headlamp NISSAN LATIO 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 495 of 3787

BCM (BODY CONTROL MODULE)BCS-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BCS

N

O P

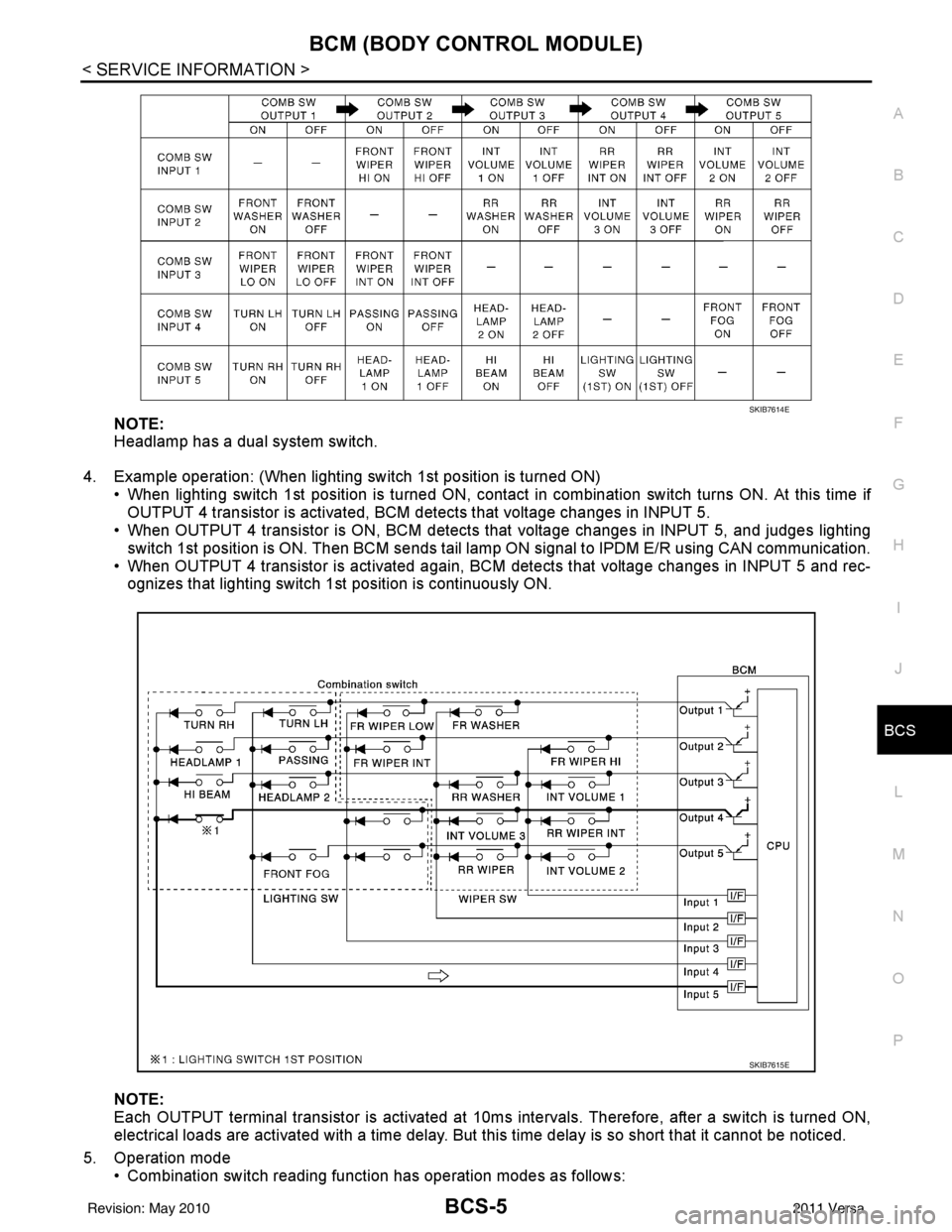

NOTE:

Headlamp has a dual system switch.

4. Example operation: (When lighting switch 1st position is turned ON) • When lighting switch 1st position is turned ON, contact in combination switch turns ON. At this time ifOUTPUT 4 transistor is activated, BCM detects that voltage changes in INPUT 5.

• When OUTPUT 4 transistor is ON, BCM detects that voltage changes in INPUT 5, and judges lighting

switch 1st position is ON. Then BCM sends tail lamp ON signal to IPDM E/R using CAN communication.

• When OUTPUT 4 transistor is activated again, BC M detects that voltage changes in INPUT 5 and rec-

ognizes that lighting switch 1st position is continuously ON.

NOTE:

Each OUTPUT terminal transistor is activated at 10ms intervals. Therefore, after a switch is turned ON,

electrical loads are activated with a time delay. But this time delay is so short that it cannot be noticed.

5. Operation mode • Combination switch reading functi on has operation modes as follows:

SKIB7614E

SKIB7615E

Revision: May 2010 2011 Versa

Page 497 of 3787

BCM (BODY CONTROL MODULE)BCS-7

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BCS

N

O P

• When CAN communication operation is detected, it switches to CAN communication status.

• When a state of the following switches changes , it switches to CAN communication state:

- Ignition switch

- Key switch (without Intelligent Key)

- Key switch and ignition knob switch (with Intelligent Key)

- Hazard switch

- Door lock/unlock switch (with power door locks)

- Front door switch (LH, RH)

- Rear door switch (LH, RH)

- Back door lock assembly (Hatchback)

- Trunk key cylinder switch (Sedan)

- Trunk lamp switch and trunk release solenoid (Sedan)

- Combination switch (passing, lighting switch 1st position, front fog lamp)

- Keyfob (lock/unlock signal) (with power door locks)

- Front door key cylinder switch LH

• When control performed only by BCM is required by switch, it shifts to CAN communication inactive mode.

• Status of combination switch reading function is changed.

SYSTEMS CONTROLLED BY BCM DIRECTLY

• Power door lock system (with power door locks). Refer to BL-23, "System Description" .

• Remote keyless entry system. Refer to BL-58, "

System Description" .

• Power window system (with power windows). Refer to GW-19, "

System Description" . NOTE

• Sunroof system (with sunroof). Refer to RF-11, "System Description". NOTE

• Room lamp timer. Refer to LT-93, "System Description" .

• Rear wiper and washer system (Hatchback). Refer to WW-27, "

System Description" .

NOTE:

Power supply only. No system control.

SYSTEMS CONTROLLED BY BCM AND IPDM E/R

• Panic system. Refer to BL-58, "System Description" .

• Vehicle security (theft warning) system. Refer to BL-218, "

System Description" .

• NVIS(NATS) system. Refer to BL-246, "

System Description" .

• Headlamp, tail lamp and battery saver control systems. Refer to LT-74, "

System Description", LT- 5 , "System

Description" or LT-27, "System Description" .

• Front fog lamp (with front fog lamps). Refer to LT-41, "

System Description" .

• Front wiper and washer system. Refer to WW-5, "

System Description" .

• Rear window defogger system. Refer to GW-51, "

System Description" .

SYSTEMS CONTROLLED BY BCM AND COMBINATION METER

• Warning chime. Refer to DI-43, "System Description" .

• Turn signal and hazard warning lamps. Refer to LT-50, "

System Description" .

SYSTEMS CONTROLLED BY BCM AND INTELLIGENT KEY UNIT (WITH INTELLIGENT KEY)

• Intelligent Key system. Refer to BL-88, "System Description" .

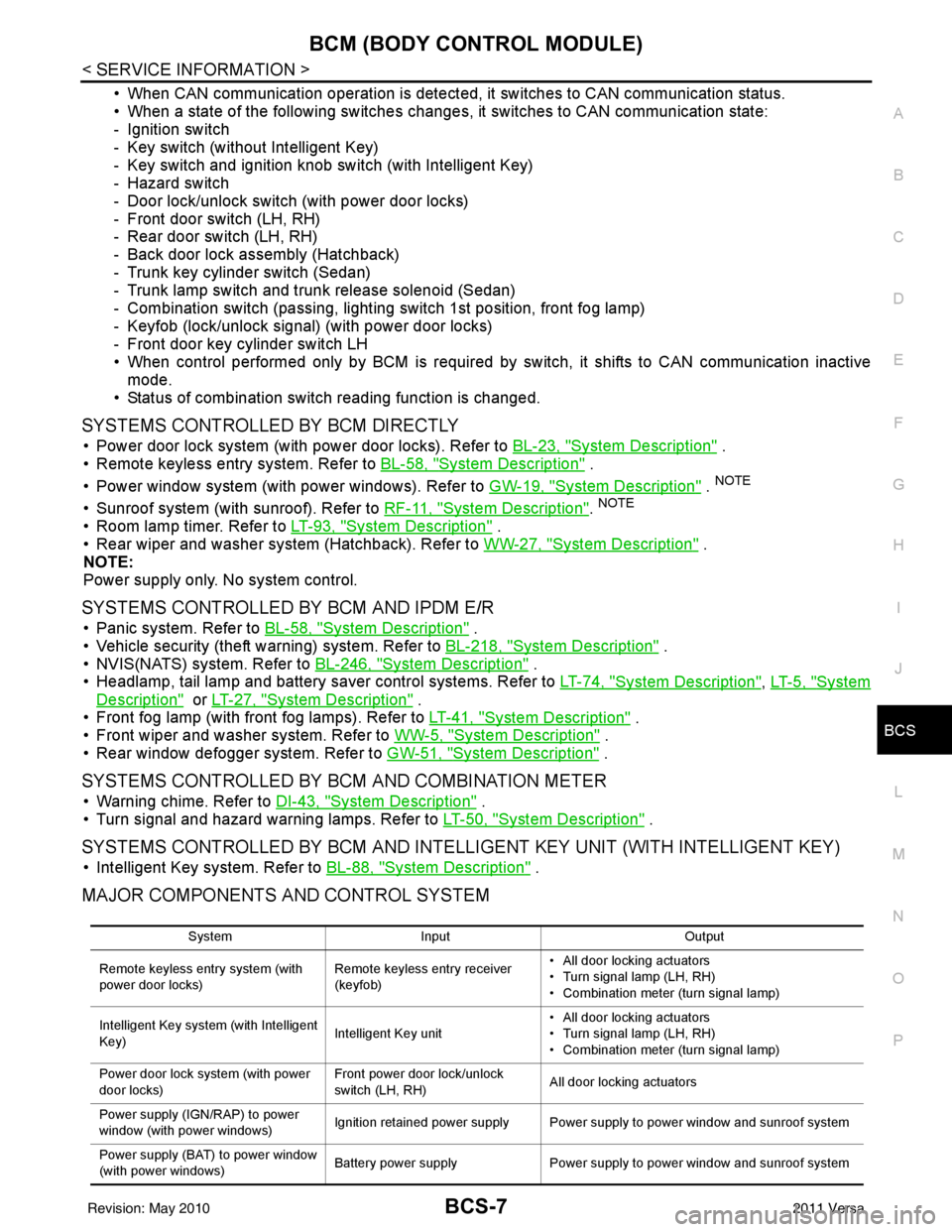

MAJOR COMPONENTS AND CONTROL SYSTEM

System Input Output

Remote keyless entry system (with

power door locks) Remote keyless entry receiver

(keyfob)• All door locking actuators

• Turn signal lamp (LH, RH)

• Combination meter (turn signal lamp)

Intelligent Key system (with Intelligent

Key) Intelligent Key unit• All door locking actuators

• Turn signal lamp (LH, RH)

• Combination meter (turn signal lamp)

Power door lock system (with power

door locks) Front power door lock/unlock

switch (LH, RH)

All door locking actuators

Power supply (IGN /RAP) to power

window (with power windows) Ignition retained power supply Power supply to power window and sunroof system

Power supply (BAT) to power window

(with power windows) Battery power supply

Power supply to power window and sunroof system

Revision: May 2010 2011 Versa

Page 498 of 3787

BCS-8

< SERVICE INFORMATION >

BCM (BODY CONTROL MODULE)

CAN Communication System Description

INFOID:0000000005929256

Refer to LAN-7, "System Description".

Panic alarm •Key switch

•KeyfobIPDM E/R

Vehicle security system • All door switches

•Keyfob

• Door lock/unlock switch

• Trunk key cylinder switch (Se-

dan)

• Front door key cylinder switch LH • IPDM/ER

• Security indicator lamp

Battery save r control • Ignition switch

• Combination switch

IPDM E/R

Headlamp Combination switch IPDM E/R

Tail lamp Combination switchIPDM E/R

Front fog lamp (with front fog lamps) Combination switch IPDM E/R

Turn signal lamp Combination switch• Turn signal lamp

• Combination meter

Hazard lamp Hazard switch• Turn signal lamp

• Combination meter

Room lamp timer •Key switch

•Keyfob

• Main power window and door

lock/unlock switch

• Front door switch LH

• All door switch Interior room lamp

Back door switch signal (Hatchback) Back door lock assembly Luggage room lamp

Back door lock signal (Hatchback) Back door lock assembly Back door opener

Trunk lamp switch signal (Sedan) Trunk lamp switch and trunk re-

lease solenoidLuggage room lamp

Trunk lid opener signal (Sedan) Trunk lamp switch and trunk re-

lease solenoid

Trunk lid opener

Key warning chime •Key switch

• Front door switch LHCombination meter (warning buzzer)

Light warning chime • Combination switch

•Key switch

• Front door switch LHCombination meter (warning buzzer)

Seat belt warning chime • Seat belt buckle switch LH

• Ignition switch

Combination meter (warning buzzer)

Front wiper and washer system • Combination switch

• Ignition switchIPDM E/R

Rear window defogger Rear window defogger switch IPDM E/R

Rear wiper and washer system

(Hatchback) • Combination switch

• Ignition switch

Rear wiper motor

A/C switch signal Front air controlECM

Blower fan switch signal Front air controlECM

A/C indicator signal Front air controlA/C indicator

Low tire pressure warning system Remote keyless entry receiver Combination meter System

Input Output

Revision: May 2010 2011 Versa

Page 508 of 3787

BCS-18

< SERVICE INFORMATION >

BCM (BODY CONTROL MODULE)

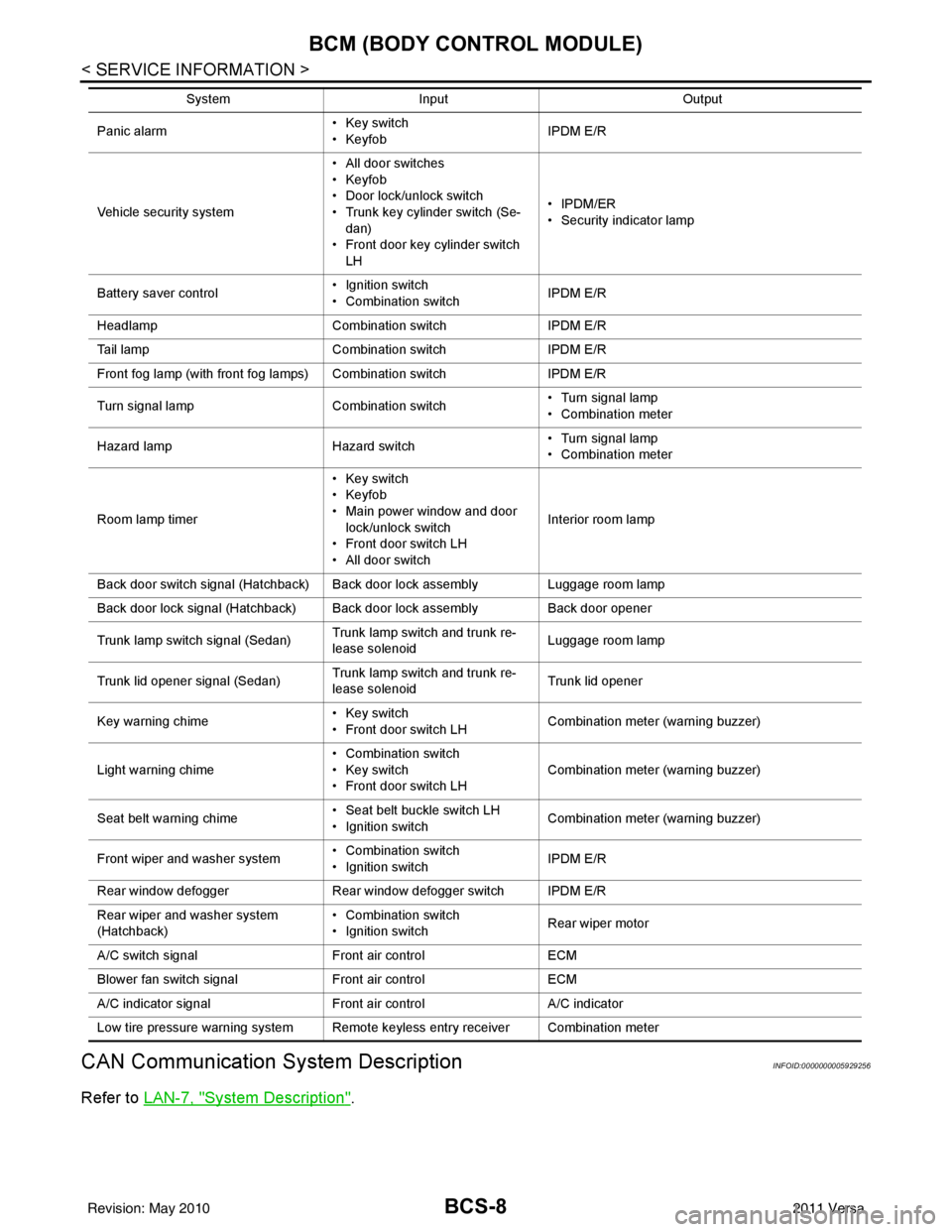

WORK SUPPORT

Display Item List

CAN Communication Inspection Using CONSULT-III (Self-Diagnosis)INFOID:0000000005929262

1.SELF-DIAGNOSTIC RESULT CHECK

1. Connect CONSULT–III and select “BCM” on “SELECT SYSTEM” screen.

2. Select “BCM” on “SELECT TEST ITEM” screen, and select “SELF-DIAG RESULTS”.

3. Check display content in self-diagnostic results.

System and item CONSULT-III

display Diagnostic test mode (Inspection by part)

WORK

SUPPORT SELF

DIAGNOS- TIC RE-

SULT CAN DIAG

SUPPORT MNTR DATA

MONITOR ECU

IDENTI- FICA-

TION AC-

TIVE

TEST CON-

FIGU-

RATION

BCM BCM×× × × ×

Power door lock sys-

tem DOOR LOCK

×× ×

Rear defogger REAR DEFOG-

GER ××

Warning chime BUZZER ××

Room lamp timer INT LAMP ×× ×

Remote keyless entry

system MULTI REMOTE

ENT

××

×

Headlamp HEAD LAMP×× ×

Wiper WIPER×× ×

Turn signal lamp

Hazard lamp FLASHER

××

Blower fan switch sig-

nal

Air conditioner switch

signal AIR CONDITION-

ER

××

Intelligent Key INTELLIGENT

KEY ×

Combination switch COMB SW ×

NVIS (NATS) IMMU ××

Interior lamp battery

saver BATTERY SAV-

ER

××

×

Back door/Trunk TRUNK ××

Theft alarm THEFT ALARM×× ×

Retained accessory

power control RETAINED PWR

×× ×

Oil pressure swit ch SIGNAL BUFFER ××

Low tire pressure moni-

tor AIR PRESSURE

MONITOR

××

× ×

Panic alarm PANIC ALARM ×

ItemDescription

RESET SETTING VALUE Return a value set with WORK SUPPORT of each system to a default value in factory shipment.

Revision: May 2010 2011 Versa

Page 512 of 3787

BL-2

Keyfob Function (Lock) Check ...............................82

Keyfob Function (Unlock) Check ............................82

ID Code Entry Procedure .................................... ...83

Keyfob Battery Replacement ............................... ...85

Removal and Installation of Remote Keyless Entry

Receiver .............................................................. ...

85

INTELLIGENT KEY SYSTEM ............................86

Component Parts and Harness Connector Loca-

tion ....................................................................... ...

86

System Description .................................................88

CAN Communication System Description ..............95

Schematic ............................................................ ...96

Wiring Diagram - I/KEY - ..................................... ...98

Intelligent Key Unit Har ness Connector Terminal

Layout .................................................................. ..

108

Terminal and Reference Value for Intelligent Key

Unit ........................................................................

108

Steering Lock Solenoid Harness Connector Ter-

minal Layout ..........................................................

110

Terminal and Reference Value for Steering Lock

Solenoid .................................................................

110

Terminal and Reference Value for BCM ................111

Trouble Diagnosis Procedure ................................115

CONSULT-III Functions (INTELLIGENT KEY) ......117

CONSULT-III Application Item ............................. ..117

Trouble Diagnosis Symptom Chart ........................119

CAN Communication System Inspection ...............126

Power Supply and Ground Circuit Inspection ........126

Key Switch (Intelligent Key Unit Input) Check .......127

Key Switch (BCM Input) Check .............................128

Ignition Knob Switch Check ................................. ..129

Door Switch Check (Hatchback) ............................131

Door Switch Check (Sedan) ..................................134

Door Request Switch Check ..................................135

Back Door Request Switch Check (Hatchback) ....137

Trunk Opener Request Switch Check (Sedan) ... ..138

Unlock Sensor Check ............................................140

Intelligent Key Warning Buzzer(s) Check ..............142

Outside Key Antenna (Dri ver Side and Passenger

Side) Check ......................................................... ..

143

Outside Key Antenna (Rear Bumper) Check .........144

Inside Key Antenna Check ....................................146

Steering Lock Solenoid Check ............................ ..147

Key Interlock Solenoid (With M/T) Check ..............149

Ignition Switch Position Check ............................ ..150

Stop Lamp Switch Check (With CVT or A/T) ....... ..150

Stop Lamp Switch Check (With M/T) .....................152

CVT or A/T Shift Selector (Park Position Switch)

Check .................................................................. ..

153

"P-SHIFT" Warning Lamp (With CVT or A/T)

Check ....................................................................

154

"LOCK" Warning Lamp (With M/T) Check .............155

"KEY" Warning Lamp (RED) Check ......................155

"KEY" Warning Lamp (G REEN) Check .................155

Check Warning Chime in Combination Meter ........156

Hazard Function Check .........................................156

Horn Function Check .... .........................................157

Headlamp Function Chec k ....................................157

Intelligent Key Battery Re placement .....................158

Remote Keyless Entry Func tion ............................158

Removal and Installation of Intelligent Key Unit ... .158

DOOR ...............................................................160

Fitting Adjustment ................................................ .160

Removal and Installation .......................................163

Back Door Stay Disposal ..................................... .166

FRONT DOOR LOCK .......................................167

Component Parts Location .................................. .167

Removal and Installation .......................................167

REAR DOOR LOCK ....................................... ..170

Component Parts Location .................................. .170

Removal and Installation .......................................170

BACK DOOR LOCK ....................................... ..173

Component Parts and Harness Connector Loca-

tion ....................................................................... .

173

System Description ...............................................173

Wiring Diagram - B/DOOR - ..................................174

Terminal and Reference Value for BCM ...............176

Terminal and Reference Value for Intelligent Key

Unit ....................................................................... .

180

CONSULT-III Function (BCM) ..............................182

Work Flow .............................................................183

Trouble Diagnosis Chart by Symptom ..................183

BCM Power Supply and Ground Circuit Inspection

.

183

Check Back Door Opener Switch Circuit (Without

Intelligent Key or Power Windows) ...................... .

184

Check Back Door Opener Switch Circuit (Without

Intelligent Key, with Power Windows) .................. .

187

Check Back Door Opener Switch Circuit (With In-

telligent Key) ........................................................ .

189

Check Back Door Lock Assembly (Actuator) Cir-

cuit ........................................................................

191

Removal and Installation .......................................193

TRUNK LID ..................................................... ..195

Fitting Adjustment ................................................ .195

Trunk Lid Assembly ..............................................195

Trunk Lid Lock ......................................................196

Trunk Lid Striker ....................................................196

TRUNK LID OPENER .......................................198

Component Parts and Harness Connector Loca-

tion ....................................................................... .

198

System Description ...............................................198

Wiring Diagram - TLID - ........................................199

Terminal and Reference Value for BCM ...............201

Terminal and Reference Value for Intelligent Key

Unit ....................................................................... .

205

CONSULT-III Function (BCM) ..............................207

Work Flow .............................................................208

Trouble Diagnosis Chart by Symptom ..................208

BCM Power Supply and Ground Circuit Inspection

.

208

Revision: May 2010 2011 Versa

Page 523 of 3787

HOODBL-13

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

HOOD

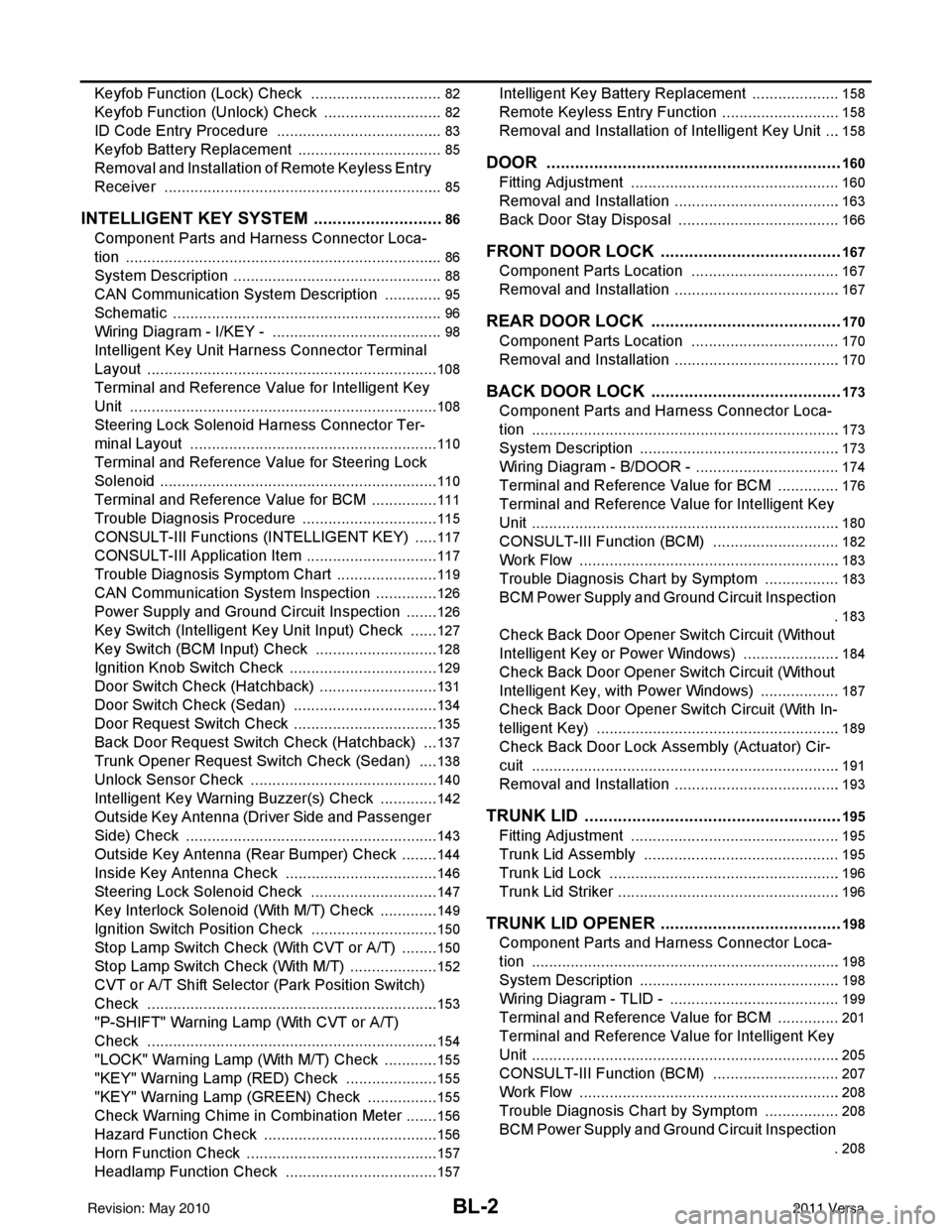

Fitting AdjustmentINFOID:0000000005929276

FRONT END HEIGHT ADJUSTMENT AND LA TERAL/LONGITUDINAL CLEARANCE ADJUST-

MENT

1. Remove the front grille. Refer to EI-23.

2. Remove hood lock. Rotate bumper rubber to adjust height until hood becomes 1.0 to 1.5 mm lower than the fender.

3. Position hood lock and engage striker. Check hood lock and striker for looseness. Tighten lock bolts to the specified torque.

4. Install the front grille. Refer to EI-23

.

CAUTION:

Adjust the clearance between hood and other parts so that the

dimensional difference left and right is as follows.

SURFACE MISMATCH ADJUSTMENT

1. Remove the front grille. Refer to EI-23.

2. Release hood lock, and adjust surface level difference of hood, fender, and headlamp according to the fit- ting standard dimension, using RH and LH bumper rubbers.

3. Install and align the hood lock until the center of the striker and the hood lock are vertically aligned.

4. Press the hood lightly with [approx. 29 N (3 kg] of force and adjust A and B as shown.

PIIB6508E

Hood and headlamp (B - B) : Less than 2.0 mm (0.08 in)

Hood and fender (C - C) : Less than 1.5 mm (0.06 in)

Hood and fender (D - D) : Less than 1.5 mm (0.06 in)PIIB2526J

Hood and front bumper (A - A) : -1.3 - 2.7 mm (-0.05 - 0.11 in)

Hood and fender (D - D) : -0.4 - 1.7 mm (-0.16 - 0.07 in)

Revision: May 2010 2011 Versa

Page 529 of 3787

RADIATOR CORE SUPPORTBL-19

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

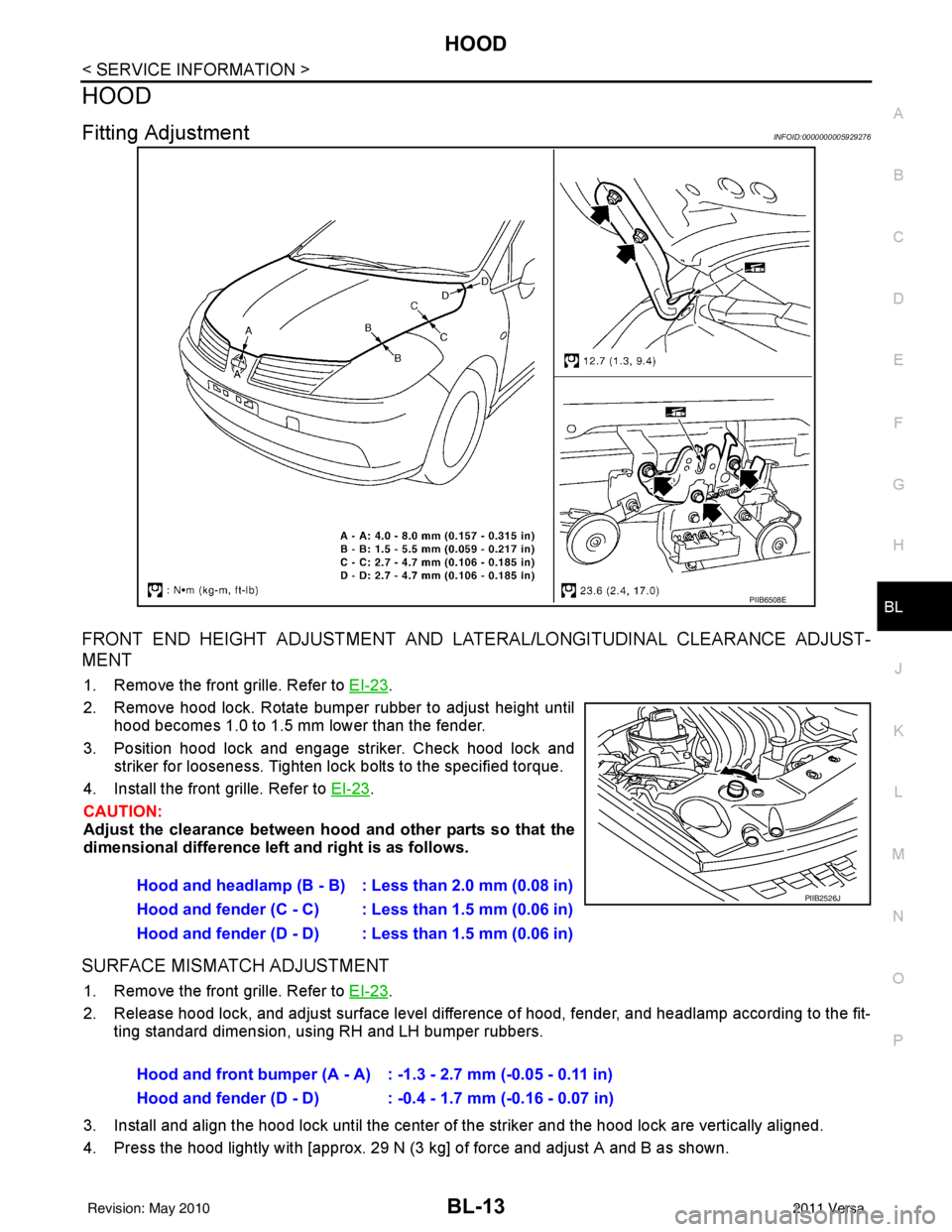

RADIATOR CORE SUPPORT

Removal and InstallationINFOID:0000000005929280

REMOVAL

Radiator Core Support Upper

1. Remove the air duct. Refer to EM-135, "Removal and Installation" .

2. Remove the headlamp (LH/RH). Refer to LT-25, "

Removal and Installation" .

3. Remove the hood lock assembly, and remove hood lock cable. Refer to BL-15

.

4. Remove the air guide and hood lock cable clip.

5. Remove the washer tank inlet. Refer to WW-25, "

Removal and Installation of Washer Tank" .

6. Remove the radiator core support upper.

Radiator Core Support Lower

1. Remove the air duct. Refer to EM-135, "Removal and Installation" .

2. Remove the front bumper. Refer to EI-15, "

Removal and Installation" .

3. Remove the headlamp (LH/RH). Refer to LT-25, "

Removal and Installation" .

4. Remove the hood lock assembly, and remove hood lock cable. Refer to BL-15

.

5. Remove the air guide and hood lock cable mounting clip.

6. Remove the front bumper reinforcement. Refer to EI-15, "

Removal and Installation" .

7. Remove the radiator core lower stay.

8. Remove the undercover.

PIIB6515E

1. Radiator core support upper 2. Radiator core support lower 3. Radiator core support lower stay

4. Radiator core support side stay 5. Air guide

24.5 N·m (2.5 kg-m, 18 ft-lb)

Revision: May 2010 2011 Versa

Page 531 of 3787

FRONT FENDERBL-21

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

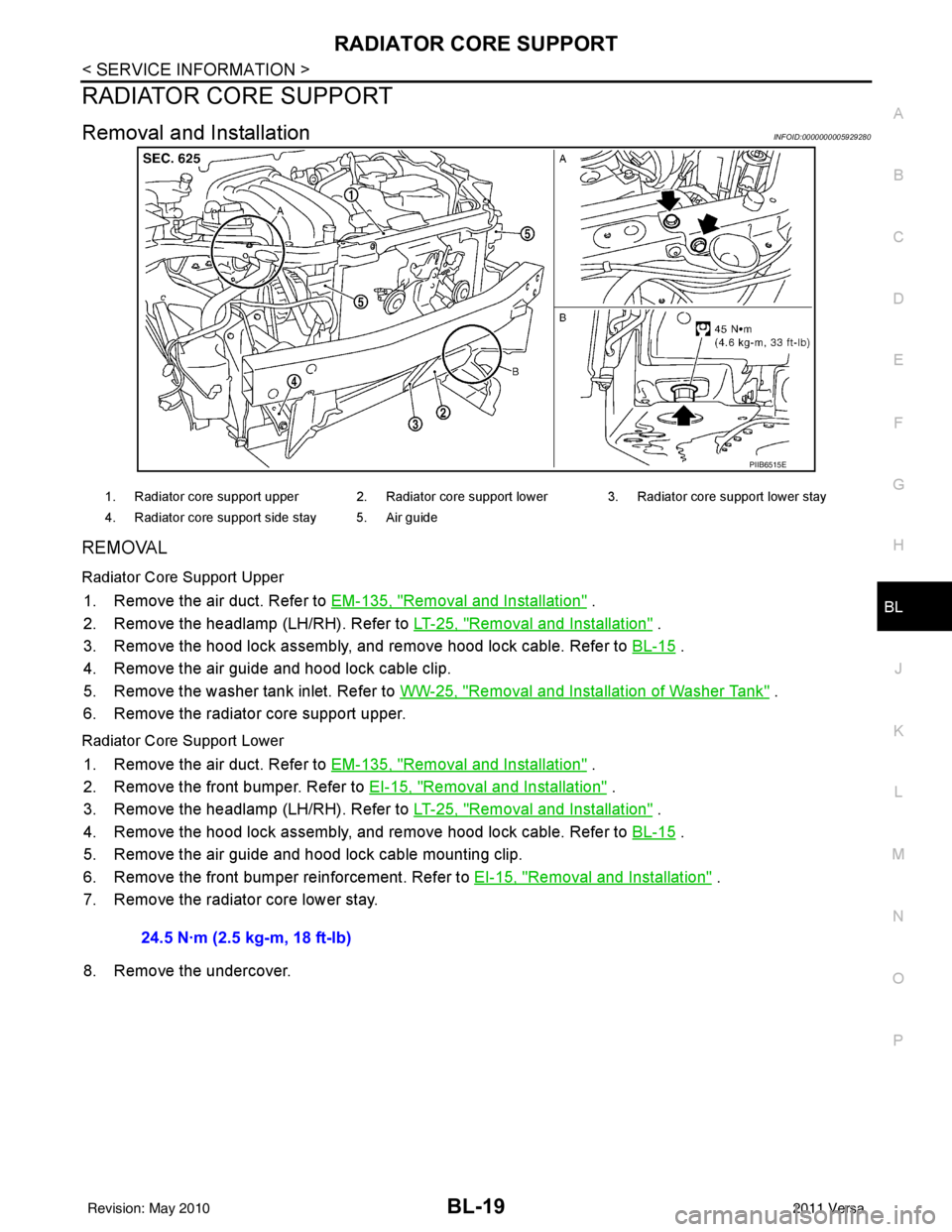

FRONT FENDER

Removal and InstallationINFOID:0000000005929281

REMOVAL

1. Remove the headlamp assemblies. Refer to LT-25, "Removal and Installation".

2. Remove the cowl top cover (LH/RH). Refer to EI-24, "

Removal and Installation".

3. Remove the front fender protector. Refer to EI-26, "

Component".

4. Remove the bolt and the front fender.

CAUTION:

While removing use a shop cloth to pr otect the vechicle body from damage.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• After installing, apply touch-up paint on to the head of the front fender bolts.

• After installing, check front fender adjustment. Refer to BL-13, "

Fitting Adjustment" and BL-160, "Fit-

ting Adjustment".

1. Front fender 2 Bolt (LH 7 bolts required) (RH 8 bolts

required)

LIIA2657E

Revision: May 2010 2011 Versa

Page 601 of 3787

INTELLIGENT KEY SYSTEMBL-91

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

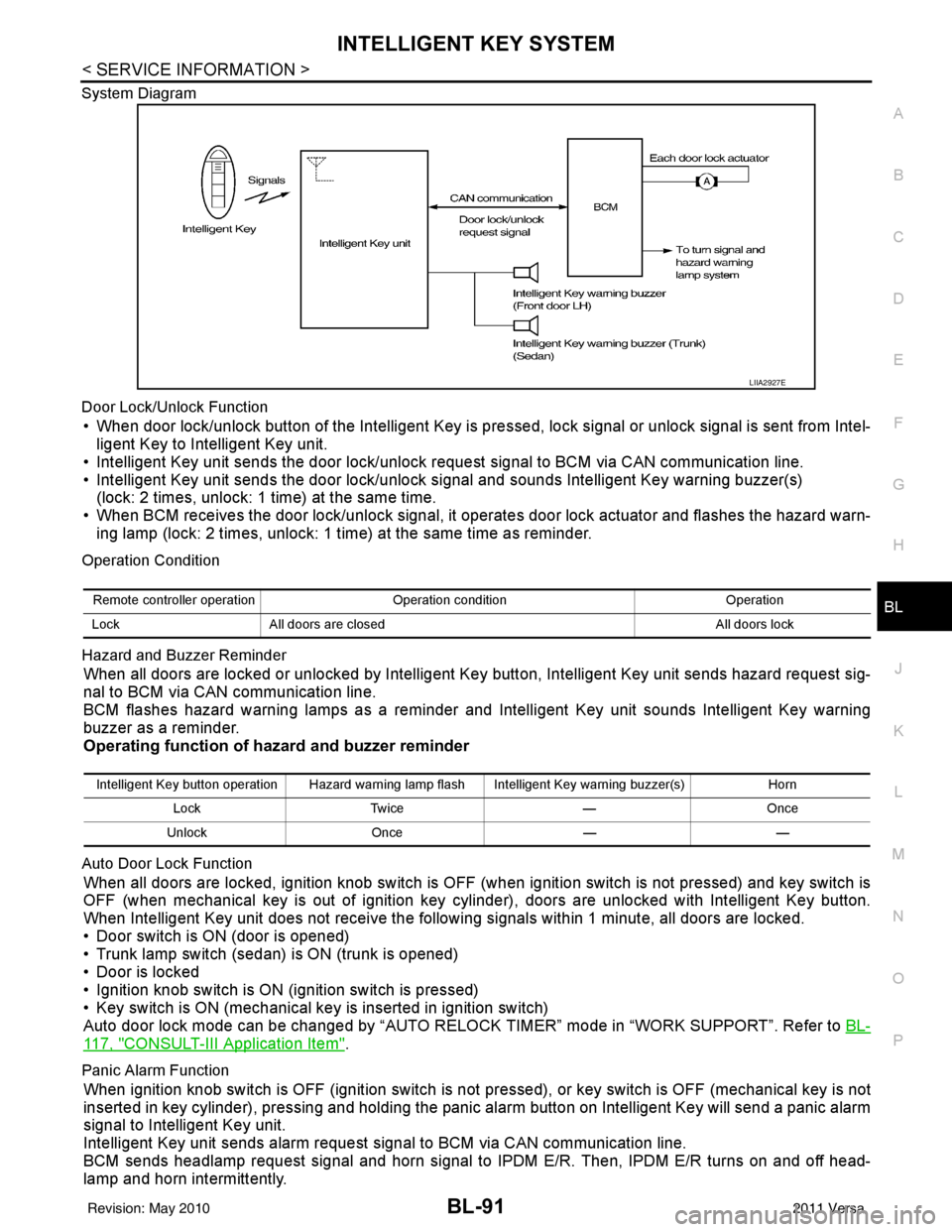

System Diagram

Door Lock/Unlock Function

• When door lock/unlock button of the Intelligent Key is pr

essed, lock signal or unlock signal is sent from Intel-

ligent Key to Intelligent Key unit.

• Intelligent Key unit sends the door lock/unlock request signal to BCM via CAN communication line.

• Intelligent Key unit sends the door lock/unlock signal and sounds Intelligent Key warning buzzer(s) (lock: 2 times, unlock: 1 time) at the same time.

• When BCM receives the door lock/unlock signal, it oper ates door lock actuator and flashes the hazard warn-

ing lamp (lock: 2 times, unlock: 1 time) at the same time as reminder.

Operation Condition

Hazard and Buzzer Reminder

When all doors are locked or unlocked by Intelligent Ke y button, Intelligent Key unit sends hazard request sig-

nal to BCM via CAN communication line.

BCM flashes hazard warning lamps as a reminder and Intelligent Key unit sounds Intelligent Key warning

buzzer as a reminder.

Operating function of hazard and buzzer reminder

Auto Door Lock Function

When all doors are locked, ignition knob switch is OFF (when ignition switch is not pressed) and key switch is

OFF (when mechanical key is out of ignition key cyli nder), doors are unlocked with Intelligent Key button.

When Intelligent Key unit does not receive the following signals within 1 minute, all doors are locked.

• Door switch is ON (door is opened)

• Trunk lamp switch (sedan) is ON (trunk is opened)

• Door is locked

• Ignition knob switch is ON (ignition switch is pressed)

• Key switch is ON (mechanical key is inserted in ignition switch)

Auto door lock mode can be changed by “AUTO RELOCK TIMER” mode in “WORK SUPPORT”. Refer to BL-

117, "CONSULT-III Application Item".

Panic Alarm Function

When ignition knob switch is OFF (ignition switch is not pressed), or key switch is OFF (mechanical key is not

inserted in key cylinder), pressing and holding the panic alarm button on Intelligent Key will send a panic alarm

signal to Intelligent Key unit.

Intelligent Key unit sends alarm request signal to BCM via CAN communication line.

BCM sends headlamp request signal and horn signal to IPDM E/R. Then, IPDM E/R turns on and off head-

lamp and horn intermittently.

LIIA2927E

Remote controller operation Operation condition Operation

Lock All doors are closed All doors lock

Intelligent Key button operation Hazard warning lamp flash Intelligent Key warning buzzer(s) Horn

Lock Twice —Once

Unlock Once ——

Revision: May 2010 2011 Versa

Page 602 of 3787

BL-92

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

The headlamp flashes and the horn sounds intermittently.

The alarm automatically turns off:

• After 25 seconds

• When Intelligent Key unit receives any signal from remote controller of Intelligent Key

• When door request switch is pressed (Intelligent Key is outside vehicle)

Panic alarm function's press and holding time value can be changed in “PANIC ALARM DELAY” mode in

“WORK SUPPORT”. Refer to BL-117, "

CONSULT-III Application Item".

List of Operation Related Parts

Parts marked with × are the parts related to operation.

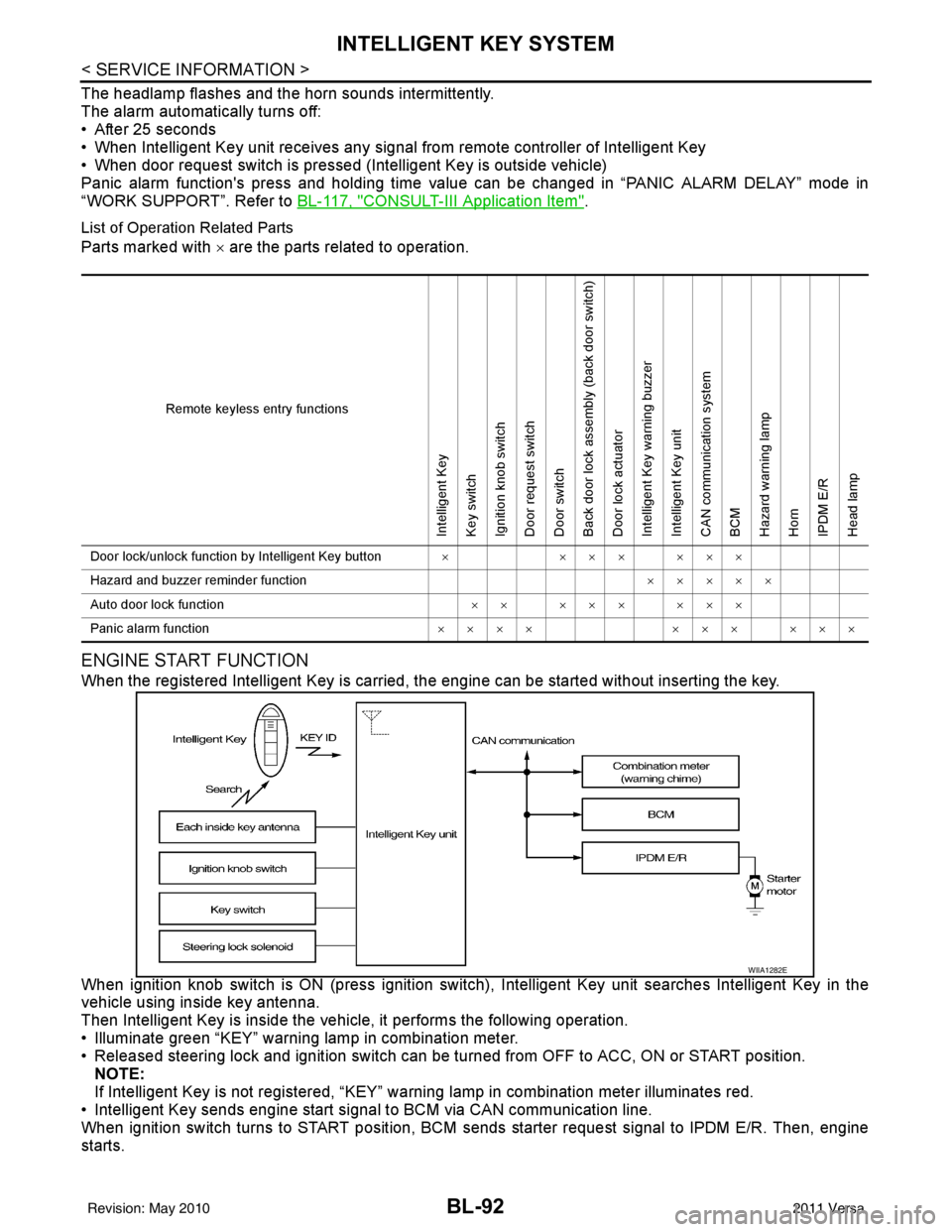

ENGINE START FUNCTION

When the registered Intelligent Key is carried, the engine can be started without inserting the key.

When ignition knob switch is ON (press ignition switch ), Intelligent Key unit searches Intelligent Key in the

vehicle using inside key antenna.

Then Intelligent Key is inside the vehicle, it performs the following operation.

• Illuminate green “KEY” warning lamp in combination meter.

• Released steering lock and ignition switch can be turned from OFF to ACC, ON or START position.

NOTE:

If Intelligent Key is not registered, “KEY” warning lamp in combination meter illuminates red.

• Intelligent Key sends engine start signal to BCM via CAN communication line.

When ignition switch turns to START position, BCM sends starter request signal to IPDM E/R. Then, engine

starts.

Remote keyless entry functions

Intelligent Key

Key switch

Ignition knob switch

Door request switch

Door switch

Back door lock assembly (back door switch)

Door lock actuator

Intelligent Key warning buzzer

Intelligent Key unit

CAN communication system

BCM

Hazard warning lamp

Horn

IPDM E/R

Head lamp

Door lock/unlock function by Intelligent Key button × ××× ×××

Hazard and buzzer reminder function ×××××

Auto door lock function ×× ××× ×××

Panic alarm function ×××× ××× ×××

WIIA1282E

Revision: May 2010 2011 Versa