torque NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1578 of 3171

FFD-32

FRONT FINAL DRIVE ASSEMBLY

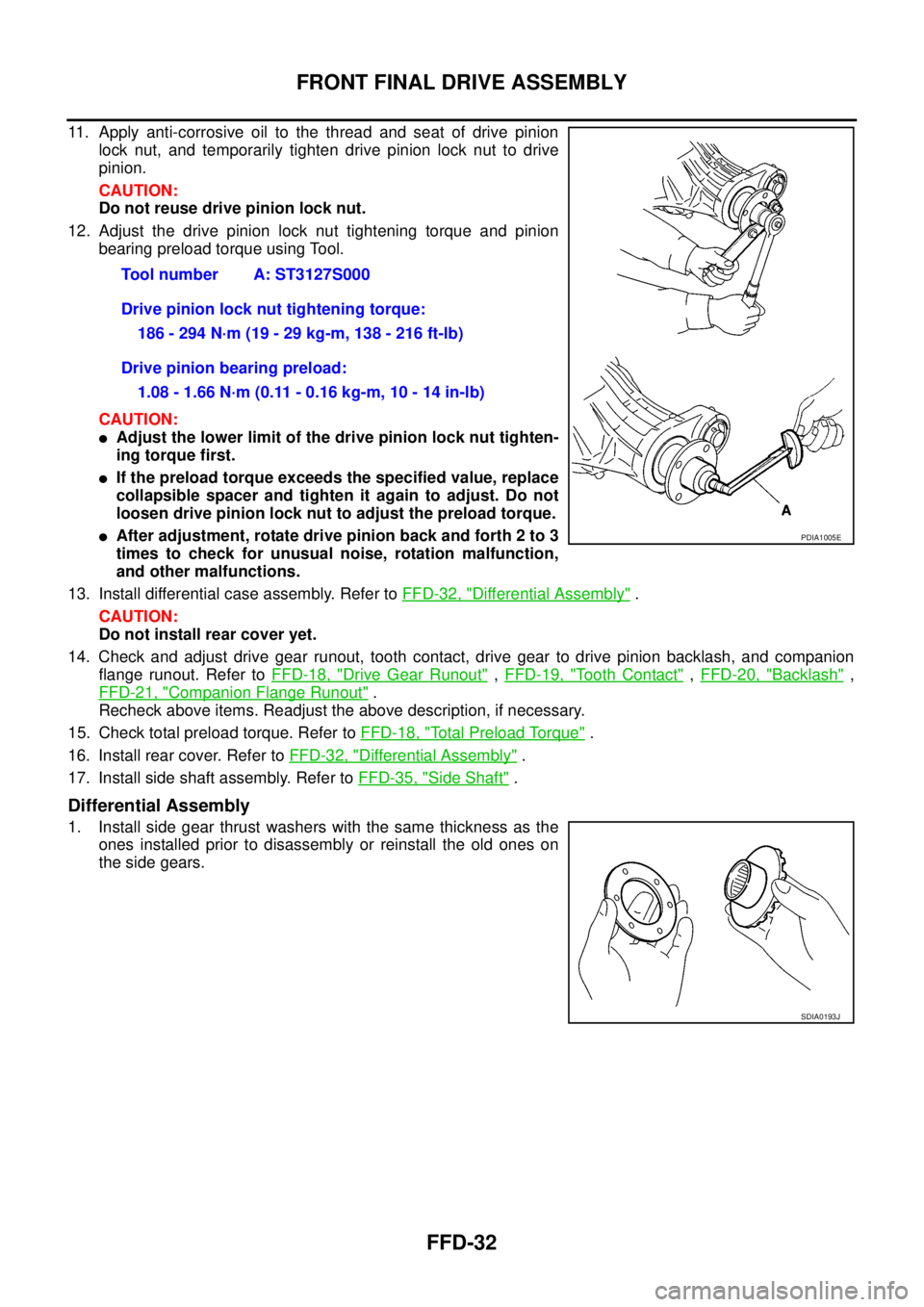

11. Apply anti-corrosive oil to the thread and seat of drive pinion

lock nut, and temporarily tighten drive pinion lock nut to drive

pinion.

CAUTION:

Do not reuse drive pinion lock nut.

12. Adjust the drive pinion lock nut tightening torque and pinion

bearing preload torque using Tool.

CAUTION:

lAdjust the lower limit of the drive pinion lock nut tighten-

ing torque first.

lIf the preload torque exceeds the specified value, replace

collapsible spacer and tighten it again to adjust. Do not

loosen drive pinion lock nut to adjust the preload torque.

lAfter adjustment, rotate drive pinion back and forth 2 to 3

times to check for unusual noise, rotation malfunction,

and other malfunctions.

13. Install differential case assembly. Refer toFFD-32, "

Differential Assembly".

CAUTION:

Do not install rear cover yet.

14. Check and adjust drive gear runout, tooth contact, drive gear to drive pinion backlash, and companion

flange runout. Refer toFFD-18, "

Drive Gear Runout",FFD-19, "To o t h C o n t a c t",FFD-20, "Backlash",

FFD-21, "

Companion Flange Runout".

Recheck above items. Readjust the above description, if necessary.

15. Check total preload torque. Refer toFFD-18, "

Total Preload Torque".

16. Install rear cover. Refer toFFD-32, "

Differential Assembly".

17. Install side shaft assembly. Refer toFFD-35, "

Side Shaft".

Differential Assembly

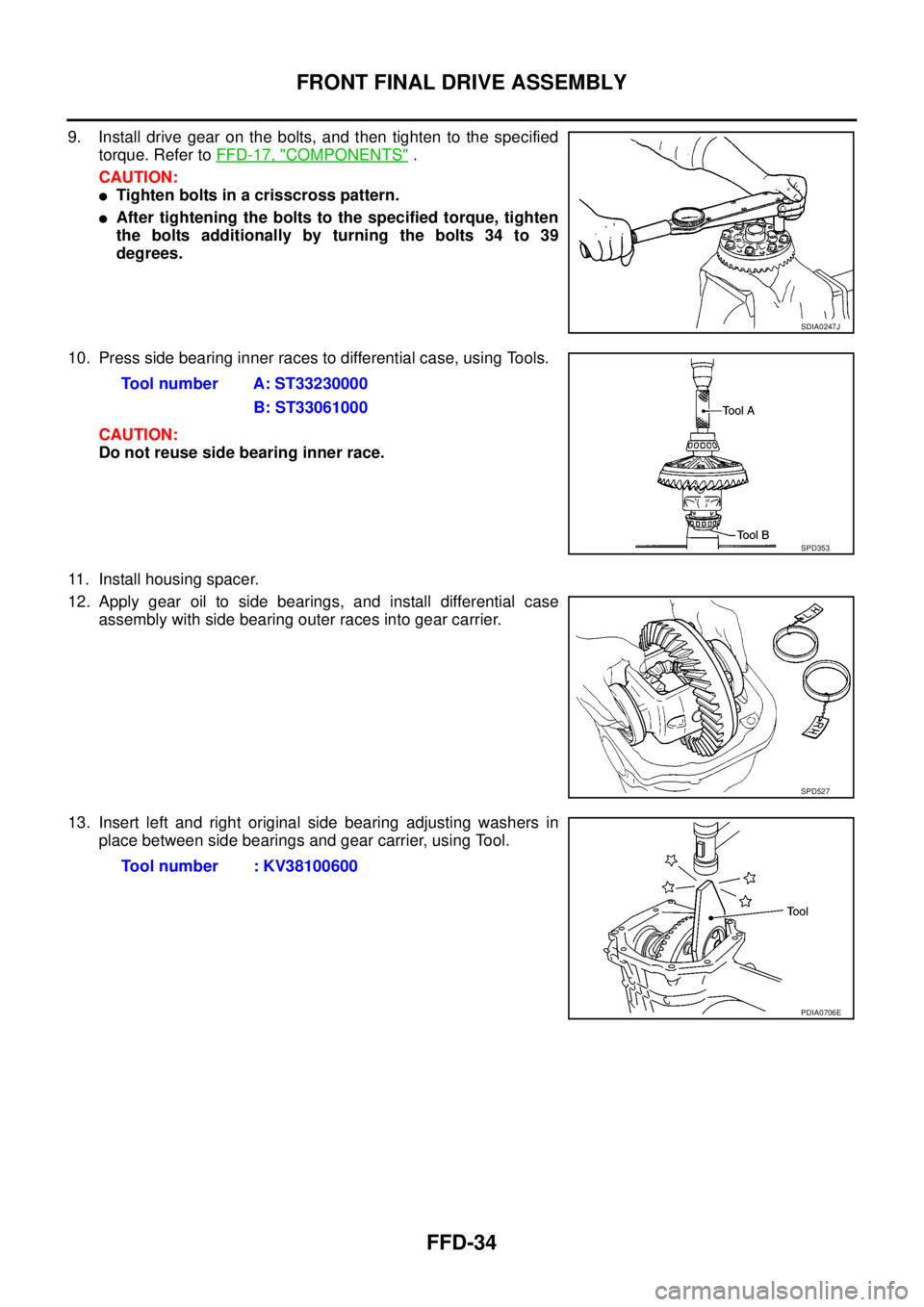

1. Install side gear thrust washers with the same thickness as the

ones installed prior to disassembly or reinstall the old ones on

the side gears.Tool number A: ST3127S000

Drive pinion lock nut tightening torque:

186 - 294 N·m (19 - 29 kg-m, 138 - 216 ft-lb)

Drive pinion bearing preload:

1.08 - 1.66 N·m (0.11 - 0.16 kg-m, 10 - 14 in-lb)

PDIA1005E

SDIA0193J

Page 1580 of 3171

FFD-34

FRONT FINAL DRIVE ASSEMBLY

9. Install drive gear on the bolts, and then tighten to the specified

torque. Refer toFFD-17, "

COMPONENTS".

CAUTION:

lTighten bolts in a crisscross pattern.

lAfter tightening the bolts to the specified torque, tighten

the bolts additionally by turning the bolts 34 to 39

degrees.

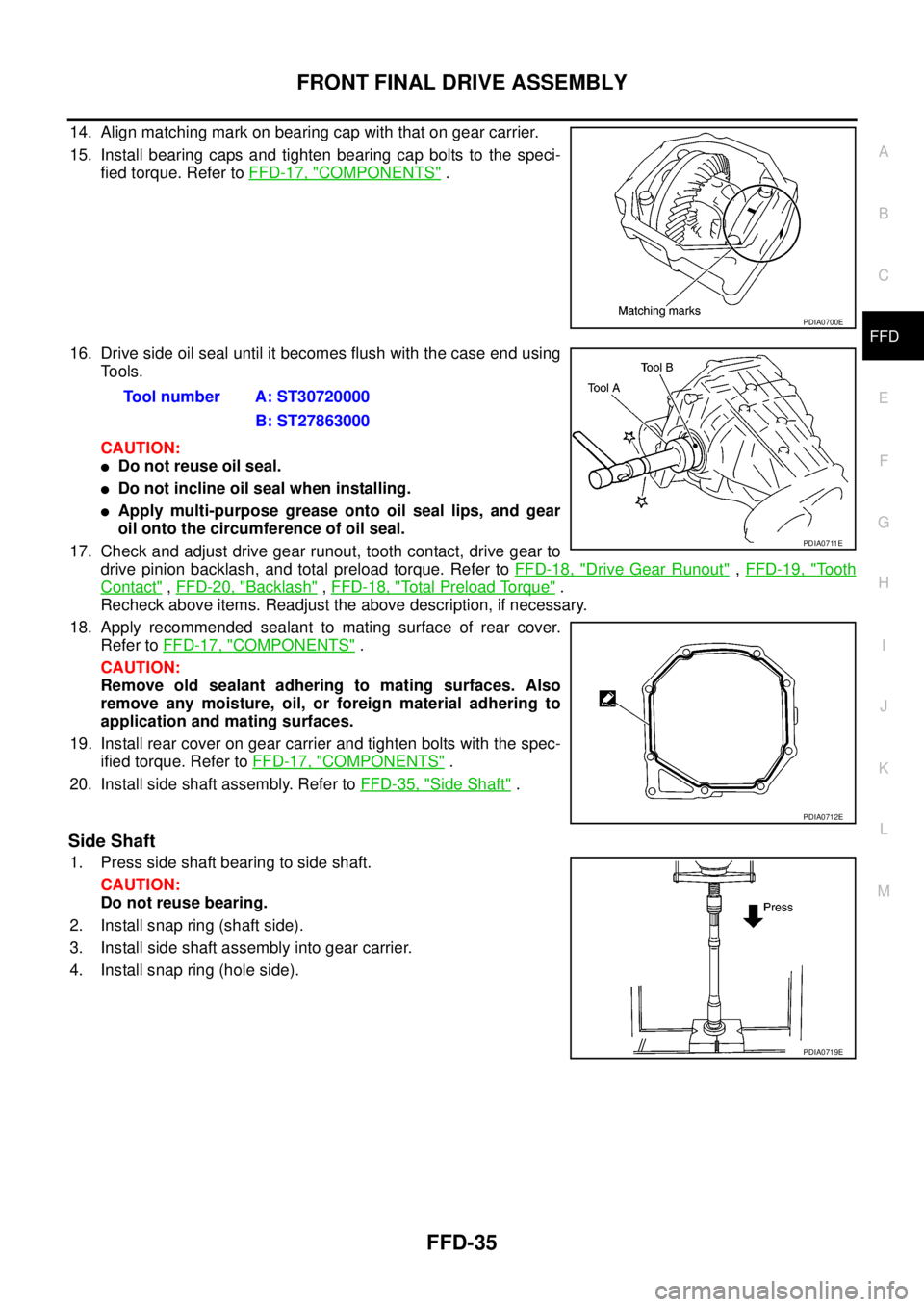

10. Press side bearing inner races to differential case, using Tools.

CAUTION:

Do not reuse side bearing inner race.

11. Install housing spacer.

12. Apply gear oil to side bearings, and install differential case

assembly with side bearing outer races into gear carrier.

13. Insert left and right original side bearing adjusting washers in

place between side bearings and gear carrier, using Tool.

SDIA0247J

Tool number A: ST33230000

B: ST33061000

SPD353

SPD527

Tool number : KV38100600

PDIA0706E

Page 1581 of 3171

FRONT FINAL DRIVE ASSEMBLY

FFD-35

C

E

F

G

H

I

J

K

L

MA

B

FFD

14. Alignmatchingmarkonbearingcapwiththatongearcarrier.

15. Install bearing caps and tighten bearing cap bolts to the speci-

fied torque. Refer toFFD-17, "

COMPONENTS".

16. Drive side oil seal until it becomes flush with the case end using

Tools.

CAUTION:

lDo not reuse oil seal.

lDo not incline oil seal when installing.

lApply multi-purpose grease onto oil seal lips, and gear

oil onto the circumference of oil seal.

17. Check and adjust drive gear runout, tooth contact, drive gear to

drive pinion backlash, and total preload torque. Refer toFFD-18, "

Drive Gear Runout",FFD-19, "To o t h

Contact",FFD-20, "Backlash",FFD-18, "Total Preload Torque".

Recheck above items. Readjust the above description, if necessary.

18. Apply recommended sealant to mating surface of rear cover.

Refer toFFD-17, "

COMPONENTS".

CAUTION:

Remove old sealant adhering to mating surfaces. Also

remove any moisture, oil, or foreign material adhering to

application and mating surfaces.

19. Install rear cover on gear carrier and tighten bolts with the spec-

ified torque. Refer toFFD-17, "

COMPONENTS".

20. Install side shaft assembly. Refer toFFD-35, "

Side Shaft".

Side Shaft

1. Press side shaft bearing to side shaft.

CAUTION:

Do not reuse bearing.

2. Install snap ring (shaft side).

3. Install side shaft assembly into gear carrier.

4. Install snap ring (hole side).

PDIA0700E

Tool number A: ST30720000

B: ST27863000

PDIA0711E

PDIA0712E

PDIA0719E

Page 1583 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

FFD-37

C

E

F

G

H

I

J

K

L

MA

B

FFD

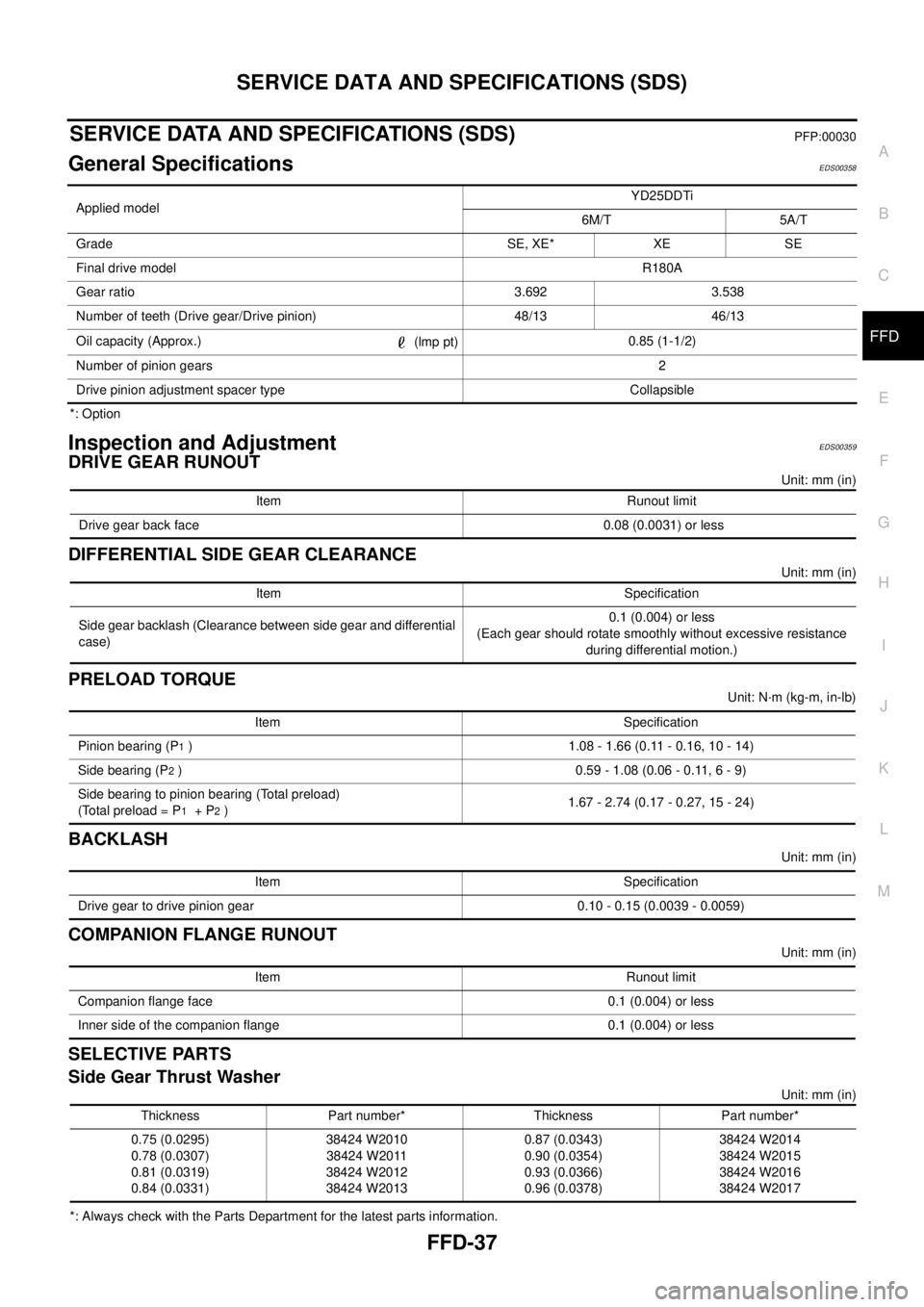

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsEDS00358

*: Option

Inspection and AdjustmentEDS00359

DRIVE GEAR RUNOUT

Unit: mm (in)

DIFFERENTIAL SIDE GEAR CLEARANCE

Unit: mm (in)

PRELOAD TORQUE

Unit: N·m (kg-m, in-lb)

BACKLASH

Unit: mm (in)

COMPANION FLANGE RUNOUT

Unit: mm (in)

SELECTIVE PARTS

Side Gear Thrust Washer

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.Applied modelYD25DDTi

6M/T 5A/T

Grade SE, XE* XE SE

Final drive modelR180A

Gear ratio 3.692 3.538

Number of teeth (Drive gear/Drive pinion) 48/13 46/13

Oil capacity (Approx.)

(lmp pt)0.85 (1-1/2)

Number of pinion gears2

Drive pinion adjustment spacer type Collapsible

Item Runout limit

Drive gear back face 0.08 (0.0031) or less

Item Specification

Side gear backlash (Clearance between side gear and differential

case)0.1 (0.004) or less

(Each gear should rotate smoothly without excessive resistance

during differential motion.)

Item Specification

Pinion bearing (P

1) 1.08 - 1.66 (0.11 - 0.16, 10 - 14)

Side bearing (P

2) 0.59 - 1.08 (0.06 - 0.11, 6 - 9)

Side bearing to pinion bearing (Total preload)

(Total preload = P

1+P2)1.67 - 2.74 (0.17 - 0.27, 15 - 24)

Item Specification

Drive gear to drive pinion gear 0.10 - 0.15 (0.0039 - 0.0059)

Item Runout limit

Companion flange face 0.1 (0.004) or less

Inner side of the companion flange 0.1 (0.004) or less

Thickness Part number* Thickness Part number*

0.75 (0.0295)

0.78 (0.0307)

0.81 (0.0319)

0.84 (0.0331)38424 W2010

38424 W2011

38424 W2012

38424 W20130.87 (0.0343)

0.90 (0.0354)

0.93 (0.0366)

0.96 (0.0378)38424 W2014

38424 W2015

38424 W2016

38424 W2017

Page 1589 of 3171

FUEL FILTER

FL-5

C

D

E

F

G

H

I

J

K

L

MA

FL

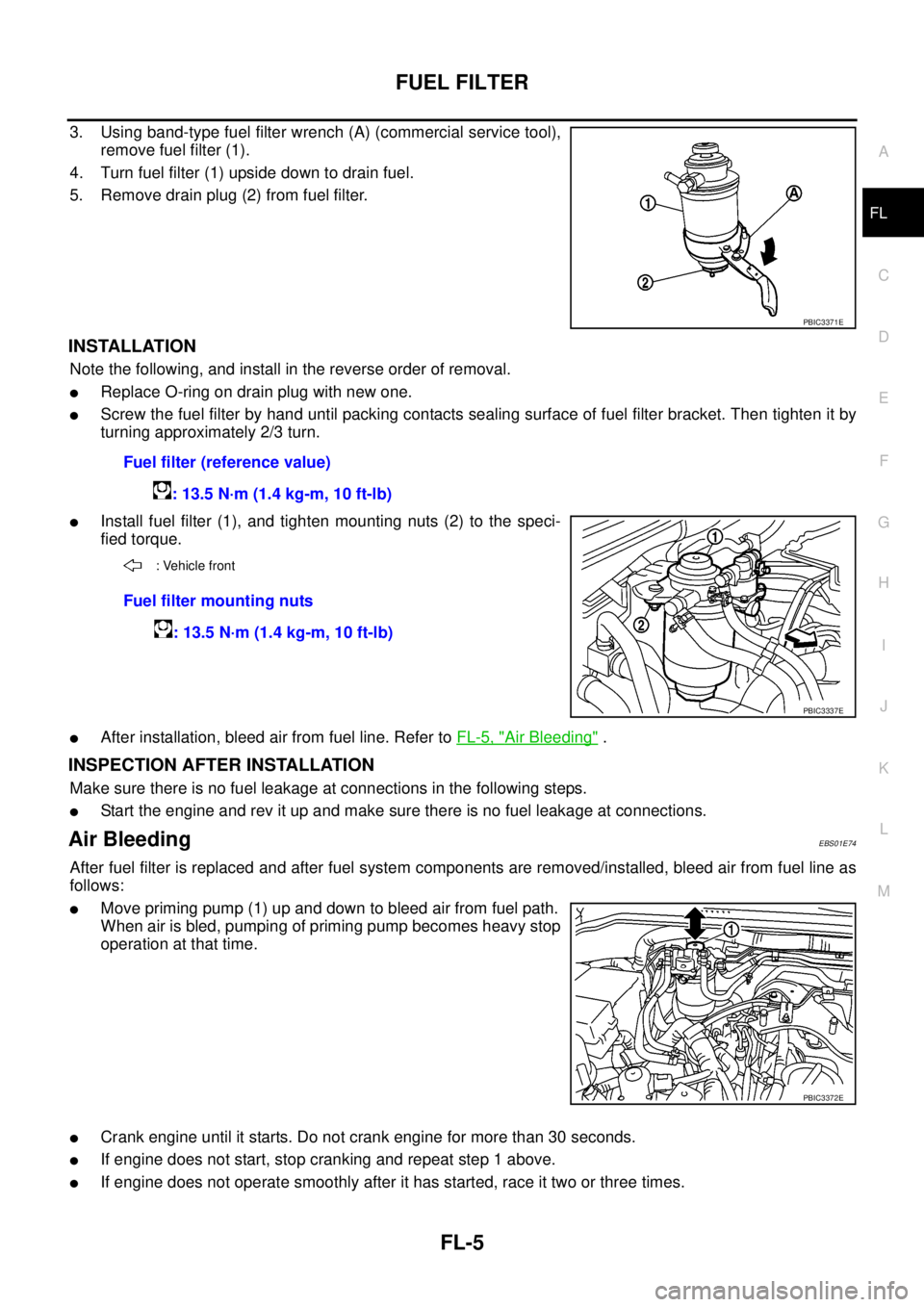

3. Using band-type fuel filter wrench (A) (commercial service tool),

remove fuel filter (1).

4. Turn fuel filter (1) upside down to drain fuel.

5. Remove drain plug (2) from fuel filter.

INSTALLATION

Note the following, and install in the reverse order of removal.

lReplace O-ring on drain plug with new one.

lScrew the fuel filter by hand until packing contacts sealing surface of fuel filter bracket. Then tighten it by

turning approximately 2/3 turn.

lInstall fuel filter (1), and tighten mounting nuts (2) to the speci-

fied torque.

lAfter installation, bleed air from fuel line. Refer toFL-5, "Air Bleeding".

INSPECTION AFTER INSTALLATION

Make sure there is no fuel leakage at connections in the following steps.

lStart the engine and rev it up and make sure there is no fuel leakage at connections.

Air BleedingEBS01E74

After fuel filter is replaced and after fuel system components are removed/installed, bleed air from fuel line as

follows:

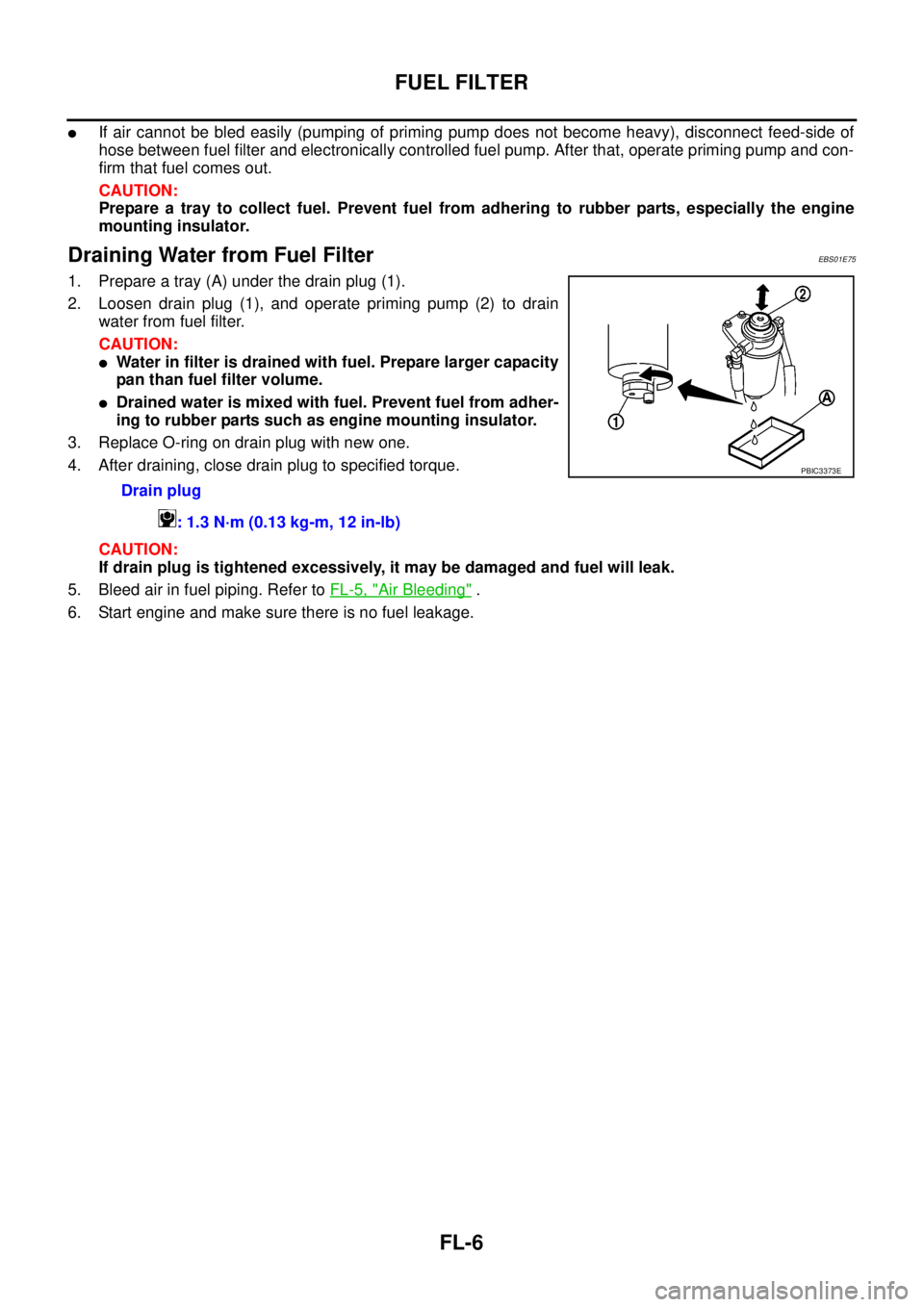

lMove priming pump (1) up and down to bleed air from fuel path.

When air is bled, pumping of priming pump becomes heavy stop

operation at that time.

lCrank engine until it starts. Do not crank engine for more than 30 seconds.

lIf engine does not start, stop cranking and repeat step 1 above.

lIf engine does not operate smoothly after it has started, race it two or three times.

PBIC3371E

Fuel filter (reference value)

: 13.5 N·m (1.4 kg-m, 10 ft-lb)

: Vehicle front

Fuel filter mounting nuts

: 13.5 N·m (1.4 kg-m, 10 ft-lb)

PBIC3337E

PBIC3372E

Page 1590 of 3171

FL-6

FUEL FILTER

lIf air cannot be bled easily (pumping of priming pump does not become heavy), disconnect feed-side of

hose between fuel filter and electronically controlled fuel pump. After that, operate priming pump and con-

firm that fuel comes out.

CAUTION:

Prepare a tray to collect fuel. Prevent fuel from adhering to rubber parts, especially the engine

mounting insulator.

Draining Water from Fuel FilterEBS01E75

1. Prepare a tray (A) under the drain plug (1).

2. Loosen drain plug (1), and operate priming pump (2) to drain

water from fuel filter.

CAUTION:

lWater in filter is drained with fuel. Prepare larger capacity

pan than fuel filter volume.

lDrained water is mixed with fuel. Prevent fuel from adher-

ing to rubber parts such as engine mounting insulator.

3. Replace O-ring on drain plug with new one.

4. After draining, close drain plug to specified torque.

CAUTION:

If drain plug is tightened excessively, it may be damaged and fuel will leak.

5. Bleed air in fuel piping. Refer toFL-5, "

Air Bleeding".

6. Start engine and make sure there is no fuel leakage.Drain plug

: 1.3 N·m (0.13 kg-m, 12 in-lb)

PBIC3373E

Page 1596 of 3171

FL-12

FUEL TANK

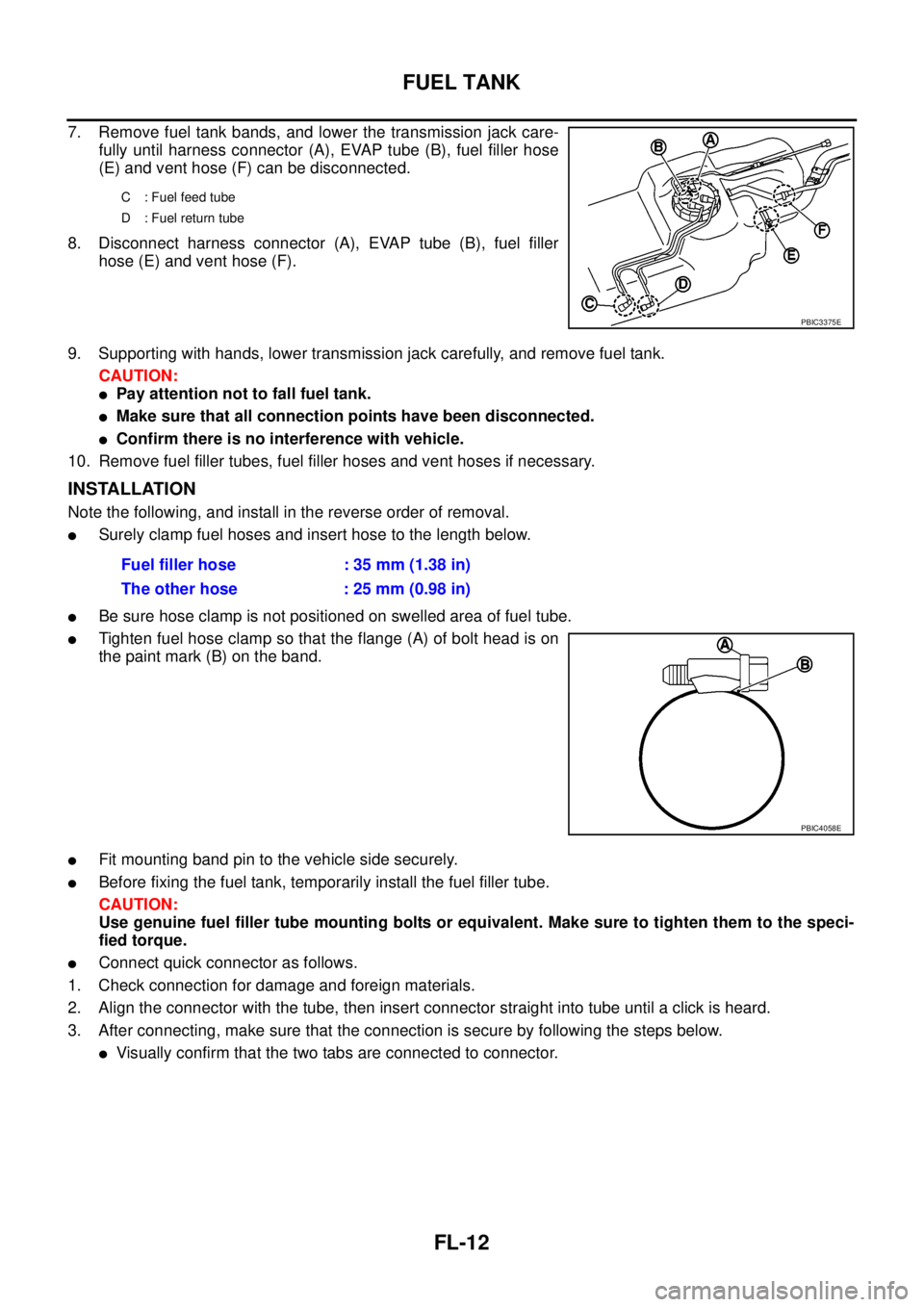

7. Remove fuel tank bands, and lower the transmission jack care-

fully until harness connector (A), EVAP tube (B), fuel filler hose

(E) and vent hose (F) can be disconnected.

8. Disconnect harness connector (A), EVAP tube (B), fuel filler

hose (E) and vent hose (F).

9. Supporting with hands, lower transmission jack carefully, and remove fuel tank.

CAUTION:

lPay attention not to fall fuel tank.

lMake sure that all connection points have been disconnected.

lConfirm there is no interference with vehicle.

10. Remove fuel filler tubes, fuel filler hoses and vent hoses if necessary.

INSTALLATION

Note the following, and install in the reverse order of removal.

lSurely clamp fuel hoses and insert hose to the length below.

lBe sure hose clamp is not positioned on swelled area of fuel tube.

lTighten fuel hose clamp so that the flange (A) of bolt head is on

the paint mark (B) on the band.

lFit mounting band pin to the vehicle side securely.

lBefore fixing the fuel tank, temporarily install the fuel filler tube.

CAUTION:

Use genuine fuel filler tube mounting bolts or equivalent. Make sure to tighten them to the speci-

fied torque.

lConnect quick connector as follows.

1. Check connection for damage and foreign materials.

2. Align the connector with the tube, then insert connector straight into tube until a click is heard.

3. After connecting, make sure that the connection is secure by following the steps below.

lVisually confirm that the two tabs are connected to connector.

C : Fuel feed tube

D : Fuel return tube

PBIC3375E

Fuel filler hose : 35 mm (1.38 in)

The other hose : 25 mm (0.98 in)

PBIC4058E

Page 1607 of 3171

ON-VEHICLE SERVICE

FSU-7

C

D

F

G

H

I

J

K

L

MA

B

FSU

ON-VEHICLE SERVICEPFP:00000

Front Suspension PartsEES002KM

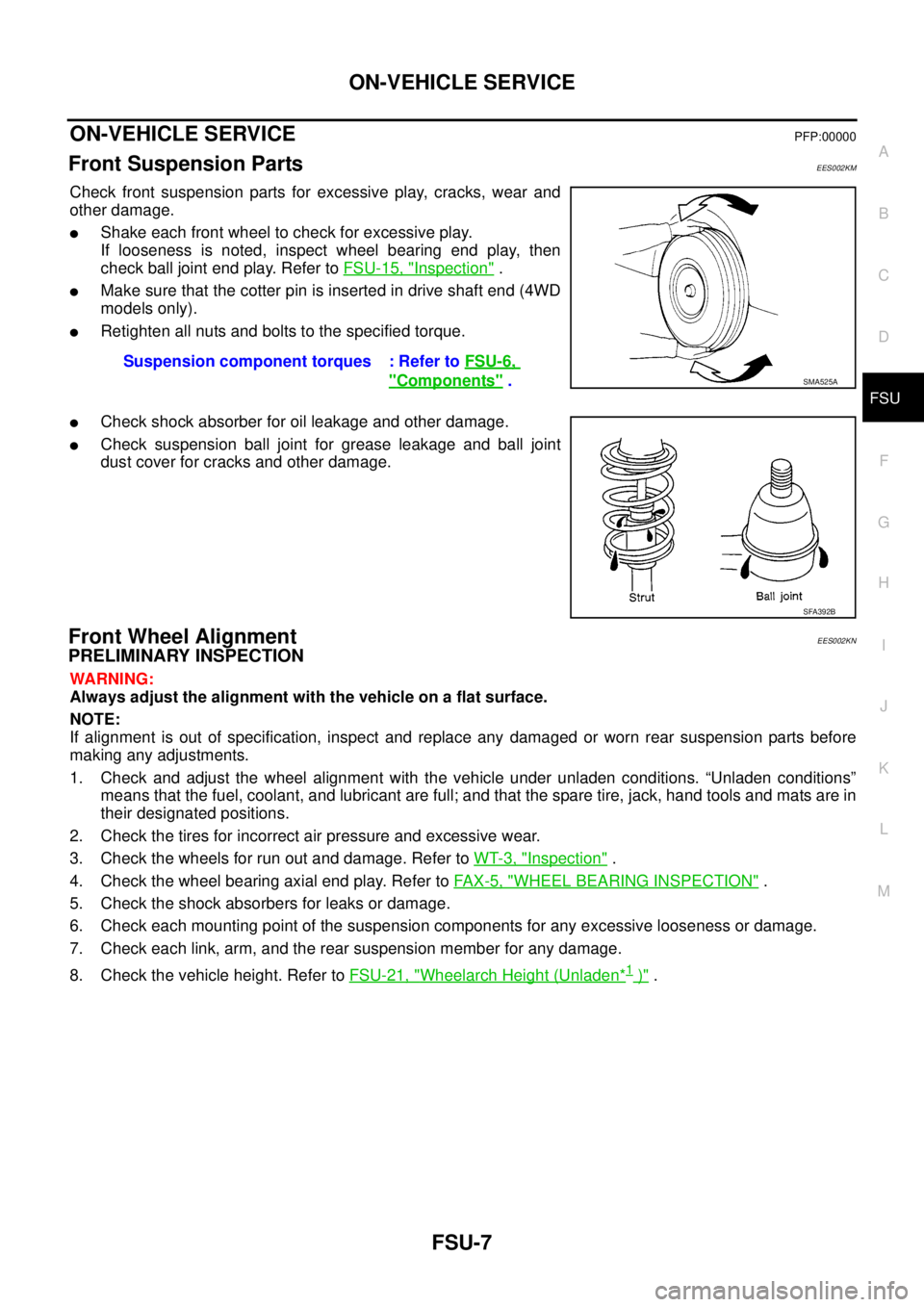

Check front suspension parts for excessive play, cracks, wear and

other damage.

lShake each front wheel to check for excessive play.

If looseness is noted, inspect wheel bearing end play, then

check ball joint end play. Refer toFSU-15, "

Inspection".

lMake sure that the cotter pin is inserted in drive shaft end (4WD

models only).

lRetighten all nuts and bolts to the specified torque.

lCheck shock absorber for oil leakage and other damage.

lCheck suspension ball joint for grease leakage and ball joint

dust cover for cracks and other damage.

Front Wheel AlignmentEES002KN

PRELIMINARY INSPECTION

WARNING:

Always adjust the alignment with the vehicle on a flat surface.

NOTE:

If alignment is out of specification, inspect and replace any damaged or worn rear suspension parts before

making any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, coolant, and lubricant are full; and that the spare tire, jack, hand tools and mats are in

their designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer toWT-3, "

Inspection".

4. Check the wheel bearing axial end play. Refer toFA X - 5 , "

WHEEL BEARING INSPECTION".

5. Check the shock absorbers for leaks or damage.

6. Check each mounting point of the suspension components for any excessive looseness or damage.

7. Check each link, arm, and the rear suspension member for any damage.

8. Check the vehicle height. Refer toFSU-21, "

Wheelarch Height (Unladen*1)". Suspension component torques : Refer toFSU-6,

"Components".SMA525A

SFA392B

Page 1615 of 3171

UPPER BALL JOINT AND LOWER BALL JOINT

FSU-15

C

D

F

G

H

I

J

K

L

MA

B

FSU

UPPER BALL JOINT AND LOWER BALL JOINTPFP:40110

Removal and InstallationEES002KT

The ball joints are part of the upper and lower links. Refer toFSU-13, "Removal and Installation"(upper link),

FSU-14, "

Removal and Installation"(lower link).

InspectionEES002KU

lCheck the ball joint for excessive play. Replace the upper or lower link assembly if any of the following

exists:

lBall joint stud is worn.

lBalljointishardtoswing.

lBall joint play in axial directions or end play is excessive.

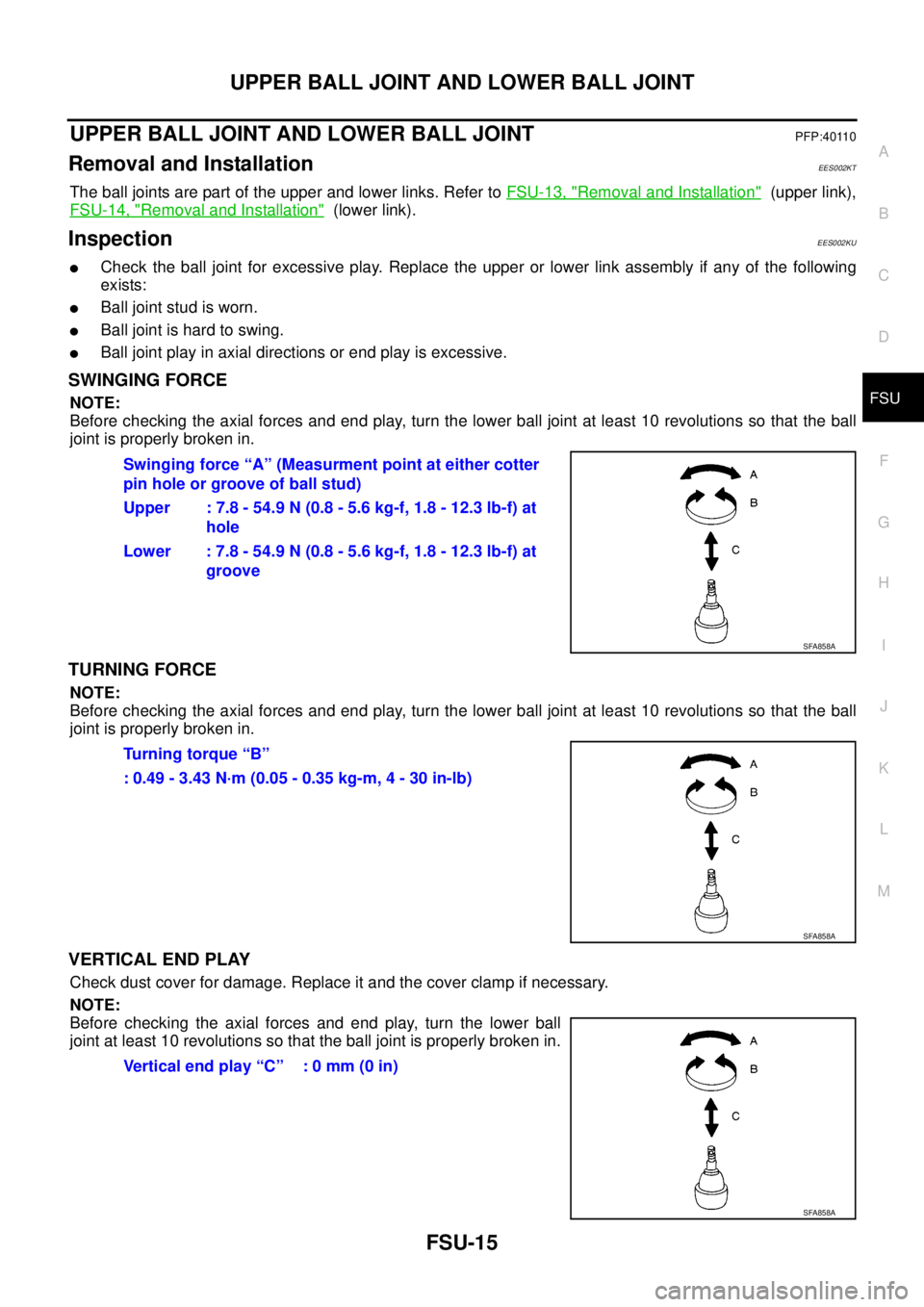

SWINGING FORCE

NOTE:

Before checking the axial forces and end play, turn the lower ball joint at least 10 revolutions so that the ball

joint is properly broken in.

TURNING FORCE

NOTE:

Before checking the axial forces and end play, turn the lower ball joint at least 10 revolutions so that the ball

joint is properly broken in.

VERTICAL END PLAY

Check dust cover for damage. Replace it and the cover clamp if necessary.

NOTE:

Before checking the axial forces and end play, turn the lower ball

joint at least 10 revolutions so that the ball joint is properly broken in.Swinging force “A” (Measurment point at either cotter

pin hole or groove of ball stud)

Upper : 7.8 - 54.9 N (0.8 - 5.6 kg-f, 1.8 - 12.3 lb-f) at

hole

Lower : 7.8 - 54.9 N (0.8 - 5.6 kg-f, 1.8 - 12.3 lb-f) at

groove

SFA858A

Turning torque “B”

: 0.49 - 3.43 N·m (0.05 - 0.35 kg-m, 4 - 30 in-lb)

SFA858A

Vertical end play “C” : 0 mm (0 in)

SFA858A

Page 1618 of 3171

FSU-18

KNUCKLE

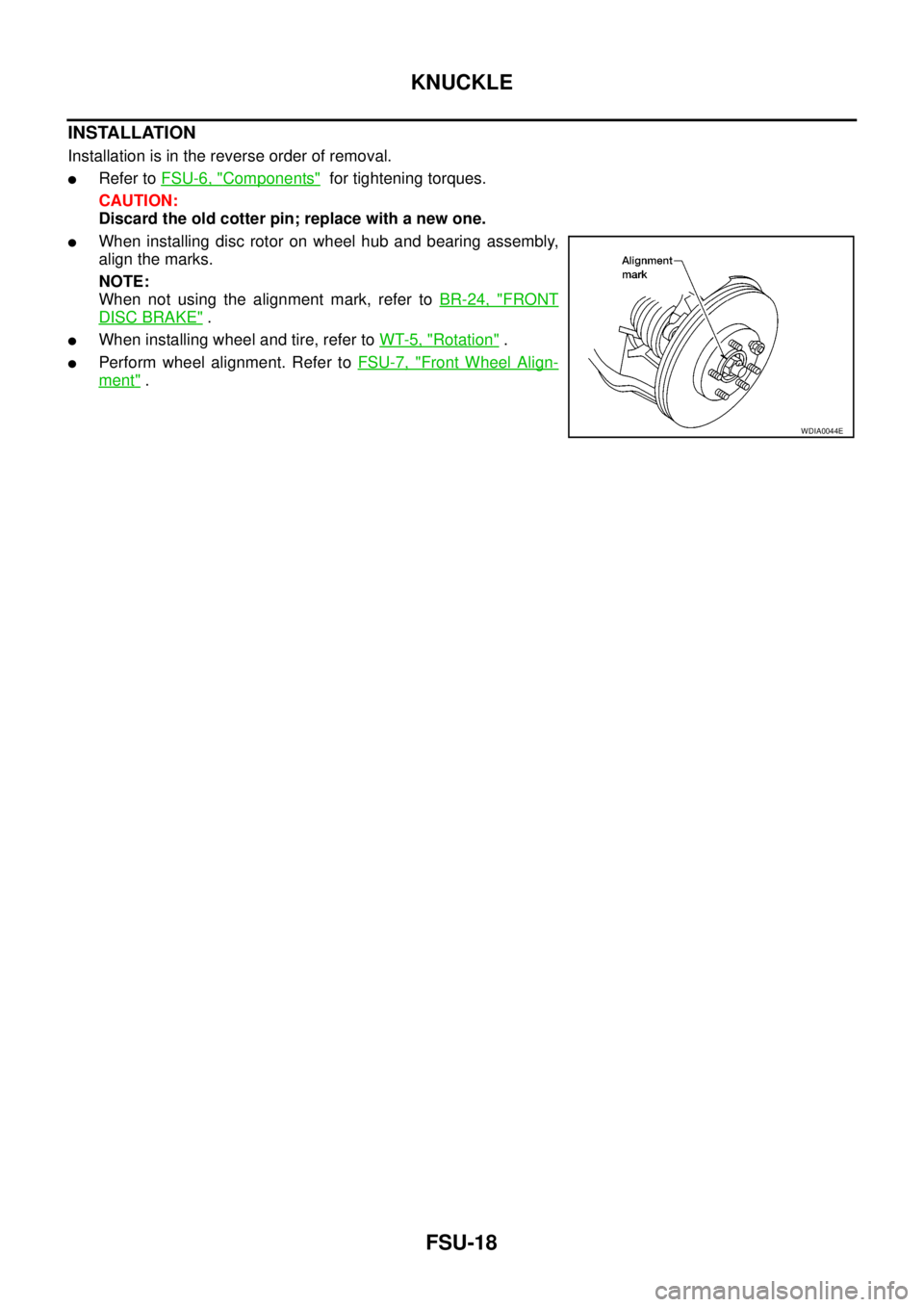

INSTALLATION

Installation is in the reverse order of removal.

lRefer toFSU-6, "Components"for tightening torques.

CAUTION:

Discard the old cotter pin; replace with a new one.

lWhen installing disc rotor on wheel hub and bearing assembly,

align the marks.

NOTE:

When not using the alignment mark, refer toBR-24, "

FRONT

DISC BRAKE".

lWhen installing wheel and tire, refer toWT-5, "Rotation".

lPerform wheel alignment. Refer toFSU-7, "Front Wheel Align-

ment".

WDIA0044E