NISSAN LATIO 2011 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 3321 of 3787

PRECAUTIONSMTC-5

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

been shown to be combustible at elevated pressures. These mixtures, if ignited, may cause injury or

property damage. Additional health and safety info rmation may be obtained from refrigerant manu-

facturers.

Oil PrecautionINFOID:0000000005930828

• Use only specified oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) components. If oil

other than that specified is used, comp ressor malfunction is likely to occur.

• The specified HFC-134a (R-134a) oil rapidly absorbs moisture from the atmosphere. The following handling

precautions must be observed:

- When removing refrigerant components from a vehicle, immediately cap (seal) the component to minimize the entry of moisture from the atmosphere.

- When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just before con- necting the components. Connect all refrigerant loop components as quickly as possible to minimize the

entry of moisture into system.

- Only use the specified oil from a sealed container. Imm ediately reseal containers of oil. Without proper seal-

ing, oil will become moisture saturated and should not be used.

• Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a) refrigerant. If accidental

system discharge occurs, ventilate work area before resuming service. Additional health and safety informa-

tion may be obtained from refrigerant and oil manufacturers.

• Do not allow A/C oil to come in contact with styrofoam parts. Damage may result.

Precaution for Refrigerant ConnectionINFOID:0000000005930829

A new type refrigerant connection has been introduced to a ll refrigerant lines except the following location.

• Expansion valve to evaporator

• Refrigerant pressure sensor to condenser

FEATURES OF NEW TYPE REFRIGERANT CONNECTION

• The O-ring has been relocated. It has also been provided with a groove for proper installation. This elimi-

nates the chance of the O-ring being caught in, or damaged by, the mating part. The sealing direction of the

O-ring is now set vertically in relation to the contacti ng surface of the mating part to improve sealing charac-

teristics.

• The reaction force of the O-ring will not occur in the direction that causes the joint to pull out, thereby facili- tating piping connections.

O-RING AND REFRIGERANT CONNECTION

SHA815E

Revision: May 2010 2011 Versa

Page 3322 of 3787

MTC-6

< SERVICE INFORMATION >

PRECAUTIONS

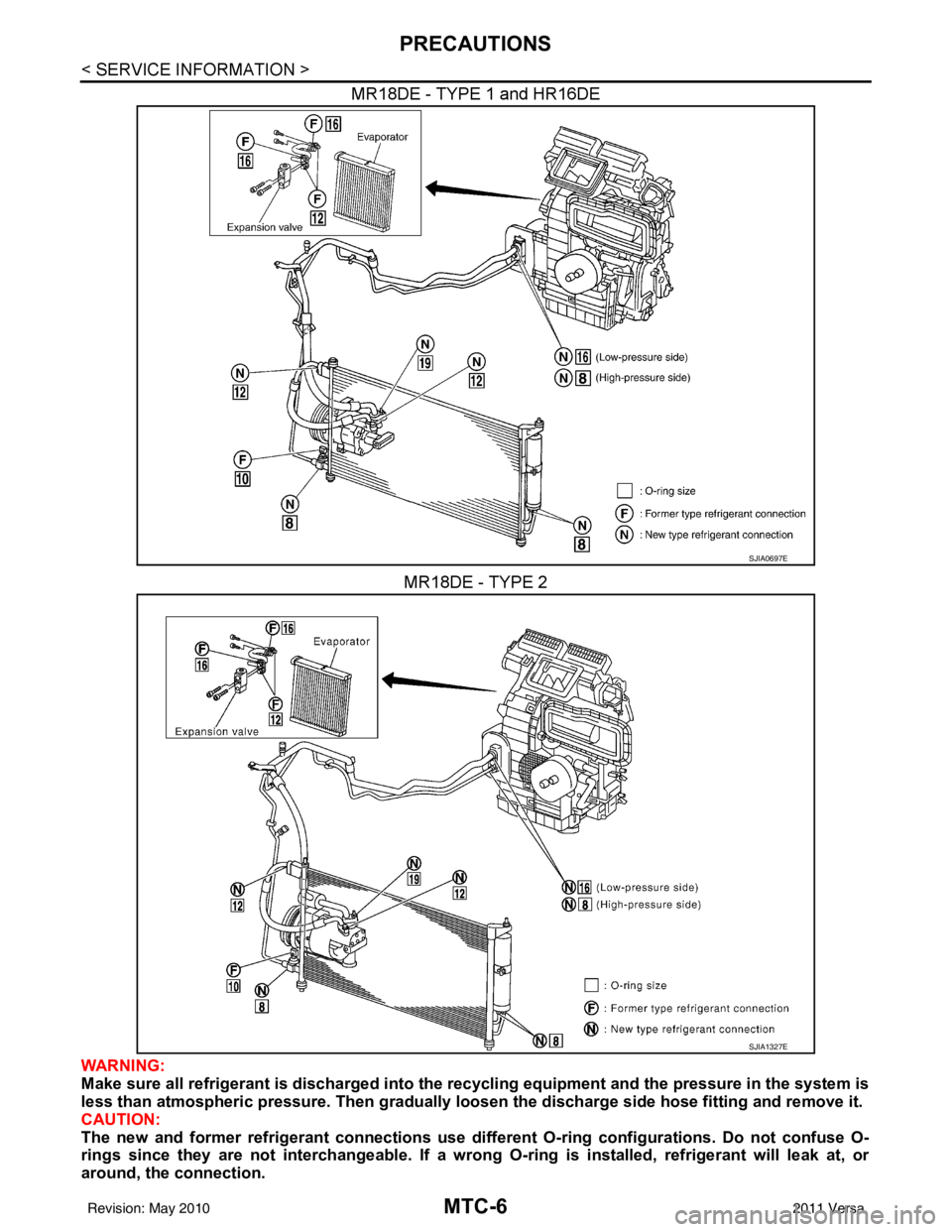

MR18DE - TYPE 1 and HR16DEMR18DE - TYPE 2

WARNING:

Make sure all refrigerant is discharged into the recycling equipment and the pressure in the system is

less than atmospheric pressure. Then gradually loo sen the discharge side hose fitting and remove it.

CAUTION:

The new and former refrigerant connections use different O-ring configurations. Do not confuse O-

rings since they are not interchangeable. If a wrong O-ring is installed, refrigerant will leak at, or

around, the connection.

SJIA0697E

SJIA1327E

Revision: May 2010 2011 Versa

Page 3323 of 3787

PRECAUTIONSMTC-7

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

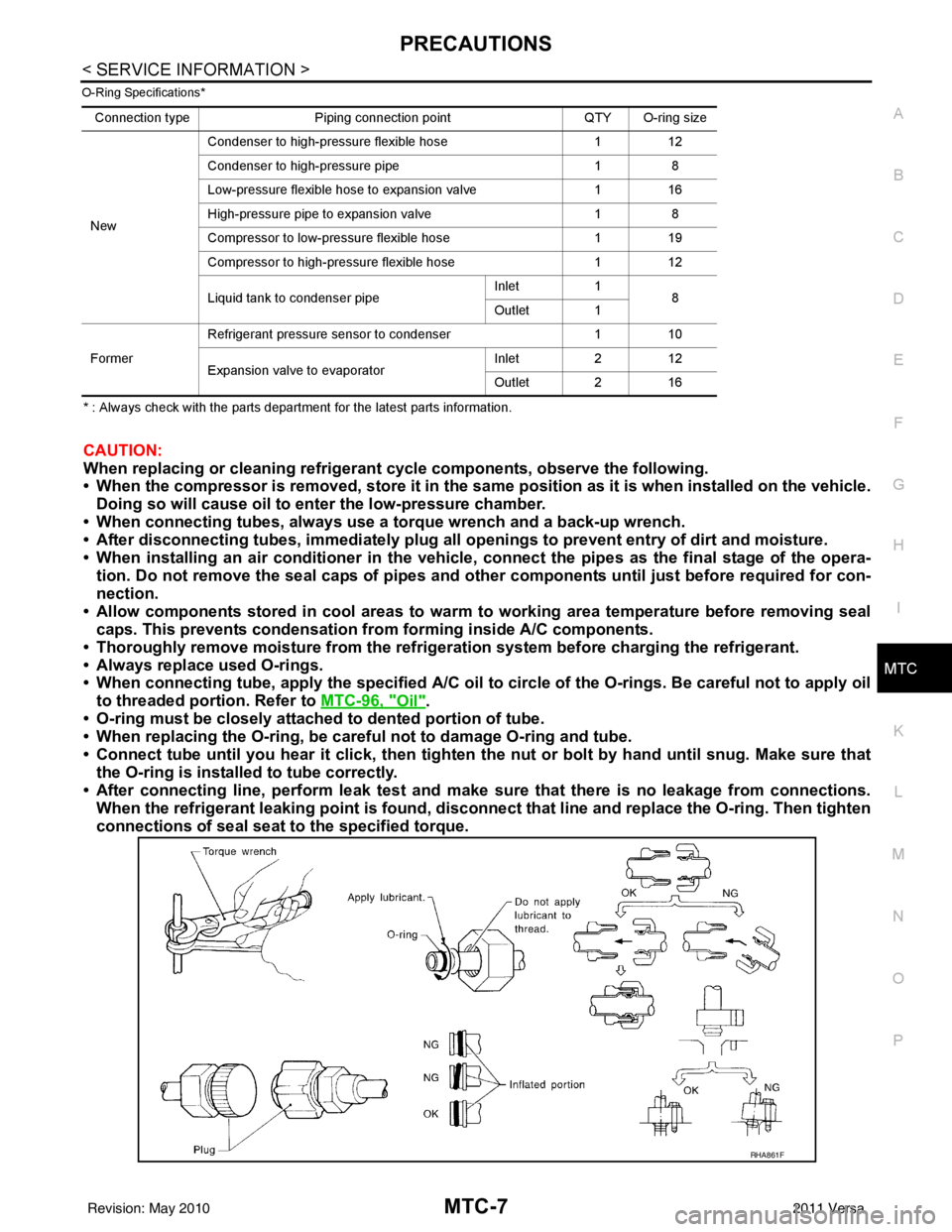

O-Ring Specifications*

* : Always check with the parts department for the latest parts information.

CAUTION:

When replacing or cleaning refrigerant cycle components, observe the following.

• When the compressor is removed, store it in the sam e position as it is when installed on the vehicle.

Doing so will cause oil to en ter the low-pressure chamber.

• When connecting tubes, always use a to rque wrench and a back-up wrench.

• After disconnecting tubes, immediately plug all op enings to prevent entry of dirt and moisture.

• When installing an air conditione r in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and other components until just before required for con-

nection.

• Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

• Thoroughly remove moisture from the refrigeration system before charging the refrigerant.

• Always replace used O-rings.

• When connecting tube, apply the speci fied A/C oil to circle of the O-rings. Be careful not to apply oil

to threaded portion. Refer to MTC-96, "

Oil".

• O-ring must be closely attached to dented portion of tube.

• When replacing the O-ring, be careful not to damage O-ring and tube.

• Connect tube until you hear it cl ick, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to tube correctly.

• After connecting line, perform leak test and make sure that there is no leakage from connections.

When the refrigerant leaking point is found, disconnect that line and replace the O-ring. Then tighten

connections of seal seat to the specified torque.

Connection type Piping connection point QTY O-ring size

New Condenser to high-pressure flexible hose

112

Condenser to high-pressure pipe 18

Low-pressure flexible hose to expansion valve 116

High-pressure pipe to expansion valve 18

Compressor to low-pressure flexible hose 119

Compressor to high-pressure flexible hose 112

Liquid tank to condenser pipe Inlet

1

8

Outlet 1

Former Refrigerant pressure sensor to condenser

110

Expansion valve to evaporator Inlet

212

Outlet 2 16

RHA861F

Revision: May 2010 2011 Versa

Page 3324 of 3787

MTC-8

< SERVICE INFORMATION >

PRECAUTIONS

Precaution for Service of Compressor

INFOID:0000000005930830

• Plug all openings to prevent moisture and foreign matter from entering.

• When the compressor is removed, store it in th e same position as it is when mounted on the car.

• When replacing or repairing compressor, follow “Maintenance of Oil Quantity in Compressor”

exactly. Refer to MTC-17, "

Maintenance of Oil Quantity in Compressor".

• Keep friction surfaces between clut ch and pulley clean. If the surface is contaminated, with oil, wipe

it off by using a clean waste cloth moistened with thinner.

• After compressor service operation, turn the compresso r shaft by hand more than five turns in both

directions. This will equally distribute oil inside the compressor. After the compressor is installed,

let the engine idle and operate the compressor for one hour.

• After replacing the compressor magnet clutch, ap ply voltage to the new one and check for usual

operation.

Precaution for Service EquipmentINFOID:0000000005930831

RECOVERY/RECYCLING EQUIPMENT

Be certain to follow the manufacturer’s instructions for machine operation and machine maintenance. Never

introduce any refrigerant other than that specified into the machine.

ELECTRONIC LEAK DETECTOR

Be certain to follow the manufacturer’s instruct ions for tester operation and tester maintenance.

VACUUM PUMP

The oil contained inside the vacuum pump is not compatible with the

specified oil for HFC-134a (R-134a) A/C systems. The vent side of

the vacuum pump is exposed to atmospheric pressure. So the vac-

uum pump oil may migrate out of the pump into the service hose.

This is possible when the pump is switched off after evacuation (vac-

uuming) and hose is connected to it.

To prevent this migration, use a manual valve placed near the hose-

to-pump connection, as follows.

• Usually vacuum pumps have a manual isolator valve as part of the pump. Close this valve to isolat e the service hose from the pump.

• For pumps without an isolator, use a hose equipped with a manual shut-off valve near the pump end. Close the valve to isolate the

hose from the pump.

• If the hose has an automatic shut -off valve, disconnect the hose

from the pump. As long as the hose is connected, the valve is open

and lubricating oil may migrate.

Some one-way valves open when vacuum is applied and close

under a no vacuum condition. Such valves may restrict the pump’s

ability to pull a deep vacuum and are not recommended.

MANIFOLD GAUGE SET

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2 ″-16 ACME threaded connections for ser-

vice hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) and specified oils.

RHA270DA

SHA533D

Revision: May 2010 2011 Versa

Page 3325 of 3787

PRECAUTIONSMTC-9

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

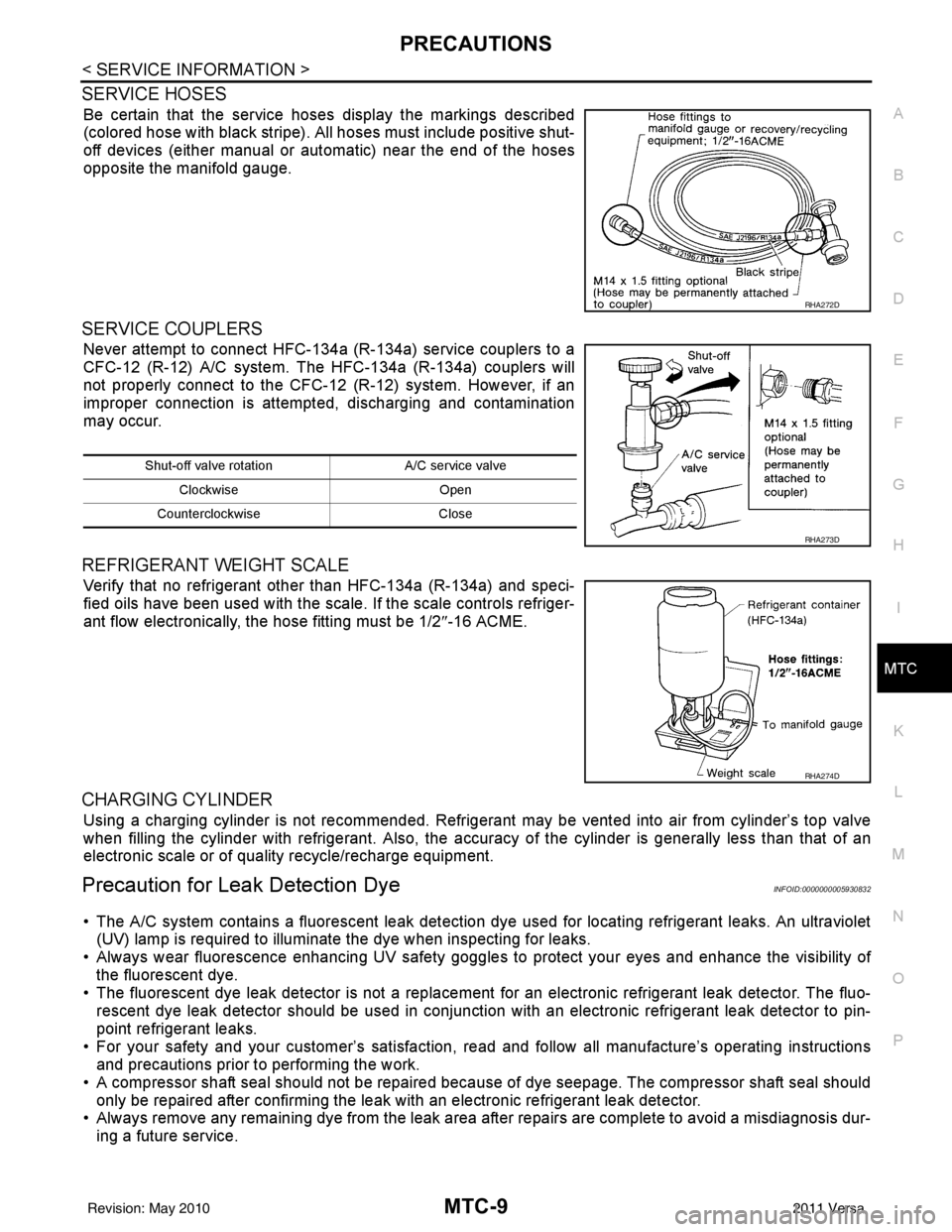

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must include positive shut-

off devices (either manual or aut omatic) near the end of the hoses

opposite the manifold gauge.

SERVICE COUPLERS

Never attempt to connect HFC-134a (R-134a) service couplers to a

CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers will

not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and speci-

fied oils have been used with the scale. If the scale controls refriger-

ant flow electronically, the hose fitting must be 1/2 ″-16 ACME.

CHARGING CYLINDER

Using a charging cylinder is not re commended. Refrigerant may be vented into air from cylinder’s top valve

when filling the cylinder with refrigerant. Also, the accura cy of the cylinder is generally less than that of an

electronic scale or of quality recycle/recharge equipment.

Precaution for Leak Detection DyeINFOID:0000000005930832

• The A/C system contains a fluorescent leak detection dy e used for locating refrigerant leaks. An ultraviolet

(UV) lamp is required to illuminate the dye when inspecting for leaks.

• Always wear fluorescence enhancing UV safety goggles to protect your eyes and enhance the visibility of

the fluorescent dye.

• The fluorescent dye leak detector is not a replacement for an electronic refrigerant leak detector. The fluo-

rescent dye leak detector should be used in conjunction with an electronic refrigerant leak detector to pin-

point refrigerant leaks.

• For your safety and your customer’s satisfaction, read and follow all manufacture’s operating instructions

and precautions prior to performing the work.

• A compressor shaft seal should not be repaired because of dye seepage. The compressor shaft seal should

only be repaired after confirming the leak with an electronic refrigerant leak detector.

• Always remove any remaining dye from the leak area after repairs are complete to avoid a misdiagnosis dur-

ing a future service.

RHA272D

Shut-off valve rotati on A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D

Revision: May 2010 2011 Versa

Page 3326 of 3787

MTC-10

< SERVICE INFORMATION >

PRECAUTIONS

• Do not allow dye to come into contact with painted body panels or interior components. If dye is spilled,

clean immediately with the approved dye cleaner. Fluoresc ent dye left on a surface for an extended period of

time cannot be removed.

• Do not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

• Do not use more than one refrigerant dye bot tle (1/4 ounce /7.4 cc) per A/C system.

• Leak detection dyes for HFC-134a (R-134a) and CFC-12 (R-12) A/C systems are different. Do not use HFC-

134a (R-134a) leak detection dye in CFC-12 (R-12) A/C s ystem or CFC-12 (R-12) leak detector dye in HFC-

134a (R-134a) A/C syst em or A/C system damage may result.

• The fluorescent properties of the dye will remain for over three (3) years unless a compressor malfunction

occurs.

IDENTIFICATION LABEL FOR VEHICLE

Vehicles with factory installed fluorescent dye have an identification label on the front underside of the hood.

NOTE:

• Vehicles with factory installed fluorescent dye have a green label.

• Vehicles without factory installed fluorescent dye have a blue label.

Revision: May 2010 2011 Versa

Page 3327 of 3787

PREPARATIONMTC-11

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

PREPARATION

HFC-134a (R-134a) Service Tool and EquipmentINFOID:0000000005930833

Never mix HFC-134a refrigerant and/or its specified oil with CFC-12 (R-12) refrigerant and/or its oil.

Separate and non-interchangeable service equipment must be used for handling each type of refrigerant/oil.

Refrigerant container fittings, service hose fittings and service equipment fittings (equipment which handles

refrigerant and/or oil) are different between CFC-12 (R-12) and HFC-134a (R-134a). This is to avoid mixed

use of the refrigerants/oil.

Adapters that convert one size fitting to another must never be used refrigerant/oil contamination will occur

and compressor failure will result.

Tool number

(Kent-Moore No.)

Tool name Description

HFC-134a (R-134a)

(—)

Refrigerant Container color: Light blue

Container marking: HFC-134a (R-

134a)

Fitting size: Thread size

• large container 1/2”-16 ACME

—

(—)

NISSAN A/C System Oil Type S Type: Poly Alkylene glycol oil (PAG),

type S

Application: HFC-134a (R-134a) vari-

able displacement swash plate com-

pressors (NISSAN only)

—

(—)

NISSAN A/C System Oil Type R Type: Poly Alkylene glycol oil (PAG),

type R

Application: HFC-134a (R-134a) vane

rotary compressors (NISSAN only)

KV991J0130

(ACR2005-NI)

ACR5 A/C Se rvice Center Refrigerant recovery, recycling and re-

charging

—

(J-41995)

Electronic refrigerant leak detector Checking for refrigerant leaks

Power supply: DC 12V (battery termi-

nal)

S-NT196

S-NT197

S-NT197

WJIA0293E

AHA281A

Revision: May 2010

2011 Versa

Page 3328 of 3787

MTC-12

< SERVICE INFORMATION >

PREPARATION

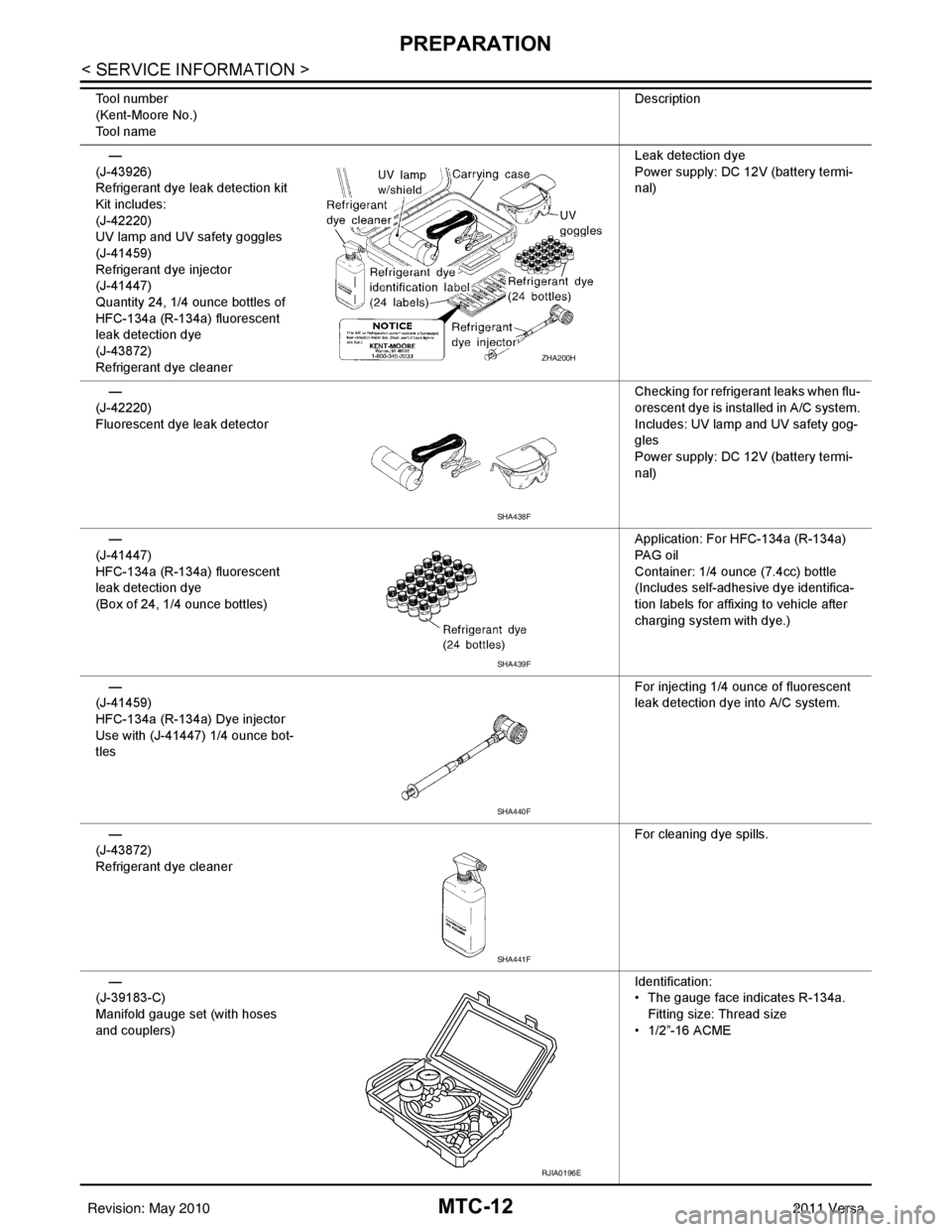

—

(J-43926)

Refrigerant dye leak detection kit

Kit includes:

(J-42220)

UV lamp and UV safety goggles

(J-41459)

Refrigerant dye injector

(J-41447)

Quantity 24, 1/4 ounce bottles of

HFC-134a (R-134a) fluorescent

leak detection dye

(J-43872)

Refrigerant dye cleaner Leak detection dye

Power supply: DC 12

V (battery termi-

nal)

—

(J-42220)

Fluorescent dye leak detector Checking for refrigerant leaks when flu-

orescent dye is installed in A/C system.

Includes: UV lamp and UV safety gog-

gles

Power supply: DC 12

V (battery termi-

nal)

—

(J-41447)

HFC-134a (R-134a) fluorescent

leak detection dye

(Box of 24, 1/4 ounce bottles) Application: For HFC-134a (R-134a)

PA G o i l

Container: 1/4 ounce (7.4cc) bottle

(Includes self-adhesive dye identifica-

tion labels for affixing to vehicle after

charging system with dye.)

—

(J-41459)

HFC-134a (R-134a) Dye injector

Use with (J-41447) 1/4 ounce bot-

tles For injecting 1/4 ounce of fluorescent

leak detection dye into A/C system.

—

(J-43872)

Refrigerant dye cleaner For cleaning dye spills.

—

(J-39183-C)

Manifold gauge set (with hoses

and couplers) Identification:

• The gauge face indicates R-134a.

Fitting size: Thread size

• 1/2”-16 ACME

Tool number

(Kent-Moore No.)

Tool name

Description

ZHA200H

SHA438F

SHA439F

SHA440F

SHA441F

RJIA0196E

Revision: May 2010

2011 Versa

Page 3329 of 3787

PREPARATIONMTC-13

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

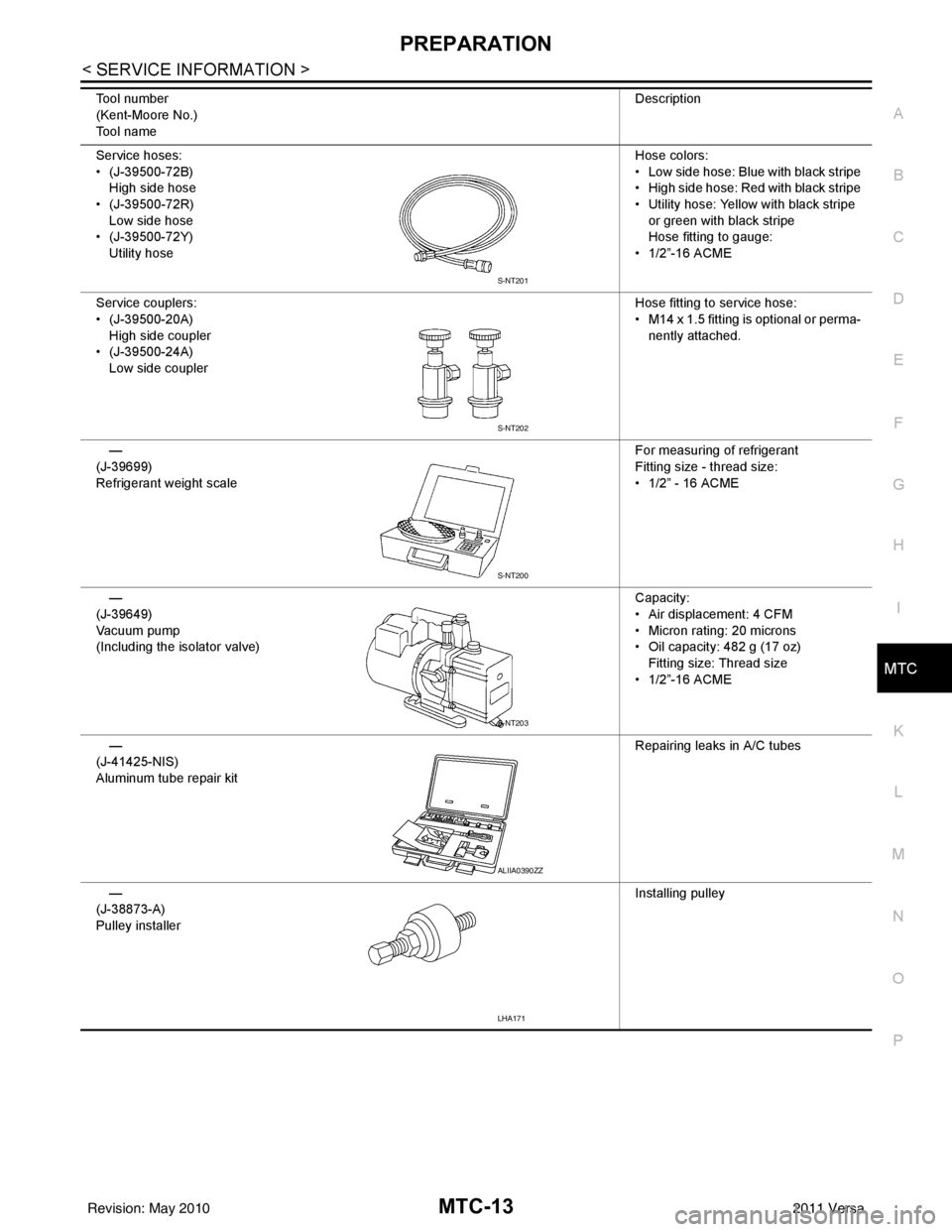

Service hoses:

• (J-39500-72B) High side hose

• (J-39500-72R) Low side hose

• (J-39500-72Y)

Utility hose Hose colors:

• Low side hose: Blue with black stripe

• High side hose: Red with black stripe

• Utility hose: Yellow with black stripe

or green with black stripe

Hose fitting to gauge:

• 1/2”-16 ACME

Service couplers:

• (J-39500-20A) High side coupler

• (J-39500-24A)

Low side coupler Hose fitting to service hose:

• M14 x 1.5 fitting is optional or perma-

nently attached.

—

(J-39699)

Refrigerant weight scale For measuring of refrigerant

Fitting size - thread size:

• 1/2” - 16 ACME

—

(J-39649)

Va c u u m p u m p

(Including the isolator valve) Capacity:

• Air displacement: 4 CFM

• Micron rating: 20 microns

• Oil capacity: 482 g (17 oz)

Fitting size: Thread size

• 1/2”-16 ACME

—

(J-41425-NIS)

Aluminum tube repair kit Repairing leaks in A/C tubes

—

(J-38873-A)

Pulley installer Installing pulley

Tool number

(Kent-Moore No.)

Tool name

Description

S-NT201

S-NT202

S-NT200

S-NT203

ALIIA0390ZZ

LHA171

Revision: May 2010

2011 Versa

Page 3330 of 3787

MTC-14

< SERVICE INFORMATION >

PREPARATION

Commercial Service Tool

INFOID:0000000005930834

—

(J-44614)

Clutch disc holding tool Clutch disc holding tool

—

(J-46534)

Trim tool set Removing trim parts

Tool number

(Kent-Moore No.)

Tool name

Description

WHA230

AWJIA0483ZZ

(Kent-Moore No.)

Tool name

Description

(J-41810-NI)

Refrigerant identifier equipment (R-

134a) For checking refrigerant purity and

system contamination

Power tool Loosening bolts and nuts

RJIA0197E

PIIB1407E

Revision: May 2010 2011 Versa