NISSAN LATIO 2011 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 3211 of 3787

MA-40

< SERVICE INFORMATION >

CHASSIS AND BODY MAINTENANCE

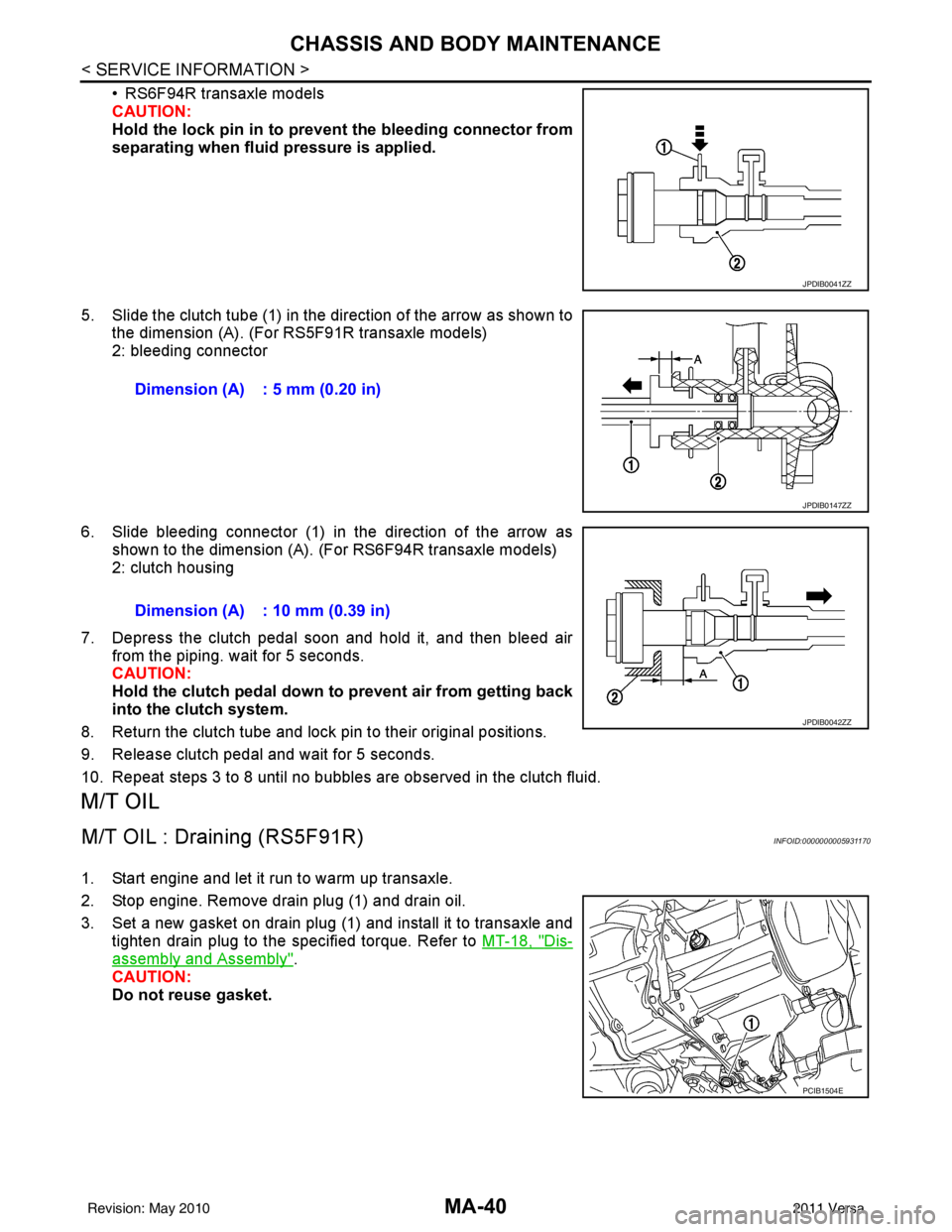

• RS6F94R transaxle models

CAUTION:

Hold the lock pin in to prevent the bleeding connector from

separating when fluid pressure is applied.

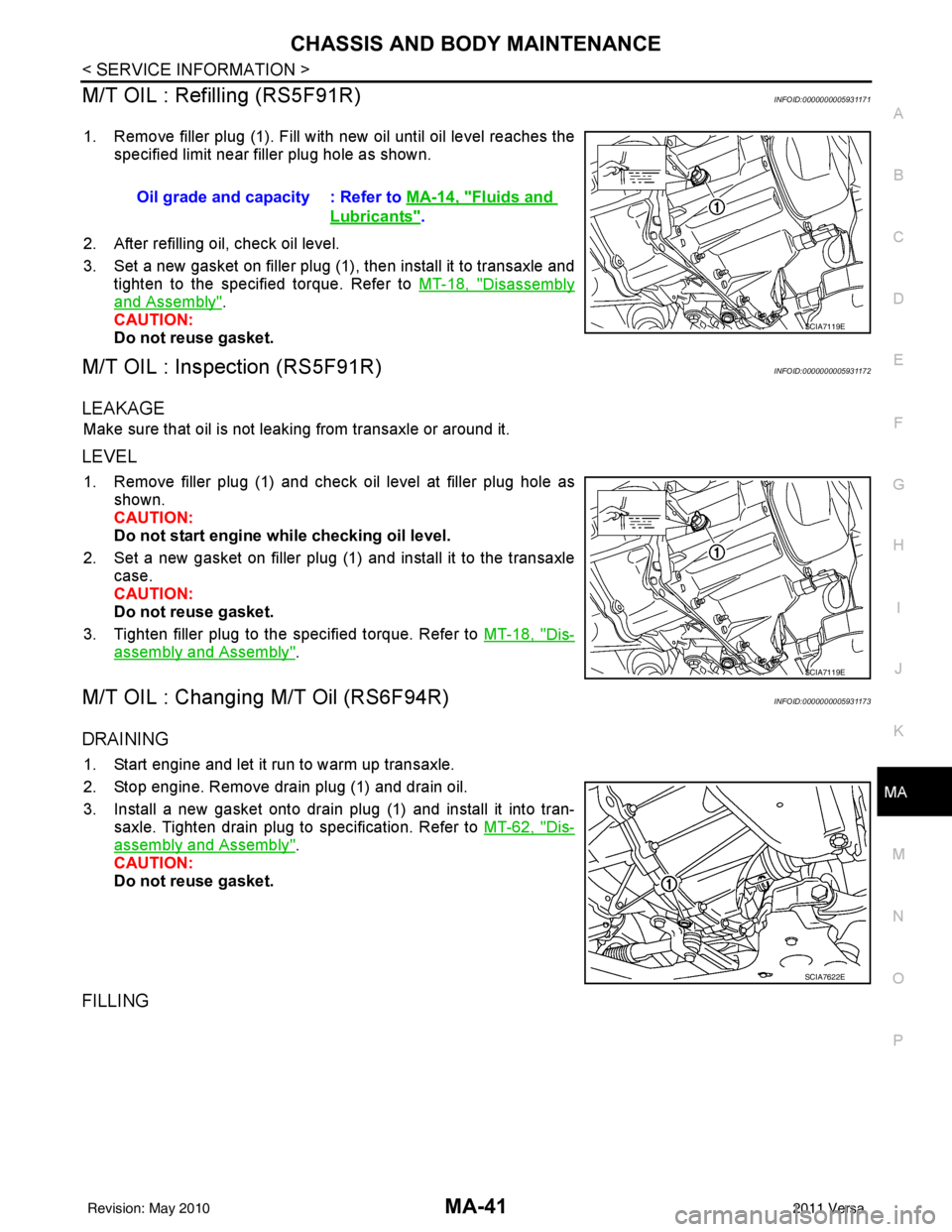

5. Slide the clutch tube (1) in the direction of the arrow as shown to the dimension (A). (For RS5F91R transaxle models)

2: bleeding connector

6. Slide bleeding connector (1) in the direction of the arrow as shown to the dimension (A). (For RS6F94R transaxle models)

2: clutch housing

7. Depress the clutch pedal soon and hold it, and then bleed air from the piping. wait for 5 seconds.

CAUTION:

Hold the clutch pedal down to prevent air from getting back

into the clutch system.

8. Return the clutch tube and lock pin to their original positions.

9. Release clutch pedal and wait for 5 seconds.

10. Repeat steps 3 to 8 until no bubbles are observed in the clutch fluid.

M/T OIL

M/T OIL : Draining (RS5F91R)INFOID:0000000005931170

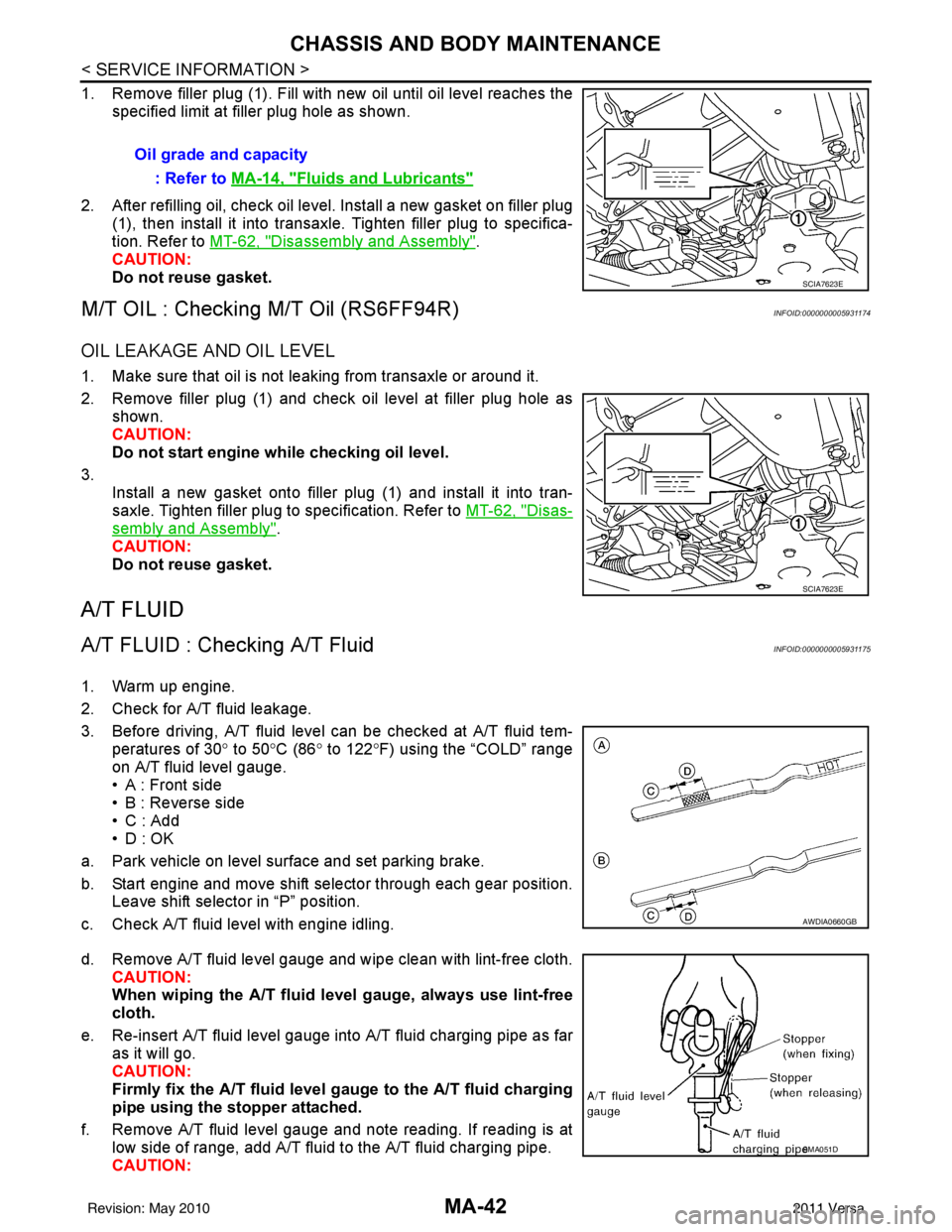

1. Start engine and let it run to warm up transaxle.

2. Stop engine. Remove drain plug (1) and drain oil.

3. Set a new gasket on drain plug (1) and install it to transaxle and tighten drain plug to the specified torque. Refer to MT-18, "

Dis-

assembly and Assembly".

CAUTION:

Do not reuse gasket.

JPDIB0041ZZ

Dimension (A) : 5 mm (0.20 in)

JPDIB0147ZZ

Dimension (A) : 10 mm (0.39 in)

JPDIB0042ZZ

PCIB1504E

Revision: May 2010 2011 Versa

Page 3212 of 3787

CHASSIS AND BODY MAINTENANCEMA-41

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

M/T OIL : Refilling (RS5F91R)INFOID:0000000005931171

1. Remove filler plug (1). Fill with new oil until oil level reaches the specified limit near filler plug hole as shown.

2. After refilling oil, check oil level.

3. Set a new gasket on filler plug (1), then install it to transaxle and tighten to the specified torque. Refer to MT-18, "

Disassembly

and Assembly".

CAUTION:

Do not reuse gasket.

M/T OIL : Inspection (RS5F91R)INFOID:0000000005931172

LEAKAGE

Make sure that oil is not leaking from transaxle or around it.

LEVEL

1. Remove filler plug (1) and check oil level at filler plug hole as shown.

CAUTION:

Do not start engine while checking oil level.

2. Set a new gasket on filler plug (1) and install it to the transaxle case.

CAUTION:

Do not reuse gasket.

3. Tighten filler plug to the specified torque. Refer to MT-18, "

Dis-

assembly and Assembly".

M/T OIL : Changing M/T Oil (RS6F94R)INFOID:0000000005931173

DRAINING

1. Start engine and let it run to warm up transaxle.

2. Stop engine. Remove drain plug (1) and drain oil.

3. Install a new gasket onto drain plug (1) and install it into tran-

saxle. Tighten drain plug to specification. Refer to MT-62, "

Dis-

assembly and Assembly".

CAUTION:

Do not reuse gasket.

FILLING

Oil grade and capacity : Refer to MA-14, "Fluids and

Lubricants".

SCIA7119E

SCIA7119E

SCIA7622E

Revision: May 2010 2011 Versa

Page 3213 of 3787

MA-42

< SERVICE INFORMATION >

CHASSIS AND BODY MAINTENANCE

1. Remove filler plug (1). Fill with new oil until oil level reaches thespecified limit at filler plug hole as shown.

2. After refilling oil, check oil level. Install a new gasket on filler plug (1), then install it into transaxle. Tighten filler plug to specifica-

tion. Refer to MT-62, "

Disassembly and Assembly".

CAUTION:

Do not reuse gasket.

M/T OIL : Checking M/T Oil (RS6FF94R)INFOID:0000000005931174

OIL LEAKAGE AND OIL LEVEL

1. Make sure that oil is not leaking from transaxle or around it.

2. Remove filler plug (1) and check oil level at filler plug hole as shown.

CAUTION:

Do not start engine wh ile checking oil level.

3. Install a new gasket onto filler plug (1) and install it into tran-

saxle. Tighten filler plug to specification. Refer to MT-62, "

Disas-

sembly and Assembly".

CAUTION:

Do not reuse gasket.

A/T FLUID

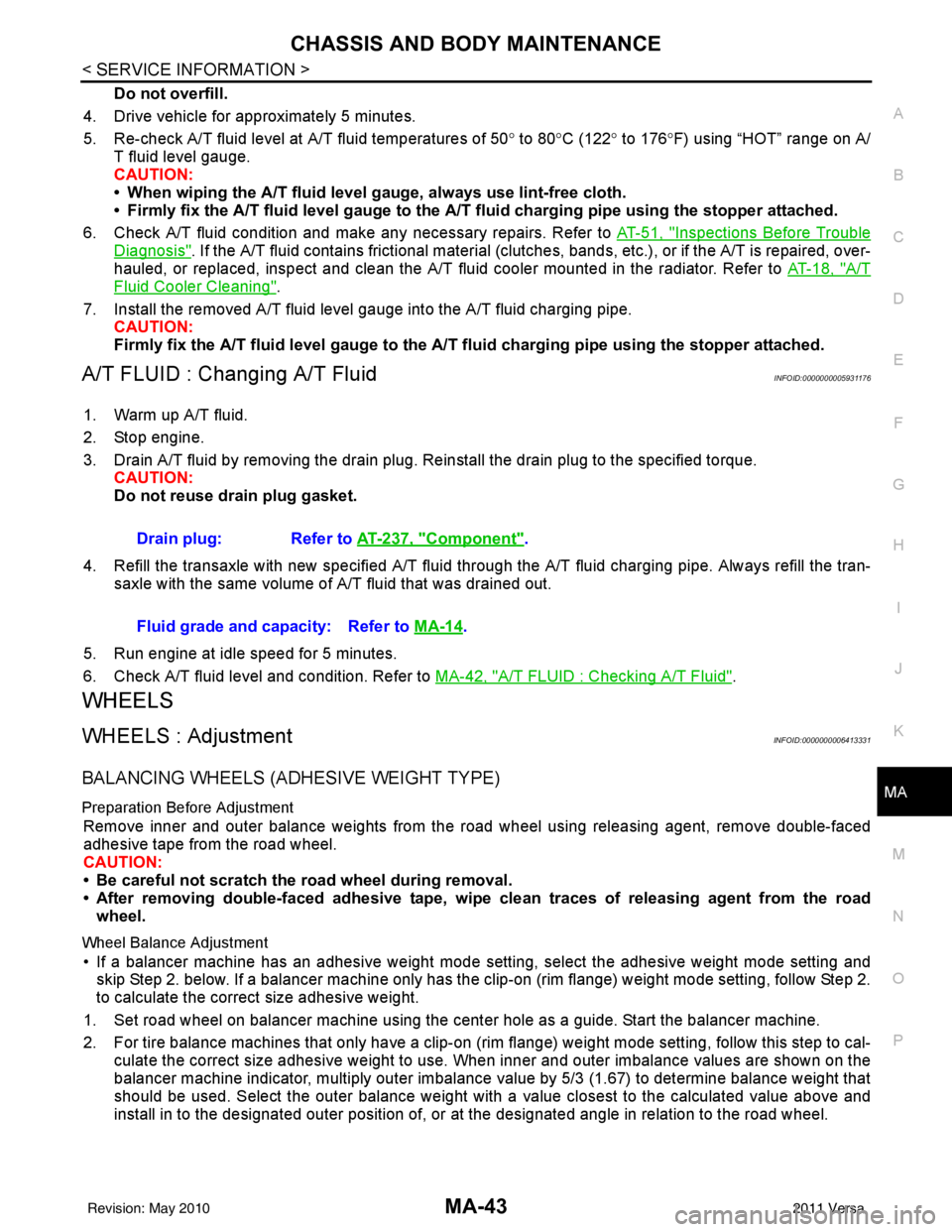

A/T FLUID : Checking A/T FluidINFOID:0000000005931175

1. Warm up engine.

2. Check for A/T fluid leakage.

3. Before driving, A/T fluid level can be checked at A/T fluid tem- peratures of 30 ° to 50 °C (86° to 122° F) using the “COLD” range

on A/T fluid level gauge.

• A : Front side

• B : Reverse side

• C : Add

• D : OK

a. Park vehicle on level surface and set parking brake.

b. Start engine and move shift selector through each gear position. Leave shift selector in “P” position.

c. Check A/T fluid level with engine idling.

d. Remove A/T fluid level gauge and wipe clean with lint-free cloth. CAUTION:

When wiping the A/T fluid level gauge, always use lint-free

cloth.

e. Re-insert A/T fluid level gauge into A/T fluid charging pipe as far as it will go.

CAUTION:

Firmly fix the A/T fluid level gauge to the A/T fluid charging

pipe using the stopper attached.

f. Remove A/T fluid level gauge and note reading. If reading is at low side of range, add A/T fluid to the A/T fluid charging pipe.

CAUTION:Oil grade and capacity

: Refer to MA-14, "

Fluids and Lubricants"

SCIA7623E

SCIA7623E

AWDIA0660GB

SMA051D

Revision: May 2010 2011 Versa

Page 3214 of 3787

CHASSIS AND BODY MAINTENANCEMA-43

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

Do not overfill.

4. Drive vehicle for approximately 5 minutes.

5. Re-check A/T fluid level at A/T fluid temperatures of 50° to 80 °C (122° to 176°F) using “HOT” range on A/

T fluid level gauge.

CAUTION:

• When wiping the A/T fluid level gauge, always use lint-free cloth.

• Firmly fix the A/T fluid level ga uge to the A/T fluid charging pipe using the stopper attached.

6. Check A/T fluid condition and make any necessary repairs. Refer to AT-51, "

Inspections Before Trouble

Diagnosis". If the A/T fluid contains frictional material (clutches, bands, etc.), or if the A/T is repaired, over-

hauled, or replaced, inspect and clean the A/T fluid cooler mounted in the radiator. Refer to AT-18, "

A/T

Fluid Cooler Cleaning".

7. Install the removed A/T fluid level gauge into the A/T fluid charging pipe. CAUTION:

Firmly fix the A/T fluid level gaug e to the A/T fluid charging pipe using the stopper attached.

A/T FLUID : Changing A/T FluidINFOID:0000000005931176

1. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid by removing the drain plug. Re install the drain plug to the specified torque.

CAUTION:

Do not reuse drain plug gasket.

4. Refill the transaxle with new specified A/T fluid through the A/T fluid charging pipe. Always refill the tran- saxle with the same volume of A/T fluid that was drained out.

5. Run engine at idle speed for 5 minutes.

6. Check A/T fluid level and condition. Refer to MA-42, "

A/T FLUID : Checking A/T Fluid".

WHEELS

WHEELS : AdjustmentINFOID:0000000006413331

BALANCING WHEELS (ADHESIVE WEIGHT TYPE)

Preparation Before Adjustment

Remove inner and outer balance weights from the r oad wheel using releasing agent, remove double-faced

adhesive tape from the road wheel.

CAUTION:

• Be careful not scratch the road wheel during removal.

• After removing double-faced adhesive tape, wipe clean traces of releasing agent from the road

wheel.

Wheel Balance Adjustment

• If a balancer machine has an adhesive weight mode setting, select the adhesive weight mode setting and skip Step 2. below. If a balancer machine only has the clip-on (rim flange) weight mode setting, follow Step 2.

to calculate the correct size adhesive weight.

1. Set road wheel on balancer machine using the cent er hole as a guide. Start the balancer machine.

2. For tire balance machines that only have a clip-on (ri m flange) weight mode setting, follow this step to cal-

culate the correct size adhesive weight to use. When inner and outer imbalance values are shown on the

balancer machine indicator, multiply outer imbalance value by 5/3 (1.67) to determine balance weight that

should be used. Select the outer balance weight with a value closest to the calculated value above and

install in to the designated outer position of, or at the designated angle in relation to the road wheel.

Drain plug: Refer to

AT-237, "

Component".

Fluid grade and capacity: Refer to MA-14

.

Revision: May 2010 2011 Versa

Page 3215 of 3787

MA-44

< SERVICE INFORMATION >

CHASSIS AND BODY MAINTENANCE

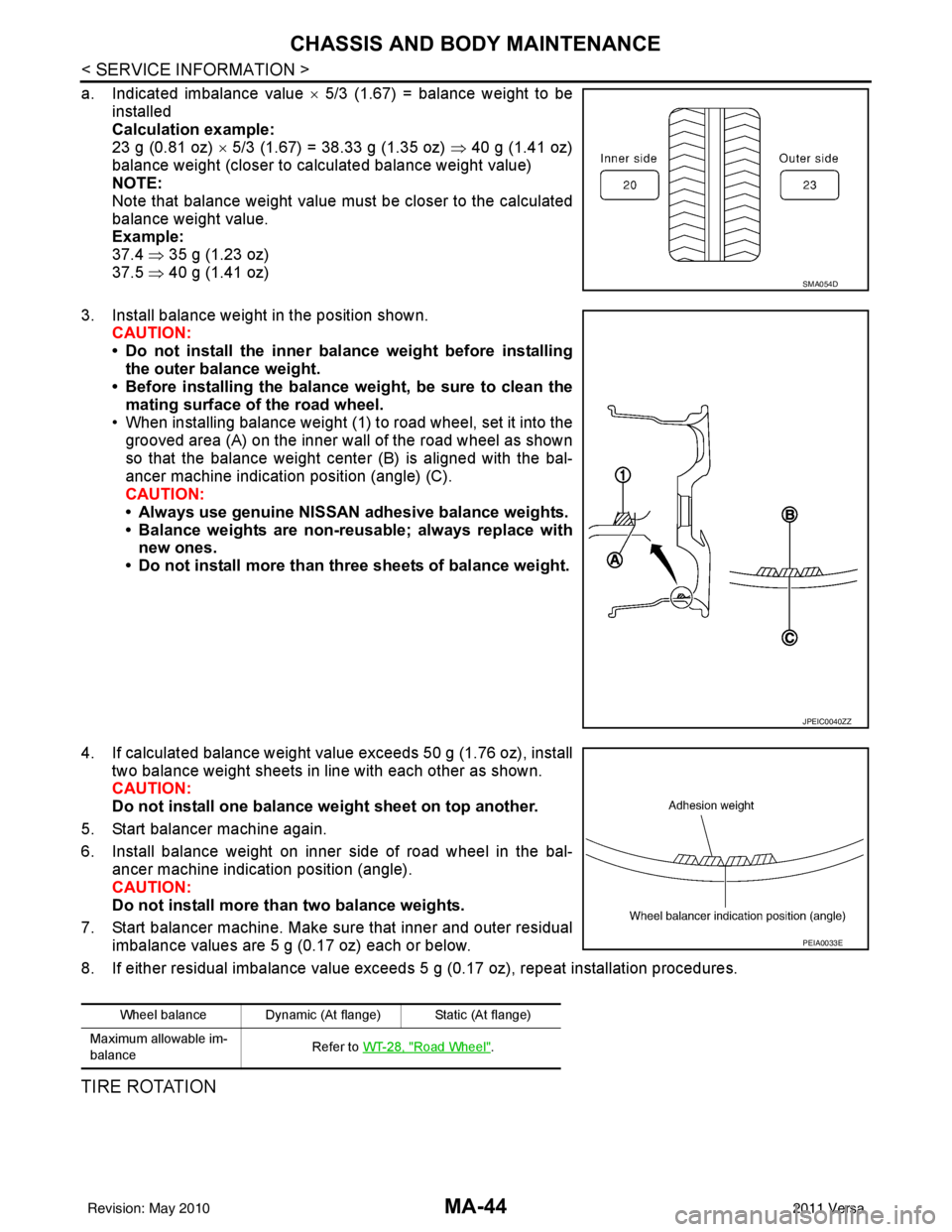

a. Indicated imbalance value × 5/3 (1.67) = balance weight to be

installed

Calculation example:

23 g (0.81 oz) × 5/3 (1.67) = 38.33 g (1.35 oz) ⇒ 40 g (1.41 oz)

balance weight (closer to calculated balance weight value)

NOTE:

Note that balance weight value must be closer to the calculated

balance weight value.

Example:

37.4 ⇒ 35 g (1.23 oz)

37.5 ⇒ 40 g (1.41 oz)

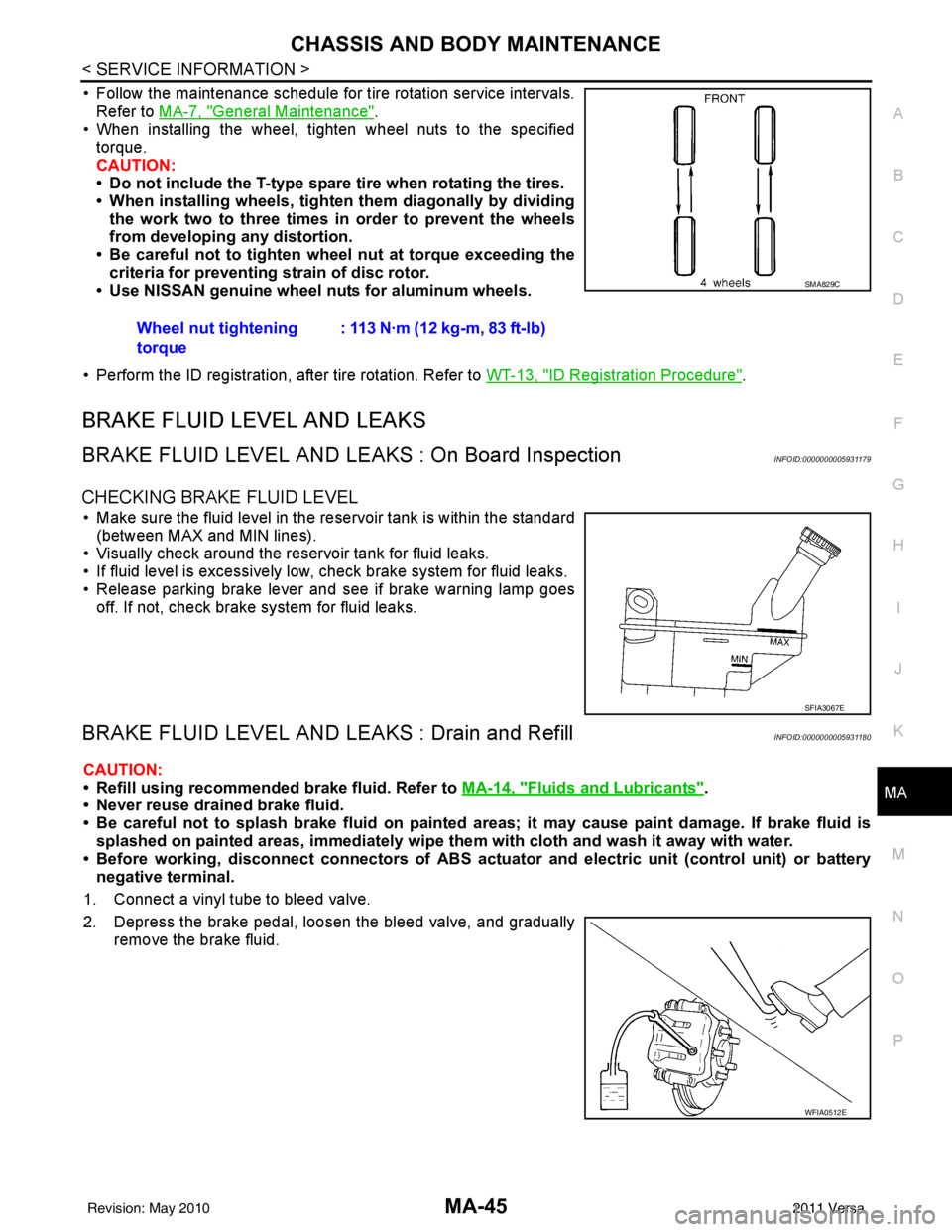

3. Install balance weight in the position shown. CAUTION:

• Do not install the inner bala nce weight before installing

the outer balance weight.

• Before installing the balance weight, be sure to clean the

mating surface of the road wheel.

• When installing balance weight (1) to road wheel, set it into the grooved area (A) on the inner wall of the road wheel as shown

so that the balance weight center (B) is aligned with the bal-

ancer machine indication position (angle) (C).

CAUTION:

• Always use genuine NISSAN adhesive balance weights.

• Balance weights are non-reusable; always replace withnew ones.

• Do not install more than three sheets of balance weight.

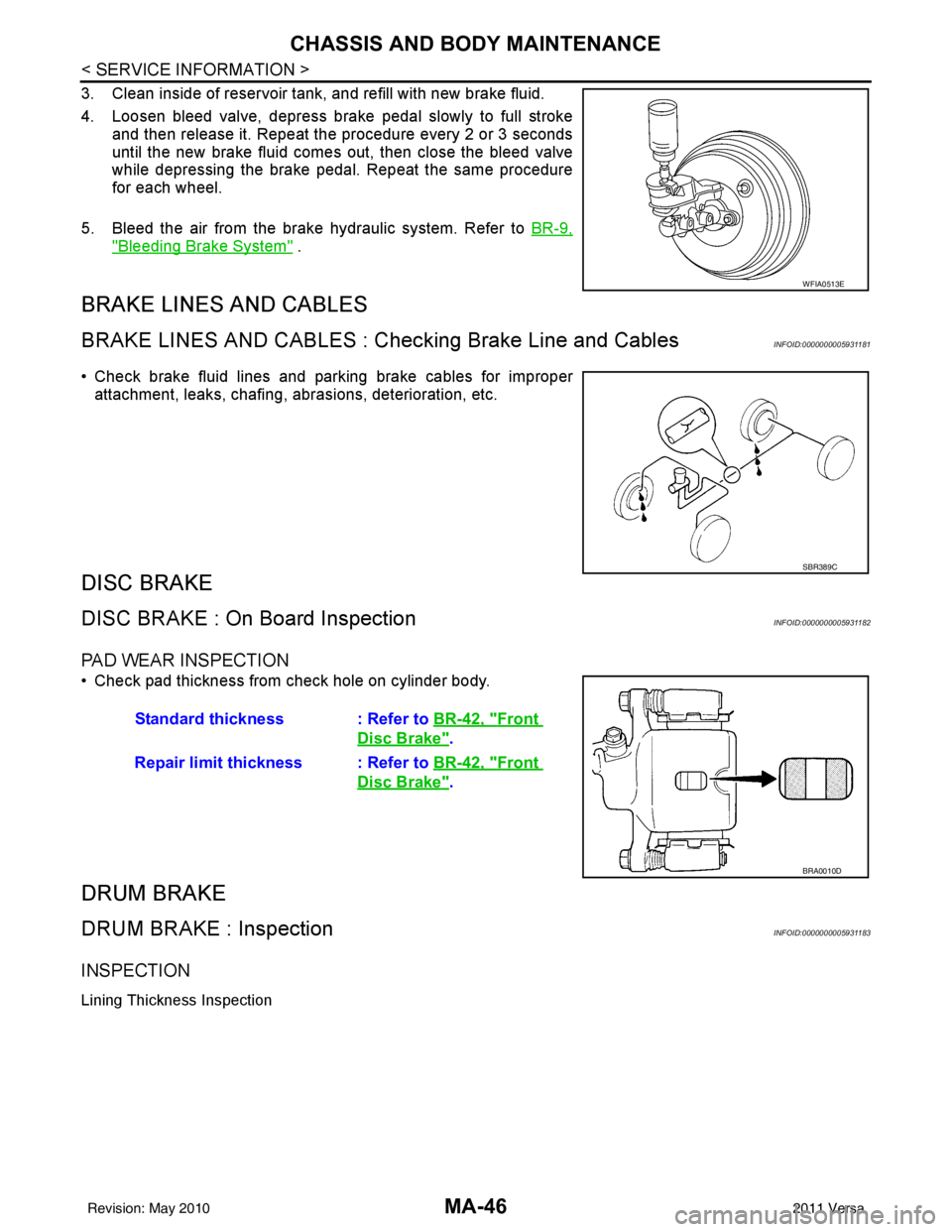

4. If calculated balance weight value exceeds 50 g (1.76 oz), install two balance weight sheets in line with each other as shown.

CAUTION:

Do not install one balance weight sheet on top another.

5. Start balancer machine again.

6. Install balance weight on inner side of road wheel in the bal- ancer machine indication position (angle).

CAUTION:

Do not install more than two balance weights.

7. Start balancer machine. Make sure that inner and outer residual imbalance values are 5 g (0.17 oz) each or below.

8. If either residual imbalance value exceeds 5 g (0.17 oz), repeat installation procedures.

TIRE ROTATION

SMA054D

JPEIC0040ZZ

Wheel balance Dynamic (At flange) Static (At flange)

Maximum allowable im-

balance Refer to

WT-28, "

Road Wheel".

PEIA0033E

Revision: May 2010 2011 Versa

Page 3216 of 3787

CHASSIS AND BODY MAINTENANCEMA-45

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

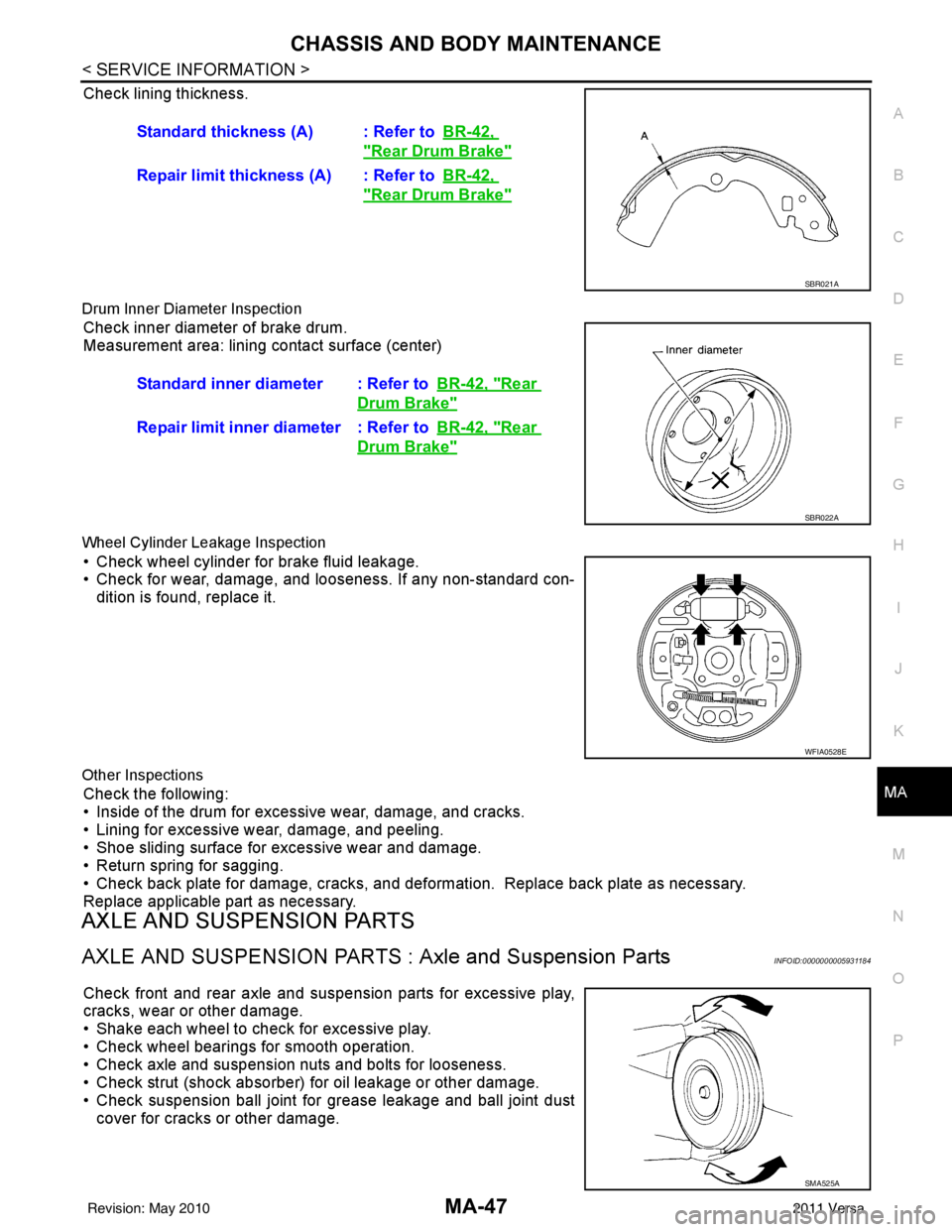

• Follow the maintenance schedule for tire rotation service intervals. Refer to MA-7, "

General Maintenance".

• When installing the wheel, tighten wheel nuts to the specified

torque.

CAUTION:

• Do not include the T-type spare tire when rotating the tires.

• When installing wheels, tighte n them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

• Be careful not to tighten wh eel nut at torque exceeding the

criteria for preventing strain of disc rotor.

• Use NISSAN genuine wheel nuts for aluminum wheels.

• Perform the ID registration, after tire rotation. Refer to WT-13, "

ID Registration Procedure".

BRAKE FLUID LEVEL AND LEAKS

BRAKE FLUID LEVEL AND LEAKS : On Board InspectionINFOID:0000000005931179

CHECKING BRAKE FLUID LEVEL

• Make sure the fluid level in the reservoir tank is within the standard

(between MAX and MIN lines).

• Visually check around the reservoir tank for fluid leaks.

• If fluid level is excessively low, check brake system for fluid leaks.

• Release parking brake lever and see if brake warning lamp goes off. If not, check brake system for fluid leaks.

BRAKE FLUID LEVEL AND LEAKS : Drain and RefillINFOID:0000000005931180

CAUTION:

• Refill using recommended brake fluid. Refer to MA-14, "

Fluids and Lubricants".

• Never reuse drained brake fluid.

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, immediately wipe th em with cloth and wash it away with water.

• Before working, disconnect connect ors of ABS actuator and electric unit (control unit) or battery

negative terminal.

1. Connect a vinyl tube to bleed valve.

2. Depress the brake pedal, loosen the bleed valve, and gradually remove the brake fluid.Wheel nut tightening

torque

: 113 N·m (12 kg-m, 83 ft-lb)

SMA829C

SFIA3067E

WFIA0512E

Revision: May 2010

2011 Versa

Page 3217 of 3787

MA-46

< SERVICE INFORMATION >

CHASSIS AND BODY MAINTENANCE

3. Clean inside of reservoir tank, and refill with new brake fluid.

4. Loosen bleed valve, depress brake pedal slowly to full strokeand then release it. Repeat the procedure every 2 or 3 seconds

until the new brake fluid comes out, then close the bleed valve

while depressing the brake pedal. Repeat the same procedure

for each wheel.

5. Bleed the air from the brake hydraulic system. Refer to BR-9,

"Bleeding Brake System" .

BRAKE LINES AND CABLES

BRAKE LINES AND CABLES : Ch ecking Brake Line and CablesINFOID:0000000005931181

• Check brake fluid lines and parking brake cables for improper

attachment, leaks, chafing, abrasions, deterioration, etc.

DISC BRAKE

DISC BRAKE : On Board InspectionINFOID:0000000005931182

PAD WEAR INSPECTION

• Check pad thickness from check hole on cylinder body.

DRUM BRAKE

DRUM BRAKE : InspectionINFOID:0000000005931183

INSPECTION

Lining Thickness Inspection

WFIA0513E

SBR389C

Standard thickness : Refer to BR-42, "Front

Disc Brake".

Repair limit thickness : Refer to BR-42, "

Front

Disc Brake".

BRA0010D

Revision: May 2010 2011 Versa

Page 3218 of 3787

CHASSIS AND BODY MAINTENANCEMA-47

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

Check lining thickness.

Drum Inner Diameter Inspection

Check inner diameter of brake drum.

Measurement area: lining contact surface (center)

Wheel Cylinder Leakage Inspection

• Check wheel cylinder for brake fluid leakage.

• Check for wear, damage, and looseness. If any non-standard con- dition is found, replace it.

Other Inspections

Check the following:

• Inside of the drum for excessive wear, damage, and cracks.

• Lining for excessive wear, damage, and peeling.

• Shoe sliding surface for excessive wear and damage.

• Return spring for sagging.

• Check back plate for damage, cracks, and deformation. Replace back plate as necessary.

Replace applicable part as necessary.

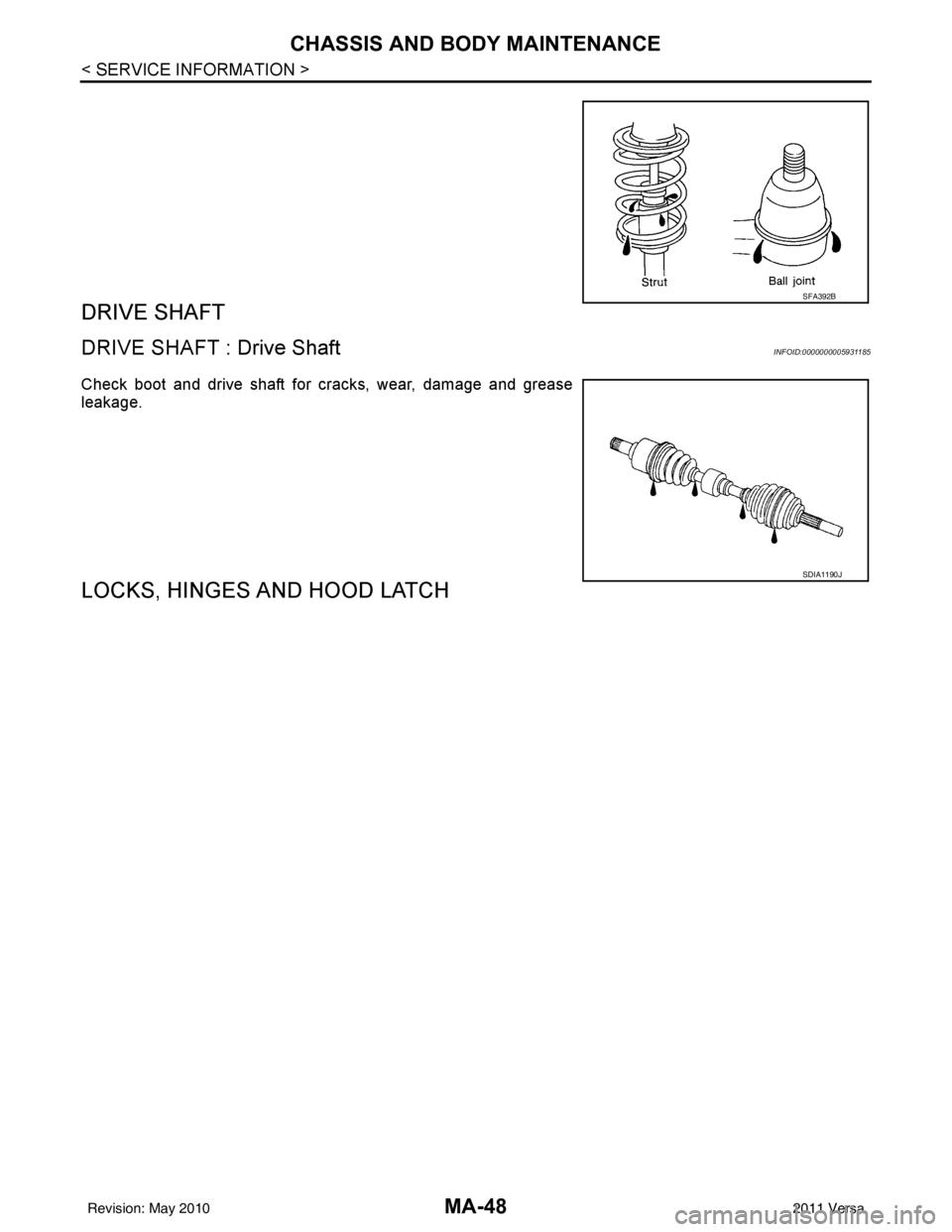

AXLE AND SUSPENSION PARTS

AXLE AND SUSPENSION PARTS : Axle and Suspension PartsINFOID:0000000005931184

Check front and rear axle and suspension parts for excessive play,

cracks, wear or other damage.

• Shake each wheel to check for excessive play.

• Check wheel bearings for smooth operation.

• Check axle and suspension nuts and bolts for looseness.

• Check strut (shock absorber) for oil leakage or other damage.

• Check suspension ball joint for grease leakage and ball joint dust

cover for cracks or other damage. Standard thickness (A) : Refer to

BR-42,

"Rear Drum Brake"

Repair limit thickness (A) : Refer toBR-42,

"Rear Drum Brake"

SBR021A

Standard inner diameter : Refer toBR-42, "Rear

Drum Brake"

Repair limit inner diameter : Refer toBR-42, "Rear

Drum Brake"

SBR022A

WFIA0528E

SMA525A

Revision: May 2010 2011 Versa

Page 3219 of 3787

MA-48

< SERVICE INFORMATION >

CHASSIS AND BODY MAINTENANCE

DRIVE SHAFT

DRIVE SHAFT : Drive ShaftINFOID:0000000005931185

Check boot and drive shaft for cracks, wear, damage and grease

leakage.

LOCKS, HINGES AND HOOD LATCH

SFA392B

SDIA1190J

Revision: May 2010 2011 Versa

Page 3220 of 3787

CHASSIS AND BODY MAINTENANCEMA-49

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

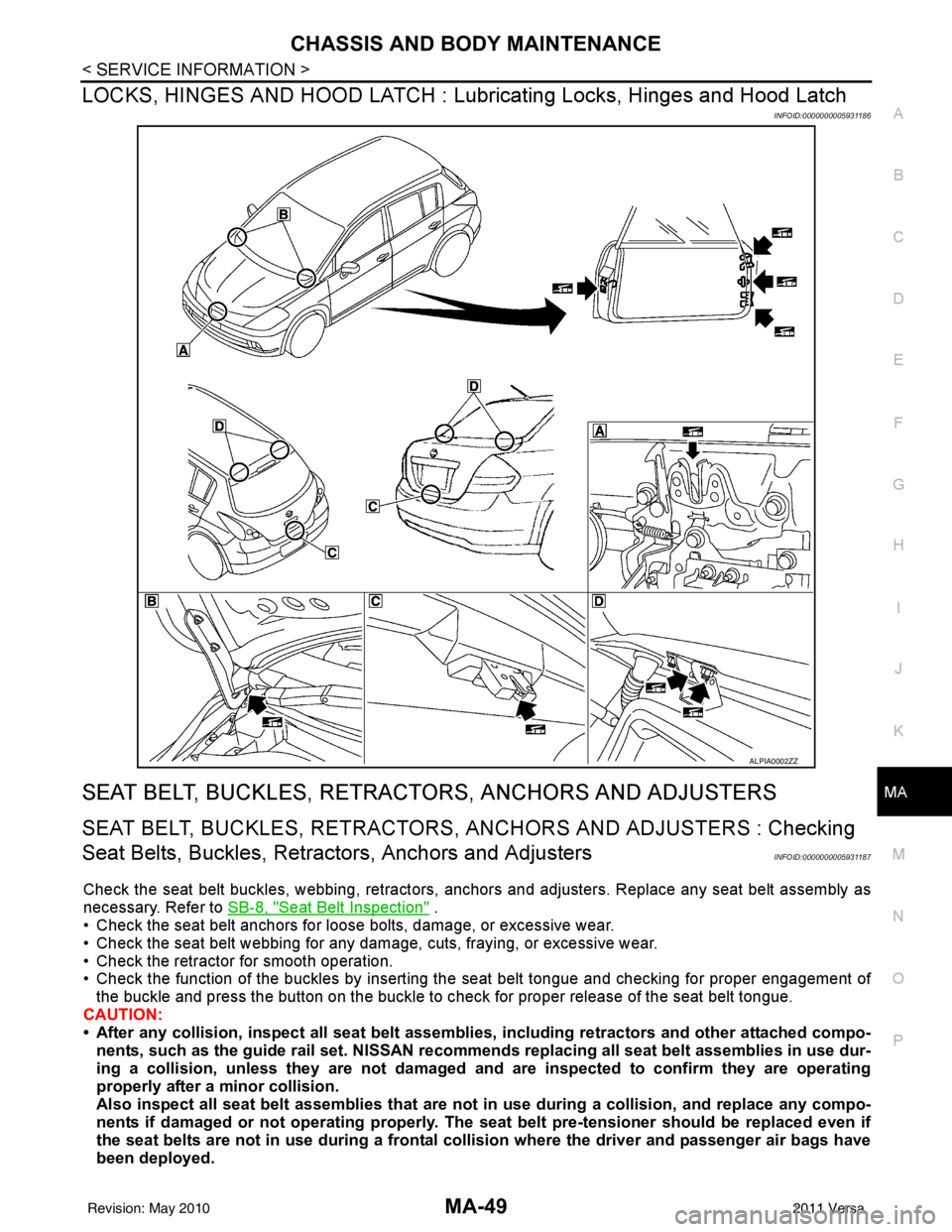

LOCKS, HINGES AND HOOD LATCH : Lubricating Locks, Hinges and Hood Latch

INFOID:0000000005931186

SEAT BELT, BUCKLES, RETRAC TORS, ANCHORS AND ADJUSTERS

SEAT BELT, BUCKLES, RETRACTORS, ANCHORS AND ADJUSTERS : Checking

Seat Belts, Buckles, Retrac tors, Anchors and Adjusters

INFOID:0000000005931187

Check the seat belt buckles, webbing, retractors, anc hors and adjusters. Replace any seat belt assembly as

necessary. Refer to SB-8, "

Seat Belt Inspection" .

• Check the seat belt anchors for loose bolts, damage, or excessive wear.

• Check the seat belt webbing for any damage, cuts, fraying, or excessive wear.

• Check the retractor for smooth operation.

• Check the function of the buckles by inserting the seat belt tongue and checking for proper engagement of

the buckle and press the button on the buckle to c heck for proper release of the seat belt tongue.

CAUTION:

• After any collision, inspect al l seat belt assemblies, including retractors and other attached compo-

nents, such as the guide rail set. NISSAN recomme nds replacing all seat belt assemblies in use dur-

ing a collision, unless they are not damaged an d are inspected to confirm they are operating

properly after a minor collision.

Also inspect all seat belt assemblies that are not in use during a collision, and replace any compo-

nents if damaged or not operating properly. The seat belt pre-tensioner should be replaced even if

the seat belts are not in use during a frontal collision where the driver and passenger air bags have

been deployed.

ALPIA0002ZZ

Revision: May 2010 2011 Versa