cooling NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2459 of 3171

MTC-72

TROUBLE DIAGNOSIS

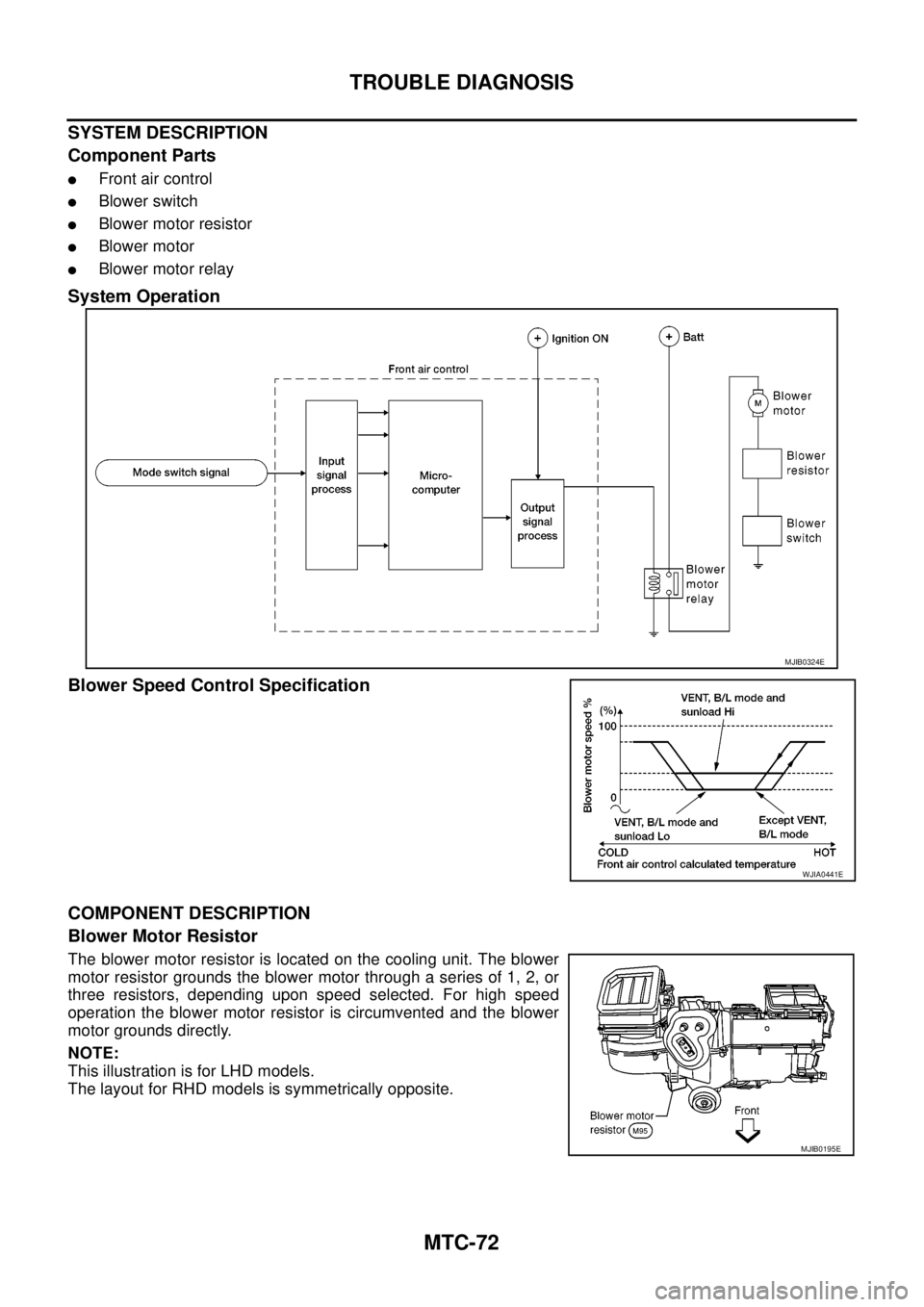

SYSTEM DESCRIPTION

Component Parts

lFront air control

lBlower switch

lBlower motor resistor

lBlower motor

lBlower motor relay

System Operation

Blower Speed Control Specification

COMPONENT DESCRIPTION

Blower Motor Resistor

The blower motor resistor is located on the cooling unit. The blower

motor resistor grounds the blower motor through a series of 1, 2, or

three resistors, depending upon speed selected. For high speed

operation the blower motor resistor is circumvented and the blower

motor grounds directly.

NOTE:

This illustration is for LHD models.

The layout for RHD models is symmetrically opposite.

MJIB0324E

WJIA0441E

MJIB0195E

Page 2473 of 3171

MTC-86

TROUBLE DIAGNOSIS

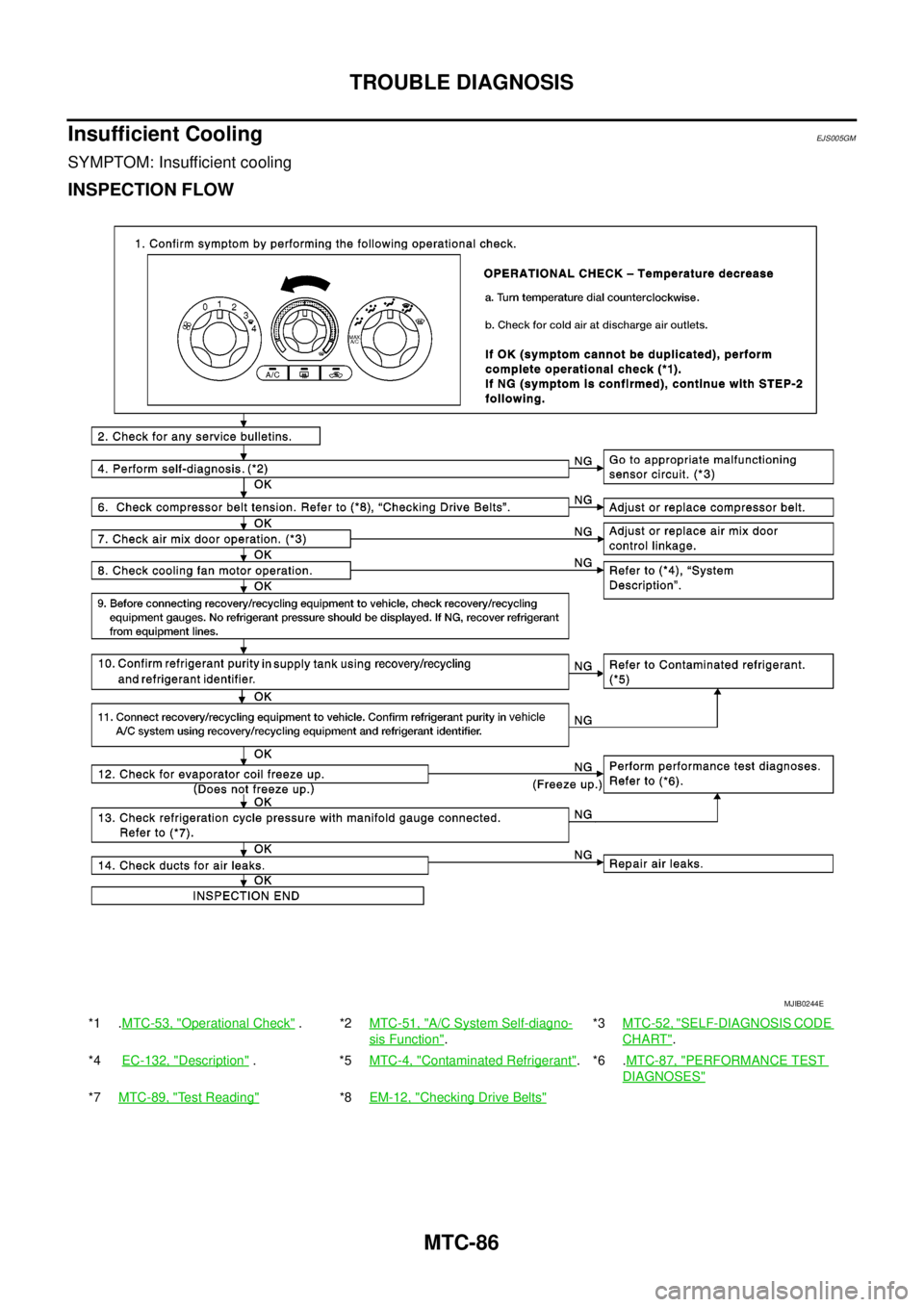

Insufficient Cooling

EJS005GM

SYMPTOM: Insufficient cooling

INSPECTION FLOW

*1 .MTC-53, "Operational Check".*2MTC-51, "A/C System Self-diagno-

sis Function".*3MTC-52, "

SELF-DIAGNOSIS CODE

CHART".

*4EC-132, "

Description".*5MTC-4, "Contaminated Refrigerant".*6 .MTC-87, "PERFORMANCE TEST

DIAGNOSES"

*7MTC-89, "Test Reading"*8EM-12, "Checking Drive Belts"

MJIB0244E

Page 2477 of 3171

MTC-90

TROUBLE DIAGNOSIS

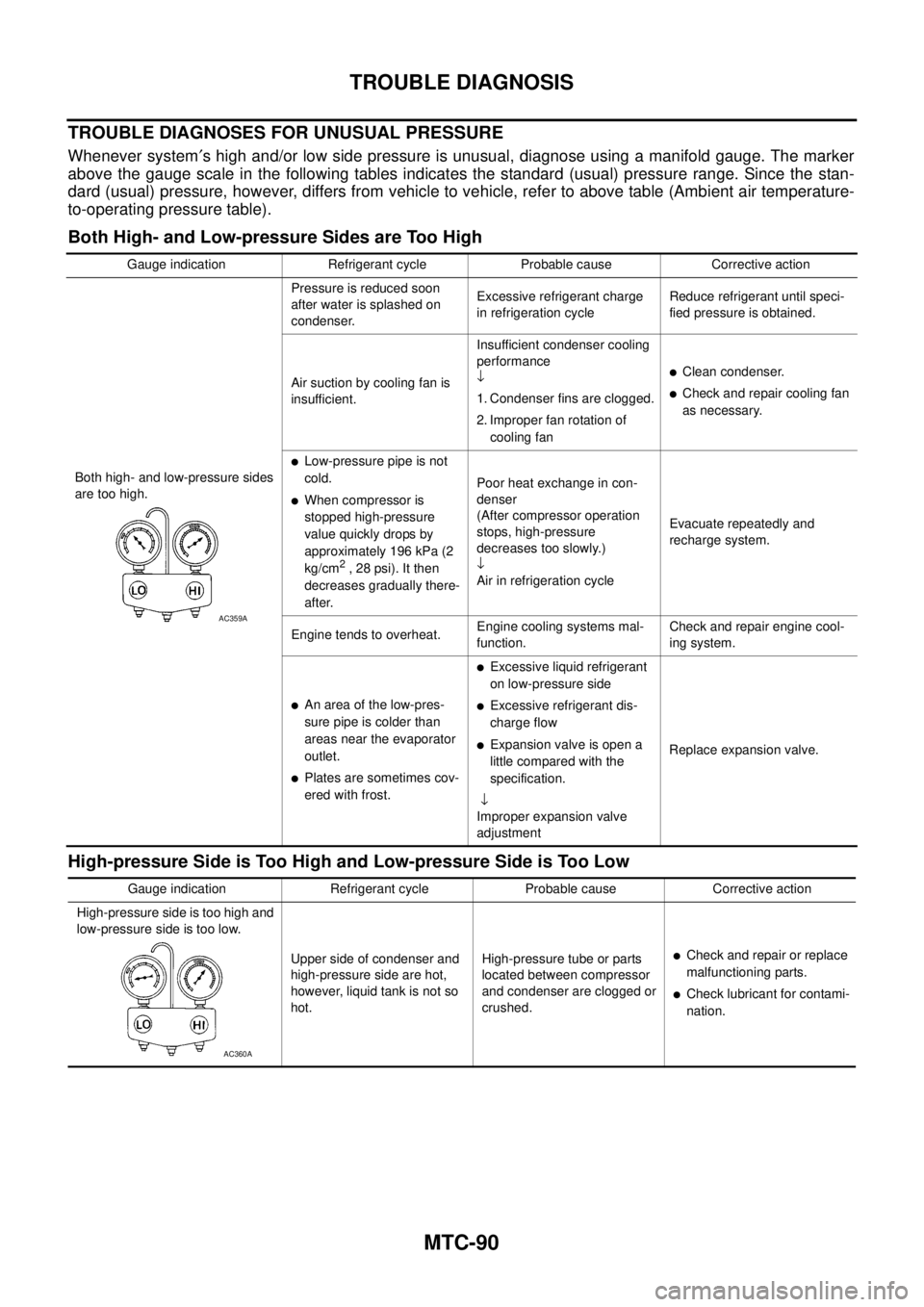

TROUBLE DIAGNOSES FOR UNUSUAL PRESSURE

Whenever system¢s high and/or low side pressure is unusual, diagnose using a manifold gauge. The marker

above the gauge scale in the following tables indicates the standard (usual) pressure range. Since the stan-

dard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air temperature-

to-operating pressure table).

Both High- and Low-pressure Sides are Too High

High-pressure Side is Too High and Low-pressure Side is Too Low

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure sides

are too high.Pressure is reduced soon

after water is splashed on

condenser.Excessive refrigerant charge

in refrigeration cycleReduce refrigerant until speci-

fied pressure is obtained.

Air suction by cooling fan is

insufficient.Insufficient condenser cooling

performance

¯

1. Condenser fins are clogged.

2. Improper fan rotation of

cooling fan

lClean condenser.

lCheck and repair cooling fan

as necessary.

lLow-pressure pipe is not

cold.

lWhen compressor is

stopped high-pressure

value quickly drops by

approximately 196 kPa (2

kg/cm

2,28psi).Itthen

decreases gradually there-

after.Poor heat exchange in con-

denser

(After compressor operation

stops, high-pressure

decreases too slowly.)

¯

Air in refrigeration cycleEvacuate repeatedly and

recharge system.

Engine tends to overheat.Engine cooling systems mal-

function.Check and repair engine cool-

ing system.

lAn area of the low-pres-

sure pipe is colder than

areas near the evaporator

outlet.

lPlates are sometimes cov-

ered with frost.

lExcessive liquid refrigerant

on low-pressure side

lExcessive refrigerant dis-

charge flow

lExpansion valve is open a

littlecomparedwiththe

specification.

¯

Improper expansion valve

adjustmentReplace expansion valve.

AC359A

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too high and

low-pressure side is too low.

Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tube or parts

located between compressor

and condenser are clogged or

crushed.

lCheck and repair or replace

malfunctioning parts.

lCheck lubricant for contami-

nation.

AC360A

Page 2479 of 3171

MTC-92

TROUBLE DIAGNOSIS

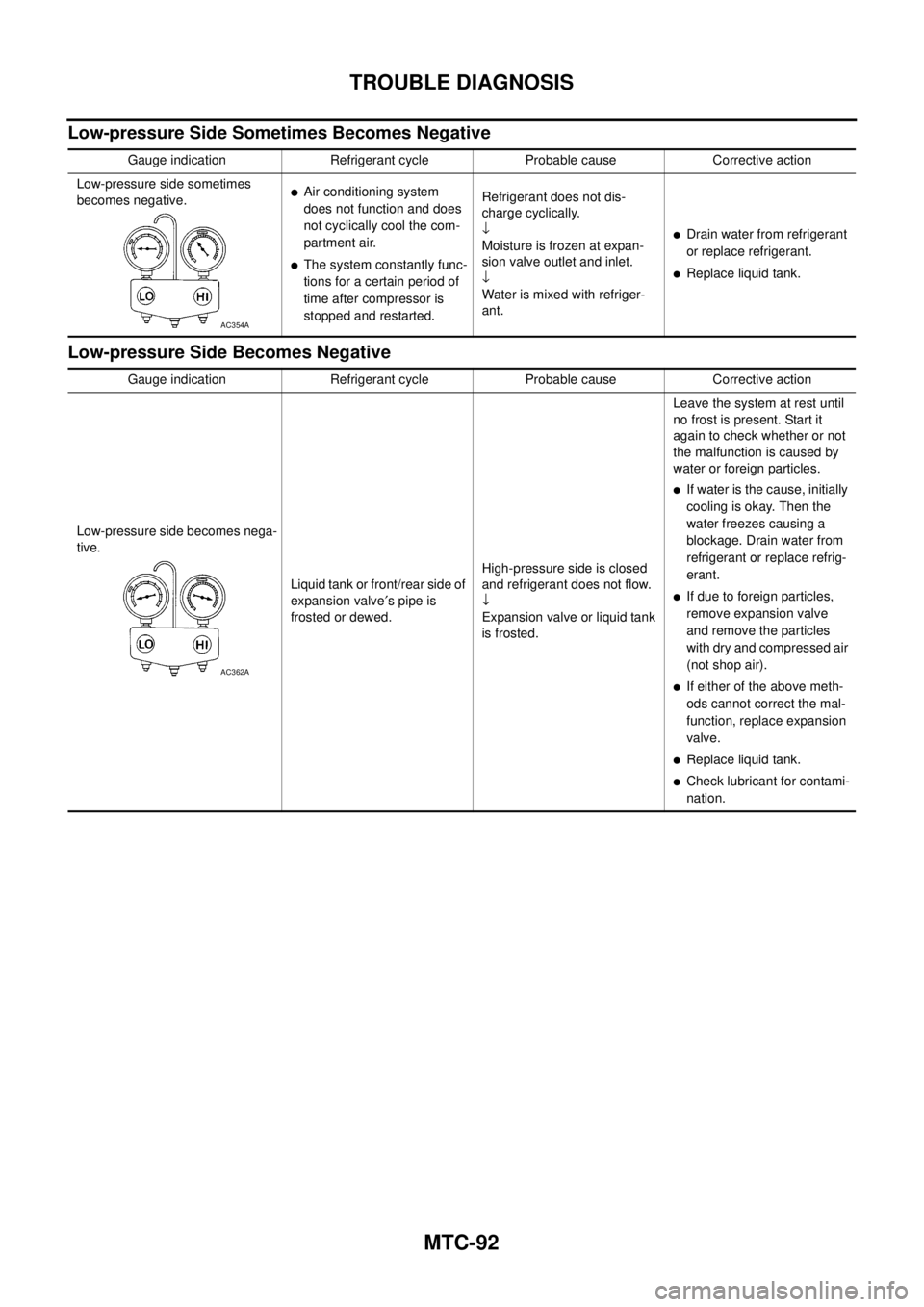

Low-pressure Side Sometimes Becomes Negative

Low-pressure Side Becomes Negative

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side sometimes

becomes negative.

lAir conditioning system

does not function and does

not cyclically cool the com-

partment air.

lThe system constantly func-

tions for a certain period of

time after compressor is

stopped and restarted.Refrigerant does not dis-

charge cyclically.

¯

Moisture is frozen at expan-

sion valve outlet and inlet.

¯

Water is mixed with refriger-

ant.

lDrain water from refrigerant

or replace refrigerant.

lReplace liquid tank.

AC354A

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side becomes nega-

tive.

Liquid tank or front/rear side of

expansion valve¢spipeis

frosted or dewed.High-pressure side is closed

and refrigerant does not flow.

¯

Expansion valve or liquid tank

is frosted.Leave the system at rest until

no frost is present. Start it

again to check whether or not

the malfunction is caused by

waterorforeignparticles.

lIf water is the cause, initially

cooling is okay. Then the

water freezes causing a

blockage. Drain water from

refrigerant or replace refrig-

erant.

lIf due to foreign particles,

remove expansion valve

and remove the particles

with dry and compressed air

(not shop air).

lIf either of the above meth-

ods cannot correct the mal-

function, replace expansion

valve.

lReplace liquid tank.

lCheck lubricant for contami-

nation.

AC362A

Page 2482 of 3171

TROUBLE DIAGNOSIS

MTC-95

C

D

E

F

G

H

I

K

L

MA

B

MTC

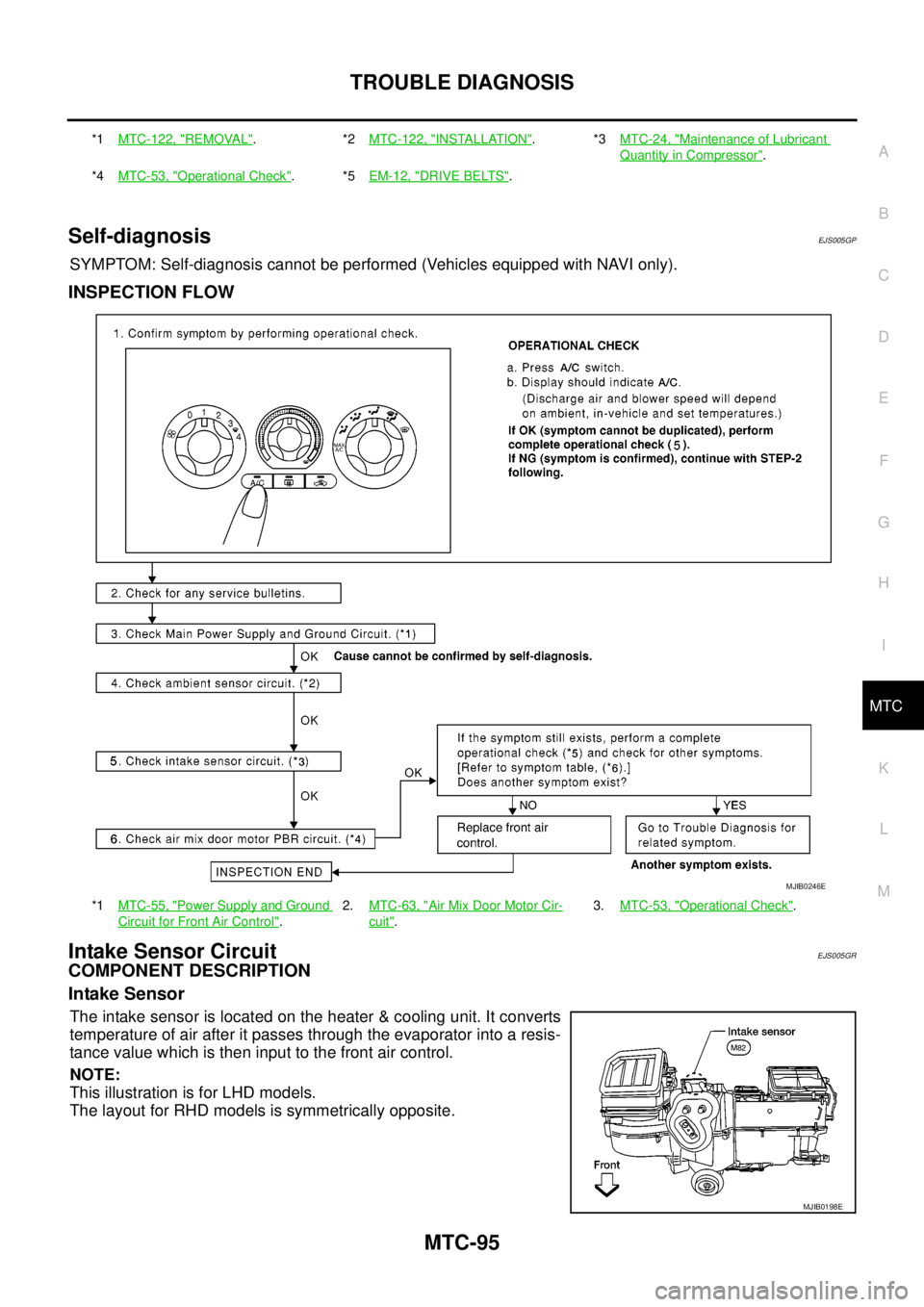

Self-diagnosisEJS005GP

SYMPTOM: Self-diagnosis cannot be performed (Vehicles equipped with NAVI only).

INSPECTION FLOW

Intake Sensor CircuitEJS005GR

COMPONENT DESCRIPTION

Intake Sensor

The intake sensor is located on the heater & cooling unit. It converts

temperature of air after it passes through the evaporator into a resis-

tance value which is then input to the front air control.

NOTE:

This illustration is for LHD models.

The layout for RHD models is symmetrically opposite.

*1MTC-122, "REMOVAL".*2MTC-122, "INSTALLATION".*3MTC-24, "Maintenance of Lubricant

Quantity in Compressor".

*4MTC-53, "

Operational Check".*5EM-12, "DRIVE BELTS".

*1MTC-55, "

Power Supply and Ground

Circuit for Front Air Control".2.MTC-63, "

Air Mix Door Motor Cir-

cuit".3.MTC-53, "

Operational Check".

MJIB0246E

MJIB0198E

Page 2486 of 3171

INTAKE SENSOR

MTC-99

C

D

E

F

G

H

I

K

L

MA

B

MTC

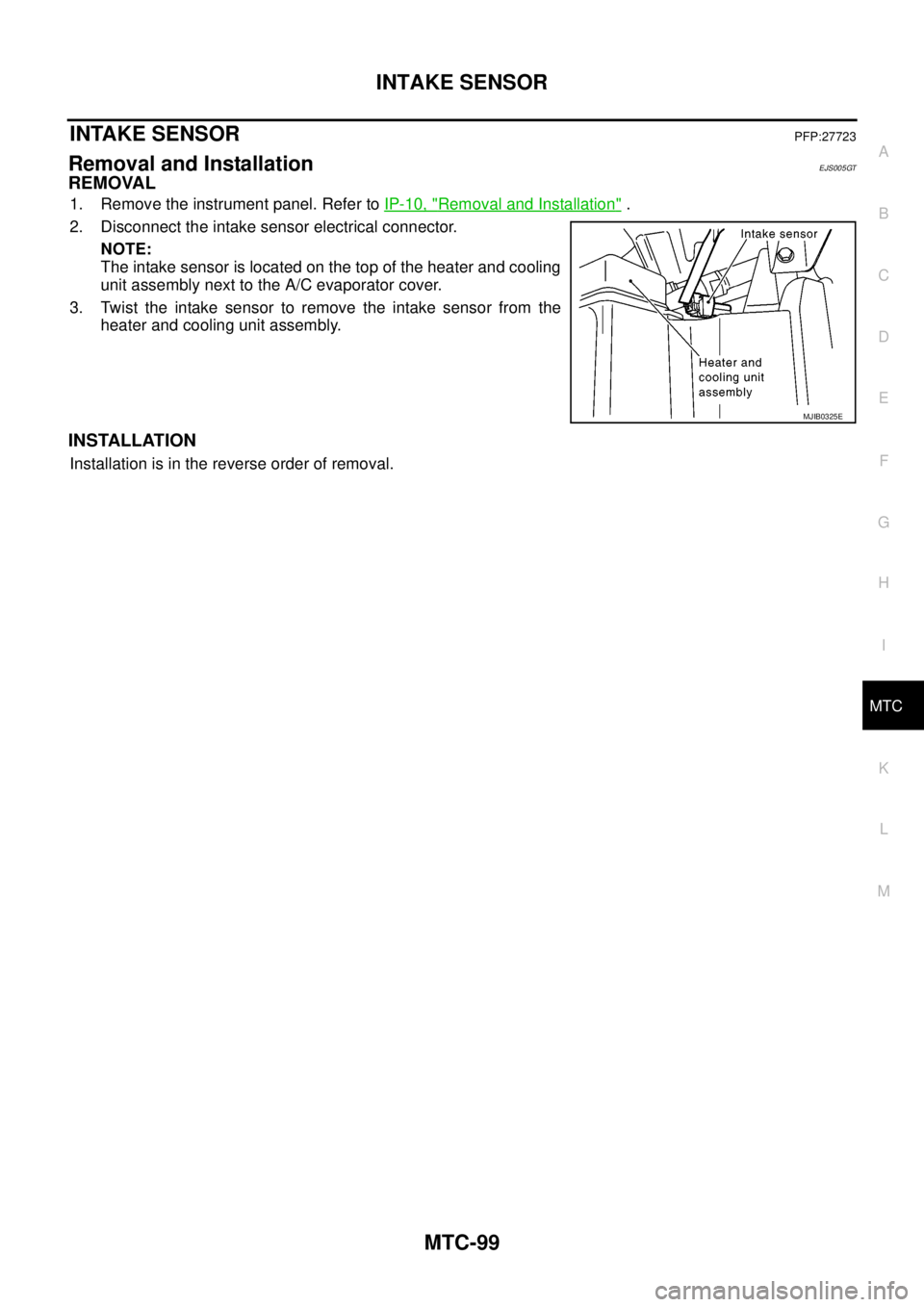

INTAKE SENSORPFP:27723

Removal and InstallationEJS005GT

REMOVAL

1. Remove the instrument panel. Refer toIP-10, "Removal and Installation".

2. Disconnect the intake sensor electrical connector.

NOTE:

The intake sensor is located on the top of the heater and cooling

unit assembly next to the A/C evaporator cover.

3. Twist the intake sensor to remove the intake sensor from the

heater and cooling unit assembly.

INSTALLATION

Installation is in the reverse order of removal.

MJIB0325E

Page 2487 of 3171

MTC-100

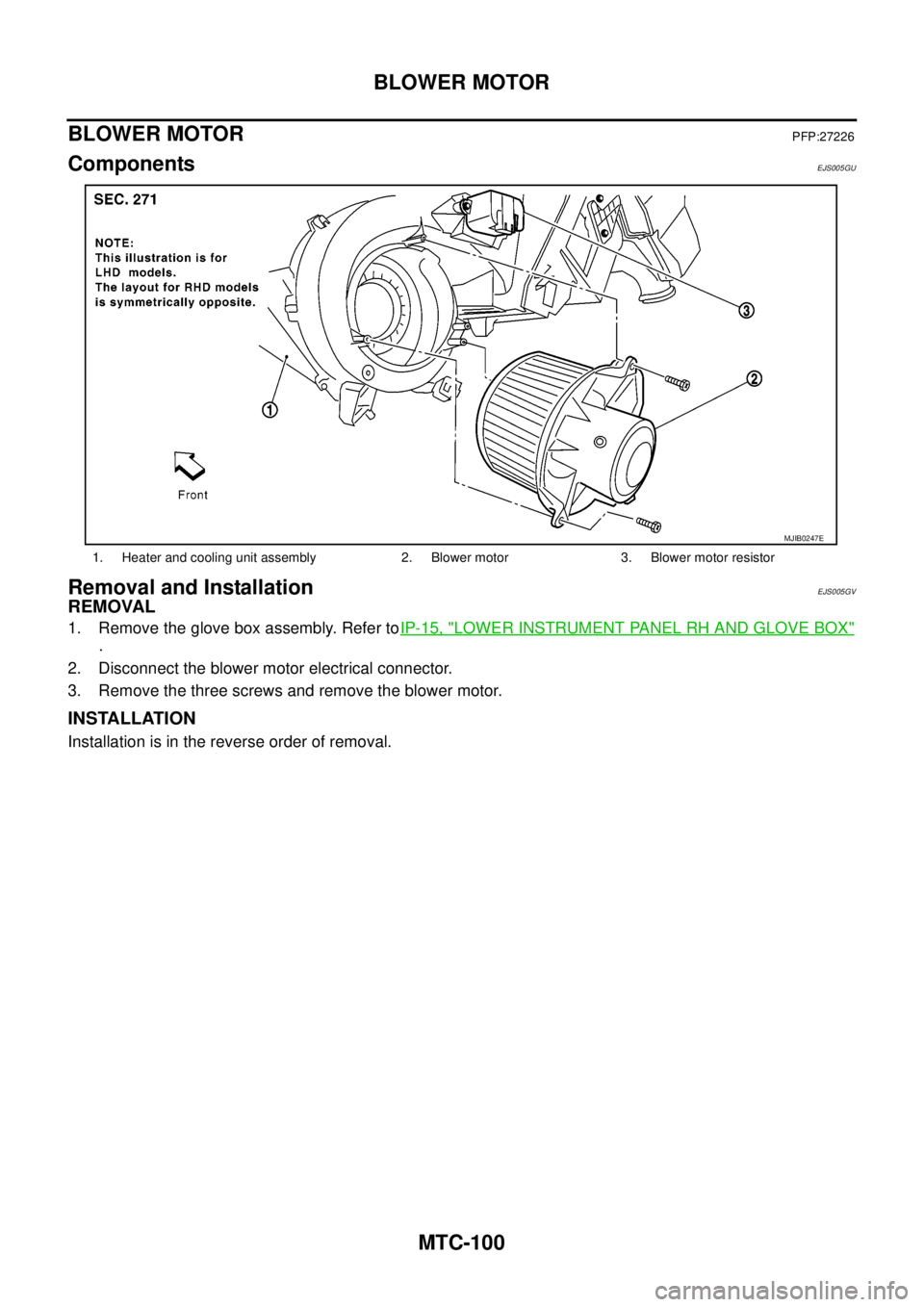

BLOWER MOTOR

BLOWER MOTOR

PFP:27226

ComponentsEJS005GU

Removal and InstallationEJS005GV

REMOVAL

1. Remove the glove box assembly. Refer toIP-15, "LOWER INSTRUMENT PANEL RH AND GLOVE BOX"

.

2. Disconnect the blower motor electrical connector.

3. Remove the three screws and remove the blower motor.

INSTALLATION

Installation is in the reverse order of removal.

1. Heater and cooling unit assembly 2. Blower motor 3. Blower motor resistor

MJIB0247E

Page 2488 of 3171

AIR CONDITIONER FILTER

MTC-101

C

D

E

F

G

H

I

K

L

MA

B

MTC

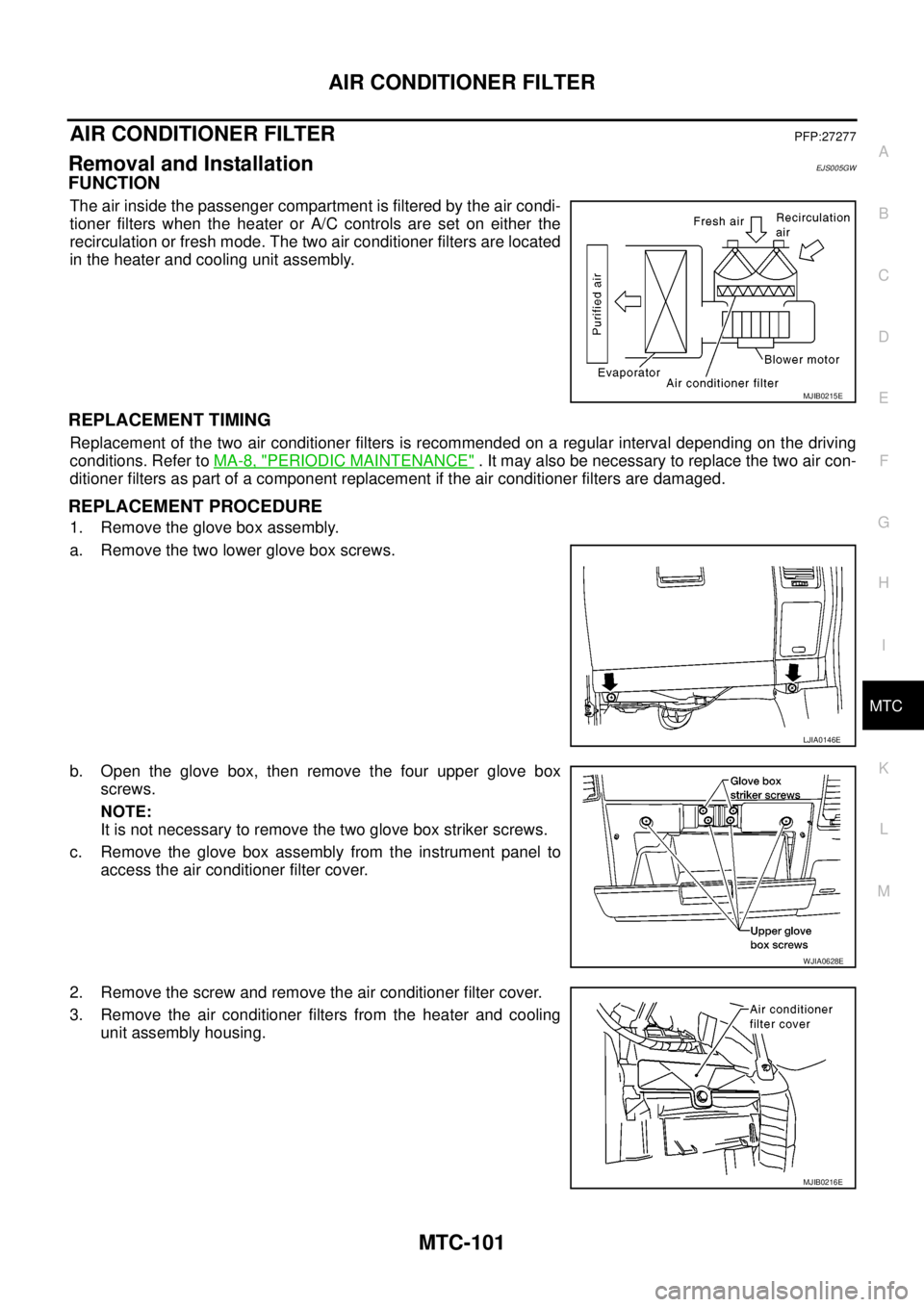

AIR CONDITIONER FILTERPFP:27277

Removal and InstallationEJS005GW

FUNCTION

The air inside the passenger compartment is filtered by the air condi-

tioner filters when the heater or A/C controls are set on either the

recirculation or fresh mode. The two air conditioner filters are located

in the heater and cooling unit assembly.

REPLACEMENT TIMING

Replacement of the two air conditioner filters is recommended on a regular interval depending on the driving

conditions. Refer toMA-8, "

PERIODIC MAINTENANCE". It may also be necessary to replace the two air con-

ditioner filters as part of a component replacement if the air conditioner filters are damaged.

REPLACEMENT PROCEDURE

1. Remove the glove box assembly.

a. Remove the two lower glove box screws.

b. Open the glove box, then remove the four upper glove box

screws.

NOTE:

It is not necessary to remove the two glove box striker screws.

c. Remove the glove box assembly from the instrument panel to

access the air conditioner filter cover.

2. Remove the screw and remove the air conditioner filter cover.

3. Remove the air conditioner filters from the heater and cooling

unit assembly housing.

MJIB0215E

LJIA0146E

WJIA0628E

MJIB0216E

Page 2489 of 3171

MTC-102

AIR CONDITIONER FILTER

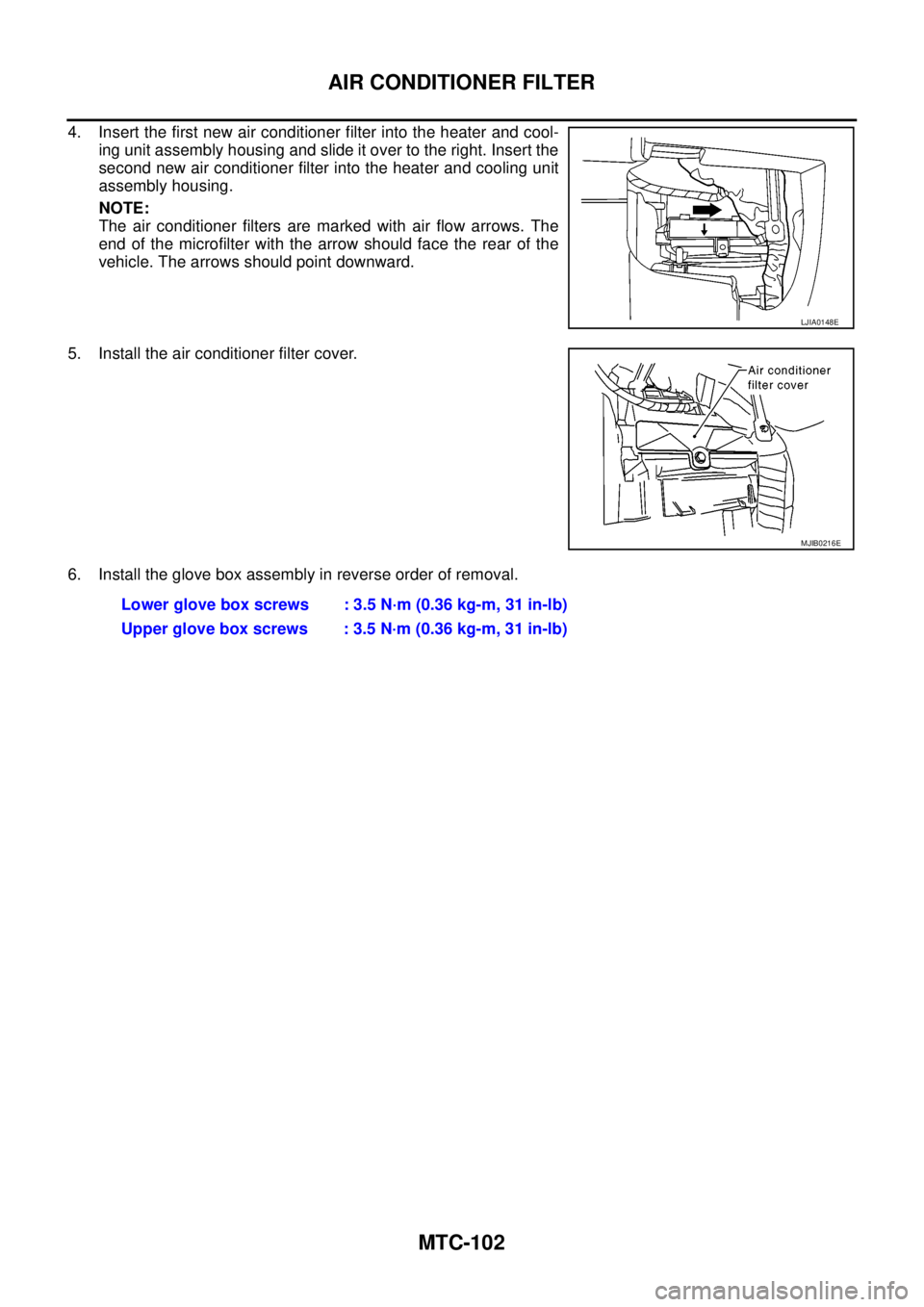

4. Insert the first new air conditioner filter into the heater and cool-

ing unit assembly housing and slide it over to the right. Insert the

second new air conditioner filter into the heater and cooling unit

assembly housing.

NOTE:

The air conditioner filters are marked with air flow arrows. The

end of the microfilter with the arrow should face the rear of the

vehicle. The arrows should point downward.

5. Install the air conditioner filter cover.

6. Install the glove box assembly in reverse order of removal.

LJIA0148E

MJIB0216E

Lower glove box screws : 3.5 N·m (0.36 kg-m, 31 in-lb)

Upper glove box screws : 3.5 N·m (0.36 kg-m, 31 in-lb)

Page 2490 of 3171

HEATER & COOLING UNIT ASSEMBLY

MTC-103

C

D

E

F

G

H

I

K

L

MA

B

MTC

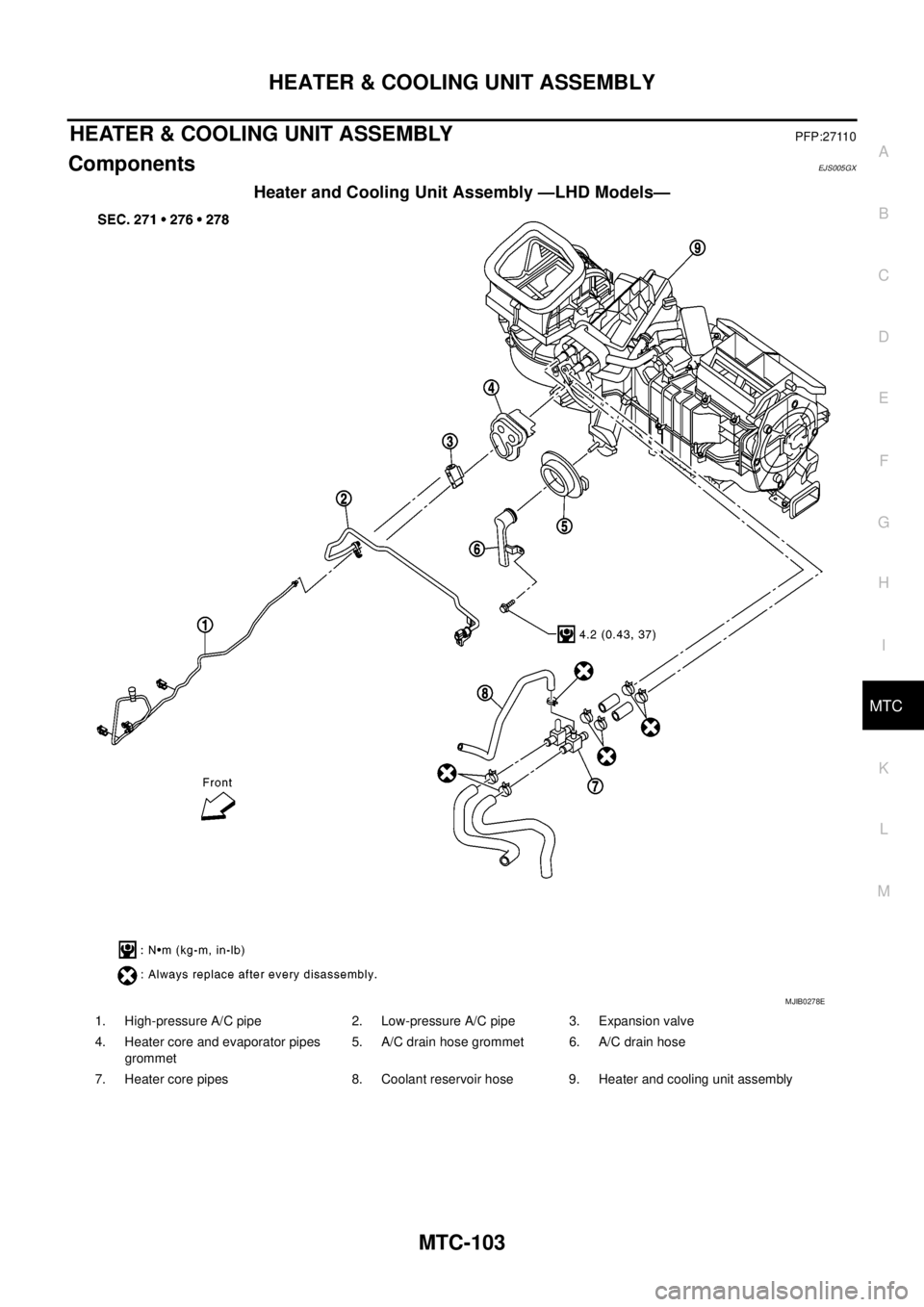

HEATER & COOLING UNIT ASSEMBLYPFP:27110

ComponentsEJS005GX

Heater and Cooling Unit Assembly —LHD Models—

MJIB0278E

1. High-pressure A/C pipe 2. Low-pressure A/C pipe 3. Expansion valve

4. Heater core and evaporator pipes

grommet5. A/C drain hose grommet 6. A/C drain hose

7. Heater core pipes 8. Coolant reservoir hose 9. Heater and cooling unit assembly