headlamp NISSAN LATIO 2011 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 3073 of 3787

FRONT FOG LAMPLT-41

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

FRONT FOG LAMP

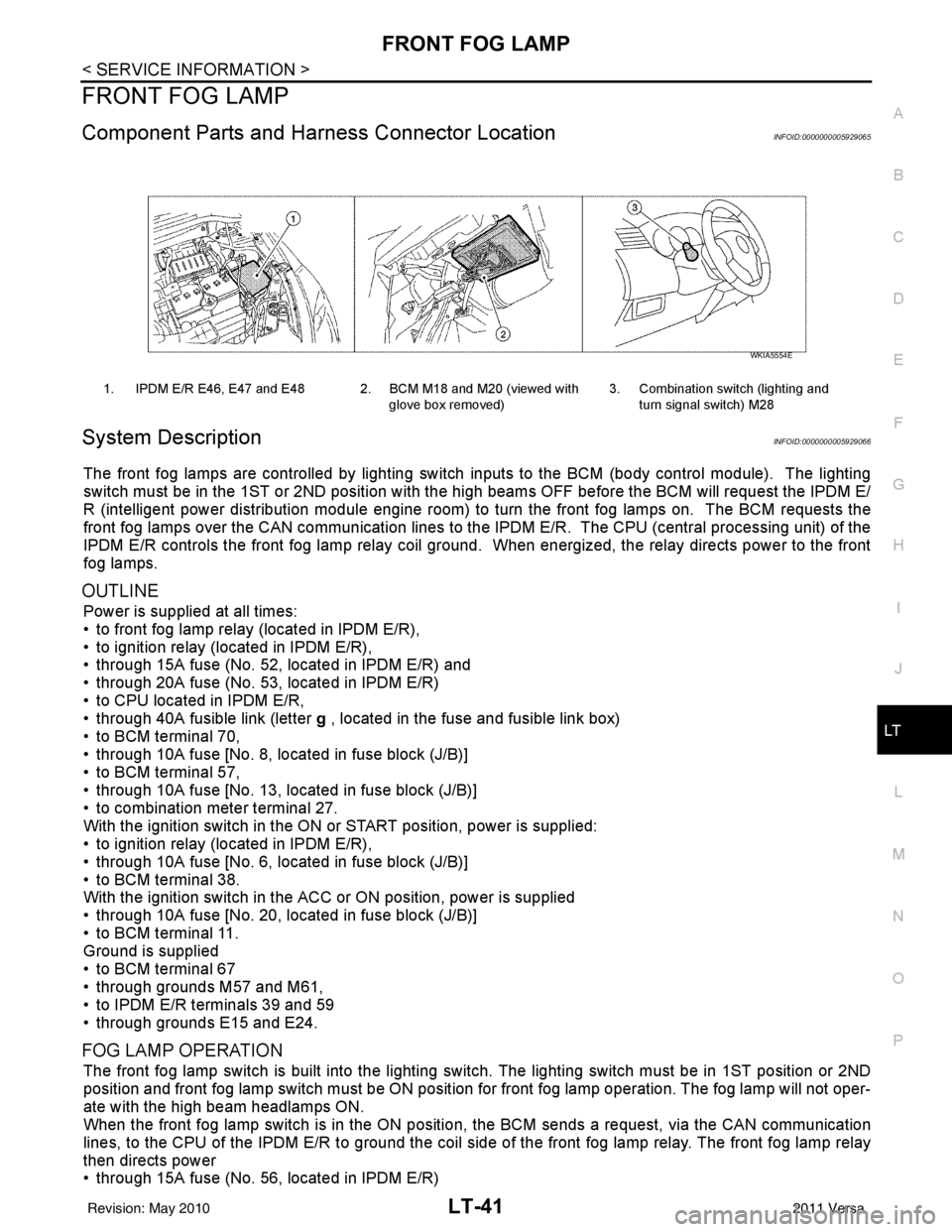

Component Parts and Har ness Connector LocationINFOID:0000000005929065

System DescriptionINFOID:0000000005929066

The front fog lamps are controlled by lighting switch inputs to the BCM (body control module). The lighting

switch must be in the 1ST or 2ND position with the high beams OFF before the BCM will request the IPDM E/

R (intelligent power distribution module engine room) to turn the front fog lamps on. The BCM requests the

front fog lamps over the CAN communication lines to the IPDM E/R. The CPU (central processing unit) of the

IPDM E/R controls the front fog lamp relay coil ground. When energized, the relay directs power to the front

fog lamps.

OUTLINE

Power is supplied at all times:

• to front fog lamp relay (located in IPDM E/R),

• to ignition relay (located in IPDM E/R),

• through 15A fuse (No. 52, located in IPDM E/R) and

• through 20A fuse (No. 53, located in IPDM E/R)

• to CPU located in IPDM E/R,

• through 40A fusible link (letter g , located in the fuse and fusible link box)

• to BCM terminal 70,

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57,

• through 10A fuse [No. 13, located in fuse block (J/B)]

• to combination meter terminal 27.

With the ignition switch in the ON or START position, power is supplied:

• to ignition relay (located in IPDM E/R),

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in fuse block (J/B)]

• to BCM terminal 11.

Ground is supplied

• to BCM terminal 67

• through grounds M57 and M61,

• to IPDM E/R terminals 39 and 59

• through grounds E15 and E24.

FOG LAMP OPERATION

The front fog lamp switch is built into the lighting switch. The lighting switch must be in 1ST position or 2ND

position and front fog lamp switch must be ON position for front fog lamp operation. The fog lamp will not oper-

ate with the high beam headlamps ON.

When the front fog lamp switch is in the ON positi on, the BCM sends a request, via the CAN communication

lines, to the CPU of the IPDM E/R to ground the coil side of the front fog lamp relay. The front fog lamp relay

then directs power

• through 15A fuse (No. 56, located in IPDM E/R)

1. IPDM E/R E46, E47 and E48 2. BCM M18 and M20 (viewed with

glove box removed)3. Combination switch (lighting and

turn signal switch) M28

WKIA5554E

Revision: May 2010 2011 Versa

Page 3080 of 3787

LT-48

< SERVICE INFORMATION >

FRONT FOG LAMP

1. Check continuity between front fog lamp harness connector and

ground.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and

Installation of IPDM E/R" .

NG >> Repair harness or connector.

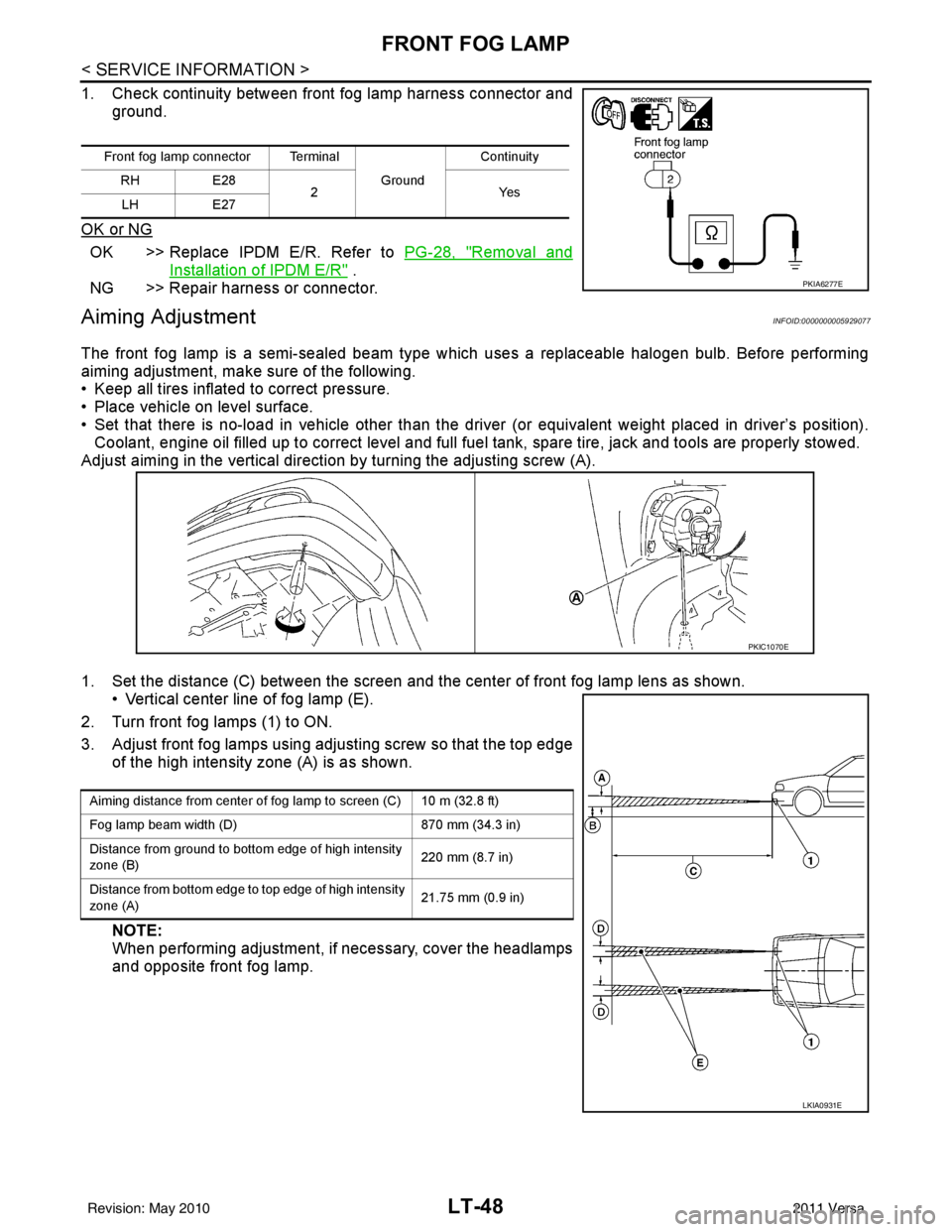

Aiming AdjustmentINFOID:0000000005929077

The front fog lamp is a semi-sealed beam type which uses a replaceable halogen bulb. Before performing

aiming adjustment, make sure of the following.

• Keep all tires inflated to correct pressure.

• Place vehicle on level surface.

• Set that there is no-load in vehicle other than the driv er (or equivalent weight placed in driver’s position).

Coolant, engine oil filled up to correct level and full fuel tank, spare tire, jack and tools are properly stowed.

Adjust aiming in the vertical direct ion by turning the adjusting screw (A).

1. Set the distance (C) between the screen and the center of front fog lamp lens as shown. • Vertical center line of fog lamp (E).

2. Turn front fog lamps (1) to ON.

3. Adjust front fog lamps using adjusting screw so that the top edge of the high intensity zone (A) is as shown.

NOTE:

When performing adjustment, if necessary, cover the headlamps

and opposite front fog lamp.

Front fog lamp connector Terminal

Ground Continuity

RH E28

2Y es

LH E27

PKIA6277E

PKIC1070E

Aiming distance from center of fog lamp to screen (C) 10 m (32.8 ft)

Fog lamp beam width (D) 870 mm (34.3 in)

Distance from ground to bottom edge of high intensity

zone (B) 220 mm (8.7 in)

Distance from bottom edge to top edge of high intensity

zone (A) 21.75 mm (0.9 in)

LKIA0931E

Revision: May 2010

2011 Versa

Page 3116 of 3787

LT-84

< SERVICE INFORMATION >

PARKING, LICENSE PLATE AND TAIL LAMPS

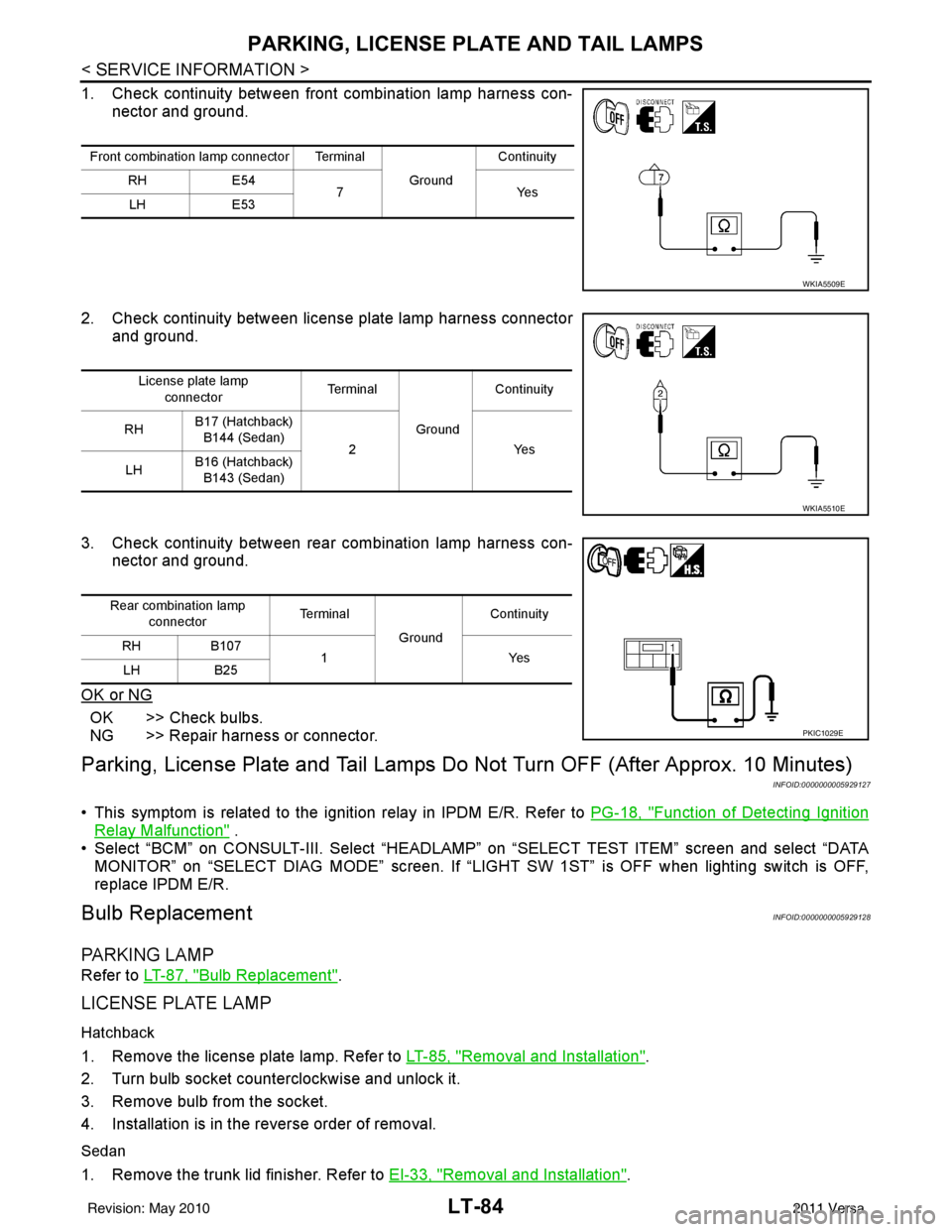

1. Check continuity between front combination lamp harness con-nector and ground.

2. Check continuity between license plate lamp harness connector and ground.

3. Check continuity between rear combination lamp harness con- nector and ground.

OK or NG

OK >> Check bulbs.

NG >> Repair harness or connector.

Parking, License Plate and Tail Lamps Do Not Turn OFF (After Approx. 10 Minutes)

INFOID:0000000005929127

• This symptom is related to the ignition relay in IPDM E/R. Refer to PG-18, "Function of Detecting Ignition

Relay Malfunction" .

• Select “BCM” on CONSULT-III. Select “HEADLAMP” on “SELECT TEST ITEM” screen and select “DATA

MONITOR” on “SELECT DIAG MODE” sc reen. If “LIGHT SW 1ST” is OFF when lighting switch is OFF,

replace IPDM E/R.

Bulb ReplacementINFOID:0000000005929128

PA R K I N G L A M P

Refer to LT-87, "Bulb Replacement".

LICENSE PLATE LAMP

Hatchback

1. Remove the license plate lamp. Refer to LT-85, "Removal and Installation".

2. Turn bulb socket counterclockwise and unlock it.

3. Remove bulb from the socket.

4. Installation is in the reverse order of removal.

Sedan

1. Remove the trunk lid finisher. Refer to EI-33, "Removal and Installation".

Front combination lamp connector Terminal

GroundContinuity

RH E54

7Y es

LH E53

WKIA5509E

License plate lamp

connector Te r m i n a l

GroundContinuity

RH B17 (Hatchback)

B144 (Sedan) 2 Yes

LH B16 (Hatchback)

B143 (Sedan)

WKIA5510E

Rear combination lamp connector Te r m i n a l

GroundContinuity

RH B107

1Y es

LH B25

PKIC1029E

Revision: May 2010 2011 Versa

Page 3135 of 3787

INTERIOR ROOM LAMPLT-103

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

2. Understand operation description and function description. Refer to LT-93, "System Description" .

3. Perform the preliminary check. Refer to LT-103, "

Preliminary Check" .

4. Check symptom and repair or replace the cause of the malfunction.

5. Does the interior room lamp operate norma lly? If YES, GO TO 6. If NO, GO TO 4.

6. Inspection End

Preliminary CheckINFOID:0000000005929144

CHECK POWER SUPPLY AND GROUND CIRCUIT FOR BCM

Refer to BCS-16, "BCM Power Supply and Ground Circuit Inspection" .

CHECK POWER SUPPLY AND GROUND CIRCUIT FOR IPDM E/R

Refer to PG-27, "IPDM E/R Power/Ground Circuit Inspection" .

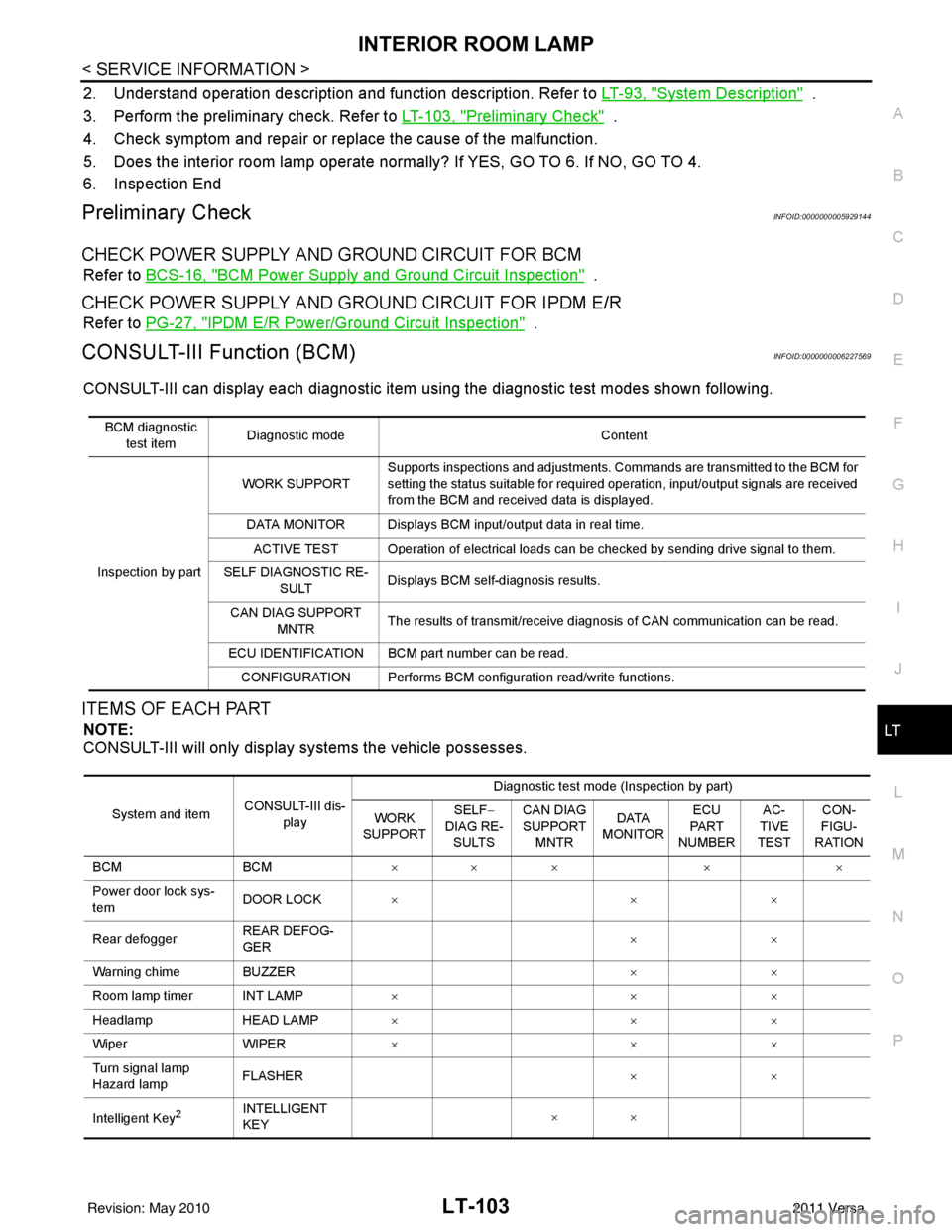

CONSULT-III Function (BCM)INFOID:0000000006227569

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

ITEMS OF EACH PART

NOTE:

CONSULT-III will only display systems the vehicle possesses.

BCM diagnostic

test item Diagnostic mode

Content

Inspection by part WORK SUPPORT

Supports inspections and adjustments. Commands are transmitted to the BCM for

setting the status suitable for required operation, input/output signals are received

from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF DIAGNOSTIC RE- SULT Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The results of transmit/receive diagnosis of CAN communication can be read.

ECU IDENTIFICATION BCM part number can be read. CONFIGURATION Performs BCM configuration read/write functions.

System and item CONSULT-III dis-

play Diagnostic test mode (Inspection by part)

WORK

SUPPORT SELF

−

DIAG RE- SULTS CAN DIAG

SUPPORT MNTR DATA

MONITOR ECU

PA R T

NUMBER AC-

TIVE

TEST CON-

FIGU-

RATION

BCM BCM××× × ×

Power door lock sys-

tem DOOR LOCK

×× ×

Rear defogger REAR DEFOG-

GER

××

Warning chime BUZZER ××

Room lamp timer INT LAMP ×× ×

Headlamp HEAD LAMP×× ×

Wiper WIPER×× ×

Turn signal lamp

Hazard lamp FLASHER

××

Intelligent Key

2INTELLIGENT

KEY ××

Revision: May 2010

2011 Versa

Page 3148 of 3787

LT-116

< SERVICE INFORMATION >

BULB SPECIFICATIONS

BULB SPECIFICATIONS

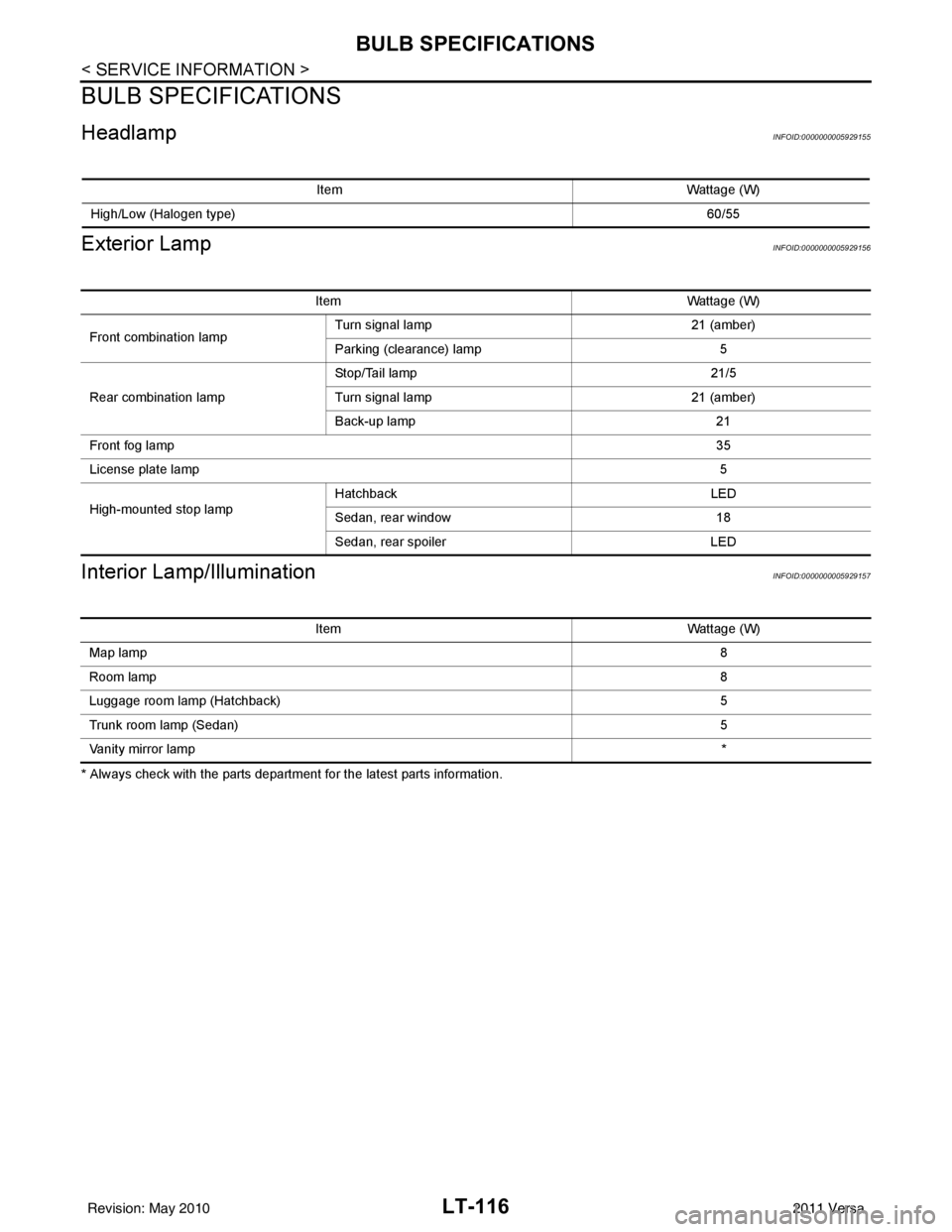

HeadlampINFOID:0000000005929155

Exterior LampINFOID:0000000005929156

Interior Lamp/IlluminationINFOID:0000000005929157

* Always check with the parts department for the latest parts information.Item

Wattage (W)

High/Low (Halogen type) 60/55

ItemWattage (W)

Front combination lamp Turn signal lamp

21 (amber)

Parking (clearance) lamp 5

Rear combination lamp Stop/Tail lamp

21/5

Turn signal lamp 21 (amber)

Back-up lamp 21

Front fog lamp 35

License plate lamp 5

High-mounted stop lamp Hatchback

LED

Sedan, rear window 18

Sedan, rear spoiler LED

ItemWattage (W)

Map lamp 8

Room lamp 8

Luggage room lamp (Hatchback) 5

Trunk room lamp (Sedan) 5

Vanity mirror lamp *

Revision: May 2010 2011 Versa

Page 3178 of 3787

GENERAL MAINTENANCEMA-7

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

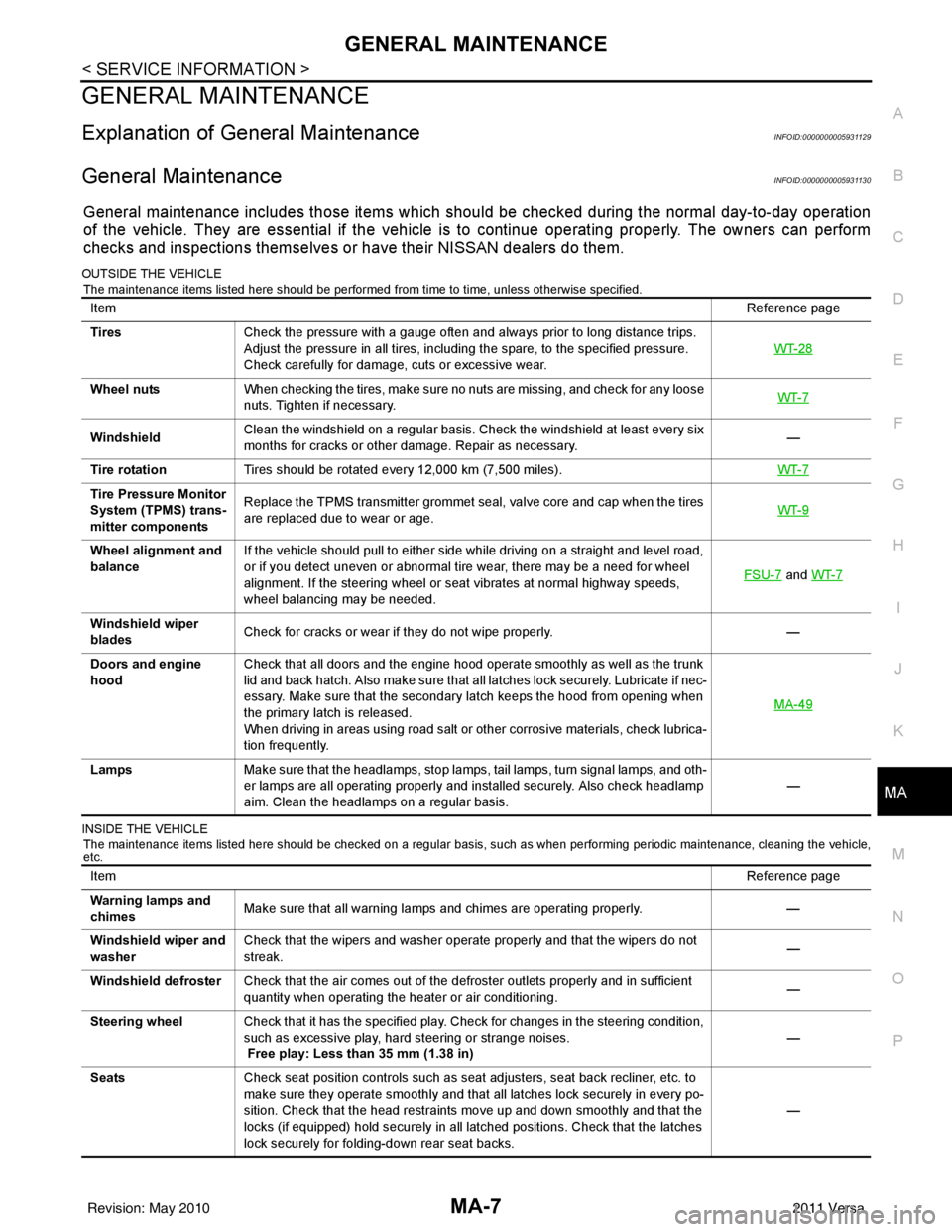

GENERAL MAINTENANCE

Explanation of Gene ral MaintenanceINFOID:0000000005931129

General MaintenanceINFOID:0000000005931130

General maintenance includes those items which shoul d be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or have their NISSAN dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

INSIDE THE VEHICLE The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Tires Check the pressure with a gauge often and always prior to long distance trips.

Adjust the pressure in all tires, including the spare, to the specified pressure.

Check carefully for damage, cuts or excessive wear. WT-28

Wheel nuts

When checking the tires, make sure no nuts are missing, and check for any loose

nuts. Tighten if necessary. WT-7

WindshieldClean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary.

—

Tire rotation Tires should be rotated every 12,000 km (7,500 miles). WT-7

Tire Pressure Monitor

System (TPMS) trans-

mitter componentsReplace the TPMS transmitter grommet seal, valve core and cap when the tires

are replaced due to wear or age.

WT-9

Wheel alignment and

balanceIf the vehicle should pull to either side while driving on a straight and level road,

or if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed. FSU-7

and

WT-7

Windshield wiper

blades Check for cracks or wear if they do not wipe properly.

—

Doors and engine

hood Check that all doors and the engine hood operate smoothly as well as the trunk

lid and back hatch. Also make sure that all latches lock securely. Lubricate if nec-

essary. Make sure that the secondary latch keeps the hood from opening when

the primary latch is released.

When driving in areas using road salt or other corrosive materials, check lubrica-

tion frequently. MA-49

Lamps

Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and oth-

er lamps are all operating properly and installed securely. Also check headlamp

aim. Clean the headlamps on a regular basis. —

Item

Reference page

Warning lamps and

chimes Make sure that all warning lamps and chimes are operating properly.

—

Windshield wiper and

washer Check that the wipers and washer operate properly and that the wipers do not

streak.

—

Windshield defroster Check that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioning. —

Steering wheel Check that it has the specified play. Check for changes in the steering condition,

such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in) —

Seats Check seat position controls such as seat adjusters, seat back recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every po-

sition. Check that the head restraints move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seat backs. —

Revision: May 2010

2011 Versa

Page 3338 of 3787

MTC-22

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

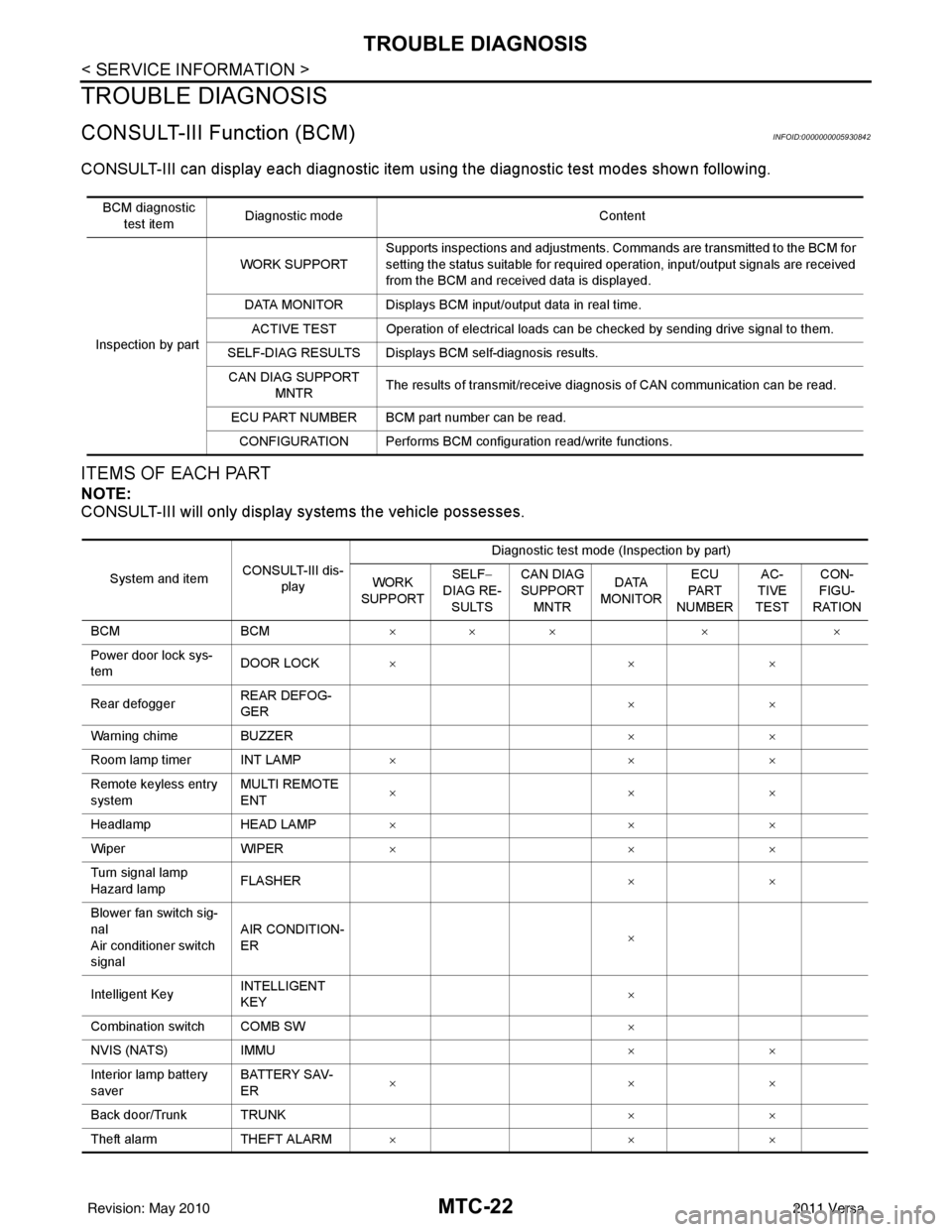

TROUBLE DIAGNOSIS

CONSULT-III Function (BCM)INFOID:0000000005930842

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

ITEMS OF EACH PART

NOTE:

CONSULT-III will only display systems the vehicle possesses.

BCM diagnostic

test item Diagnostic mode

Content

Inspection by part WORK SUPPORT

Supports inspections and adjustments. Commands are transmitted to the BCM for

setting the status suitable for required operation, input/output signals are received

from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results. CAN DIAG SUPPORT MNTR The results of transmit/receive diagnosis of CAN communication can be read.

ECU PART NUMBER BCM part number can be read. CONFIGURATION Performs BCM configuration read/write functions.

System and item CONSULT-III dis-

play Diagnostic test mode (Inspection by part)

WORK

SUPPORT SELF

−

DIAG RE-

SULTS CAN DIAG

SUPPORT

MNTR DATA

MONITOR ECU

PA R T

NUMBER AC-

TIVE

TEST CON-

FIGU-

RATION

BCM BCM×× × × ×

Power door lock sys-

tem DOOR LOCK

×× ×

Rear defogger REAR DEFOG-

GER ××

Warning chime BUZZER ××

Room lamp timer INT LAMP ×× ×

Remote keyless entry

system MULTI REMOTE

ENT

××

×

Headlamp HEAD LAMP×× ×

Wiper WIPER×× ×

Turn signal lamp

Hazard lamp FLASHER

××

Blower fan switch sig-

nal

Air conditioner switch

signal AIR CONDITION-

ER

×

Intelligent Key INTELLIGENT

KEY ×

Combination switch COMB SW ×

NVIS (NATS) IMMU ××

Interior lamp battery

saver BATTERY SAV-

ER

××

×

Back door/Trunk TRUNK ××

Theft alarm THEFT ALARM×× ×

Revision: May 2010 2011 Versa

Page 3405 of 3787

REFRIGERANT LINESMTC-89

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

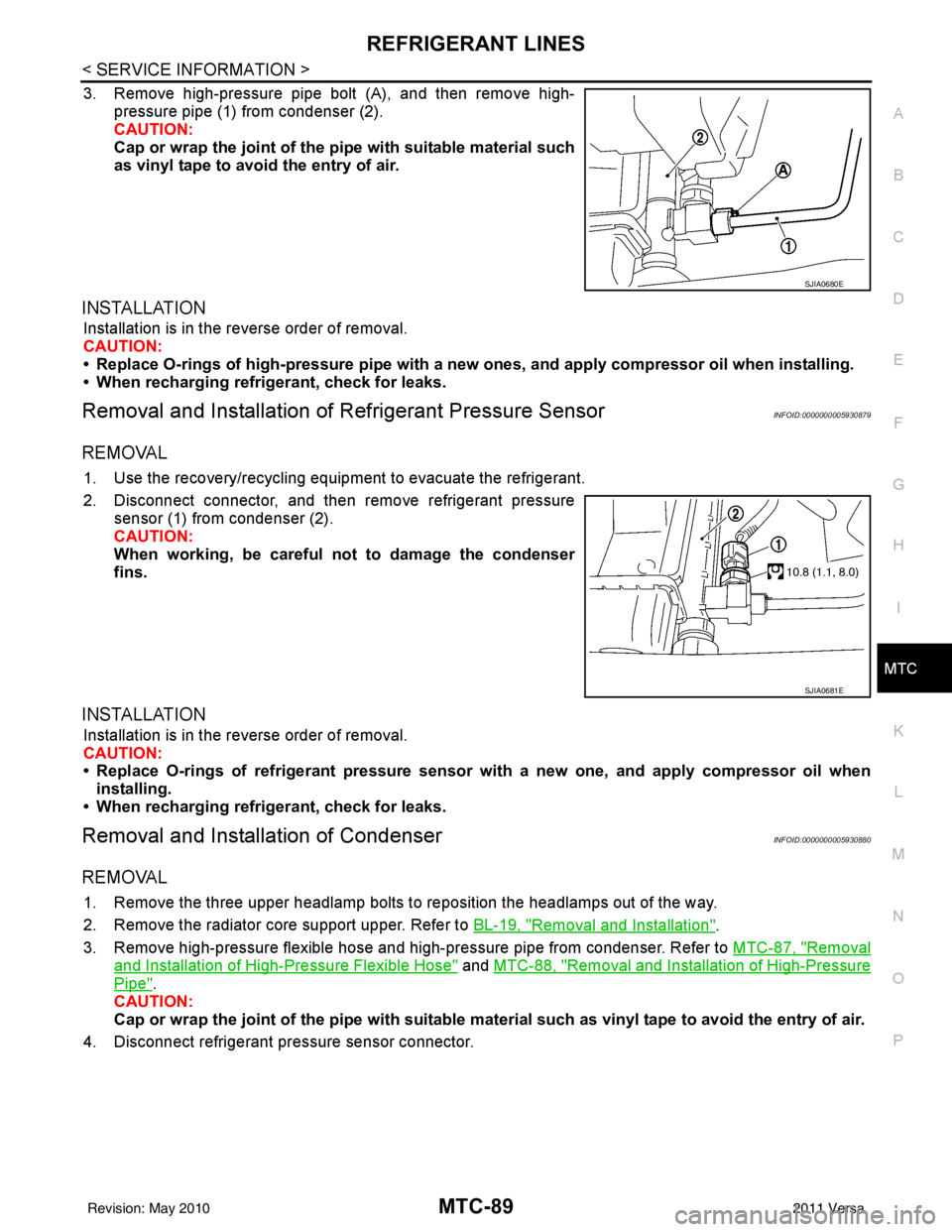

3. Remove high-pressure pipe bolt (A), and then remove high- pressure pipe (1) from condenser (2).

CAUTION:

Cap or wrap the joint of the pi pe with suitable material such

as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings of high-pressure pipe with a new ones, and apply compr essor oil when installing.

• When recharging refrigerant, check for leaks.

Removal and Installation of Refrigerant Pressure SensorINFOID:0000000005930879

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant.

2. Disconnect connector, and then remove refrigerant pressure

sensor (1) from condenser (2).

CAUTION:

When working, be careful not to damage the condenser

fins.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings of refrigerant pressure senso r with a new one, and apply compressor oil when

installing.

• When recharging refrigerant, check for leaks.

Removal and Installation of CondenserINFOID:0000000005930880

REMOVAL

1. Remove the three upper headlamp bolts to reposition the headlamps out of the way.

2. Remove the radiator core support upper. Refer to BL-19, "

Removal and Installation".

3. Remove high-pressure flexible hose and high-pressure pipe from condenser. Refer to MTC-87, "

Removal

and Installation of High-Pressure Flexible Hose" and MTC-88, "Removal and Installation of High-Pressure

Pipe".

CAUTION:

Cap or wrap the joint of the pipe with suitable ma terial such as vinyl tape to avoid the entry of air.

4. Disconnect refrigerant pr essure sensor connector.

SJIA0680E

SJIA0681E

Revision: May 2010 2011 Versa

Page 3437 of 3787

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-17

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

PG

N

O P

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

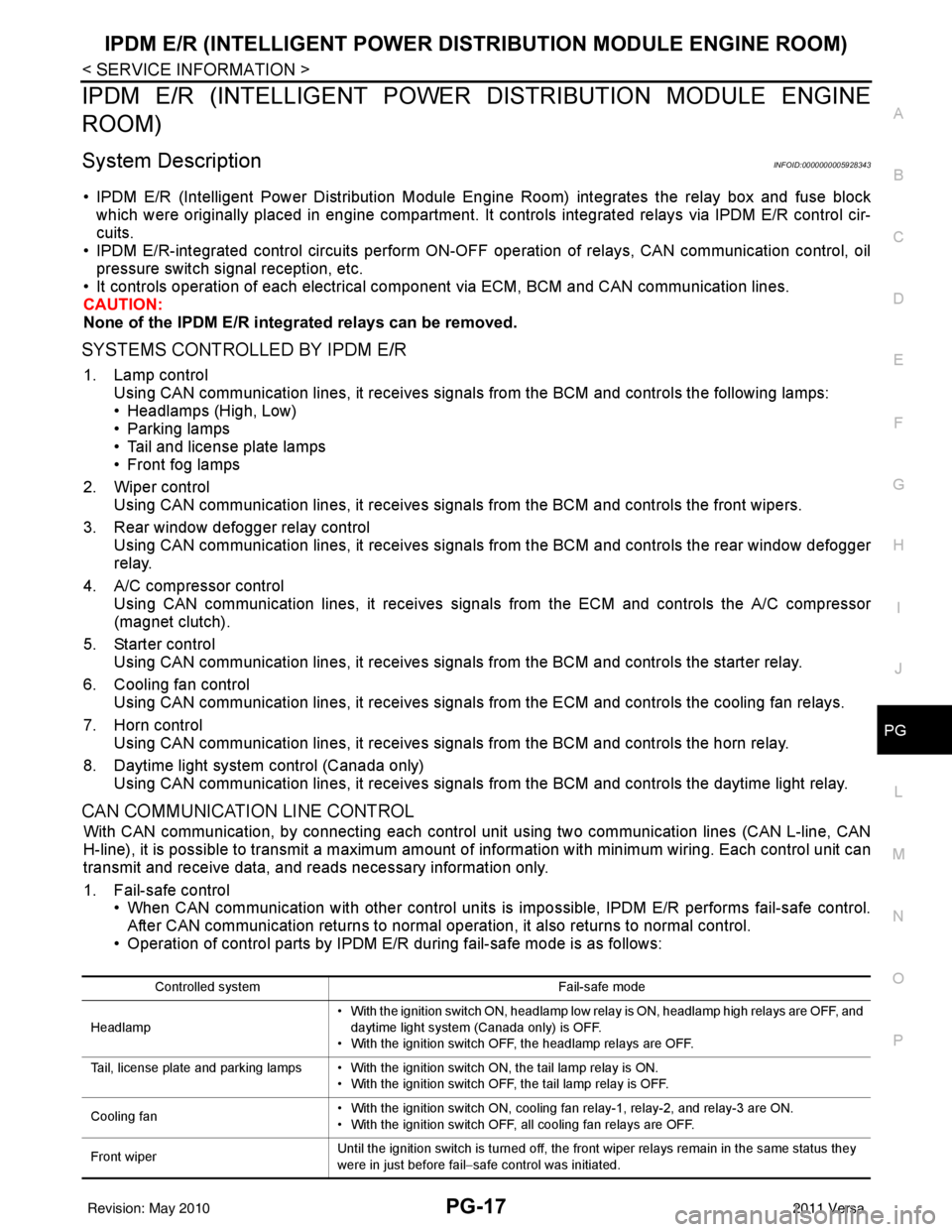

System DescriptionINFOID:0000000005928343

• IPDM E/R (Intelligent Power Distribution Module Engi ne Room) integrates the relay box and fuse block

which were originally placed in engine compartment. It controls integrated relays via IPDM E/R control cir-

cuits.

• IPDM E/R-integrated control circuits perform ON-OFF operation of relays, CAN communication control, oil pressure switch signal reception, etc.

• It controls operation of each electrical co mponent via ECM, BCM and CAN communication lines.

CAUTION:

None of the IPDM E/R integr ated relays can be removed.

SYSTEMS CONTROLLED BY IPDM E/R

1. Lamp control

Using CAN communication lines, it receives signals from the BCM and controls the following lamps:

• Headlamps (High, Low)

• Parking lamps

• Tail and license plate lamps

• Front fog lamps

2. Wiper control Using CAN communication lines, it receives signals from the BCM and controls the front wipers.

3. Rear window defogger relay control Using CAN communication lines, it receives signals from the BCM and controls the rear window defogger

relay.

4. A/C compressor control Using CAN communication lines, it receives signal s from the ECM and controls the A/C compressor

(magnet clutch).

5. Starter control Using CAN communication lines, it receives signals from the BCM and controls the starter relay.

6. Cooling fan control Using CAN communication lines, it receives signals from the ECM and controls the cooling fan relays.

7. Horn control Using CAN communication lines, it receives signals from the BCM and controls the horn relay.

8. Daytime light system control (Canada only) Using CAN communication lines, it receives signals from the BCM and controls the daytime light relay.

CAN COMMUNICATION LINE CONTROL

With CAN communication, by connecting each control unit using two communication lines (CAN L-line, CAN

H-line), it is possible to transmit a maximum amount of information with minimum wiring. Each control unit can

transmit and receive data, and reads necessary information only.

1. Fail-safe control • When CAN communication with other control units is impossible, IPDM E/R performs fail-safe control.

After CAN communication returns to normal operation, it also returns to normal control.

• Operation of control parts by IPDM E/ R during fail-safe mode is as follows:

Controlled system Fail-safe mode

Headlamp • With the ignition switch ON, headlamp low relay is ON, headlamp high relays are OFF, and

daytime light system (Canada only) is OFF.

• With the ignition switch OFF, the headlamp relays are OFF.

Tail, license plate and parking lamps • With the ignition switch ON, the tail lamp relay is ON. • With the ignition switch OFF, the tail lamp relay is OFF.

Cooling fan • With the ignition switch ON, cooling fan relay-1, relay-2, and relay-3 are ON.

• With the ignition switch OFF, all cooling fan relays are OFF.

Front wiper Until the ignition switch is turned off, the front wiper relays remain in the same status they

were in just before fail

−safe control was initiated.

Revision: May 2010 2011 Versa

Page 3439 of 3787

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-19

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

PG

N

O P

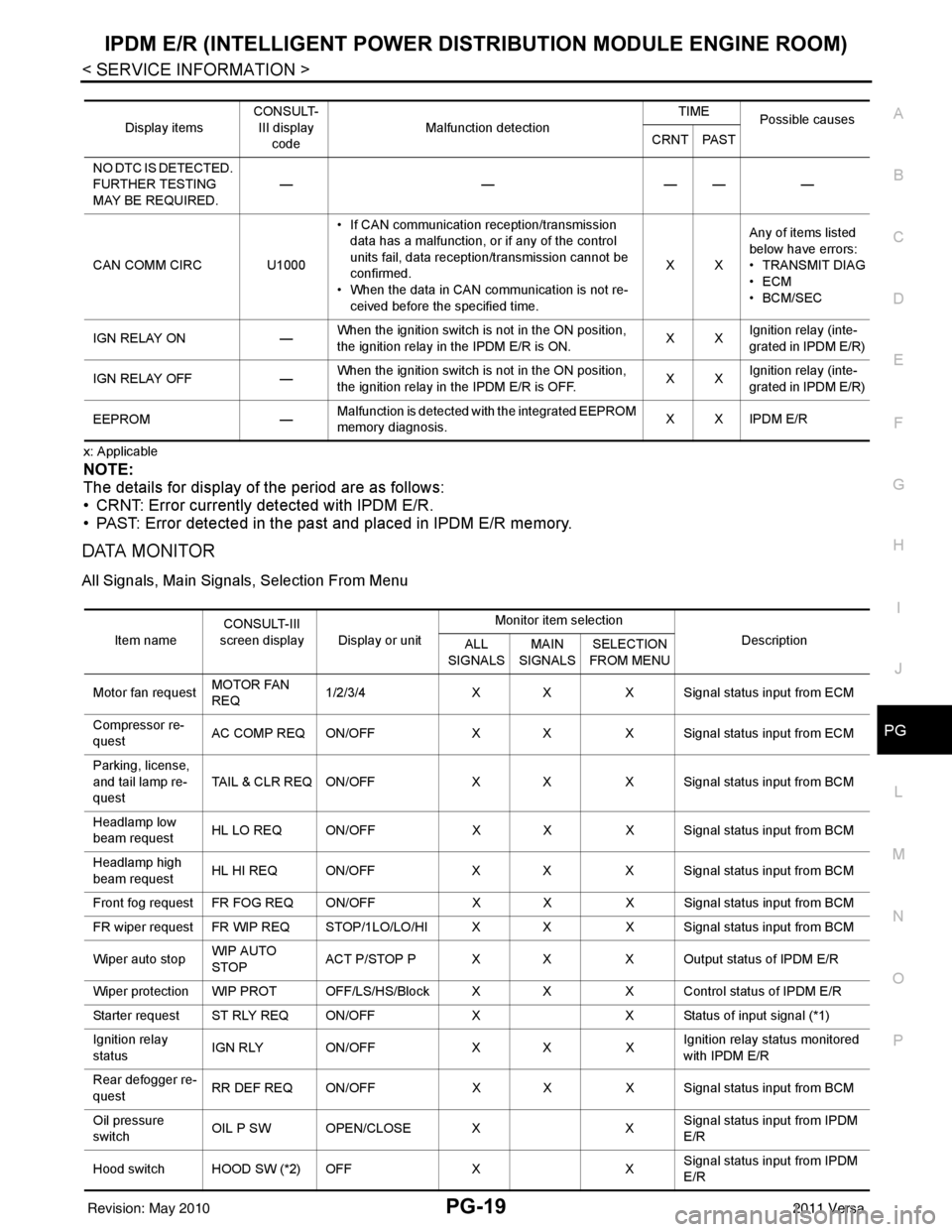

x: Applicable

NOTE:

The details for display of the period are as follows:

• CRNT: Error currently detected with IPDM E/R.

• PAST: Error detected in the past and placed in IPDM E/R memory.

DATA MONITOR

All Signals, Main Signals, Selection From Menu

Display items CONSULT-

III display code Malfunction detection TIME

Possible causes

CRNT PAST

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED. ———

——

CAN COMM CIRC U1000 • If CAN communication reception/transmission

data has a malfunction, or if any of the control

units fail, data reception/transmission cannot be

confirmed.

• When the data in CAN communication is not re-

ceived before the specified time. XX

Any of items listed

below have

errors:

• TRANSMIT DIAG

•ECM

• BCM/SEC

IGN RELAY ON —When the ignition switch is not in the ON position,

the ignition relay in the IPDM E/R is ON. XX

Ignition relay (inte-

grated in IPDM E/R)

IGN RELAY OFF —When the ignition switch is not in the ON position,

the ignition relay in the IPDM E/R is OFF. XXIgnition relay (inte-

grated in IPDM E/R)

EEPROM —Malfunction is detected with the integrated EEPROM

memory diagnosis.

X X IPDM E/R

Item nameCONSULT-III

screen display Display or unit Monitor item selection

Description

ALL

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

Motor fan request MOTOR FAN

REQ1/2/3/4

X X X Signal status input from ECM

Compressor re-

quest AC COMP REQ ON/OFF

X XX Signal status input from ECM

Parking, license,

and tail lamp re-

quest TAIL & CLR REQ ON/OFF

X XX Signal status input from BCM

Headlamp low

beam request HL LO REQ ON/OFF

X XX Signal status input from BCM

Headlamp high

beam request HL HI REQ ON/OFF

X XX Signal status input from BCM

Front fog request FR FOG REQ ON/OFF X XX Signal status input from BCM

FR wiper request FR WIP REQ STOP/1LO/LO/HI X X X Signal status input from BCM

Wiper auto stop WIP AUTO

STOPACT P/STOP P X X

X Output status of IPDM E/R

Wiper protection WIP PROT OFF/LS/HS/Block X X X Control status of IPDM E/R

Starter request ST RLY REQ ON/OFF XX Status of input signal (*1)

Ignition relay

status IGN RLY ON/OFF

X XXIgnition relay status monitored

with IPDM E/R

Rear defogger re-

quest RR DEF REQ ON/OFF

X XX Signal status input from BCM

Oil pressure

switch OIL P SW OPEN/CLOSE X

XSignal status input from IPDM

E/R

Hood switch HOOD SW (*2) OFF XXSignal status input from IPDM

E/R

Revision: May 2010

2011 Versa