steering wheel adjustment NISSAN LATIO 2011 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 2648 of 3787

FAX-6

< SERVICE INFORMATION >

FRONT WHEEL HUB AND KNUCKLE

FRONT WHEEL HUB AND KNUCKLE

On-Vehicle Inspection and ServiceINFOID:0000000005931068

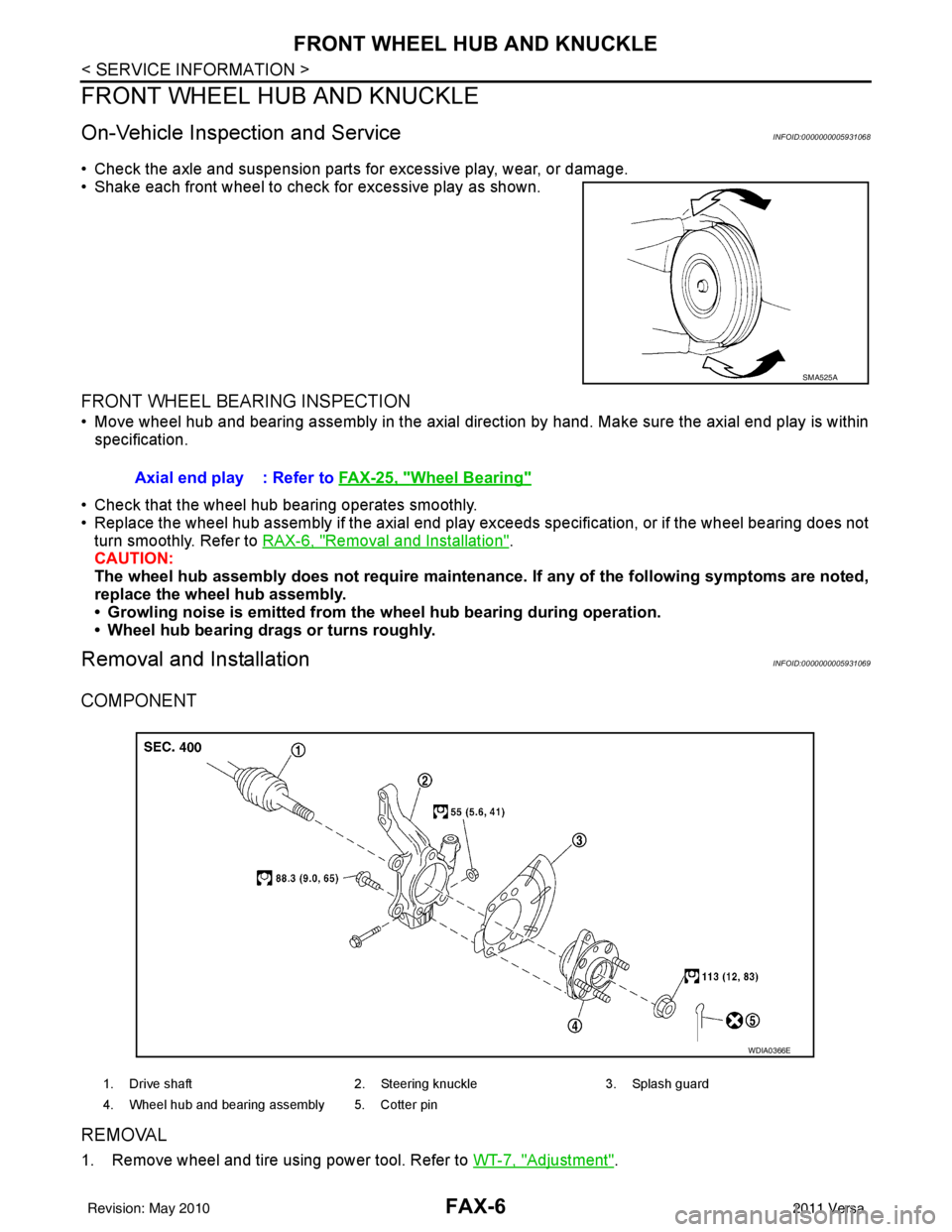

• Check the axle and suspension parts for excessive play, wear, or damage.

• Shake each front wheel to check for excessive play as shown.

FRONT WHEEL BEARING INSPECTION

• Move wheel hub and bearing assembly in the axial direction by hand. Make sure the axial end play is within

specification.

• Check that the wheel hub bearing operates smoothly.

• Replace the wheel hub assembly if the axial end play exceeds specification, or if the wheel bearing does not turn smoothly. Refer to RAX-6, "

Removal and Installation".

CAUTION:

The wheel hub assembly does not requ ire maintenance. If any of the following symptoms are noted,

replace the wheel hub assembly.

• Growling noise is emitted from the wheel hub bearing during operation.

• Wheel hub bearing drags or turns roughly.

Removal and InstallationINFOID:0000000005931069

COMPONENT

REMOVAL

1. Remove wheel and tire using power tool. Refer to WT-7, "Adjustment".

SMA525A

Axial end play : Refer to FAX-25, "Wheel Bearing"

1. Drive shaft 2. Steering knuckle3. Splash guard

4. Wheel hub and bearing assembly 5. Cotter pin

WDIA0366E

Revision: May 2010 2011 Versa

Page 2651 of 3787

FRONT DRIVE SHAFTFAX-9

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

FRONT DRIVE SHAFT

On-Vehicle Inspection and ServiceINFOID:0000000005931070

• Check drive shaft mounting point and joint for looseness and other damage.

• Check boot for cracks and other damage.

Replace or repair components as necessary. Refer to FAX-9, "

Removal and Installation (Left Side)", FAX-10,

"Removal and Installation (Right Side)", FAX-13, "Disassembly and Assembly (Left Side)", or FAX-18, "Disas-

sembly and Assembly (Right Side)".

CAUTION:

Replace entire drive shaft assembly when noi se or vibration occur from drive shaft.

Removal and Installation (Left Side)INFOID:0000000005931071

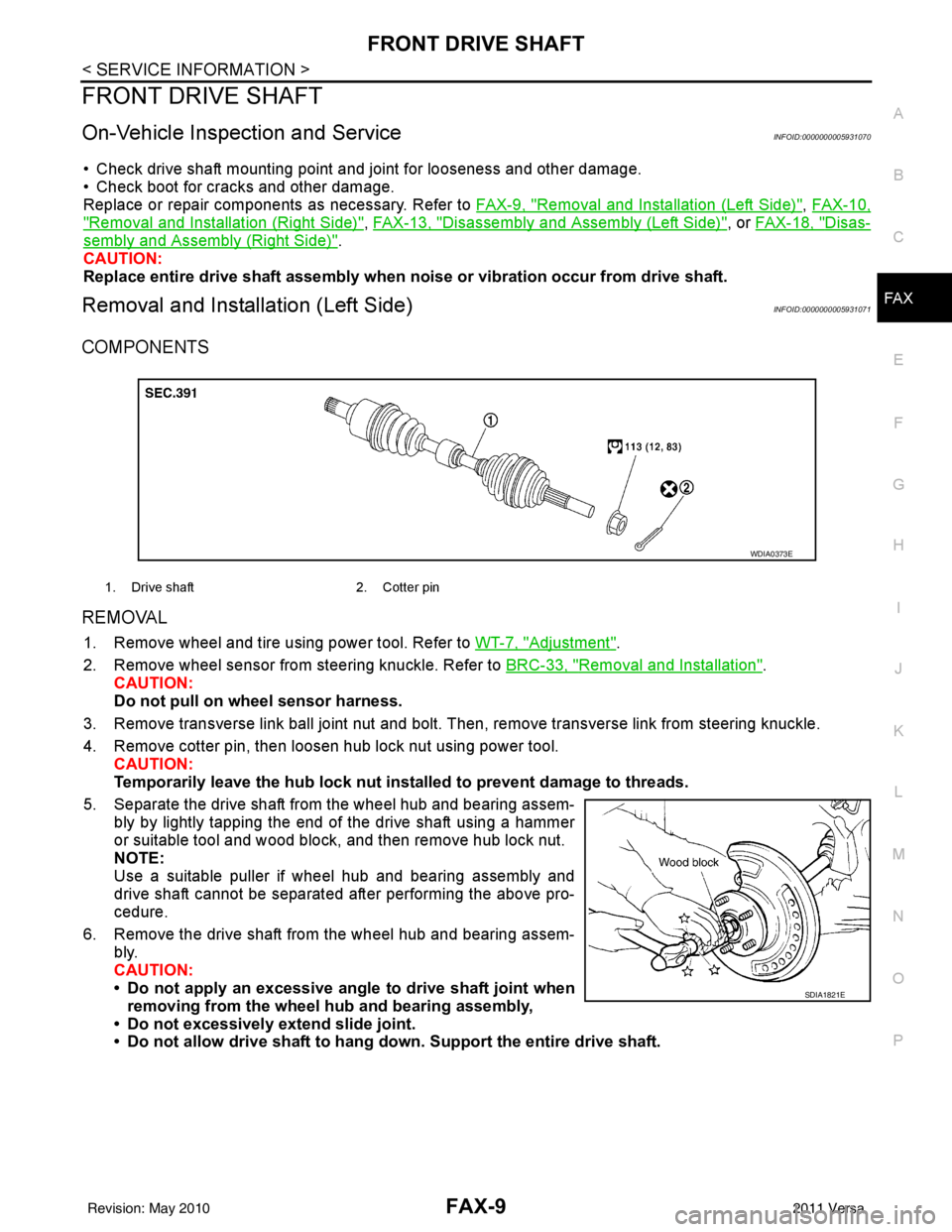

COMPONENTS

REMOVAL

1. Remove wheel and tire using power tool. Refer to WT-7, "Adjustment".

2. Remove wheel sensor from steering knuckle. Refer to BRC-33, "

Removal and Installation".

CAUTION:

Do not pull on wheel sensor harness.

3. Remove transverse link ball joint nut and bolt. Then, remove transverse link from steering knuckle.

4. Remove cotter pin, then loosen hub lock nut using power tool. CAUTION:

Temporarily leave the hub lock nut inst alled to prevent damage to threads.

5. Separate the drive shaft from the wheel hub and bearing assem- bly by lightly tapping the end of the drive shaft using a hammer

or suitable tool and wood block, and then remove hub lock nut.

NOTE:

Use a suitable puller if wheel hub and bearing assembly and

drive shaft cannot be separated after performing the above pro-

cedure.

6. Remove the drive shaft from the wheel hub and bearing assem- bly.

CAUTION:

• Do not apply an excessive angle to drive shaft joint when

removing from the wheel hub and bearing assembly,

• Do not excessively extend slide joint.

• Do not allow drive shaft to hang do wn. Support the entire drive shaft.

1. Drive shaft 2. Cotter pin

WDIA0373E

SDIA1821E

Revision: May 2010 2011 Versa

Page 2653 of 3787

FRONT DRIVE SHAFTFAX-11

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

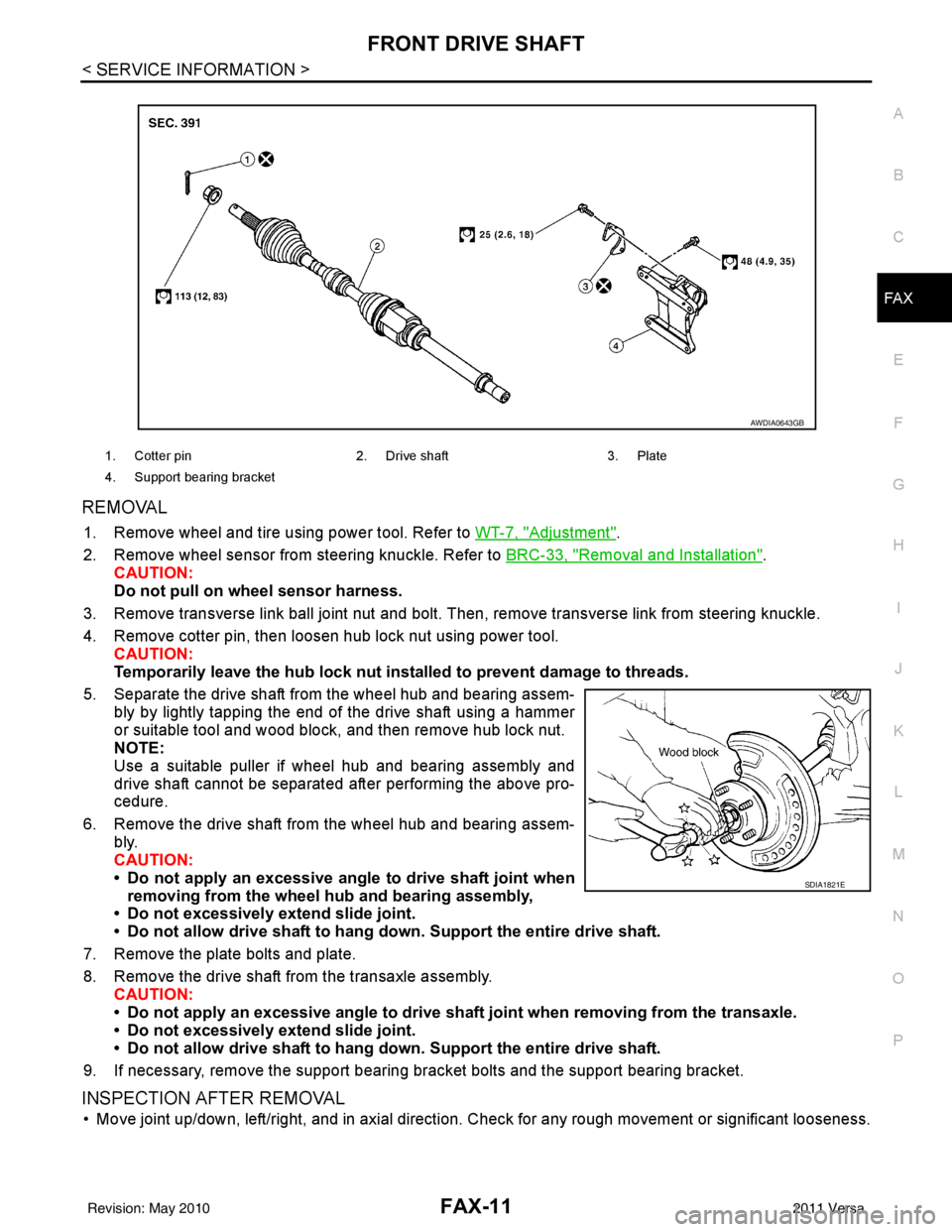

REMOVAL

1. Remove wheel and tire using power tool. Refer to WT-7, "Adjustment".

2. Remove wheel sensor from steering knuckle. Refer to BRC-33, "

Removal and Installation".

CAUTION:

Do not pull on wheel sensor harness.

3. Remove transverse link ball joint nut and bolt. Then, remove transverse link from steering knuckle.

4. Remove cotter pin, then loosen hub lock nut using power tool. CAUTION:

Temporarily leave the hub lock nut inst alled to prevent damage to threads.

5. Separate the drive shaft from the wheel hub and bearing assem- bly by lightly tapping the end of the drive shaft using a hammer

or suitable tool and wood block, and then remove hub lock nut.

NOTE:

Use a suitable puller if wheel hub and bearing assembly and

drive shaft cannot be separated after performing the above pro-

cedure.

6. Remove the drive shaft from the wheel hub and bearing assem- bly.

CAUTION:

• Do not apply an excessive angle to drive shaft joint when

removing from the wheel hub and bearing assembly,

• Do not excessively extend slide joint.

• Do not allow drive shaft to hang do wn. Support the entire drive shaft.

7. Remove the plate bolts and plate.

8. Remove the drive shaft from the transaxle assembly. CAUTION:

• Do not apply an excessive angle to drive shaf t joint when removing from the transaxle.

• Do not excessively extend slide joint.

• Do not allow drive shaft to hang do wn. Support the entire drive shaft.

9. If necessary, remove the support bearing bracket bolts and the support bearing bracket.

INSPECTION AFTER REMOVAL

• Move joint up/down, left/right, and in axial direction. Check for any rough movement or significant looseness.

1. Cotter pin 2. Drive shaft 3. Plate

4. Support bearing bracket

AWDIA0643GB

SDIA1821E

Revision: May 2010 2011 Versa

Page 2692 of 3787

FRONT SUSPENSION ASSEMBLYFSU-7

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

FRONT SUSPENSION ASSEMBLY

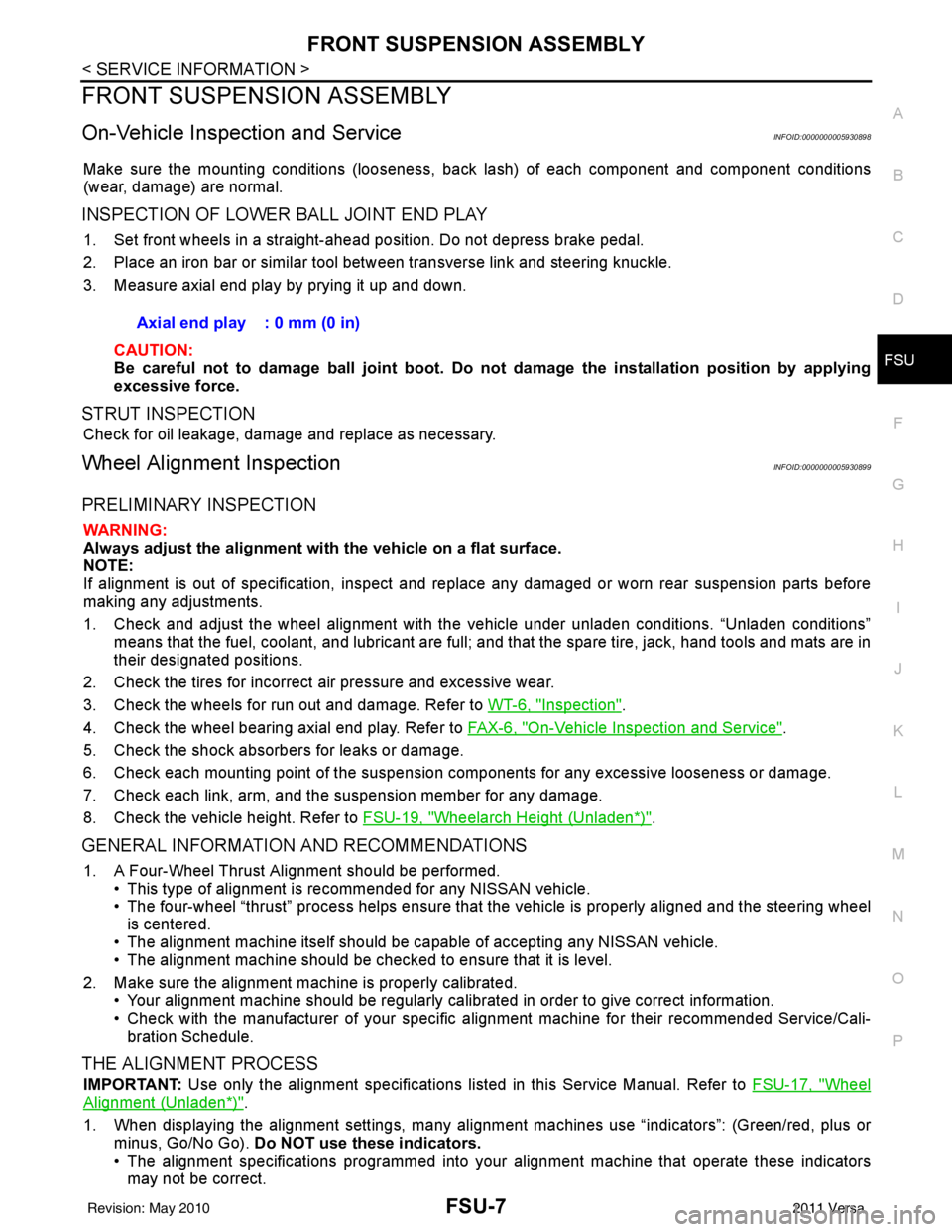

On-Vehicle Inspection and ServiceINFOID:0000000005930898

Make sure the mounting conditions (looseness, back lash) of each component and component conditions

(wear, damage) are normal.

INSPECTION OF LOWER BALL JOINT END PLAY

1. Set front wheels in a straight-ahead position. Do not depress brake pedal.

2. Place an iron bar or similar tool between transverse link and steering knuckle.

3. Measure axial end play by prying it up and down.

CAUTION:

Be careful not to damage ball joint boot. Do not damage the installation position by applying

excessive force.

STRUT INSPECTION

Check for oil leakage, damage and replace as necessary.

Wheel Alignment InspectionINFOID:0000000005930899

PRELIMINARY INSPECTION

WARNING:

Always adjust the alignment with the vehicle on a flat surface.

NOTE:

If alignment is out of specification, inspect and replace any damaged or worn rear suspension parts before

making any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, coolant, and lubricant are full; and that the spare tire, jack, hand tools and mats are in

their designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer to WT-6, "

Inspection".

4. Check the wheel bearing axial end play. Refer to FAX-6, "

On-Vehicle Inspection and Service".

5. Check the shock absorbers for leaks or damage.

6. Check each mounting point of the suspension components for any excessive looseness or damage.

7. Check each link, arm, and the suspension member for any damage.

8. Check the vehicle height. Refer to FSU-19, "

Wheelarch Height (Unladen*)".

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

• This type of alignment is re commended for any NISSAN vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be ca pable of accepting any NISSAN vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated. • Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific a lignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to FSU-17, "Wheel

Alignment (Unladen*)".

1. When displaying the alignment settings, many alignm ent machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

• The alignment specifications programmed into your alignment machine that operate these indicators may not be correct.Axial end play : 0 mm (0 in)

Revision: May 2010

2011 Versa

Page 2700 of 3787

TRANSVERSE LINKFSU-15

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

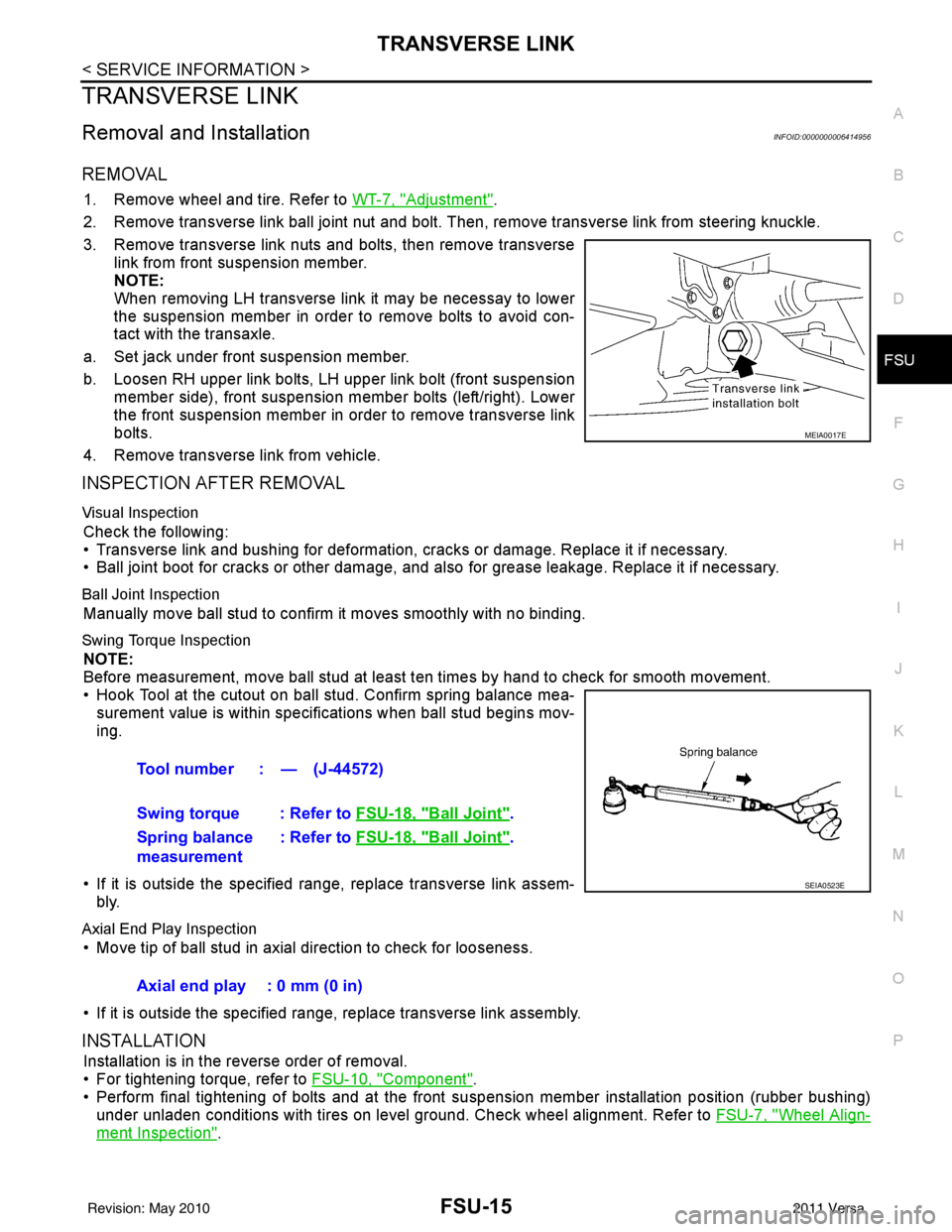

TRANSVERSE LINK

Removal and InstallationINFOID:0000000006414956

REMOVAL

1. Remove wheel and tire. Refer to WT-7, "Adjustment".

2. Remove transverse link ball joint nut and bolt. Then, remove transverse link from steering knuckle.

3. Remove transverse link nuts and bolts, then remove transverse link from front suspension member.

NOTE:

When removing LH transverse link it may be necessay to lower

the suspension member in order to remove bolts to avoid con-

tact with the transaxle.

a. Set jack under front suspension member.

b. Loosen RH upper link bolts, LH upper link bolt (front suspension member side), front suspension member bolts (left/right). Lower

the front suspension member in order to remove transverse link

bolts.

4. Remove transverse link from vehicle.

INSPECTION AFTER REMOVAL

Visual Inspection

Check the following:

• Transverse link and bushing for deformation, cracks or damage. Replace it if necessary.

• Ball joint boot for cracks or other damage, and also for grease leakage. Replace it if necessary.

Ball Joint Inspection

Manually move ball stud to confirm it moves smoothly with no binding.

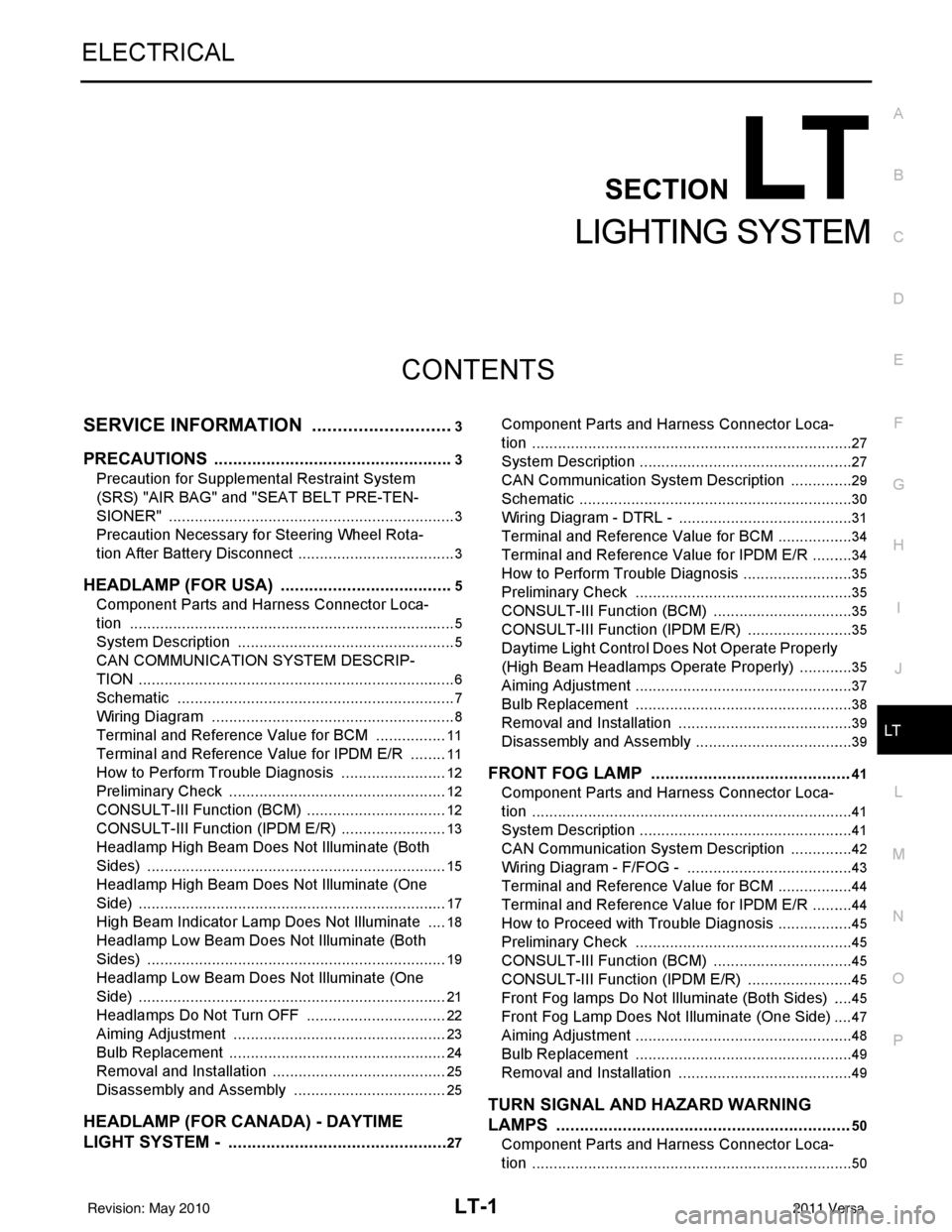

Swing Torque Inspection

NOTE:

Before measurement, move ball stud at least ten times by hand to check for smooth movement.

• Hook Tool at the cutout on ball stud. Confirm spring balance mea- surement value is within specifications when ball stud begins mov-

ing.

• If it is outside the specified range, replace transverse link assem- bly.

Axial End Play Inspection

• Move tip of ball stud in axial direction to check for looseness.

• If it is outside the specified range, replace transverse link assembly.

INSTALLATION

Installation is in the reverse order of removal.

• For tightening torque, refer to FSU-10, "

Component".

• Perform final tightening of bolts and at the front suspension member installation position (rubber bushing)

under unladen conditions with tires on level ground. Check wheel alignment. Refer to FSU-7, "

Wheel Align-

ment Inspection".

MEIA0017E

Tool number : — (J-44572)

Swing torque : Refer to FSU-18, "

Ball Joint".

Spring balance

measurement : Refer to

FSU-18, "

Ball Joint".

SEIA0523E

Axial end play : 0 mm (0 in)

Revision: May 2010 2011 Versa

Page 3033 of 3787

LT-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION LT

A

B

LT

N

O P

CONTENTS

LIGHTING SYSTEM

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

HEADLAMP (FOR USA) .....................................5

Component Parts and Harness Connector Loca-

tion ...................................................................... ......

5

System Description ...................................................5

CAN COMMUNICATION SYSTEM DESCRIP-

TION .................................................................... ......

6

Schematic .................................................................7

Wiring Diagram .........................................................8

Terminal and Reference Value for BCM .................11

Terminal and Reference Value for IPDM E/R .........11

How to Perform Trouble Diagnosis .........................12

Preliminary Check ...................................................12

CONSULT-III Function (BCM) .................................12

CONSULT-III Function (IPDM E/R) .........................13

Headlamp High Beam Does Not Illuminate (Both

Sides) .................................................................. ....

15

Headlamp High Beam Does Not Illuminate (One

Side) .................................................................... ....

17

High Beam Indicator Lamp Does Not Illuminate .....18

Headlamp Low Beam Does Not Illuminate (Both

Sides) .................................................................. ....

19

Headlamp Low Beam Does Not Illuminate (One

Side) .................................................................... ....

21

Headlamps Do Not Turn OFF .................................22

Aiming Adjustment ..................................................23

Bulb Replacement ...................................................24

Removal and Installation .........................................25

Disassembly and Assembly ................................ ....25

HEADLAMP (FOR CANADA) - DAYTIME

LIGHT SYSTEM - ........................................... ....

27

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

27

System Description ..................................................27

CAN Communication System Description ...............29

Schematic ................................................................30

Wiring Diagram - DTRL - .........................................31

Terminal and Reference Value for BCM ..................34

Terminal and Reference Value for IPDM E/R ...... ....34

How to Perform Trouble Diagnosis ..........................35

Preliminary Check ...................................................35

CONSULT-III Function (BCM) .................................35

CONSULT-III Function (IPDM E/R) ..................... ....35

Daytime Light Control Does Not Operate Properly

(High Beam Headlamps Operate Properly) .............

35

Aiming Adjustment ...................................................37

Bulb Replacement ...................................................38

Removal and Installation .........................................39

Disassembly and Assembly .....................................39

FRONT FOG LAMP ..........................................41

Component Parts and Harness Connector Loca-

tion ...........................................................................

41

System Description ..................................................41

CAN Communication System Description ...............42

Wiring Diagram - F/FOG - .......................................43

Terminal and Reference Value for BCM ..................44

Terminal and Reference Value for IPDM E/R ...... ....44

How to Proceed with Trouble Diagnosis ..................45

Preliminary Check ............................................... ....45

CONSULT-III Function (BCM) .................................45

CONSULT-III Function (IPDM E/R) ..................... ....45

Front Fog lamps Do Not Illuminate (Both Sides) .....45

Front Fog Lamp Does Not Illuminate (One Side) ....47

Aiming Adjustment ...................................................48

Bulb Replacement ...................................................49

Removal and Installation .........................................49

TURN SIGNAL AND HAZARD WARNING

LAMPS ..............................................................

50

Component Parts and Harness Connector Loca-

tion ...........................................................................

50

Revision: May 2010 2011 Versa

Page 3172 of 3787

MA-1

MAINTENANCE

C

DE

F

G H

I

J

K

M

SECTION MA

A

B

MA

N

O P

CONTENTS

MAINTENANCE

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

PREPARATION ...................................................5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................6

GENERAL MAINTENANCE ........................... .....7

Explanation of General Maintenance .................. ......7

General Maintenance ................................................7

PERIODIC MAINTENANCE ................................9

Introduction of Periodic Maintenance .................. ......9

Schedule 1 ................................................................9

Schedule 2 ..............................................................11

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................

14

Fluids and Lubricants .......................................... ....14

SAE Viscosity Number ............................................15

Anti-freeze Coolant Mixture Ratio ...........................15

ENGINE MAINTENANCE (HR16DE) .................16

DRIVE BELT .......................................................... ....16

DRIVE BELT : Checking .........................................16

DRIVE BELT : Tension Adjustment ........................16

ENGINE COOLANT ............................................... ....17

ENGINE COOLANT : Inspection .............................17

ENGINE COOLANT : Changing Engine Coolant ....17

FUEL LINES .......................................................... ....19

FUEL LINES : Checking Fuel Line ..........................19

AIR CLEANER FILTER ......................................... ....19

AIR CLEANER FILTER : Removal and Installation

....

20

ENGINE OIL ........................................................... ....20

ENGINE OIL : Inspection .........................................20

ENGINE OIL : Draining ............................................22

ENGINE OIL : Refilling ............................................22

OIL FILTER ............................................................ ....23

OIL FILTER : Removal and Installation ...................23

SPARK PLUG (HR16DE) ...................................... ....23

SPARK PLUG (HR16DE) : Exploded View .............24

SPARK PLUG (HR16DE) : Removal and Installa-

tion ....................................................................... ....

24

EVAP VAPOR LINES ............................................ ....25

EVAP VAPOR LINES : Checking EVAP Vapor

Line ..........................................................................

25

ENGINE MAINTENANCE (MR18DE) ...............26

DRIVE BELT .......................................................... ....26

DRIVE BELT : Component ......................................26

DRIVE BELT : Checking Drive Belts .......................26

DRIVE BELT : Tension Adjustment .........................26

ENGINE COOLANT ............................................... ....26

ENGINE COOLANT : Inspection .............................26

ENGINE COOLANT : Changing Engine Coolant ....27

FUEL LINES ........................................................... ....29

FUEL LINES : Checking Fuel Line ..........................29

AIR CLEANER FILTER ......................................... ....29

AIR CLEANER FILTER : Component ......................29

AIR CLEANER FILTER : Changing Air Cleaner

Filter .........................................................................

30

ENGINE OIL ........................................................... ....30

ENGINE OIL : Inspection .........................................30

ENGINE OIL : Changing Engine Oil ........................32

OIL FILTER ............................................................ ....33

Revision: May 2010 2011 Versa

Page 3317 of 3787

MTC-1

AIR CONDITIONER

C

DE

F

G H

I

K L

M

SECTION MTC

A

B

MTC

N

O P

CONTENTS

MANUAL AIR CONDITIONER

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

Precaution for Procedure without Cowl Top Cover ......4

Precaution for Working with HFC-134a (R-134a) ......4

General Refrigerant Precaution ................................4

Oil Precaution ............................................................5

Precaution for Refrigerant Connection ......................5

Precaution for Service of Compressor ................ ......8

Precaution for Service Equipment ....................... ......8

Precaution for Leak Detection Dye ...........................9

PREPARATION ..................................................11

HFC-134a (R-134a) Service Tool and Equipment ....11

Commercial Service Tool ........................................14

REFRIGERATION SYSTEM ..............................15

Refrigerant Cycle ................................................ ....15

Refrigerant System Protection ................................15

Component Part Location ................................... ....16

OIL ......................................................................17

Maintenance of Oil Quantity in Compressor ....... ....17

AIR CONDITIONER CONTROL .........................19

Control Operation ................................................ ....19

Discharge Air Flow ..................................................20

System Description .................................................20

TROUBLE DIAGNOSIS .....................................22

CONSULT-III Function (BCM) ............................. ....22

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ......................................................

23

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

23

Schematic ...............................................................26

Wiring Diagram - Heater - .......................................27

Wiring Diagram - A/C,M - .................................... ....28

Operational Check ...................................................31

Mode Door ...............................................................32

Air Mix Door .............................................................33

Intake Door ..............................................................34

Front Blower Motor Circuit .......................................34

Magnet Clutch Circuit (If Equipped) ..................... ....38

Insufficient Cooling ..................................................46

Insufficient Heating ..................................................53

Noise .......................................................................54

CONTROLLER ..................................................56

Removal and Installation .........................................56

Disassembly and Assembly .....................................57

THERMO CONTROL AMPLIFIER ....................58

Removal and Installation .........................................58

A/C UNIT ASSEMBLY ......................................59

Removal and Installation .........................................59

Disassembly and Assembly .....................................61

BLOWER MOTOR ............................................63

Removal and Installation .........................................63

INTAKE DOOR ..................................................64

Intake Door Cable Adjustment .................................64

AIR MIX DOOR .................................................65

Air Mix Door Cable Adjustment ...............................65

MODE DOOR ....................................................66

Mode Door Cable Adjustment .................................66

BLOWER FAN RESISTOR ...............................67

Removal and Installation .........................................67

HEATER CORE .................................................68

Removal and Installation .........................................68

DUCTS AND GRILLES .....................................69

Removal and Installation .........................................69

Revision: May 2010 2011 Versa

Page 3500 of 3787

PS-6

< SERVICE INFORMATION >

STEERING WHEEL

STEERING WHEEL

On-Vehicle Inspection and ServiceINFOID:0000000006416714

CHECKING CONDITION OF INSTALLATION

• Check installation conditions of steering gear assembly, front suspension assembly, axle and steering col-

umn assembly.

• Check if movement exists when steering wheel is mo ved up and down, to the left and right and to the axial

direction.

• Check steering gear assembly bolts and nuts for looseness. Refer to PS-15, "

Removal and Installation".

CHECKING STEERING WHEEL PLAY

• Turn steering wheel so that front wheels come to the straight-ahead position. Start engine and lightly turn

steering wheel to the left and right until front wheels start to move. Measure steering wheel movement on the

outer circumference.

• When the measurement value is outside the standard val ue, check backlash for each joint of steering col-

umn assembly and installation condition of steering gear assembly.

CHECKING NEUTRAL POSITION STEERING WHEEL

• Make sure that steering gear assembly, steering column assembly and steering wheel are installed in the correct position.

• Perform neutral position inspection after wheel alignment. Refer to PS-2, "

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"".

• Set vehicle to the straight-ahead position and c onfirm steering wheel is in the neutral position.

• Loosen outer socket lock nut and turn inner socket to left and right equally to make fine adjustments if steer-

ing wheel is not in the neutral position.

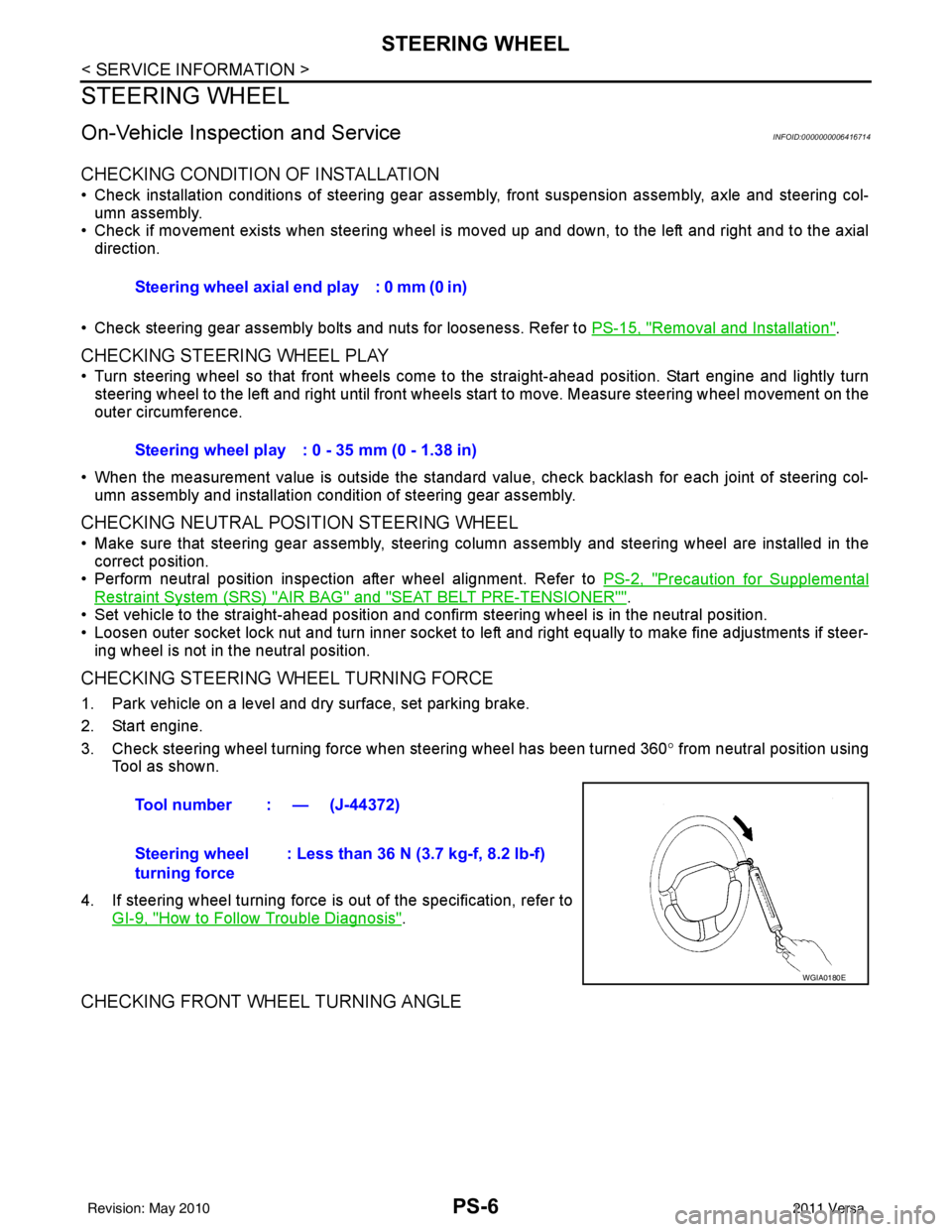

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level and dry surface, set parking brake.

2. Start engine.

3. Check steering wheel turning force when steering wheel has been turned 360 ° from neutral position using

Tool as shown.

4. If steering wheel turning force is out of the specification, refer to GI-9, "

How to Follow Trouble Diagnosis".

CHECKING FRONT WHEEL TURNING ANGLE

Steering wheel axial end play : 0 mm (0 in)

Steering wheel play : 0 - 35 mm (0 - 1.38 in)

Tool number : — (J-44372)

Steering wheel

turning force : Less than 36 N (3.7 kg-f, 8.2 lb-f)

WGIA0180E

Revision: May 2010

2011 Versa

Page 3512 of 3787

PS-18

< SERVICE INFORMATION >

POWER STEERING GEAR

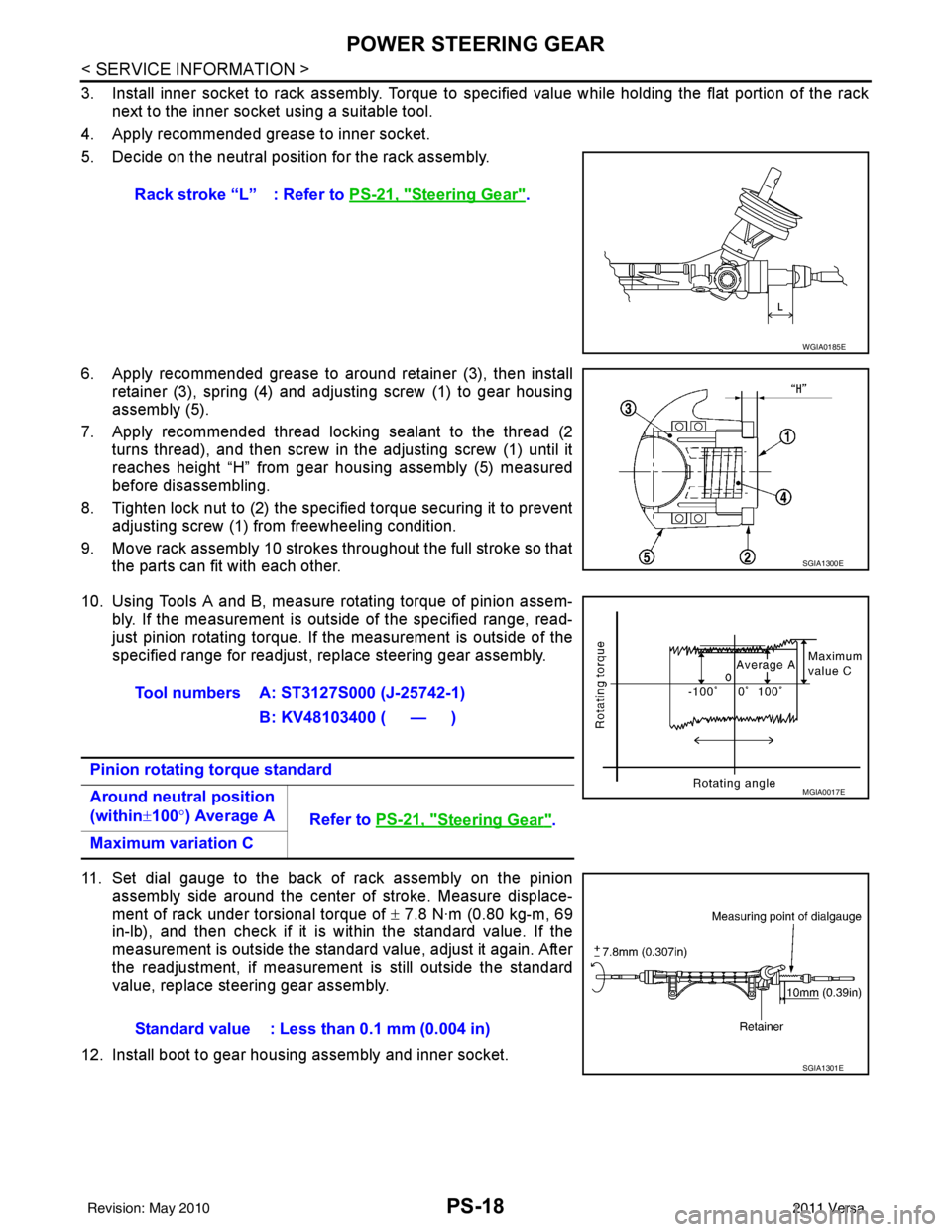

3. Install inner socket to rack assembly. Torque to specified value while holding the flat portion of the racknext to the inner socket using a suitable tool.

4. Apply recommended grease to inner socket.

5. Decide on the neutral position for the rack assembly.

6. Apply recommended grease to around retainer (3), then install retainer (3), spring (4) and adjusting screw (1) to gear housing

assembly (5).

7. Apply recommended thread locking sealant to the thread (2 turns thread), and then screw in the adjusting screw (1) until it

reaches height “H” from gear housing assembly (5) measured

before disassembling.

8. Tighten lock nut to (2) the specified torque securing it to prevent adjusting screw (1) from freewheeling condition.

9. Move rack assembly 10 strokes throughout the full stroke so that the parts can fit with each other.

10. Using Tools A and B, measure rotating torque of pinion assem- bly. If the measurement is out side of the specified range, read-

just pinion rotating torque. If the measurement is outside of the

specified range for readjust, replace steering gear assembly.

11. Set dial gauge to the back of rack assembly on the pinion assembly side around the center of stroke. Measure displace-

ment of rack under torsional torque of ± 7.8 N·m (0.80 kg-m, 69

in-lb), and then check if it is within the standard value. If the

measurement is outside the standard value, adjust it again. After

the readjustment, if measurement is still outside the standard

value, replace steering gear assembly.

12. Install boot to gear housing assembly and inner socket. Rack stroke “L” : Refer to

PS-21, "

Steering Gear".

WGIA0185E

SGIA1300E

Tool numbers A: ST3127S000 (J-25742-1)

B: KV48103400 ( — )

Pinion rotating torque standard

Around neutral position

(within ±100° ) Average A

Refer to PS-21, "

Steering Gear".

Maximum variation C

MGIA0017E

Standard value : Less than 0.1 mm (0.004 in)

SGIA1301E

Revision: May 2010 2011 Versa