NISSAN LATIO 2011 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 3221 of 3787

MA-50

< SERVICE INFORMATION >

CHASSIS AND BODY MAINTENANCE

• If any component of the seat belt assembly is suspected of being damaged or not operating prop-

erly, do not repair the component. Replace the components as an assembly.

• If the seat belt webbing is cut, frayed, or damaged then replace the seat belt assembly.

• Never lubricate the seat belt buckle or tongue.

• When replacing any seat belt assembly al ways use a Genuine NISSAN seat belt assembly.

Revision: May 2010 2011 Versa

Page 3222 of 3787

MT-1

TRANSMISSION/TRANSAXLE

DE

F

G H

I

J

K L

M

SECTION MT

A

B

MT

N

O P

CONTENTS

MANUAL TRANSAXLE

RS5F91R

SERVICE INFORMATION .. ..........................

3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

Precaution for Procedure without Cowl Top Cover ......4

Service Notice or Precaution .....................................4

PREPARATION ...................................................5

Special Service Tools ........................................ ......5

Commercial Service Tools .......................................7

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

8

NVH Troubleshooting Chart ................................ ......8

DESCRIPTION ....................................................9

System Diagram .................................................. ......9

System Description ...................................................9

M/T OIL ...............................................................11

Draining ...................................................................11

Refilling ...................................................................11

Inspection ................................................................11

SIDE OIL SEAL ..................................................12

Removal and Installation .........................................12

POSITION SWITCH ........................................ ....13

Checking ............................................................. ....13

CONTROL LINKAGE .........................................14

Exploded View .................................................... ....14

Removal and Installation .........................................14

Inspection ............................................................ ....15

AIR BREATHER HOSE ......................................16

Exploded View .................................................... ....16

Removal and Installation ..................................... ....16

TRANSAXLE ASSEMBLY ................................17

Exploded View .........................................................17

Removal and Installation .........................................17

Disassembly and Assembly .....................................18

INPUT SHAFT AND GEAR ...............................36

Disassembly and Assembly .....................................36

MAINSHAFT AND GEAR .................................37

Disassembly and Assembly .....................................37

FINAL DRIVE ....................................................41

Disassembly and Assembly .....................................41

SHIFT CONTROL ..............................................42

Inspection ................................................................42

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

43

General Specification ..............................................43

RS6F94R

SERVICE INFORMATION .. .........................

44

PRECAUTIONS .................................................44

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

44

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

44

Precaution for Procedure without Cowl Top Cover ....45

Precaution ...............................................................45

PREPARATION .................................................46

Special Service Tool ................................................46

Commercial Service Tool ........................................48

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ...........................

51

NVH Troubleshooting Chart ....................................51

Revision: May 2010 2011 Versa

Page 3223 of 3787

MT-2

DESCRIPTION ...................................................52

Cross-Sectional View .......................................... ...52

M/T OIL ..............................................................54

Changing M/T Oil ................................................. ...54

Checking M/T Oil ....................................................54

VEHICLE SPEED SENSOR ..............................55

Removal and Installation ..................................... ...55

SIDE OIL SEAL .................................................56

Removal and Installation ..................................... ...56

POSITION SWITCH ...........................................57

Checking .............................................................. ...57

CONTROL LINKAGE ........................................58

Component of Control Device and Cable ............ ...58

Removal and Installation ........................................58

AIR BREATHER HOSE .....................................60

Removal and Installation ..................................... ...60

TRANSAXLE ASSEMBLY ................................61

Component .......................................................... ...61

Removal and Installation .........................................61

Disassembly and Assembly ................................. ...62

INPUT SHAFT AND GEARS .............................80

Disassembly and Assembly ................................. ...80

MAINSHAFT AND GEARS ...............................85

Disassembly and Assembly ................................. ...85

REVERSE IDLER SHAFT AND GEARS ...........90

Disassembly and Assembly ................................. ...90

FINAL DRIVE .....................................................92

Disassembly and Assembly ....................................92

SHIFT CONTROL ..............................................94

Inspection ............................................................. ...94

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

95

General Specification ........................................... ...95

Revision: May 2010 2011 Versa

Page 3224 of 3787

![NISSAN LATIO 2011 Service Repair Manual PRECAUTIONSMT-3

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TEN NISSAN LATIO 2011 Service Repair Manual PRECAUTIONSMT-3

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TEN](/img/5/57357/w960_57357-3223.png)

PRECAUTIONSMT-3

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005929653

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005929654

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 3225 of 3787

![NISSAN LATIO 2011 Service Repair Manual MT-4

< SERVICE INFORMATION >[RS5F91R]

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the NISSAN LATIO 2011 Service Repair Manual MT-4

< SERVICE INFORMATION >[RS5F91R]

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the](/img/5/57357/w960_57357-3224.png)

MT-4

< SERVICE INFORMATION >[RS5F91R]

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of a ll control units using CONSULT-III.

Precaution for Procedure without Cowl Top CoverINFOID:0000000005929655

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Service Notice or PrecautionINFOID:0000000005929656

•Use recommended brake fluid when adding flui d to the clutch reservoir tank. Refer to MA-14.

• Never reuse fluid drained from clutch system.

• Be careful not to splash brake fluid on painted areas.

• Use new brake fluid to clean or wash all part s of master cylinder and operating cylinder.

• Never use mineral oils such as gasoline or kerosene. It will ruin the rubber parts of the hydraulic sys-

tem.

• If transaxle assembly is removed from the vehicle , always replace CSC (Concentric slave cylinder).

Return CSC to original position to remove transaxle assembly. Dust on clutch disc sliding parts may

damage CSC seal and may cause clutch fluid leakage.

• Do not disassemble clutch master cylinder and CSC.

WARNING:

After cleaning clutch disc, clean it with a dust collector. Do not use compressed air.

PIIB3706J

Revision: May 2010 2011 Versa

Page 3226 of 3787

![NISSAN LATIO 2011 Service Repair Manual PREPARATIONMT-5

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

PREPARATION

Special Service ToolsINFOID:0000000005929657

The actual shapes of tools may differ from those of special NISSAN LATIO 2011 Service Repair Manual PREPARATIONMT-5

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

PREPARATION

Special Service ToolsINFOID:0000000005929657

The actual shapes of tools may differ from those of special](/img/5/57357/w960_57357-3225.png)

PREPARATIONMT-5

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

PREPARATION

Special Service ToolsINFOID:0000000005929657

The actual shapes of tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name Description

—

( J-46534 )

Trim tool set For removing trim

KV32500QAA

(—)

(Renault SST: B.vi 1666)

Drift set Installing differential side oil seal

1. ( – )

(Stamping number: B.vi 1666-A)

Drift

a: 54.3 mm (2.138 in) dia

b: 45 mm (1.77 in) dia

c: 26.6 mm (1.047 in) dia

2. ( – )

(Stamping number: B.vi 1666-B)

Drift

a: 54 mm (2.13 in) dia

b: 48.6 mm (1.913 in) dia

c: 26.6 mm (1.047 in) dia

KV32300QAC

(—)

Puller Removing 5th main gear

KV32300QAD

(—)

Puller Removing 5th main gear

ST35300000

(—)

Drift • Removing and installing input shaft rear

bearing

• Removing and installing mainshaft rear bearing

a: 45 mm (1.77 in) dia.

b: 59 mm (2.23 in) dia.

AWJIA0483ZZ

JPDIC0730ZZ

SCIA1781J

SCIA1782J

ZZA0969D

Revision: May 2010 2011 Versa

Page 3227 of 3787

![NISSAN LATIO 2011 Service Repair Manual MT-6

< SERVICE INFORMATION >[RS5F91R]

PREPARATION

K V 111 0 11 S 0

(—)

Va l v e s e a t r e m o v e rRemoving mainshaft front bearing

ST33400001

(J-26082)

Drift Installing mainshaft front bearing

NISSAN LATIO 2011 Service Repair Manual MT-6

< SERVICE INFORMATION >[RS5F91R]

PREPARATION

K V 111 0 11 S 0

(—)

Va l v e s e a t r e m o v e rRemoving mainshaft front bearing

ST33400001

(J-26082)

Drift Installing mainshaft front bearing](/img/5/57357/w960_57357-3226.png)

MT-6

< SERVICE INFORMATION >[RS5F91R]

PREPARATION

K V 111 0 11 S 0

(—)

Va l v e s e a t r e m o v e rRemoving mainshaft front bearing

ST33400001

(J-26082)

Drift Installing mainshaft front bearing

a: 60 mm (2.36 in) dia.

a: 47 mm (1.85 in) dia.

KV40100900

(—)

Drift Installing input shaft front bearing

a: 52 mm (2.05 in) dia.

a: 39.5 mm (1.55 in) dia.

KV32300QAE

(—)

Drift Installing differential side bearing outer race

a: 65 mm (2.56 in) dia.

a: 63 mm (2.48 in) dia.

ST33052000

(—)

Drift Removing differential side bearing

a: 22 mm (0.87 in) dia.

a: 28 mm (1.10 in) dia.

KV40104920

(—)

Drift Installing differential side bearing

a: 21.7 mm (0.85 in) dia.

a: 44.7 mm (1.76 in) dia.

Tool number

(Kent-Moore No.)

Tool name

Description

ZZA0872D

ZZA0814D

NT084

SCIA1783J

ZZA0969D

ZZA0969D

Revision: May 2010

2011 Versa

Page 3228 of 3787

![NISSAN LATIO 2011 Service Repair Manual PREPARATIONMT-7

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

Commercial Service ToolsINFOID:0000000005929658

Tool name Description

Drift Removing input shaft front bearing

a: 38 NISSAN LATIO 2011 Service Repair Manual PREPARATIONMT-7

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

Commercial Service ToolsINFOID:0000000005929658

Tool name Description

Drift Removing input shaft front bearing

a: 38](/img/5/57357/w960_57357-3227.png)

PREPARATIONMT-7

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

Commercial Service ToolsINFOID:0000000005929658

Tool name Description

Drift Removing input shaft front bearing

a: 38 mm (1.50 in) dia.

Drift Installing bushing

a: 14.5 mm (0.571 in) dia.

Socket Removing and installing drain plug

a: 8 mm (0.31 in)

b: 5 mm (0.20 in)

Puller • Removing 5th-reverse synchronizer hub

• Removing differential side bearing

Bearing remover Removing bushing

S-NT063

S-NT063

PCIB1776E

NT077

S-NT134

Revision: May 2010 2011 Versa

Page 3229 of 3787

![NISSAN LATIO 2011 Service Repair Manual MT-8

< SERVICE INFORMATION >[RS5F91R]

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000005929659

Use th NISSAN LATIO 2011 Service Repair Manual MT-8

< SERVICE INFORMATION >[RS5F91R]

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000005929659

Use th](/img/5/57357/w960_57357-3228.png)

MT-8

< SERVICE INFORMATION >[RS5F91R]

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000005929659

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

Reference pageMT-18MT-18MT-14MT-18MT-18

SUSPECTED PARTS

(Possible cause)

OIL (Oil level is low.)

OIL (Wrong oil.)

OIL (Oil level is high.)

GASKET (Damaged)

OIL SEAL (Worn or damaged)

O-RING (Worn or damaged)

SHIFT CONTROL LINKAGE (Worn)

SHIFT FORK (Worn)

GEAR (Worn or damaged)

BEARING (Worn or damaged)

BAULK RING (Worn or damaged)

INSERT SPRING (Damaged)

SymptomsNoise

1 2 3 3

Oil leakage 31222

Hard to shift or will not shift 1 123 3

Jumps out of gear 1 2 2

Revision: May 2010 2011 Versa

Page 3230 of 3787

![NISSAN LATIO 2011 Service Repair Manual DESCRIPTIONMT-9

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

DESCRIPTION

System DiagramINFOID:0000000005929660

CROSS-SECTIONAL VIEW

System DescriptionINFOID:0000000005929661

DOUB NISSAN LATIO 2011 Service Repair Manual DESCRIPTIONMT-9

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

DESCRIPTION

System DiagramINFOID:0000000005929660

CROSS-SECTIONAL VIEW

System DescriptionINFOID:0000000005929661

DOUB](/img/5/57357/w960_57357-3229.png)

DESCRIPTIONMT-9

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

DESCRIPTION

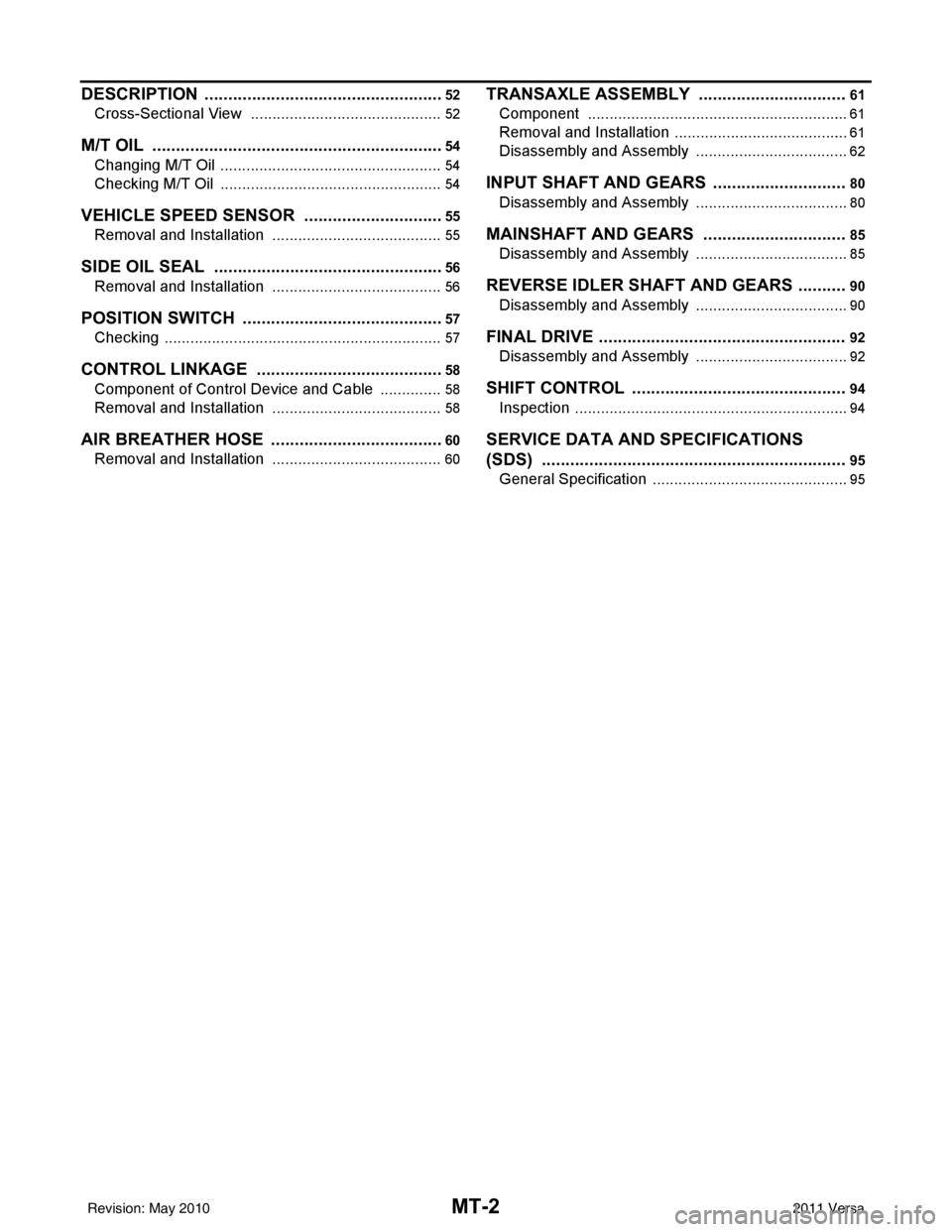

System DiagramINFOID:0000000005929660

CROSS-SECTIONAL VIEW

System DescriptionINFOID:0000000005929661

DOUBLE-CONE SYNCHRONIZER

1. Clutch housing 2. 1st-2nd synchronizer hub assembly 3. 3rd-4th synchronizer hub assembly

4. 5th input gear 5. 5th-reverse synchronizer hub assembly 6. 5th-reverse baulk ring

7. 5th main gear 8. 4th main gear 9. 3rd main gear

10. 2nd main gear 11. 2nd double cone synchronizer 12. 1st double cone synchronizer

13. 1st main gear 14. Differential side bearing 15. Differential

16. Final gear 17. Mainshaft 18. Input shaft

JPDIC0580ZZ

Revision: May 2010 2011 Versa