check transmission fluid NISSAN LATIO 2011 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 968 of 3787

![NISSAN LATIO 2011 Service Owners Guide TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

BRC-79

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Check the self-diagnosis results.

Is the above displayed in the self-diagnosi NISSAN LATIO 2011 Service Owners Guide TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

BRC-79

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Check the self-diagnosis results.

Is the above displayed in the self-diagnosi](/img/5/57357/w960_57357-967.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

BRC-79

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Check the self-diagnosis results.

Is the above displayed in the self-diagnosis display items?

YES >> GO TO 2.

NO >> Inspection End.

2.CONNECTOR INSPECTION

1. Disconnect the ABS actuator and el ectric unit (control unit) and brake fluid level switch connectors.

2. Check the terminals for deformation, disconnection, looseness or damage.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace as necessary.

3.CHECK TRANSMISSION RANGE SWITCH

Perform transmission range switch inspection. Refer to AT-94, "

Component Inspection" (with A/T) or CVT-65,

"Component Inspection" (with CVT).

Is the inspection result normal?

YES >> Replace ABS actuator and electr ic unit (control unit). Refer to BRC-89, "Removal and Installa-

tion".

NO >> Repair or replace malfunctioning components.

CAN Communication System InspectionINFOID:0000000005928496

INSPECTION PROCEDURE

1.SELF-DIAGNOSIS RESULT CHECK

Check the self-diagnosis results.

Is the above displayed in the self-diagnosis display items?

YES >> GO TO 2.

NO >> Inspection End.

2.CHECK CONNECTOR

1. Disconnect the ABS actuator and electric unit (control unit) connector, and check the terminals for defor- mation, disconnection, looseness, and so on. If there is a malfunction, repair or replace the terminals.

2. Reconnect connector to perform self-diagnosis. Refer to BRC-60, "

CONSULT-III Function (ABS)".

Is

“CAN COMM CIRCUIT” displayed in the self-diagnosis display items?

YES >> Refer to LAN-17, "Trouble Diagnosis Flow Chart".

NO >> Connector terminal connection is loose, damaged, open, or shorted.

Component InspectionINFOID:0000000005928497

VDC OFF SWITCH

Self-diagnosis results

PNP POS SIG

Self-diagnosis results

ST ANG SEN COM CIR CAN COMM CIRCUIT

Revision: May 2010 2011 Versa

Page 1042 of 3787

![NISSAN LATIO 2011 Service Owners Guide CO-42

< SERVICE INFORMATION >[MR18DE]

RADIATOR

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Blee NISSAN LATIO 2011 Service Owners Guide CO-42

< SERVICE INFORMATION >[MR18DE]

RADIATOR

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Blee](/img/5/57357/w960_57357-1041.png)

CO-42

< SERVICE INFORMATION >[MR18DE]

RADIATOR

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec-

ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc. Item

Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Transmission/

transaxle fluid A/T and CVT Models

LeakageLevel/Leakage Leakage

M/T Models Level/Leakage LeakageLevel/Leakage

Other oils and fluids* LevelLeakage Level

Fuel LeakageLeakage Leakage

Exhaust gas —Leakage —

Revision: May 2010 2011 Versa

Page 1048 of 3787

![NISSAN LATIO 2011 Service Owners Guide CO-48

< SERVICE INFORMATION >[MR18DE]

THERMOSTAT

INSTALLATION

Installation is in the reverse order of removal.

• Use the following procedure to install the thermostat.

- Install thermostat making su NISSAN LATIO 2011 Service Owners Guide CO-48

< SERVICE INFORMATION >[MR18DE]

THERMOSTAT

INSTALLATION

Installation is in the reverse order of removal.

• Use the following procedure to install the thermostat.

- Install thermostat making su](/img/5/57357/w960_57357-1047.png)

CO-48

< SERVICE INFORMATION >[MR18DE]

THERMOSTAT

INSTALLATION

Installation is in the reverse order of removal.

• Use the following procedure to install the thermostat.

- Install thermostat making sure rubber ring (1) groove fits securely

to thermostat flange (A).

CAUTION:

Replace the rubber ring with a new one.

- Install thermostat (1) into the thermostat housing (2) with jiggle valve (A) facing upwards.

• Use the following procedure to install the thermostat housing.

- Securely insert the rubber ring into the mating groove of thermostat housing and install it. CAUTION:

Replace the rubber ring with a new one.

- Install the thermostat housing to the cylinder block without displacing the gasket from the gasket position.

InspectionINFOID:0000000006413349

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-14, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

• Start engine. With engine speed increased, che ck again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

PBIC3315J

PBIC3548J

Item Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Transmission/

transaxle fluid A/T and CVT Models

LeakageLevel/Leakage Leakage

M/T Models Level/Leakage LeakageLevel/Leakage

Other oils and fluids* LevelLeakage Level

Revision: May 2010 2011 Versa

Page 1054 of 3787

![NISSAN LATIO 2011 Service Owners Guide CO-54

< SERVICE INFORMATION >[MR18DE]

WATER OUTLET AND WATER CONTROL VALVE

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including

engine oil NISSAN LATIO 2011 Service Owners Guide CO-54

< SERVICE INFORMATION >[MR18DE]

WATER OUTLET AND WATER CONTROL VALVE

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including

engine oil](/img/5/57357/w960_57357-1053.png)

CO-54

< SERVICE INFORMATION >[MR18DE]

WATER OUTLET AND WATER CONTROL VALVE

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec-

ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc. Item

Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Transmission/

transaxle fluid A/T and CVT Models

LeakageLevel/Leakage Leakage

M/T Models Level/Leakage LeakageLevel/Leakage

Other oils and fluids* LevelLeakage Level

Fuel LeakageLeakage Leakage

Exhaust gas —Leakage —

Revision: May 2010 2011 Versa

Page 1056 of 3787

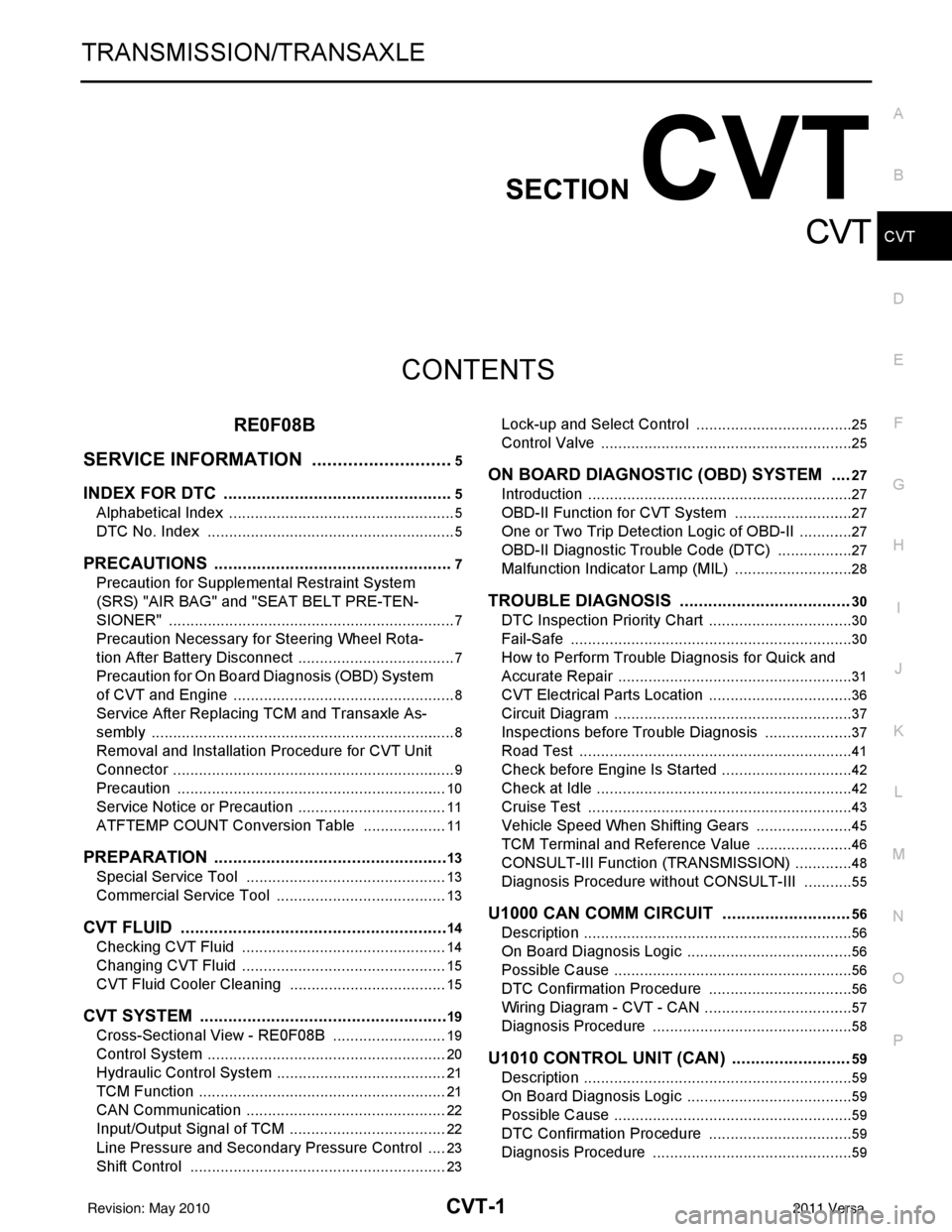

CVT-1

TRANSMISSION/TRANSAXLE

DE

F

G H

I

J

K L

M

SECTION CVT

A

B

CVT

N

O P

CONTENTS

CVT

RE0F08B

SERVICE INFORMATION .. ..........................

5

INDEX FOR DTC ............................................ .....5

Alphabetical Index ............................................... ......5

DTC No. Index ..........................................................5

PRECAUTIONS ...................................................7

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

7

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

7

Precaution for On Board Diagnosis (OBD) System

of CVT and Engine ....................................................

8

Service After Replacing TCM and Transaxle As-

sembly .......................................................................

8

Removal and Installation Procedure for CVT Unit

Connector ............................................................ ......

9

Precaution ...............................................................10

Service Notice or Precaution ...................................11

ATFTEMP COUNT Conversion Table ....................11

PREPARATION .............................................. ....13

Special Service Tool ........................................... ....13

Commercial Service Tool ........................................13

CVT FLUID .........................................................14

Checking CVT Fluid ............................................ ....14

Changing CVT Fluid ................................................15

CVT Fluid Cooler Cleaning .....................................15

CVT SYSTEM ................................................. ....19

Cross-Sectional View - RE0F08B ....................... ....19

Control System .................................................... ....20

Hydraulic Control System ........................................21

TCM Function ...................................................... ....21

CAN Communication ...............................................22

Input/Output Signal of TCM .....................................22

Line Pressure and Secondary Pressure Control .....23

Shift Control ............................................................23

Lock-up and Select Control .....................................25

Control Valve ....................................................... ....25

ON BOARD DIAGNOSTIC (OBD) SYSTEM ....27

Introduction ..............................................................27

OBD-II Function for CVT System ............................27

One or Two Trip Detection Logic of OBD-II .............27

OBD-II Diagnostic Trouble Code (DTC) ..................27

Malfunction Indicator Lamp (MIL) ............................28

TROUBLE DIAGNOSIS ....................................30

DTC Inspection Priority Chart ..................................30

Fail-Safe ..................................................................30

How to Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

31

CVT Electrical Parts Location ..................................36

Circuit Diagram ........................................................37

Inspections before Trouble Diagnosis .....................37

Road Test ................................................................41

Check before Engine Is Started ...............................42

Check at Idle ............................................................42

Cruise Test ..............................................................43

Vehicle Speed When Shifting Gears .......................45

TCM Terminal and Reference Value .......................46

CONSULT-III Function (TRANSMISSION) .......... ....48

Diagnosis Procedure without CONSULT-III ............55

U1000 CAN COMM CIRCUIT ...........................56

Description ........................................................... ....56

On Board Diagnosis Logic .......................................56

Possible Cause ........................................................56

DTC Confirmation Procedure ..................................56

Wiring Diagram - CVT - CAN ...................................57

Diagnosis Procedure ...............................................58

U1010 CONTROL UNIT (CAN) .........................59

Description ...............................................................59

On Board Diagnosis Logic .......................................59

Possible Cause ........................................................59

DTC Confirmation Procedure ..................................59

Diagnosis Procedure ...............................................59

Revision: May 2010 2011 Versa

Page 1070 of 3787

![NISSAN LATIO 2011 Service Owners Guide CVT FLUIDCVT-15

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

FLUID CONDITION CHECK

Changing CVT FluidINFOID:0000000005928731

1. Warm up CVT fluid by driving the vehicle for 10 m NISSAN LATIO 2011 Service Owners Guide CVT FLUIDCVT-15

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

FLUID CONDITION CHECK

Changing CVT FluidINFOID:0000000005928731

1. Warm up CVT fluid by driving the vehicle for 10 m](/img/5/57357/w960_57357-1069.png)

CVT FLUIDCVT-15

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

FLUID CONDITION CHECK

Changing CVT FluidINFOID:0000000005928731

1. Warm up CVT fluid by driving the vehicle for 10 minutes.

• : Vehicle front

• Radiator (2)

• CVT fluid cooler hose [inlet side (3)]

• Transaxle assembly (4)

2. Drain CVT fluid from CVT fluid cooler hose [outlet side (1)] and refill with new specified NISSAN CVT fluid in the CVT fluid

charging pipe with the engine running at idle speed.

CAUTION:

Only use the specifi ed NISSAN CVT fluid.

3. Refill until new CVT fluid comes out from CVT fluid cooler hose [outlet side (1)]. NOTE:

About 30 to 50% extra fluid will be required for this procedure.

4. Check fluid level and condition. Refer to CVT-14, "

Checking CVT Fluid".

CAUTION:

Delete CVT fluid deterioration date with CONSULT-III after changing CVT fluid. Refer to CVT-48,

"CONSULT-III Function (TRANSMISSION)".

CVT Fluid Cooler CleaningINFOID:0000000005928732

Whenever a CVT is repaired, overhauled, or replaced, the CVT fluid cooler mounted in the radiator must be

inspected and cleaned.

Metal debris and friction material, if present, can be trapped or become deposit in the CVT fluid cooler. This

debris can contaminate the newly serviced CVT or, in severe cases, can block or restrict the flow of CVT fluid.

In either case, malfunction of the newly serviced CVT may occur.

Debris, if present, may deposit as CVT fluid enters the cool er inlet. It will be necessary to back flush the cooler

through the cooler outlet in order to flush out any built up debris.

CVT FLUID COOLER CLEANING PROCEDURE

1. Identify the CVT inlet and outlet fluid cooler hoses.

2. Position an oil pan under the inlet and outlet cooler hoses.

Fluid status Conceivable cause Required operation

Varnished (viscous

varnish state) Clutch, brake

scorchedReplace the CVT fluid and check the

CVT main unit and the vehicle for

malfunctions (wire harness, cooler

pipes, etc.)

Milky white or cloudy Water in the fluid Replace the CVT fluid and check for places where water is getting in.

Large amount of

metal powder mixed

in fluid Unusual wear of

sliding parts within

CVTReplace the CVT fluid and check for

improper operation of the CVT.

ATA0022D

Fluid capacity and grade: Refer to

MA-14, "Fluids

and Lubricants".SCIA6088E

Revision: May 2010 2011 Versa

Page 1124 of 3787

![NISSAN LATIO 2011 Service Owners Guide P0710 TRANSMISSION FLUID TEMPERATURE SENSOR ACVT-69

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

Diagnosis ProcedureINFOID:0000000005928793

1. CHECK CVT FLUID TEMP ERATURE SENSO NISSAN LATIO 2011 Service Owners Guide P0710 TRANSMISSION FLUID TEMPERATURE SENSOR ACVT-69

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

Diagnosis ProcedureINFOID:0000000005928793

1. CHECK CVT FLUID TEMP ERATURE SENSO](/img/5/57357/w960_57357-1123.png)

P0710 TRANSMISSION FLUID TEMPERATURE SENSOR ACVT-69

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

Diagnosis ProcedureINFOID:0000000005928793

1. CHECK CVT FLUID TEMP ERATURE SENSOR SIGNAL

With CONSULT-III

1. Start engine.

2. Select “ECU INPUT SIGNALS” in “DATA MONITO R” mode for “TRANSMISSION” with CONSULT-III.

3. Read out the value of “ATF TEMP SEN”.

Without CONSULT-III

1. Start engine.

2. Check voltage between TCM connector terminals.

3. Turn ignition switch OFF.

4. Disconnect TCM connector.

5. Check if there is continuity between connector terminal and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

2. CHECK CVT FLUID TEMP ERATURE SENSOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect the TCM connector.

3. Check resistance between TCM connector terminals.

OK or NG

OK >> GO TO 5.

NG >> GO TO 3.

3. CHECK CVT FLUID TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disconnect CVT unit harness connector.

Item name Condition Display value

(Approx.)

ATF TEMP SEN When CVT fluid temperature is 20

°C

(68 °F). 2.0 V

When CVT fluid temperature is 80 °C

(176 °F). 1.0 V

Name Connector Terminal

Temperature

°C ( °F) Voltage

(Approx.)

CVT fluid tem-

perature sen-

sor E32

47 - 42 20 (68) 2.0 V

80 (176) 1.0 V

SCIA2027E

Name Connector Terminal Temperature

°C ( °F) Resistance

(Approx.)

CVT fluid tem-

perature sensor E32

47 - 42 20 (68) 6.5 k

Ω

80 (176) 0.9 k Ω

SCIA2510E

Revision: May 2010 2011 Versa

Page 1125 of 3787

![NISSAN LATIO 2011 Service Owners Guide CVT-70

< SERVICE INFORMATION >[RE0F08B]

P0710 TRANSMISSION FLUID

TEMPERATURE SENSOR A

3. Check resistance between CVT unit harness connector termi-

nals.

4. Reinstall any part removed.

OK or NG

OK >> NISSAN LATIO 2011 Service Owners Guide CVT-70

< SERVICE INFORMATION >[RE0F08B]

P0710 TRANSMISSION FLUID

TEMPERATURE SENSOR A

3. Check resistance between CVT unit harness connector termi-

nals.

4. Reinstall any part removed.

OK or NG

OK >>](/img/5/57357/w960_57357-1124.png)

CVT-70

< SERVICE INFORMATION >[RE0F08B]

P0710 TRANSMISSION FLUID

TEMPERATURE SENSOR A

3. Check resistance between CVT unit harness connector termi-

nals.

4. Reinstall any part removed.

OK or NG

OK >> GO TO 4.

NG >> Replace the transaxle assembly. Refer to CVT-180, "

Removal and Installation".

4. CHECK HARNESS BETWEEN TCM AND CVT FLUID TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disconnect the TCM connector and CVT unit harness connector.

3. Check continuity between TCM connector terminals and CVT unit harness connector terminals.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

5.CHECK DTC

Perform CVT-67, "

DTC Confirmation Procedure" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 6.

6.CHECK TCM

1. Check TCM input/output signals. Refer to CVT-46, "

TCM Terminal and Reference Value" .

2. If NG, re-check TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Component InspectionINFOID:0000000005928794

CVT FLUID TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disconnect CVT unit harness connector.

Name Connector Terminal Te m p e r a -

ture °C ( °F) Resistance

(Approx.)

CVT fluid

temperature

sensor F46

17 - 19 20 (68) 6.5 k

Ω

80 (176) 0.9 k Ω

SCIA4679E

ItemConnector Terminal Continuity

TCM E3242

Ye s

CVT unit harness connector F46 19

TCM E3247

Ye s

CVT unit harness connector F46 17

SCIA4680E

Revision: May 2010 2011 Versa

Page 1126 of 3787

![NISSAN LATIO 2011 Service Owners Guide P0710 TRANSMISSION FLUID TEMPERATURE SENSOR ACVT-71

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

3. Check resistance between CVT unit harness connector termi- nals.

4. If NG, re NISSAN LATIO 2011 Service Owners Guide P0710 TRANSMISSION FLUID TEMPERATURE SENSOR ACVT-71

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

3. Check resistance between CVT unit harness connector termi- nals.

4. If NG, re](/img/5/57357/w960_57357-1125.png)

P0710 TRANSMISSION FLUID TEMPERATURE SENSOR ACVT-71

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

3. Check resistance between CVT unit harness connector termi- nals.

4. If NG, replace the transaxle assembly. Refer to CVT-180,

"Removal and Installation" .

Name Connector Terminal Te m p e r a -

ture ° C (°F) Resistance

(Approx.)

CVT fluid

temperature

sensor F46

17 - 19 20 (68) 6.5 k

Ω

80 (176) 0.9 k Ω

SCIA4679E

Revision: May 2010 2011 Versa

Page 1138 of 3787

![NISSAN LATIO 2011 Service Owners Guide P0730 INCORRECT GEAR RATIOCVT-83

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0730 INCORRECT GEAR RATIO

DescriptionINFOID:0000000005928815

TCM selects the gear ratio using the NISSAN LATIO 2011 Service Owners Guide P0730 INCORRECT GEAR RATIOCVT-83

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0730 INCORRECT GEAR RATIO

DescriptionINFOID:0000000005928815

TCM selects the gear ratio using the](/img/5/57357/w960_57357-1137.png)

P0730 INCORRECT GEAR RATIOCVT-83

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0730 INCORRECT GEAR RATIO

DescriptionINFOID:0000000005928815

TCM selects the gear ratio using the engine load (throttle position), the primary pulley revolution speed, and

the secondary pulley revolution speed as input signal. T hen it changes the operating pressure of the primary

pulley and the secondary pulley and changes the groove width of the pulley.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005928816

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000005928817

• This is not an OBD-II self-diagnostic item.

• TCM calculates the actual gear ratio with primary speed sensor and secondary speed sensor.

• Diagnostic trouble code “P0730” with CONSULT-III is detected, when TCM receives an unexpected gear

ratio signal.

Possible CauseINFOID:0000000005928818

Transaxle assembly

DTC Confirmation ProcedureINFOID:0000000005928819

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN: 1.0 - 2.0 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to

increase the voltage (c ool down the fluid)

3. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

4. Start engine and maintain the following conditions for at least 30 consecutive seconds. TEST START FROM 0 km/h (0 MPH)

CONSTANT ACCELERATION: Keep 30 sec or more

VEHICLE SPEED: 10 km/h (6 MPH) or more

ACC PEDAL OPEN: More than 1.0/8

RANGE: “D” position

ENG SPEED: 450 rpm or more

5. If DTC is detected, go to CVT-83, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005928820

1.CHECK DTC

Perform CVT-83, "

DTC Confirmation Procedure".

Are any DTC displayed?

YES - 1>> DTC except for “P0730” is displayed: Go to Check the DTC detected item. Refer to CVT-48,

"CONSULT-III Function (TRANSMISSION)".

YES - 2>> DTC for “P0730” is displayed: Replace the transaxle assembly. Refer to CVT-180, "

Removal and

Installation".

NO >> INSPECTION END

Item name Condition Display value (Approx.)

GEAR RATIO During driving 2.56 - 0.43

Revision: May 2010 2011 Versa