cooling NISSAN NAVARA 2005 Repair Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2297 of 3171

MA-22

ENGINE MAINTENANCE

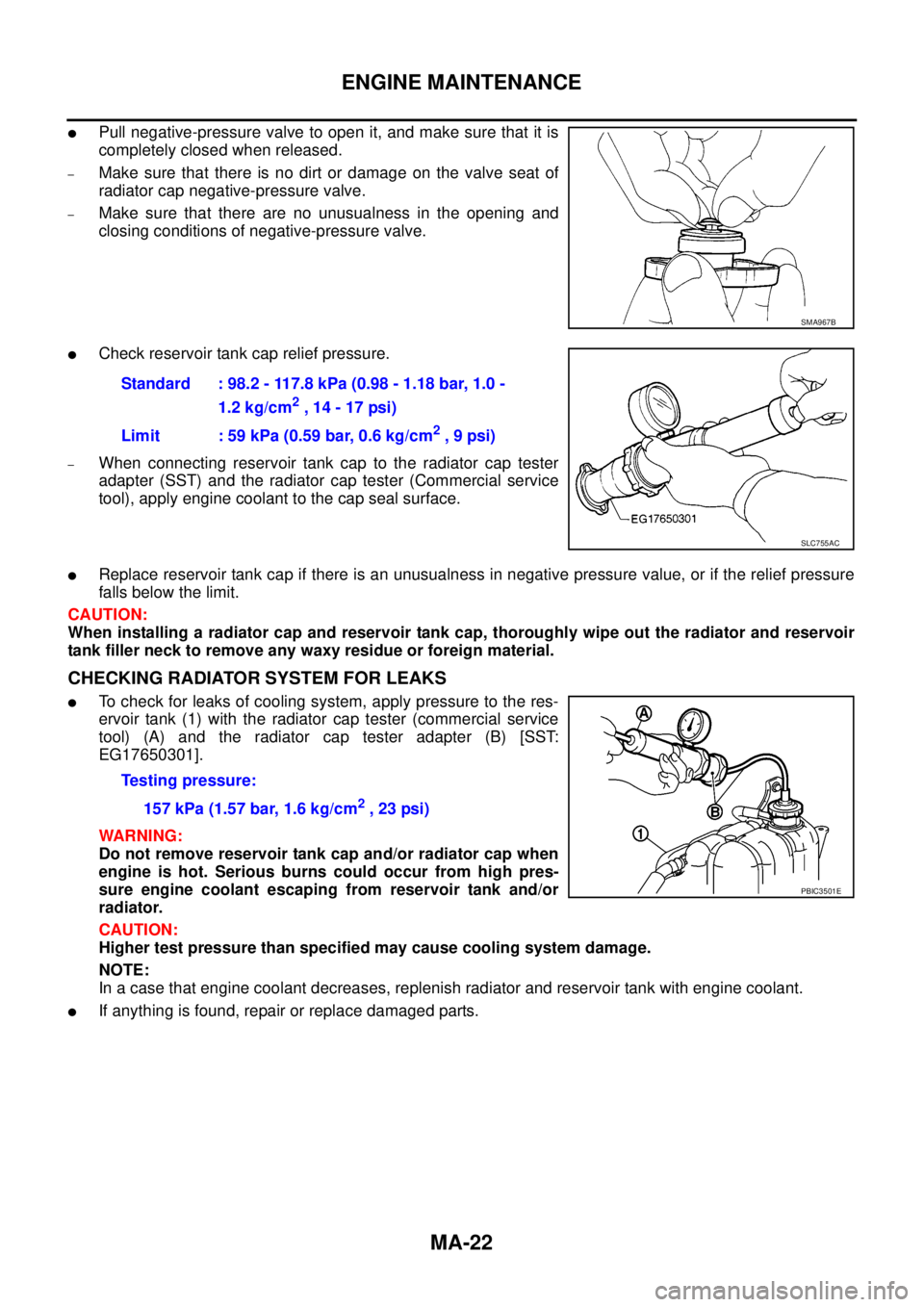

lPull negative-pressure valve to open it, and make sure that it is

completely closed when released.

–Makesurethatthereisnodirtordamageonthevalveseatof

radiator cap negative-pressure valve.

–Make sure that there are no unusualness in the opening and

closing conditions of negative-pressure valve.

lCheck reservoir tank cap relief pressure.

–When connecting reservoir tank cap to the radiator cap tester

adapter (SST) and the radiator cap tester (Commercial service

tool), apply engine coolant to the cap seal surface.

lReplace reservoir tank cap if there is an unusualness in negative pressure value, or if the relief pressure

falls below the limit.

CAUTION:

When installing a radiator cap and reservoir tank cap, thoroughly wipe out the radiator and reservoir

tank filler neck to remove any waxy residue or foreign material.

CHECKING RADIATOR SYSTEM FOR LEAKS

lTo check for leaks of cooling system, apply pressure to the res-

ervoir tank (1) with the radiator cap tester (commercial service

tool) (A) and the radiator cap tester adapter (B) [SST:

EG17650301].

WARNING:

Do not remove reservoir tank cap and/or radiator cap when

engine is hot. Serious burns could occur from high pres-

sure engine coolant escaping from reservoir tank and/or

radiator.

CAUTION:

Higher test pressure than specified may cause cooling system damage.

NOTE:

In a case that engine coolant decreases, replenish radiator and reservoir tank with engine coolant.

lIf anything is found, repair or replace damaged parts.

SMA967B

Standard : 98.2 - 117.8 kPa (0.98 - 1.18 bar, 1.0 -

1.2 kg/cm

2,14-17psi)

Limit : 59 kPa (0.59 bar, 0.6 kg/cm

2,9psi)

SLC755AC

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2,23psi)

PBIC3501E

Page 2305 of 3171

MA-30

CHASSIS AND BODY MAINTENANCE

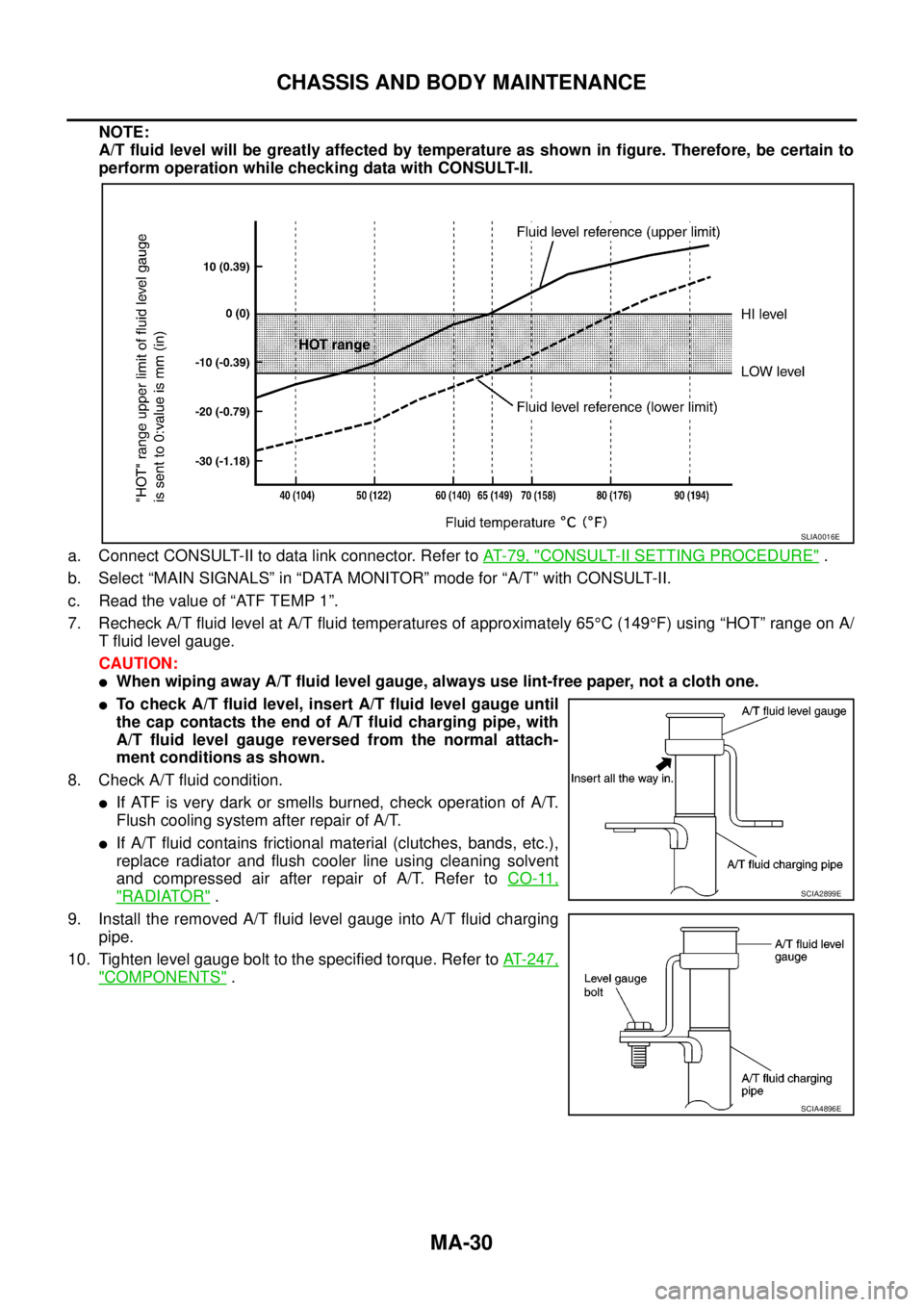

NOTE:

A/T fluid level will be greatly affected by temperature as shown in figure. Therefore, be certain to

perform operation while checking data with CONSULT-II.

a. Connect CONSULT-II to data link connector. Refer toAT-79, "

CONSULT-II SETTING PROCEDURE".

b. Select “MAIN SIGNALS” in “DATA MONITOR” mode for “A/T” with CONSULT-II.

c. Readthevalueof“ATFTEMP1”.

7. Recheck A/T fluid level at A/T fluid temperatures of approximately 65°C(149°F)using“HOT”rangeonA/

T fluid level gauge.

CAUTION:

lWhen wiping away A/T fluid level gauge, always use lint-free paper, not a cloth one.

lTo check A/T fluid level, insert A/T fluid level gauge until

the cap contacts the end of A/T fluid charging pipe, with

A/T fluid level gauge reversed from the normal attach-

ment conditions as shown.

8. Check A/T fluid condition.

lIf ATF is very dark or smells burned, check operation of A/T.

Flush cooling system after repair of A/T.

lIf A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer toCO-11,

"RADIATOR".

9. Install the removed A/T fluid level gauge into A/T fluid charging

pipe.

10. Tighten level gauge bolt to the specified torque. Refer toAT-247,

"COMPONENTS".

SLIA0016E

SCIA2899E

SCIA4896E

Page 2389 of 3171

MTC-2

Schematic —LHD MODELS— ............................... 38

Wiring Diagram —A/C— —LHD MODELS— ......... 39

Schematic —RHD MODELS— ............................... 44

Wiring Diagram —A/C— —RHD MODELS— ......... 45

Front Air Control Terminals and Reference Value... 49

PIN CONNECTOR TERMINAL LAYOUT ............ 49

TERMINALS AND REFERENCE VALUE FOR

FRONT AIR CONTROL ....................................... 49

A/C System Self-diagnosis Function ...................... 51

DESCRIPTION .................................................... 51

Operational Check .................................................. 53

CHECKING BLOWER ......................................... 53

CHECKING DISCHARGE AIR ............................ 53

CHECKING RECIRCULATION ............................ 53

CHECKING TEMPERATURE DECREASE ......... 54

CHECKING TEMPERATURE INCREASE .......... 54

CHECK A/C SWITCH .......................................... 54

Power Supply and Ground Circuit for Front Air Con-

trol ........................................................................... 55

INSPECTION FLOW ........................................... 55

COMPONENT DESCRIPTION ............................ 56

DIAGNOSTIC PROCEDURE FOR A/C SYSTEM... 56

Mode Door Motor Circuit ........................................ 58

INSPECTION FLOW ........................................... 58

SYSTEM DESCRIPTION .................................... 59

COMPONENT DESCRIPTION ............................ 59

DIAGNOSTIC PROCEDURE FOR MODE

DOOR MOTOR ................................................... 59

Air Mix Door Motor Circuit ...................................... 63

INSPECTION FLOW ........................................... 63

SYSTEM DESCRIPTION .................................... 64

COMPONENT DESCRIPTION ............................ 64

DIAGNOSTIC PROCEDURE FOR AIR MIX

DOOR MOTOR (FRONT) .................................... 64

Intake Door Motor Circuit ........................................ 68

INSPECTION FLOW ........................................... 68

SYSTEM DESCRIPTION .................................... 69

COMPONENT DESCRIPTION ............................ 69

DIAGNOSTIC PROCEDURE FOR INTAKE

DOOR MOTOR ................................................... 69

Blower Motor Circuit ............................................... 71

INSPECTION FLOW ........................................... 71

SYSTEM DESCRIPTION .................................... 72

COMPONENT DESCRIPTION ............................ 72

DIAGNOSTIC PROCEDURE FOR BLOWER

MOTOR ............................................................... 73

COMPONENT INSPECTION .............................. 77

Magnet Clutch Circuit ............................................. 79

INSPECTION FLOW ........................................... 79

SYSTEM DESCRIPTION .................................... 80

DIAGNOSTIC PROCEDURE FOR MAGNET

CLUTCH .............................................................. 80

COMPONENT INSPECTION .............................. 85

Insufficient Cooling ................................................. 86

INSPECTION FLOW ........................................... 86

PERFORMANCE TEST DIAGNOSES ................ 87

PERFORMANCE CHART ................................... 89

TROUBLE DIAGNOSES FOR UNUSUAL PRES-

SURE ................................................................... 90Insufficient Heating ................................................. 93

INSPECTION FLOW ............................................ 93

Noise ....................................................................... 94

INSPECTION FLOW ............................................ 94

Self-diagnosis ......................................................... 95

INSPECTION FLOW ............................................ 95

Intake Sensor Circuit ............................................... 95

COMPONENT DESCRIPTION ............................ 95

DIAGNOSTIC PROCEDURE FOR INTAKE SEN-

SOR ..................................................................... 96

COMPONENT INSPECTION ............................... 97

CONTROL UNIT ........................................................ 98

Removal and Installation ......................................... 98

REMOVAL ............................................................ 98

INSTALLATION .................................................... 98

INTAKE SENSOR ...................................................... 99

Removal and Installation ......................................... 99

REMOVAL ............................................................ 99

INSTALLATION .................................................... 99

BLOWER MOTOR ...................................................100

Components ..........................................................100

Removal and Installation .......................................100

REMOVAL ..........................................................100

INSTALLATION ..................................................100

AIR CONDITIONER FILTER ...................................101

Removal and Installation .......................................101

FUNCTION ........................................................101

REPLACEMENT TIMING ..................................101

REPLACEMENT PROCEDURE ........................101

HEATER & COOLING UNIT ASSEMBLY ...............103

Components ..........................................................103

Removal and Installation .......................................105

REMOVAL ..........................................................105

INSTALLATION ..................................................105

HEATER CORE .......................................................106

Components ..........................................................106

Removal and Installation .......................................107

REMOVAL ..........................................................107

INSTALLATION ..................................................107

DEFROSTER DOOR MOTOR .................................108

Components ..........................................................108

Removal and Installation .......................................108

REMOVAL ..........................................................108

INSTALLATION ..................................................108

INTAKE DOOR MOTOR ..........................................109

Components ..........................................................109

Removal and Installation .......................................109

REMOVAL ..........................................................109

INSTALLATION ..................................................109

MODE DOOR MOTOR ............................................110

Components ..........................................................110

Removal and Installation .......................................110

REMOVAL ..........................................................110

INSTALLATION ..................................................110

AIR MIX DOOR MOTOR ......................................... 111

Components .......................................................... 111

Removal and Installation ....................................... 111

REMOVAL .......................................................... 111

INSTALLATION .................................................. 111

Page 2392 of 3171

PRECAUTIONS

MTC-5

C

D

E

F

G

H

I

K

L

MA

B

MTC

lIf the vehicle is within the warranty period, the air conditioner warranty is void. Please contact NISSAN

Customer Affairs for further assistance.

General Refrigerant PrecautionsEJS00628

WARNING:

lDo not release refrigerant into the air. Use approved recovery/recycling equipment to capture the

refrigerant every time an air conditioning system is discharged.

lAlways wear eye and hand protection (goggles and gloves) when working with any refrigerant or

air conditioning system.

lDo not store or heat refrigerant containers above 52°C.

lDo not heat a refrigerant container with an open flame; if container warming is required, place the

bottom of the container in a warm pail of water.

lDo not intentionally drop, puncture, or incinerate refrigerant containers.

lKeep refrigerant away from open flames: poisonous gas will be produced if refrigerant burns.

lRefrigerant will displace oxygen, therefore be certain to work in well ventilated areas to prevent

suffocation.

lDo not pressure test or leak test HFC-134a (R-134a) service equipment and/or vehicle air condi-

tioning systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a)

have been shown to be combustible at elevated pressures. These mixtures, if ignited, may cause

injury or property damage. Additional health and safety information may be obtained from refriger-

ant manufacturers.

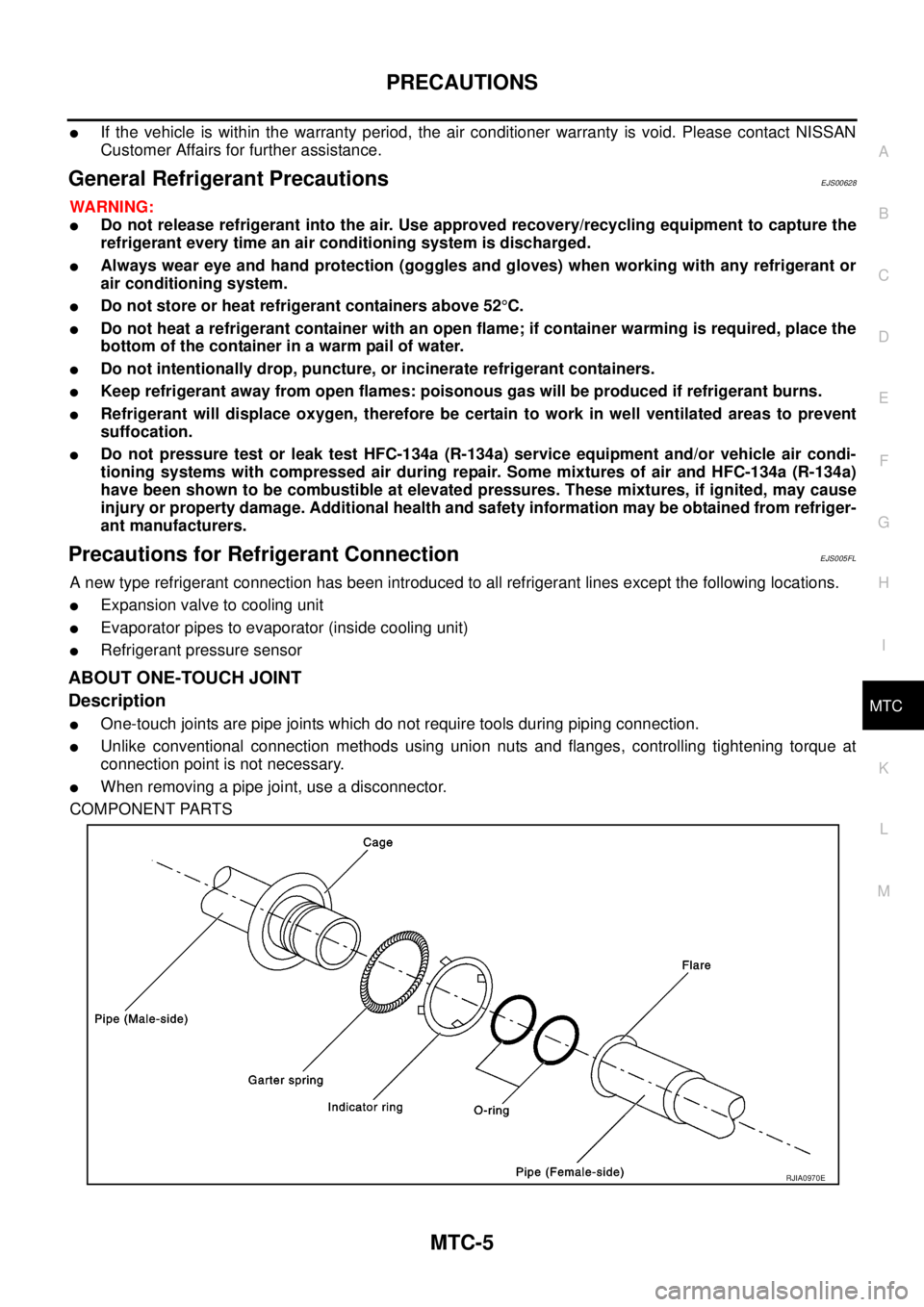

Precautions for Refrigerant ConnectionEJS005FL

A new type refrigerant connection has been introduced to all refrigerant lines except the following locations.

lExpansion valve to cooling unit

lEvaporator pipes to evaporator (inside cooling unit)

lRefrigerant pressure sensor

ABOUT ONE-TOUCH JOINT

Description

lOne-touch joints are pipe joints which do not require tools during piping connection.

lUnlike conventional connection methods using union nuts and flanges, controlling tightening torque at

connection point is not necessary.

lWhen removing a pipe joint, use a disconnector.

COMPONENT PARTS

RJIA0970E

Page 2410 of 3171

REFRIGERATION SYSTEM

MTC-23

C

D

E

F

G

H

I

K

L

MA

B

MTC

1. Defroster nozzle 2. LH side demister duct 3. LH ventilator duct

4. RH side demister duct 5. RH ventilator duct 6. Center ventilator duct

7. Heater and cooling unit assembly 8. Floor duct 9. Clips

10. Heat duct

Page 2411 of 3171

MTC-24

LUBRICANT

LUBRICANT

PFP:KLG00

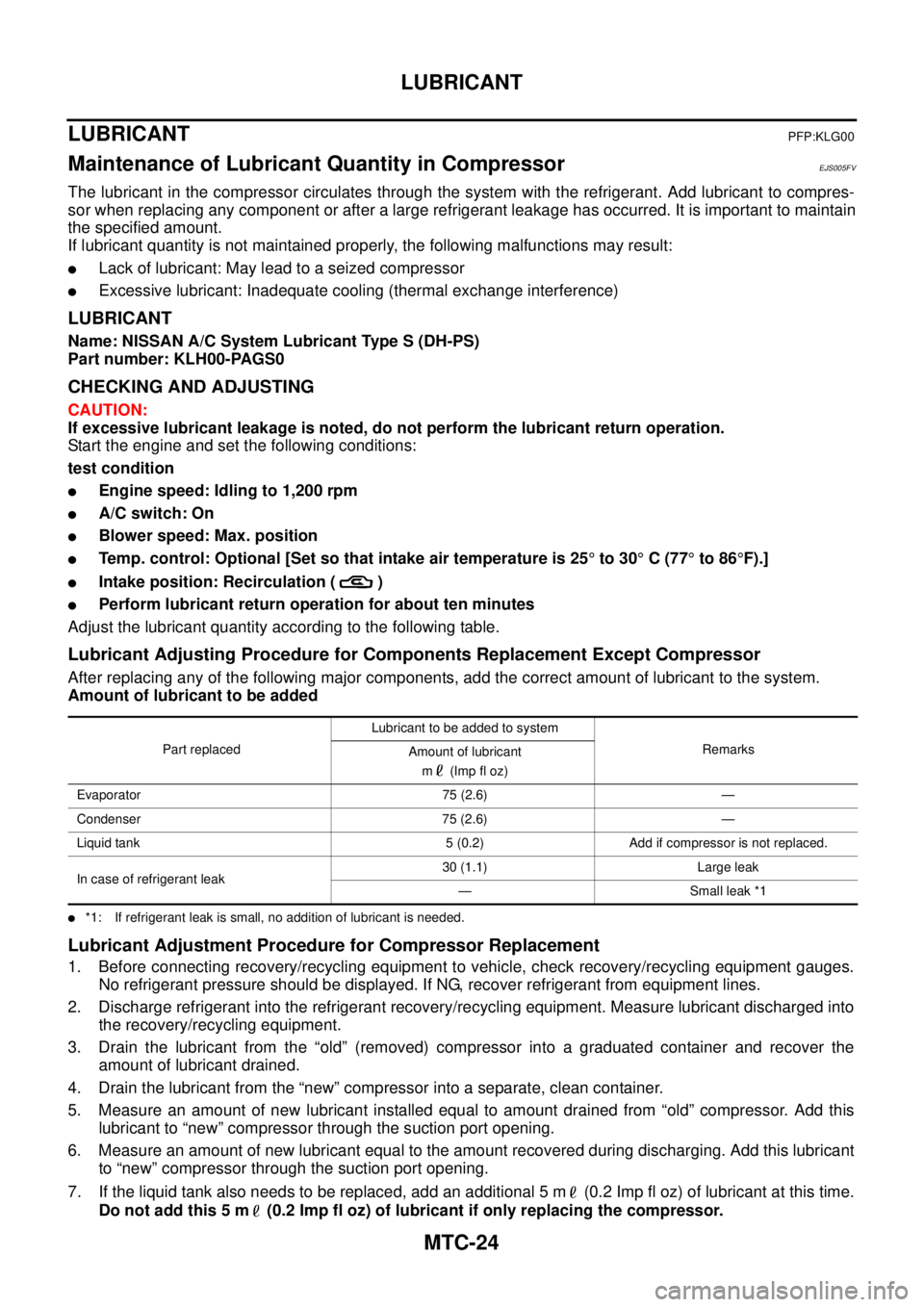

Maintenance of Lubricant Quantity in CompressorEJS005FV

The lubricant in the compressor circulates through the system with the refrigerant. Add lubricant to compres-

sor when replacing any component or after a large refrigerant leakage has occurred. It is important to maintain

the specified amount.

If lubricant quantity is not maintained properly, the following malfunctions may result:

lLack of lubricant: May lead to a seized compressor

lExcessive lubricant: Inadequate cooling (thermal exchange interference)

LUBRICANT

Name: NISSAN A/C System Lubricant Type S (DH-PS)

Part number: KLH00-PAGS0

CHECKING AND ADJUSTING

CAUTION:

If excessive lubricant leakage is noted, do not perform the lubricant return operation.

Start the engine and set the following conditions:

test condition

lEngine speed: Idling to 1,200 rpm

lA/C switch: On

lBlower speed: Max. position

lTemp. control: Optional [Set so that intake air temperature is 25°to 30°C(77°to 86°F).]

lIntake position: Recirculation ( )

lPerform lubricant return operation for about ten minutes

Adjust the lubricant quantity according to the following table.

Lubricant Adjusting Procedure for Components Replacement Except Compressor

After replacing any of the following major components, add the correct amount of lubricant to the system.

Amount of lubricant to be added

l*1: If refrigerant leak is small, no addition of lubricant is needed.

Lubricant Adjustment Procedure for Compressor Replacement

1. Before connecting recovery/recycling equipment to vehicle, check recovery/recycling equipment gauges.

No refrigerant pressure should be displayed. If NG, recover refrigerant from equipment lines.

2. Discharge refrigerant into the refrigerant recovery/recycling equipment. Measure lubricant discharged into

the recovery/recycling equipment.

3. Drain the lubricant from the “old” (removed) compressor into a graduated container and recover the

amount of lubricant drained.

4. Drain the lubricant from the “new” compressor into a separate, clean container.

5. Measure an amount of new lubricant installed equal to amount drained from “old” compressor. Add this

lubricant to “new” compressor through the suction port opening.

6. Measure an amount of new lubricant equal to the amount recovered during discharging. Add this lubricant

to “new” compressor through the suction port opening.

7. If the liquid tank also needs to be replaced, add an additional 5 m (0.2 Imp fl oz) of lubricant at this time.

Do not add this 5 m (0.2 Imp fl oz) of lubricant if only replacing the compressor.

Part replacedLubricant to be added to system

Remarks

Amount of lubricant

m(Impfloz)

Evaporator 75 (2.6) —

Condenser 75 (2.6) —

Liquid tank 5 (0.2) Add if compressor is not replaced.

In case of refrigerant leak30 (1.1) Large leak

— Small leak *1

Page 2422 of 3171

TROUBLE DIAGNOSIS

MTC-35

C

D

E

F

G

H

I

K

L

MA

B

MTC

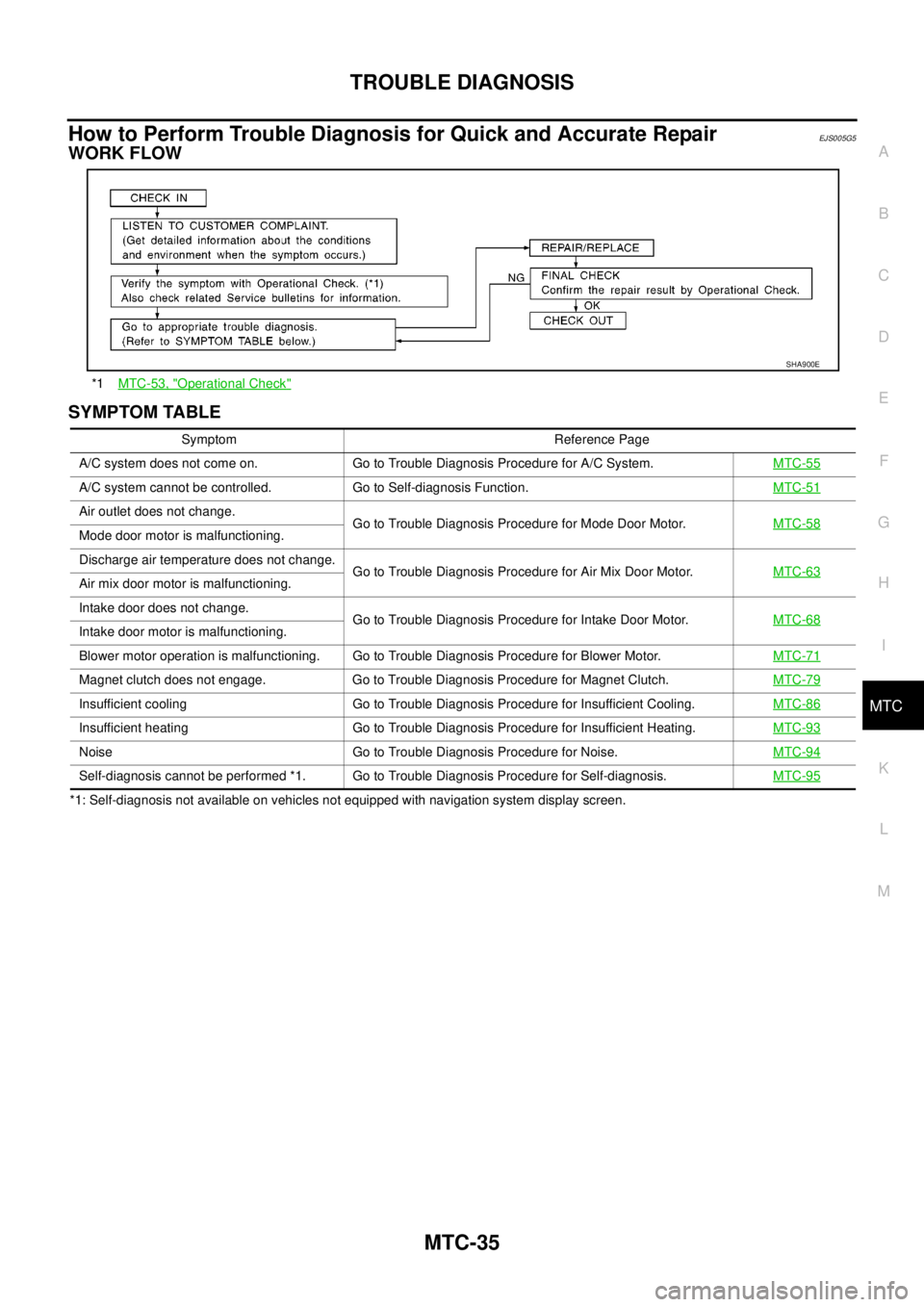

How to Perform Trouble Diagnosis for Quick and Accurate RepairEJS005G5

WORK FLOW

SYMPTOM TABLE

*1: Self-diagnosis not available on vehicles not equipped with navigation system display screen.*1MTC-53, "

Operational Check"

SHA900E

Symptom Reference Page

A/C system does not come on. Go to Trouble Diagnosis Procedure for A/C System.MTC-55

A/C system cannot be controlled. Go to Self-diagnosis Function.MTC-51

Air outlet does not change.

Go to Trouble Diagnosis Procedure for Mode Door Motor.MTC-58

Mode door motor is malfunctioning.

Discharge air temperature does not change.

Go to Trouble Diagnosis Procedure for Air Mix Door Motor.MTC-63

Air mix door motor is malfunctioning.

Intake door does not change.

Go to Trouble Diagnosis Procedure for Intake Door Motor.MTC-68

Intake door motor is malfunctioning.

Blower motor operation is malfunctioning. Go to Trouble Diagnosis Procedure for Blower Motor.MTC-71

Magnet clutch does not engage. Go to Trouble Diagnosis Procedure for Magnet Clutch.MTC-79

Insufficient cooling Go to Trouble Diagnosis Procedure for Insufficient Cooling.MTC-86

Insufficient heating Go to Trouble Diagnosis Procedure for Insufficient Heating.MTC-93

Noise Go to Trouble Diagnosis Procedure for Noise.MTC-94

Self-diagnosis cannot be performed *1. Go to Trouble Diagnosis Procedure for Self-diagnosis.MTC-95

Page 2441 of 3171

MTC-54

TROUBLE DIAGNOSIS

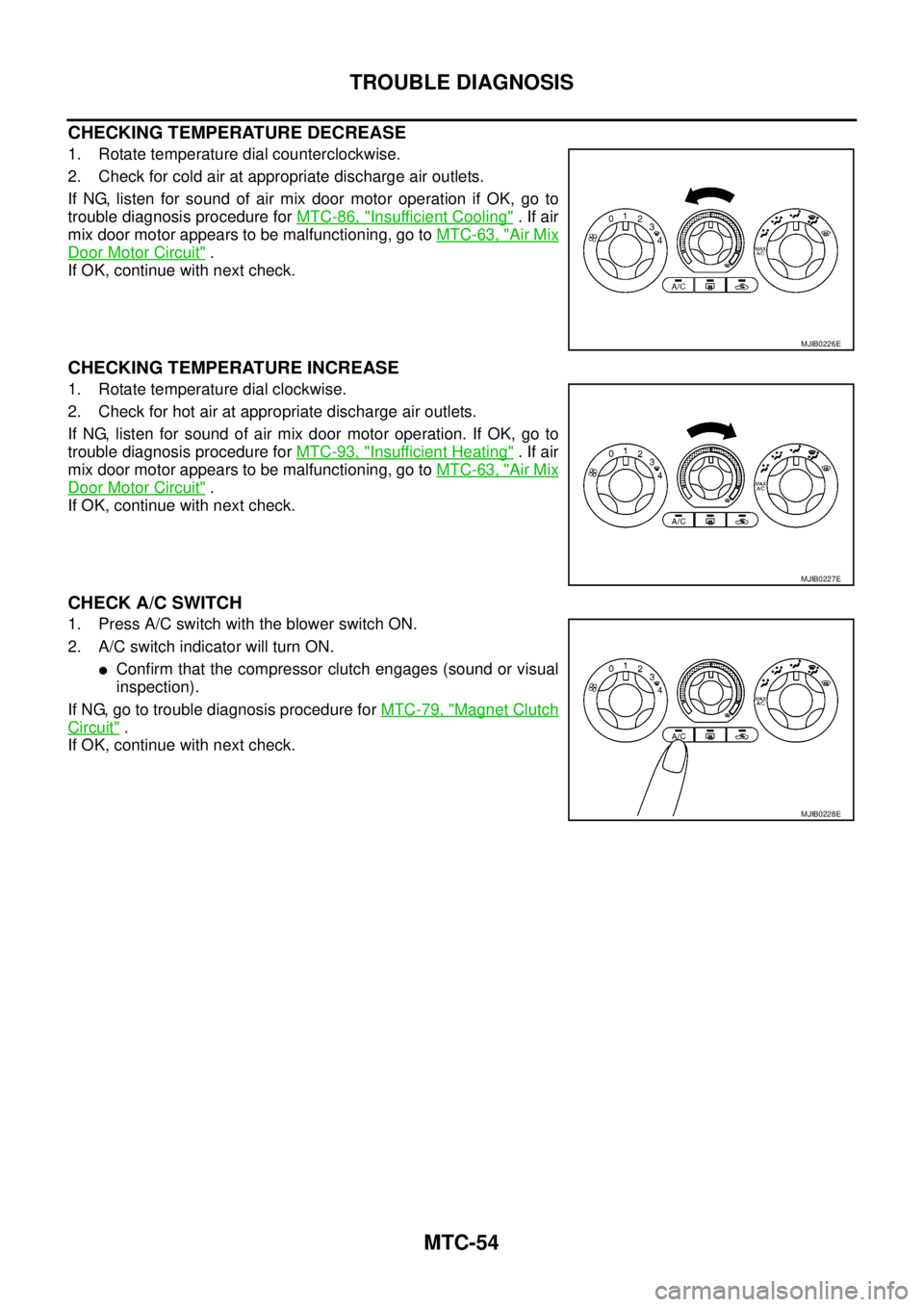

CHECKING TEMPERATURE DECREASE

1. Rotate temperature dial counterclockwise.

2. Check for cold air at appropriate discharge air outlets.

If NG, listen for sound of air mix door motor operation if OK, go to

trouble diagnosis procedure forMTC-86, "

Insufficient Cooling".Ifair

mix door motor appears to be malfunctioning, go toMTC-63, "

Air Mix

Door Motor Circuit".

If OK, continue with next check.

CHECKING TEMPERATURE INCREASE

1. Rotate temperature dial clockwise.

2. Check for hot air at appropriate discharge air outlets.

If NG, listen for sound of air mix door motor operation. If OK, go to

trouble diagnosis procedure forMTC-93, "

Insufficient Heating".Ifair

mix door motor appears to be malfunctioning, go toMTC-63, "

Air Mix

Door Motor Circuit".

If OK, continue with next check.

CHECK A/C SWITCH

1. Press A/C switch with the blower switch ON.

2. A/C switch indicator will turn ON.

lConfirm that the compressor clutch engages (sound or visual

inspection).

If NG, go to trouble diagnosis procedure forMTC-79, "

Magnet Clutch

Circuit".

If OK, continue with next check.

MJIB0226E

MJIB0227E

MJIB0228E

Page 2446 of 3171

TROUBLE DIAGNOSIS

MTC-59

C

D

E

F

G

H

I

K

L

MA

B

MTC

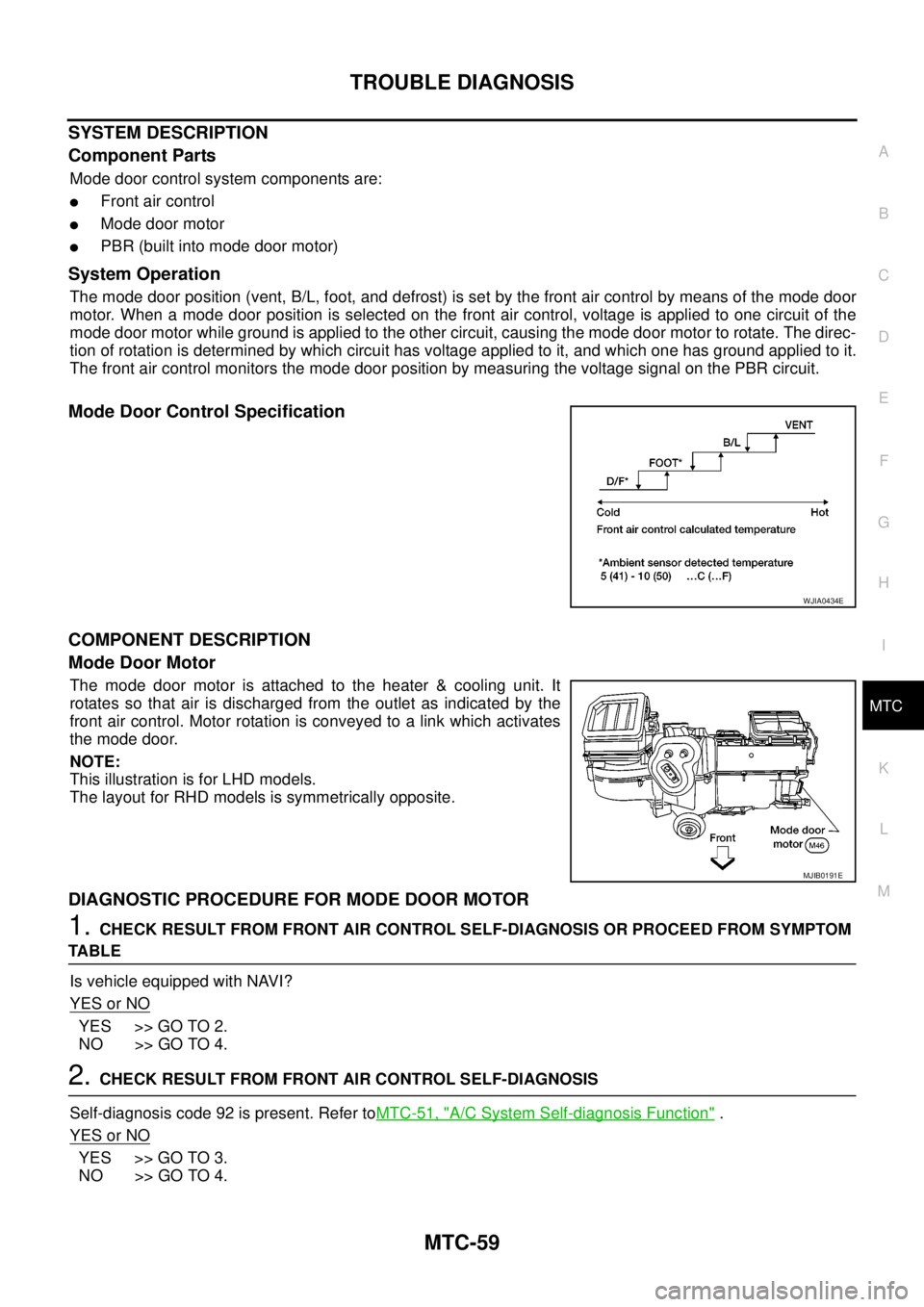

SYSTEM DESCRIPTION

Component Parts

Mode door control system components are:

lFront air control

lMode door motor

lPBR (built into mode door motor)

System Operation

The mode door position (vent, B/L, foot, and defrost) is set by the front air control by means of the mode door

motor. When a mode door position is selected on the front air control, voltage is applied to one circuit of the

mode door motor while ground is applied to the other circuit, causing the mode door motor to rotate. The direc-

tion of rotation is determined by which circuit has voltage applied to it, and which one has ground applied to it.

The front air control monitors the mode door position by measuring the voltage signal on the PBR circuit.

Mode Door Control Specification

COMPONENT DESCRIPTION

Mode Door Motor

The mode door motor is attached to the heater & cooling unit. It

rotates so that air is discharged from the outlet as indicated by the

front air control. Motor rotation is conveyed to a link which activates

themodedoor.

NOTE:

This illustration is for LHD models.

The layout for RHD models is symmetrically opposite.

DIAGNOSTIC PROCEDURE FOR MODE DOOR MOTOR

1.CHECK RESULT FROM FRONT AIR CONTROL SELF-DIAGNOSIS OR PROCEED FROM SYMPTOM

TABLE

Is vehicle equipped with NAVI?

YES or NO

YES >> GO TO 2.

NO >> GO TO 4.

2.CHECK RESULT FROM FRONT AIR CONTROL SELF-DIAGNOSIS

Self-diagnosis code 92 is present. Refer toMTC-51, "

A/C System Self-diagnosis Function".

YES or NO

YES >> GO TO 3.

NO >> GO TO 4.

WJIA0434E

MJIB0191E

Page 2451 of 3171

MTC-64

TROUBLE DIAGNOSIS

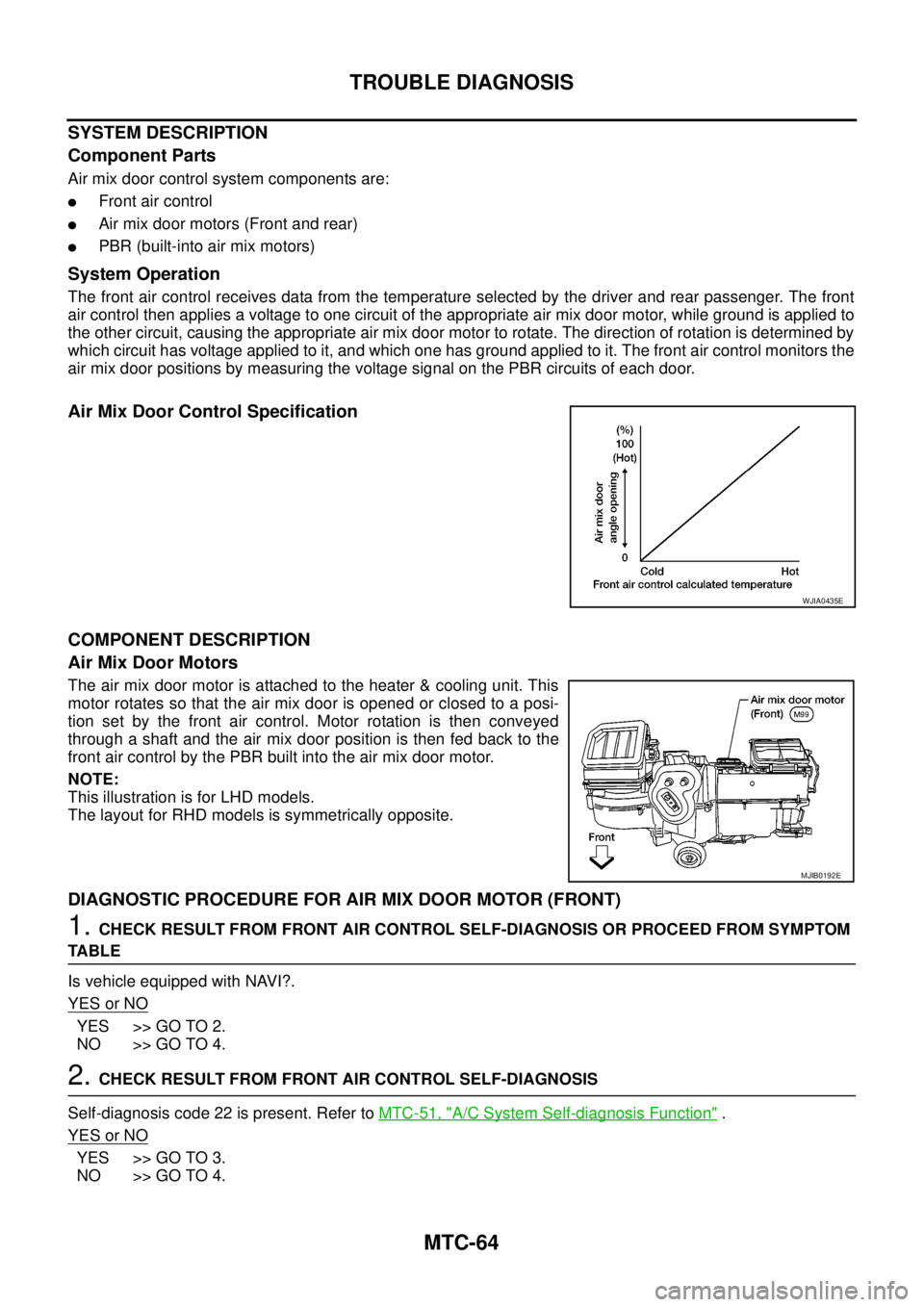

SYSTEM DESCRIPTION

Component Parts

Air mix door control system components are:

lFront air control

lAir mix door motors (Front and rear)

lPBR (built-into air mix motors)

System Operation

The front air control receives data from the temperature selected by the driver and rear passenger. The front

air control then applies a voltage to one circuit of the appropriate air mix door motor, while ground is applied to

the other circuit, causing the appropriate air mix door motor to rotate. The direction of rotation is determined by

which circuit has voltage applied to it, and which one has ground applied to it. The front air control monitors the

air mix door positions by measuring the voltage signal on the PBR circuits of each door.

Air Mix Door Control Specification

COMPONENT DESCRIPTION

Air Mix Door Motors

The air mix door motor is attached to the heater & cooling unit. This

motor rotates so that the air mix door is opened or closed to a posi-

tion set by the front air control. Motor rotation is then conveyed

through a shaft and the air mix door position is then fed back to the

front air control by the PBR built into the air mix door motor.

NOTE:

This illustration is for LHD models.

The layout for RHD models is symmetrically opposite.

DIAGNOSTIC PROCEDURE FOR AIR MIX DOOR MOTOR (FRONT)

1.CHECK RESULT FROM FRONT AIR CONTROL SELF-DIAGNOSIS OR PROCEED FROM SYMPTOM

TABLE

Is vehicle equipped with NAVI?.

YESorNO

YES >> GO TO 2.

NO >> GO TO 4.

2.CHECK RESULT FROM FRONT AIR CONTROL SELF-DIAGNOSIS

Self-diagnosis code 22 is present. Refer toMTC-51, "

A/C System Self-diagnosis Function".

YESorNO

YES >> GO TO 3.

NO >> GO TO 4.

WJIA0435E

MJIB0192E