torque NISSAN NAVARA 2005 Repair Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 868 of 3171

CL-4

PREPARATION

Flare nut torque wrench

a: 14 mm (0.55 in)Removing and installing clutch piping (For

LHD models)

PullerRemoving release bearing Tool nameDescription

S-NT406

NT077

Page 871 of 3171

CLUTCH PEDAL

CL-7

D

E

F

G

H

I

J

K

L

MA

B

CL

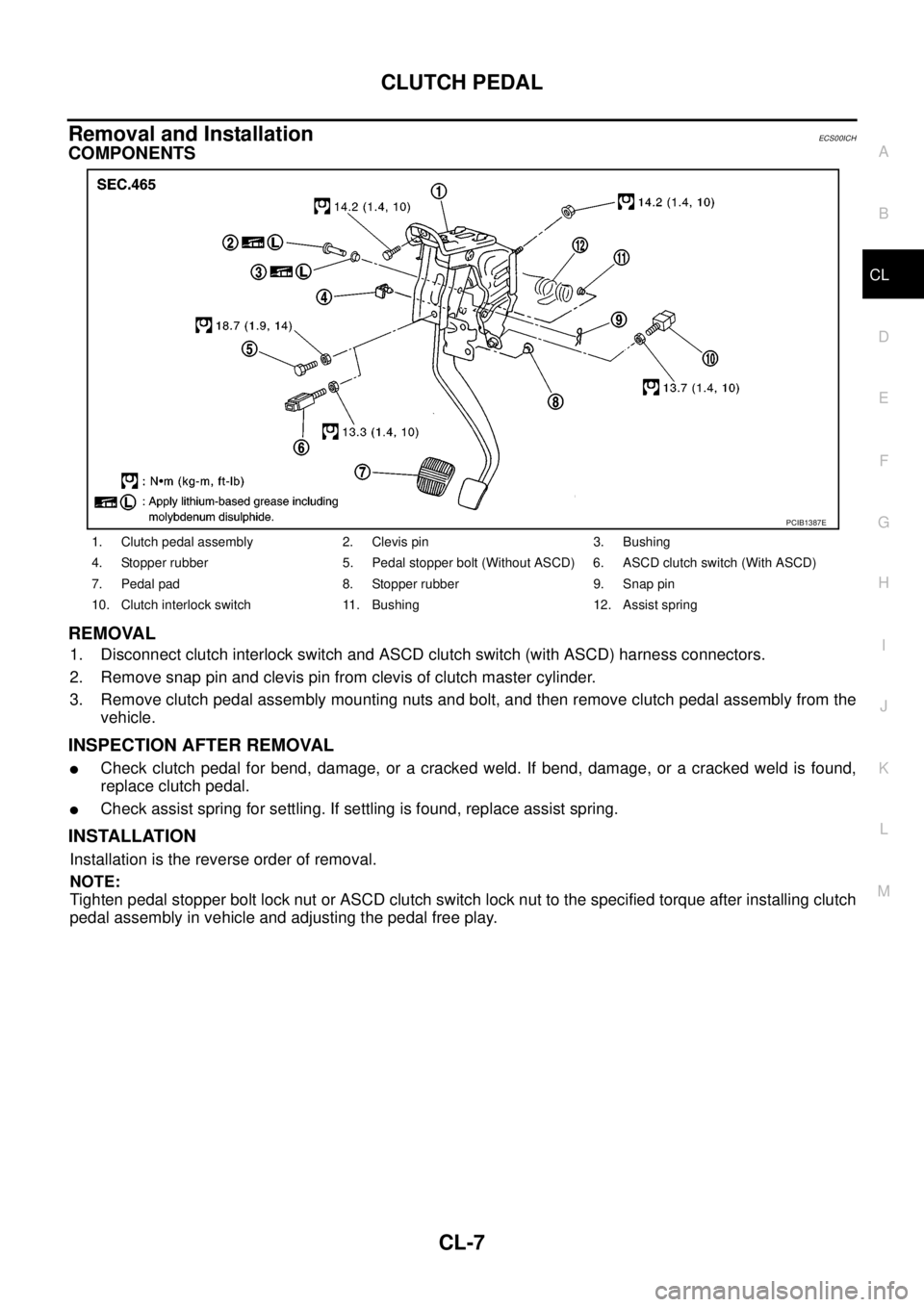

Removal and InstallationECS00ICH

COMPONENTS

REMOVAL

1. Disconnect clutch interlock switch and ASCD clutch switch (with ASCD) harness connectors.

2. Remove snap pin and clevis pin from clevis of clutch master cylinder.

3. Remove clutch pedal assembly mounting nuts and bolt, and then remove clutch pedal assembly from the

vehicle.

INSPECTION AFTER REMOVAL

lCheck clutch pedal for bend, damage, or a cracked weld. If bend, damage, or a cracked weld is found,

replace clutch pedal.

lCheck assist spring for settling. If settling is found, replace assist spring.

INSTALLATION

Installation is the reverse order of removal.

NOTE:

Tighten pedal stopper bolt lock nut or ASCD clutch switch lock nut to the specified torque after installing clutch

pedal assembly in vehicle and adjusting the pedal free play.

1. Clutch pedal assembly 2. Clevis pin 3. Bushing

4. Stopper rubber 5. Pedal stopper bolt (Without ASCD) 6. ASCD clutch switch (With ASCD)

7. Pedal pad 8. Stopper rubber 9. Snap pin

10. Clutch interlock switch 11. Bushing 12. Assist spring

PCIB1387E

Page 872 of 3171

CL-8

CLUTCH FLUID

CLUTCH FLUID

PFP:00017

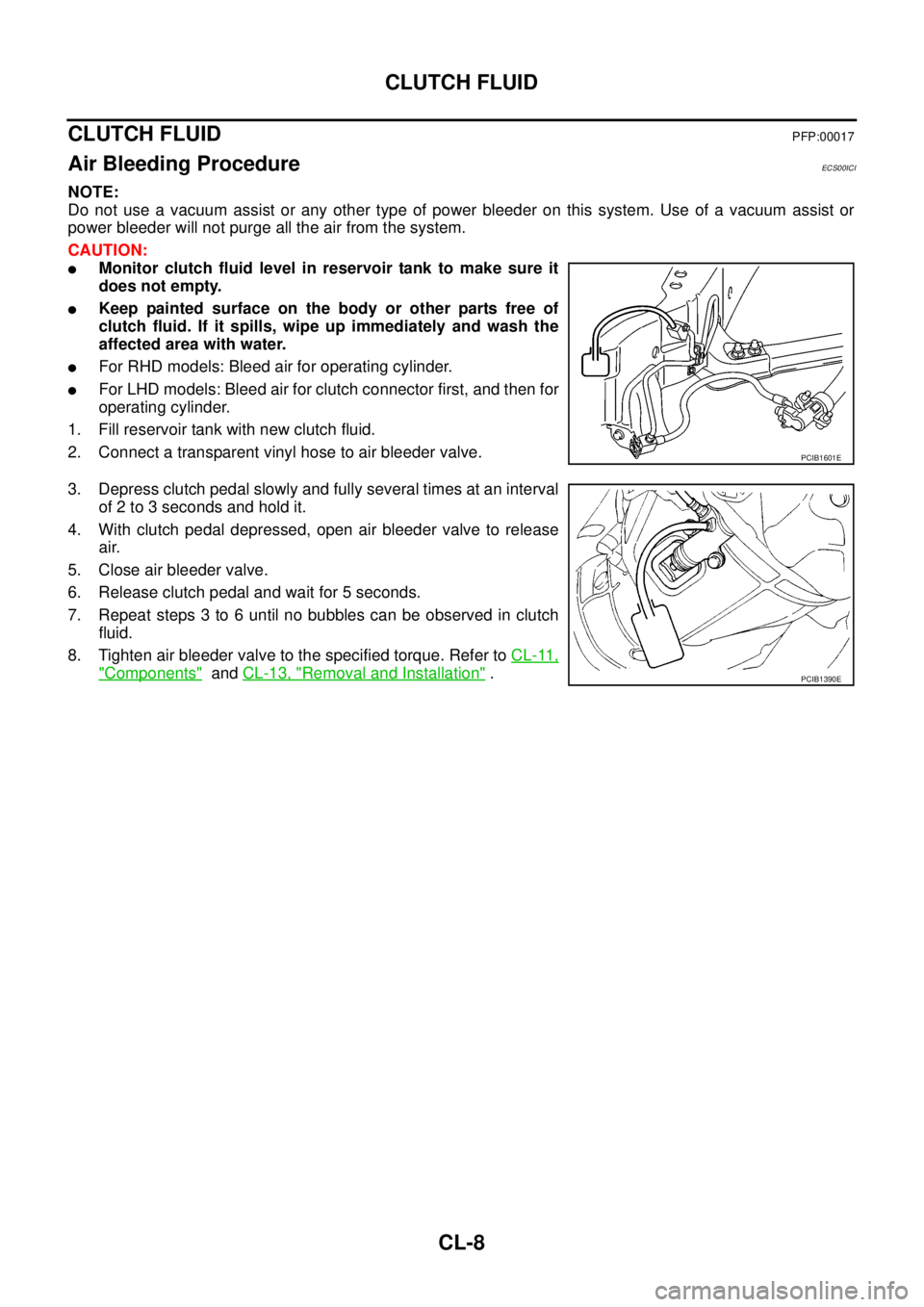

Air Bleeding ProcedureECS00ICI

NOTE:

Do not use a vacuum assist or any other type of power bleeder on this system. Use of a vacuum assist or

power bleeder will not purge all the air from the system.

CAUTION:

lMonitor clutch fluid level in reservoir tank to make sure it

does not empty.

lKeep painted surface on the body or other parts free of

clutch fluid. If it spills, wipe up immediately and wash the

affected area with water.

lFor RHD models: Bleed air for operating cylinder.

lFor LHD models: Bleed air for clutch connector first, and then for

operating cylinder.

1. Fill reservoir tank with new clutch fluid.

2. Connect a transparent vinyl hose to air bleeder valve.

3. Depress clutch pedal slowly and fully several times at an interval

of 2 to 3 seconds and hold it.

4. With clutch pedal depressed, open air bleeder valve to release

air.

5. Close air bleeder valve.

6. Release clutch pedal and wait for 5 seconds.

7. Repeat steps 3 to 6 until no bubbles can be observed in clutch

fluid.

8. Tighten air bleeder valve to the specified torque. Refer toCL-11,

"Components"andCL-13, "Removal and Installation".

PCIB1601E

PCIB1390E

Page 873 of 3171

CLUTCH MASTER CYLINDER

CL-9

D

E

F

G

H

I

J

K

L

MA

B

CL

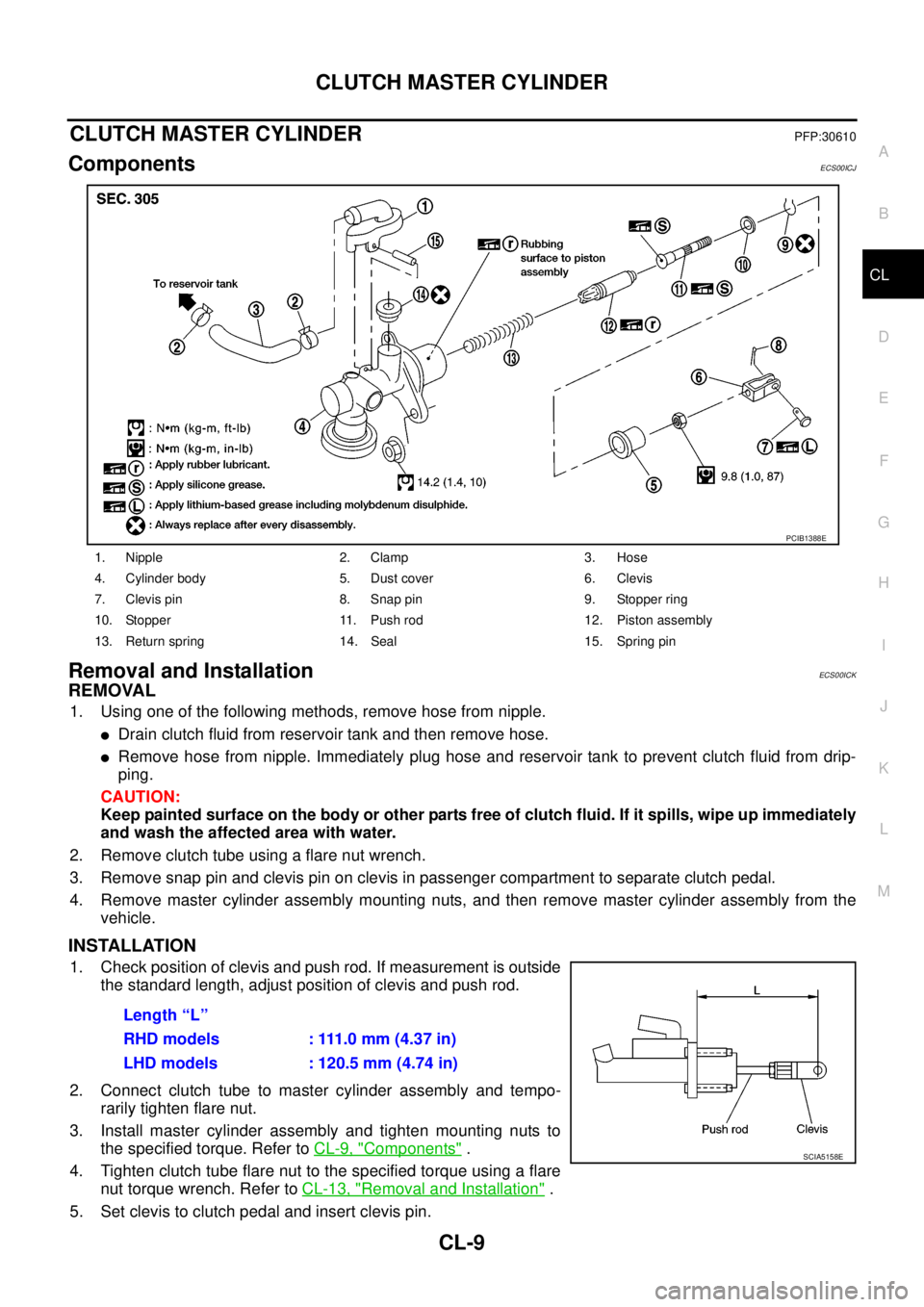

CLUTCH MASTER CYLINDERPFP:30610

ComponentsECS00ICJ

Removal and InstallationECS00ICK

REMOVAL

1. Using one of the following methods, remove hose from nipple.

lDrain clutch fluid from reservoir tank and then remove hose.

lRemove hose from nipple. Immediately plug hose and reservoir tank to prevent clutch fluid from drip-

ping.

CAUTION:

Keep painted surface on the body or other parts free of clutch fluid. If it spills, wipe up immediately

and wash the affected area with water.

2. Remove clutch tube using a flare nut wrench.

3. Remove snap pin and clevis pin on clevis in passenger compartment to separate clutch pedal.

4. Remove master cylinder assembly mounting nuts, and then remove master cylinder assembly from the

vehicle.

INSTALLATION

1. Check position of clevis and push rod. If measurement is outside

the standard length, adjust position of clevis and push rod.

2. Connect clutch tube to master cylinder assembly and tempo-

rarily tighten flare nut.

3. Install master cylinder assembly and tighten mounting nuts to

the specified torque. Refer toCL-9, "

Components".

4. Tightenclutchtubeflarenuttothespecifiedtorqueusingaflare

nut torque wrench. Refer toCL-13, "

Removal and Installation".

5. Set clevis to clutch pedal and insert clevis pin.

1. Nipple 2. Clamp 3. Hose

4. Cylinder body 5. Dust cover 6. Clevis

7. Clevis pin 8. Snap pin 9. Stopper ring

10. Stopper 11. Push rod 12. Piston assembly

13. Return spring 14. Seal 15. Spring pin

PCIB1388E

Length “L”

RHD models : 111.0 mm (4.37 in)

LHD models : 120.5 mm (4.74 in)

SCIA5158E

Page 874 of 3171

CL-10

CLUTCH MASTER CYLINDER

6. Attach snap pin to clevis pin.

7. Install hose to nipple.

8. After completing this procedure, inspect and adjust for clutch pedal and then bleed the air from the clutch

hydraulic system. Refer toCL-6, "

On-Vehicle Inspection and Adjustment"andCL-8, "Air Bleeding Proce-

dure".

Disassembly and AssemblyECS00ICL

DISASSEMBLY

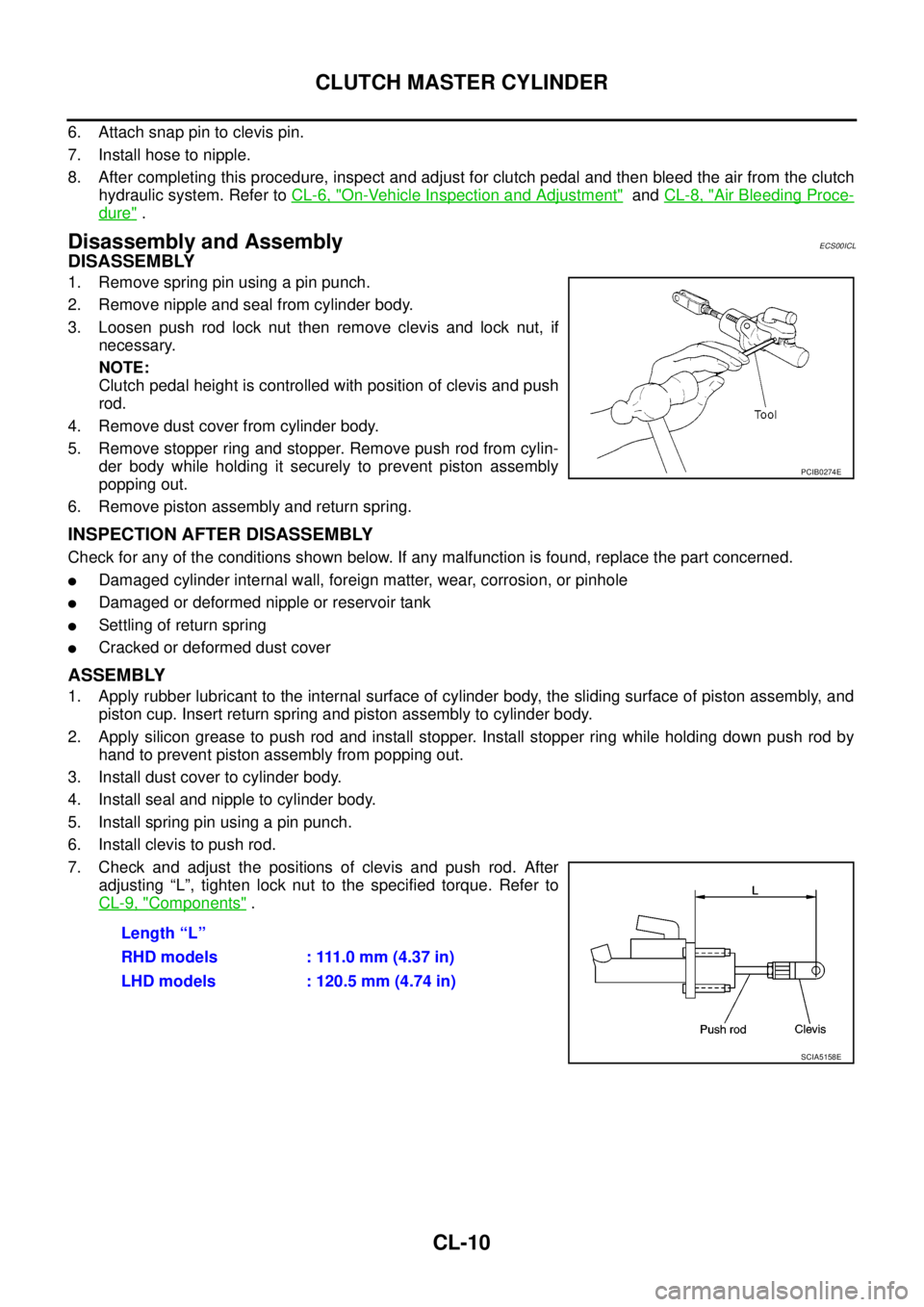

1. Remove spring pin using a pin punch.

2. Remove nipple and seal from cylinder body.

3. Loosen push rod lock nut then remove clevis and lock nut, if

necessary.

NOTE:

Clutch pedal height is controlled with position of clevis and push

rod.

4. Remove dust cover from cylinder body.

5. Remove stopper ring and stopper. Remove push rod from cylin-

der body while holding it securely to prevent piston assembly

popping out.

6. Remove piston assembly and return spring.

INSPECTION AFTER DISASSEMBLY

Check for any of the conditions shown below. If any malfunction is found, replace the part concerned.

lDamaged cylinder internal wall, foreign matter, wear, corrosion, or pinhole

lDamaged or deformed nipple or reservoir tank

lSettling of return spring

lCracked or deformed dust cover

ASSEMBLY

1. Apply rubber lubricant to the internal surface of cylinder body, the sliding surface of piston assembly, and

piston cup. Insert return spring and piston assembly to cylinder body.

2. Apply silicon grease to push rod and install stopper. Install stopper ring while holding down push rod by

hand to prevent piston assembly from popping out.

3. Install dust cover to cylinder body.

4. Install seal and nipple to cylinder body.

5. Install spring pin using a pin punch.

6. Install clevis to push rod.

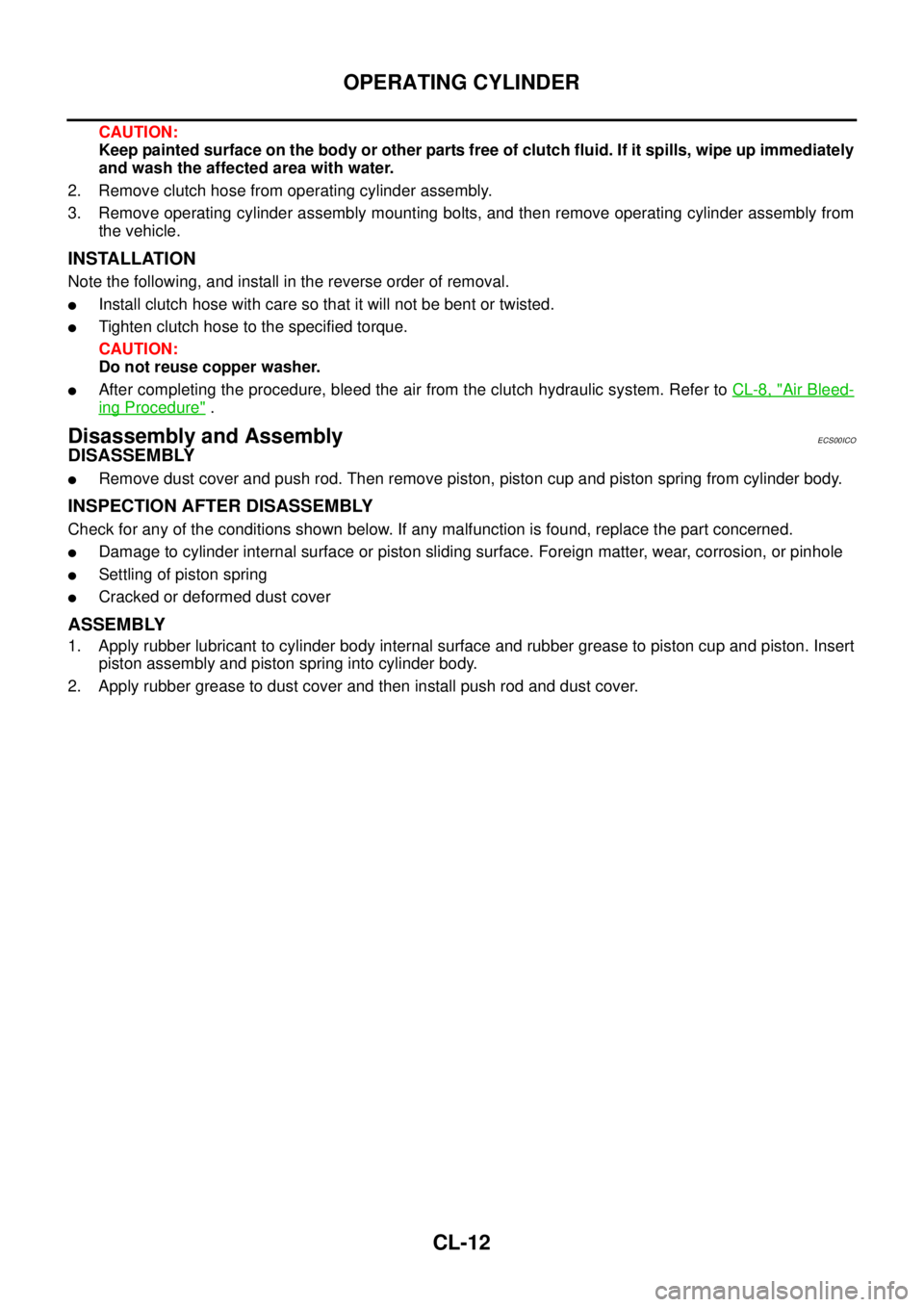

7. Check and adjust the positions of clevis and push rod. After

adjusting “L”, tighten lock nut to the specified torque. Refer to

CL-9, "

Components".

PCIB0274E

Length “L”

RHD models : 111.0 mm (4.37 in)

LHD models : 120.5 mm (4.74 in)

SCIA5158E

Page 876 of 3171

CL-12

OPERATING CYLINDER

CAUTION:

Keep painted surface on the body or other parts free of clutch fluid. If it spills, wipe up immediately

and wash the affected area with water.

2. Remove clutch hose from operating cylinder assembly.

3. Remove operating cylinder assembly mounting bolts, and then remove operating cylinder assembly from

the vehicle.

INSTALLATION

Note the following, and install in the reverse order of removal.

lInstall clutch hose with care so that it will not be bent or twisted.

lTightenclutchhosetothespecifiedtorque.

CAUTION:

Do not reuse copper washer.

lAfter completing the procedure, bleed the air from the clutch hydraulic system. Refer toCL-8, "Air Bleed-

ing Procedure".

Disassembly and AssemblyECS00ICO

DISASSEMBLY

lRemove dust cover and push rod. Then remove piston, piston cup and piston spring from cylinder body.

INSPECTION AFTER DISASSEMBLY

Check for any of the conditions shown below. If any malfunction is found, replace the part concerned.

lDamage to cylinder internal surface or piston sliding surface. Foreign matter, wear, corrosion, or pinhole

lSettling of piston spring

lCracked or deformed dust cover

ASSEMBLY

1. Apply rubber lubricant to cylinder body internal surface and rubber grease to piston cup and piston. Insert

piston assembly and piston spring into cylinder body.

2. Apply rubber grease to dust cover and then install push rod and dust cover.

Page 877 of 3171

CLUTCH PIPING

CL-13

D

E

F

G

H

I

J

K

L

MA

B

CL

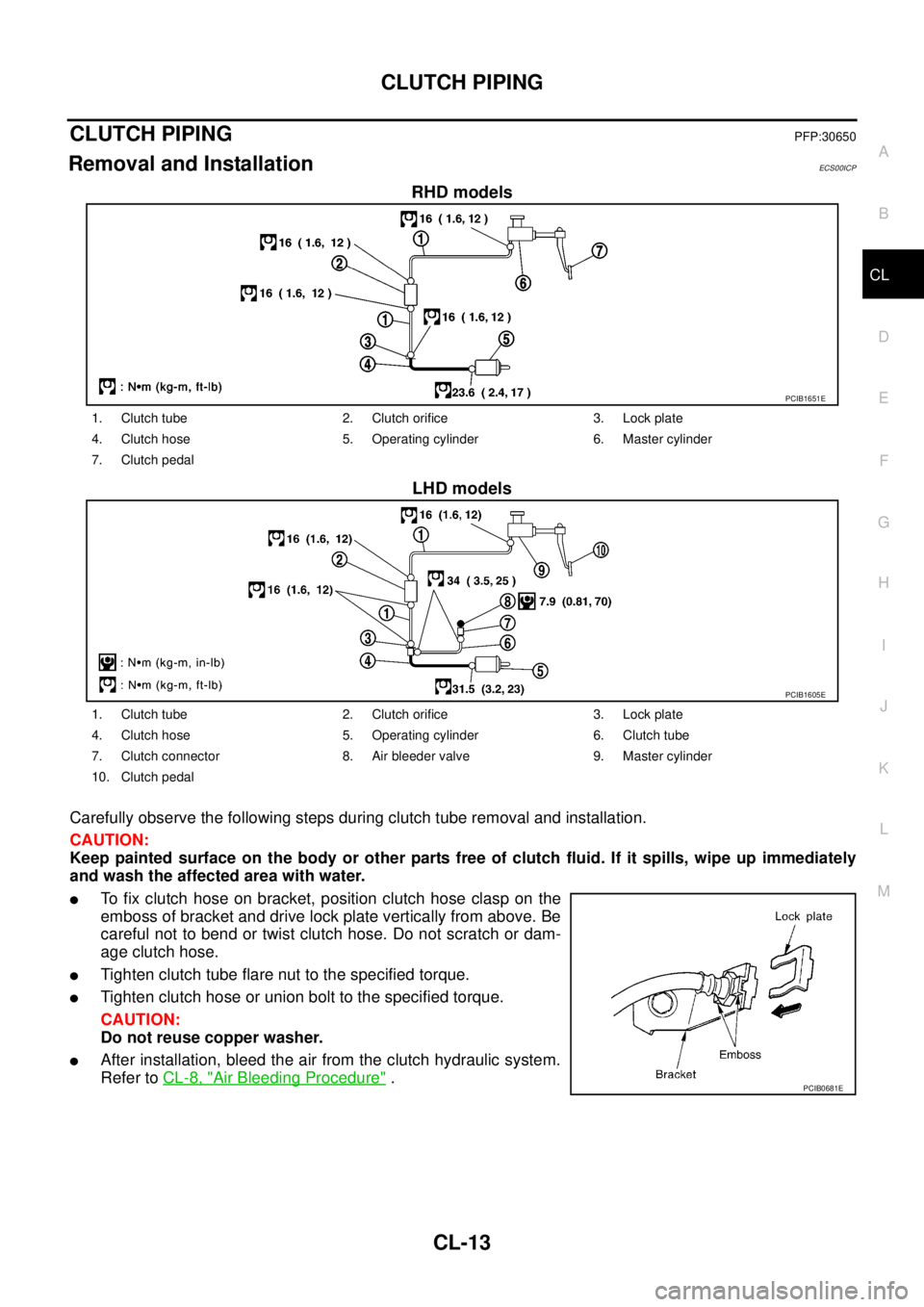

CLUTCH PIPINGPFP:30650

Removal and InstallationECS00ICP

RHD models

LHD models

Carefully observe the following steps during clutch tube removal and installation.

CAUTION:

Keep painted surface on the body or other parts free of clutch fluid. If it spills, wipe up immediately

and wash the affected area with water.

lTo fix clutch hose on bracket, position clutch hose clasp on the

emboss of bracket and drive lock plate vertically from above. Be

careful not to bend or twist clutch hose. Do not scratch or dam-

age clutch hose.

lTighten clutch tube flare nut to the specified torque.

lTighten clutch hose or union bolt to the specified torque.

CAUTION:

Do not reuse copper washer.

lAfter installation, bleed the air from the clutch hydraulic system.

Refer toCL-8, "

Air Bleeding Procedure".

PCIB1651E

1. Clutch tube 2. Clutch orifice 3. Lock plate

4. Clutch hose 5. Operating cylinder 6. Master cylinder

7. Clutch pedal

PCIB1605E

1. Clutch tube 2. Clutch orifice 3. Lock plate

4. Clutch hose 5. Operating cylinder 6. Clutch tube

7. Clutch connector 8. Air bleeder valve 9. Master cylinder

10. Clutch pedal

PCIB0681E

Page 1281 of 3171

GLOW CONTROL SYSTEM

EC-301

C

D

E

F

G

H

I

J

K

L

MA

EC

15.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

Component InspectionEBS01KLP

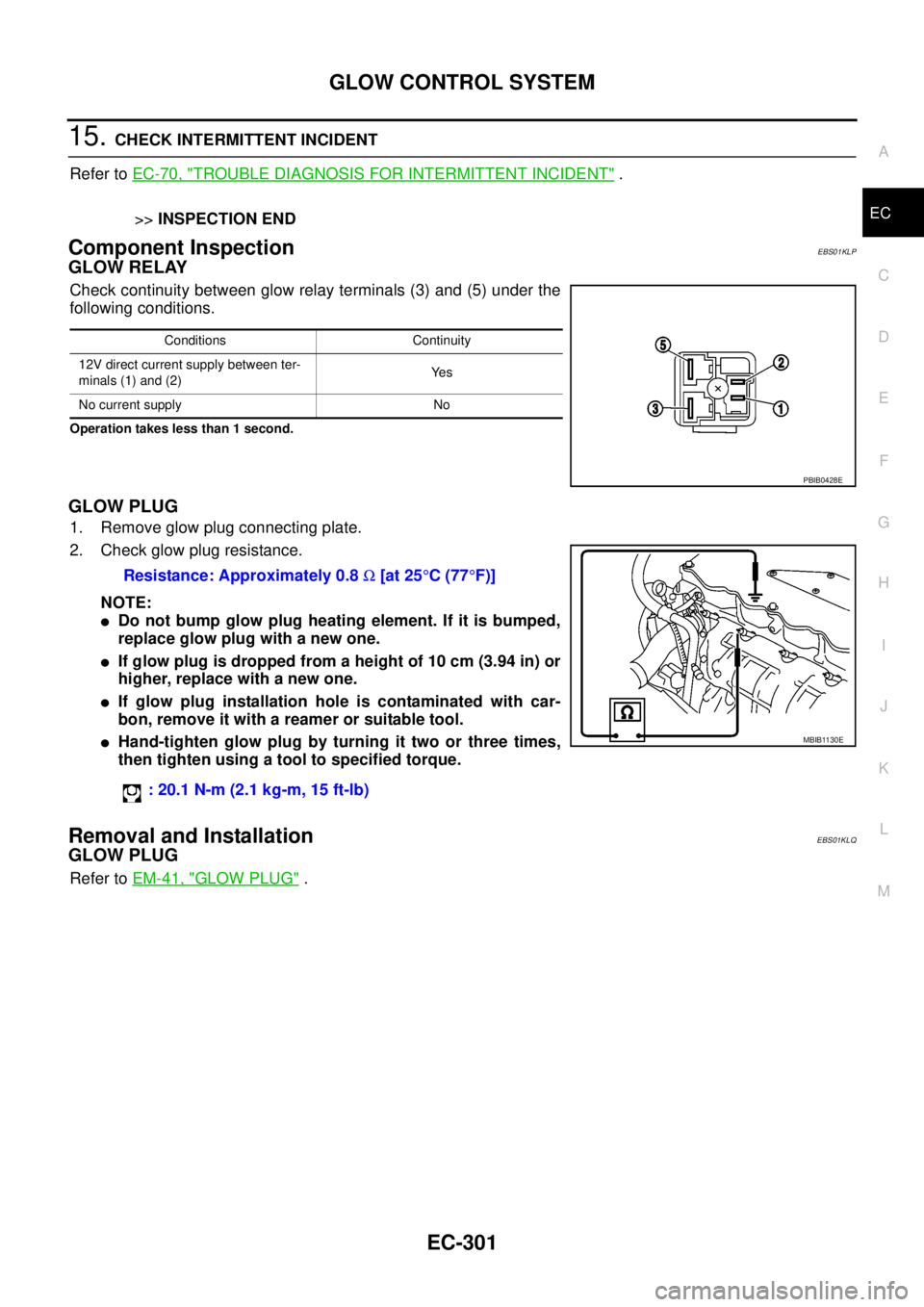

GLOW RELAY

Check continuity between glow relay terminals (3) and (5) under the

following conditions.

Operation takes less than 1 second.

GLOW PLUG

1. Remove glow plug connecting plate.

2. Check glow plug resistance.

NOTE:

lDo not bump glow plug heating element. If it is bumped,

replace glow plug with a new one.

lIf glow plug is dropped from a height of 10 cm (3.94 in) or

higher, replace with a new one.

lIf glow plug installation hole is contaminated with car-

bon, remove it with a reamer or suitable tool.

lHand-tighten glow plug by turning it two or three times,

then tighten using a tool to specified torque.

Removal and InstallationEBS01KLQ

GLOW PLUG

Refer toEM-41, "GLOW PLUG".

Conditions Continuity

12V direct current supply between ter-

minals (1) and (2)Ye s

No current supply No

PBIB0428E

Resistance: Approximately 0.8W[at 25°C(77°F)]

: 20.1 N-m (2.1 kg-m, 15 ft-lb)

MBIB1130E

Page 1386 of 3171

EM-4

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Draining Engine CoolantEBS01E5H

Drain engine coolant when engine is cooled.

Precautions for Disconnecting Fuel PipingEBS01E5I

lBefore starting work, make sure no fire or spark producing items are in the work area.

lAfter disconnecting pipes, plug openings to stop fuel leakage.

Precautions for Removal and DisassemblyEBS01E5J

lWhen instructed to use SST, use the specified tools. Always be careful to work safely, avoid forceful or

uninstructed operations.

lExercise maximum care to avoid damage to mating or sliding surfaces.

lCover openings of engine system with tape or the equivalent, if necessary, to seal out foreign materials.

lMark and arrange disassembly parts in an organized way for easy troubleshooting and re-assembly.

lWhen loosening nuts and bolts, as a basic rule, start with the one furthest outside, then the one diagonally

opposite, and so on. If the order of loosening is specified, do exactly as specified.

Precautions for Inspection, Repair and ReplacementEBS01E5K

Before repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way, and

replace if necessary.

Precautions for Assembly and InstallationEBS01E5L

lUsetorquewrenchtotightenboltsornutstospecification.

lWhen tightening nuts and bolts, as a basic rule, equally tighten in several different steps starting with the

ones in center, then ones on inside and outside diagonally in this order. If the order of tightening is speci-

fied, do exactly as specified.

lReplace with new liquid gasket, packing, oil seal or O-ring.

lDowel pins are used for several parts alignment. When replacing and reassembling parts with dowel pins,

make sure that dowel pins are installed in the original position.

lThoroughly wash, clean, and air-blow each part. Carefully check engine oil or engine coolant passages for

any restriction and blockage.

lAvoid damaging sliding or mating surfaces. Completely remove foreign materials such as cloth lint or dust.

Before assembly, oil sliding surfaces well.

lRelease air within route when refilling after draining engine coolant.

lAfter repairing, start engine and increase engine speed to check engine coolant, fuel, engine oil, and

exhaust systems for leakage.

Parts Requiring Angle TighteningEBS01E5M

lUse an angle wrench [SST: KV10112100] for the final tightening of the following engine parts:

–Cylinder head bolts

–Main bearing cap bolts

–Connecting rod cap nuts

–Crankshaft pulley bolt (No angle wrench is required as the bolt flange is provided with notches for angle

tightening)

lDo not use a torque value for final tightening.

lThe torque value for these parts are for a preliminary step.

lEnsure thread and seat surfaces are clean and coated with engine oil.

Page 1396 of 3171

EM-14

DRIVE BELTS

A/C COMPRESSOR, ALTERNATOR AND WATER PUMP BELT

1. Loosen idler pulley lock nut (D).

2. Turn adjusting nut (C) to adjust. Refer toEM-13, "

Deflection Adjustment".

3. Tighten lock nut (D).

Removal and InstallationEBS01EJ6

REMOVAL

1. Loosen each belt. Refer toEM-13, "Deflection Adjustment".

2. Remove power steering oil pump belt. Refer toEM-13, "

POWER STEERING OIL PUMP BELT".

3. Remove A/C compressor, alternator and water pump belt. Refer toEM-14, "

A/C COMPRESSOR, ALTER-

NATOR AND WATER PUMP BELT".

INSTALLATION

1. Install each belt on pulley in the reverse order of removal.

2. Adjust belt deflection. Refer toEM-13, "

Deflection Adjustment".

3. Tighten nuts provided for adjustment to the specified torque.

4. Make sure again that each belt deflection is as specified.Nut D:

: 45.0 N·m (4.6 kg-m, 33 ft-lb)