sensor NISSAN LATIO 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 742 of 3787

BL-232

< SERVICE INFORMATION >

VEHICLE SECURITY (THEFT WARNING) SYSTEM

*1: With continuously variable transmissi on (CVT) or automatic transmission (A/T).

*2: With manual transmission (M/T).

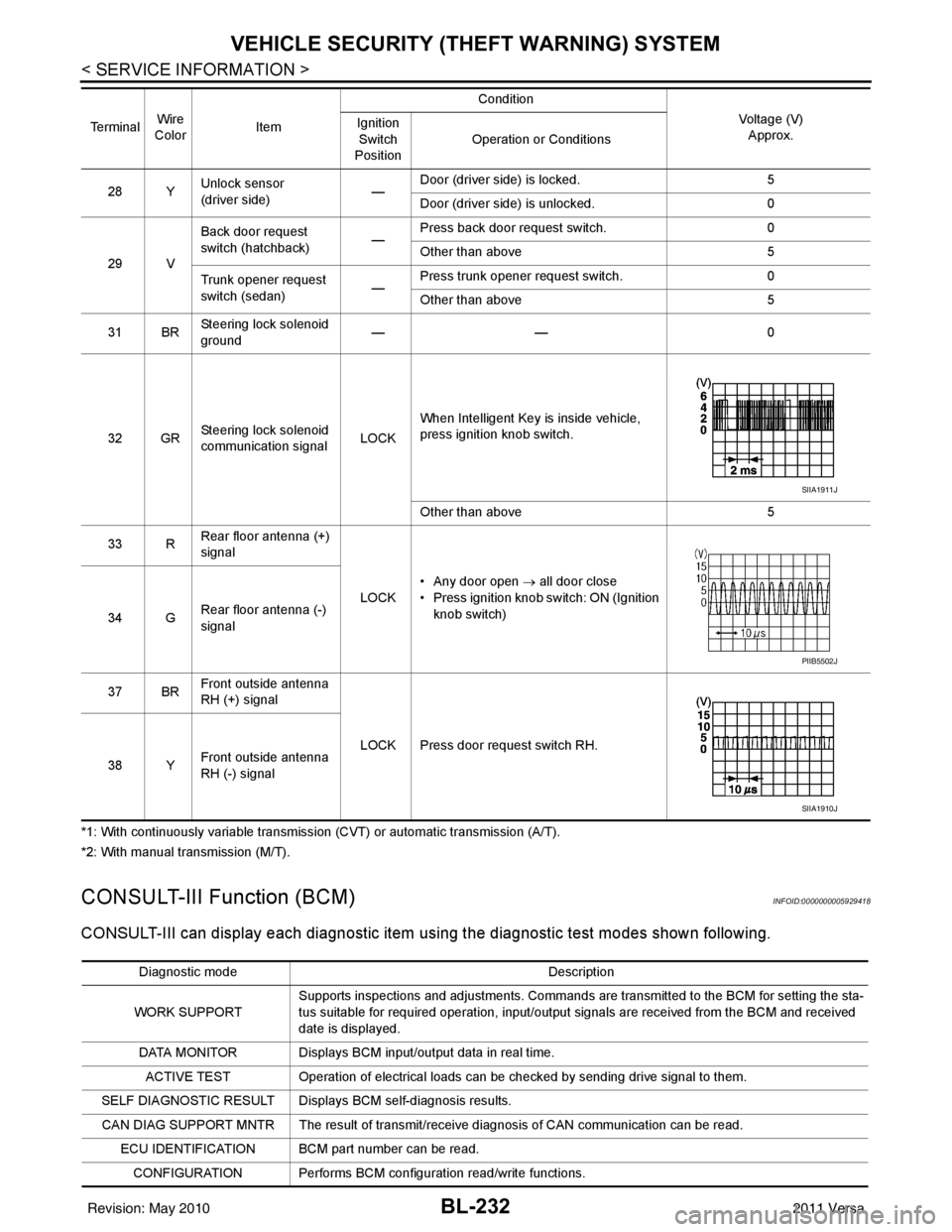

CONSULT-III Function (BCM)INFOID:0000000005929418

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

28 YUnlock sensor

(driver side) —Door (driver si

de) is locked. 5

Door (driver side ) is unlocked. 0

29 V Back door request

switch (hatchback)

—Press back door request switch.

0

Other than above 5

Trunk opener request

switch (sedan) —Press trunk opener request switch.

0

Other than above 5

31 BR Steering lock solenoid

ground ——

0

32 GR Steering lock solenoid

communication signal LOCKWhen Intelligent Key is inside vehicle,

press ignition knob switch.

Other than above

5

33 R Rear floor antenna (+)

signal

LOCK• Any door open

→ all door close

• Press ignition knob switch: ON (Ignition

knob switch)

34 G Rear floor antenna (-)

signal

37 BR Front outside antenna

RH (+) signal

LOCK Press door request switch RH.

38 Y Front outside antenna

RH (-) signal

Te r m i n a l

Wire

Color Item Condition

Voltage (V)Approx.

Ignition

Switch

Position Operation or Conditions

SIIA1911J

PIIB5502J

SIIA1910J

Diagnostic mode

Description

WORK SUPPORT Supports inspections and adjustments. Commands are transmitted to the BCM for setting the sta-

tus suitable for required operation, input/output signals are received from the BCM and received

date is displayed.

DATA MONITOR Displays BCM input/output data in real time. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF DIAGNOSTIC RESULT Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ECU IDENTIFICATION BCM part number can be read.CONFIGURATION Performs BCM configuration read/write functions.

Revision: May 2010 2011 Versa

Page 849 of 3787

BR-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005928385

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005928386

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 855 of 3787

BR-8

< SERVICE INFORMATION >

BRAKE PEDAL

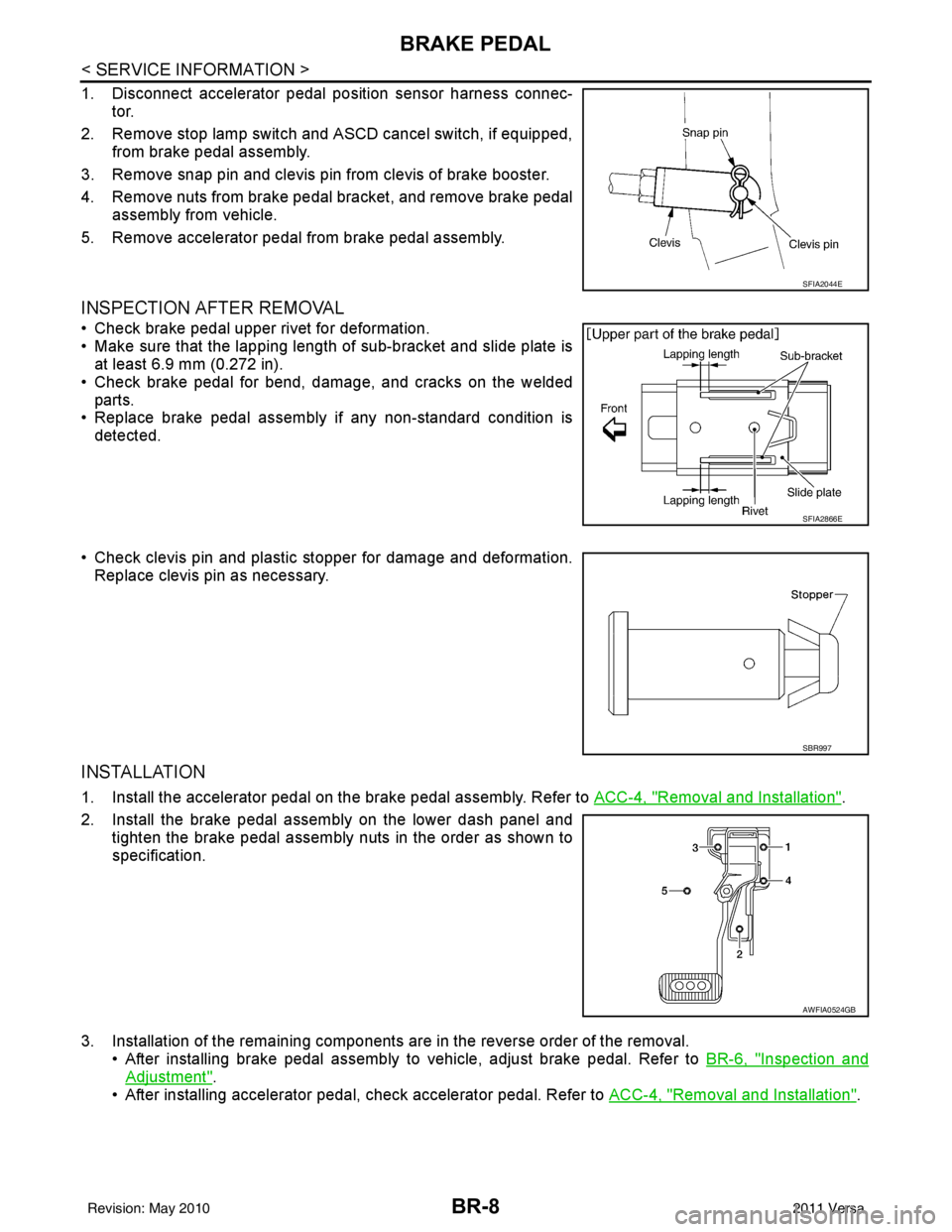

1. Disconnect accelerator pedal position sensor harness connec-tor.

2. Remove stop lamp switch and ASCD cancel switch, if equipped, from brake pedal assembly.

3. Remove snap pin and clevis pin from clevis of brake booster.

4. Remove nuts from brake pedal bracket, and remove brake pedal assembly from vehicle.

5. Remove accelerator pedal from brake pedal assembly.

INSPECTION AFTER REMOVAL

• Check brake pedal upper rivet for deformation.

• Make sure that the lapping length of sub-bracket and slide plate is at least 6.9 mm (0.272 in).

• Check brake pedal for bend, damage, and cracks on the welded parts.

• Replace brake pedal assembly if any non-standard condition is

detected.

• Check clevis pin and plastic stopper for damage and deformation. Replace clevis pin as necessary.

INSTALLATION

1. Install the accelerator pedal on the brake pedal assembly. Refer to ACC-4, "Removal and Installation".

2. Install the brake pedal assembly on the lower dash panel and tighten the brake pedal assembly nuts in the order as shown to

specification.

3. Installation of the remaining components are in the reverse order of the removal. • After installing brake pedal assembly to vehicle, adjust brake pedal. Refer to BR-6, "

Inspection and

Adjustment".

• After installing accelerator pedal, check accelerator pedal. Refer to ACC-4, "

Removal and Installation".

SFIA2044E

SFIA2866E

SBR997

AWFIA0524GB

Revision: May 2010 2011 Versa

Page 872 of 3787

FRONT DISC BRAKEBR-25

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

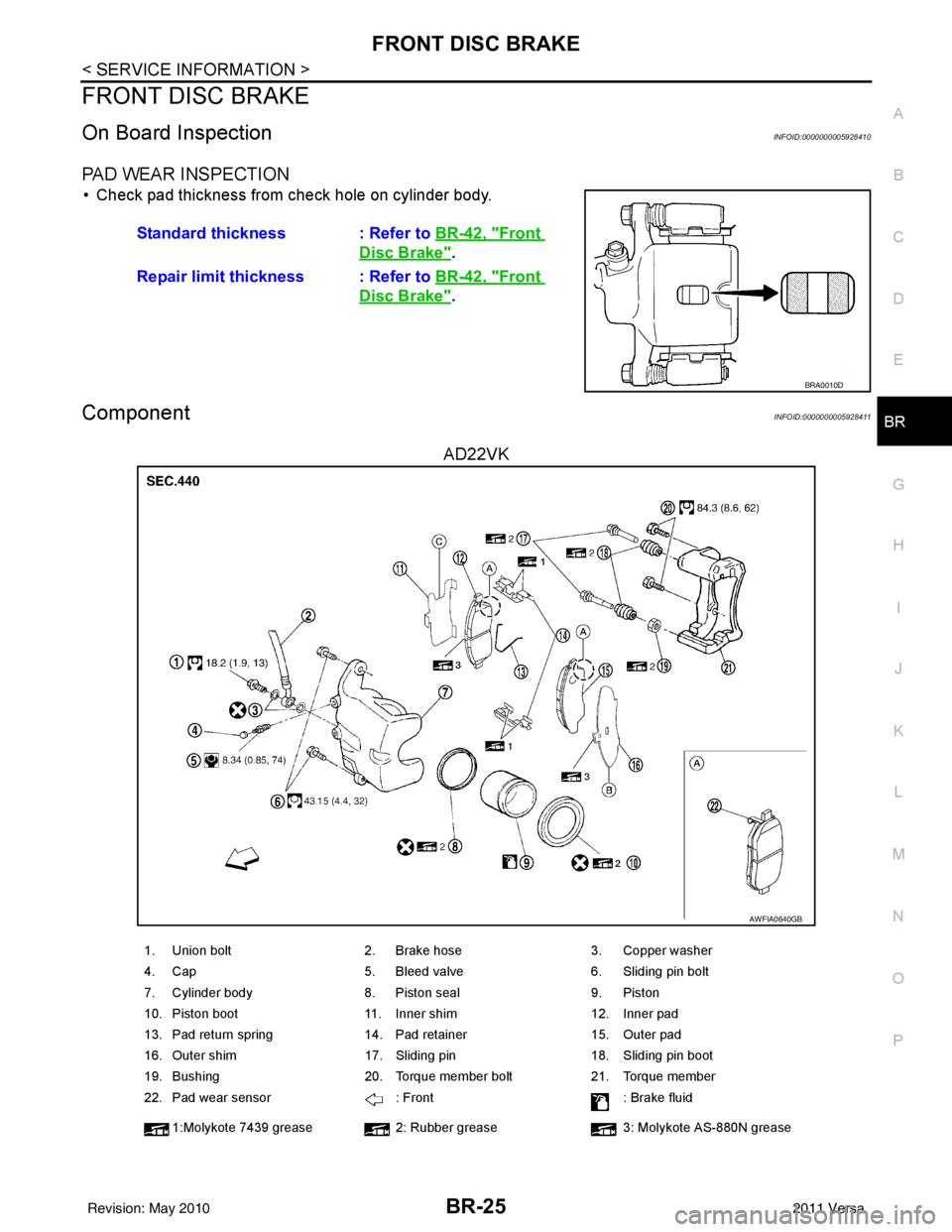

FRONT DISC BRAKE

On Board InspectionINFOID:0000000005928410

PAD WEAR INSPECTION

• Check pad thickness from check hole on cylinder body.

ComponentINFOID:0000000005928411

AD22VK

Standard thickness : Refer to BR-42, "Front

Disc Brake".

Repair limit thickness : Refer to BR-42, "

Front

Disc Brake".

BRA0010D

AWFIA0640GB

1. Union bolt2. Brake hose 3. Copper washer

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Cylinder body 8. Piston seal 9. Piston

10. Piston boot 11. Inner shim 12. Inner pad

13. Pad return spring 14. Pad retainer 15. Outer pad

16. Outer shim 17. Sliding pin 18. Sliding pin boot

19. Bushing 20. Torque member bolt 21. Torque member

22. Pad wear sensor : Front: Brake fluid

1:Molykote 7439 grease 2: Rubber grease 3: Molykote AS-880N grease

Revision: May 2010 2011 Versa

Page 873 of 3787

BR-26

< SERVICE INFORMATION >

FRONT DISC BRAKE

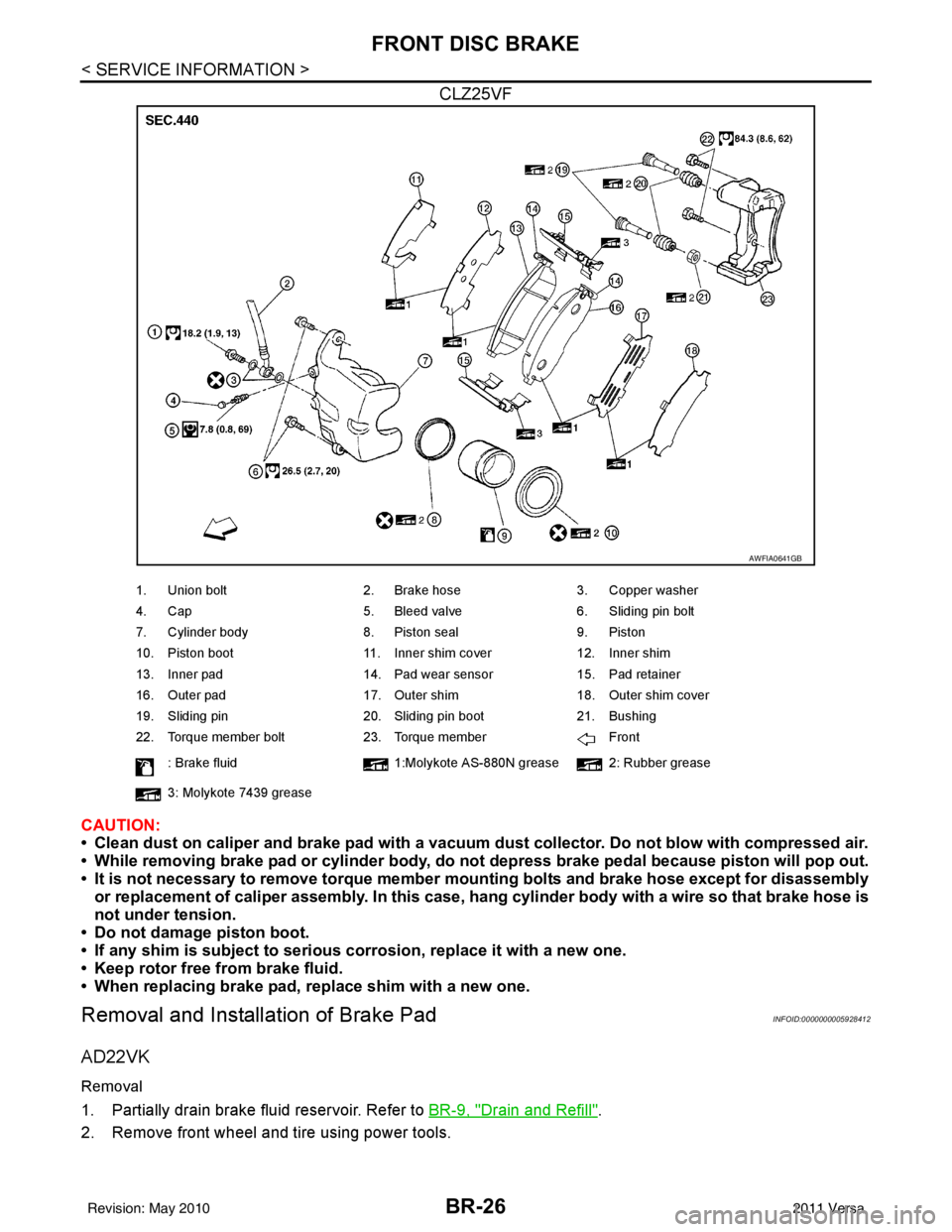

CLZ25VF

CAUTION:

• Clean dust on caliper and brake pad with a vacuum dust collector. Do not blow with compressed air.

• While removing brake pad or cylinder body, do not depress brake pedal because piston will pop out.

• It is not necessary to remove torque member mounting bolts and brake hose except for disassembly

or replacement of caliper assembly. In this case, hang cylinder body with a wire so that brake hose is

not under tension.

• Do not damage piston boot.

• If any shim is subject to serious corrosion, replace it with a new one.

• Keep rotor free from brake fluid.

• When replacing brake pad, replace shim with a new one.

Removal and Installation of Brake PadINFOID:0000000005928412

AD22VK

Removal

1. Partially drain brake fluid reservoir. Refer to BR-9, "Drain and Refill".

2. Remove front wheel and tire using power tools.

AWFIA0641GB

1. Union bolt 2. Brake hose3. Copper washer

4. Cap 5. Bleed valve6. Sliding pin bolt

7. Cylinder body 8. Piston seal9. Piston

10. Piston boot 11. Inner shim cover12. Inner shim

13. Inner pad 14. Pad wear sensor15. Pad retainer

16. Outer pad 17. Outer shim18. Outer shim cover

19. Sliding pin 20. Sliding pin boot21. Bushing

22. Torque member bolt 23. Torque member Front

: Brake fluid 1:Molykote AS-880N grease 2: Rubber grease

3: Molykote 7439 grease

Revision: May 2010 2011 Versa

Page 890 of 3787

BRC-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION BRC

A

B

BRC

N

O P

CONTENTS

BRAKE CONTROL SYSTEM

ABS

SERVICE INFORMATION .. ..........................

3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Brake System ....................................3

Precaution for Brake Control .....................................4

Precaution for CAN System ................................ ......4

PREPARATION ...................................................5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

SYSTEM DESCRIPTION .....................................6

System Component ............................................. ......6

ABS Function ............................................................6

EBD Function ............................................................6

Fail-Safe Function .....................................................6

Hydraulic Circuit Diagram .........................................7

CAN COMMUNICATION ................................ .....8

System Description ............................................. ......8

TROUBLE DIAGNOSIS ......................................9

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ........................................................

9

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

12

Schematic ...............................................................13

Wiring Diagram - ABS - ...........................................14

Basic Inspection .................................................. ....17

Warning Lamp and Indicator Timing .......................18

Control Unit Input/Output Signal Standard ..............18

CONSULT-III Function (ABS) .................................19

TROUBLE DIAGNOSIS FOR SELF-DIAG-

NOSTIC ITEMS ..................................................

25

Wheel Sensor System .............................................25

ABS Control Unit Inspection ....................................26

Solenoid Valve System Inspection ...................... ....26

Actuator Motor, Motor Relay, and Circuit Inspec-

tion ....................................................................... ....

27

ABS Control Unit Power and Ground Systems In-

spection ...................................................................

28

CAN Communication System Inspection .................29

TROUBLE DIAGNOSES FOR SYMPTOMS .....30

ABS Works Frequently ............................................30

Unexpected Pedal Action ........................................30

Long Stopping Distance ..........................................31

ABS Does Not Work ................................................31

Pedal Vibration or ABS Operation Noise .................31

WHEEL SENSORS ...........................................33

Removal and Installation ..................................... ....33

SENSOR ROTOR ..............................................35

Removal and Installation .........................................35

ACTUATOR AND ELECTRIC UNIT (ASSEM-

BLY) ..................................................................

36

Removal and Installation .........................................36

VDC/TCS/ABS

SERVICE INFORMATION .. .........................

38

PRECAUTIONS .................................................38

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

38

Precautions Necessary for Steering Wheel Rota-

tion after Battery Disconnect ...................................

38

Precaution for Brake System ...................................39

Precaution for Brake Control ...................................39

Precaution for CAN System .....................................40

PREPARATION .................................................41

Special Service Tool ................................................41

Commercial Service Tool ........................................41

SYSTEM DESCRIPTION ..................................42

Revision: May 2010 2011 Versa

Page 891 of 3787

BRC-2

System Component ................................................42

ABS Function ....................................... ...................42

EBD Function ...................................................... ...42

TCS Function ..........................................................43

VDC Function .........................................................43

Wheel Sensors .......................................................43

Fail-Safe Function ..................................................43

Hydraulic Circuit Diagram .......................................44

CAN COMMUNICATION ...................................45

System Description .................................................45

TROUBLE DIAGNOSIS .....................................46

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ................................................... ...

46

Component Parts and Harness Connector Loca-

tion ..........................................................................

49

Schematic ...............................................................51

Wiring Diagram - VDC - ..........................................52

Basic Inspection .....................................................56

Warning Lamp and Indicator Timing .......................57

Control Unit Input/Output Signal Standard .............57

CONSULT-III Function (ABS) .................................60

TROUBLE DIAGNOSIS FOR SELF-DIAG-

NOSTIC ITEMS ............................................... ...

67

Wheel Sensor System Inspection ...........................67

Engine System Inspection ................................... ...68

ABS/TCS/VDC Control Unit Inspection ..................68

Steering Angle Sensor System Inspection .......... ...69

Yaw Rate/Side/Decel G Sensor System Inspec-

tion ....................................................................... ...

70

Solenoid and VDC Change-Over Valve System

Inspection ...............................................................

72

Actuator Motor, Motor Relay, and Circuit Inspec-

tion ....................................................................... ...

73

Stop Lamp Switch System Inspection ....................74

ABS/TCS/VDC Control Unit Power and Ground

Systems Inspection .............................................. ...

75

Brake Fluid Level Switch System Inspection ..........76

Pressure Sensor System Inspection .......................77

Transmission Range Switch System Inspection .. ...78

CAN Communication System Inspection ................79

Component Inspection ............................................79

TROUBLE DIAGNOSES FOR SYMPTOMS .....81

ABS Works Frequently ............................................81

Unexpected Pedal Action ..................................... ...81

Long Stopping Distance ..........................................82

ABS Does Not Work ...............................................82

Pedal Vibration or ABS Op eration Noise ................82

ABS Warning Lamp Does Not Come On When Ig-

nition Switch Is Turned On ................................... ...

83

ABS Warning Lamp Stays On When Ignition

Switch Is Turned On ............................................ ...

83

Vehicle Jerks During TCS/VDC Activation ..............84

ON-VEHICLE SERVICE ....................................85

Adjustment of Steering Angle Sensor Neutral Po-

sition ..................................................................... ...

85

WHEEL SENSORS ............................................86

Removal and Installation .........................................86

SENSOR ROTOR ........................................... ...88

Removal and Installation .........................................88

ACTUATOR AND ELECTRIC UNIT (ASSEM-

BLY) ................................................................ ...

89

Removal and Installation .........................................89

STEERING ANGLE SENSOR ........................ ...91

Removal and Installation .........................................91

G SENSOR ........................................................92

Removal and Installation .........................................92

Revision: May 2010 2011 Versa

Page 892 of 3787

![NISSAN LATIO 2011 Service Repair Manual PRECAUTIONSBRC-3

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSI NISSAN LATIO 2011 Service Repair Manual PRECAUTIONSBRC-3

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSI](/img/5/57357/w960_57357-891.png)

PRECAUTIONSBRC-3

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005928426

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution for Brake SystemINFOID:0000000005928427

CAUTION:

• Refer to MA-14

for recommended brake fluid.

• Never reuse drained brake fluid.

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

• To clean or wash all parts of master cylin der and disc brake caliper, use clean brake fluid.

• Never use mineral oils such as gasoline or kerosen e. They will ruin rubber parts of the hydraulic sys-

tem.

• Use flare nut wrench when removing and installing brake tube.

• If a brake fluid leak is found, the part must be disassembled

without fail. Then it has to be replaced with a new one if a

defect exists.

• Turn the ignition switch OFF and remove the connector of the

ABS actuator and electric unit (con trol unit) or the battery ter-

minal before performing the work.

• Always torque brake lines when installing.

• Burnish the brake contact surf aces after refinishing or replac-

ing rotors, after replacing pads, or if a soft pedal occurs at

very low mileage. Refer to BR-34, "

Brake Burnishing Proce-

dure".

WARNING:

• Clean brake pads and shoes with a waste cl oth, then wipe with a dust collector.

SBR686C

Revision: May 2010 2011 Versa

Page 894 of 3787

![NISSAN LATIO 2011 Service Repair Manual PREPARATIONBRC-5

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PREPARATION

Special Service ToolINFOID:0000000005928430

The actual shapes of Kent-Moore tools may differ from those of NISSAN LATIO 2011 Service Repair Manual PREPARATIONBRC-5

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PREPARATION

Special Service ToolINFOID:0000000005928430

The actual shapes of Kent-Moore tools may differ from those of](/img/5/57357/w960_57357-893.png)

PREPARATIONBRC-5

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PREPARATION

Special Service ToolINFOID:0000000005928430

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000005928431

Tool number

(Kent-Moore No.)

Tool name Description

KV991J0080

(J-45741)

ABS active wheel sensor tester Checking operation of ABS active wheel sen-

sors

WFIA0101E

Tool name

Description

1. Flare nut crowfoot

2. Torque wrench Removing and installing brake piping

a: 10 mm (0.39 in)/12 mm (0.47 in)

S-NT360

Revision: May 2010

2011 Versa

Page 898 of 3787

![NISSAN LATIO 2011 Service Repair Manual TROUBLE DIAGNOSISBRC-9

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

TROUBLE DIAGNOSIS

How to Perform Trouble Diagnosis for Quick and Accurate RepairINFOID:0000000005928438

INTRODUCT NISSAN LATIO 2011 Service Repair Manual TROUBLE DIAGNOSISBRC-9

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

TROUBLE DIAGNOSIS

How to Perform Trouble Diagnosis for Quick and Accurate RepairINFOID:0000000005928438

INTRODUCT](/img/5/57357/w960_57357-897.png)

TROUBLE DIAGNOSISBRC-9

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

TROUBLE DIAGNOSIS

How to Perform Trouble Diagnosis for Quick and Accurate RepairINFOID:0000000005928438

INTRODUCTION

The ABS system has an electronic control unit to control major func-

tions. The control unit accepts i nput signals from sensors and con-

trols actuator operation. It is also important to check for air leaks in

the booster or brake and vacuum lines, lack of brake fluid, or other

malfunctions in the brake system.

It is much more difficult to diagnose a malfunction that occurs inter-

mittently rather than continuously. Most intermittent conditions are

caused by poor electrical connec tions or damaged wiring. In this

case, careful checking of suspicious circuits may help prevent the

replacement of good parts.

A visual check only may not find t he cause of the malfunction, so a

road test should be performed.

Before undertaking actual checks, take just a few minutes to talk with

a customer who approaches with an ABS complaint. The customer

is a very good source of information, especially for intermittent condi-

tions. Through the talks with the cu stomer, find out what symptoms

are present and under what conditions they occur.

Start your diagnosis by looking fo r “conventional” malfunctions first.

This is one of the best ways to troubleshoot brake malfunctions on

an ABS equipped vehicle. Also check related Service Bulletins for

information.

SEF233G

SEF234G

Revision: May 2010 2011 Versa