brake NISSAN LATIO 2010 Service Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: LATIO, Model: NISSAN LATIO 2010Pages: 3745, PDF Size: 73.67 MB

Page 333 of 3745

AT-316

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

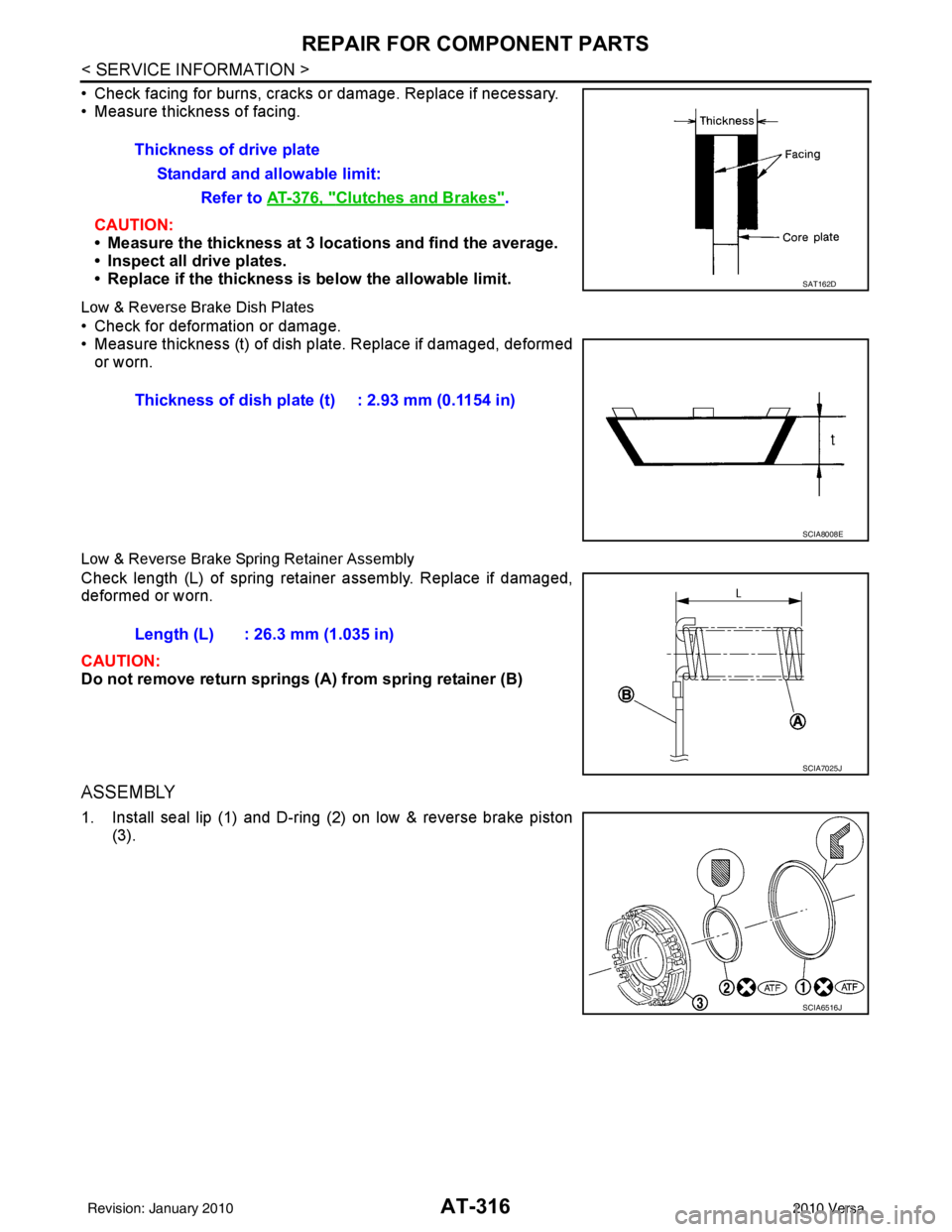

• Check facing for burns, cracks or damage. Replace if necessary.

• Measure thickness of facing.CAUTION:

• Measure the thickness at 3 locations and find the average.

• Inspect all drive plates.

• Replace if the thickness is below the allowable limit.

Low & Reverse Brake Dish Plates

• Check for deformation or damage.

• Measure thickness (t) of dish pl ate. Replace if damaged, deformed

or worn.

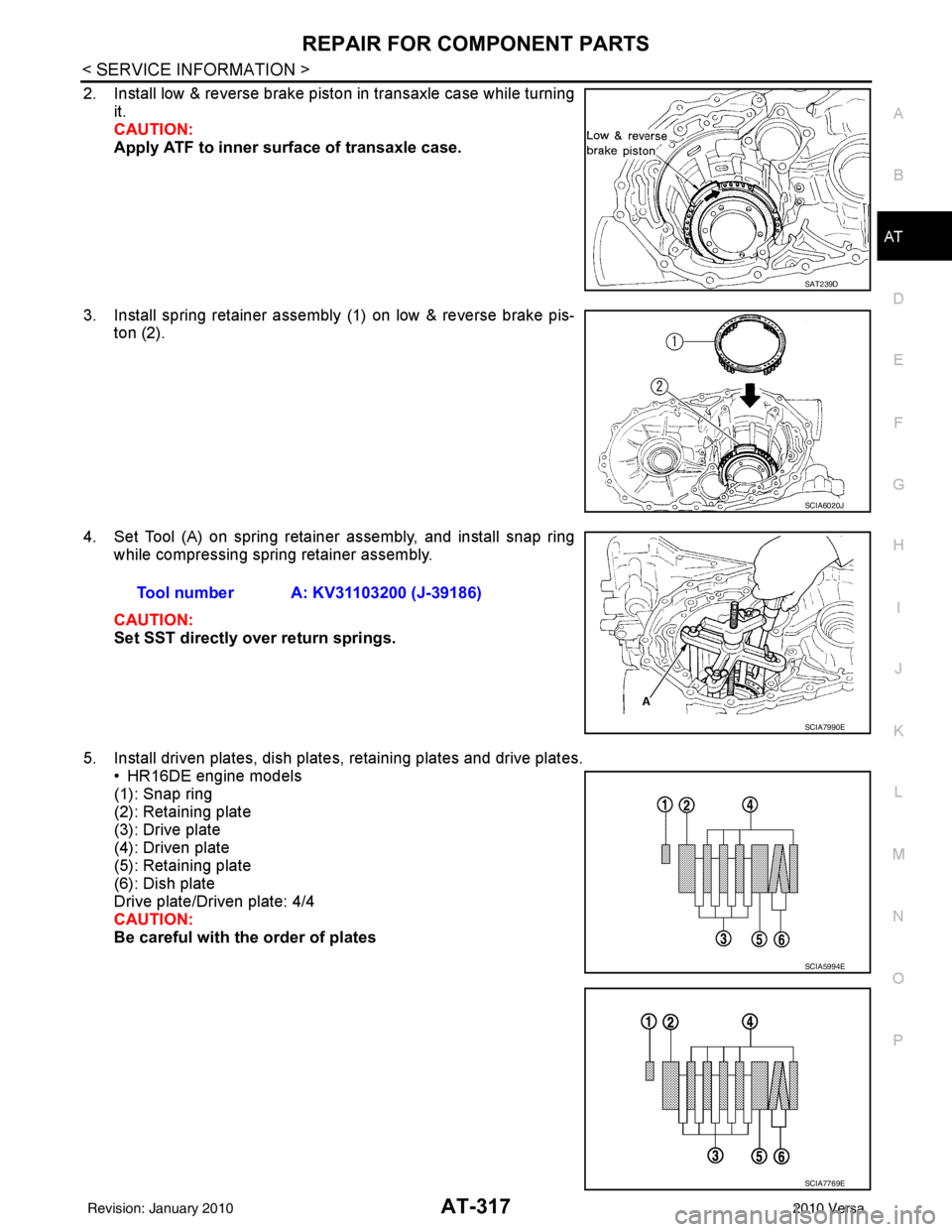

Low & Reverse Brake Spring Retainer Assembly

Check length (L) of spring retainer assembly. Replace if damaged,

deformed or worn.

CAUTION:

Do not remove return springs (A ) from spring retainer (B)

ASSEMBLY

1. Install seal lip (1) and D-ring (2) on low & reverse brake piston

(3).Thickness of drive plate

Standard and allowable limit: Refer to AT-376, "

Clutches and Brakes".

SAT162D

Thickness of dish plate (t) : 2.93 mm (0.1154 in)

SCIA8008E

Length (L) : 26.3 mm (1.035 in)

SCIA7025J

SCIA6516J

Revision: January 20102010 Versa

Page 334 of 3745

REPAIR FOR COMPONENT PARTSAT-317

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

2. Install low & reverse brake piston in transaxle case while turning it.

CAUTION:

Apply ATF to inner surface of transaxle case.

3. Install spring retainer assembly (1) on low & reverse brake pis- ton (2).

4. Set Tool (A) on spring retainer assembly, and install snap ring while compressing spring retainer assembly.

CAUTION:

Set SST directly over return springs.

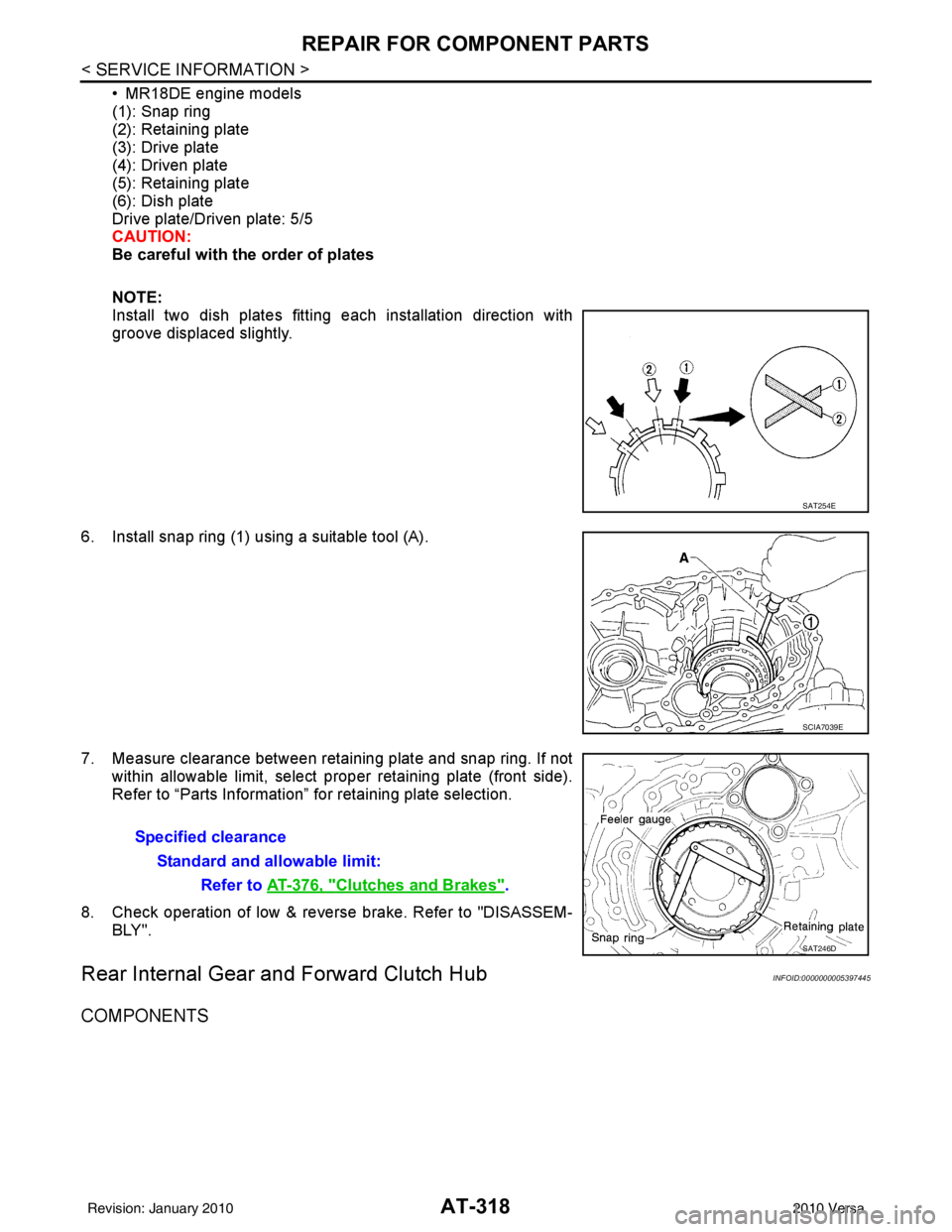

5. Install driven plates, dish plates, retaining plates and drive plates. • HR16DE engine models

(1): Snap ring

(2): Retaining plate

(3): Drive plate

(4): Driven plate

(5): Retaining plate

(6): Dish plate

Drive plate/Driven plate: 4/4

CAUTION:

Be careful with the order of plates

SAT239D

SCIA6020J

Tool number A: KV31103200 (J-39186)

SCIA7990E

SCIA5994E

SCIA7769E

Revision: January 20102010 Versa

Page 335 of 3745

AT-318

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

• MR18DE engine models

(1): Snap ring

(2): Retaining plate

(3): Drive plate

(4): Driven plate

(5): Retaining plate

(6): Dish plate

Drive plate/Driven plate: 5/5

CAUTION:

Be careful with the order of plates

NOTE:

Install two dish plates fitting each installation direction with

groove displaced slightly.

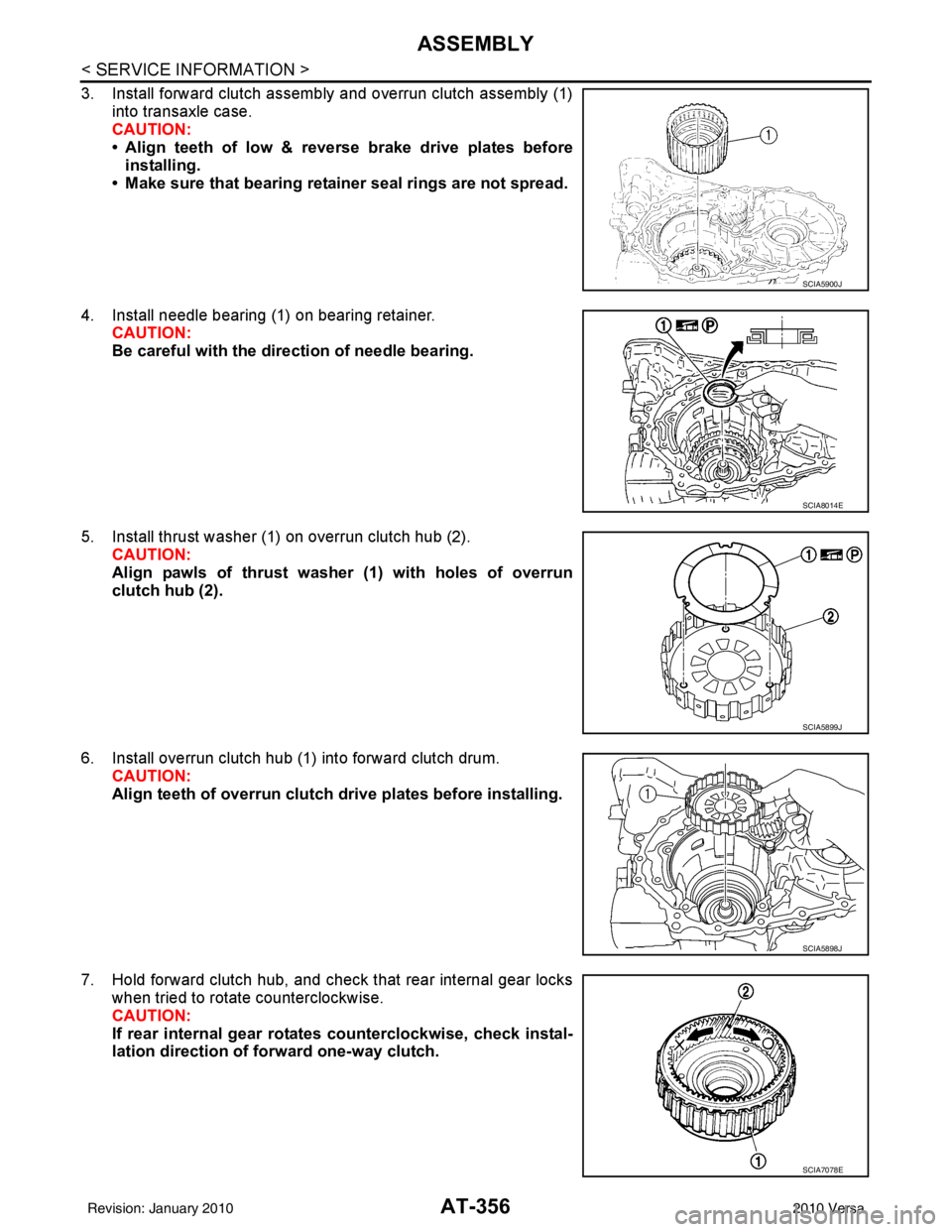

6. Install snap ring (1) using a suitable tool (A).

7. Measure clearance between retaining plate and snap ring. If not within allowable limit, select proper retaining plate (front side).

Refer to “Parts Information” for retaining plate selection.

8. Check operation of low & revers e brake. Refer to "DISASSEM-

BLY".

Rear Internal Gear and Forward Clutch HubINFOID:0000000005397445

COMPONENTS

SAT254E

SCIA7039E

Specified clearance

Standard and allowable limit: Refer to AT-376, "

Clutches and Brakes".

SAT246D

Revision: January 20102010 Versa

Page 373 of 3745

AT-356

< SERVICE INFORMATION >

ASSEMBLY

3. Install forward clutch assembly and overrun clutch assembly (1)into transaxle case.

CAUTION:

• Align teeth of low & reverse brake drive plates beforeinstalling.

• Make sure that bearing retainer seal rings are not spread.

4. Install needle bearing (1) on bearing retainer. CAUTION:

Be careful with the dir ection of needle bearing.

5. Install thrust washer (1) on overrun clutch hub (2). CAUTION:

Align pawls of thrust washer (1) with holes of overrun

clutch hub (2).

6. Install overrun clutch hub (1) into forward clutch drum. CAUTION:

Align teeth of overrun clutch drive plates before installing.

7. Hold forward clutch hub, and check that rear internal gear locks when tried to rotate counterclockwise.

CAUTION:

If rear internal gear rotat es counterclockwise, check instal-

lation direction of forward one-way clutch.

SCIA5900J

SCIA8014E

SCIA5899J

SCIA5898J

SCIA7078E

Revision: January 20102010 Versa

Page 381 of 3745

AT-364

< SERVICE INFORMATION >

ASSEMBLY

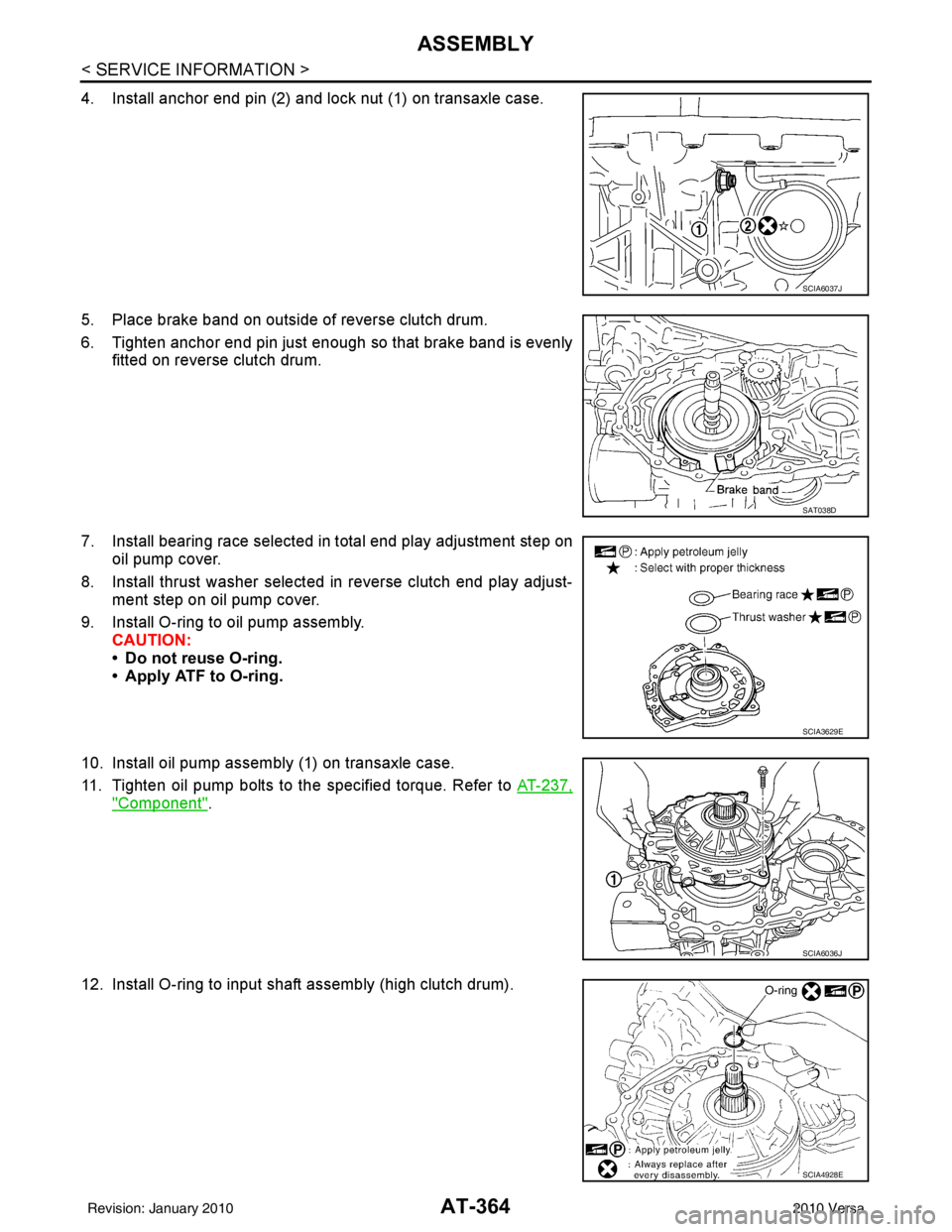

4. Install anchor end pin (2) and lock nut (1) on transaxle case.

5. Place brake band on outside of reverse clutch drum.

6. Tighten anchor end pin just enough so that brake band is evenlyfitted on reverse clutch drum.

7. Install bearing race selected in total end play adjustment step on oil pump cover.

8. Install thrust washer selected in reverse clutch end play adjust- ment step on oil pump cover.

9. Install O-ring to oil pump assembly. CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

10. Install oil pump assembly (1) on transaxle case.

11. Tighten oil pump bolts to the specified torque. Refer to AT-237,

"Component".

12. Install O-ring to input shaft assembly (high clutch drum).

SCIA6037J

SAT038D

SCIA3629E

SCIA6036J

SCIA4928E

Revision: January 20102010 Versa

Page 382 of 3745

ASSEMBLYAT-365

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

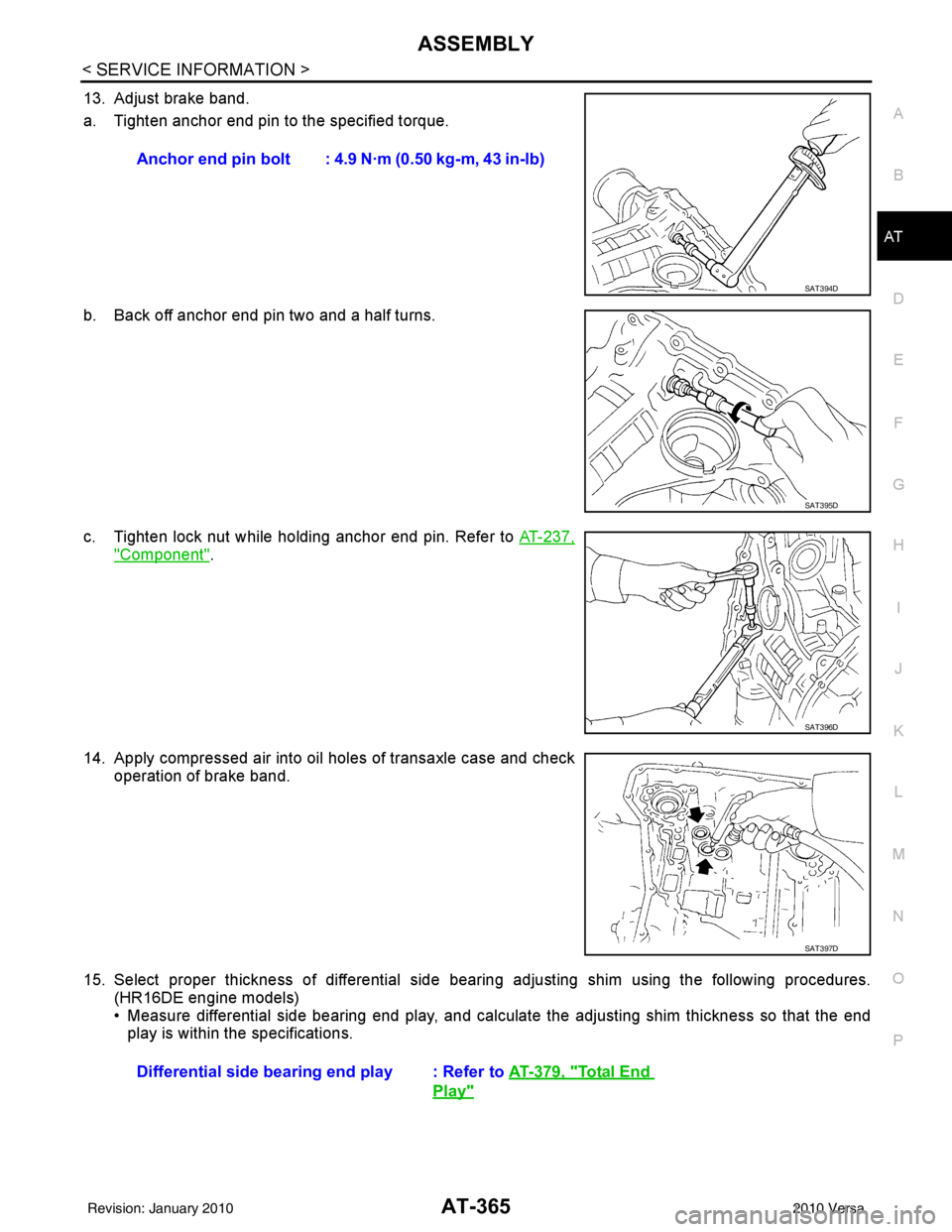

13. Adjust brake band.

a. Tighten anchor end pin to the specified torque.

b. Back off anchor end pin two and a half turns.

c. Tighten lock nut while holding anchor end pin. Refer to AT-237,

"Component".

14. Apply compressed air into oil holes of transaxle case and check operation of brake band.

15. Select proper thickness of differential side bear ing adjusting shim using the following procedures.

(HR16DE engine models)

• Measure differential side bearing end play, and calculat e the adjusting shim thickness so that the end

play is within the specifications. Anchor end pin bolt : 4.9 N·m (0.50 kg-m, 43 in-lb)

SAT394D

SAT395D

SAT396D

SAT397D

Differential side bearin

g end play : Refer to AT-379, "Total End

Play"

Revision: January 20102010 Versa

Page 393 of 3745

AT-376

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

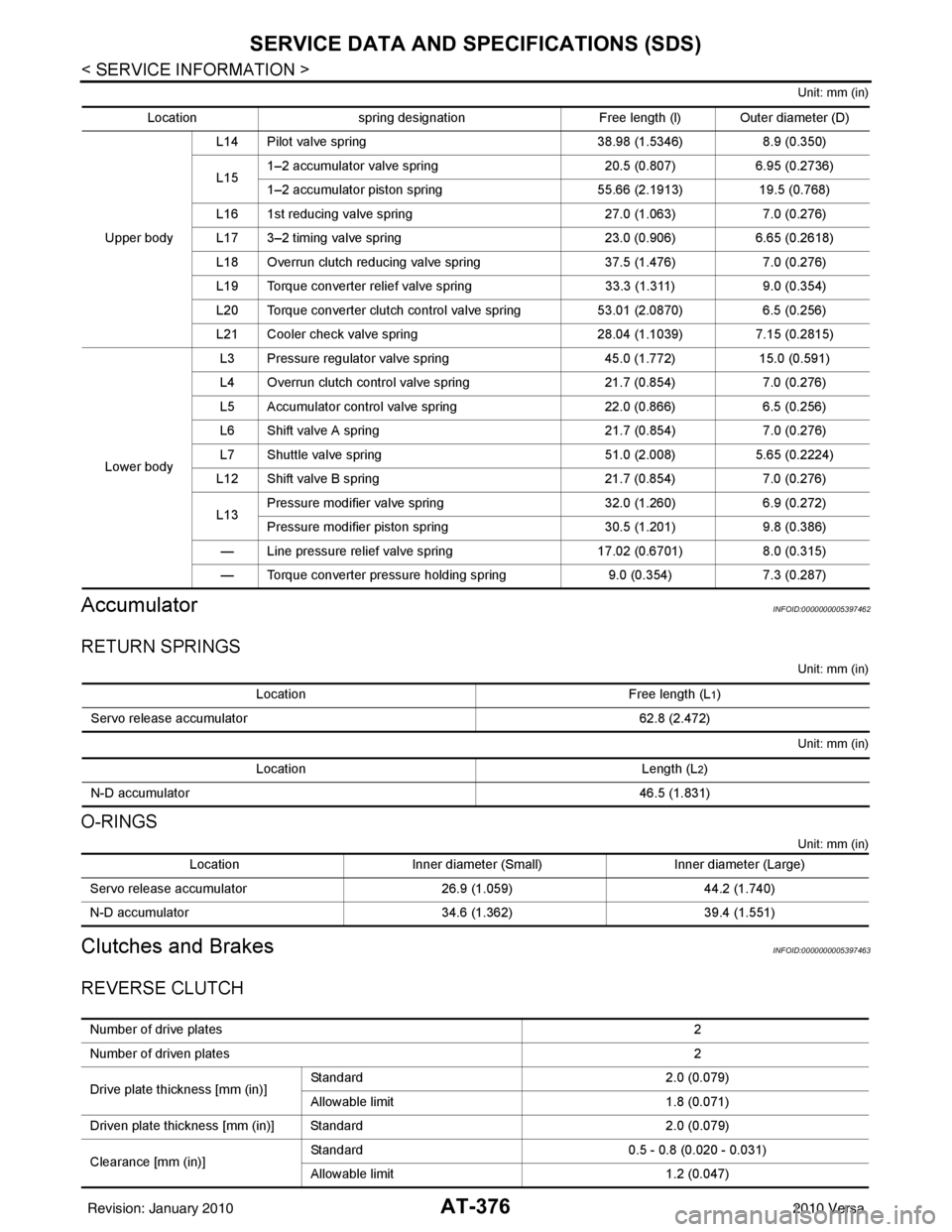

Unit: mm (in)

AccumulatorINFOID:0000000005397462

RETURN SPRINGS

Unit: mm (in)

Unit: mm (in)

O-RINGS

Unit: mm (in)

Clutches and BrakesINFOID:0000000005397463

REVERSE CLUTCH

Locationspring designation Free length (l) Outer diameter (D)

Upper body L14 Pilot valve spring

38.98 (1.5346)8.9 (0.350)

L15 1–2 accumulator valve spring

20.5 (0.807)6.95 (0.2736)

1–2 accumulator piston spring 55.66 (2.1913)19.5 (0.768)

L16 1st reducing valve spring 27.0 (1.063)7.0 (0.276)

L17 3–2 timing valve spring 23.0 (0.906)6.65 (0.2618)

L18 Overrun clutch reducing valve spring37.5 (1.476)7.0 (0.276)

L19 Torque converter relief valve spring 33.3 (1.311)9.0 (0.354)

L20 Torque converter clutch control valve spring 53.01 (2.0870)6.5 (0.256)

L21 Cooler check valve spring 28.04 (1.1039)7.15 (0.2815)

Lower body L3 Pressure regulator valve spring

45.0 (1.772)15.0 (0.591)

L4 Overrun clutch control valve spring 21.7 (0.854)7.0 (0.276)

L5 Accumulator control valve spring 22.0 (0.866)6.5 (0.256)

L6 Shift valve A spring 21.7 (0.854)7.0 (0.276)

L7 Shuttle valve spring 51.0 (2.008)5.65 (0.2224)

L12 Shift valve B spring 21.7 (0.854)7.0 (0.276)

L13 Pressure modifier valve spring

32.0 (1.260)6.9 (0.272)

Pressure modifier piston spring 30.5 (1.201)9.8 (0.386)

— Line pressure relief valve spring 17.02 (0.6701)8.0 (0.315)

— Torque converter pressure holding spring 9.0 (0.354)7.3 (0.287)

Location Free length (L1)

Servo release accumulator 62.8 (2.472)

LocationLength (L2)

N-D accumulator 46.5 (1.831)

LocationInner diameter (Small) Inner diameter (Large)

Servo release accumulator 26.9 (1.059)44.2 (1.740)

N-D accumulator 34.6 (1.362)39.4 (1.551)

Number of drive plates 2

Number of driven plates 2

Drive plate thickness [mm (in)] Standard

2.0 (0.079)

Allowable limit 1.8 (0.071)

Driven plate thickness [mm (in)] Standard 2.0 (0.079)

Clearance [mm (in)] Standard

0.5 - 0.8 (0.020 - 0.031)

Allowable limit 1.2 (0.047)

Revision: January 20102010 Versa

Page 394 of 3745

SERVICE DATA AND SPECIFICATIONS (SDS)AT-377

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

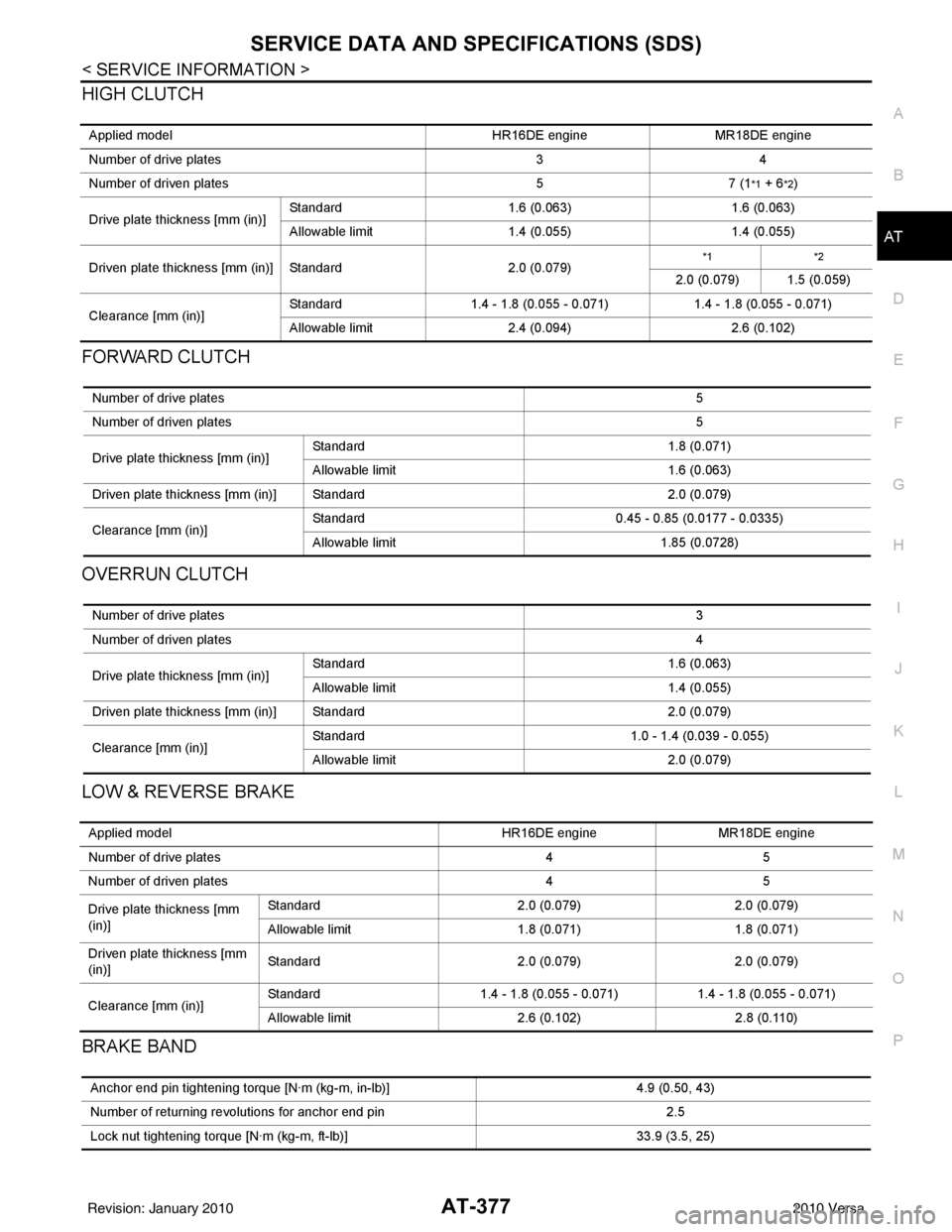

HIGH CLUTCH

FORWARD CLUTCH

OVERRUN CLUTCH

LOW & REVERSE BRAKE

BRAKE BAND

Applied model HR16DE engineMR18DE engine

Number of drive plates 34

Number of driven plates 57 (1

*1 + 6*2)

Drive plate thickness [mm (in)] Standard

1.6 (0.063) 1.6 (0.063)

Allowable limit 1.4 (0.055) 1.4 (0.055)

Driven plate thickness [mm (in)] Standard 2.0 (0.079)

*1*2

2.0 (0.079) 1.5 (0.059)

Clearance [mm (in)] Standard

1.4 - 1.8 (0.055 - 0.071) 1.4 - 1.8 (0.055 - 0.071)

Allowable limit 2.4 (0.094) 2.6 (0.102)

Number of drive plates 5

Number of driven plates 5

Drive plate thickness [mm (in)] Standard

1.8 (0.071)

Allowable limit 1.6 (0.063)

Driven plate thickness [mm (in)] Standard 2.0 (0.079)

Clearance [mm (in)] Standard

0.45 - 0.85 (0.0177 - 0.0335)

Allowable limit 1.85 (0.0728)

Number of drive plates 3

Number of driven plates 4

Drive plate thickness [mm (in)] Standard

1.6 (0.063)

Allowable limit 1.4 (0.055)

Driven plate thickness [mm (in)] Standard 2.0 (0.079)

Clearance [mm (in)] Standard

1.0 - 1.4 (0.039 - 0.055)

Allowable limit 2.0 (0.079)

Applied model HR16DE engineMR18DE engine

Number of drive plates 45

Number of driven plates 45

Drive plate thickness [mm

(in)] Standard

2.0 (0.079)2.0 (0.079)

Allowable limit 1.8 (0.071)1.8 (0.071)

Driven plate thickness [mm

(in)] Standard

2.0 (0.079)2.0 (0.079)

Clearance [mm (in)] Standard

1.4 - 1.8 (0.055 - 0.071) 1.4 - 1.8 (0.055 - 0.071)

Allowable limit 2.6 (0.102)2.8 (0.110)

Anchor end pin tightening torque [N·m (kg-m, in-lb)] 4.9 (0.50, 43)

Number of returning revolutions for anchor end pin 2.5

Lock nut tightening torque [N·m (kg-m, ft-lb)] 33.9 (3.5, 25)

Revision: January 20102010 Versa

Page 618 of 3745

INTELLIGENT KEY SYSTEMBL-109

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

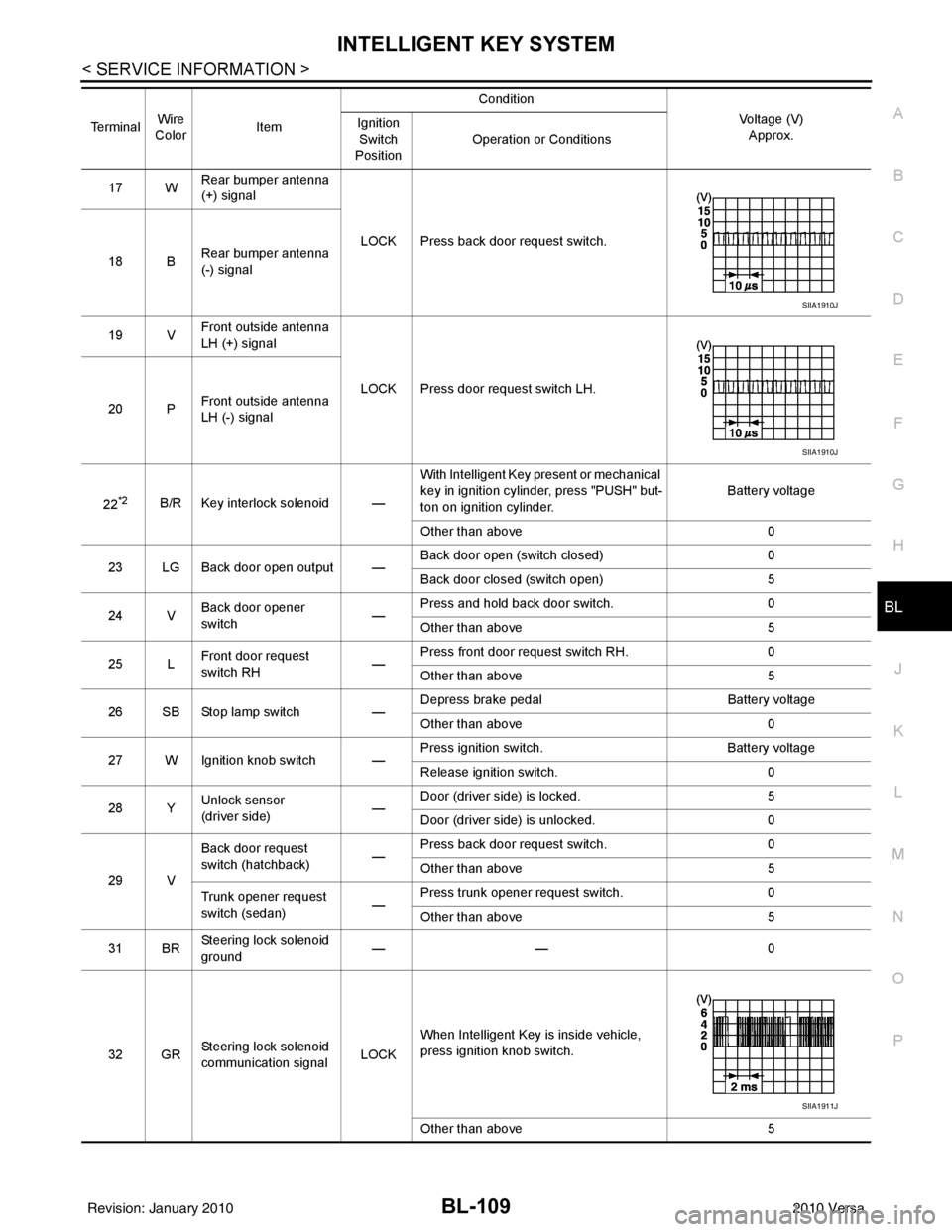

17 W Rear bumper antenna

(+) signal

LOCK Press back door request switch.

18 B Rear bumper antenna

(-) signal

19 V Front outside antenna

LH (+) signal

LOCK Press door request switch LH.

20 P Front outside antenna

LH (-) signal

22

*2B/R Key interlock solenoid — With Intelligent Key present or mechanical

key in ignition cylinder, press "PUSH" but-

ton on ignition cylinder.

Battery voltage

Other than above 0

23 LG Back door open output — Back door open (switch closed)

0

Back door closed (switch open) 5

24 V Back door opener

switch —Press and hold back door switch.

0

Other than above 5

25 L Front door request

switch RH —Press front door request switch RH.

0

Other than above 5

26 SB Stop lamp switch —Depress brake pedal

Battery voltage

Other than above 0

27 W Ignition knob switch — Press ignition switch.

Battery voltage

Release ignition switch. 0

28 Y Unlock sensor

(driver side) —Door (driver si

de) is locked. 5

Door (driver side ) is unlocked. 0

29 V Back door request

switch (hatchback)

—Press back door request switch.

0

Other than above 5

Trunk opener request

switch (sedan) —Press trunk opener request switch.

0

Other than above 5

31 BR Steering lock solenoid

ground

——

0

32 GR Steering lock solenoid

communication signal LOCKWhen Intelligent Key is inside vehicle,

press ignition knob switch.

Other than above

5

Terminal

Wire

Color Item Condition

Voltage (V)Approx.

Ignition

Switch

Position Operation or Conditions

SIIA1910J

SIIA1910J

SIIA1911J

Revision: January 20102010 Versa

Page 660 of 3745

INTELLIGENT KEY SYSTEMBL-151

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

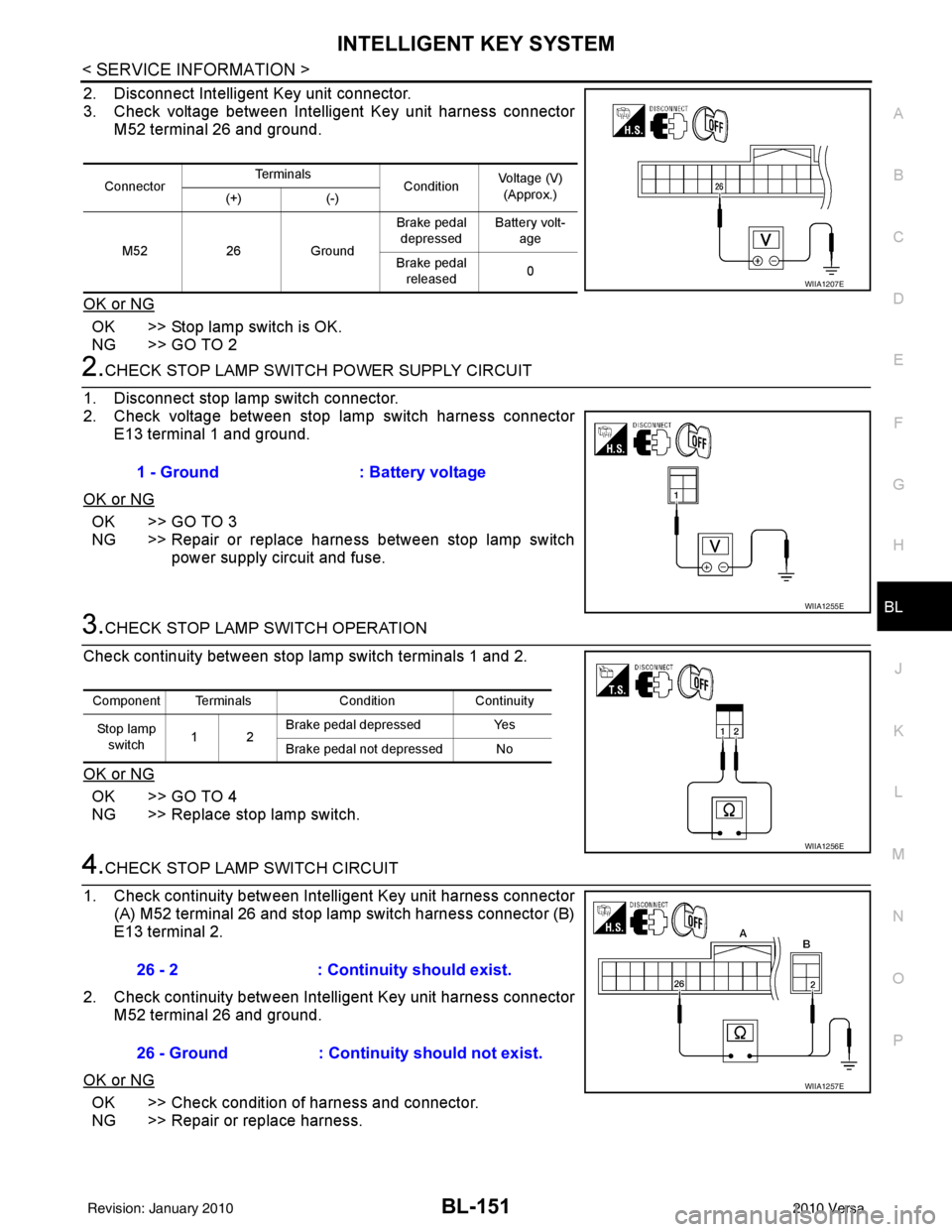

2. Disconnect Intelligent Key unit connector.

3. Check voltage between Intelligent Key unit harness connector M52 terminal 26 and ground.

OK or NG

OK >> Stop lamp switch is OK.

NG >> GO TO 2

2.CHECK STOP LAMP SWIT CH POWER SUPPLY CIRCUIT

1. Disconnect stop lamp switch connector.

2. Check voltage between stop lamp switch harness connector E13 terminal 1 and ground.

OK or NG

OK >> GO TO 3

NG >> Repair or replace harness between stop lamp switch power supply circuit and fuse.

3.CHECK STOP LAMP SWITCH OPERATION

Check continuity between stop lamp switch terminals 1 and 2.

OK or NG

OK >> GO TO 4

NG >> Replace stop lamp switch.

4.CHECK STOP LAMP SWITCH CIRCUIT

1. Check continuity between Intelligent Key unit harness connector (A) M52 terminal 26 and stop lamp switch harness connector (B)

E13 terminal 2.

2. Check continuity between Intelligent Key unit harness connector M52 terminal 26 and ground.

OK or NG

OK >> Check condition of harness and connector.

NG >> Repair or replace harness.

Connector Te r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

M52 26Ground Brake pedal

depressed Battery volt-

age

Brake pedal released 0

WIIA1207E

1 - Ground

: Battery voltage

WIIA1255E

Component Terminals ConditionContinuity

Stop lamp switch 12 Brake pedal depressed

Yes

Brake pedal not depressed No

WIIA1256E

26 - 2 : Continuity should exist.

26 - Ground : Continuity should not exist.

WIIA1257E

Revision: January 20102010 Versa