NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 2641 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

EC-1285

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Yes >> GO TO 4.

No >> GO TO 9. 4.

CHECK FUEL INJEC NISSAN LATIO 2009 Service Repair Manual DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

EC-1285

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Yes >> GO TO 4.

No >> GO TO 9. 4.

CHECK FUEL INJEC](/img/5/57359/w960_57359-2640.png)

DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

EC-1285

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Yes >> GO TO 4.

No >> GO TO 9. 4.

CHECK FUEL INJECTOR

Does each fuel injector make an operating sound at idle?

Yes or No Yes >> GO TO 5.

No >> Check fuel injector(s) and circuit(s). Refer to EC-1508 .

5.

CHECK FUNCTION OF IGNITION COIL-I

CAUTION:

Do the following procedure in the place where ventilation is good without the combustible.

1. Turn ignition switch OFF.

2. Remove fuel pump fuse (1) in IPDM E/R (2) to release fuel pres- sure.

NOTE:

Do not use CONSULT-III to release fuel pressure, or fuel pres-

sure applies again during the following procedure.

- : Vehicle front

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel

pressure.

5. Turn ignition switch OFF.

6. Remove all ignition coil harness connectors to avoid the electri-

cal discharge from the ignition coils.

7. Remove ignition coil and spark plug of the cylinder to be checked.

8. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

9. Connect spark plug and harness connector to ignition coil.

10. Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 - 0.66 in) between the edge of the spark plug and grounded metal

portion as shown in the figure.

11. Crank engine for about 3 seconds, and check whether spark is generated between the spark plug and the grounded metal por-

tion.

CAUTION:

• Do not approach to the spar k plug and the ignition coil

within 50cm. Be careful not to get an electrical shock

while checking, because the el ectrical discharge voltage

becomes 20kV or more.

• It might cause to damage the igni tion coil if the gap of more than 17 mm (0.66 in) is taken.

NOTE:

When the gap is less than 13 mm (0.52 in), the sp ark might be generated even if the coil is mal-

functioning.

OK or NG OK >> GO TO 9.

NG >> GO TO 6. 6.

CHECK FUNCTION OF IGNITION COIL-II

1. Turn ignition switch OFF.

2. Disconnect spark plug and connect a known-good spark plug. PBIB3332E

Spark should be generated. PBIB2958E

PBIB2325E

Page 2642 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1286< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

3. Crank engine for about 3 seconds, and recheck whether spark is generated between NISSAN LATIO 2009 Service Repair Manual EC-1286< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

3. Crank engine for about 3 seconds, and recheck whether spark is generated between](/img/5/57359/w960_57359-2641.png)

EC-1286< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

3. Crank engine for about 3 seconds, and recheck whether spark is generated between the spark plug and the grounded metal portion.

OK or NG OK >> GO TO 7.

NG >> Check ignition coil, power transistor and their circuits. Refer to EC-1518 .

7.

CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

OK or NG OK >> Replace spark plug(s) with standard type one(s). For

spark plug type, refer to EM-227, " Standard and Limit " .

NG >> 1. Repair or clean spark plug. 2. GO TO 8. 8.

CHECK FUNCTION OF IGNITION COIL-III

1. Reconnect the initial spark plugs.

2. Crank engine for about three seconds, and recheck whether spark is generated between the spark plug

and the grounded portion.

OK or NG OK >>

INSPECTION END

NG >> Replace spark plug(s) with standard type one(s). For spark plug type, refer to EM-227, " Standard

and Limit " .

9.

CHECK COMPRESSION PRESSURE

Check compression pressure. Refer to EM-185, " On-Vehicle Service " .

OK or NG OK >> GO TO 10.

NG >> Check pistons, piston rings, valves, valve seats and cylinder head gaskets. 10.

CHECK FUEL PRESSURE

1. Install all removed parts.

2. Release fuel pressure to zero. Refer to EC-1086, " Fuel Pressure Check " .

3. Install fuel pressure gauge and check fuel pressure. Refer to EC-1086, " Fuel Pressure Check " .

OK or NG OK >> GO TO 12.

NG >> GO TO 11. 11.

DETECT MALFUNCTIONING PART

Check the following.

• Fuel pump and circuit (Refer to EC-1513 .)

• Fuel pressure regulator (Refer to EC-1086, " Fuel Pressure Check " .)

• Fuel lines (Refer to FL-4, " Checking Fuel Line " .)

• Fuel filter for clogging

>> Repair or replace.

Spark should be generated.

SEF156I

Spark should be generated.

At idling: Approximately 350 kPa (3.57 kg/cm 2

, 51 psi)

Page 2643 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

EC-1287

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O 12.

CHECK IGNITION TIMING

Check the following item NISSAN LATIO 2009 Service Repair Manual DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

EC-1287

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O 12.

CHECK IGNITION TIMING

Check the following item](/img/5/57359/w960_57359-2642.png)

DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

EC-1287

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O 12.

CHECK IGNITION TIMING

Check the following items. Refer to EC-1078, " Basic Inspection " .

OK or NG OK >> GO TO 13.

NG >> Follow the EC-1078, " Basic Inspection " .

13.

CHECK AIR FUEL RATIO (A/F) SENS OR 1 CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect air fuel ratio (A/F ) sensor 1 harness connector (1).

- Air fuel ratio (A/F) sensor 1 (2)

3. Disconnect ECM harness connector.

4. Check harness continuity between the following terminals. Refer to Wiring Diagram.

5. Check harness continuity between ECM terminals 49, 53 or A/F sensor 1 terminals 1, 2 and ground.

Refer to Wiring Diagram.

6. Also check harness for short to power.

OK or NG OK >> GO TO 14.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. 14.

CHECK AIR FUEL RATIO (A/F) SENSOR 1 HEATER

Refer to EC-1158, " Component Inspection " .

OK or NG OK >> GO TO 16.

NG >> GO TO 15. 15.

REPLACE AIR FUEL RATIO (A/F) SENSOR 1

Replace air fuel ratio (A/F) sensor 1.

CAUTION:

• Discard any A/F sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

• Before installing new A/F senso r, clean exhaust system threads using Oxygen Sensor Thread

Cleaner tool J-43897-18 or J-43897-12 and approved anti-seize lubricant.

>> INSPECTION END 16.

CHECK MASS AIR FLOW SENSORItems Specifications

Target idle speed A/T: 700

± 50 rpm (in P or N position)

CVT: 700 ± 50 rpm (in P or N position)

M/T: 700 ± 50 rpm (in Neutral position)

Ignition timing A/T: 13

± 5 ° BTDC (in P or N position)

CVT: 13 ± 5 ° BTDC (in Neutral position)

M/T: 13 ± 5 ° BTDC (in Neutral position) A/F sensor 1 terminal ECM terminal

1 49

2 53

Continuity should exist.

Continuity should not exist. BBIA0699E

Page 2644 of 4331

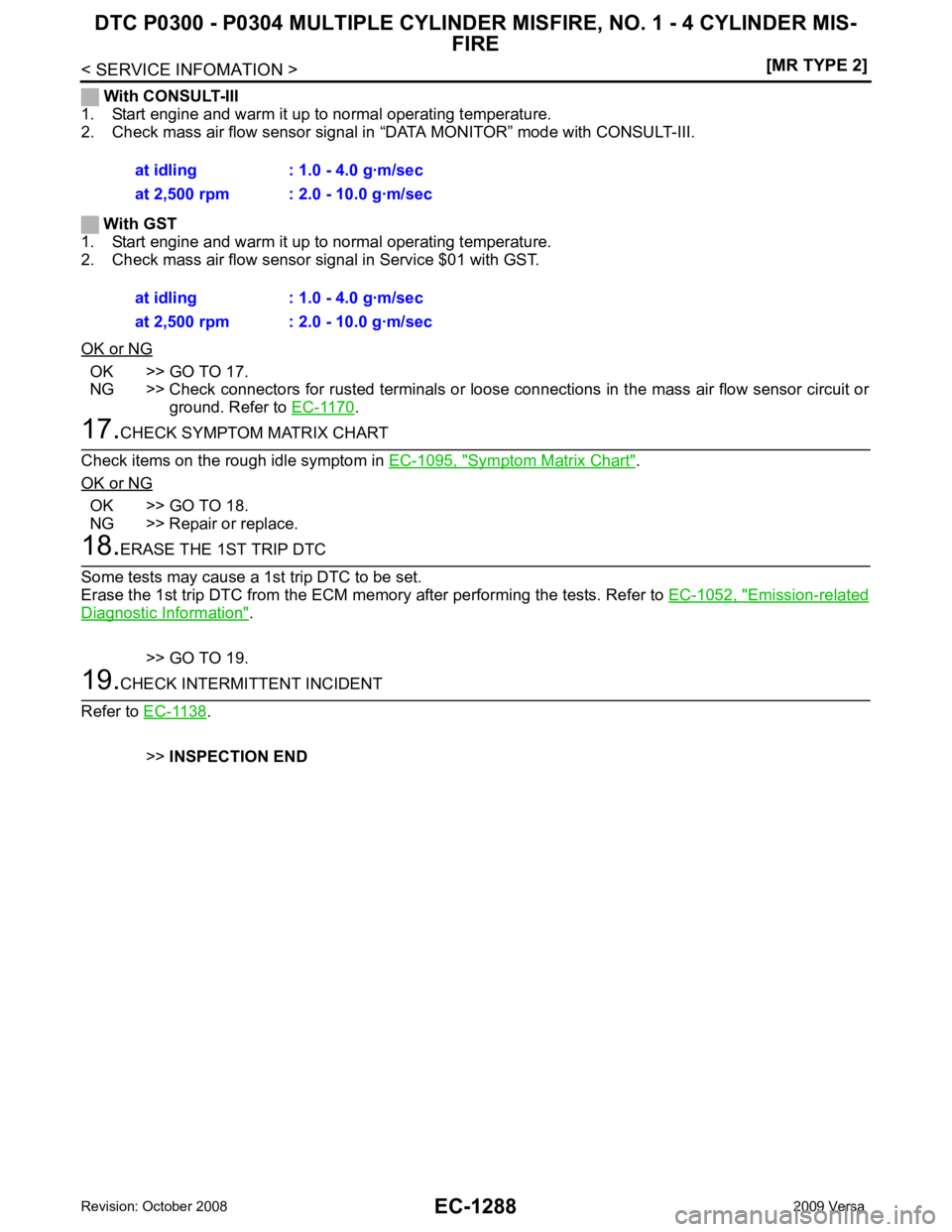

OK >> GO TO 17.

NG >> Check connectors for rusted terminals or loose connections in the mass air flow sensor circuit or

ground. Refer to EC-1170 .

Symptom Matrix Chart " .

OK or NG OK >> GO TO 18.

NG >> Repair or replace. Emission-related

Diagnostic Information " .

>> GO TO 19. .

>> INSPECTION END

at idling : 1.0 - 4.0 g·m/sec

at 2,500 rpm : 2.0 - 10.0 g·m/sec

at idling : 1.0 - 4.0 g·m/sec

at 2,500 rpm : 2.0 - 10.0 g·m/sec

Page 2645 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0327, P0328 KS

EC-1289

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0327, P0328 KS

Component Description INFOID:0000000004500143

The knock sensor (1) is attached NISSAN LATIO 2009 Service Repair Manual DTC P0327, P0328 KS

EC-1289

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0327, P0328 KS

Component Description INFOID:0000000004500143

The knock sensor (1) is attached](/img/5/57359/w960_57359-2644.png)

DTC P0327, P0328 KS

EC-1289

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0327, P0328 KS

Component Description INFOID:0000000004500143

The knock sensor (1) is attached to the cylinder block. It senses

engine knocking using a piezoelectric element. A knocking vibration

from the cylinder block is sensed as vibrational pressure. This pres-

sure is converted into a voltage signal and sent to the ECM.

• : Vehicle front

On Board Diagnosis Logic INFOID:0000000004500144

The MIL will not light up for these self-diagnoses.

DTC Confirmation Procedure INFOID:0000000004500145

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10V at idle.

1. Start engine and run it for at least 5 seconds at idle speed.

2. Check 1st trip DTC.

3. If 1st trip DTC is detected, go to EC-1291, " Diagnosis Procedure " . PBIB3264E

DTC No. Trouble Diagno

sis Name DTC Detected Co ndition Possible Cause

P0327

0327 Knock sensor circuit low

input An excessively low voltage from the sensor is

sent to ECM. • Harness or connectors

(Knock sensor circuit is open or shorted.)

• Knock sensor

P0328

0328 Knock sensor circuit high

input An excessively high voltage from the sensor is

sent to ECM.

Page 2646 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1290< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0327, P0328 KS

Wiring Diagram INFOID:0000000004500146

Specification data are reference values and are measured between each terminal and ground.

CAUTION: NISSAN LATIO 2009 Service Repair Manual EC-1290< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0327, P0328 KS

Wiring Diagram INFOID:0000000004500146

Specification data are reference values and are measured between each terminal and ground.

CAUTION:](/img/5/57359/w960_57359-2645.png)

EC-1290< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0327, P0328 KS

Wiring Diagram INFOID:0000000004500146

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring in put/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground ot her than ECM terminals, such as the ground. BBWA2637E

Page 2647 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0327, P0328 KS

EC-1291

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045001471.

CHECK KNOCK SENSOR INPUT SIGNAL CIRCUIT-I

1. Turn ignition NISSAN LATIO 2009 Service Repair Manual DTC P0327, P0328 KS

EC-1291

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045001471.

CHECK KNOCK SENSOR INPUT SIGNAL CIRCUIT-I

1. Turn ignition](/img/5/57359/w960_57359-2646.png)

DTC P0327, P0328 KS

EC-1291

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045001471.

CHECK KNOCK SENSOR INPUT SIGNAL CIRCUIT-I

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check resistance between ECM terminal 37 and ground. Refer to Wiring Diagram. NOTE:

It is necessary to use an ohmmeter which can measure more than 10 M Ω.

4. Also check harness for short to ground and short to power.

OK or NG OK >> GO TO 4.

NG >> GO TO 2. 2.

CHECK KNOCK SENSOR INPUT SIGNAL CIRCUIT-II

1. Disconnect knock sensor (1) harness connector.

- : Vehicle front

2. Check harness continuity between ECM terminal 37 and knock sensor terminal 1. Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors. 3.

CHECK KNOCK SENSOR

Refer to EC-1292, " Component Inspection " .

OK or NG OK >> GO TO 6.

NG >> Replace knock sensor. 4.

CHECK GROUND CONNECTIONS

Loosen and retighten ground screws on the body.

Refer to EC-1144, " Ground Inspection " .

TERMI-

NAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

37 W Knock sensor [Engine is running]

• Idle speed Approximately 2.5V

40 — Sensor ground

(Knock sensor) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0VResistance: Approximately 532 - 588k

Ω [at 20 °C (68 °F)]

Continuity should exist. PBIB3264E

BBIA0698E

Page 2648 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1292< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0327, P0328 KS

OK or NG OK >> GO TO 5.

NG >> Repair or replace ground connections. 5.

CHECK KNOCK SENSOR SHIELD CIRCUIT FOR OPEN AND SHORT

1. Reconnect k NISSAN LATIO 2009 Service Repair Manual EC-1292< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0327, P0328 KS

OK or NG OK >> GO TO 5.

NG >> Repair or replace ground connections. 5.

CHECK KNOCK SENSOR SHIELD CIRCUIT FOR OPEN AND SHORT

1. Reconnect k](/img/5/57359/w960_57359-2647.png)

EC-1292< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0327, P0328 KS

OK or NG OK >> GO TO 5.

NG >> Repair or replace ground connections. 5.

CHECK KNOCK SENSOR SHIELD CIRCUIT FOR OPEN AND SHORT

1. Reconnect knock sensor harness connector.

2. Check harness continuity between ECM terminal 40 and knock sensor terminal 2.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG OK >> GO TO 6.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. 6.

CHECK INTERMITTENT INCIDENT

Refer to EC-1138 .

>> INSPECTION END

Component Inspection INFOID:0000000004500148

KNOCK SENSOR

1. Check resistance between knock sensor terminal 1 and ground. NOTE:

It is necessary to use an ohmmeter which can measure

more than 10 M Ω.

CAUTION:

Do not use any knock sensors that have been dropped or

physically damaged. Use only new ones.

2. If NG, replace knock sensor.

Removal and Installation INFOID:0000000004500149

KNOCK SENSOR

Refer to EM-199, " Component " .

:

Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15 Continuity should exist

Resistance: Approximately 532 - 588k Ω [at 20 °C (68 °F)] SEF227W

Page 2649 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0335 CKP SENSOR (POS)

EC-1293

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0335 CKP SENSOR (POS)

Component Description INFOID:0000000004500150

The crankshaft position NISSAN LATIO 2009 Service Repair Manual DTC P0335 CKP SENSOR (POS)

EC-1293

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0335 CKP SENSOR (POS)

Component Description INFOID:0000000004500150

The crankshaft position](/img/5/57359/w960_57359-2648.png)

DTC P0335 CKP SENSOR (POS)

EC-1293

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0335 CKP SENSOR (POS)

Component Description INFOID:0000000004500150

The crankshaft position sensor (POS) is located on the cylinder

block rear housing facing the gear t eeth (cogs) of the signal plate at

the end of the crankshaft. It detects the fluctuation of the engine rev-

olution. The sensor consists of a permanent magnet and Hall IC.

When the engine is running, the high and low parts of the teeth

cause the gap with the sensor to change. The changing gap causes

the magnetic field near the sensor to change. Due to the changing

magnetic field, the voltage from the sensor changes. The ECM

receives the voltage signal and detects the fluctuation of the engine

revolution.

ECM receives the signals as shown in the figure.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004500151

Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004500152

DTC Confirmation Procedure INFOID:0000000004500153

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION: PBIA9209J

PBIB2997E

MONITOR ITEM CONDITION SPECIFICATION

ENG SPEED • Run engine and compare CONSULT-III value with the tachometer indica-

tion. Almost the same speed as the ta-

chometer indication. DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0335

0335 Crankshaft position sen-

sor (POS) circuit • The crankshaft position sensor (POS) signal is not

detected by the ECM during the first few seconds of

engine cranking.

• The proper pulse signal from the crankshaft position sensor (POS) is not sent to ECM while the engine is

running.

• The crankshaft position sensor (POS) signal is not in the normal pattern during engine running. • Harness or connectors

[Crankshaft position sensor (POS)

circuit is open or shorted.]

(Accelerator pedal position sensor

circuit is shorted.)

(Refrigerant pressure sensor circuit

is shorted.)

(EVAP control system pressure

sensor circuit is shorted.)

• Crankshaft position sensor (POS)

• Accelerator pedal position sensor

• Refrigerant pressure sensor

• EVAP control system pressure sen- sor

• Signal plate

Page 2650 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1294< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0335 CKP SENSOR (POS)

Before performing the following pro cedure, confirm that battery voltage is more than 10.5V with igni-

tion switch ON.

1. Crank eng NISSAN LATIO 2009 Service Repair Manual EC-1294< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0335 CKP SENSOR (POS)

Before performing the following pro cedure, confirm that battery voltage is more than 10.5V with igni-

tion switch ON.

1. Crank eng](/img/5/57359/w960_57359-2649.png)

EC-1294< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0335 CKP SENSOR (POS)

Before performing the following pro cedure, confirm that battery voltage is more than 10.5V with igni-

tion switch ON.

1. Crank engine for at least 2 seconds and run it for at least 5 seconds at idle speed.

2. Check 1st trip DTC.

3. If 1st trip DTC is detected, go to EC-1295, " Diagnosis Procedure " .

Wiring Diagram INFOID:0000000004500154 BBWA3071E