sensor NISSAN LATIO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 2634 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1278< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0222, P0223 TP SENSOR

DTC P0222, P0223 TP SENSOR

Component Description INFOID:0000000004501170

Electric throttle control actuator consists of throt NISSAN LATIO 2009 Service Repair Manual EC-1278< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0222, P0223 TP SENSOR

DTC P0222, P0223 TP SENSOR

Component Description INFOID:0000000004501170

Electric throttle control actuator consists of throt](/img/5/57359/w960_57359-2633.png)

EC-1278< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0222, P0223 TP SENSOR

DTC P0222, P0223 TP SENSOR

Component Description INFOID:0000000004501170

Electric throttle control actuator consists of throttle control motor,

throttle position sensor, etc. The throttle position sensor responds to

the throttle valve movement.

The throttle position sensor has two sensors. These sensors are a

kind of potentiometers which transform the throttle valve position into

output voltage, and emit the voltage signal to the ECM. In addition,

these sensors detect the opening and closing speed of the throttle

valve and feed the voltage signals to the ECM. The ECM judges the

current opening angle of the throttle valve from these signals and the

ECM controls the throttle control motor to make the throttle valve

opening angle properly in response to driving condition.

CONSULT-III Reference Value in Data Monitor Mode INFOID:0000000004501171

Specification data are reference values.

*: Throttle position sensor 2 signal is converted by ECM internally. Thus, it differs from ECM terminal voltage signal.

On Board Diagn osis Logic INFOID:0000000004500134

These self-diagnoses have the one trip detection logic.

NOTE:

If DTC P0222 or P0223 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643.

Refer to EC-1396 .

FAIL-SAFE MODE

When the malfunction is detected, the ECM enters fail-safe mode and the MIL lights up.

DTC Confirmation Procedure INFOID:0000000004500135

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 8V at idle.

1. Start engine and let it idle for 1 second. PBIB0145E

MONITOR ITEM CONDITION SPECIFICATION

TP SEN 1-B1

TP SEN 2-B1* • Ignition switch: ON

(Engine stopped)

• Shift lever: D (A/T, CVT),

1st (M/T) Accelerator pedal: Fully released More than 0.36V

Accelerator pedal: Fully depressed Less than 4.75V DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0222

0222 Throttle position sensor

1 circuit low input An excessively low voltage from the TP sensor

1 is sent to ECM. • Harness or connectors

(TP sensor 1 circuit is open or shorted.)

(APP sensor 2 circuit is shorted.)

• Electric throttle control actuator (TP sensor 1)

• Accelerator pedal position sensor (APP sensor 2)

P0223

0223 Throttle position sensor

1 circuit high input An excessively high voltage from the TP sensor

1 is sent to ECM. Engine operation condition in fail-safe mode

The ECM controls the electric throttle control actuator in regulating the throttle opening in order for the idle position to be within +10

degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal condition.

So, the acceleration will be poor.

Page 2635 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0222, P

0223 TP SENSOR

EC-1279

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Check DTC.

3. If DTC is detected, go to EC-1280, " Diagnosis Procedure " .

Wiring Diagram INF NISSAN LATIO 2009 Service Repair Manual DTC P0222, P

0223 TP SENSOR

EC-1279

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Check DTC.

3. If DTC is detected, go to EC-1280, " Diagnosis Procedure " .

Wiring Diagram INF](/img/5/57359/w960_57359-2634.png)

DTC P0222, P

0223 TP SENSOR

EC-1279

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Check DTC.

3. If DTC is detected, go to EC-1280, " Diagnosis Procedure " .

Wiring Diagram INFOID:0000000004500136

Specification data are reference values and are measured between each terminal and ground.

CAUTION: BBWA2655E

Page 2636 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1280< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0222, P0223 TP SENSOR

Do not use ECM ground terminals when measuring in put/output voltage. Doing so may result in dam-

age to the ECMs transistor. Use NISSAN LATIO 2009 Service Repair Manual EC-1280< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0222, P0223 TP SENSOR

Do not use ECM ground terminals when measuring in put/output voltage. Doing so may result in dam-

age to the ECMs transistor. Use](/img/5/57359/w960_57359-2635.png)

EC-1280< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0222, P0223 TP SENSOR

Do not use ECM ground terminals when measuring in put/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground ot her than ECM terminals, such as the ground.

Diagnosis Procedure INFOID:00000000045001371.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screw on the body. Refer to EC-1144, " Ground Inspection " .

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. 2.

CHECK THROTTLE POSITION SE NSOR 1 POWER SUPPLY CIRCUIT-I

TERMI-

NAL

NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

33 LG Throttle position sensor 1 [Ignition switch: ON]

• Engine stopped

• Shift lever: D (A/T, CVT), 1st (M/T)

• Accelerator pedal: Fully released More than 0.36V

[Ignition switch: ON]

• Engine stopped

• Shift lever: D (A/T, CVT), 1st (M/T)

• Accelerator pedal: Fully depressed Less than 4.75V

34 O Throttle position sensor 2 [Ignition switch: ON]

• Engine stopped

• Shift lever: D (A/T, CVT), 1st (M/T)

• Accelerator pedal: Fully released Less than 4.75V

[Ignition switch: ON]

• Engine stopped

• Shift lever: D (A/T, CVT), 1st (M/T)

• Accelerator pedal: Fully depressed More than 0.36V

36 Y Sensor ground

(Throttle position sensor) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0V

72 V Sensor power supply

(Throttle position sensor) [Ignition switch: ON]

Approximately 5V:

Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15 BBIA0698E

Page 2637 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0222, P

0223 TP SENSOR

EC-1281

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Disconnect electric throttle c

ontrol actuator (1) harness connec-

tor.

- : Vehicle front

2. T NISSAN LATIO 2009 Service Repair Manual DTC P0222, P

0223 TP SENSOR

EC-1281

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Disconnect electric throttle c

ontrol actuator (1) harness connec-

tor.

- : Vehicle front

2. T](/img/5/57359/w960_57359-2636.png)

DTC P0222, P

0223 TP SENSOR

EC-1281

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Disconnect electric throttle c

ontrol actuator (1) harness connec-

tor.

- : Vehicle front

2. Turn ignition switch ON.

3. Check voltage between electric throttle control actuator terminal 2 and ground with CONSULT-III or tester.

OK or NG OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power in harness connectors. 3.

CHECK THROTTLE POSITI ON SENSOR 1 GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 36 and electric throttle control actuator terminal 4.

Refer to Wiring Diagram.

4. Also check harness for short to ground or short to power.

OK or NG OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. 4.

CHECK THROTTLE POSI TION SENSOR 1 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 33 and electric throttle control actuator terminal 1.

Refer to Wiring Diagram.

2. Also check harness for short to ground and short to power.

OK or NG OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. 5.

CHECK THROTTLE POSITION SENSOR

Refer to EC-1282, " Component Inspection " .

OK or NG OK >> GO TO 7.

NG >> GO TO 6. 6.

REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

1. Replace the electric throttle control actuator.

2. Perform EC-1084, " Throttle Valve Closed Position Learning " .

3. Perform EC-1084, " Idle Air Volume Learning " . PBIB3325E

Voltage: Approximately 5V

PBIB3311E

Continuity should exist.

Continuity should exist.

Page 2638 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1282< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0222, P0223 TP SENSOR

>> INSPECTION END 7.

CHECK INTERMITTENT INCIDENT

Refer to EC-1138 .

>> INSPECTION END

Component Inspection INFOID:0000000004501172 NISSAN LATIO 2009 Service Repair Manual EC-1282< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0222, P0223 TP SENSOR

>> INSPECTION END 7.

CHECK INTERMITTENT INCIDENT

Refer to EC-1138 .

>> INSPECTION END

Component Inspection INFOID:0000000004501172](/img/5/57359/w960_57359-2637.png)

EC-1282< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0222, P0223 TP SENSOR

>> INSPECTION END 7.

CHECK INTERMITTENT INCIDENT

Refer to EC-1138 .

>> INSPECTION END

Component Inspection INFOID:0000000004501172

THROTTLE POSITION SENSOR

1. Reconnect all harness connectors disconnected.

2. Perform EC-1084, " Throttle Valve Closed Position Learning " .

3. Turn ignition switch ON.

4. Set shift lever to D position (A/T, CVT) or 1st position (M/T).

5. Check voltage between ECM terminals 33 (TP sensor 1 signal), 34 (TP sensor 2 signal) and ground under the following condi-

tions.

6. If NG, replace electric throttle control actuator and go to the next step.

7. Perform EC-1084, " Throttle Valve Closed Position Learning " .

8. Perform EC-1084, " Idle Air Volume Learning " .

Removal and Installation INFOID:0000000004501173

ELECTRIC THROTTLE CONTROL ACTUATOR

Refer to EM-141, " Removal and Installation " .

Terminal Accelerator pedal Voltage

33

(Throttle position sensor 1) Fully released More than 0.36V

Fully depressed Less than 4.75V

34

(Throttle position sensor 2) Fully released Less than 4.75V

Fully depressed More than 0.36V PBIB3038E

Page 2639 of 4331

EC

NP

O

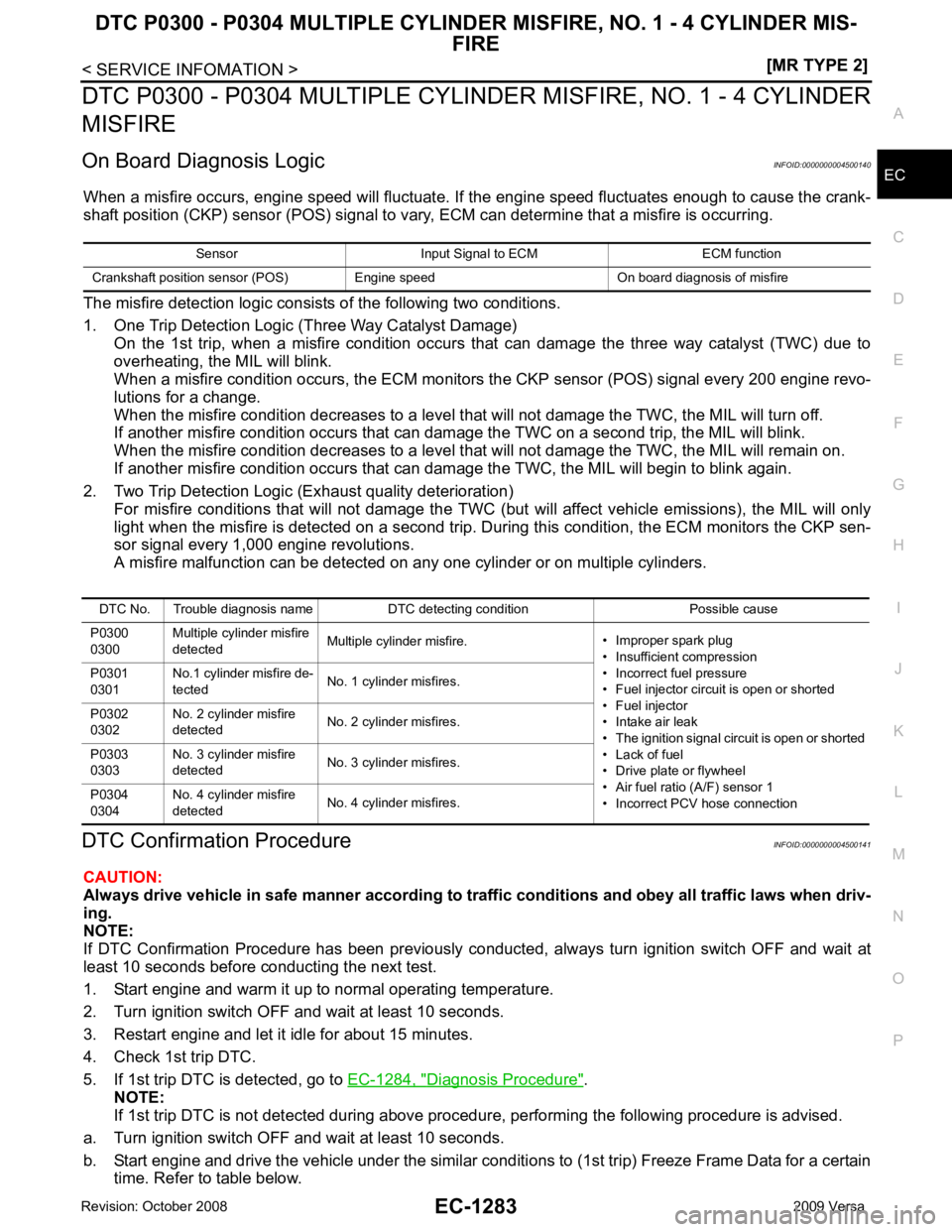

DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER

MISFIRE

On Board Diagnosis Logic INFOID:0000000004500140

When a misfire occurs, engine speed will fluctuate. If the engine speed fluctuates enough to cause the crank-

shaft position (CKP) sensor (POS) signal to vary , ECM can determine that a misfire is occurring.

The misfire detection logic consists of the following two conditions.

1. One Trip Detection Logic (Three Way Catalyst Damage) On the 1st trip, when a misfire condition occurs that can damage the three way catalyst (TWC) due to

overheating, the MIL will blink.

When a misfire condition occurs, the ECM monitors the CKP sensor (POS) signal every 200 engine revo-

lutions for a change.

When the misfire condition decreases to a level t hat will not damage the TWC, the MIL will turn off.

If another misfire condition occurs that can damage the TWC on a second trip, the MIL will blink.

When the misfire condition decreases to a level t hat will not damage the TWC, the MIL will remain on.

If another misfire condition occurs that can damage the TWC, the MIL will begin to blink again.

2. Two Trip Detection Logic (Exhaust quality deterioration) For misfire conditions that will not damage the TWC (but will affect vehicle emissions), the MIL will only

light when the misfire is detected on a second trip. Du ring this condition, the ECM monitors the CKP sen-

sor signal every 1,000 engine revolutions.

A misfire malfunction can be detected on any one cylinder or on multiple cylinders.

DTC Confirmation Procedure INFOID:0000000004500141

CAUTION:

Always drive vehicle in safe manner according to traf fic conditions and obey all traffic laws when driv-

ing.

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Restart engine and let it idle for about 15 minutes.

4. Check 1st trip DTC.

5. If 1st trip DTC is detected, go to EC-1284, " Diagnosis Procedure " .

NOTE:

If 1st trip DTC is not detected during above proc edure, performing the following procedure is advised.

a. Turn ignition switch OFF and wait at least 10 seconds.

b. Start engine and drive the vehicle under the similar conditi ons to (1st trip) Freeze Frame Data for a certain

time. Refer to table below. Sensor Input Signal to ECM ECM function

Crankshaft position sensor (POS) Engine speed On board diagnosis of misfire DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0300

0300 Multiple cylinder misfire

detected Multiple cylinder misfire.

• Improper spark plug

• Insufficient compression

• Incorrect fuel pressure

• Fuel injector circuit is open or shorted

• Fuel injector

• Intake air leak

• The ignition signal circuit is open or shorted

• Lack of fuel

• Drive plate or flywheel

• Air fuel ratio (A/F) sensor 1

• Incorrect PCV hose connection

P0301

0301 No.1 cylinder misfire de-

tected No. 1 cylinder misfires.

P0302

0302 No. 2 cylinder misfire

detected No. 2 cylinder misfires.

P0303

0303 No. 3 cylinder misfire

detected No. 3 cylinder misfires.

P0304

0304 No. 4 cylinder misfire

detected No. 4 cylinder misfires.

Page 2643 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

EC-1287

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O 12.

CHECK IGNITION TIMING

Check the following item NISSAN LATIO 2009 Service Repair Manual DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

EC-1287

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O 12.

CHECK IGNITION TIMING

Check the following item](/img/5/57359/w960_57359-2642.png)

DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

EC-1287

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O 12.

CHECK IGNITION TIMING

Check the following items. Refer to EC-1078, " Basic Inspection " .

OK or NG OK >> GO TO 13.

NG >> Follow the EC-1078, " Basic Inspection " .

13.

CHECK AIR FUEL RATIO (A/F) SENS OR 1 CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect air fuel ratio (A/F ) sensor 1 harness connector (1).

- Air fuel ratio (A/F) sensor 1 (2)

3. Disconnect ECM harness connector.

4. Check harness continuity between the following terminals. Refer to Wiring Diagram.

5. Check harness continuity between ECM terminals 49, 53 or A/F sensor 1 terminals 1, 2 and ground.

Refer to Wiring Diagram.

6. Also check harness for short to power.

OK or NG OK >> GO TO 14.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. 14.

CHECK AIR FUEL RATIO (A/F) SENSOR 1 HEATER

Refer to EC-1158, " Component Inspection " .

OK or NG OK >> GO TO 16.

NG >> GO TO 15. 15.

REPLACE AIR FUEL RATIO (A/F) SENSOR 1

Replace air fuel ratio (A/F) sensor 1.

CAUTION:

• Discard any A/F sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

• Before installing new A/F senso r, clean exhaust system threads using Oxygen Sensor Thread

Cleaner tool J-43897-18 or J-43897-12 and approved anti-seize lubricant.

>> INSPECTION END 16.

CHECK MASS AIR FLOW SENSORItems Specifications

Target idle speed A/T: 700

± 50 rpm (in P or N position)

CVT: 700 ± 50 rpm (in P or N position)

M/T: 700 ± 50 rpm (in Neutral position)

Ignition timing A/T: 13

± 5 ° BTDC (in P or N position)

CVT: 13 ± 5 ° BTDC (in Neutral position)

M/T: 13 ± 5 ° BTDC (in Neutral position) A/F sensor 1 terminal ECM terminal

1 49

2 53

Continuity should exist.

Continuity should not exist. BBIA0699E

Page 2644 of 4331

OK >> GO TO 17.

NG >> Check connectors for rusted terminals or loose connections in the mass air flow sensor circuit or

ground. Refer to EC-1170 .

Symptom Matrix Chart " .

OK or NG OK >> GO TO 18.

NG >> Repair or replace. Emission-related

Diagnostic Information " .

>> GO TO 19. .

>> INSPECTION END

at idling : 1.0 - 4.0 g·m/sec

at 2,500 rpm : 2.0 - 10.0 g·m/sec

at idling : 1.0 - 4.0 g·m/sec

at 2,500 rpm : 2.0 - 10.0 g·m/sec

Page 2645 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0327, P0328 KS

EC-1289

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0327, P0328 KS

Component Description INFOID:0000000004500143

The knock sensor (1) is attached NISSAN LATIO 2009 Service Repair Manual DTC P0327, P0328 KS

EC-1289

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0327, P0328 KS

Component Description INFOID:0000000004500143

The knock sensor (1) is attached](/img/5/57359/w960_57359-2644.png)

DTC P0327, P0328 KS

EC-1289

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0327, P0328 KS

Component Description INFOID:0000000004500143

The knock sensor (1) is attached to the cylinder block. It senses

engine knocking using a piezoelectric element. A knocking vibration

from the cylinder block is sensed as vibrational pressure. This pres-

sure is converted into a voltage signal and sent to the ECM.

• : Vehicle front

On Board Diagnosis Logic INFOID:0000000004500144

The MIL will not light up for these self-diagnoses.

DTC Confirmation Procedure INFOID:0000000004500145

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10V at idle.

1. Start engine and run it for at least 5 seconds at idle speed.

2. Check 1st trip DTC.

3. If 1st trip DTC is detected, go to EC-1291, " Diagnosis Procedure " . PBIB3264E

DTC No. Trouble Diagno

sis Name DTC Detected Co ndition Possible Cause

P0327

0327 Knock sensor circuit low

input An excessively low voltage from the sensor is

sent to ECM. • Harness or connectors

(Knock sensor circuit is open or shorted.)

• Knock sensor

P0328

0328 Knock sensor circuit high

input An excessively high voltage from the sensor is

sent to ECM.

Page 2647 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0327, P0328 KS

EC-1291

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045001471.

CHECK KNOCK SENSOR INPUT SIGNAL CIRCUIT-I

1. Turn ignition NISSAN LATIO 2009 Service Repair Manual DTC P0327, P0328 KS

EC-1291

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045001471.

CHECK KNOCK SENSOR INPUT SIGNAL CIRCUIT-I

1. Turn ignition](/img/5/57359/w960_57359-2646.png)

DTC P0327, P0328 KS

EC-1291

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045001471.

CHECK KNOCK SENSOR INPUT SIGNAL CIRCUIT-I

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check resistance between ECM terminal 37 and ground. Refer to Wiring Diagram. NOTE:

It is necessary to use an ohmmeter which can measure more than 10 M Ω.

4. Also check harness for short to ground and short to power.

OK or NG OK >> GO TO 4.

NG >> GO TO 2. 2.

CHECK KNOCK SENSOR INPUT SIGNAL CIRCUIT-II

1. Disconnect knock sensor (1) harness connector.

- : Vehicle front

2. Check harness continuity between ECM terminal 37 and knock sensor terminal 1. Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors. 3.

CHECK KNOCK SENSOR

Refer to EC-1292, " Component Inspection " .

OK or NG OK >> GO TO 6.

NG >> Replace knock sensor. 4.

CHECK GROUND CONNECTIONS

Loosen and retighten ground screws on the body.

Refer to EC-1144, " Ground Inspection " .

TERMI-

NAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

37 W Knock sensor [Engine is running]

• Idle speed Approximately 2.5V

40 — Sensor ground

(Knock sensor) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0VResistance: Approximately 532 - 588k

Ω [at 20 °C (68 °F)]

Continuity should exist. PBIB3264E

BBIA0698E