NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 2671 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0442 EVAP CONTROL SYSTEM

EC-1315

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0442 EVAP CONTROL SYSTEM

On Board Diagnosis Logic INFOID:0000000004500175

This diagnosis d NISSAN LATIO 2009 Service Repair Manual DTC P0442 EVAP CONTROL SYSTEM

EC-1315

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0442 EVAP CONTROL SYSTEM

On Board Diagnosis Logic INFOID:0000000004500175

This diagnosis d](/img/5/57359/w960_57359-2670.png)

DTC P0442 EVAP CONTROL SYSTEM

EC-1315

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0442 EVAP CONTROL SYSTEM

On Board Diagnosis Logic INFOID:0000000004500175

This diagnosis detects leaks in the EVAP purge line using engine intake manifold vacuum.

If pressure does not increase, the ECM will check for l eaks in the line between the fuel tank and EVAP canister

purge volume control solenoid valve, under the following Vacuum test conditions.

The EVAP canister vent control valve is closed to s hut the EVAP purge line off. The EVAP canister purge vol-

ume control solenoid valve will then be opened to depressurize the EVAP purge line using intake manifold

vacuum. After this occurs, the EVAP canister purge volume control solenoid valve will be closed.

CAUTION:

• Use only a genuine NISSAN fuel filler cap as a replacemen t. If an incorrect fuel filler cap is used, the

MIL may come on.

• If the fuel filler cap is not tigh tened properly, the MIL may come on.

• Use only a genuine NISSAN rubber tube as a replacement. DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0442

0442 EVAP control system

small leak detected

(negative pressure) EVAP control system has a leak, EVAP

control system does not operate prop-

erly. • Incorrect fuel tank vacuum relief valve

• Incorrect fuel filler cap used

• Fuel filler cap remains open or fails to close.

• Foreign matter caught in fuel filler cap.

• Leak is in line between intake manifold and EVAP canister purge volume control solenoid valve.

• Foreign matter caught in EVAP canister vent con- trol valve.

• EVAP canister or fuel tank leaks

• EVAP purge line (pipe and rubber tube) leaks

• EVAP purge line rubber tube bent

• Loose or disconnected rubber tube

• EVAP canister vent control valve and the circuit

• EVAP canister purge volume control solenoid valve and the circuit

• Fuel tank temperature sensor

• O-ring of EVAP canister vent control valve is missing or damaged

• Drain filter

• EVAP canister is saturated with water

• EVAP control system pressure sensor

• Fuel level sensor and the circuit

• Refueling EVAP vapor cut valve

• ORVR system leaks PBIB3640E

Page 2672 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1316< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0442 EVAP CONTROL SYSTEM

DTC Confirmation Procedure INFOID:0000000004500176

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, a NISSAN LATIO 2009 Service Repair Manual EC-1316< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0442 EVAP CONTROL SYSTEM

DTC Confirmation Procedure INFOID:0000000004500176

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, a](/img/5/57359/w960_57359-2671.png)

EC-1316< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0442 EVAP CONTROL SYSTEM

DTC Confirmation Procedure INFOID:0000000004500176

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

• Perform “DTC WORK SUPPORT” when the fuel level is between 1/4 and 3/4 full, and vehicle is placed

on flat level surface.

• Always perform test at a temperature of 0 to 30 °C (32 to 86 °F).

• Open engine hood before conducting following procedure.

WITH CONSULT-III

1. Turn ignition switch ON.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT-III.

4. Check the following conditions are met.

COOLAN TEMP/S: 0 - 70 °C (32 - 158 °F)

INT/A TEMP SE: 0 - 30 °C (32 - 86 °F)

5. Select “EVAP SML LEAK P0442/P1442” of “EV APORATIVE SYSTEM” in “DTC WORK SUPPORT” mode

with CONSULT-III.

Follow the instruction displayed.

NOTE:

If the engine speed cannot be maintained within t he range displayed on the CONSULT-III screen, go to

EC-1078, " Basic Inspection " .

6. Make sure that “OK” is displayed. If “NG” is displayed, refer to EC-1316, " Diagnosis Procedure " .

NOTE:

Make sure that EVAP hoses are connected to th e EVAP canister purge volume control solenoid

valve properly.

WITH GST

NOTE:

Be sure to read the explanation of Driving Pattern on EC-1052, " Emission-related Diagnostic Information "

before driving vehicle.

1. Start engine.

2. Drive vehicle according to Driving Pattern, EC-1052, " Emission-related Diagnostic Information " .

3. Stop vehicle.

4. Turn ignition switch OFF and wait at leas t 10 seconds and then turn ignition switch ON.

5. Select Service $07 with GST.

- If P0442 is displayed on the screen, go to EC-1316, " Diagnosis Procedure " .

- If P0441 is displayed on the screen, go to EC-1311, " Diagnosis Procedure " for DTC P0441.

Diagnosis Procedure INFOID:00000000045001771.

CHECK FUEL FILLER CAP DESIGN

1. Turn ignition switch OFF.

2. Check for genuine NISSAN fuel filler cap design.

OK or NG OK >> GO TO 2.

NG >> Replace with genuine NISSAN fuel filler cap. 2.

CHECK FUEL FILLER CAP INSTALLATION

Check that the cap is tightened proper ly by rotating the cap clockwise. SEF915U

Page 2673 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0442 EVAP CONTROL SYSTEM

EC-1317

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 3.

NG >> 1. Open fuel filler cap, then clean cap and fuel filler neck thre NISSAN LATIO 2009 Service Repair Manual DTC P0442 EVAP CONTROL SYSTEM

EC-1317

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 3.

NG >> 1. Open fuel filler cap, then clean cap and fuel filler neck thre](/img/5/57359/w960_57359-2672.png)

DTC P0442 EVAP CONTROL SYSTEM

EC-1317

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 3.

NG >> 1. Open fuel filler cap, then clean cap and fuel filler neck threads using air blower.

2. Retighten until reteaching sound is heard. 3.

CHECK FUEL FILLER CAP FUNCTION

Check for air releasing sound while opening the fuel filler cap.

OK or NG OK >> GO TO 5.

NG >> GO TO 4. 4.

CHECK FUEL TANK VACUUM RELIEF VALVE

Refer to EC-1038, " Component Inspection " .

OK or NG OK >> GO TO 5.

NG >> Replace fuel filler cap with a genuine one. 5.

INSTALL THE PRESSURE PUMP

To locate the EVAP leak, install EVAP service port adapter and pressure pump to EVAP service port securely.

For the location of EVAP service port (2), refer to EC-1036, " Descrip-

tion " .

• EVAP canister purge volume control solenoid valve (1)

• : Vehicle front

NOTE:

Improper installation of the EV AP service port adapter to the

EVAP service port may cause leaking.

With CONSULT-III>>GO TO 6.

Without CONSULT-III>>GO TO 7. 6.

CHECK FOR EVAP LEAK

With CONSULT-III

1. Turn ignition switch ON.

2. Select “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode with CONSULT-III.

3. Touch “START” and apply pressure into the EVAP li ne until the pressure indicator reaches the middle of

the bar graph.

CAUTION:

• Never use compressed air or a high pressure pump.

• Do not exceed 4.12 kPa (0.042 kg/cm 2

, 0.6 psi) of pressure in the system. BBIA0703E

SEF916U

Page 2674 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1318< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0442 EVAP CONTROL SYSTEM

4. Using EVAP leak detector, locate the EVAP leak. For the leak detector, refer to the instruction manual for more det NISSAN LATIO 2009 Service Repair Manual EC-1318< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0442 EVAP CONTROL SYSTEM

4. Using EVAP leak detector, locate the EVAP leak. For the leak detector, refer to the instruction manual for more det](/img/5/57359/w960_57359-2673.png)

EC-1318< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0442 EVAP CONTROL SYSTEM

4. Using EVAP leak detector, locate the EVAP leak. For the leak detector, refer to the instruction manual for more details.

Refer to EC-1036, " Description " .

OK or NG OK >> GO TO 8.

NG >> Repair or replace. 7.

CHECK FOR EVAP LEAK

Without CONSULT-III

1. Turn ignition switch OFF.

2. Apply 12 volts DC to EVAP canister vent control valve. The valve will close. (Continue to appl y 12 volts until the end of test.)

- EVAP control system pressure sensor (1)

- EVAP canister (2)

- EVAP canister vent control valve (3)

3. Pressurize the EVAP line using pressure pump with 1.3 to 2.7

kPa (10 to 20 mmHg, 0.39 to 0.79 inHg), then remove pump and

EVAP service port adapter.

CAUTION:

• Never use compressed air or a high pressure pump.

• Do not exceed 4.12 kPa (0.042 kg/cm 2

, 0.6 psi) of pressure

in the system.

4. Using EVAP leak detector, locate the EVAP leak. For the leak detector, refer to the instruction manual for more details. Refer

to EC-1036, " Description " .

OK or NG OK >> GO TO 8.

NG >> Repair or replace. 8.

CHECK DRAIN FILTER

Refer to EC-1321, " Component Inspection " .

OK or NG OK >> GO TO 9.

NG >> Replace drain filter. 9.

CHECK EVAP CANISTER VENT CONTROL VALVE

Check the following,

• EVAP canister vent control valve is installed properly. Refer to EC-1040, " Removal and Installation " .

• EVAP canister vent control valve.

Refer to EC-1340, " Component Inspection " .

OK or NG OK >> GO TO 10.

NG >> Repair or replace EVAP cani ster vent control valve and O-ring.10.

CHECK IF EVAP CANISTER SATURATED WITH WATER SEF200U

BBIA0693E

SEF200U

Page 2675 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0442 EVAP CONTROL SYSTEM

EC-1319

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Remove EVAP canister with EVAP canister vent c

ontrol valve and EVAP control system pressure NISSAN LATIO 2009 Service Repair Manual DTC P0442 EVAP CONTROL SYSTEM

EC-1319

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Remove EVAP canister with EVAP canister vent c

ontrol valve and EVAP control system pressure](/img/5/57359/w960_57359-2674.png)

DTC P0442 EVAP CONTROL SYSTEM

EC-1319

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Remove EVAP canister with EVAP canister vent c

ontrol valve and EVAP control system pressure sensor

attached.

2. Does water drain from the EVAP canister?

Yes or No Yes >> GO TO 11.

No (With CONSULT-III)>>GO TO 13.

No (Without CONSULT-III)>>GO TO 14. 11.

CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pressure sen-

sorattached.

The weight should be less than 1.9 kg (4.2 lb).

OK or NG OK (With CONSULT-III)>>GO TO 13.

OK (Without CONSULT-III)>>GO TO 14.

NG >> GO TO 12. 12.

DETECT MALFUNCTIONING PART

Check the following.

• EVAP canister for damage

• EVAP hose connected to EVAP canister for clogging or poor connection

>> Repair hose or replace EVAP canister. 13.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

With CONSULT-III

1. Disconnect vacuum hose to EVAP canister purge volu me control solenoid valve at EVAP service port.

2. Start engine.

3. Perform “PURG VOL CONT/V ” in “ACTIVE TEST” mode.

4. Touch “Qu” on CONSULT-III screen to increase “PURG VOL CONT/V” opening to 100%.

5. Check vacuum hose for vacuum.

OK or NG OK >> GO TO 16.

NG >> GO TO 15. 14.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

Without CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Disconnect vacuum hose to EVAP canister purge volu me control solenoid valve at EVAP service port.

4. Start engine and let it idle for at least 80 seconds.

5. Check vacuum hose for vacuum when revving engine up to 2,000 rpm.

OK or NG OK >> GO TO 16.

NG >> GO TO 15. 15.

CHECK VACUUM HOSE PBIB1213E

Vacuum should exist.

Vacuum should exist.

Page 2676 of 4331

Vacuum Hose Drawing " .

OK or NG OK >> GO TO 16.

NG >> Repair or reconnect the hose. Component Inspection " .

OK or NG OK >> GO TO 17.

NG >> Replace EVAP canister purge volume control solenoid valve. Component Inspection " .

OK or NG OK >> GO TO 18.

NG >> Replace fuel level sensor unit. Component Inspection " .

OK or NG OK >> GO TO 19.

NG >> Replace EVAP control system pressure sensor. .

OK or NG OK >> GO TO 20.

NG >> Repair or reconnect the hose. .

OK or NG OK >> GO TO 22.

NG >> Repair or replace hoses and tubes. OK >> GO TO 23.

NG >> Repair or replace hoses, tubes or filler neck tube. Component Inspection " .

OK or NG OK >> GO TO 24.

NG >> Replace refueling EVAP vapor cut valve with fuel tank. .

Page 2677 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0442 EVAP CONTROL SYSTEM

EC-1321

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 25.

NG >> Replace fuel level sensor unit. 25.

CHECK INTERMITTENT INCIDENT

NISSAN LATIO 2009 Service Repair Manual DTC P0442 EVAP CONTROL SYSTEM

EC-1321

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 25.

NG >> Replace fuel level sensor unit. 25.

CHECK INTERMITTENT INCIDENT](/img/5/57359/w960_57359-2676.png)

DTC P0442 EVAP CONTROL SYSTEM

EC-1321

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 25.

NG >> Replace fuel level sensor unit. 25.

CHECK INTERMITTENT INCIDENT

Refer to EC-1138 .

>> INSPECTION END

Component Inspection INFOID:0000000004535233

DRAIN FILTER 1. Check visually for insect nests in the drain filter air inlet.

2. Check visually for cracks or flaws in the appearance.

3. Check visually for cracks or flaws in the hose.

4. Blow air into port A and check that it flows freely out of port B.

5. Block port B.

6. Blow air into port A and check that there is no leakage.

7. If NG, replace drain filter. PBIB3641E

Page 2678 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1322< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0443 EVAP CANISTER PURGE VO

LUME CONTROL SOLENOID VALVE

DTC P0443 EVAP CANISTER PURG E VOLUME CONTROL SOLENOID

VALVE

Description INFOID:0000000004 NISSAN LATIO 2009 Service Repair Manual EC-1322< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0443 EVAP CANISTER PURGE VO

LUME CONTROL SOLENOID VALVE

DTC P0443 EVAP CANISTER PURG E VOLUME CONTROL SOLENOID

VALVE

Description INFOID:0000000004](/img/5/57359/w960_57359-2677.png)

EC-1322< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0443 EVAP CANISTER PURGE VO

LUME CONTROL SOLENOID VALVE

DTC P0443 EVAP CANISTER PURG E VOLUME CONTROL SOLENOID

VALVE

Description INFOID:0000000004500178

SYSTEM DESCRIPTION

*1: ECM determines the start signal status by the signals of engine speed and battery voltage.

*2: This signal is sent to the ECM though CAN communication line.

This system controls flow rate of fuel vapor from the EVAP canister. The opening of the vapor by-pass pas-

sage in the EVAP canister purge volume control sol enoid valve changes to control the flow rate. The EVAP

canister purge volume control solenoid valve repeats ON/O FF operation according to the signal sent from the

ECM. The opening of the valve varies for optimum engi ne control. The optimum value stored in the ECM is

determined by considering various engine conditions. When t he engine is operating, the flow rate of fuel vapor

from the EVAP canister is r egulated as the air flow changes.

COMPONENT DESCRIPTION

The EVAP canister purge volume control solenoid valve uses a ON/

OFF duty to control the flow rate of fuel vapor from the EVAP canis-

ter. The EVAP canister purge volume control solenoid valve is

moved by ON/OFF pulses from the ECM. The longer the ON pulse,

the greater the amount of fuel vapor that will flow through the valve.

CONSULT-III Reference Value in Data Monitor Mode INFOID:0000000004500179

Specification data are reference values. Sensor Input Signal to ECM

ECM

function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed*

1

EVAP can-

ister purge

flow control EVAP canister purge volume

control solenoid valve

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Battery Battery voltage*1

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Air fuel ratio (A/F) sensor 1 Density of oxygen in exhaust gas

(Mixture ratio feedback signal)

Fuel tank temperature sensor Fuel temperature in fuel tank

ABS actuator and electric unit (control unit) Vehicle speed*2

Combination meter PBIA9215J

MONITOR ITEM CONDITION SPECIFICATION

PURG VOL C/V • Engine: After warming up

• Shift lever: P or N (A/T, CVT), Neutral (M/T)

• Air conditioner switch: OFF

• No load Idle

(Accelerator pedal is not depressed

even slightly, after engine starting) 0%

2,000 rpm 0 - 50%

Page 2679 of 4331

EC

NP

O

On Board Diagnosis Logic

INFOID:0000000004500180

DTC Confirmation Procedure INFOID:0000000004500181

Perform PROCEDURE FOR MALFUNCTION A first.

If the DTC cannot be confirmed, perform PROCEDURE FOR MALFUNCTION B.

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

PROCEDURE FOR MALFUNCTION A TESTING CONDITION:

• Perform "DTC Confirmation Procedure" when the fuel le vel is between 1/4 and 3/4 full, and vehicle is placed

on flat level surface.

• Always perform test at a temperature of 5 to 60 °C (41 to 140 °F).

• Cool the vehicle so that engine coolant temperat ure becomes same level as ambient temperature.

With CONSULT-III

1. Turn ignition switch ON and select "DATA MONITOR" mode with CONSULT-III.

2. Check that the following condition are met. FUEL T/TMP SE: 0 – 35 °C (32 – 95 °F)

3. Start engine and wait at least 60 seconds.

4. Check 1st trip DTC.

5. If 1st trip DTC is detected, go to EC-1326, " Diagnosis Procedure " .

With GST

1. Turn ignition switch ON.

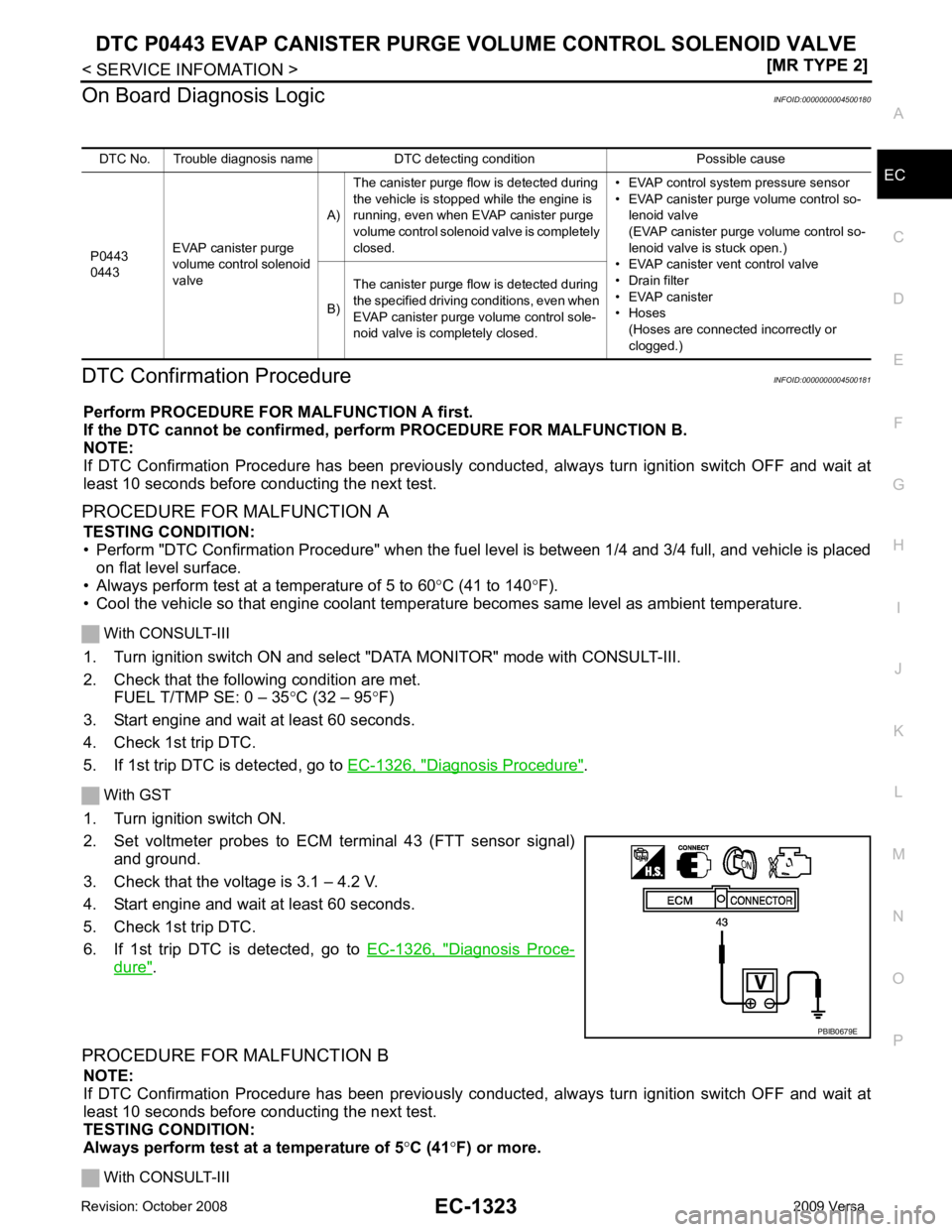

2. Set voltmeter probes to ECM terminal 43 (FTT sensor signal) and ground.

3. Check that the voltage is 3.1 – 4.2 V.

4. Start engine and wait at least 60 seconds.

5. Check 1st trip DTC.

6. If 1st trip DTC is detected, go to EC-1326, " Diagnosis Proce-

dure " .

PROCEDURE FOR MALFUNCTION B NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Always perform test at a temperature of 5 °C (41 °F) or more.

With CONSULT-III

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0443

0443 EVAP canister purge

volume control solenoid

valve A)

The canister purge flow is detected during

the vehicle is stopped while the engine is

running, even when EVAP canister purge

volume control solenoid valve is completely

closed. • EVAP control system pressure sensor

• EVAP canister purge volume control so-

lenoid valve

(EVAP canister purge volume control so-

lenoid valve is stuck open.)

• EVAP canister vent control valve

• Drain filter

• EVAP canister

• Hoses (Hoses are connected incorrectly or

clogged.)

B)

The canister purge flow is detected during

the specified driving conditions, even when

EVAP canister purge volume control sole-

noid valve is completely closed.

Page 2680 of 4331

1326, " Diagnosis Procedure " .

With GST

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and let it idle for at least 20 seconds.

4. Select Service $07 with GST.

5. If 1st trip DTC is detected, go to EC-1326, " Diagnosis Procedure " .