NISSAN LATIO 2011 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 2781 of 3787

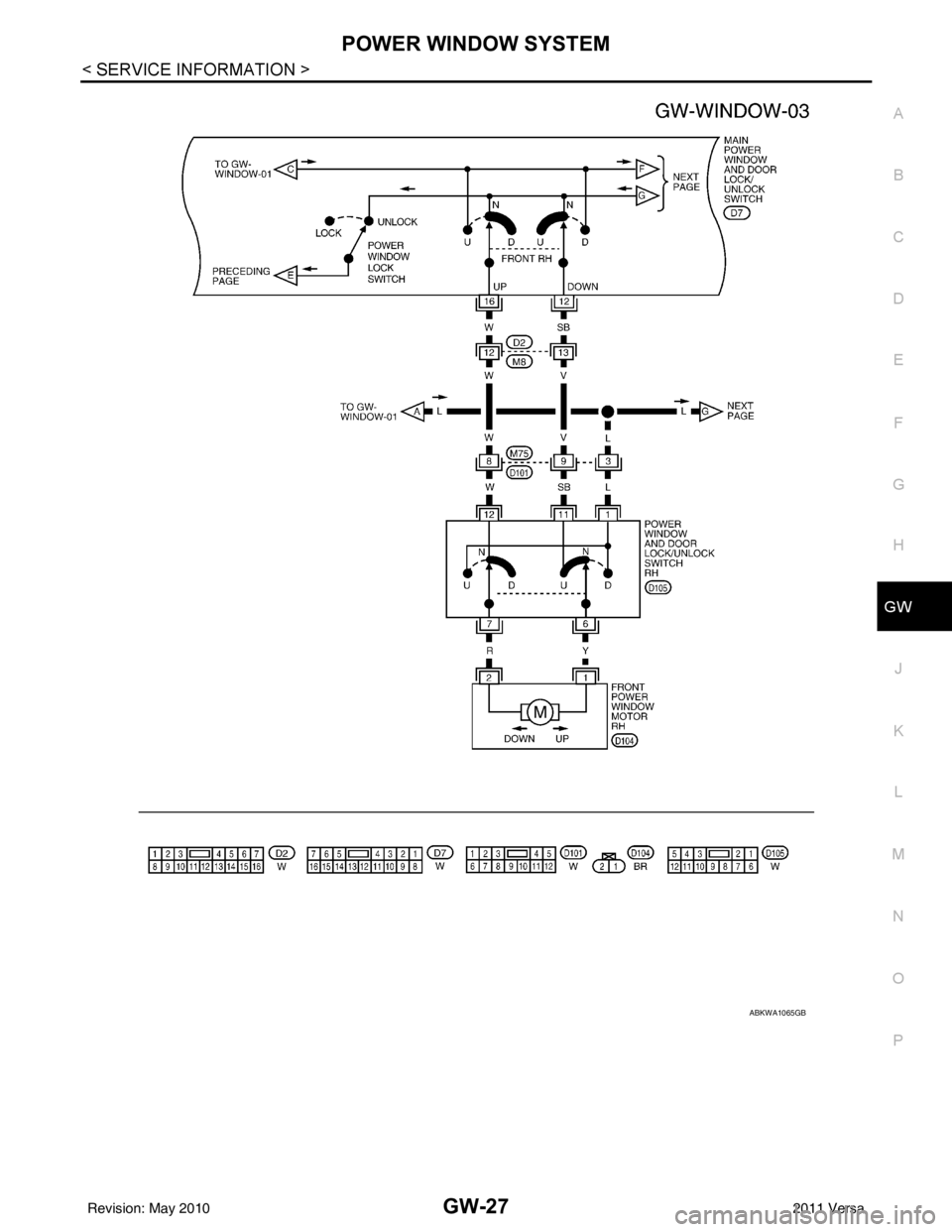

POWER WINDOW SYSTEMGW-27

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

ABKWA1065GB

Revision: May 2010 2011 Versa

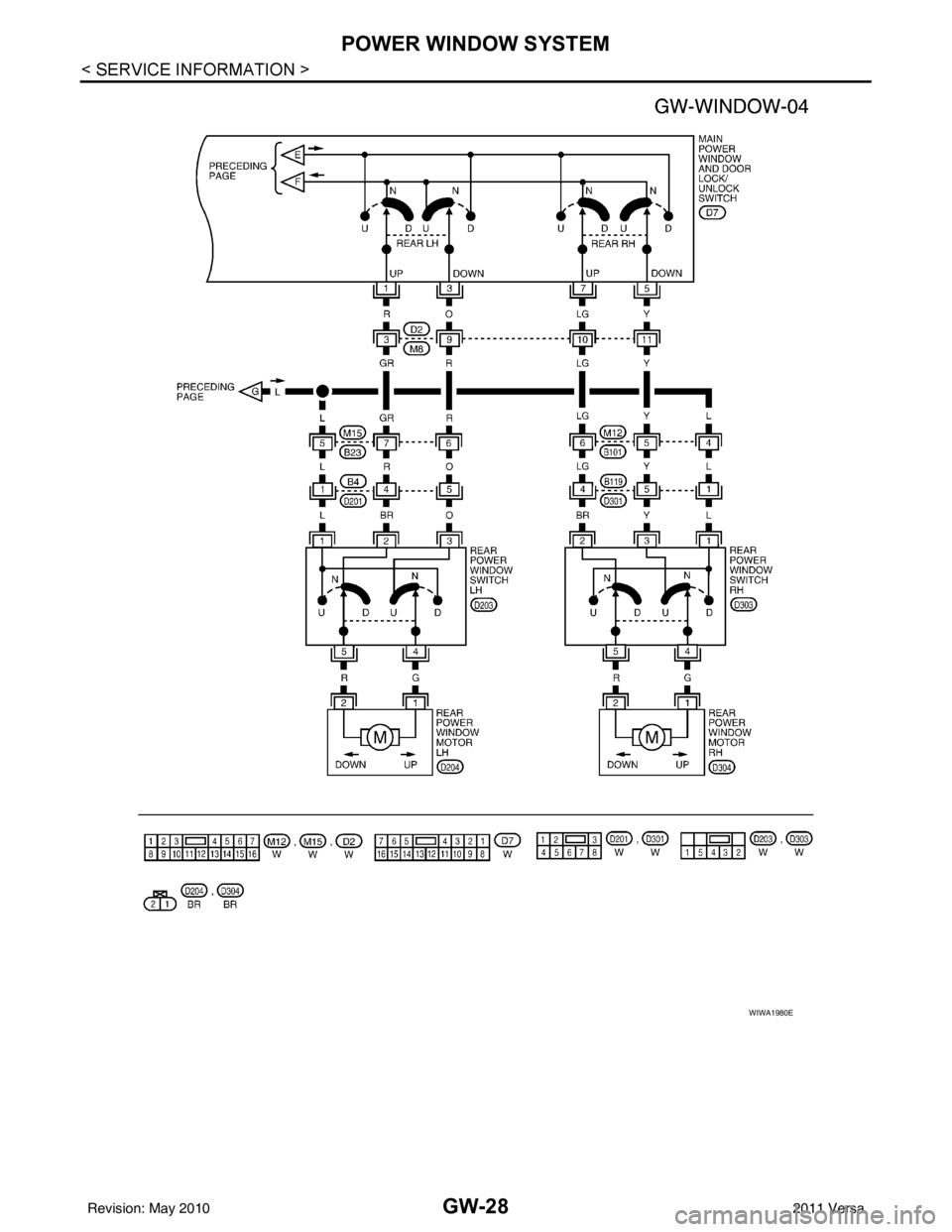

Page 2782 of 3787

GW-28

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

WIWA1980E

Revision: May 20102011 Versa

Page 2783 of 3787

POWER WINDOW SYSTEMGW-29

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

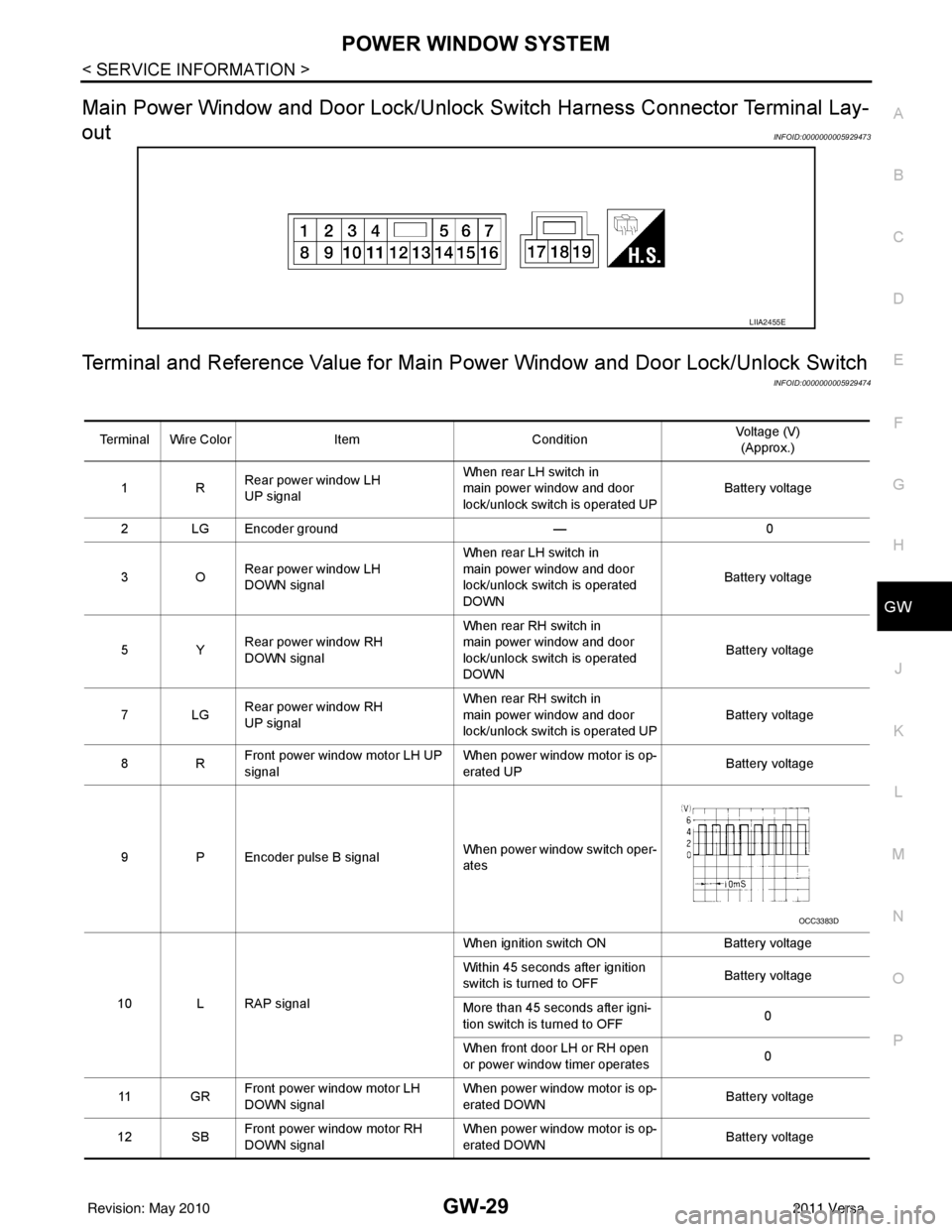

Main Power Window and Door Lock/Unlock Switch Harness Connector Terminal Lay-

out

INFOID:0000000005929473

Terminal and Reference Value for Main Po wer Window and Door Lock/Unlock Switch

INFOID:0000000005929474

LIIA2455E

Terminal Wire ColorItemCondition Voltage (V)

(Approx.)

1R Rear power window LH

UP signal When rear LH switch in

main power window and door

lock/unlock switch is operated UP

Battery voltage

2 LG Encoder ground — 0

3O Rear power window LH

DOWN signal When rear LH switch in

main power window and door

lock/unlock switch is operated

DOWN

Battery voltage

5Y Rear power window RH

DOWN signal When rear RH switch in

main power window and door

lock/unlock switch is operated

DOWN

Battery voltage

7LG Rear power window RH

UP signal When rear RH switch in

main power window and door

lock/unlock switch is operated UP

Battery voltage

8R Front power window motor LH UP

signal When power window motor is op-

erated UP

Battery voltage

9 P Encoder pulse B signal When power window switch oper-

ates

10 L RAP signal When ignition switch ON

Battery voltage

Within 45 seconds after ignition

switch is turned to OFF Battery voltage

More than 45 seconds after igni-

tion switch is turned to OFF 0

When front door LH or RH open

or power window timer operates 0

11 G R Front power window motor LH

DOWN signal When power window motor is op-

erated DOWN

Battery voltage

12 SB Front power window motor RH

DOWN signal When power window motor is op-

erated DOWN

Battery voltage

OCC3383D

Revision: May 2010

2011 Versa

Page 2784 of 3787

GW-30

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

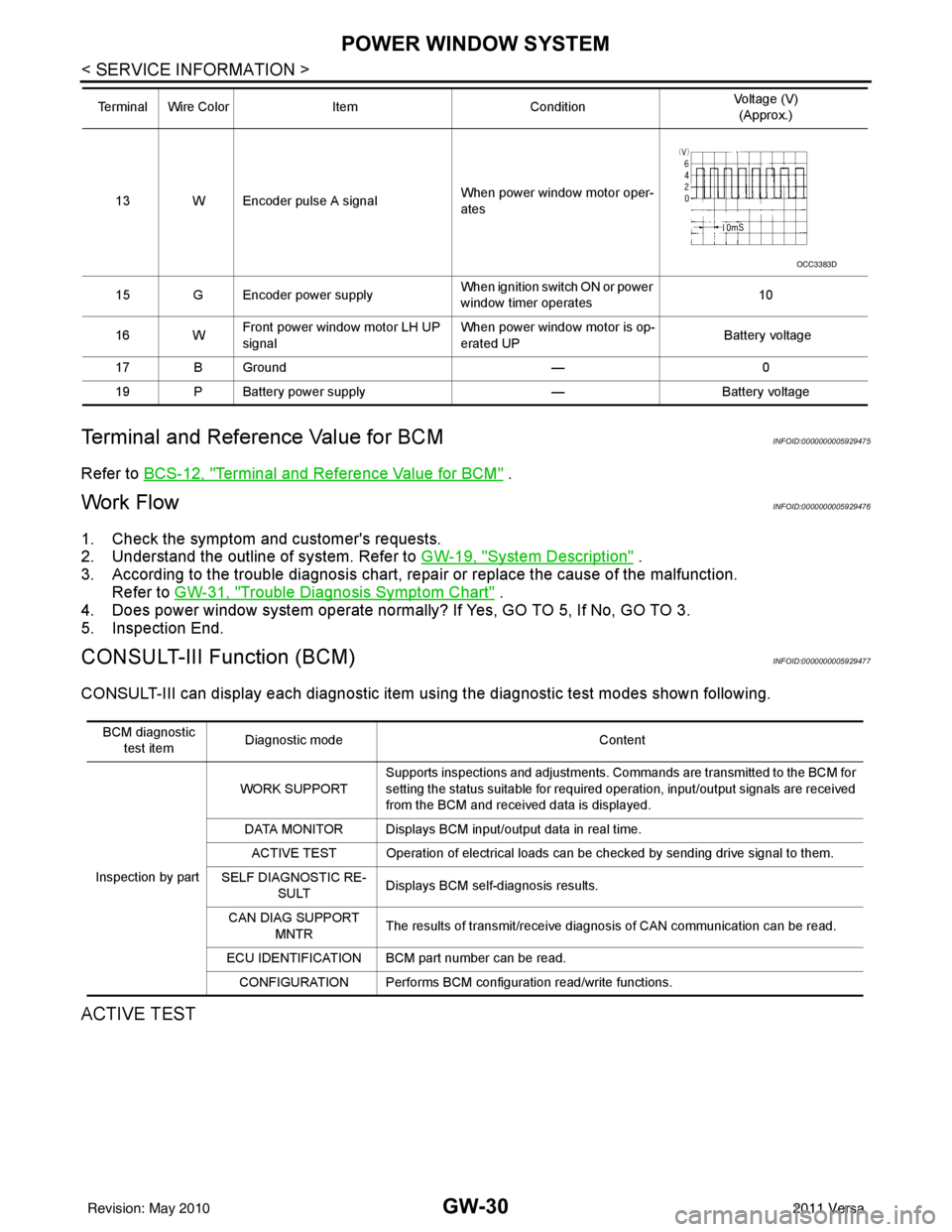

Terminal and Reference Value for BCM

INFOID:0000000005929475

Refer to BCS-12, "Terminal and Reference Value for BCM" .

Work FlowINFOID:0000000005929476

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer to GW-19, "

System Description" .

3. According to the trouble diagnosis chart, repa ir or replace the cause of the malfunction.

Refer to GW-31, "

Trouble Diagnosis Symptom Chart" .

4. Does power window system operate normally? If Yes, GO TO 5, If No, GO TO 3.

5. Inspection End.

CONSULT-III Function (BCM)INFOID:0000000005929477

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

ACTIVE TEST

13 W Encoder pulse A signal When power window motor oper-

ates

15 G Encoder power supply When ignition switch ON or power

window timer operates10

16 W Front power window motor LH UP

signal When power window motor is op-

erated UP

Battery voltage

17 B Ground —0

19 P Battery power supply —Battery voltage

Terminal Wire Color

ItemCondition Voltage (V)

(Approx.)

OCC3383D

BCM diagnostic

test item Diagnostic mode

Content

Inspection by part WORK SUPPORT

Supports inspections and adjustments. Commands are transmitted to the BCM for

setting the status suitable for required operation, input/output signals are received

from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF DIAGNOSTIC RE- SULT Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The results of transmit/receive diagnosis of CAN communication can be read.

ECU IDENTIFICATION BCM part number can be read. CONFIGURATION Performs BCM configuration read/write functions.

Revision: May 2010 2011 Versa

Page 2785 of 3787

POWER WINDOW SYSTEMGW-31

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

WORK SUPPORT

DATA MONITOR

Power Window Auto Operation InitializationINFOID:0000000005929478

1. Turn the ignition switch ON.

2. Open the window—all the way DOWN.

3. Pull all the way UP on the switch and hold (close the window). • Continue holding the switch all the way UP for 4 seconds after the window is closed.

4. Confirm the window is now operating correctly. NOTE:

• If the window is still not operating correctly, refer to GW-31, "

Trouble Diagnosis Symptom Chart".

• The above initialization procedure must be performed if any of the following occur:

- Battery cable is disconnected

- Power window switch connector is disconnected

- Power window regulator is replaced

- Power window motor is replaced

- Window glass is removed

- Window glass run rubber is replaced

- Power window fuse is blown

- Window is partly opened and/or closed many times without being fully closed.

Trouble Diagnosis Symptom ChartINFOID:0000000005929479

Check that other systems us ing the signal of the following systems operate normally.

Test Item Description

RETAINED PWR This test is able to supply RAP signal (powe

r) from BCM (body control module) to power window

system and power sunroof system (if equipped). Those systems can be operated when turning on

“RETAINED PWR” on CONSULT-III screen even if the ignition switch is turned OFF.

NOTE:

During this test, CONSULT-III can be operated with ignition switch in OFF position. “RETAINED

PWR” should be turned “ON” or “OFF” on CONSULT-III screen when ignition switch is ON. Then

turn ignition switch OFF to check retained power operation. CONSULT-III might be stuck if “RE-

TAINED PWR” is turned “ON” or “OFF” on CONSULT-III screen when ignition switch is OFF.

Work item Description

RETAINED PWR RAP signal’s power supply period can be changed by mode setting. Selects RAP signal’s power

supply period between three steps

• MODE1 (45 sec.)/MODE2 (OFF)/MODE3 (2 min.).

Work item

Description

IGN ON SW Indicates (ON/OFF) condition of ignition switch

DOOR SW-DR Indicates (ON/OFF) condition of front door switch LH

DOOR SW-AS Indicates (ON/OFF) condition of front door switch RH

Symptom Repair orderRefer to page

None of the power windows can be operated using any switch 1. BCM power supply and ground circuit check

BCS-16

2. Main power window and door lock/unlock

power supply and ground circuit check GW-32

3. Replace main power window and door lock/

unlock switch

EI-36

Front power window LH alone does not operate 1. Front power window motor LH circuit check

GW-332. Replace main power window and door lock/

unlock switch EI-36

Revision: May 2010

2011 Versa

Page 2786 of 3787

GW-32

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

BCM Power Supply and Ground Circuit Inspection

INFOID:0000000005929480

Refer to BCS-16, "BCM Power Supply and Ground Circuit Inspection" .

Main Power Window and Door Lock/Unlock Switch Po wer Supply and Ground Circuit

Inspection

INFOID:0000000005929481

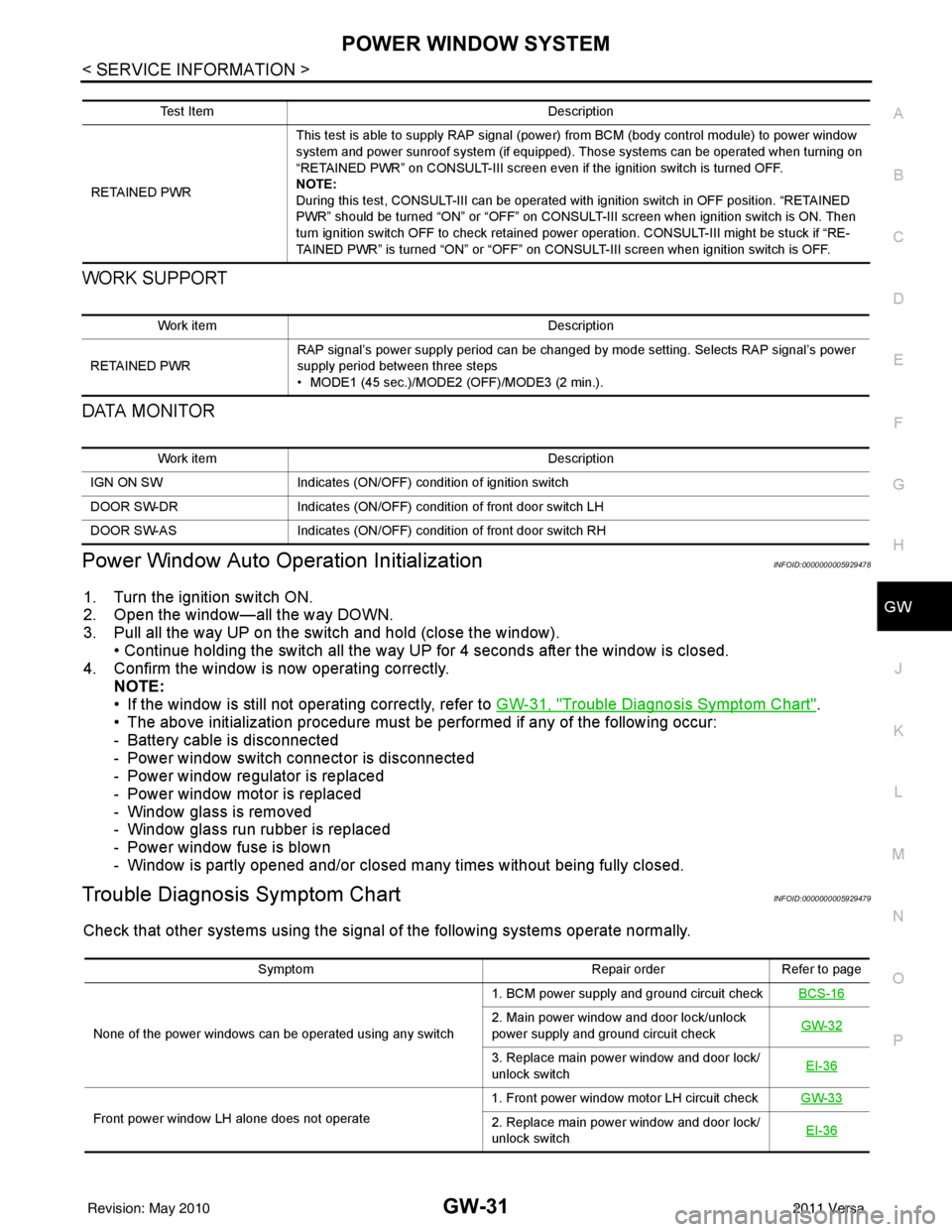

1.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between main power window and door lock/ unlock switch connector D7 terminal 10, D8 terminal 19 and

ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2.CHECK GROUND CIRCUIT

Front power window RH does not operate from power window and

door lock/unlock switch RH only 1. Front power window RH circuit check (power

window and door lock/unlock switch RH opera-

tion)

GW-34

Front power window RH does not operate from main power window

and door lock/unlock switch only 1. Replace main power window and door lock/

unlock switch

EI-36

Front power window RH does not operate from any switch 1. Front power window motor RH circuit check

GW-35

Anti-pinch system does not operate normally (Front LH)1. Door window sliding part malfunction

• A foreign material adheres to window glass or

glass run rubber.

• Glass run rubber wear or deformation.

• Sash is tilted too much, or not enough. —

2. Encoder circuit check GW-36

Front power window LH automatic operation does not function

properly 1. Power window system initiailization

GW-462. Main power window and door lock/unlock

power supply and ground circuit checkGW-32

3. Encoder circuit check

GW-36

Rear power window LH does not operate from rear power window

switch LH only 1. Rear power window LH circuit check (rear

power window switch LH operation)

GW-39

Rear power window LH does not operate from main power window

and door lock/unlock switch only 1. Replace main power window and door lock/

unlock switch

EI-36

Rear power window LH does not operate from any switch 1. Rear power window motor LH circuit check

GW-40

Rear power window RH does not operate from rear power window

switch RH only1. Rear power window RH circuit check (rear

window switch RH operation)

GW-40

Rear power window RH does not operate from main power window

and door lock/unlock switch only 1. Replace main power window and door lock/

unlock switch

EI-36

Rear power window RH does not operate from any switch 1. Rear power window motor RH circuit check

GW-42

Power window retained power operation does not operate properly1. Check the retained power operation mode

setting.

GW-302. Door switch check

GW-38

3. Replace BCM.BCS-19

Symptom Repair orderRefer to page

10 - Ground: Battery voltage

19 - Ground : Battery voltage

LIIA2297E

Revision: May 2010 2011 Versa

Page 2787 of 3787

POWER WINDOW SYSTEMGW-33

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

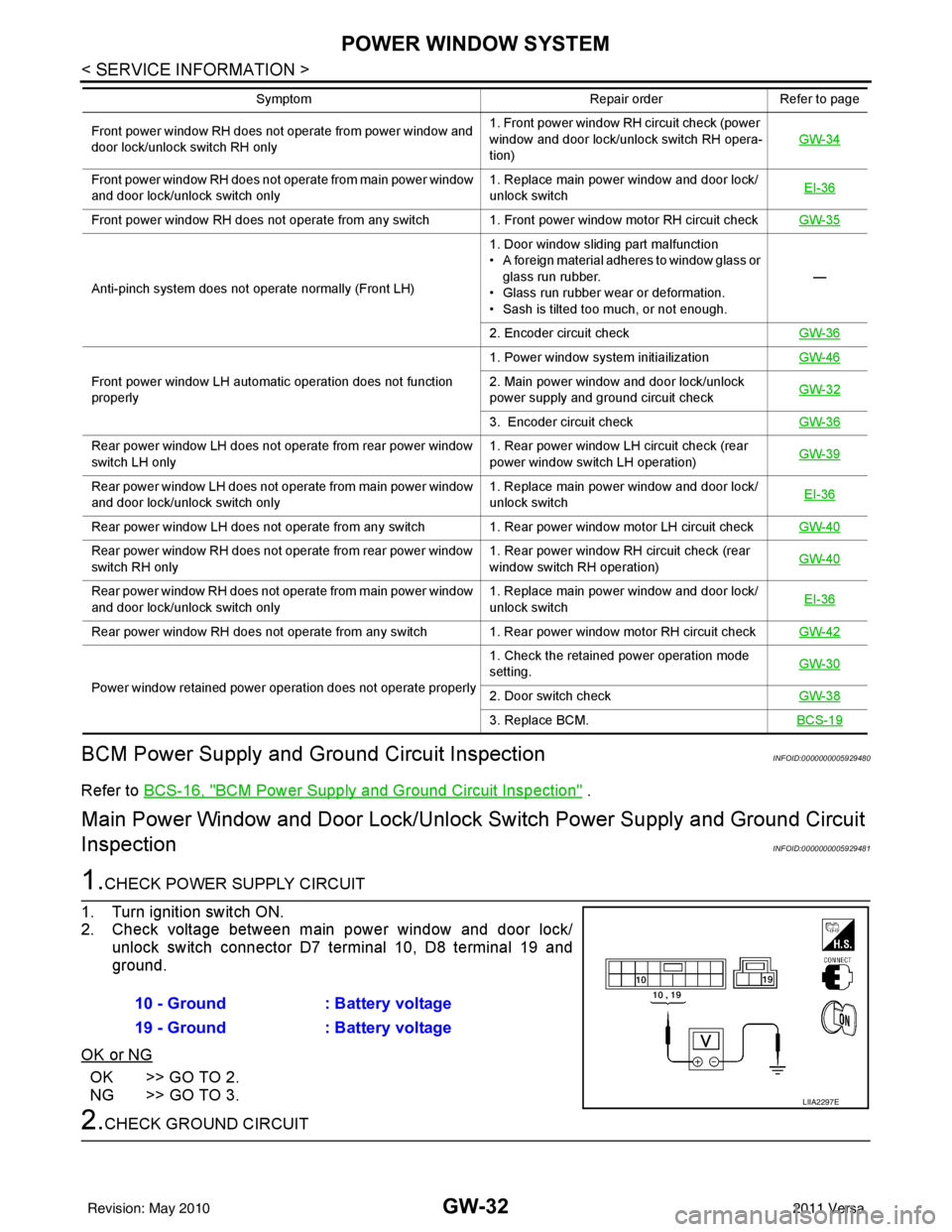

1. Turn ignition switch OFF.

2. Disconnect main power window and door lock/unlock switch.

3. Check continuity between main power window and door lock/ unlock switch connector D8 terminal 17 and ground.

OK or NG

OK >> Power supply and ground circuit are OK.

NG >> Repair or replace harness.

3.CHECK MAIN POWER WINDOW AND DOOR LOCK/UNLOCK SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM and main power window and door lock/unlock

switch.

3. Check continuity between BCM connector and main power win- dow and door lock/unlock switch connectors.

4. Check continuity between BCM and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4.CHECK BCM OUTPUT SIGNAL

1. Connect BCM.

2. Turn ignition switch ON.

3. Check voltage between BCM connector M20 terminals 68, 69 and ground.

OK or NG

OK >> Check the condition of the harness and the connector.

NG >> Replace BCM. Refer to BCS-19, "

Removal and Installa-

tion of BCM" .

Front Power Window Motor LH Circuit InspectionINFOID:0000000005929482

1.CHECK MAIN POWER WINDOW AND DOOR LOCK/UNLOCK SWITCH OUTPUT SIGNAL

17 - Ground

: Continuity should exist.

LIIA0392E

Connector

Te r m i n a l Connector

Terminal Continuity

AB

BCM: M20 68

Main power window and

door lock/unlock switch: D7 10 Yes

69 C

19

Main power window and

door lock/unlock switch:

D8 Ye s

Connector Te r m i n a l

GroundContinuity

A

BCM: M20 68

No

69 No

LIIA2215E

68 - Ground: Battery voltage

69 - Ground : Battery voltage

LIIA0917E

Revision: May 2010 2011 Versa

Page 2788 of 3787

GW-34

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

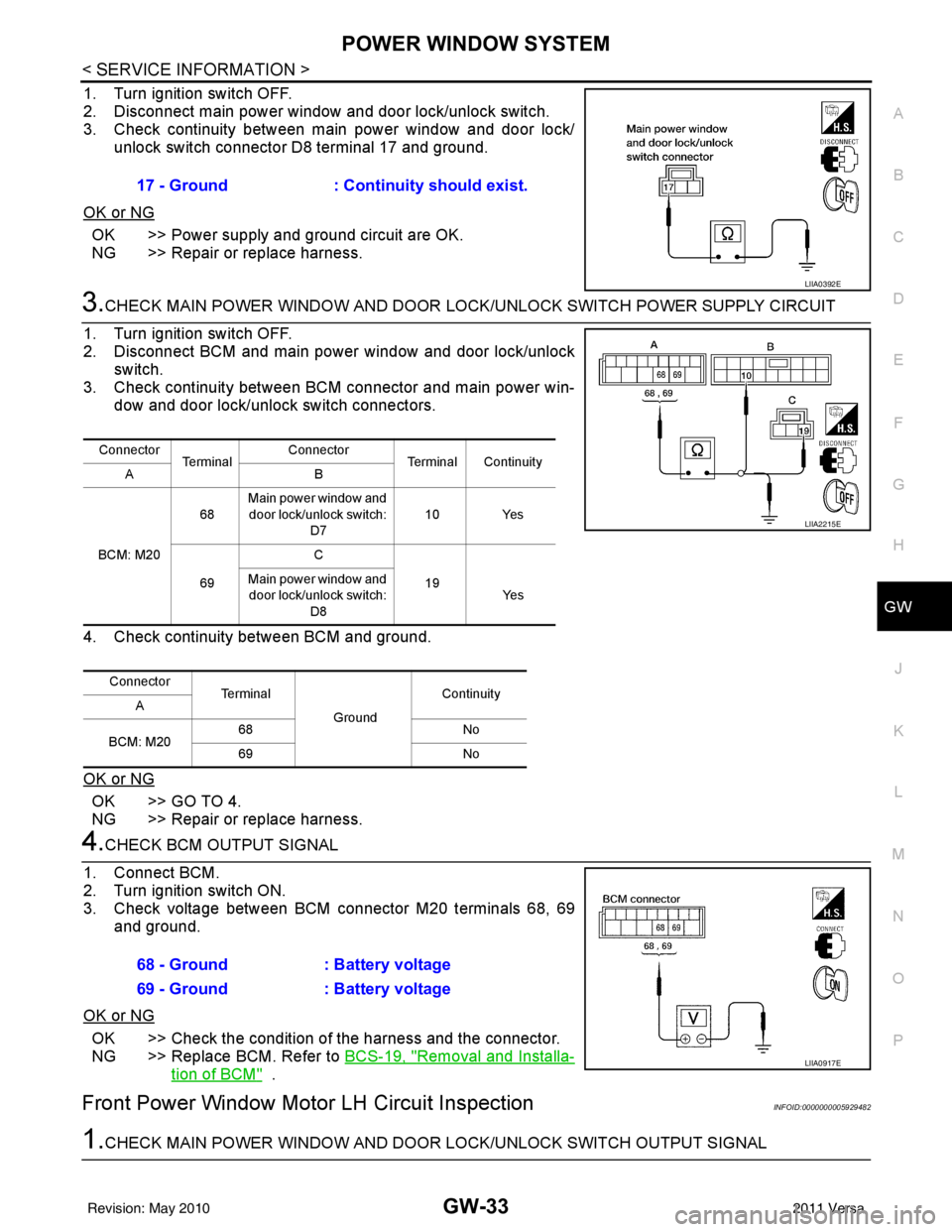

1. Turn ignition switch OFF.

2. Check voltage between main power window and door lock/unlock switch connector D7 terminals 8, 11 and ground.

OK or NG

OK >> GO TO 2.

NG >> Replace main power window and door lock/unlock switch. Refer to EI-36, "

Removal and Installa-

tion" .

2.CHECK POWER WINDOW MOTOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect main power window and door lock/unlock switch and front power window motor LH.

3. Check continuity between main power window and door lock/ unlock switch connector and front power window motor LH con-

nector.

4. Check continuity between main power window and door lock/unlock switch connector and ground.

OK or NG

OK >> Replace front power window motor LH. Refer to GW-44 .

NG >> Repair or replace harness.

Front Power Window RH Circuit Inspecti on (Power Window and Door Lock/Unlock

Switch RH Operation)

INFOID:0000000005929483

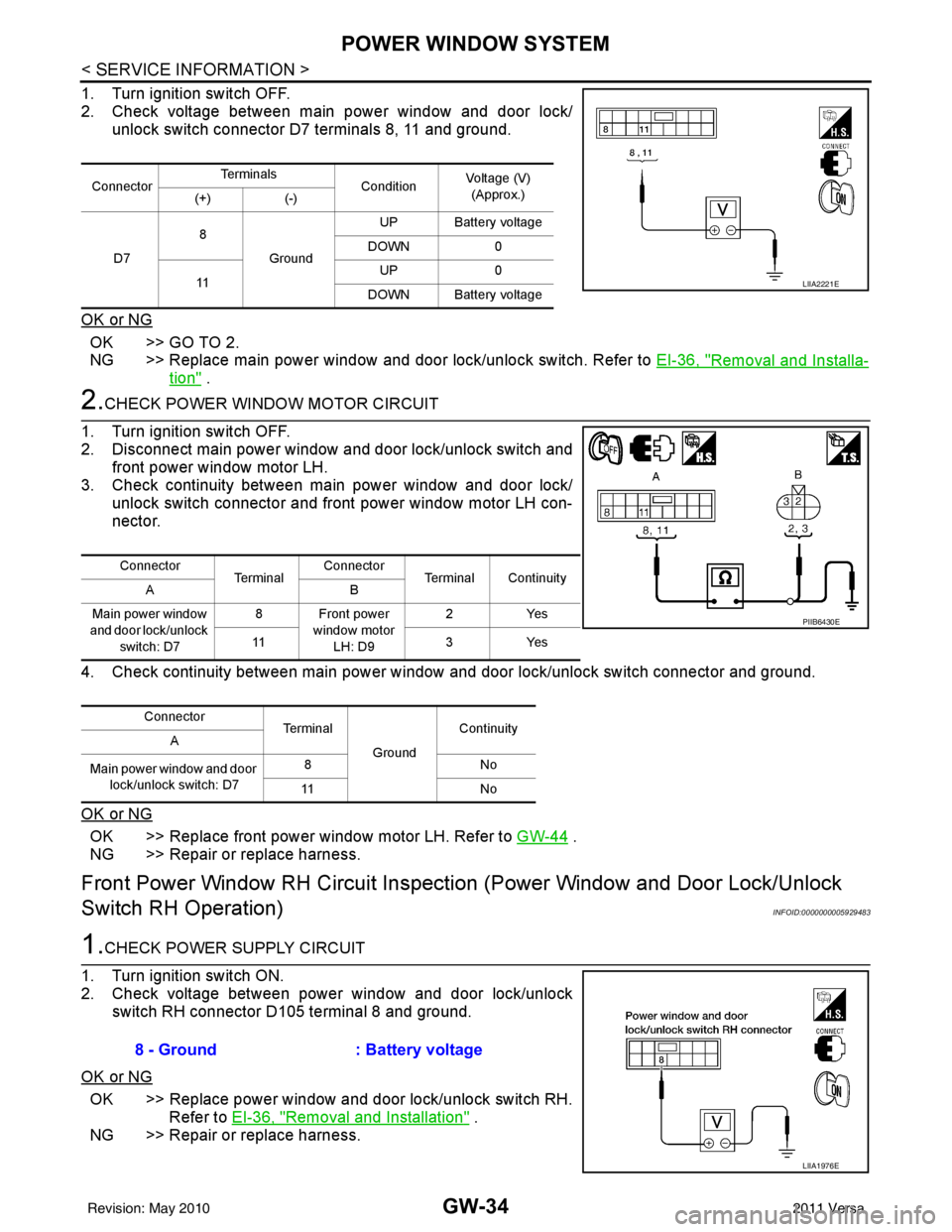

1.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between power window and door lock/unlock switch RH connector D105 terminal 8 and ground.

OK or NG

OK >> Replace power window and door lock/unlock switch RH. Refer to EI-36, "

Removal and Installation" .

NG >> Repair or replace harness.

Connector Te r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

D7 8

Ground UP Battery voltage

DOWN 0

11 UP

0

DOWN Battery voltage

LIIA2221E

Connector Te r m i n a lConnector

Terminal Continuity

AB

Main power window

and door lock/unlock switch: D7 8 Front power

window motor LH: D9 2Y

es

11 3Ye s

Connector Terminal

GroundContinuity

A

Main power window and door lock/unlock switch: D7 8N

o

11 N o

PIIB6430E

8 - Ground: Battery voltage

LIIA1976E

Revision: May 2010 2011 Versa

Page 2789 of 3787

POWER WINDOW SYSTEMGW-35

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

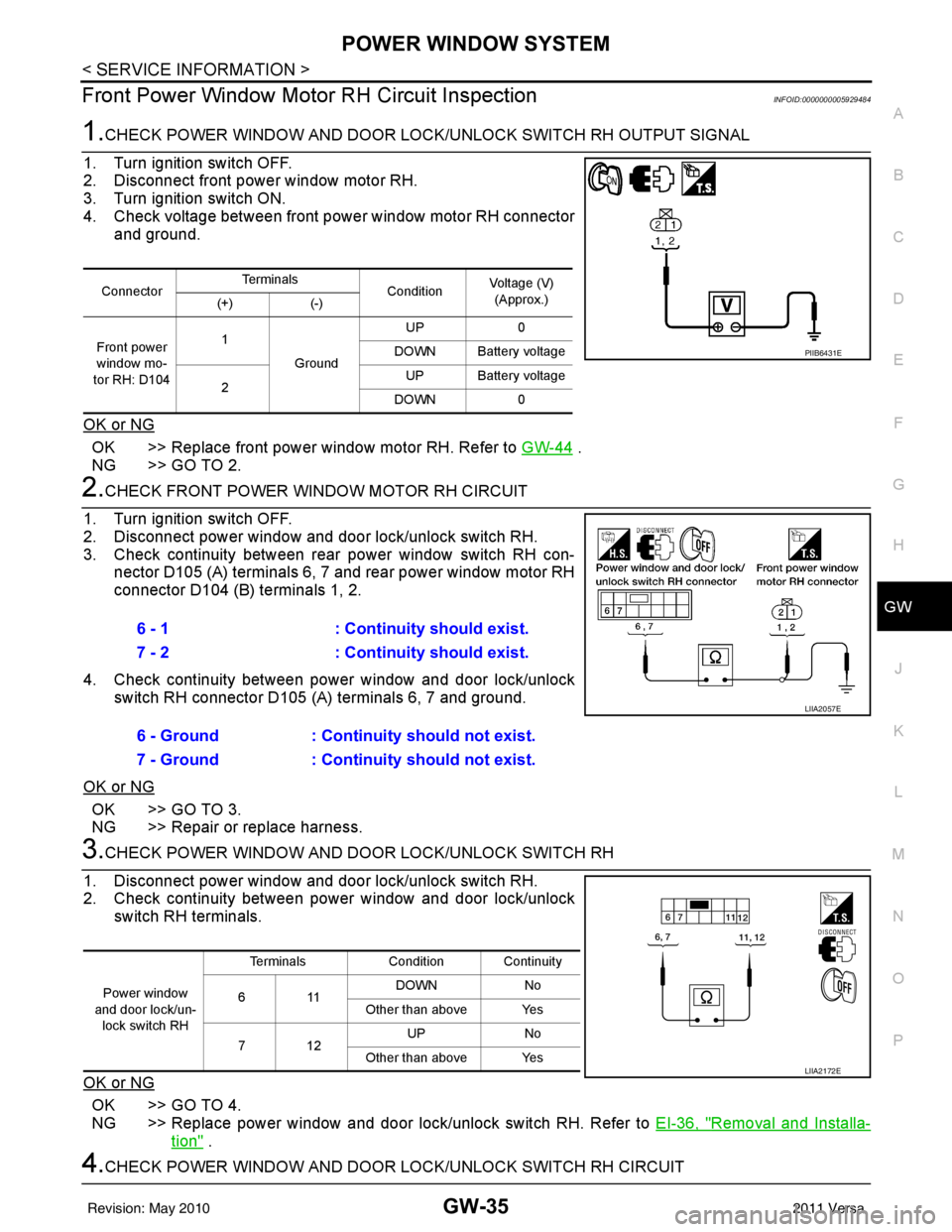

Front Power Window Motor RH Circuit InspectionINFOID:0000000005929484

1.CHECK POWER WINDOW AND DOOR LOCK/UNLOCK SWITCH RH OUTPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front power window motor RH.

3. Turn ignition switch ON.

4. Check voltage between front power window motor RH connector and ground.

OK or NG

OK >> Replace front power window motor RH. Refer to GW-44 .

NG >> GO TO 2.

2.CHECK FRONT POWER WINDOW MOTOR RH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect power window and door lock/unlock switch RH.

3. Check continuity between rear power window switch RH con- nector D105 (A) terminals 6, 7 and rear power window motor RH

connector D104 (B) terminals 1, 2.

4. Check continuity between power window and door lock/unlock switch RH connector D105 (A) terminals 6, 7 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

3.CHECK POWER WINDOW AND DOOR LOCK/UNLOCK SWITCH RH

1. Disconnect power window and door lock/unlock switch RH.

2. Check continuity between power window and door lock/unlock switch RH terminals.

OK or NG

OK >> GO TO 4.

NG >> Replace power window and door lock/unlock switch RH. Refer to EI-36, "

Removal and Installa-

tion" .

4.CHECK POWER WINDOW AND DOOR LOCK/UNLOCK SWITCH RH CIRCUIT

ConnectorTe r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

Front power

window mo-

tor RH: D104 1

Ground UP

0

DOWN Battery voltage

2 UP Battery voltage

DOWN 0

PIIB6431E

6 - 1 : Continuity should exist.

7 - 2 : Continuity should exist.

6 - Ground : Continuity should not exist.

7 - Ground : Continuity should not exist.

LIIA2057E

Power window

and door lock/un- lock switch RH Terminals

Condition Continuity

611 DOWN

No

Other than above Yes

712 UP

No

Other than above Yes

LIIA2172E

Revision: May 2010 2011 Versa

Page 2790 of 3787

GW-36

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

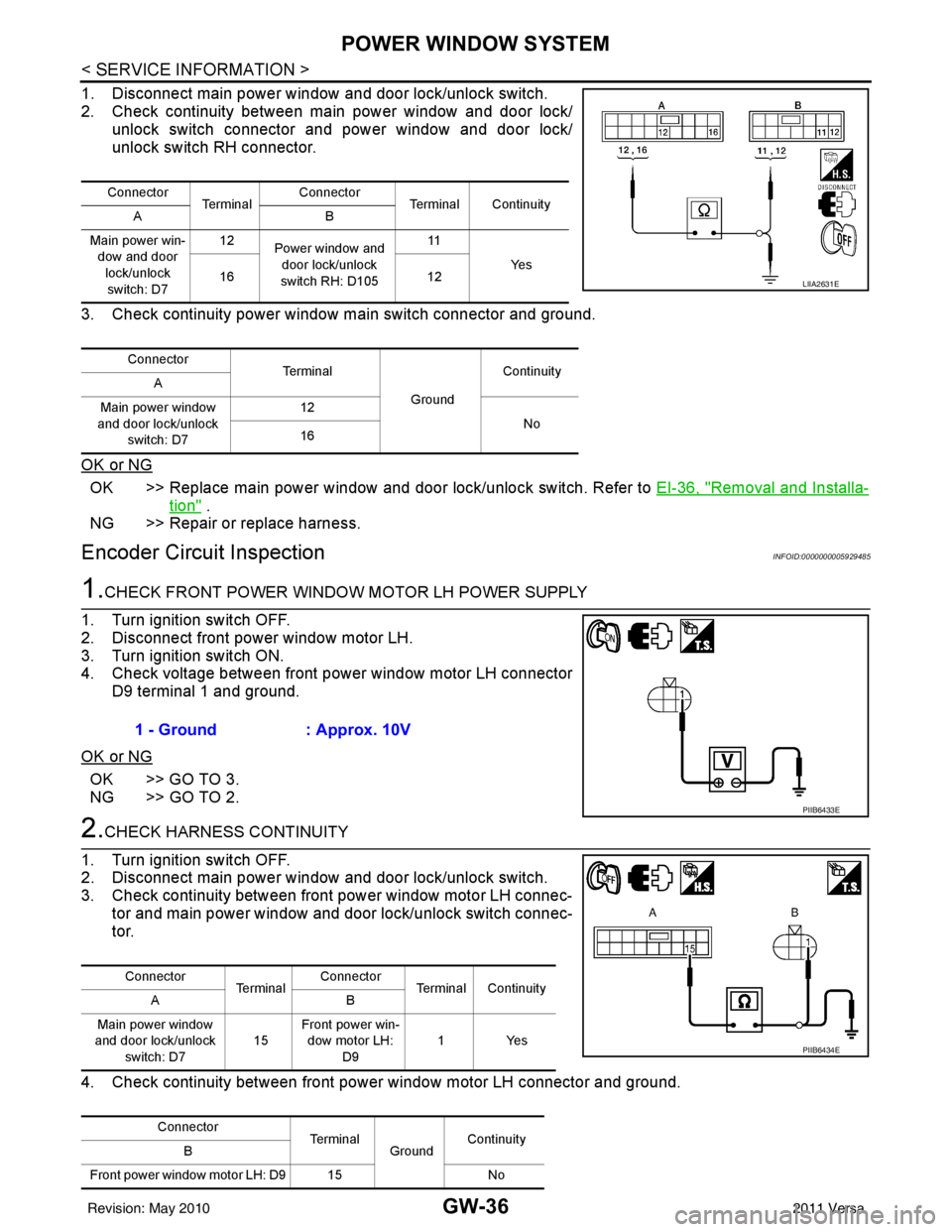

1. Disconnect main power window and door lock/unlock switch.

2. Check continuity between main power window and door lock/ unlock switch connector and power window and door lock/

unlock switch RH connector.

3. Check continuity power window main switch connector and ground.

OK or NG

OK >> Replace main power window and door lock/unlock switch. Refer to EI-36, "Removal and Installa-

tion" .

NG >> Repair or replace harness.

Encoder Circuit InspectionINFOID:0000000005929485

1.CHECK FRONT POWER WINDOW MOTOR LH POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect front power window motor LH.

3. Turn ignition switch ON.

4. Check voltage between front power window motor LH connector D9 terminal 1 and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect main power window and door lock/unlock switch.

3. Check continuity between front power window motor LH connec-

tor and main power window and door lock/unlock switch connec-

tor.

4. Check continuity between front power window motor LH connector and ground.

Connector Te r m i n a l Connector

Terminal Continuity

AB

Main power win- dow and door

lock/unlock switch: D7 12

Power window and

door lock/unlock

switch RH: D105 11

Ye s

16 12

Connector Te r m i n a l

GroundContinuity

A

Main power window

and door lock/unlock switch: D7 12

No

16

LIIA2631E

1 - Ground : Approx. 10V

PIIB6433E

Connector

Te r m i n a lConnector

Terminal Continuity

AB

Main power window

and door lock/unlock switch: D7 15Front power win-

dow motor LH: D9 1Yes

Connector TerminalGroundContinuity

B

Front power window motor LH: D9 15 No

PIIB6434E

Revision: May 2010 2011 Versa