NISSAN LATIO 2010 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2010, Model line: LATIO, Model: NISSAN LATIO 2010Pages: 3745, PDF Size: 73.67 MB

Page 391 of 3745

AT-374

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

Stall Speed

INFOID:0000000005397458

Line PressureINFOID:0000000005397459

Adjusting shims, Needle Bearings , Thrust Washers and Snap RingsINFOID:0000000005397460

OUTER DIAMETER AND INNER DIAMETER OF NEEDLE BEARINGS

HR16DE Engine Models

Unit: mm (in)

MR18DE Engine Models

Unit: mm (in)

OUTER DIAMETER AND INNER DIAMETER OF THRUST WASHERS

HR16DE Engine Models

Unit: mm (in)

MR18DE Engine Models

Engine HR16DEMR18DE

Stall revolution (rpm) 2,250 - 2,7002,310 - 2,770

Engine speed Line pressure kPa (kg/cm2, psi)

“D”, “2” and “1” po sitions “R” position

Idle speed 500 (5.1, 73)778 (7.9, 113)

Stall speed 1,173 (12.0, 170)1,825 (18.6, 265)

LocationOuter diameter Inner diameter

A 47.0 (1.850) 32.0 (1.260)

B 35.0 (1.378) 20.1 (0.791)

C 60.0 (2.362) 42.0 (1.654)

D 60.0 (2.362) 45.0 (1.772)

E 47.0 (1.850) 30.0 (1.181)

F 42.6 (1.677) 26.1 (1.028)

G 48.0 (1.890) 33.5 (1.319)

H 59.0 (2.323) 42.1 (1.657)

LocationOuter diameter Inner diameter

A 47.0 (1.850) 32.0 (1.260)

B 35.0 (1.378) 20.1 (0.791)

C 60.0 (2.362) 42.0 (1.654)

D 60.0 (2.362) 45.0 (1.772)

E 47.0 (1.850) 30.0 (1.181)

F 42.6 (1.677) 26.1 (1.028)

G 48.0 (1.890) 33.5 (1.319)

H 55.0 (2.165) 40.5 (1.594)

I 60.0 (2.362) 40.0 (1.575)

LocationOuter diameter Inner diameter

I 72.0 (2.835) 55.5 (2.185)

J, K 82.0 (3.228) 59.0 (2.323)

L 78.5 (3.091) 62.4 (2.457)

Revision: January 20102010 Versa

Page 392 of 3745

SERVICE DATA AND SPECIFICATIONS (SDS)AT-375

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

Unit: mm (in)

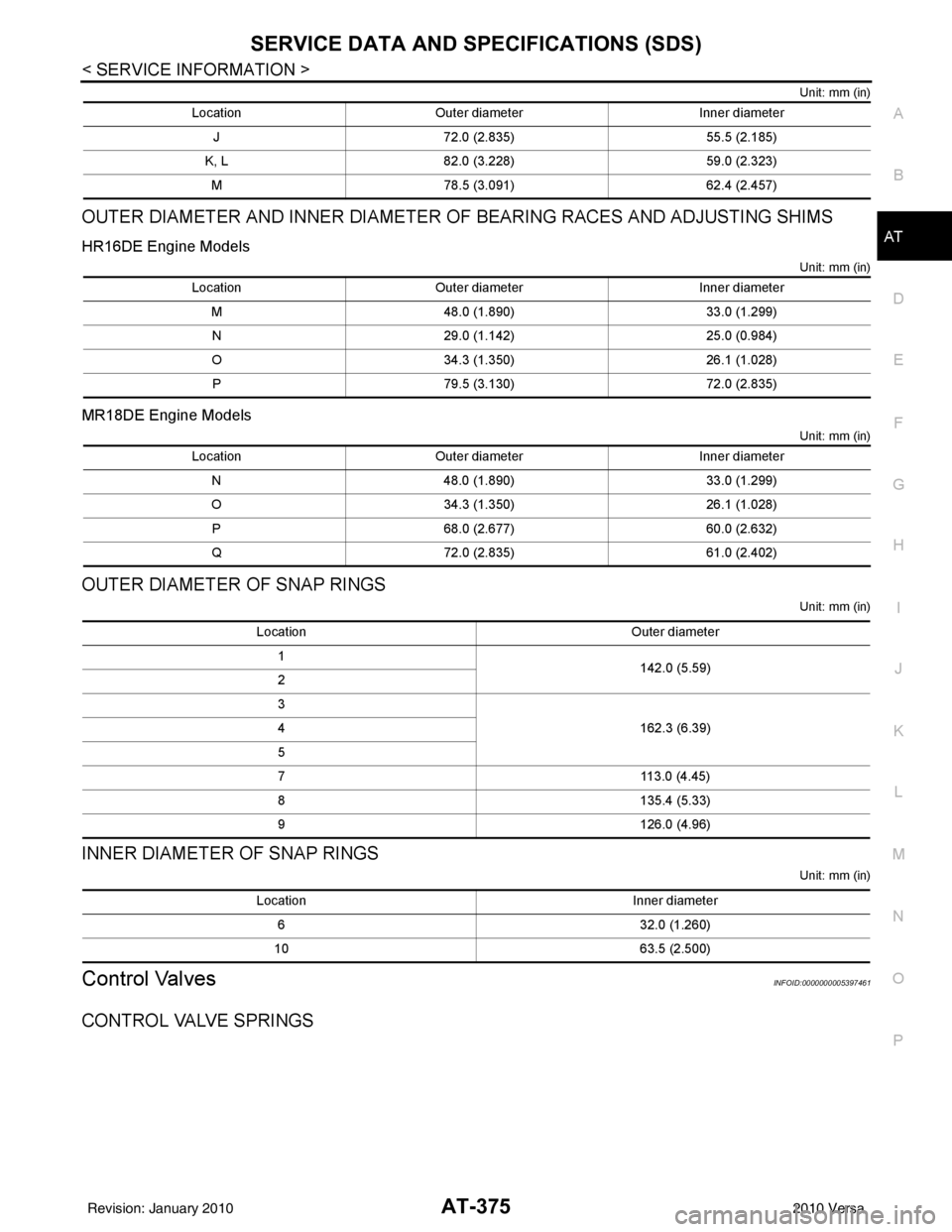

OUTER DIAMETER AND INNER DIAMETER OF BEARING RACES AND ADJUSTING SHIMS

HR16DE Engine Models

Unit: mm (in)

MR18DE Engine Models

Unit: mm (in)

OUTER DIAMETER OF SNAP RINGS

Unit: mm (in)

INNER DIAMETER OF SNAP RINGS

Unit: mm (in)

Control ValvesINFOID:0000000005397461

CONTROL VALVE SPRINGS

Location Outer diameter Inner diameter

J 72.0 (2.835) 55.5 (2.185)

K, L 82.0 (3.228) 59.0 (2.323)

M 78.5 (3.091) 62.4 (2.457)

LocationOuter diameter Inner diameter

M 48.0 (1.890) 33.0 (1.299)

N 29.0 (1.142) 25.0 (0.984)

O 34.3 (1.350) 26.1 (1.028)

P 79.5 (3.130) 72.0 (2.835)

LocationOuter diameter Inner diameter

N 48.0 (1.890) 33.0 (1.299)

O 34.3 (1.350) 26.1 (1.028)

P 68.0 (2.677) 60.0 (2.632)

Q 72.0 (2.835) 61.0 (2.402)

Location Outer diameter

1 142.0 (5.59)

2

3

162.3 (6.39)

4

5

7 113.0 (4.45)

8 135.4 (5.33)

9 126.0 (4.96)

Location Inner diameter

6 32.0 (1.260)

10 63.5 (2.500)

Revision: January 20102010 Versa

Page 393 of 3745

AT-376

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

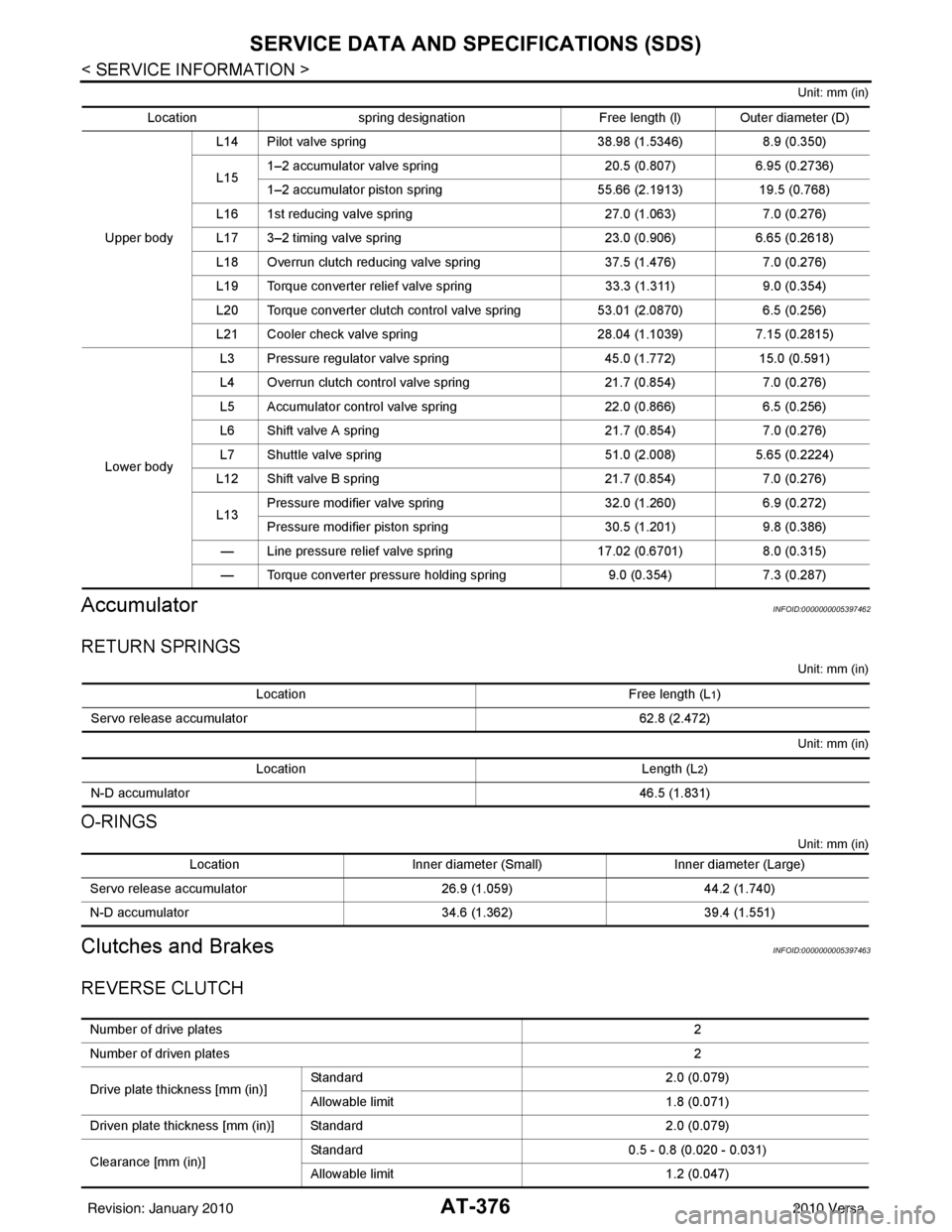

Unit: mm (in)

AccumulatorINFOID:0000000005397462

RETURN SPRINGS

Unit: mm (in)

Unit: mm (in)

O-RINGS

Unit: mm (in)

Clutches and BrakesINFOID:0000000005397463

REVERSE CLUTCH

Locationspring designation Free length (l) Outer diameter (D)

Upper body L14 Pilot valve spring

38.98 (1.5346)8.9 (0.350)

L15 1–2 accumulator valve spring

20.5 (0.807)6.95 (0.2736)

1–2 accumulator piston spring 55.66 (2.1913)19.5 (0.768)

L16 1st reducing valve spring 27.0 (1.063)7.0 (0.276)

L17 3–2 timing valve spring 23.0 (0.906)6.65 (0.2618)

L18 Overrun clutch reducing valve spring37.5 (1.476)7.0 (0.276)

L19 Torque converter relief valve spring 33.3 (1.311)9.0 (0.354)

L20 Torque converter clutch control valve spring 53.01 (2.0870)6.5 (0.256)

L21 Cooler check valve spring 28.04 (1.1039)7.15 (0.2815)

Lower body L3 Pressure regulator valve spring

45.0 (1.772)15.0 (0.591)

L4 Overrun clutch control valve spring 21.7 (0.854)7.0 (0.276)

L5 Accumulator control valve spring 22.0 (0.866)6.5 (0.256)

L6 Shift valve A spring 21.7 (0.854)7.0 (0.276)

L7 Shuttle valve spring 51.0 (2.008)5.65 (0.2224)

L12 Shift valve B spring 21.7 (0.854)7.0 (0.276)

L13 Pressure modifier valve spring

32.0 (1.260)6.9 (0.272)

Pressure modifier piston spring 30.5 (1.201)9.8 (0.386)

— Line pressure relief valve spring 17.02 (0.6701)8.0 (0.315)

— Torque converter pressure holding spring 9.0 (0.354)7.3 (0.287)

Location Free length (L1)

Servo release accumulator 62.8 (2.472)

LocationLength (L2)

N-D accumulator 46.5 (1.831)

LocationInner diameter (Small) Inner diameter (Large)

Servo release accumulator 26.9 (1.059)44.2 (1.740)

N-D accumulator 34.6 (1.362)39.4 (1.551)

Number of drive plates 2

Number of driven plates 2

Drive plate thickness [mm (in)] Standard

2.0 (0.079)

Allowable limit 1.8 (0.071)

Driven plate thickness [mm (in)] Standard 2.0 (0.079)

Clearance [mm (in)] Standard

0.5 - 0.8 (0.020 - 0.031)

Allowable limit 1.2 (0.047)

Revision: January 20102010 Versa

Page 394 of 3745

SERVICE DATA AND SPECIFICATIONS (SDS)AT-377

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

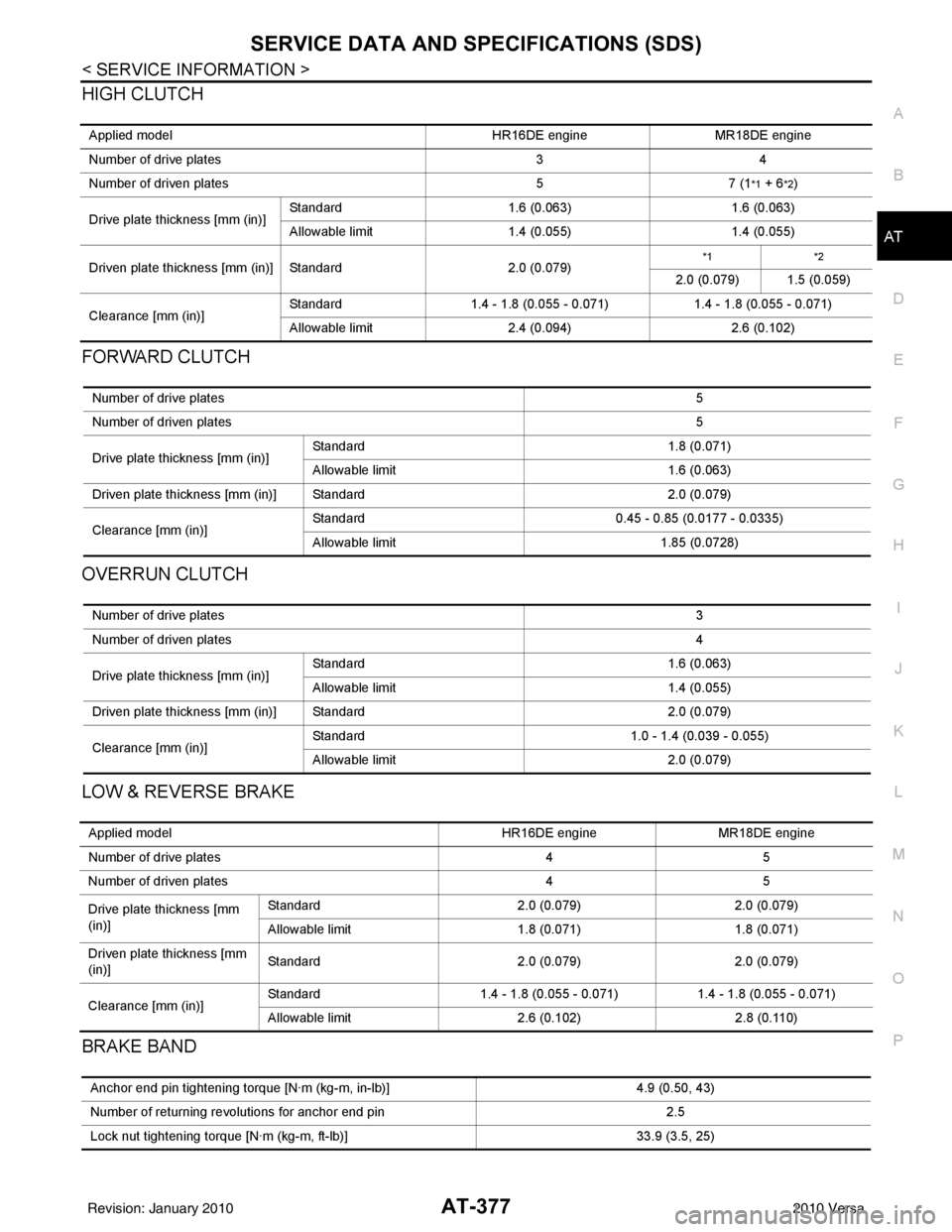

HIGH CLUTCH

FORWARD CLUTCH

OVERRUN CLUTCH

LOW & REVERSE BRAKE

BRAKE BAND

Applied model HR16DE engineMR18DE engine

Number of drive plates 34

Number of driven plates 57 (1

*1 + 6*2)

Drive plate thickness [mm (in)] Standard

1.6 (0.063) 1.6 (0.063)

Allowable limit 1.4 (0.055) 1.4 (0.055)

Driven plate thickness [mm (in)] Standard 2.0 (0.079)

*1*2

2.0 (0.079) 1.5 (0.059)

Clearance [mm (in)] Standard

1.4 - 1.8 (0.055 - 0.071) 1.4 - 1.8 (0.055 - 0.071)

Allowable limit 2.4 (0.094) 2.6 (0.102)

Number of drive plates 5

Number of driven plates 5

Drive plate thickness [mm (in)] Standard

1.8 (0.071)

Allowable limit 1.6 (0.063)

Driven plate thickness [mm (in)] Standard 2.0 (0.079)

Clearance [mm (in)] Standard

0.45 - 0.85 (0.0177 - 0.0335)

Allowable limit 1.85 (0.0728)

Number of drive plates 3

Number of driven plates 4

Drive plate thickness [mm (in)] Standard

1.6 (0.063)

Allowable limit 1.4 (0.055)

Driven plate thickness [mm (in)] Standard 2.0 (0.079)

Clearance [mm (in)] Standard

1.0 - 1.4 (0.039 - 0.055)

Allowable limit 2.0 (0.079)

Applied model HR16DE engineMR18DE engine

Number of drive plates 45

Number of driven plates 45

Drive plate thickness [mm

(in)] Standard

2.0 (0.079)2.0 (0.079)

Allowable limit 1.8 (0.071)1.8 (0.071)

Driven plate thickness [mm

(in)] Standard

2.0 (0.079)2.0 (0.079)

Clearance [mm (in)] Standard

1.4 - 1.8 (0.055 - 0.071) 1.4 - 1.8 (0.055 - 0.071)

Allowable limit 2.6 (0.102)2.8 (0.110)

Anchor end pin tightening torque [N·m (kg-m, in-lb)] 4.9 (0.50, 43)

Number of returning revolutions for anchor end pin 2.5

Lock nut tightening torque [N·m (kg-m, ft-lb)] 33.9 (3.5, 25)

Revision: January 20102010 Versa

Page 395 of 3745

AT-378

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

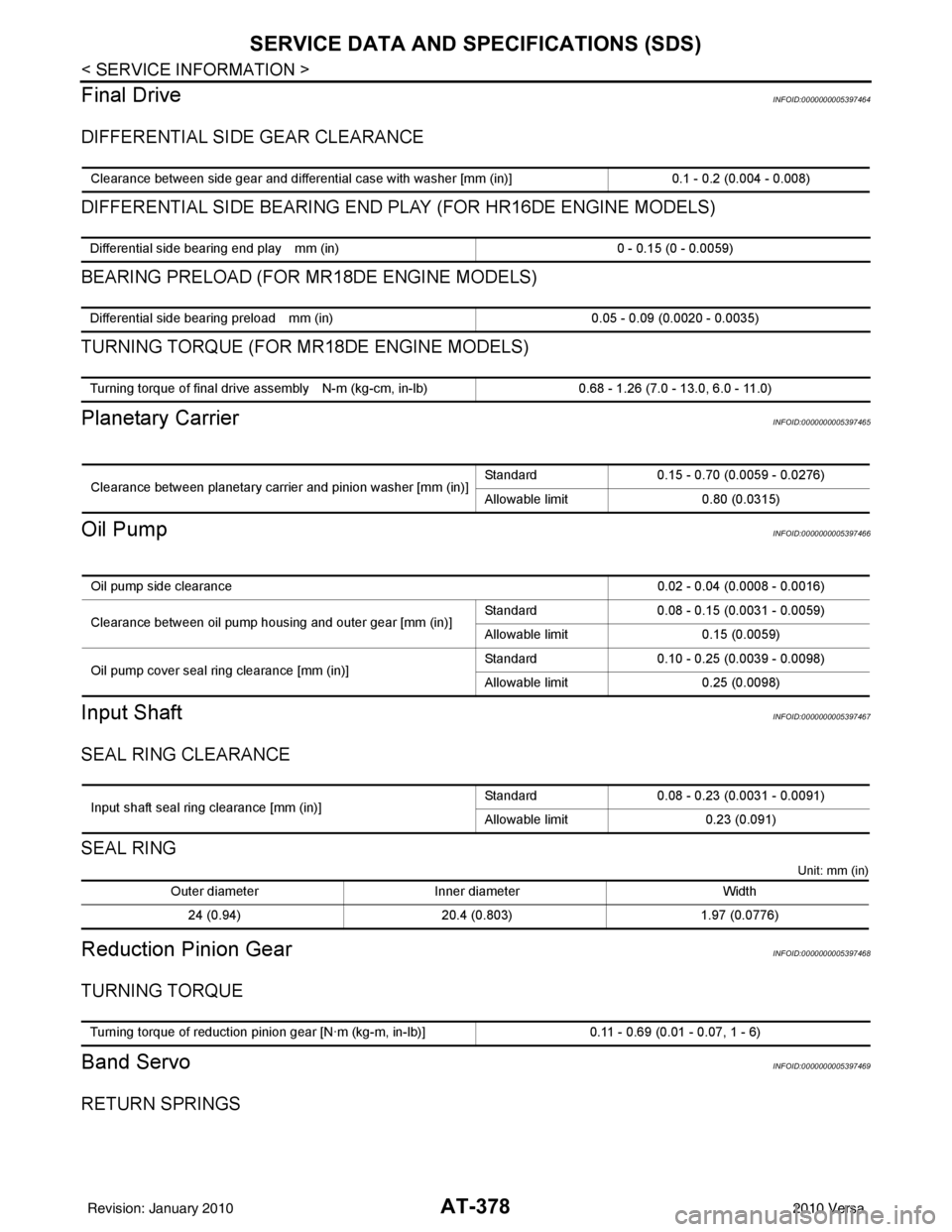

Final Drive

INFOID:0000000005397464

DIFFERENTIAL SIDE GEAR CLEARANCE

DIFFERENTIAL SIDE BEARING END PL AY (FOR HR16DE ENGINE MODELS)

BEARING PRELOAD (FOR MR18DE ENGINE MODELS)

TURNING TORQUE (FOR MR18DE ENGINE MODELS)

Planetary CarrierINFOID:0000000005397465

Oil PumpINFOID:0000000005397466

Input ShaftINFOID:0000000005397467

SEAL RING CLEARANCE

SEAL RING

Unit: mm (in)

Reduction Pinion GearINFOID:0000000005397468

TURNING TORQUE

Band ServoINFOID:0000000005397469

RETURN SPRINGS

Clearance between side gear and differential case with washer [mm (in)] 0.1 - 0.2 (0.004 - 0.008)

Differential side bearing end play mm (in)0 - 0.15 (0 - 0.0059)

Differential side bearing preload mm (in)0.05 - 0.09 (0.0020 - 0.0035)

Turning torque of final drive assembly N-m (kg-cm, in-lb)0.68 - 1.26 (7.0 - 13.0, 6.0 - 11.0)

Clearance between planetary carrier and pinion washer [mm (in)]Standard 0.15 - 0.70 (0.0059 - 0.0276)

Allowable limit

0.80 (0.0315)

Oil pump side clearance 0.02 - 0.04 (0.0008 - 0.0016)

Clearance between oil pump housing and outer gear [mm (in)] Standard

0.08 - 0.15 (0.0031 - 0.0059)

Allowable limit 0.15 (0.0059)

Oil pump cover seal ring clearance [mm (in)] Standard

0.10 - 0.25 (0.0039 - 0.0098)

Allowable limit 0.25 (0.0098)

Input shaft seal ring clearance [mm (in)] Standard 0.08 - 0.23 (0.0031 - 0.0091)

Allowable limit

0.23 (0.091)

Outer diameter Inner diameter Width

24 (0.94) 20.4 (0.803) 1.97 (0.0776)

Turning torque of reduction pinion gear [N·m (kg-m, in-lb)] 0.11 - 0.69 (0.01 - 0.07, 1 - 6)

Revision: January 20102010 Versa

Page 396 of 3745

SERVICE DATA AND SPECIFICATIONS (SDS)AT-379

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

Unit: mm (in)

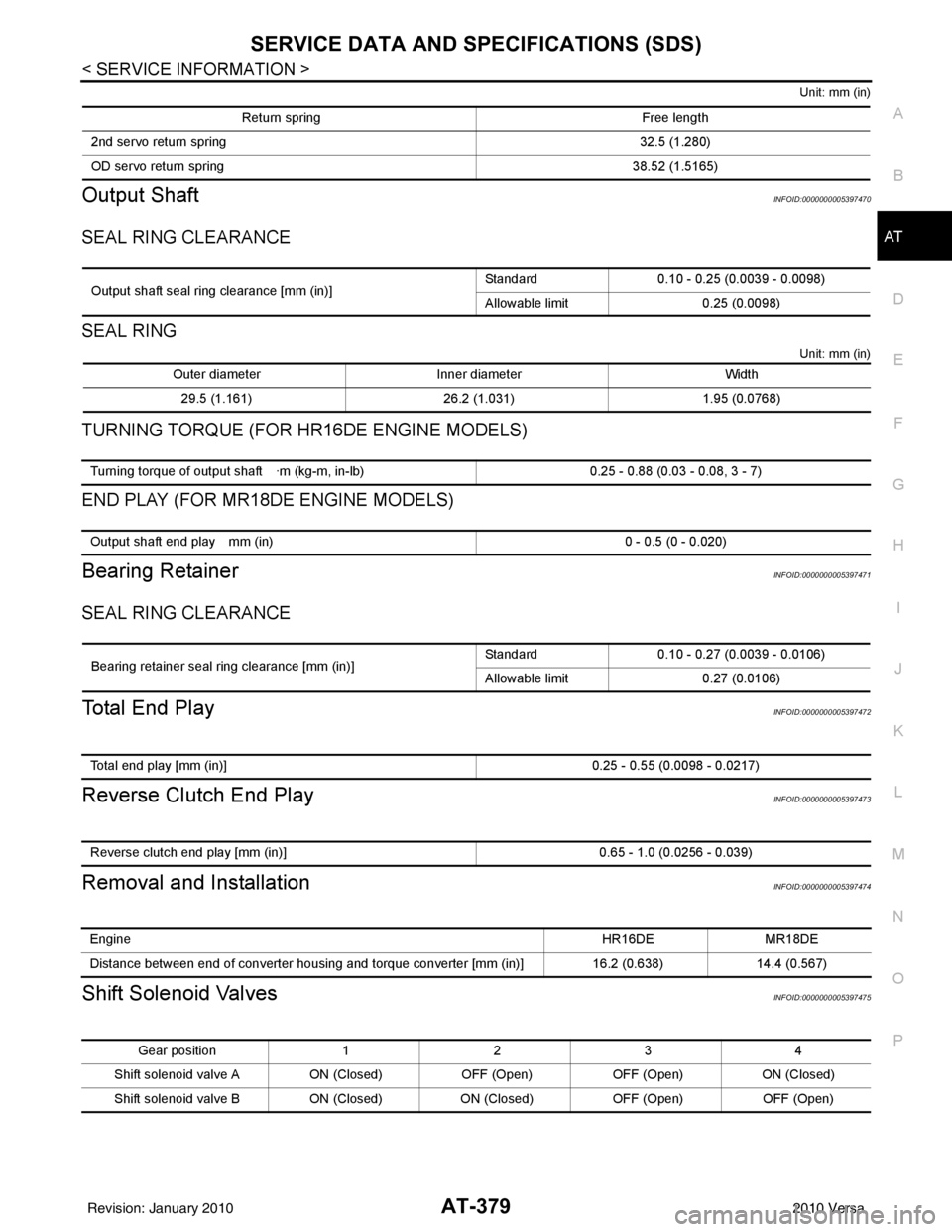

Output ShaftINFOID:0000000005397470

SEAL RING CLEARANCE

SEAL RING

Unit: mm (in)

TURNING TORQUE (FOR HR16DE ENGINE MODELS)

END PLAY (FOR MR18DE ENGINE MODELS)

Bearing RetainerINFOID:0000000005397471

SEAL RING CLEARANCE

Total End PlayINFOID:0000000005397472

Reverse Clutch End PlayINFOID:0000000005397473

Removal and InstallationINFOID:0000000005397474

Shift Solenoid ValvesINFOID:0000000005397475

Return spring Free length

2nd servo return sp ring 32.5 (1.280)

OD servo return sp ring 38.52 (1.5165)

Output shaft seal ring clearance [mm (in)]Standard 0.10 - 0.25 (0.0039 - 0.0098)

Allowable limit

0.25 (0.0098)

Outer diameter Inner diameter Width

29.5 (1.161) 26.2 (1.031)1.95 (0.0768)

Turning torque of output shaft ·m (kg-m, in-lb) 0.25 - 0.88 (0.03 - 0.08, 3 - 7)

Output shaft end play mm (in) 0 - 0.5 (0 - 0.020)

Bearing retainer seal ring clearance [mm (in)]Standard 0.10 - 0.27 (0.0039 - 0.0106)

Allowable limit

0.27 (0.0106)

Total end play [mm (in)] 0.25 - 0.55 (0.0098 - 0.0217)

Reverse clutch end play [mm (in)] 0.65 - 1.0 (0.0256 - 0.039)

Engine HR16DE MR18DE

Distance between end of converter housing and torque converter [mm (in)] 16.2 (0.638)14.4 (0.567)

Gear position 1234

Shift solenoid valve A ON (Closed)OFF (Open)OFF (Open)ON (Closed)

Shift solenoid valve B ON (Closed)ON (Closed) OFF (Open)OFF (Open)

Revision: January 20102010 Versa

Page 397 of 3745

AT-380

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

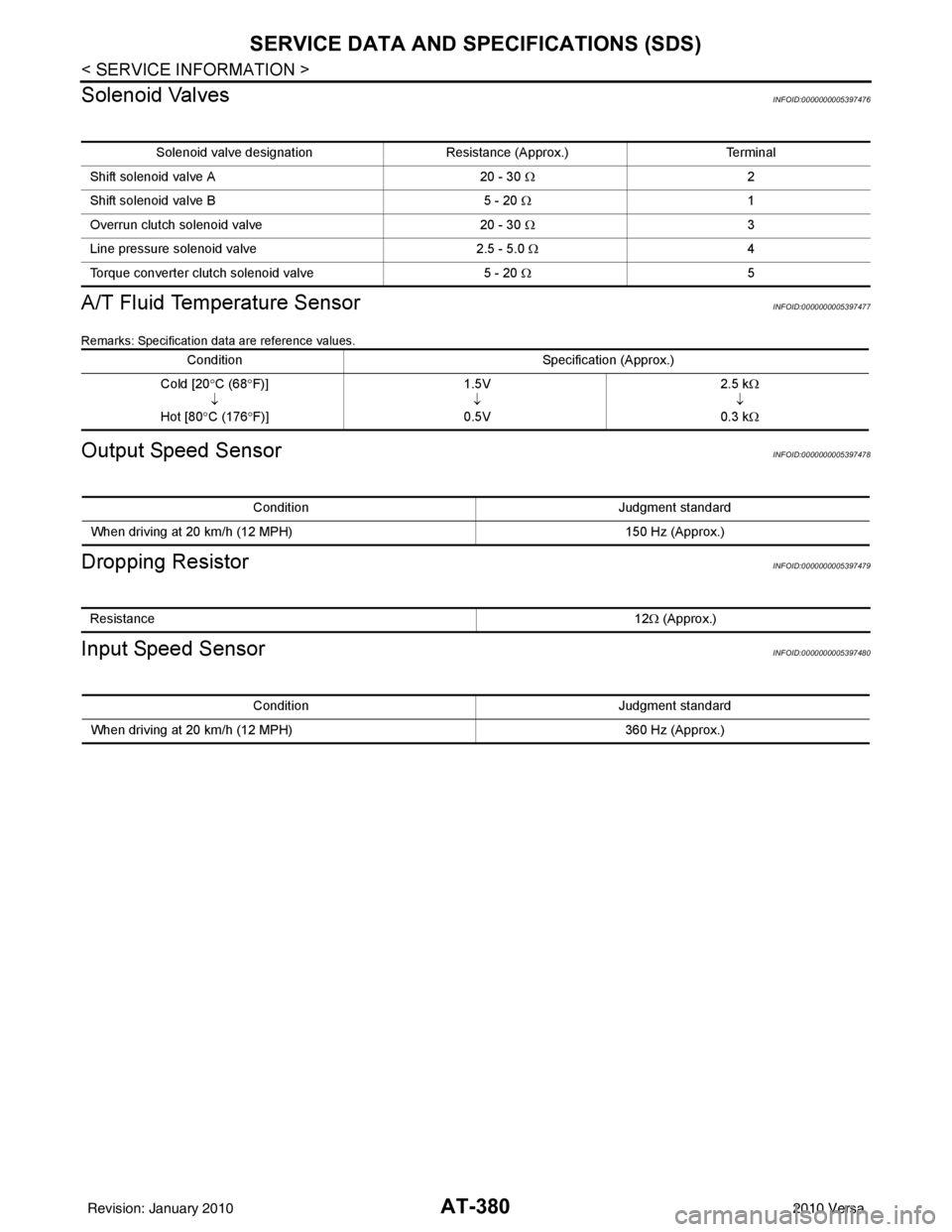

Solenoid Valves

INFOID:0000000005397476

A/T Fluid Temperature SensorINFOID:0000000005397477

Remarks: Specification data are reference values.

Output Speed SensorINFOID:0000000005397478

Dropping ResistorINFOID:0000000005397479

Input Speed SensorINFOID:0000000005397480

Solenoid valve designation Resistance (Approx.)Terminal

Shift solenoid valve A 20 - 30 Ω 2

Shift solenoid valve B 5 - 20 Ω1

Overrun clutch solenoid valve 20 - 30 Ω 3

Line pressure solenoid valve 2.5 - 5.0 Ω 4

Torque converter clutch solenoid valve 5 - 20 Ω 5

Condition Specification (Approx.)

Cold [20 °C (68 °F)]

↓

Hot [80 °C (176 °F)] 1.5V

↓

0.5V 2.5 k

Ω

↓

0.3 k Ω

Condition Judgment standard

When driving at 20 km/h (12 MPH) 150 Hz (Approx.)

Resistance 12Ω (Approx.)

Condition Judgment standard

When driving at 20 km/h (12 MPH) 360 Hz (Approx.)

Revision: January 20102010 Versa

Page 398 of 3745

AV-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

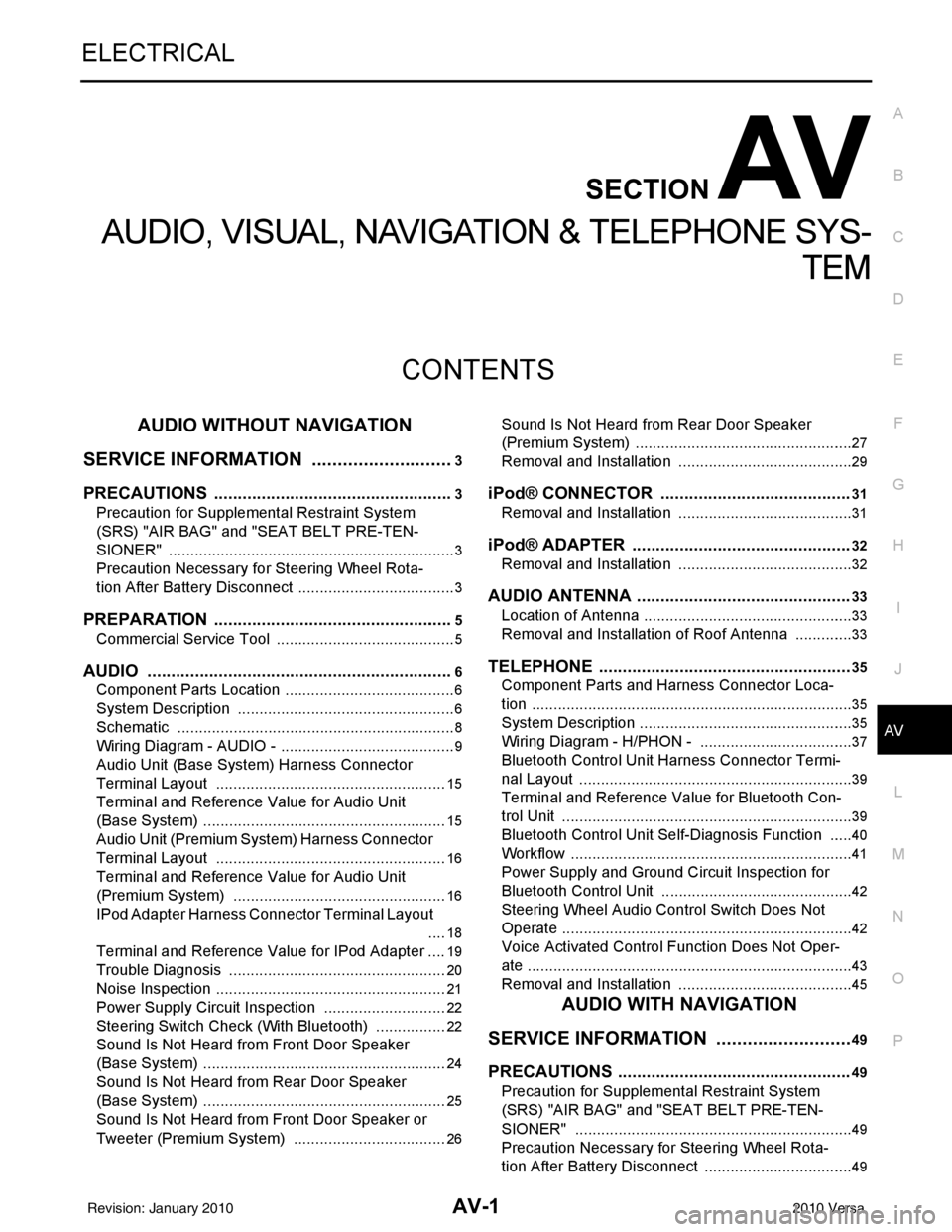

SECTION AV

A

B

AV

N

O P

CONTENTS

AUDIO, VISUAL, NAVIGATION & TELEPHONE SYS- TEM

AUDIO WITHOUT NAVIGATION

SERVICE INFORMATION .. ..........................

3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

PREPARATION ...................................................5

Commercial Service Tool .................................... ......5

AUDIO .................................................................6

Component Parts Location .................................. ......6

System Description ...................................................6

Schematic .................................................................8

Wiring Diagram - AUDIO - .........................................9

Audio Unit (Base System) Harness Connector

Terminal Layout ......................................................

15

Terminal and Reference Value for Audio Unit

(Base System) .........................................................

15

Audio Unit (Premium System) Harness Connector

Terminal Layout ......................................................

16

Terminal and Reference Value for Audio Unit

(Premium System) ..................................................

16

IPod Adapter Harness Connector Terminal Layout

....

18

Terminal and Reference Value for IPod Adapter ....19

Trouble Diagnosis ...................................................20

Noise Inspection ......................................................21

Power Supply Circuit Inspection .............................22

Steering Switch Check (With Bluetooth) .................22

Sound Is Not Heard from Front Door Speaker

(Base System) .........................................................

24

Sound Is Not Heard from Rear Door Speaker

(Base System) .........................................................

25

Sound Is Not Heard from Front Door Speaker or

Tweeter (Premium System) ....................................

26

Sound Is Not Heard from Rear Door Speaker

(Premium System) ............................................... ....

27

Removal and Installation .........................................29

iPod® CONNECTOR ........................................31

Removal and Installation .........................................31

iPod® ADAPTER ..............................................32

Removal and Installation .........................................32

AUDIO ANTENNA .............................................33

Location of Antenna ............................................. ....33

Removal and Installation of Roof Antenna ..............33

TELEPHONE .....................................................35

Component Parts and Harness Connector Loca-

tion ...........................................................................

35

System Description ..................................................35

Wiring Diagram - H/PHON - ....................................37

Bluetooth Control Unit Harness Connector Termi-

nal Layout ............................................................ ....

39

Terminal and Reference Value for Bluetooth Con-

trol Unit ....................................................................

39

Bluetooth Control Unit Self-Diagnosis Function ......40

Workflow .............................................................. ....41

Power Supply and Ground Circuit Inspection for

Bluetooth Control Unit .............................................

42

Steering Wheel Audio Co ntrol Switch Does Not

Operate ................................................................ ....

42

Voice Activated Control Function Does Not Oper-

ate ........................................................................ ....

43

Removal and Installation .........................................45

AUDIO WITH NAVIGATION

SERVICE INFORMATION .. .........................

49

PRECAUTIONS .................................................49

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

49

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

49

Revision: January 20102010 Versa

Page 399 of 3745

AV-2

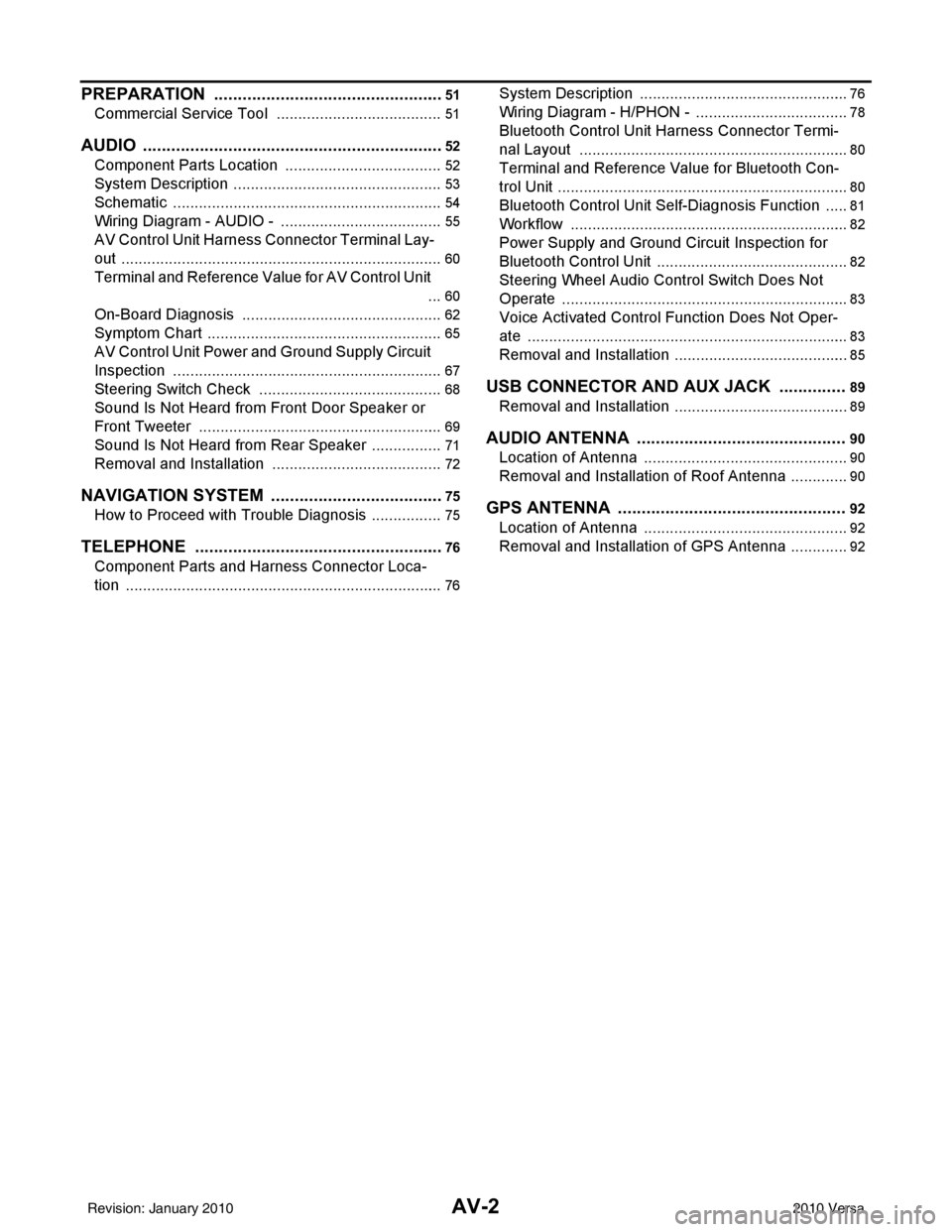

PREPARATION .............................................. ...51

Commercial Service Tool .................................... ...51

AUDIO ................................................................52

Component Parts Location .................................. ...52

System Description .................................................53

Schematic ...............................................................54

Wiring Diagram - AUDIO - ......................................55

AV Control Unit Harness Connector Terminal Lay-

out ...........................................................................

60

Terminal and Reference Value for AV Control Unit

...

60

On-Board Diagnosis ...............................................62

Symptom Chart .................................................... ...65

AV Control Unit Power and Ground Supply Circuit

Inspection ............................................................ ...

67

Steering Switch Check ...........................................68

Sound Is Not Heard from Front Door Speaker or

Front Tweeter .........................................................

69

Sound Is Not Heard from Rear Speaker .................71

Removal and Installation ..................................... ...72

NAVIGATION SYSTEM .................................. ...75

How to Proceed with Trouble Diagnosis .............. ...75

TELEPHONE .....................................................76

Component Parts and Harness Connector Loca-

tion ....................................................................... ...

76

System Description .............................................. ...76

Wiring Diagram - H/PHON - ....................................78

Bluetooth Control Unit Harness Connector Termi-

nal Layout ...............................................................

80

Terminal and Reference Value for Bluetooth Con-

trol Unit ....................................................................

80

Bluetooth Control Unit Self-Diagnosis Function ......81

Workflow .................................................................82

Power Supply and Ground Circuit Inspection for

Bluetooth Control Unit .............................................

82

Steering Wheel Audio Control Switch Does Not

Operate ...................................................................

83

Voice Activated Control Function Does Not Oper-

ate ...........................................................................

83

Removal and Installation .........................................85

USB CONNECTOR AND AUX JACK ............ ...89

Removal and Installation .........................................89

AUDIO ANTENNA .......................................... ...90

Location of Antenna ............................................. ...90

Removal and Installation of Roof Antenna ..............90

GPS ANTENNA .................................................92

Location of Antenna ............................................. ...92

Removal and Installation of GPS Antenna ..............92

Revision: January 20102010 Versa

Page 400 of 3745

![NISSAN LATIO 2010 Service Repair Manual PRECAUTIONSAV-3

< SERVICE INFORMATION > [AUDIO WITHOUT NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "S NISSAN LATIO 2010 Service Repair Manual PRECAUTIONSAV-3

< SERVICE INFORMATION > [AUDIO WITHOUT NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "S](/img/5/57358/w960_57358-399.png)

PRECAUTIONSAV-3

< SERVICE INFORMATION > [AUDIO WITHOUT NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005395303

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005975903

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa