stop start NISSAN LATIO 2011 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 1138 of 3787

![NISSAN LATIO 2011 Service Service Manual P0730 INCORRECT GEAR RATIOCVT-83

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0730 INCORRECT GEAR RATIO

DescriptionINFOID:0000000005928815

TCM selects the gear ratio using the NISSAN LATIO 2011 Service Service Manual P0730 INCORRECT GEAR RATIOCVT-83

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0730 INCORRECT GEAR RATIO

DescriptionINFOID:0000000005928815

TCM selects the gear ratio using the](/img/5/57357/w960_57357-1137.png)

P0730 INCORRECT GEAR RATIOCVT-83

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0730 INCORRECT GEAR RATIO

DescriptionINFOID:0000000005928815

TCM selects the gear ratio using the engine load (throttle position), the primary pulley revolution speed, and

the secondary pulley revolution speed as input signal. T hen it changes the operating pressure of the primary

pulley and the secondary pulley and changes the groove width of the pulley.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005928816

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000005928817

• This is not an OBD-II self-diagnostic item.

• TCM calculates the actual gear ratio with primary speed sensor and secondary speed sensor.

• Diagnostic trouble code “P0730” with CONSULT-III is detected, when TCM receives an unexpected gear

ratio signal.

Possible CauseINFOID:0000000005928818

Transaxle assembly

DTC Confirmation ProcedureINFOID:0000000005928819

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN: 1.0 - 2.0 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to

increase the voltage (c ool down the fluid)

3. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

4. Start engine and maintain the following conditions for at least 30 consecutive seconds. TEST START FROM 0 km/h (0 MPH)

CONSTANT ACCELERATION: Keep 30 sec or more

VEHICLE SPEED: 10 km/h (6 MPH) or more

ACC PEDAL OPEN: More than 1.0/8

RANGE: “D” position

ENG SPEED: 450 rpm or more

5. If DTC is detected, go to CVT-83, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005928820

1.CHECK DTC

Perform CVT-83, "

DTC Confirmation Procedure".

Are any DTC displayed?

YES - 1>> DTC except for “P0730” is displayed: Go to Check the DTC detected item. Refer to CVT-48,

"CONSULT-III Function (TRANSMISSION)".

YES - 2>> DTC for “P0730” is displayed: Replace the transaxle assembly. Refer to CVT-180, "

Removal and

Installation".

NO >> INSPECTION END

Item name Condition Display value (Approx.)

GEAR RATIO During driving 2.56 - 0.43

Revision: May 2010 2011 Versa

Page 1160 of 3787

![NISSAN LATIO 2011 Service Service Manual P0840 TRANSMISSION FLUID PRESSURE SEN/SW ACVT-105

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0840 TRANSMISSION FLUI D PRESSURE SEN/SW A

DescriptionINFOID:0000000005928863

• NISSAN LATIO 2011 Service Service Manual P0840 TRANSMISSION FLUID PRESSURE SEN/SW ACVT-105

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0840 TRANSMISSION FLUI D PRESSURE SEN/SW A

DescriptionINFOID:0000000005928863

•](/img/5/57357/w960_57357-1159.png)

P0840 TRANSMISSION FLUID PRESSURE SEN/SW ACVT-105

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0840 TRANSMISSION FLUI D PRESSURE SEN/SW A

DescriptionINFOID:0000000005928863

• The secondary pressure sensor is included in the control valve assembly.

• The secondary pressure sensor detects secondar y pressure of CVT and sends TCM the signal.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005928864

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000005928865

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0840” with CONSULT-III is detected when TCM detects an improper voltage drop

when it receives the sensor signal.

Possible CauseINFOID:0000000005928866

• Secondary pressure sensor

• Harness or connectors

(Switch circuit is open or shorted.)

DTC Confirmation ProcedureINFOID:0000000005928867

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that output voltage of line temperature sensor is within the range below. ATF TEMP SEN: 1.0 - 2.0 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to

increase the voltage (c ool down the fluid)

3. Start engine and wait for at least 5 consecutive seconds.

4. If DTC is detected, go to CVT-107, "

Diagnosis Procedure" .

WITH GST

Follow the procedure “WITH CONSULT-III”.

Item name Condition Display value (Approx.)

SEC HYDR SEN “N” position idle 1.0 V

SEC PRESS 0.8 MPa

Revision: May 2010 2011 Versa

Page 1166 of 3787

![NISSAN LATIO 2011 Service Service Manual P0868 TRANSMISSION FLUID PRESSURECVT-111

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0868 TRANSMISSION FLUID PRESSURE

DescriptionINFOID:0000000005928876

• The secondary pres NISSAN LATIO 2011 Service Service Manual P0868 TRANSMISSION FLUID PRESSURECVT-111

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0868 TRANSMISSION FLUID PRESSURE

DescriptionINFOID:0000000005928876

• The secondary pres](/img/5/57357/w960_57357-1165.png)

P0868 TRANSMISSION FLUID PRESSURECVT-111

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0868 TRANSMISSION FLUID PRESSURE

DescriptionINFOID:0000000005928876

• The secondary pressure solenoid valve is included in the control valve assembly.

• The secondary pressure solenoid valve regulates the secondary pressure to suit the driving condition in

response to a signal sent from the TCM.

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000005928877

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000005928878

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0868” with CONSULT-III is det ected when secondary fluid pressure is too low

compared with the commanded value while driving.

Possible CauseINFOID:0000000005928879

• Harness or connectors (Solenoid circuit is open or shorted.)

• Secondary pressure solenoid valve system

• Secondary pressure sensor

• Line pressure control system

DTC Confirmation ProcedureINFOID:0000000005928880

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN: 1.0 - 2.0 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to

increase the voltage (c ool down the fluid)

3. Start engine and maintain the following conditions for at least 10 consecutive seconds. VEHICLE SPEED (accelerate slowly): 0 → 50 km/h (31 MPH)

ACC PEDAL OPEN: 0.5/8 - 1.0/8

RANGE: “D” position

4. If DTC is detected, go to CVT-111, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005928881

1.CHECK INPUT SIGNAL

With CONSULT-III

1. Start engine.

2. Select “MAIN SIGNALS” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Start vehicle and read out the value of “SEC PRESS”.

OK or NG

Item name Condition Display value (Approx.)

SEC PRESS “N” position idle 0.8 MPa

Item nameConditionDisplay value (Approx.)

SEC PRESS “N” position idle0.8 MPa

Revision: May 2010 2011 Versa

Page 1168 of 3787

![NISSAN LATIO 2011 Service Service Manual P1701 TCMCVT-113

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1701 TCM

DescriptionINFOID:0000000005928882

When the power supply to the TCM is cut OFF, for exam ple because the NISSAN LATIO 2011 Service Service Manual P1701 TCMCVT-113

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1701 TCM

DescriptionINFOID:0000000005928882

When the power supply to the TCM is cut OFF, for exam ple because the](/img/5/57357/w960_57357-1167.png)

P1701 TCMCVT-113

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1701 TCM

DescriptionINFOID:0000000005928882

When the power supply to the TCM is cut OFF, for exam ple because the battery is removed, and the self-diag-

nosis memory function stop s, malfunction is detected.

NOTE:

Since “P1701” will be indicated when replacing TCM, perform diagnosis after erasing “SELF-DIAG

RESULTS”

On Board Diagnosis LogicINFOID:0000000005928883

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1701” with CONSULT-III is detected when TCM does not receive the voltage sig- nal from the battery power supply.

• This is not a malfunction message. (Whenever shutti ng OFF a power supply to the TCM, this message

appears on the screen.)

Possible CauseINFOID:0000000005928884

Harness or connectors

(Battery or ignition switch and TCM circuit is open or shorted.)

DTC Confirmation ProcedureINFOID:0000000005928885

NOTE:

If “DTC Confirmation Procedure” has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Wait for at least 2 consecutive seconds.

4. If DTC is detected, go to CVT-115, "

Diagnosis Procedure" .

Revision: May 2010 2011 Versa

Page 1183 of 3787

![NISSAN LATIO 2011 Service Service Manual CVT-128

< SERVICE INFORMATION >[RE0F08B]

P1745 LINE PRESSURE CONTROL

P1745 LINE PRESSURE CONTROL

DescriptionINFOID:0000000005928918

The line pressure solenoid valve regulates the oil pump discharge pr NISSAN LATIO 2011 Service Service Manual CVT-128

< SERVICE INFORMATION >[RE0F08B]

P1745 LINE PRESSURE CONTROL

P1745 LINE PRESSURE CONTROL

DescriptionINFOID:0000000005928918

The line pressure solenoid valve regulates the oil pump discharge pr](/img/5/57357/w960_57357-1182.png)

CVT-128

< SERVICE INFORMATION >[RE0F08B]

P1745 LINE PRESSURE CONTROL

P1745 LINE PRESSURE CONTROL

DescriptionINFOID:0000000005928918

The line pressure solenoid valve regulates the oil pump discharge pressure to suit the driving condition in

response to a signal sent from the TCM.

On Board Diagn

osis LogicINFOID:0000000005928919

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1745” with CONSULT-III is detected when TCM detects the unexpected line pres-

sure.

Possible CauseINFOID:0000000005928920

TCM

DTC Confirmation ProcedureINFOID:0000000005928921

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESULTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN: 1.0 - 2.0 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to

increase the voltage (cool down the fluid)

3. If DTC is detected, go to CVT-128, "

Diagnosis Procedure" .

Diagnosis ProcedureINFOID:0000000005928922

1.CHECK DTC

1. Turn ignition switch ON. (Do not start engine.)

2. Select “SELF-DIAG RESULTS” mode fo r “TRANSMISSION” with CONSULT-III.

3. Erase self-diagnostic results. Refer to CVT-27, "

OBD-II Diagnostic Trouble Code (DTC)".

4. Turn ignition switch OFF, and wait for 10 seconds or more.

5. Start engine.

6. Confirm self-diagnostic results again. Refer to CVT-48, "

CONSULT-III Function (TRANSMISSION)" .

Is the

“P1745” displayed?

YES >> Replace TCM. Refer to CVT-159, "Removal and Installation" .

NO >> INSPECTION END

Revision: May 2010 2011 Versa

Page 1188 of 3787

![NISSAN LATIO 2011 Service Service Manual P1778 STEP MOTORCVT-133

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1778 STEP MOTOR

DescriptionINFOID:0000000005928931

• The step motor is included in the control valve asse NISSAN LATIO 2011 Service Service Manual P1778 STEP MOTORCVT-133

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1778 STEP MOTOR

DescriptionINFOID:0000000005928931

• The step motor is included in the control valve asse](/img/5/57357/w960_57357-1187.png)

P1778 STEP MOTORCVT-133

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1778 STEP MOTOR

DescriptionINFOID:0000000005928931

• The step motor is included in the control valve assembly.

• The step motor's 4 aspects of ON/OFF change according to the signal from TCM. As a result, the flow of line pressure to primary pulley is changed and pulley ratio is controlled.

• This diagnosis item is detected when electrical system is OK, but mechanical system is NG.

• This diagnosis item is detected when the state of the changing the speed mechanism in unit does not oper- ate normally.

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000005928932

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000005928933

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1778” with CONSULT-III is detected under the following conditions.

- When not changing the pulley ratio according to the instruction of TCM.

Possible CauseINFOID:0000000005928934

Step motor

DTC Confirmation ProcedureINFOID:0000000005928935

CAUTION:

• Always drive vehicle at a safe speed.

• Before starting “DTC Confirmation Procedure”, confirm “Hi” or “Mid” or “Low” fixation by “PRI

SPEED” and “VEHICLE SPEED” on “DATA MONITOR MODE”.

• If hi-geared fixation occurred, go to CVT-134, "

Diagnosis Procedure".

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESULTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN: 1.0 - 2.0 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to

increase the voltage (c ool down the fluid)

3. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

4. Start engine and maintain the following conditions for at least 30 consecutive seconds. TEST START FROM 0 km/h (0 MPH)

CONSTANT ACCELERATION: Keep 30 sec or more

VEHICLE SPEED: 10 km/h (6 MPH) or more

ACC PEDAL OPEN: More than 1.0/8

RANGE: “D” position

ENG SPEED: 450 rpm or more

5. If DTC is detected, go to CVT-134, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-III”.

Item name Condition Display value (Approx.)

STM STEP During driving(−

20) - (+180) step

GEAR RATIO 2.56 - 0.43

Revision: May 2010 2011 Versa

Page 1219 of 3787

![NISSAN LATIO 2011 Service Service Manual CVT-164

< SERVICE INFORMATION >[RE0F08B]

SHIFT CONTROL SYSTEM

1. Set shift selector handle (1) in “N” position.

2. Slide shift selector handle cover (2) downward.

3. Pull out shift selector handle NISSAN LATIO 2011 Service Service Manual CVT-164

< SERVICE INFORMATION >[RE0F08B]

SHIFT CONTROL SYSTEM

1. Set shift selector handle (1) in “N” position.

2. Slide shift selector handle cover (2) downward.

3. Pull out shift selector handle](/img/5/57357/w960_57357-1218.png)

CVT-164

< SERVICE INFORMATION >[RE0F08B]

SHIFT CONTROL SYSTEM

1. Set shift selector handle (1) in “N” position.

2. Slide shift selector handle cover (2) downward.

3. Pull out shift selector handle clip (3) from shift selector handle

(1).

4. Remove shift selector handle (1) and shift selector handle cover (2) as a set from shift selector.

CAUTION:

Do not push shift selector button.

INSTALLATION

1. Insert shift selector handle clip (1) to shift selector handle (2).

2. Install shift selector handle cover (3) to shift selector handle (2).

3. Set shift selector in “N” position.

4. Install shift selector handle onto shift selector until a click is felt.

CAUTION:

• Do not tilt shift selector hand le when installing. Install it

straight, and do not tap or apply any shock to install it.

• Do not push shift selector handle button.

Adjustment of CVT PositionINFOID:0000000005928965

CAUTION:

Make sure that parking brake is applied before adjustment.

1. Loosen the shift selector control cable nut (A) and place the manual lever (1) in “P” position.

2. Place shift selector in “P” position.

3. Push the control cable (2) in with a load of 9.8 N (approximately 1 kg, 2.2 lb). Release the shift selector control cable and tempo-

rarily tighten the shift selector control cable nut.

NOTE:

Do not move the manual lever. Make sure the manual lever

stays in the “P” position.

4. Tighten the shift selector control cable nut. CAUTION:

Secure the manual lever when tighteningshift selector con-

trol cable nut.

5. Check the operation of the CVT. Refer to CVT-164, "

Checking of CVT Position".

Checking of CVT PositionINFOID:0000000005928966

1. Place shift selector in “P” position, and turn ignition switch ON. (Do not start engine.)

2. Make sure shift selector can be shifted to other than “P” position when brake pedal is depressed. Also

make sure shift selector can be shifted from “P” position only when brake pedal is depressed.

3. Move the shift selector and check for excessive effort, sticking, noise or rattle.

4. Confirm the shift selector stops at each position with the feel of engagement when it is moved through all

the positions. Check that the actual position of the shift selector matches the position shown by the posi-

tion indicator and the manual lever on the transaxle.

SCIA6971E

SCIA6972E

Shift selector con-

trol cable nut: Refer to

CVT-160, "Removal

and Installation".

WCIA0608E

Revision: May 2010 2011 Versa

Page 1250 of 3787

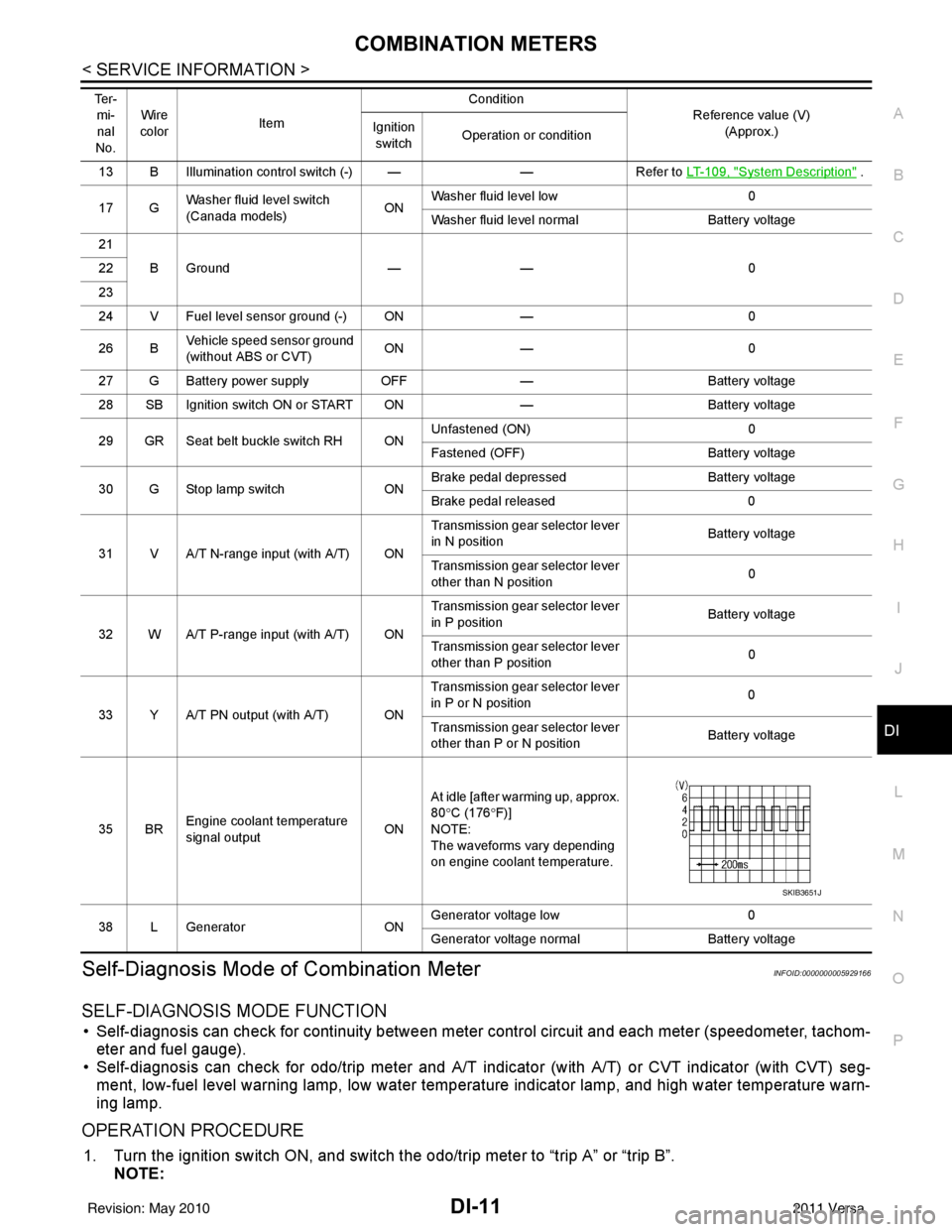

COMBINATION METERSDI-11

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

Self-Diagnosis Mode of Combination MeterINFOID:0000000005929166

SELF-DIAGNOSIS MODE FUNCTION

• Self-diagnosis can check for continuity between meter control circuit and each meter (speedometer, tachom- eter and fuel gauge).

• Self-diagnosis can check for odo/trip meter and A/T indi cator (with A/T) or CVT indicator (with CVT) seg-

ment, low-fuel level warning lamp, low water temperature indicator lamp, and high water temperature warn-

ing lamp.

OPERATION PROCEDURE

1. Turn the ignition switch ON, and switch the odo/trip meter to “trip A” or “trip B”. NOTE:

13 B Illumination control switch (-) — —Refer to LT- 1 0 9 , "System Description" .

17 G Washer fluid level switch

(Canada models)

ONWasher fluid level low

0

Washer fluid level normal Battery voltage

21 BGround —— 0

22

23

24 V Fuel level sensor ground (-) ON —0

26 B Vehicle speed sensor ground

(without ABS or CVT) ON

— 0

27 G Battery power supply OFF— Battery voltage

28 SB Ignition switch ON or START ON —Battery voltage

29 GR Seat belt buckle switch RH ON Unfastened (ON)

0

Fastened (OFF) Battery voltage

30 G Stop lamp switch ONBrake pedal depressed

Battery voltage

Brake pedal released 0

31 V A/T N-range input (with A/T) ON Transmission gear selector lever

in N position

Battery voltage

Transmission gear selector lever

other than N position 0

32 W A/T P-range input (with A/T) ON Transmission gear selector lever

in P position

Battery voltage

Transmission gear selector lever

other than P position 0

33 Y A/T PN output (with A/T) ON Transmission gear selector lever

in P or N position

0

Transmission gear selector lever

other than P or N position Battery voltage

35 BR Engine coolant temperature

signal output

ONAt idle [after warming up, approx.

80

°C (176 °F)]

NOTE:

The waveforms vary depending

on engine coolant temperature.

38 L Generator ONGenerator voltage low

0

Generator voltage no rmal Battery voltage

Te r -

mi-

nal

No. Wire

color Item Condition

Reference value (V)

(Approx.)

Ignition

switch Operation or condition

SKIB3651J

Revision: May 2010

2011 Versa

Page 1299 of 3787

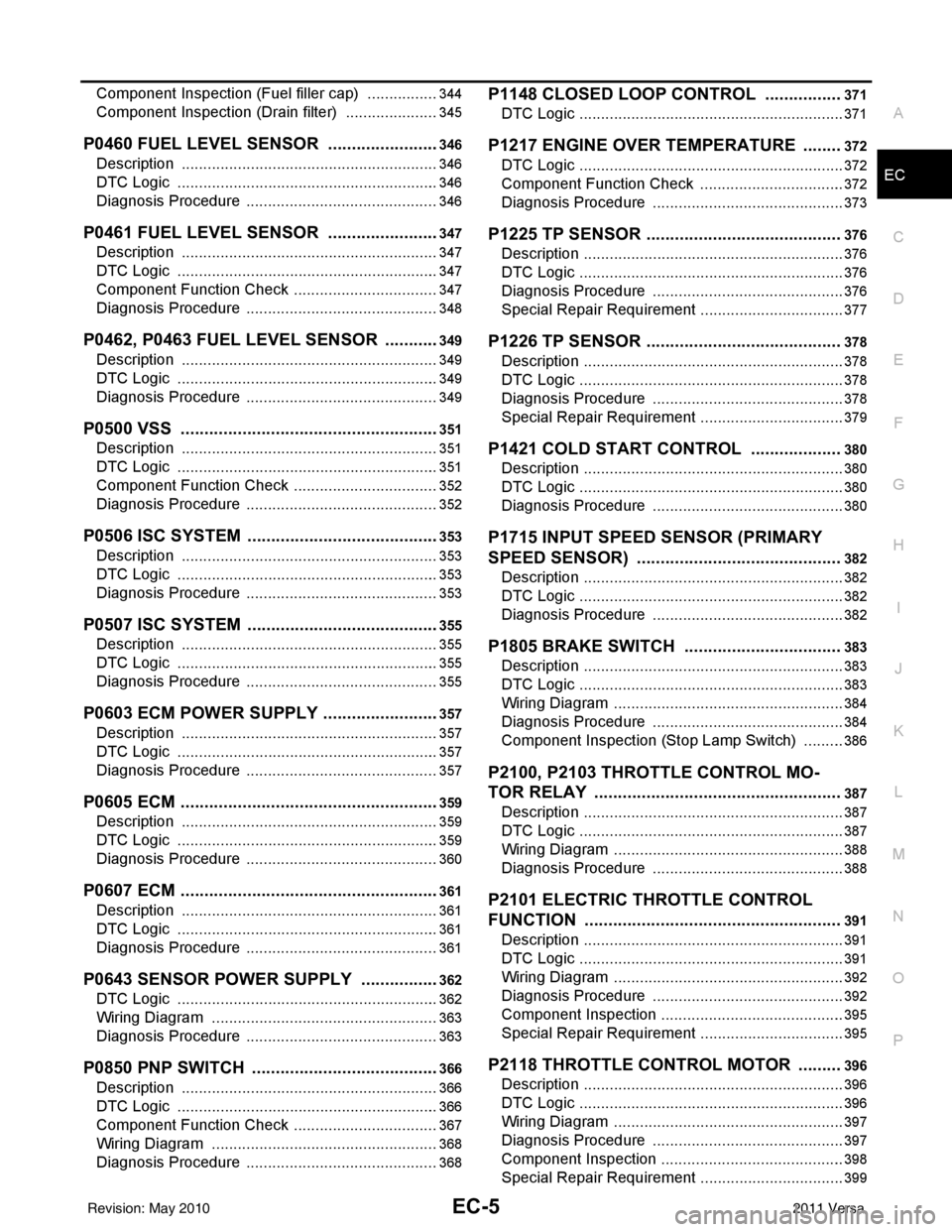

EC-5

C

DE

F

G H

I

J

K L

M

EC A

N

O P

Component Inspection (Fuel filler cap) ...............

..

344

Component Inspection (Drain filter) ......................345

P0460 FUEL LEVEL SENSOR ...................... ..346

Description .......................................................... ..346

DTC Logic .............................................................346

Diagnosis Procedure .............................................346

P0461 FUEL LEVEL SENSOR ........................347

Description .......................................................... ..347

DTC Logic .............................................................347

Component Function Check ..................................347

Diagnosis Procedure .............................................348

P0462, P0463 FUEL LEVEL SENSOR ............349

Description .......................................................... ..349

DTC Logic .............................................................349

Diagnosis Procedure .............................................349

P0500 VSS .......................................................351

Description .......................................................... ..351

DTC Logic .............................................................351

Component Function Check ..................................352

Diagnosis Procedure .............................................352

P0506 ISC SYSTEM .........................................353

Description .......................................................... ..353

DTC Logic .............................................................353

Diagnosis Procedure .............................................353

P0507 ISC SYSTEM .........................................355

Description .......................................................... ..355

DTC Logic .............................................................355

Diagnosis Procedure .............................................355

P0603 ECM POWER SUPPLY .........................357

Description .......................................................... ..357

DTC Logic .............................................................357

Diagnosis Procedure .............................................357

P0605 ECM .......................................................359

Description ............................................................359

DTC Logic .............................................................359

Diagnosis Procedure .............................................360

P0607 ECM .......................................................361

Description ............................................................361

DTC Logic .............................................................361

Diagnosis Procedure .............................................361

P0643 SENSOR POWER SUPPLY .................362

DTC Logic ........................................................... ..362

Wiring Diagram .....................................................363

Diagnosis Procedure .............................................363

P0850 PNP SWITCH ........................................366

Description ............................................................366

DTC Logic .............................................................366

Component Function Check ..................................367

Wiring Diagram .....................................................368

Diagnosis Procedure .............................................368

P1148 CLOSED LOOP CONTROL ................371

DTC Logic ............................................................ ..371

P1217 ENGINE OVER TEMPERATURE ........372

DTC Logic ..............................................................372

Component Function Check ..................................372

Diagnosis Procedure .............................................373

P1225 TP SENSOR .........................................376

Description .............................................................376

DTC Logic ..............................................................376

Diagnosis Procedure .............................................376

Special Repair Requirement ..................................377

P1226 TP SENSOR .........................................378

Description .............................................................378

DTC Logic ..............................................................378

Diagnosis Procedure .............................................378

Special Repair Requirement ..................................379

P1421 COLD START CONTROL ...................380

Description .............................................................380

DTC Logic ..............................................................380

Diagnosis Procedure .............................................380

P1715 INPUT SPEED SENSOR (PRIMARY

SPEED SENSOR) ...........................................

382

Description ........................................................... ..382

DTC Logic ..............................................................382

Diagnosis Procedure .............................................382

P1805 BRAKE SWITCH .................................383

Description .............................................................383

DTC Logic ..............................................................383

Wiring Diagram ......................................................384

Diagnosis Procedure .............................................384

Component Inspection (Stop Lamp Switch) ..........386

P2100, P2103 THROTTLE CONTROL MO-

TOR RELAY ....................................................

387

Description .............................................................387

DTC Logic ..............................................................387

Wiring Diagram ......................................................388

Diagnosis Procedure .............................................388

P2101 ELECTRIC THROTTLE CONTROL

FUNCTION ......................................................

391

Description ........................................................... ..391

DTC Logic ..............................................................391

Wiring Diagram ......................................................392

Diagnosis Procedure .............................................392

Component Inspection ...........................................395

Special Repair Requirement ..................................395

P2118 THROTTLE CONTROL MOTOR .........396

Description .............................................................396

DTC Logic ..............................................................396

Wiring Diagram ......................................................397

Diagnosis Procedure .............................................397

Component Inspection ...........................................398

Special Repair Requirement ..................................399

Revision: May 2010 2011 Versa

Page 1315 of 3787

![NISSAN LATIO 2011 Service Service Manual INSPECTION AND ADJUSTMENTEC-21

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Rev engine (2,000 to 3,000 rpm) two or three times under no

load, then run engine at idle speed for abou NISSAN LATIO 2011 Service Service Manual INSPECTION AND ADJUSTMENTEC-21

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Rev engine (2,000 to 3,000 rpm) two or three times under no

load, then run engine at idle speed for abou](/img/5/57357/w960_57357-1314.png)

INSPECTION AND ADJUSTMENTEC-21

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Rev engine (2,000 to 3,000 rpm) two or three times under no

load, then run engine at idle speed for about 1 minute.

3. Check idle speed.

For procedure, refer to EC-24, "

IDLE SPEED : Special Repair

Requirement". For specification, refer to EC-503, "Idle Speed".

Is the inspection result normal?

YES >> GO TO 10.

NO >> GO TO 4.

4.PERFORM ACCELERATOR PEDAL RE LEASED POSITION LEARNING

1. Stop engine.

2. Perform EC-25, "

ACCELERATOR PEDAL RELEASED POSITION LEARNING : Special Repair Require-

ment".

>> GO TO 5.

5.PERFORM THROTTLE VALVE CL OSED POSITION LEARNING

Perform EC-25, "

THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement".

>> GO TO 6.

6.PERFORM IDLE AIR VOLUME LEARNING

Perform EC-26, "

IDLE AIR VOLUME LEARNING : Special Repair Requirement".

Is Idle Air Volume Learning carried out successfully?

YES >> GO TO 7.

NO >> Follow the instruction of Idle Air Volume Learning. Then GO TO 4.

7.CHECK IDLE SPEED AGAIN

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed. For procedure, refer to EC-24, "

IDLE SPEED : Special Repair Requirement".

For specification, refer to EC-503, "

Idle Speed".

Is the inspection result normal?

YES >> GO TO 10.

NO >> GO TO 8.

8.DETECT MALFUNCTIONING PART

Check the Following.

• Check camshaft position sensor (PHASE) and circuit. Refer to EC-272, "

DTC Logic".

• Check crankshaft position sensor (POS) and circuit. Refer to EC-267, "

DTC Logic".

Is the inspection result normal?

YES >> GO TO 9.

NO >> Repair or replace. Then GO TO 4.

9.CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM f unction. (ECM may be the cause of an incident, but

this is rare.)

2. Perform initialization of NVIS (NATS) system and registration of all NVIS (NATS) ignition key IDs. Refer to BL-247, "

ECM Re-communicating Function".

>> GO TO 4.

10.CHECK IGNITION TIMING

1. Run engine at idle.

PBIA8513J

Revision: May 2010 2011 Versa