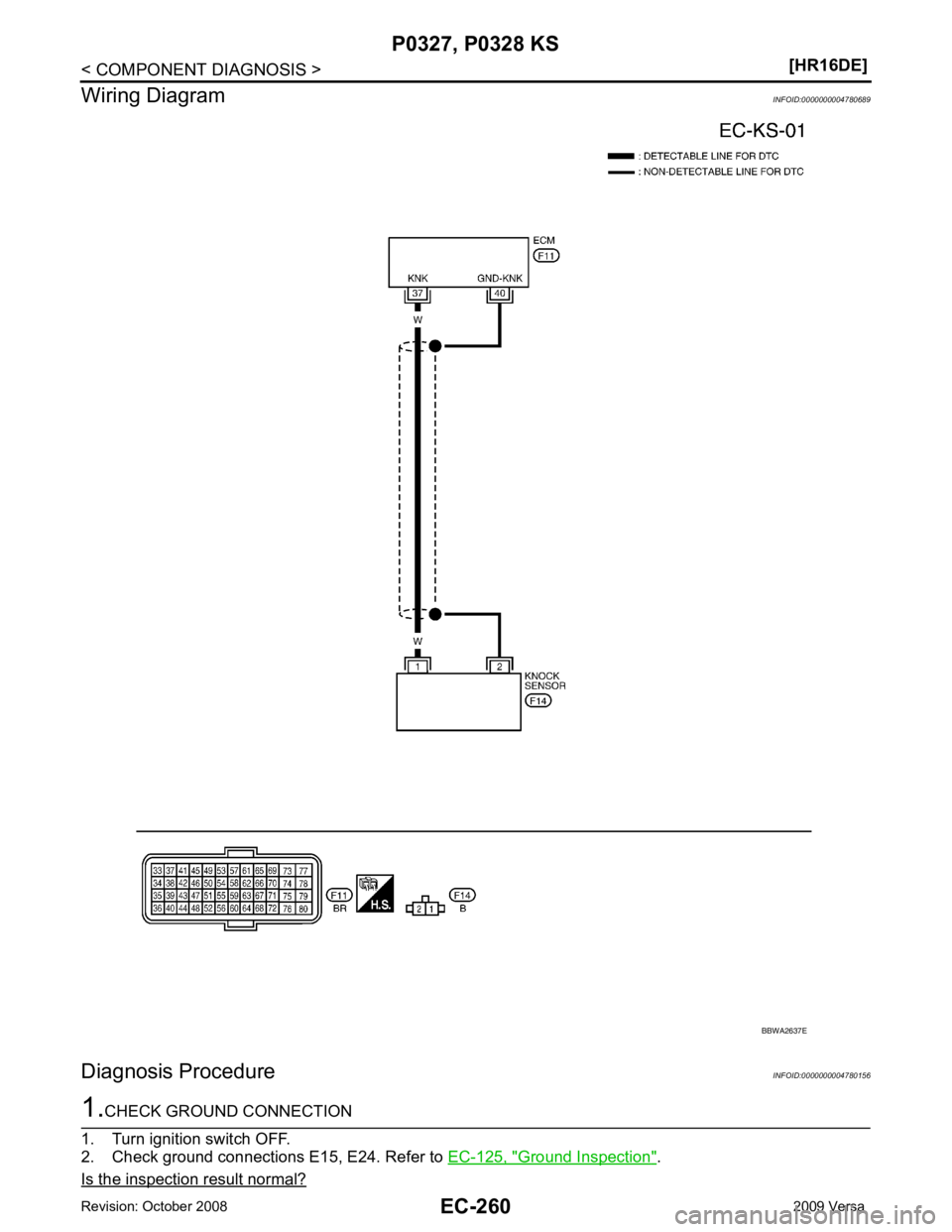

P0327, P0328 KS

Description INFOID:0000000004780154

The knock sensor is attached to the cylinder block. It senses engine knocking using a piezoelectric element. A

knocking vibration from the cylinder blo ck is sensed as vibrational pressure. This pressure is converted into a

voltage signal and sent to the ECM.

DTC Logic INFOID:0000000004780155

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE YES >> Go to

EC-260, " Diagnosis Procedure " .

NO >> INSPECTION END DTC No. Trouble diagnosis name DTC detected condition Possible cause

P0327 Knock sensor circuit low

input An excessively low voltage from the sensor is

sent to ECM. • Harness or connectors

(The sensor circuit is open or shorted.)

• Knock sensor

P0328 Knock sensor circuit high

input An excessively high voltage from the sensor is

sent to ECM.

Page 1616 of 4331

Ground Inspection " .

Is the inspection result normal?

Page 1617 of 4331

EC

NP

O

YES >> GO TO 2.

NO >> Repair or replace ground connection. YES >> GO TO 3.

NO >> Repair open circuit or short to ground or short to power in harness or connectors. YES >> GO TO 4.

NO >> Repair open circuit or short to ground or short to power in harness or connectors. Component Inspection " .

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace knock sensor. Diagnosis Procedure " .

>> INSPECTION END

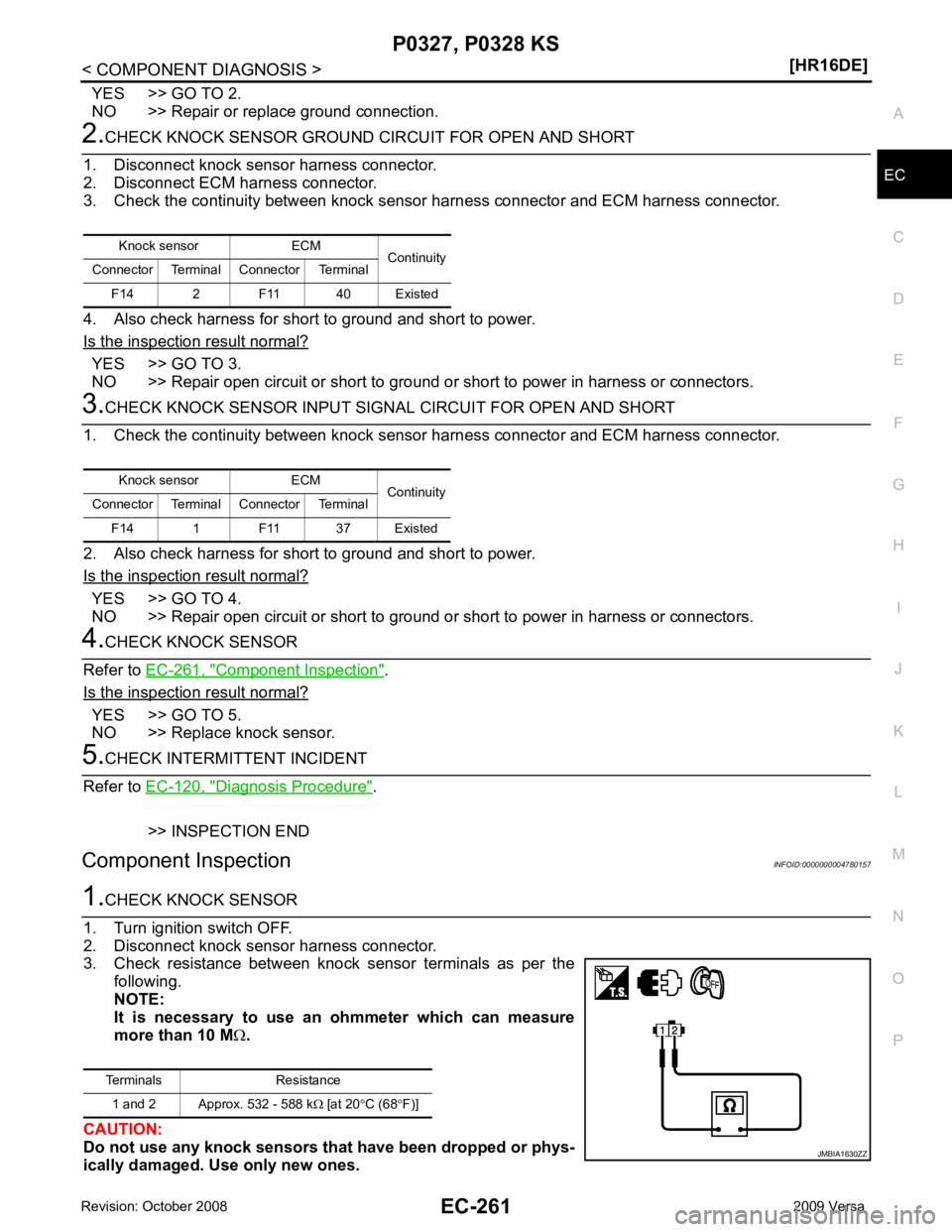

Component Inspection INFOID:0000000004780157Knock sensor ECM

Continuity

Connector Terminal Connector Terminal

F14 1 F11 37 Existed Terminals Resistance

1 and 2 Approx. 532 - 588 k Ω [at 20 °C (68 °F)]

Page 1618 of 4331

YES >> INSPECTION END

NO >> Replace knock sensor.

Page 1619 of 4331

EC

NP

O

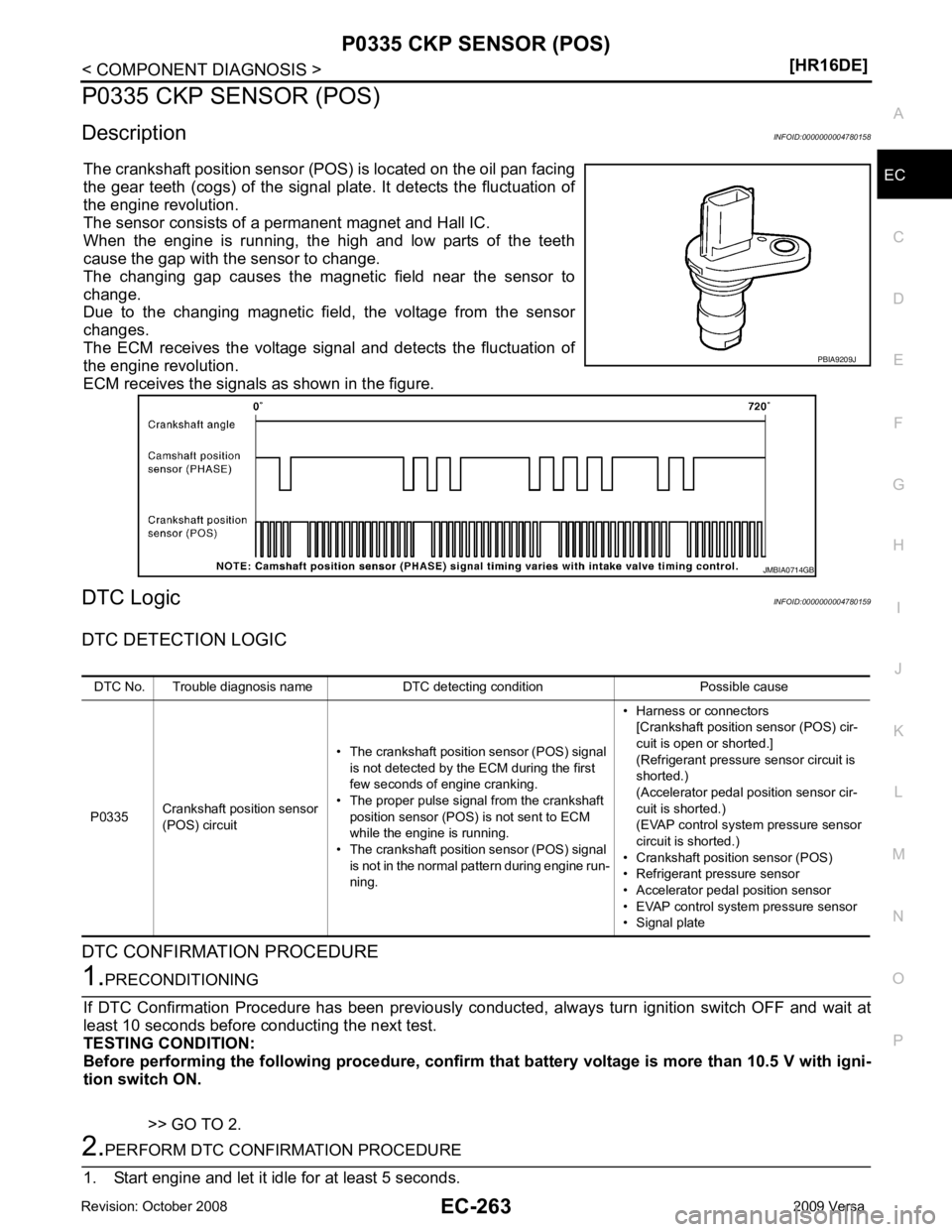

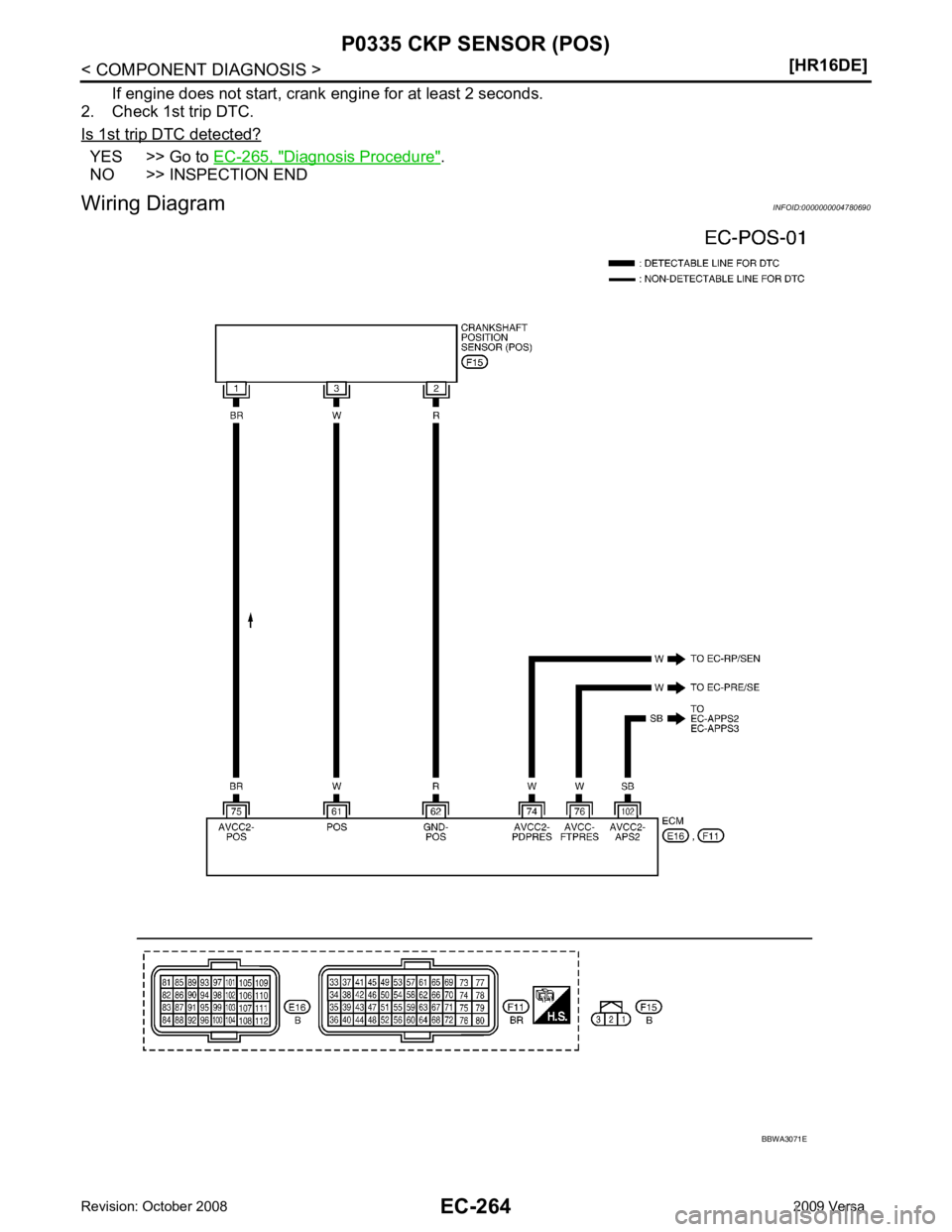

P0335 CKP SENSOR (POS)

Description INFOID:0000000004780158

The crankshaft position sensor (POS ) is located on the oil pan facing

the gear teeth (cogs) of the signal pl ate. It detects the fluctuation of

the engine revolution.

The sensor consists of a permanent magnet and Hall IC.

When the engine is running, the high and low parts of the teeth

cause the gap with the sensor to change.

The changing gap causes the magnet ic field near the sensor to

change.

Due to the changing magnetic fiel d, the voltage from the sensor

changes.

The ECM receives the voltage signal and detects the fluctuation of

the engine revolution.

ECM receives the signals as shown in the figure.

DTC Logic INFOID:0000000004780159

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

Page 1620 of 4331

YES >> Go to

EC-265, " Diagnosis Procedure " .

NO >> INSPECTION END

Wiring Diagram INFOID:0000000004780690

Trending: navigation system, jump start, coolant temperature, diagnostic menu, fuse box diagram, Drive belt, open gas tank

![NISSAN LATIO 2009 Service Repair Manual P0300, P0301, P0302,

P0303, P0304 MISFIRE

EC-255

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Listen to each fuel injector operating sound.

Is the inspection result normal? YES NISSAN LATIO 2009 Service Repair Manual P0300, P0301, P0302,

P0303, P0304 MISFIRE

EC-255

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Listen to each fuel injector operating sound.

Is the inspection result normal? YES](/img/5/57359/w960_57359-1610.png)