NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 2661 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0420 THREE WAY CATALYST FUNCTION

EC-1305

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0420 THREE WAY CATALYST FUNCTION

On Board Diagnosis Logic INFOID:0000000004500166

NISSAN LATIO 2009 Service Repair Manual DTC P0420 THREE WAY CATALYST FUNCTION

EC-1305

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0420 THREE WAY CATALYST FUNCTION

On Board Diagnosis Logic INFOID:0000000004500166](/img/5/57359/w960_57359-2660.png)

DTC P0420 THREE WAY CATALYST FUNCTION

EC-1305

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0420 THREE WAY CATALYST FUNCTION

On Board Diagnosis Logic INFOID:0000000004500166

The ECM monitors the switching frequency ratio of air fuel ratio (A/F)

sensor 1 and heated oxygen sensor 2.

A three way catalyst (manifold) with high oxygen storage capacity

will indicate a low switching frequency of heated oxygen sensor 2.

As oxygen storage capacity decr eases, the heated oxygen sensor 2

switching frequency will increase.

When the frequency ratio of air fuel ratio (A/F) sensor 1 and heated

oxygen sensor 2 approaches a specified limit value, the three way

catalyst (manifold) malfunction is diagnosed.

DTC Confirmation Procedure INFOID:0000000004500167

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-III

TESTING CONDITION:

Do not hold engine speed for more than the specified minutes below.

1. Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT-III.

2. Start engine and warm it up to the normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

5. Let engine idle for 1 minute.

6. Make sure that “COOLAN TEMP/S” indicates more than 70 °C (158 °F).

If not, warm up engine and go to next step when “COOLAN TEMP/S” indication reaches to 70°C (158 °F).

7. Open engine hood.

8. Select “DTC & SRT CONFIRMATION” then “SRT WORK SUPPORT” mode with CONSULT-III.

9. Rev engine up to 2,000 to 3,000 rpm and hold it for 3 consecutive minutes then release the accelerator pedal completely.

If “INCMP” of “CATALYST” changed to “CMPLT”, go to step 12.

10. Wait 5 seconds at idle.

11. Rev engine up to 2,000 to 3,000 rpm and maintain it unt il “INCMP” of “CATALYST” changes to “CMPLT” (It

will take approximately 5 minutes).

If not “CMPLT”, stop engine and cool it down to less than 70 °C (158 °F) and then retest from step 1.

12. Check 1st trip DTC. If 1st trip DTC is detected, go to EC-1306, " Diagnosis Procedure " .

Overall Function Check INFOID:0000000004500168

Use this procedure to check the overall function of the th ree way catalyst (manifold). During this check, a 1st

trip DTC might not be confirmed. SEF484YB

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0420

0420 Catalyst system efficiency

below threshold • Three way catalyst (manifold) does not operate

properly.

• Three way catalyst (manifold) does not have enough oxygen storage capacity. • Three way catalyst (manifold)

• Exhaust tube

• Intake air leaks

• Fuel injector

• Fuel injector leaks

• Spark plug

• Improper ignition timing

Page 2662 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1306< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0420 THREE WAY CATALYST FUNCTION

WITH GST

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at le NISSAN LATIO 2009 Service Repair Manual EC-1306< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0420 THREE WAY CATALYST FUNCTION

WITH GST

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at le](/img/5/57359/w960_57359-2661.png)

EC-1306< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0420 THREE WAY CATALYST FUNCTION

WITH GST

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4. Let engine idle for 1 minute.

5. Open engine hood.

6. Set voltmeter probe between ECM terminals 50 (HO2S2 signal) and ground.

7. Keep engine speed at 2,500 rpm constant under no load.

8. Make sure that the voltage does not vary for more than 5 sec- onds.

If the voltage fluctuation cycle takes less than 5 seconds, go to

EC-1306, " Diagnosis Procedure " .

• 1 cycle: 0.6 - 1.0 → 0 - 0.3 → 0.6 - 1.0

Diagnosis Procedure INFOID:00000000045001691.

CHECK EXHAUST SYSTEM

Visually check exhaust tubes and muffler for dent.

OK or NG OK >> GO TO 2.

NG >> Repair or replace. 2.

CHECK EXHAUST GAS LEAK

1. Start engine and run it at idle.

2. Listen for an exhaust gas leak before the three way catalyst (manifold).

OK or NG OK >> GO TO 3.

NG >> Repair or replace. 3.

CHECK INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

OK or NG OK >> GO TO 4.

NG >> Repair or replace. 4.

CHECK IGNITION TIMING

Check the following items. Refer to EC-1078, " Basic Inspection " . PBIB2996E

PBIB1216E

Page 2663 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0420 THREE WAY CATALYST FUNCTION

EC-1307

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 5.

NG >> Follow the EC-1078, " Basic Inspection " .

5.

CHECK FUEL NISSAN LATIO 2009 Service Repair Manual DTC P0420 THREE WAY CATALYST FUNCTION

EC-1307

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 5.

NG >> Follow the EC-1078, " Basic Inspection " .

5.

CHECK FUEL](/img/5/57359/w960_57359-2662.png)

DTC P0420 THREE WAY CATALYST FUNCTION

EC-1307

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 5.

NG >> Follow the EC-1078, " Basic Inspection " .

5.

CHECK FUEL INJECTOR

1. Stop engine and turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Turn ignition switch ON.

4. Check voltage between ECM terminals 25, 29, 30, 31 and ground with CONSULT-III or tester.

Refer to Wiring Diagram for fuel injectors, EC-1509, " Wiring Diagram " .

OK or NG OK >> GO TO 6.

NG >> Perform EC-1510, " Diagnosis Procedure " .

6.

CHECK FUNCTION OF IGNITION COIL-I

CAUTION:

Do the following procedure in the place where ventilation is good without the combustible.

1. Turn ignition switch OFF.

2. Remove fuel pump (1) fuse in IPDM E/R (2) to release fuel pres-

sure.

NOTE:

Do not use CONSULT-III to release fuel pressure, or fuel pres-

sure applies again during the following procedure.

- : Vehicle front

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel pressure.

5. Turn ignition switch OFF.

6. Remove all ignition coil harness connectors to avoid the electri- cal discharge from the ignition coils.

7. Remove ignition coil and spark plug of the cylinder to be checked.

8. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

9. Connect spark plug and harness connector to ignition coil.

10. Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 - 0.66 in) between the edge of the spark plug and grounded metal

portion as shown in the figure.

11. Crank engine for about 3 seconds, and check whether spark is

generated between the spark plug and the grounded metal por-

tion.

CAUTION:

• Do not approach to the spar k plug and the ignition coil

within 50cm. Be careful not to get an electrical shock

while checking, because the el ectrical discharge voltage

becomes 20kV or more. Items Specifications

Target idle speed A/T: 700

± 50 rpm (in P or N position)

CVT: 700 ± 50 rpm (in P or N position)

M/T: 700 ± 50 rpm (in Neutral position)

Ignition timing A/T: 13

± 5 ° BTDC (in P or N position)

CVT: 13 ± 5 ° BTDC (in P or N position)

M/T: 13 ± 5 ° BTDC (in Neutral position) Voltage: Battery voltage

Spark should be generated. PBIB2958E

PBIB2325E

Page 2664 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1308< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0420 THREE WAY CATALYST FUNCTION

• It might cause to damage the igni tion coil if the gap of more than 17 mm (0.66 in) is taken.

NOTE:

When the gap NISSAN LATIO 2009 Service Repair Manual EC-1308< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0420 THREE WAY CATALYST FUNCTION

• It might cause to damage the igni tion coil if the gap of more than 17 mm (0.66 in) is taken.

NOTE:

When the gap](/img/5/57359/w960_57359-2663.png)

EC-1308< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0420 THREE WAY CATALYST FUNCTION

• It might cause to damage the igni tion coil if the gap of more than 17 mm (0.66 in) is taken.

NOTE:

When the gap is less than 13 mm (0.52 in), the sp ark might be generated even if the coil is mal-

functioning.

OK or NG OK >> GO TO 10.

NG >> GO TO 7. 7.

CHECK FUNCTION OF IGNITION COIL-II

1. Turn ignition switch OFF.

2. Disconnect spark plug and connect a known-good spark plug.

3. Crank engine for about 3 seconds, and recheck whether spark is generated between the spark plug and the grounded metal portion.

OK or NG OK >> GO TO 8.

NG >> Check ignition coil, power transistor and their circuits. Refer to EC-1518 .

8.

CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

OK or NG OK >> Replace spark plug(s) with standard type one(s). For

spark plug type, refer to EM-227, " Standard and Limit " .

NG >> 1. Repair or clean spark plug.

2. GO TO 9. 9.

CHECK FUNCTION OF IGNITION COIL-III

1. Reconnect the initial spark plugs.

2. Crank engine for about 3 seconds, and recheck whether spark is generated between the spark plug and

the grounded portion.

OK or NG OK >>

INSPECTION END

NG >> Replace spark plug(s) with standard type one(s). For spark plug type, refer to EM-227, " Standard

and Limit " .

10.

CHECK FUEL INJECTOR

1. Turn ignition switch OFF.

2. Remove fuel injector assembly. Refer to EM-156, " Removal and Installation " .

Keep fuel hose and all fuel injectors connected to fuel tube.

3. Disconnect all ignition coil harness connectors.

4. Reconnect all fuel injector harness connectors disconnected.

5. Turn ignition switch ON. Make sure fuel does not drip from fuel injector.

OK or NG OK (Does not drip.)>>GO TO 11.

NG (Drips.)>>Replace the fuel injector(s) from which fuel is dripping. 11.

CHECK INTERMITTENT INCIDENT

Refer to EC-1138 .

Spark should be generated.

SEF156I

Spark should be generated.

Page 2665 of 4331

EC

NP

O

Trouble is fixed.>>

INSPECTION END

Trouble is not fixed.>>Replace three way catalyst (manifold).

Page 2666 of 4331

Page 2667 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0441 EVAP CONTROL SYSTEM

EC-1311

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and NISSAN LATIO 2009 Service Repair Manual DTC P0441 EVAP CONTROL SYSTEM

EC-1311

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and](/img/5/57359/w960_57359-2666.png)

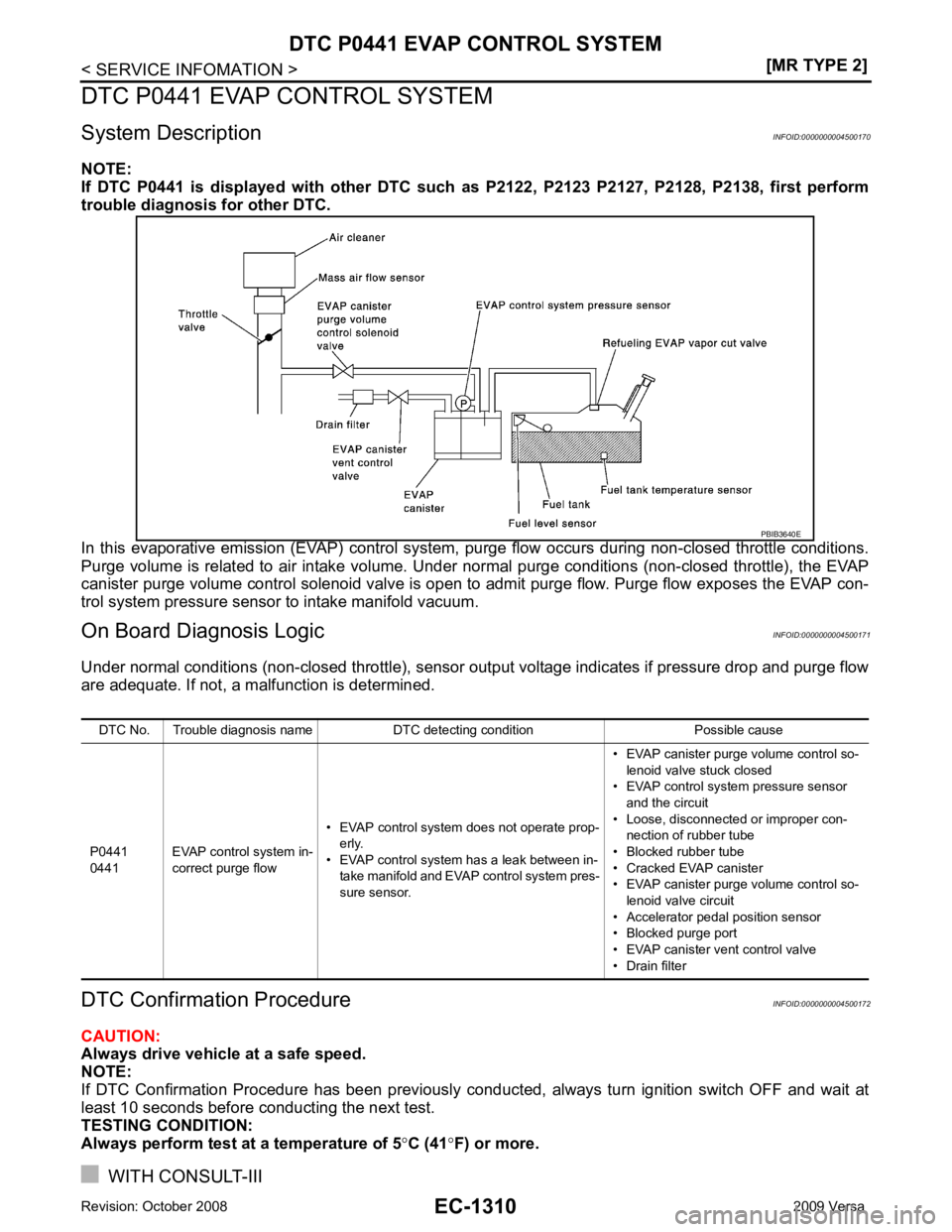

DTC P0441 EVAP CONTROL SYSTEM

EC-1311

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and let it idle for at least 70 seconds.

4. Select “PURG FLOW P0441” of “EVAPORATIVE SYSTEM” in “DTC CONFIRMATION” mode with CON-

SULT-III.

5. Touch “START”.

If “COMPLETED” is displayed, go to step 7.

6. When the following conditions are met, “TESTING ” will be displayed on the CONSULT-III screen. Maintain

the conditions continuously until “TES TING” changes to “COMPLETED”. (It will take at least 35 seconds.)

If TESTING is not changed for a long time, retry from step 2.

7. Make sure that “OK” is displayed after touching “S ELF-DIAG RESULTS”. If “NG” is displayed, refer to EC-1311, " Diagnosis Procedure " .

Overall Function Check INFOID:0000000004500173

Use this procedure to check the overall monitoring func tion of the EVAP control system purge flow monitoring.

During this check, a 1st trip DTC might not be confirmed.

WITH GST

1. Lift up drive wheels.

2. Start engine and warm it up to normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and wait at least 70 seconds.

5. Set voltmeter probes to ECM te rminals 42 (EVAP control system

pressure sensor signal) and ground.

6. Check EVAP control system pressure sensor value at idle speed and note it.

7. Establish and maintain the following conditions for at least 1 minute.

8. Verify that EVAP contro l system pressure sensor value stays 0. 1V less than the value at idle speed (mea-

sured at step 6) for at least 1 second.

9. If NG, go to EC-1311, " Diagnosis Procedure " .

Diagnosis Procedure INFOID:00000000045001741.

CHECK EVAP CANISTER

1. Turn ignition switch OFF.

2. Check EVAP canister for cracks.

OK or NG OK (With CONSULT-III)>>GO TO 2.

OK (Without CONSULT-III)>>GO TO 3.

NG >> Replace EVAP canister. 2.

CHECK PURGE FLOW

Shift lever Suitable position

VHCL SPEED SE 32 - 120 km/h (20 - 75 MPH)

ENG SPEED 500 - 3,800 rpm

B/FUEL SCHDL 1.0 - 10.0 msec

COOLAN TEMP/S More than 0 °C Air conditioner switch ON

Headlamp switch ON

Rear window defogger switch ON

Engine speed Approx. 3,000 rpm

Shift lever Any position other than P, N or R PBIB3313E

Page 2668 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1312< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0441 EVAP CONTROL SYSTEM

With CONSULT-III

1. Disconnect vacuum hose connected to EVAP canister purge volume control solenoid valve at EVAP ser-

vice p NISSAN LATIO 2009 Service Repair Manual EC-1312< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0441 EVAP CONTROL SYSTEM

With CONSULT-III

1. Disconnect vacuum hose connected to EVAP canister purge volume control solenoid valve at EVAP ser-

vice p](/img/5/57359/w960_57359-2667.png)

EC-1312< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0441 EVAP CONTROL SYSTEM

With CONSULT-III

1. Disconnect vacuum hose connected to EVAP canister purge volume control solenoid valve at EVAP ser-

vice port and install vacuum gauge. For the location of EVAP service port, refer to EC-1036, " Description " .

2. Start engine and let it idle.

3. Select “PURG VOL CONT/V” in “A CTIVE TEST” mode with CONSULT-III.

4. Rev engine up to 2,000 rpm.

5. Touch “Qd” and “Qu” on CONSULT-III screen to adjust “PURG VOL CONT/V” opening and check vacuum

existence.

OK or NG OK >> GO TO 7.

NG >> GO TO 4. 3.

CHECK PURGE FLOW

Without CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Disconnect vacuum hose connected to EVAP canister purge volume control solenoid valve at EVAP ser-

vice port and install vacuum gauge. For the location of EVAP service port, refer to EC-1036, " Description " .

4. Start engine and let it idle.

Do not depress accelerator pedal even slightly.

5. Check vacuum gauge indication before 60 seconds passed after starting engine.

6. Revving engine up to 2,000 rpm after 100 seconds passed after starting engine.

OK or NG OK >> GO TO 7.

NG >> GO TO 4. 4.

CHECK EVAP PURGE LINE

1. Turn ignition switch OFF.

2. Check EVAP purge line for improper connection or disconnection.

Refer to EC-1036, " Description " .

OK or NG OK >> GO TO 5.

NG >> Repair it. 5.

CHECK EVAP PURGE HOSE AND PURGE PORT

1. Disconnect purge hoses connected to EVAP service port A and

EVAP canister purge volume control solenoid valve B.

2. Blow air into each hose and EVAP purge port C.

PURG VOL CONT/V VACUUM

100% Should exist.

0% should not exist. Vacuum should not exist.

Vacuum should exist. SEF367U

Page 2669 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0441 EVAP CONTROL SYSTEM

EC-1313

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

3. Check that air flows freely.

OK or NG OK (With CONSULT-III)>>GO TO 6.

OK (Without CONSULT-II NISSAN LATIO 2009 Service Repair Manual DTC P0441 EVAP CONTROL SYSTEM

EC-1313

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

3. Check that air flows freely.

OK or NG OK (With CONSULT-III)>>GO TO 6.

OK (Without CONSULT-II](/img/5/57359/w960_57359-2668.png)

DTC P0441 EVAP CONTROL SYSTEM

EC-1313

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

3. Check that air flows freely.

OK or NG OK (With CONSULT-III)>>GO TO 6.

OK (Without CONSULT-III)>>GO TO 7.

NG >> Repair or clean hoses and/or purge port. 6.

CHECK EVAP CANISTER PURGE VO LUME CONTROL SOLENOID VALVE

With CONSULT-III

1. Start engine.

2. Perform “PURG VOL CONT/V” in “ACTIVE TEST” mode with CONSULT- III. Check that engine speed var-

ies according to the valve opening.

OK or NG OK >> GO TO 8.

NG >> GO TO 7. 7.

CHECK EVAP CANISTER PURGE VO LUME CONTROL SOLENOID VALVE

Refer to EC-1334, " Component Inspection " .

OK or NG OK >> GO TO 8.

NG >> Replace EVAP canister purge volume control solenoid valve. 8.

CHECK EVAP CONTRO L SYSTEM PRESSURE SENSOR CONNECTOR

1. Disconnect EVAP control system pressure sensor harness connector.

2. Check connectors for water.

OK or NG OK >> GO TO 9.

NG >> Replace EVAP control system pressure sensor. 9.

CHECK EVAP CONTRO L SYSTEM PRESSURE SENSOR FUNCTION

Refer to EC-1351 or DTC P0452 and

EC-1359 for DTC P0453.

OK or NG OK >> GO TO 10.

NG >> Replace EVAP control system pressure sensor. 10.

CHECK RUBBER TUBE FOR CLOGGING

1. Disconnect rubber tube connected to EV AP canister vent control valve.

2. Check the rubber tube for clogging.

OK or NG OK >> GO TO 11.

NG >> Clean the rubber tube using an air blower. 11.

CHECK DRAIN FILTER

Refer to EC-1314, " Component Inspection " .

OK or NG OK >> GO TO 12.

NG >> Replace Drain filter. 12.

CHECK EVAP CANISTER VENT CONTROL VALVE

Refer to EC-1340, " Component Inspection " . SEF368U

Water should not exist

Page 2670 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1314< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0441 EVAP CONTROL SYSTEM

OK or NG OK >> GO TO 13.

NG >> Replace EVAP canister vent control valve. 13.

CHECK EVAP PURGE LINE

Inspect EVAP purge line (pipe NISSAN LATIO 2009 Service Repair Manual EC-1314< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0441 EVAP CONTROL SYSTEM

OK or NG OK >> GO TO 13.

NG >> Replace EVAP canister vent control valve. 13.

CHECK EVAP PURGE LINE

Inspect EVAP purge line (pipe](/img/5/57359/w960_57359-2669.png)

EC-1314< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0441 EVAP CONTROL SYSTEM

OK or NG OK >> GO TO 13.

NG >> Replace EVAP canister vent control valve. 13.

CHECK EVAP PURGE LINE

Inspect EVAP purge line (pipe and rubber tube). Check for evidence of leaks.

Refer to EC-1036, " Description " .

OK or NG OK >> GO TO 14.

NG >> Replace it. 14.

CLEAN EVAP PURGE LINE

Clean EVAP purge line (pipe and rubber tube) using air blower.

>> GO TO 15. 15.

CHECK INTERMITTENT INCIDENT

Refer to EC-1138 .

>> INSPECTION END

Component Inspection INFOID:0000000004535232

DRAIN FILTER

1. Check visually for insect nests in the drain filter air inlet.

2. Check visually for cracks or flaws in the appearance.

3. Check visually for cracks or flaws in the hose.

4. Blow air into port A and check t hat it flows freely out of port B.

5. Block port B.

6. Blow air into port A and check that there is no leakage.

7. If NG, replace drain filter. PBIB3641E