check transmission fluid NISSAN LATIO 2011 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 201 of 3787

AT-184

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

2. Check A/T fluid condition. Refer to AT-51, "Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING ITEM

1. Disassemble A/T. Refer to AT-257, "

Disassembly" .

2. Check the following items:

- Forward clutch assembly. Refer to AT-307, "

Forward and Overrun Clutches" .

- Overrun clutch assembly. Refer to AT-307, "

Forward and Overrun Clutches" .

- Reverse clutch assembly. Refer to AT-297, "

Reverse Clutch" .

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

5.CHECK SYMPTOM

Check again. Refer to AT-56, "

Check at Idle" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 6.

6.CHECK TCM

1. Check TCM input/output signals. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Large Shock "N" → "R" PositionINFOID:0000000005928251

SYMPTOM:

There is a large shock when cha nging from “N” to “R” position.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" or AT-82, "Diagnosis Pro-

cedure without CONSULT-III" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning system. Refer to AT-77, "CONSULT-III Function (TRANSMISSION)" or

AT-82, "

Diagnosis Procedure without CONSULT-III" .

NO >> GO TO 2.

2.CHECK LINE PRESSURE

Check line pressure at idle with selector lever in “D” position. Refer to AT-51, "

Inspections Before Trouble

Diagnosis" .

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Valves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot valve and pilot fil- ter)

- Line pressure solenoid valve

- Oil pump assembly. Refer to AT-278, "

Oil Pump" .

OK or NG

Revision: May 2010 2011 Versa

Page 205 of 3787

AT-188

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

DIAGNOSTIC PROCEDURE

1.CHECK SYMPTOM

Check symptom. Refer to AT-56, "

Check at Idle" .

Is

“Vehicle Dose Not Creep Backward in “R” Position” OK?

OK >> GO TO 2.

NG >> Go to AT-185, "

Vehicle Does Not Creep Backward in "R" Position" .

2.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" or AT-82, "Diagnosis Pro-

cedure without CONSULT-III" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning system. Refer to AT-77, "CONSULT-III Function (TRANSMISSION)" or

AT-82, "

Diagnosis Procedure without CONSULT-III" .

NO >> GO TO 3.

3.CHECK ACCELERATOR PEDAL POSITION SENSOR

Check accelerator pedal position sensor. Refer to EC-415, "

Description" (HR16DE), EC-982, "Component

Description" (MR18DE).

OK or NG

OK >> GO TO 4.

NG >> Repair or replace accelerator pedal position sensor.

4.CHECK LINE PRESSURE

Check line pressure at stall point with selector lever in “D” position. Refer to AT-51, "

Inspections Before Trou-

ble Diagnosis" .

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Shift valve A

- Shift valve B

- Shift solenoid valve A

- Shift solenoid valve B

- Pilot valve

- Pilot filter

3. Disassemble A/T. Refer to AT-257, "

Disassembly" .

4. Check the following items:

- Forward clutch assembly. Refer to AT-307, "

Forward and Overrun Clutches" .

- Low one-way clutch. Refer to AT-257, "

Disassembly" .

- Forward one-way clutch. Refer to AT-318, "

Rear Internal Gear and Forward Clutch Hub" .

- High clutch assembly. Refer to AT-302, "

High Clutch" .

- Torque converter. Refer to AT-257, "

Disassembly" .

- Oil pump assembly. Refer to AT-278, "

Oil Pump" .

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

6.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 7.

NG >> GO TO 5.

Revision: May 2010 2011 Versa

Page 209 of 3787

AT-192

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

- Shift solenoid valve B

- Pilot valve

- Pilot filter

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

8.CHECK SYMPTOM

Check again. Refer to AT-58, "

Cruise Test - Part 1" and AT-61, "Cruise Test - Part 2" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 9.

9.CHECK TCM

1. Check TCM input/output signal. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

A/T Does Not Shift: D3→ D4INFOID:0000000005928257

SYMPTOM:

•A/T does not shift from D3 to D4 at the specified speed on “Cruise Test — Part 1” and “Cruise Test

— Part 2”.

• A/T must be warm before D

3 to D4 shift will occur.

DIAGNOSTIC PROCEDURE

1.CHECK SYMPTOM

Check symptom. Refer to AT-56, "

Check at Idle" and AT-58, "Cruise Test - Part 1" .

Are

“Vehicle Does Not Creep Forward in “D”, “2” or “1” Position” and “Vehicle Cannot Be Started from D1” OK?

YES >> GO TO 2.

NO >> Go to AT-186, "

Vehicle Does Not Creep Forward in "D", "2" or "1" Position" and AT-187, "Vehicle

Cannot Be Started from D1" .

2.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" or AT-82, "Diagnosis Pro-

cedure without CONSULT-III" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning system. Refer to AT-77, "CONSULT-III Function (TRANSMISSION)" or

AT-82, "

Diagnosis Procedure without CONSULT-III" .

NO >> GO TO 3.

3.CHECK ACCELERATOR PEDAL POSITION SENSOR

Check accelerator pedal position sensor. Refer to EC-415, "

Description" (HR16DE), EC-982, "Component

Description" (MR18DE).

OK or NG

OK >> GO TO 4.

NG >> Repair or replace accelerator pedal position sensor.

4.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

Revision: May 2010 2011 Versa

Page 211 of 3787

AT-194

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

2.CHECK ACCELERATOR PEDAL POSITION SENSOR

Check accelerator pedal position sensor. Refer to EC-415, "

Description" (HR16DE), EC-982, "Component

Description" (MR18DE).

OK or NG

OK >> GO TO 3.

NG >> Repair or replace accelerator pedal position sensor.

3.DETECT MALFUNCTIONING ITEM

1. Remove control valve. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check following items:

- Torque converter clutch control valve

- Torque converter clutch solenoid valve

- Torque converter relief valve

- Pilot valve

- Pilot filter

3. Disassemble A/T. Refer to AT-257, "

Disassembly" .

4. Check the following items:

- Torque converter. Refer to AT-257, "

Disassembly" .

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK SYMPTOM

Check again. Refer to AT-58, "

Cruise Test - Part 1" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 5.

5.CHECK TCM

1. Check TCM input/output signals. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

A/T Does Not Hold Lock-up ConditionINFOID:0000000005928259

SYMPTOM:

A/T does not hold lock-up condi tion for more than 30 seconds on “Cruise Test — Part 1”.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" or AT-82, "Diagnosis Pro-

cedure without CONSULT-III" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning system. Refer to AT-77, "CONSULT-III Function (TRANSMISSION)" or

AT-82, "

Diagnosis Procedure without CONSULT-III" .

NO >> GO TO 2.

2.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

Revision: May 2010 2011 Versa

Page 213 of 3787

AT-196

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

OK >>INSPECTION END

NG >> GO TO 3.

3.CHECK TCM

1. Check TCM input/output signals. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Engine Speed Does Not Return to Idle (Light Braking D4→ D3)INFOID:0000000005928261

SYMPTOM:

Engine speed does not smoothly return to idle when A/T shifts from D4 to D3 on “Cruise Test — Part

1”.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" or AT-82, "Diagnosis Pro-

cedure without CONSULT-III" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning system. Refer to AT-77, "CONSULT-III Function (TRANSMISSION)" or

AT-82, "

Diagnosis Procedure without CONSULT-III" .

NO >> GO TO 2.

2.CHECK ACCELERATOR PEDAL POSITION SENSOR

Check accelerator pedal position sensor. Refer to EC-415, "

Description" (HR16DE), EC-982, "Component

Description" (MR18DE).

OK or NG

OK >> GO TO 3.

NG >> Repair or replace accelerator pedal position sensor.

3.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Overrun clutch control valve

- Overrun clutch reducing valve

- Overrun clutch solenoid valve

3. Disassemble A/T. Refer to AT-257, "

Disassembly" .

4. Check the following items:

- Overrun clutch assembly. Refer to AT-307, "

Forward and Overrun Clutches" .

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

5.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Overrun clutch control valve

- Overrun clutch reducing valve

- Overrun clutch solenoid valve

Revision: May 2010 2011 Versa

Page 217 of 3787

AT-200

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

OK >> GO TO 3

NG >> Check transmission range switch. Refer to AT-175, "

Component Inspection" .

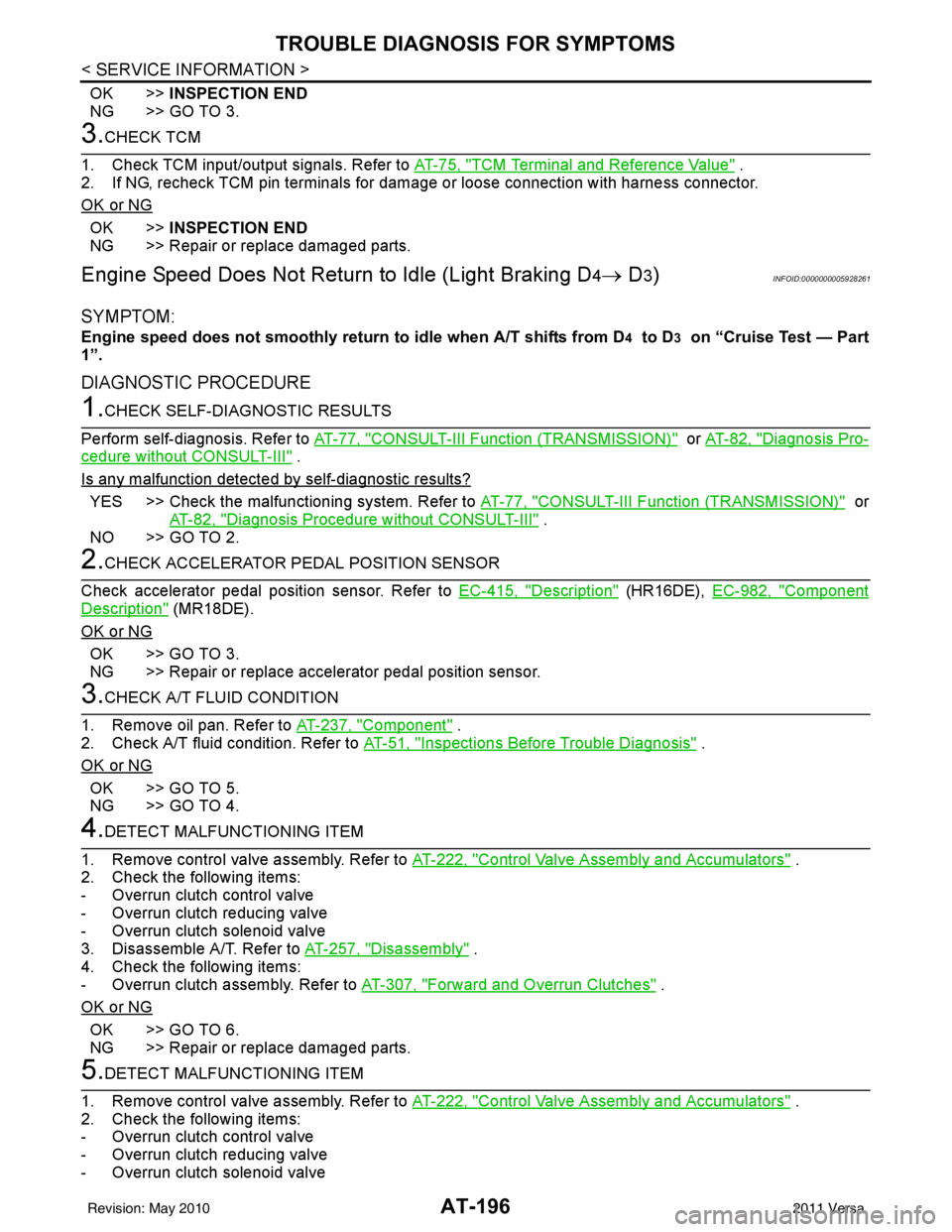

2.CHECK TRANSMISSION RANGE SWITCH CIRCUIT

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground

while moving selector lever through each position. Refer to AT-

91, "Wiring Diagram - AT - TR/SW" .

B: Battery voltage

0: 0V

OK or NG

OK >> GO TO 3

NG >> Check transmission range switch. Refer to AT-175, "

Component Inspection" .

3.CHECK A/T POSITION

Check A/T position. Refer to AT-217, "

Checking of A/T Position" .

OK or NG

OK >> GO TO 4.

NG >> Adjust A/T position. Refer to AT-217, "

Adjustment of A/T Position" .

4.CHECK OUTPUT SPEED SENSOR AND VEHICLE SPEED SIGNAL CIRCUIT

Check output speed sensor and vehicle speed signal circuit. Refer to AT-100

and/or AT-153 .

OK or NG

OK >> GO TO 5.

NG >> Repair or replace output speed sens or and/or vehicle speed signal circuits.

5.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

6.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Shift valve A

- Shift solenoid valve A

Selector lever position Te r m i n a l

36 35 34 27 26

“P”, “N” B0000 “R” 0B000

“D” 0 0 B 0 0

“2” 000B0

“1” 0000B

SCIA7162E

Revision: May 2010 2011 Versa

Page 220 of 3787

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-203

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

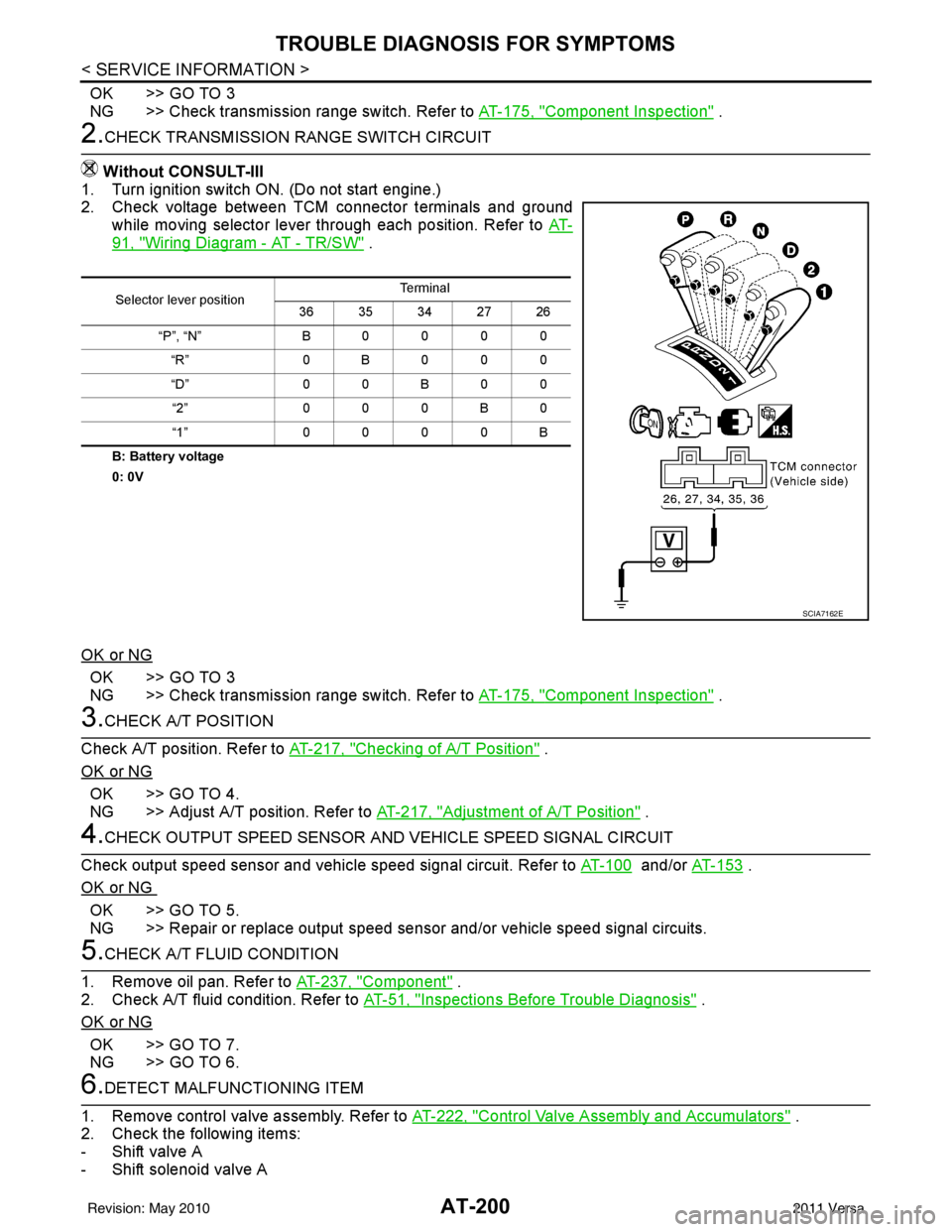

2. Check voltage between TCM connector terminals and ground while moving selector lever through each position. Refer to AT-

91, "Wiring Diagram - AT - TR/SW" .

B: Battery voltage

0: 0V

OK or NG

OK >> GO TO 5

NG >> Check transmission range switch. Refer to AT-175, "

Component Inspection" .

5.CHECK A/T POSITION

Check A/T position. Refer to AT-217, "

Checking of A/T Position" .

OK or NG

OK >> GO TO 6.

NG >> Adjust A/T position. Refer to AT-217, "

Adjustment of A/T Position" .

6.CHECK OUTPUT SPEED SENSOR AND VEHICLE SPEED SIGNAL CIRCUIT

Check output speed sensor and vehicle speed signal circuit. Refer to AT-100

and/or AT- 1 5 3 .

OK or NG

OK >> GO TO 7.

NG >> Repair or replace output speed sensor and/or vehicle speed signal circuits.

7.CHECK ACCELERATOR PEDAL POSITION SENSOR

Check accelerator pedal position sensor. Refer to EC-415, "

Description" (HR16DE), EC-982, "Component

Description" (MR18DE).

OK or NG

OK >> GO TO 8.

NG >> Repair or replace accelerator pedal position sensor.

8.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 10.

NG >> GO TO 9.

9.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following.

- Shift valve A

Selector lever position Te r m i n a l

36 35 34 27 26

“P”, “N” B 0 0 0 0

“R” 0B000

“D” 0 0 B 0 0

“2” 0 0 0 B 0

“1” 0 0 0 0 B

SCIA7162E

Revision: May 2010 2011 Versa

Page 242 of 3787

ON-VEHICLE SERVICEAT-225

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

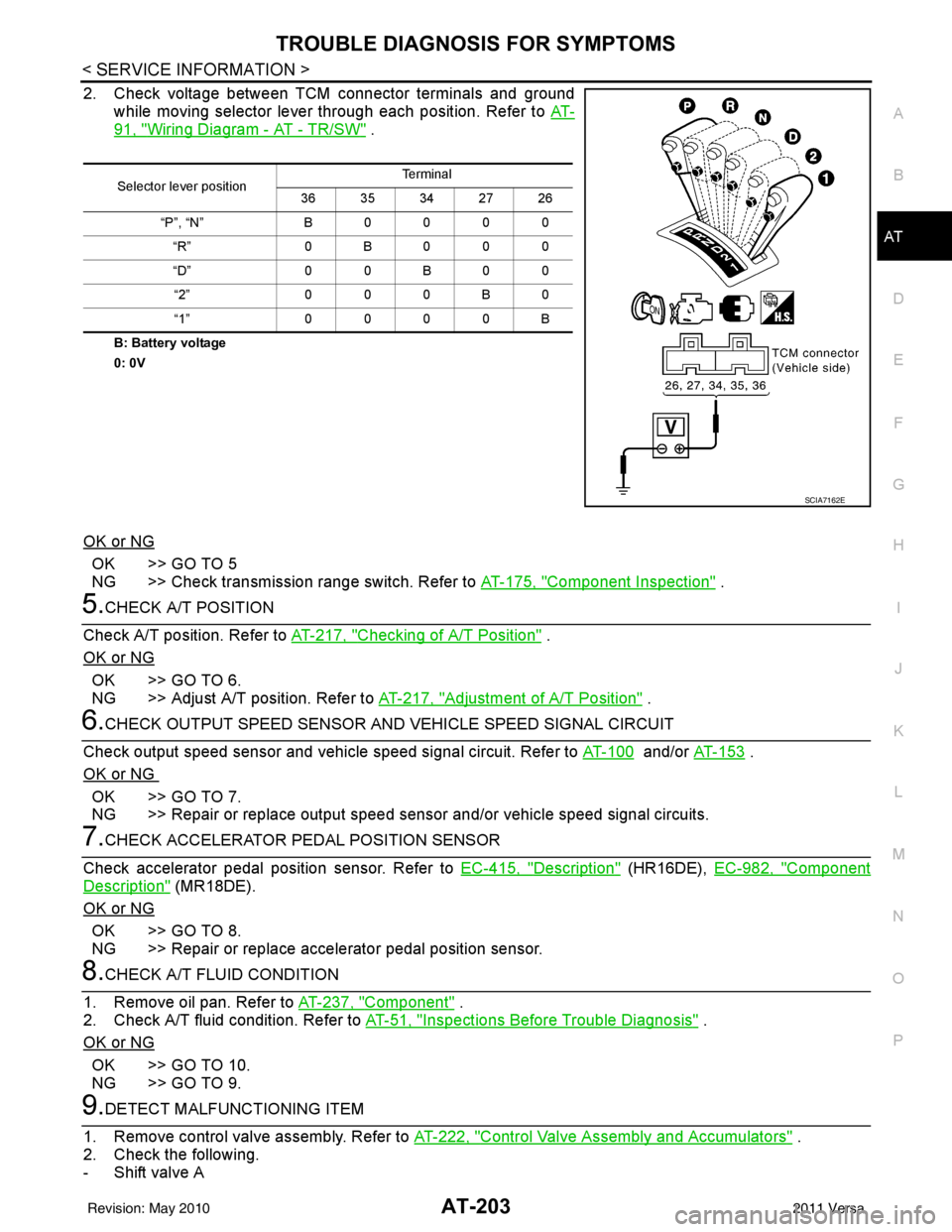

• Inspect each return spring, and replace if damaged, deformed or worn. Refer to AT-376, "

Accumulator" for free length (L1) and

length (L

2).

(1): Return spring (Servo release accumulator)

(2): Return spring (N-D accumulator)

CAUTION:

Do not remove spring retainer (3).

Installation

Installation is in the reverse order of removal.

CAUTION:

• Completely remove all moisture, oil and old gasket from the oil pan gasket mounting surface of tran-

saxle case and oil pan.

• Do not reuse O-rings, lip seals, oil pan gasket and oil pan bolts.

• Apply ATF to manual valve, O-rings, lip seals and sliding surfaces of the transaxle case.

NOTE:

• Set manual shaft in “N” position, then align manual plate (1) with groove in manual valve (2).

• After installing control valve assembly to transaxle case, make sure that shift selector can be moved to all positions.

• After completing installation, check for A/T fluid leakage and A/T fluid level. Refer to AT-17, "

Checking A/T Fluid".

Transmission Range SwitchINFOID:0000000005928279

COMPONENTS

SCIA6955E

SCIA7090E

Revision: May 2010 2011 Versa

Page 952 of 3787

![NISSAN LATIO 2011 Service Owners Manual TROUBLE DIAGNOSISBRC-63

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Note 1. If wheel sensor 2 for each wheel is indicated, check ABS actuator and electric unit (control un NISSAN LATIO 2011 Service Owners Manual TROUBLE DIAGNOSISBRC-63

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Note 1. If wheel sensor 2 for each wheel is indicated, check ABS actuator and electric unit (control un](/img/5/57357/w960_57357-951.png)

TROUBLE DIAGNOSISBRC-63

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Note 1. If wheel sensor 2 for each wheel is indicated, check ABS actuator and electric unit (control unit) power

supply voltage in addition to wheel sensor circuit check.

Note 2. If multiple malfunctions are detected including CAN communication line [U1000], perform diagnosis for

CAN communication line first.

DATA MONITOR

Display Item List

USV LINE [FL-RR]

[C1147] Front side VDC switch-over solenoid valve (cut valve) is open or

shorted, or control line is open or shorted to power supply or

ground.

BRC-72, "

Solenoid and

VDC Change-Over Valve

System Inspection"

USV LINE [FR-RL]

[C1148]Rear side VDC switch-over solenoid valve (cut valve) is open or

shorted, or control line is open or shorted to power supply or

ground.

HSV LINE [FL-RR]

[C1149] Front side VDC switch-over solenoid valve (suction valve) is open

or shorted, or control line is open or shorted to power supply or

ground.

HSV LINE [FR-RL]

[C1150] Rear side VDC switch-over solenoid valve (suction valve) is open

or shorted, or control line is open or shorted to power supply or

ground.

EMERGENCY BRAKE

[C1153] When ABS actuator and el

ectric unit (control unit) is malfunction-

ing. (Pressure increase is too much or too little) BRC-68, "

ABS/TCS/VDC

Control Unit Inspection"

PNP POS SIG

[C1154]Transmission range switch signal or communication line between

the ABS actuator and electric unit (control unit) and TCM is open

or shorted. BRC-78, "Transmission

Range Switch System In-

spection"

BR FLUID LEVEL LOW

[C1155]

Brake fluid level drops or circuit between ABS actuator and elec-

tric unit (control unit) and brake fluid level switch is open or

shorted. BRC-76, "Brake Fluid

Level Switch System In-

spection"

ST ANG SEN COM CIR

[C1156]

CAN communication line or steering angle sensor has generated

an error. BRC-79, "

CAN Commu-

nication System Inspec-

tion"

(Note 2)

VARIANT CODING

[C1170] In case where VARIANT CODING is different. BRC-68, "

ABS/TCS/VDC

Control Unit Inspection"

CAN COMM CIRCUIT

[U1000]• CAN communication line is open or shorted.

• ABS actuator and electric unit (control unit) internal malfunction

• Battery voltage for ECM is suddenly interrupted for approxi-

mately 0.5 seconds or more. BRC-79, "

CAN Commu-

nication System Inspec-

tion"

(Note 2)

Self-diagnostic item

Malfunction detecting condition Check system

Item

(Unit) Data monitor item selection

Remarks

ECU INPUT

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

FR LH SENSOR

(km/h, mph) ××× Wheel speed (km/h, mph) calculated by front LH

wheel sensor signal is displayed.

FR RH SENSOR

(km/h, mph) ××× Wheel speed (km/h, mph) calculated by front RH

wheel sensor signal is displayed.

RR LH SENSOR

(km/h, mph) ×××

Wheel speed (km/h, mph) calculated by rear LH

wheel sensor signal is displayed.

RR RH SENSOR

(km/h, mph) ××× Wheel speed (km/h, mph) calculated by rear RH

wheel sensor signal is displayed.

FR RH IN SOL

(On/Off) —

×× Front RH IN ABS solenoid (On/Off) status is dis-

played.

FR RH OUT SOL

(On/Off) —

×× Front RH OUT ABS solenoid (On/Off) status is

displayed.

FR LH IN SOL

(On/Off) —

×× Front LH IN ABS solenoid (On/Off) status is dis-

played.

Revision: May 2010

2011 Versa

Page 967 of 3787

![NISSAN LATIO 2011 Service Owners Manual BRC-78

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch connector.

3. Check continuity between stop lamp sw NISSAN LATIO 2011 Service Owners Manual BRC-78

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch connector.

3. Check continuity between stop lamp sw](/img/5/57357/w960_57357-966.png)

BRC-78

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch connector.

3. Check continuity between stop lamp switch (A) (without M/T) or

(B) (with M/T) terminals 1 and 2.

Is the inspection result normal?

YES >> GO TO 4

NO >> Replace stop lamp switch.

4.CHECK STOP LAMP SWITCH CIRCUIT

1. Disconnect ABS actuator and elec tric unit (control unit) connec-

tor.

2. Connect stop lamp switch connector.

3. Check voltage between ABS actuator and electric unit (control

unit) connector E33 terminal 20 and ground.

Is the inspection result normal?

YES >> GO TO 5

NO >> Repair or replace malfunctioning components.

5.CHECK DATA MONITOR

On “DATA MONITOR”, select “PRESS SENS OR” and check the brake fluid pressure.

Is the inspection result normal?

YES >> Replace ABS actuator and electric unit (control unit). Refer to BRC-89, "Removal and Installa-

tion".

NO >> Inspection End.

Transmission Range Switch System InspectionINFOID:0000000005928495

INSPECTION PROCEDURE

1.SELF-DIAGNOSIS RESULT CHECK

Stop lamp switch terminals ConditionContinuity

1 − 2 Brake pedal depressed

Yes

Brake pedal released No

AWFIA0609ZZ

ABS actuator and elec-

tric unit (control unit) Ground Condition Vol tag e

(Approx.)

Connector Terminal

E33 20 — Brake pedal depressed Battery voltage

Brake pedal released 0V

ALFIA0016ZZ

Condition PRESS SENSOR

(DATA MONITOR)

With ignition switch turned ON and brake pedal released. Approx. 0 bar

With ignition switch turned ON and brake pedal depressed. − 40 to 300 bar

Revision: May 2010 2011 Versa