oil level NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2328 of 3171

REAR OIL SEAL

MT-11

D

E

F

G

H

I

J

K

L

MA

B

MT

INSTALLATION

Note the following, and install in the reverse order of removal.

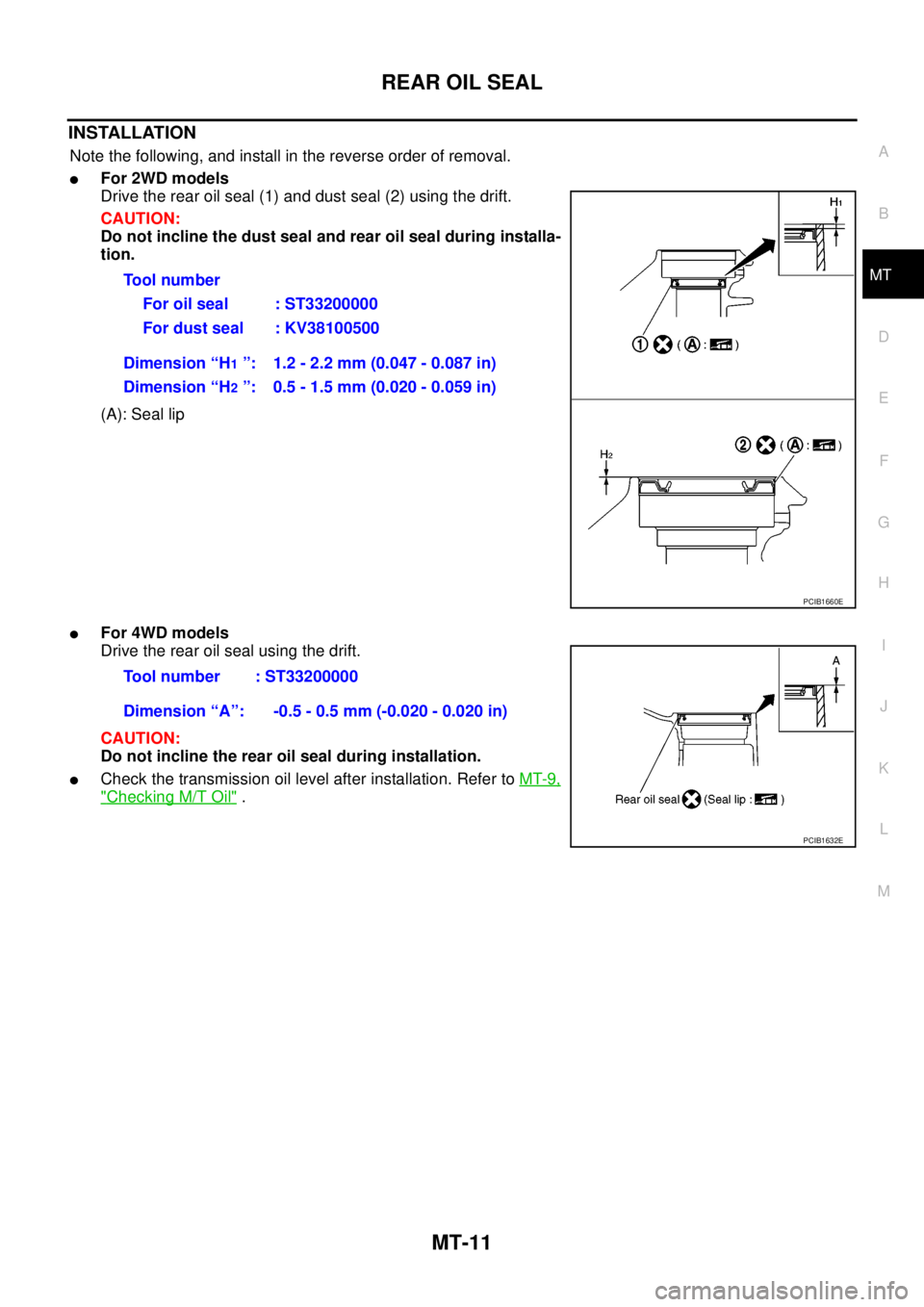

lFor 2WD models

Drive the rear oil seal (1) and dust seal (2) using the drift.

CAUTION:

Do not incline the dust seal and rear oil seal during installa-

tion.

(A): Seal lip

lFor 4WD models

Drive the rear oil seal using the drift.

CAUTION:

Do not incline the rear oil seal during installation.

lCheck the transmission oil level after installation. Refer toMT-9,

"Checking M/T Oil". Tool number

For oil seal : ST33200000

For dust seal : KV38100500

Dimension “H

1”: 1.2 - 2.2 mm (0.047 - 0.087 in)

Dimension “H

2”: 0.5 - 1.5 mm (0.020 - 0.059 in)

PCIB1660E

Tool number : ST33200000

Dimension “A”: -0.5 - 0.5 mm (-0.020 - 0.020 in)

PCIB1632E

Page 2335 of 3171

MT-18

TRANSMISSION ASSEMBLY

8. Remove crankshaft position sensor (POS) from transmission

assembly.

CAUTION:

lAvoid impacts such as a dropping.

lDo not disassemble.

lKeep it away from metal particles.

lDo not place the sensor in a location where it is exposed

to magnetism.

9. Remove starter motor. Refer toSC-31, "

Removal and Installa-

tion".

10. Disconnect the following switch connectors:

lFor transmission assembly

–Back-up lamp switch

–Park/neutral position (PNP) switch

lFor transfer assembly (For 4WD models)

–AT P s w i t c h

–Neutral 4LO switch

–Wait detection switch

–Transfer control device

–Transfer motor

–Transfer terminal cord assembly

11. Support transmission assembly with a jack.

CAUTION:

When setting a jack, be careful not to bring it into contact with switches.

12. Remove air breather hose. Refer toMT-15, "

Removal and Installation".

13. Remove protector (fuel tube), and then disconnect fuel tubes (for 4WD models). Refer toFL-7, "

Removal

and Installation (4WD Models Only)".

14. Remove insulator mounting nuts.

15. Remove transmission cross member and insulator.

16. Remove transmission assembly mounting bolts.

17. Remove transmission assembly from the vehicle.

CAUTION:

Secure transmission assembly to a jack while removing it.

18. Remove transfer assembly (for 4WD models). Refer toTF-111, "

Removal and Installation".

19. Remove release bearing sleeve assembly and withdrawal lever, if necessary. Refer toCL-14, "

Removal

and Installation".

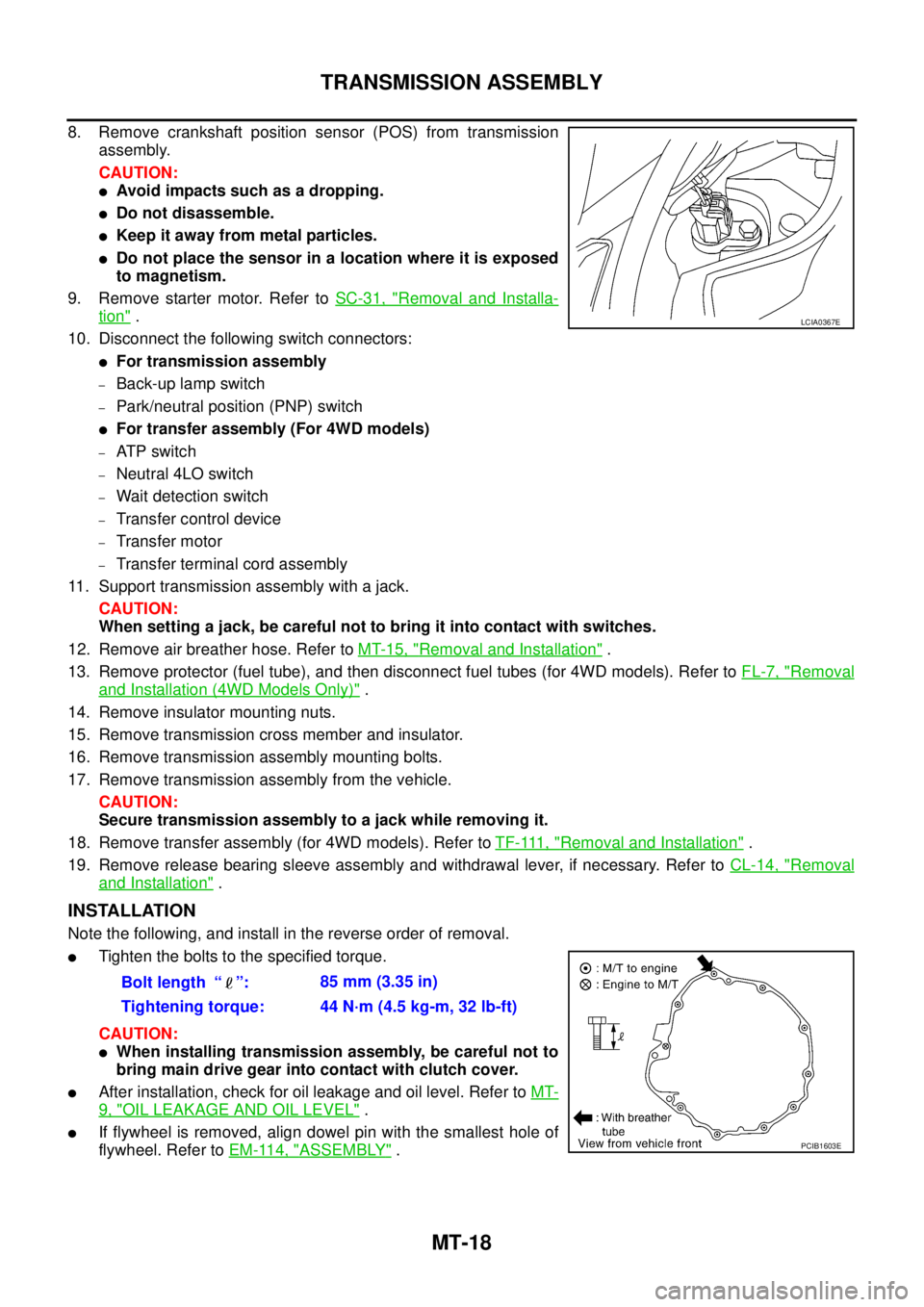

INSTALLATION

Note the following, and install in the reverse order of removal.

lTighten the bolts to the specified torque.

CAUTION:

lWhen installing transmission assembly, be careful not to

bring main drive gear into contact with clutch cover.

lAfter installation, check for oil leakage and oil level. Refer toMT-

9, "OIL LEAKAGE AND OIL LEVEL".

lIf flywheel is removed, align dowel pin with the smallest hole of

flywheel. Refer toEM-114, "

ASSEMBLY".

LCIA0367E

Bolt length “ ”:85 mm (3.35 in)

Tightening torque: 44 N·m (4.5 kg-m, 32 lb-ft)

PCIB1603E

Page 2513 of 3171

MTC-126

REFRIGERANT LINES

BREAK-IN OPERATION

When replacing compressor clutch assembly, always conduct the break-in operation. This is done by engag-

ing and disengaging the clutch about 30 times. Break-in operation raises the level of transmitted torque.

Removal and Installation for Low-pressure Flexible HoseEJS005HE

REMOVAL

1. Remove the engine room cover using power tools.

2. Remove the engine air cleaner and air ducts. Refer toEM-15, "

AIR CLEANER AND AIR DUCT".

3. Remove the cowl top extension. Refer toEI-20, "

COWL TOP".

4. Discharge the refrigerant. Refer toMTC-118, "

HFC-134a (R-134a) Service Procedure".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

5. Remove the low-pressure flexible hose. Refer toMTC-120, "

Components".

INSTALLATION

Installation is in the reverse order of removal.

Refer toMTC-120, "

Components".

CAUTION:

lReplace the O-ring of the low-pressure flexible hose with a new one, then apply compressor oil to

it when installing it.

lAfter charging refrigerant, check for leaks.

Removal and Installation for High-pressure Flexible HoseEJS005HF

REMOVAL

1. Remove the engine under cover.

2. Remove the engine air cleaner and air ducts. Refer toEM-15, "

AIR CLEANER AND AIR DUCT"

3. Discharge the refrigerant. Refer toMTC-118, "HFC-134a (R-134a) Service Procedure".

4. Remove the high-pressure flexible hose. Refer toMTC-120, "

Components".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer toMTC-120, "

Components".

CAUTION:

lReplace the O-ring of the high-pressure flexible hose with a new one, then apply compressor oil to

it when installing it.

lAfter charging refrigerant, check for leaks.

Removal and Installation for High-pressure PipeEJS005HG

REMOVAL

1. Remove the cowl top extension. Refer toEI-20, "COWL TOP".

2. Disconnect the battery negative cable.

3. Reposition the IPDM E/R aside.

4. Remove the front right wheel and tire assembly. Refer toWT-5, "

Rotation".

5. Position aside the front floor insulator.

6. Discharge the refrigerant. Refer toMTC-118, "

HFC-134a (R-134a) Service Procedure".

7. Remove the low pressure pipe. Refer toMTC-127, "

Removal and Installation for Low-pressure Pipe".

8. Remove the high-pressure pipe. Refer toMTC-120, "

Components".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer toMTC-120, "

Components".

Page 2628 of 3171

PS-1

POWER STEERING SYSTEM

G STEERING

CONTENTS

C

D

E

F

H

I

J

K

L

M

SECTIONPS

A

B

PS

POWER STEERING SYSTEM

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 2

Precautions for Steering System .............................. 2

PREPARATION ........................................................... 3

Special Service Tools [SST] ..................................... 3

Commercial Service Tools ........................................ 4

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 5

NVH Troubleshooting Chart ..................................... 5

POWER STEERING FLUID ........................................ 6

Checking Fluid Level ................................................ 6

Checking Fluid Leakage ........................................... 6

Air Bleeding Hydraulic System ................................. 6

STEERING WHEEL .................................................... 8

On-Vehicle Inspection and Service .......................... 8

CHECKING CONDITION OF INSTALLATION ...... 8

CHECKING STEERING WHEEL PLAY ................ 8

CHECKING NEUTRAL POSITION STEERING

WHEEL ................................................................. 8

CHECKING STEERING WHEEL TURNING

FORCE .................................................................. 8

CHECKING FRONT WHEEL TURNING ANGLE..... 9

Removal and Installation ........................................ 10

REMOVAL ........................................................... 10

INSTALLATION ................................................... 10

STEERING COLUMN ................................................11

Removal and Installation ......................................... 11

COMPONENT ...................................................... 11

REMOVAL ............................................................ 11

INSPECTION AFTER REMOVAL ....................... 12

INSTALLATION ................................................... 12

INSPECTION AFTER INSTALLATION ............... 13

POWER STEERING GEAR AND LINKAGE ............ 14Removal and Installation ........................................ 14

COMPONENT ..................................................... 14

REMOVAL ........................................................... 14

INSTALLATION ................................................... 15

INSPECTION AFTER INSTALLATION ................ 15

Disassembly and Assembly .................................... 16

COMPONENT ..................................................... 16

DISASSEMBLY ................................................... 17

INSPECTION AFTER DISASSEMBLY ................ 18

ASSEMBLY ......................................................... 20

POWER STEERING OIL PUMP ............................... 25

On-Vehicle Inspection and Service ......................... 25

CHECKING RELIEF OIL PRESSURE ................ 25

Removal and Installation ........................................ 25

REMOVAL ........................................................... 25

INSTALLATION ................................................... 26

Disassembly and Assembly .................................... 26

COMPONENT ..................................................... 26

INSPECTION BEFORE DISASSEMBLY ............. 26

DISASSEMBLY ................................................... 27

INSPECTION AFTER DISASSEMBLY ................ 27

ASSEMBLY ......................................................... 28

HYDRAULIC LINE .................................................... 30

Component (RHD Models) ..................................... 30

Component (LHD Models) ...................................... 32

Removal and Installation ........................................ 33

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 34

Steering Wheel ....................................................... 34

Steering Angle ........................................................ 34

Steering Column ..................................................... 34

Steering Outer Socket and Inner Socket ................ 34

Steering Gear ......................................................... 35

Oil Pump ................................................................. 35

Steering Fluid .......................................................... 35

Page 2633 of 3171

PS-6

POWER STEERING FLUID

POWER STEERING FLUID

PFP:KLF20

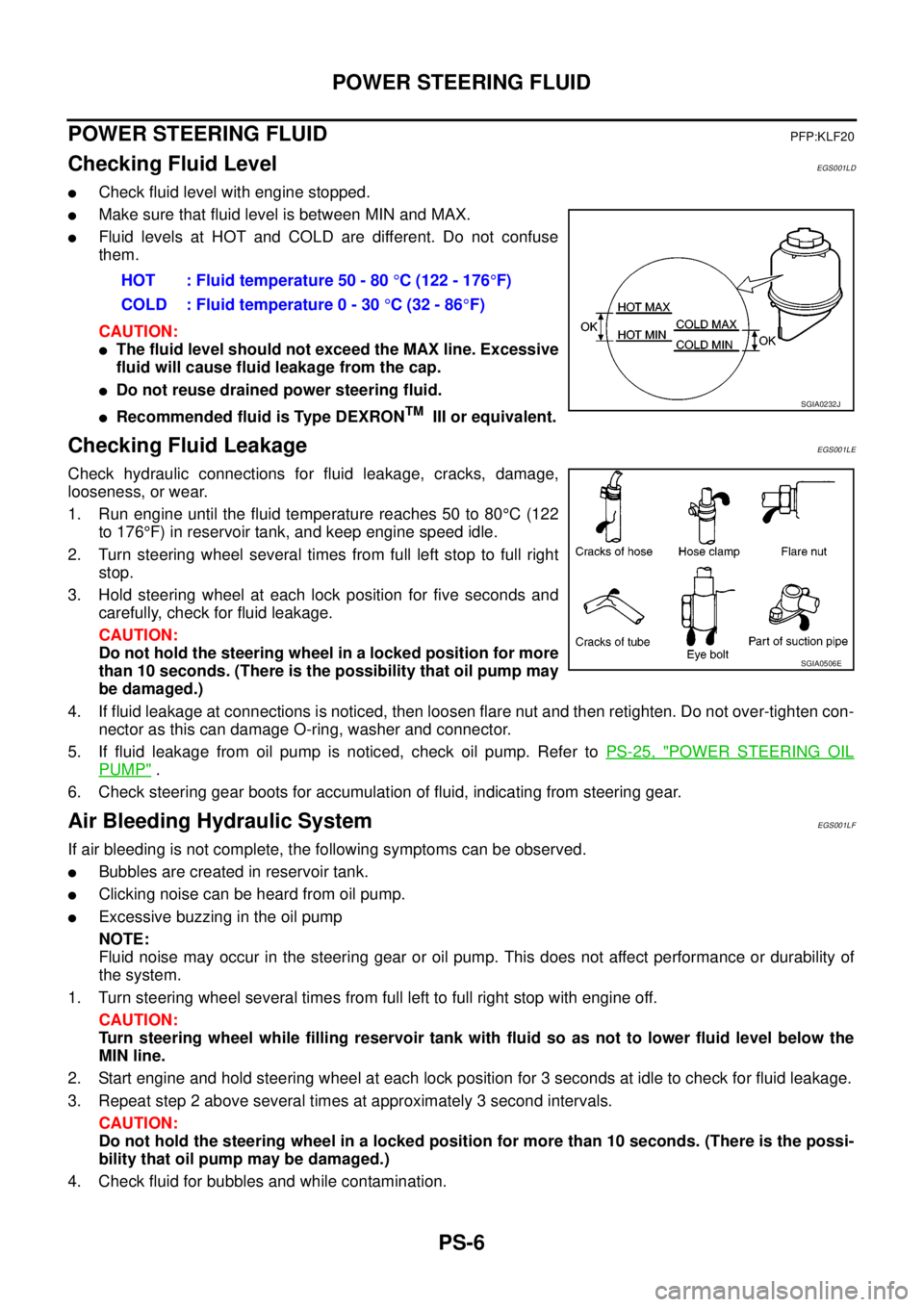

Checking Fluid LevelEGS001LD

lCheck fluid level with engine stopped.

lMake sure that fluid level is between MIN and MAX.

lFluid levels at HOT and COLD are different. Do not confuse

them.

CAUTION:

lThe fluid level should not exceed the MAX line. Excessive

fluid will cause fluid leakage from the cap.

lDo not reuse drained power steering fluid.

lRecommended fluid is Type DEXRONTMIII or equivalent.

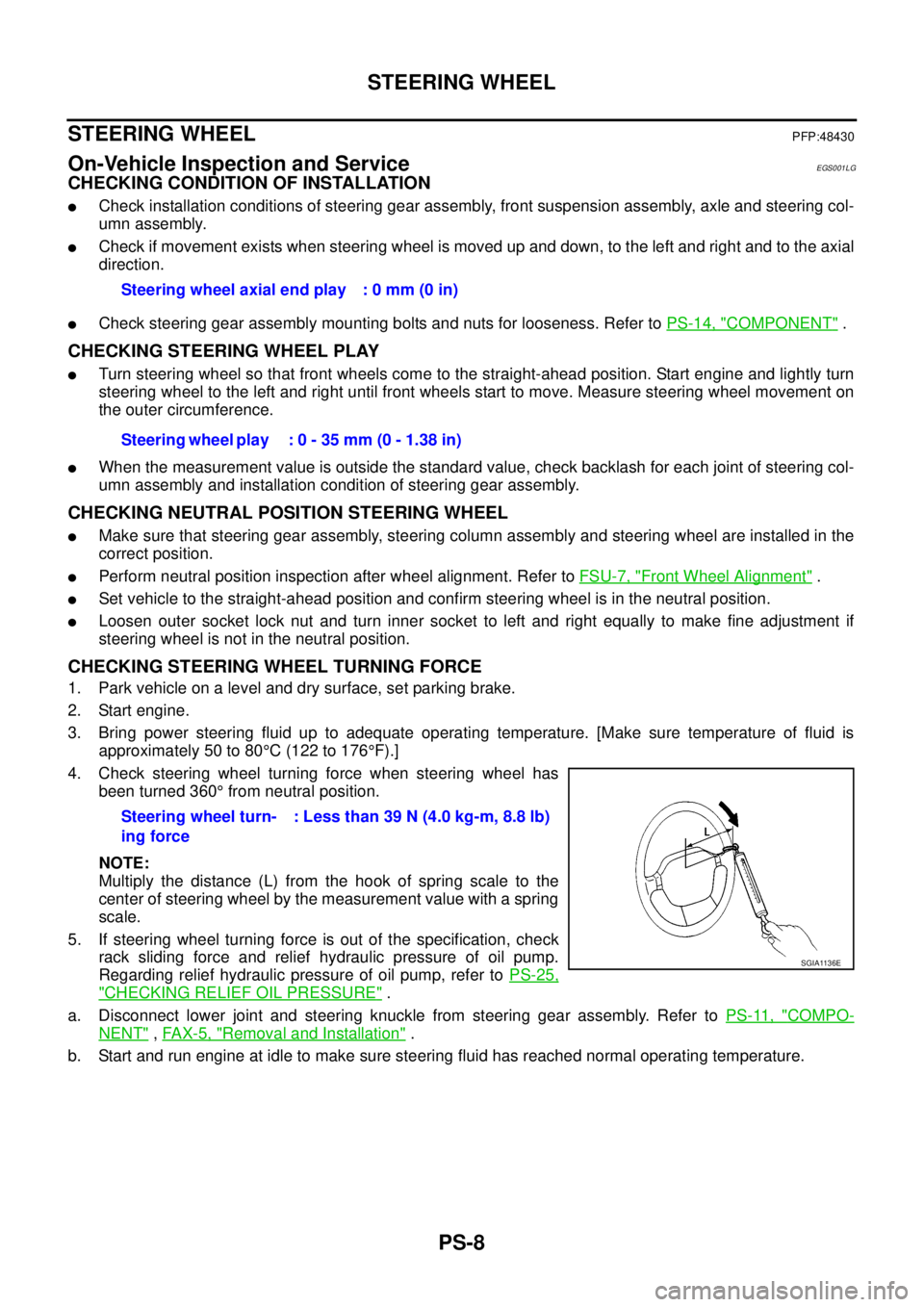

Checking Fluid LeakageEGS001LE

Check hydraulic connections for fluid leakage, cracks, damage,

looseness, or wear.

1. Run engine until the fluid temperature reaches 50 to 80°C(122

to 176°F) in reservoir tank, and keep engine speed idle.

2. Turn steering wheel several times from full left stop to full right

stop.

3. Hold steering wheel at each lock position for five seconds and

carefully, check for fluid leakage.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 10 seconds. (There is the possibility that oil pump may

be damaged.)

4. If fluid leakage at connections is noticed, then loosen flare nut and then retighten. Do not over-tighten con-

nector as this can damage O-ring, washer and connector.

5. If fluid leakage from oil pump is noticed, check oil pump. Refer toPS-25, "

POWER STEERING OIL

PUMP".

6. Check steering gear boots for accumulation of fluid, indicating from steering gear.

Air Bleeding Hydraulic SystemEGS001LF

If air bleeding is not complete, the following symptoms can be observed.

lBubbles are created in reservoir tank.

lClicking noise can be heard from oil pump.

lExcessive buzzing in the oil pump

NOTE:

Fluid noise may occur in the steering gear or oil pump. This does not affect performance or durability of

the system.

1. Turn steering wheel several times from full left to full right stop with engine off.

CAUTION:

Turn steering wheel while filling reservoir tank with fluid so as not to lower fluid level below the

MIN line.

2. Start engine and hold steering wheel at each lock position for 3 seconds at idle to check for fluid leakage.

3. Repeat step 2 above several times at approximately 3 second intervals.

CAUTION:

Do not hold the steering wheel in a locked position for more than 10 seconds. (There is the possi-

bility that oil pump may be damaged.)

4. Check fluid for bubbles and while contamination.HOT : Fluid temperature 50 - 80°C (122 - 176°F)

COLD : Fluid temperature 0 - 30°C(32-86°F)

SGIA0232J

SGIA0506E

Page 2635 of 3171

PS-8

STEERING WHEEL

STEERING WHEEL

PFP:48430

On-Vehicle Inspection and ServiceEGS001LG

CHECKING CONDITION OF INSTALLATION

lCheck installation conditions of steering gear assembly, front suspension assembly, axle and steering col-

umn assembly.

lCheck if movement exists when steering wheel is moved up and down, to the left and right and to the axial

direction.

lCheck steering gear assembly mounting bolts and nuts for looseness. Refer toPS-14, "COMPONENT".

CHECKING STEERING WHEEL PLAY

lTurn steering wheel so that front wheels come to the straight-ahead position. Start engine and lightly turn

steering wheel to the left and right until front wheels start to move. Measure steering wheel movement on

the outer circumference.

lWhen the measurement value is outside the standard value, check backlash for each joint of steering col-

umn assembly and installation condition of steering gear assembly.

CHECKING NEUTRAL POSITION STEERING WHEEL

lMake sure that steering gear assembly, steering column assembly and steering wheel are installed in the

correct position.

lPerform neutral position inspection after wheel alignment. Refer toFSU-7, "Front Wheel Alignment".

lSet vehicle to the straight-ahead position and confirm steering wheel is in the neutral position.

lLoosen outer socket lock nut and turn inner socket to left and right equally to make fine adjustment if

steering wheel is not in the neutral position.

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level and dry surface, set parking brake.

2. Start engine.

3. Bring power steering fluid up to adequate operating temperature. [Make sure temperature of fluid is

approximately 50 to 80°C(122to176°F).]

4. Check steering wheel turning force when steering wheel has

been turned 360°from neutral position.

NOTE:

Multiply the distance (L) from the hook of spring scale to the

center of steering wheel by the measurement value with a spring

scale.

5. If steering wheel turning force is out of the specification, check

rack sliding force and relief hydraulic pressure of oil pump.

Regarding relief hydraulic pressure of oil pump, refer toPS-25,

"CHECKING RELIEF OIL PRESSURE".

a. Disconnect lower joint and steering knuckle from steering gear assembly. Refer toPS-11, "

COMPO-

NENT",FAX-5, "Removal and Installation".

b. Start and run engine at idle to make sure steering fluid has reached normal operating temperature.Steering wheel axial end play : 0 mm (0 in)

Steering wheel play : 0 - 35 mm (0 - 1.38 in)

Steering wheel turn-

ing force: Less than 39 N (4.0 kg-m, 8.8 lb)

SGIA1136E

Page 2665 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RAX-2

[M226]

PRECAUTIONS

[M226]PRECAUTIONSPFP:00001

PrecautionsEDS003HT

lWhen installing the rubber bushings, the final tightening must be done under unladen condition and with

the tires on level grou NISSAN NAVARA 2005 Repair Workshop Manual RAX-2

[M226]

PRECAUTIONS

[M226]PRECAUTIONSPFP:00001

PrecautionsEDS003HT

lWhen installing the rubber bushings, the final tightening must be done under unladen condition and with

the tires on level grou](/img/5/57362/w960_57362-2664.png)

RAX-2

[M226]

PRECAUTIONS

[M226]PRECAUTIONSPFP:00001

PrecautionsEDS003HT

lWhen installing the rubber bushings, the final tightening must be done under unladen condition and with

the tires on level ground. Oil will shorten the life of the rubber bushings, so wipe off any spilled oil immedi-

ately.

lUnladen condition means the fuel tank, engine coolant and lubricants are at the full secification. The

spare tire, jack, hand tools, and mats are in their designated positions.

lLock nuts are not reusable. Always use new lock nuts for installation. New lock nuts are pre-oiled, do not

apply any additional lubrication.

Page 2672 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual AXLE SHAFT

RAX-9

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

INSPECTION AFTER REMOVAL

Axle Shaft Bearing and Cup

lCheck that the axle shaft bearing and cup roll freely and are free from noise, cracks, pitting a NISSAN NAVARA 2005 Repair Workshop Manual AXLE SHAFT

RAX-9

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

INSPECTION AFTER REMOVAL

Axle Shaft Bearing and Cup

lCheck that the axle shaft bearing and cup roll freely and are free from noise, cracks, pitting a](/img/5/57362/w960_57362-2671.png)

AXLE SHAFT

RAX-9

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

INSPECTION AFTER REMOVAL

Axle Shaft Bearing and Cup

lCheck that the axle shaft bearing and cup roll freely and are free from noise, cracks, pitting and wear.

Replace if necessary.

Axle Shaft Retainer

lCheck for deformation and cracks. Replace if necessary.

Rear Axle Case

lCheck the exterior and inner machined surfaces for deformation and cracks. Replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

When installing pay attention to following points:

lInstall a new shaft guide and a new oil seal into the rear axle case.

CAUTION:

lDo not reuse the axle oil seal. The axle oil seal must be replaced every time the axle shaft assem-

bly is removed from the axle shaft housing.

lWhen installing oil seals, apply multi-purpsose grease to oil seal lips.

lInstall four new lock nuts to secure the axle shaft assembly to the rear axle case, and tighten lock nuts to

the specified torque. Refer toRAX-7, "

Removal and Installation".

lReinstall the rear brake drum. Refer toBR-31, "Removal and Installation of Drum Brake Assembly".

lAdjust the differential gear oil level.

Refer toRFD-9, "

DIFFERENTIAL GEAR OIL", for M226 without LD.

Refer toRFD-9, "

DIFFERENTIAL GEAR OIL", for M226 with LD.

lReinstall the wheel. Refer toWT-5, "Rotation".

DISASSEMBLY

1. Remove the ABS sensor rotor. Refer toBRC-39, "SENSOR ROTOR".

2. Remove the snap ring from the axle shaft using a suitable snap ring pliers.

3. Secure the axle shaft in a suitable vise as shown, and use a

brass hammer to remove studs (4) from the axle shaft retainer.

CAUTION:

lMount the axle shaft using a soft jaw vise to avoid dam-

aging the axle shaft retainer.

MDIB9051E

Page 2704 of 3171

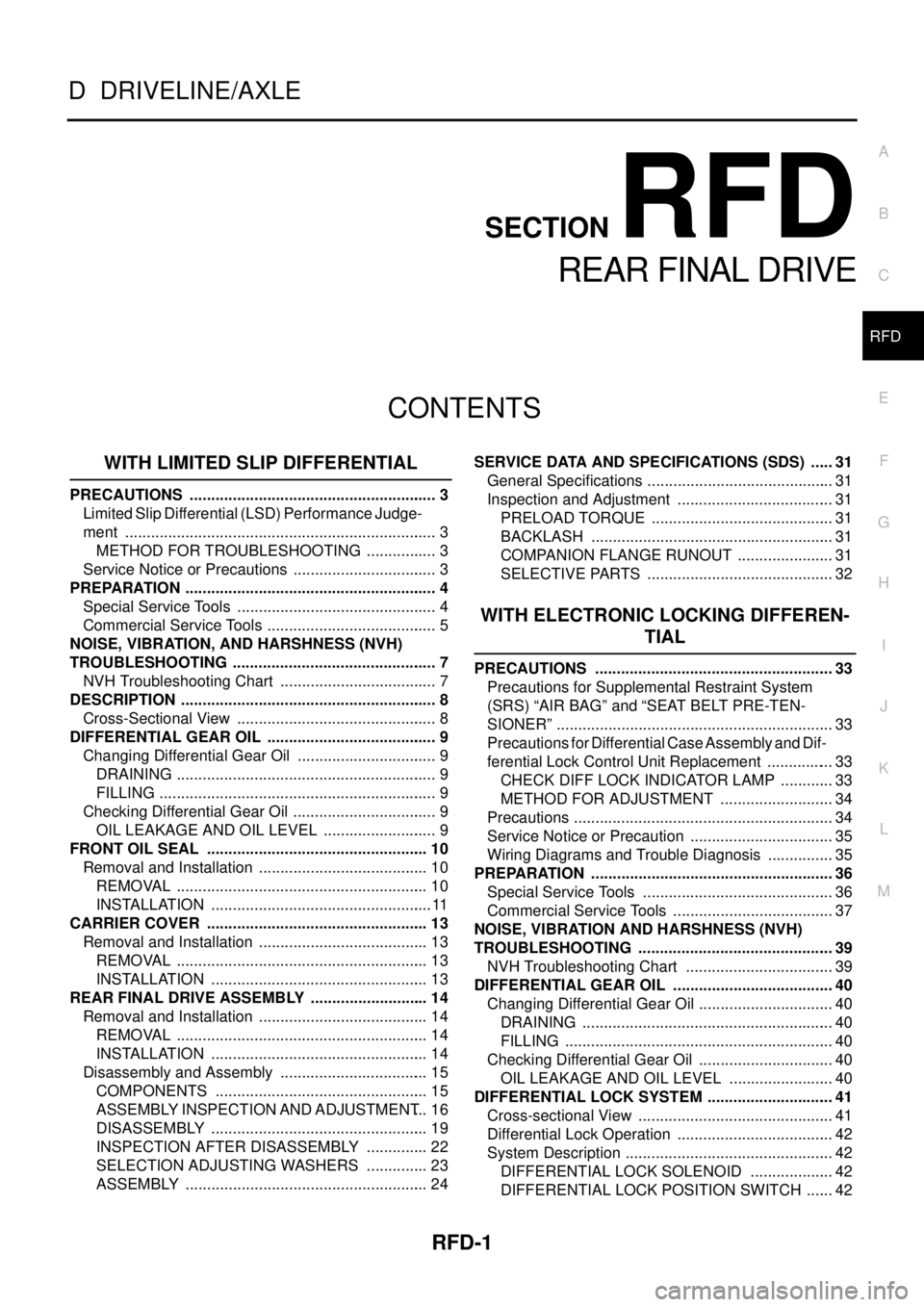

RFD-1

REAR FINAL DRIVE

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTIONRFD

A

B

RFD

REAR FINAL DRIVE

WITH LIMITED SLIP DIFFERENTIAL

PRECAUTIONS .......................................................... 3

Limited Slip Differential (LSD) Performance Judge-

ment ......................................................................... 3

METHOD FOR TROUBLESHOOTING ................. 3

Service Notice or Precautions .................................. 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 5

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 7

NVH Troubleshooting Chart ..................................... 7

DESCRIPTION ............................................................ 8

Cross-Sectional View ............................................... 8

DIFFERENTIAL GEAR OIL ........................................ 9

Changing Differential Gear Oil ................................. 9

DRAINING ............................................................. 9

FILLING ................................................................. 9

Checking Differential Gear Oil .................................. 9

OIL LEAKAGE AND OIL LEVEL ........................... 9

FRONT OIL SEAL .................................................... 10

Removal and Installation ........................................ 10

REMOVAL ........................................................... 10

INSTALLATION .................................................... 11

CARRIER COVER .................................................... 13

Removal and Installation ........................................ 13

REMOVAL ........................................................... 13

INSTALLATION ................................................... 13

REAR FINAL DRIVE ASSEMBLY ............................ 14

Removal and Installation ........................................ 14

REMOVAL ........................................................... 14

INSTALLATION ................................................... 14

Disassembly and Assembly ................................... 15

COMPONENTS .................................................. 15

ASSEMBLY INSPECTION AND ADJUSTMENT... 16

DISASSEMBLY ................................................... 19

INSPECTION AFTER DISASSEMBLY ............... 22

SELECTION ADJUSTING WASHERS ............... 23

ASSEMBLY ......................................................... 24SERVICE DATA AND SPECIFICATIONS (SDS) ...... 31

General Specifications ............................................ 31

Inspection and Adjustment ..................................... 31

PRELOAD TORQUE ........................................... 31

BACKLASH ......................................................... 31

COMPANION FLANGE RUNOUT ....................... 31

SELECTIVE PARTS ............................................ 32

WITH ELECTRONIC LOCKING DIFFEREN-

TIAL

PRECAUTIONS ........................................................ 33

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” ................................................................. 33

Precautions for Differential Case Assembly and Dif-

ferential Lock Control Unit Replacement ................ 33

CHECK DIFF LOCK INDICATOR LAMP ............. 33

METHOD FOR ADJUSTMENT ........................... 34

Precautions ............................................................. 34

Service Notice or Precaution .................................. 35

Wiring Diagrams and Trouble Diagnosis ................ 35

PREPARATION ......................................................... 36

Special Service Tools ............................................. 36

Commercial Service Tools ...................................... 37

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING .............................................. 39

NVH Troubleshooting Chart ................................... 39

DIFFERENTIAL GEAR OIL ...................................... 40

Changing Differential Gear Oil ................................ 40

DRAINING ........................................................... 40

FILLING ............................................................... 40

Checking Differential Gear Oil ................................ 40

OIL LEAKAGE AND OIL LEVEL ......................... 40

DIFFERENTIAL LOCK SYSTEM .............................. 41

Cross-sectional View .............................................. 41

Differential Lock Operation ..................................... 42

System Description ................................................. 42

DIFFERENTIAL LOCK SOLENOID .................... 42

DIFFERENTIAL LOCK POSITION SWITCH ....... 42

Page 2706 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual PRECAUTIONS

RFD-3

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH LIMITED SLIP DIFFERENTIAL]PRECAUTIONSPFP:00001

Limited Slip Differential (LSD) Performance JudgementEDS003IG

lInspec NISSAN NAVARA 2005 Repair Workshop Manual PRECAUTIONS

RFD-3

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH LIMITED SLIP DIFFERENTIAL]PRECAUTIONSPFP:00001

Limited Slip Differential (LSD) Performance JudgementEDS003IG

lInspec](/img/5/57362/w960_57362-2705.png)

PRECAUTIONS

RFD-3

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH LIMITED SLIP DIFFERENTIAL]PRECAUTIONSPFP:00001

Limited Slip Differential (LSD) Performance JudgementEDS003IG

lInspection is required when detecting any noise or malfunction while driving or turning. Improper condition

of oil or differential case assembly is suspected. Refer toRFD-3, "

METHOD FOR TROUBLESHOOTING"

.

METHOD FOR TROUBLESHOOTING

1. Check differential gear oil level and differential gear oil leakage. Refer toRFD-9, "Checking Differential

Gear Oil".

2. Changing differential gear oil. Refer toRFD-9, "

Changing Differential Gear Oil".

3. Start engine. Drive for 10 min.

4. Again changing differential gear oil. Refer toRFD-9, "

Changing Differential Gear Oil".

5. Start engine. Drive for 10 min. Check if any noise or improper oil condition is detected.

lIf OK, check differential gear oil level and differential gear oil leakage. Refer toRFD-9, "Checking Differ-

ential Gear Oil".

lIf NG, replace differential case assembly after checking each part of final drive. Refer toRFD-15, "Dis-

assembly and Assembly".

Service Notice or PrecautionsEDS0038Z

lCheck for the correct installation status prior to removal or disassembly. If matching marks are required,

be certain they do not interfere with the function of the parts when applied.

lOverhaul should be done in a clean work area, it is preferable to work in dust proof area.

lBefore disassembly completely remove sand and mud from the exterior of the unit, preventing them from

entering into the unit during disassembly or assembly.

lCheck appearance of the disassembled parts for damage, deformation, and unusual wear. Replace them

with new ones if necessary.

lGaskets, seals and O-rings should be replaced any time the unit is disassembled.

lIn principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If

tightening sequence is specified, observe it.

lClean and flush the parts sufficiently and blow-dry them.

lBe careful not to damage sliding surfaces and mating surfaces.

lWhen applying sealant, remove the old sealant from the mounting surface; then remove any moisture, oil,

and foreign materials from the application and mounting surfaces.

lAlways use shop paper for cleaning the inside of components.

lAvoid using cotton gloves or shop rags to prevent entering of lint.

lDuring assembly, observe the specified tightening torque, and apply new differential gear oil, petroleum

jelly, or multi-purpose grease as specified.