steering NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2293 of 3171

MA-18

ENGINE MAINTENANCE

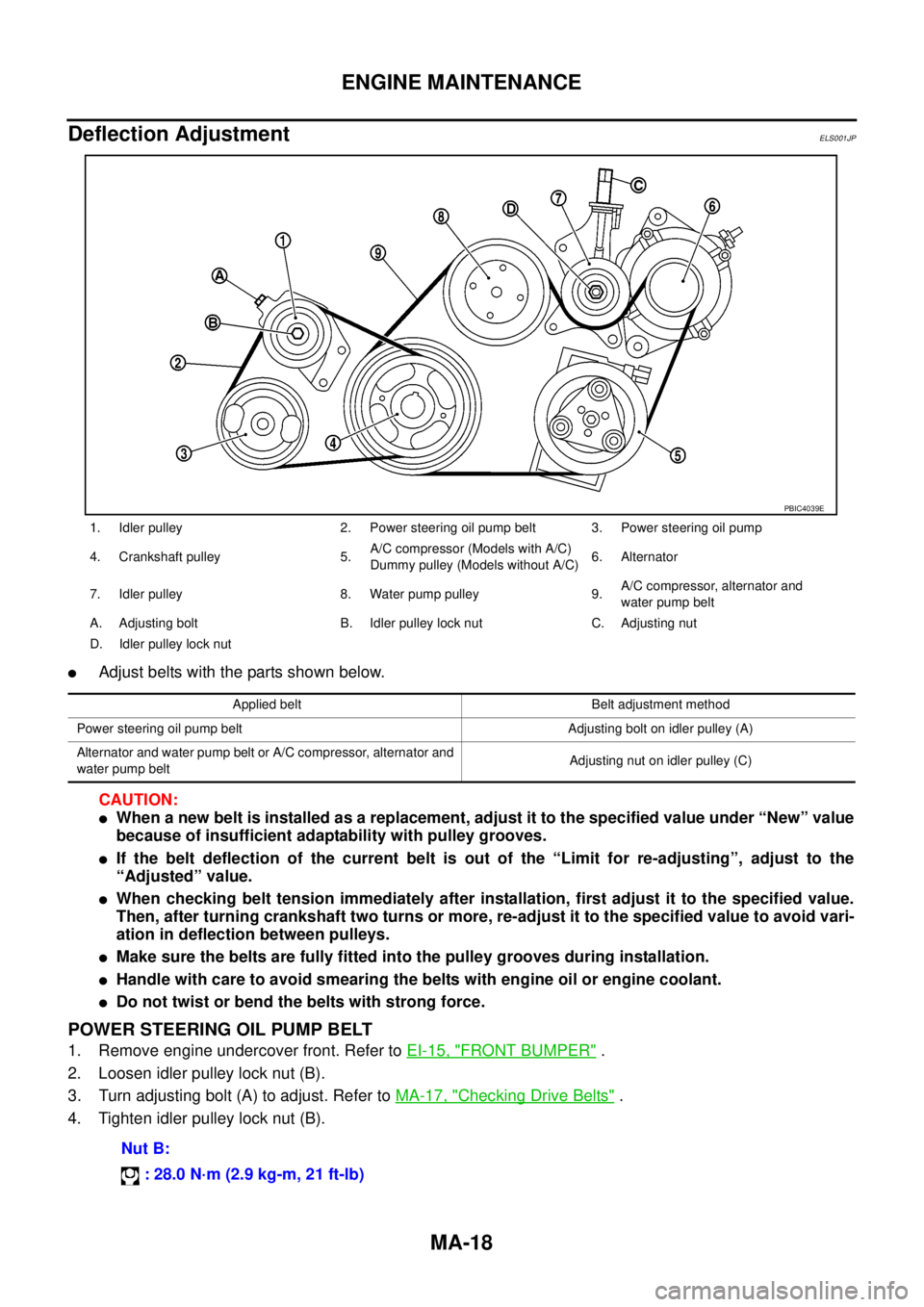

Deflection Adjustment

ELS001JP

lAdjust belts with the parts shown below.

CAUTION:

lWhen a new belt is installed as a replacement, adjust it to the specified value under “New” value

because of insufficient adaptability with pulley grooves.

lIf the belt deflection of the current belt is out of the “Limit for re-adjusting”, adjust to the

“Adjusted” value.

lWhen checking belt tension immediately after installation, first adjust it to the specified value.

Then, after turning crankshaft two turns or more, re-adjust it to the specified value to avoid vari-

ation in deflection between pulleys.

lMake sure the belts are fully fitted into the pulley grooves during installation.

lHandle with care to avoid smearing the belts with engine oil or engine coolant.

lDo not twist or bend the belts with strong force.

POWER STEERING OIL PUMP BELT

1. Remove engine undercover front. Refer toEI-15, "FRONT BUMPER".

2. Loosen idler pulley lock nut (B).

3. Turn adjusting bolt (A) to adjust. Refer toMA-17, "

Checking Drive Belts".

4. Tighten idler pulley lock nut (B).

1. Idler pulley 2. Power steering oil pump belt 3. Power steering oil pump

4. Crankshaft pulley 5.A/C compressor (Models with A/C)

Dummypulley(ModelswithoutA/C)6. Alternator

7. Idler pulley 8. Water pump pulley 9.A/C compressor, alternator and

water pump belt

A. Adjusting bolt B. Idler pulley lock nut C. Adjusting nut

D. Idler pulley lock nut

PBIC4039E

Applied belt Belt adjustment method

Power steering oil pump belt Adjusting bolt on idler pulley (A)

Alternator and water pump belt or A/C compressor, alternator and

water pump beltAdjusting nut on idler pulley (C)

Nut B:

: 28.0 N·m (2.9 kg-m, 21 ft-lb)

Page 2312 of 3171

CHASSIS AND BODY MAINTENANCE

MA-37

C

D

E

F

G

H

I

J

K

MA

B

MA

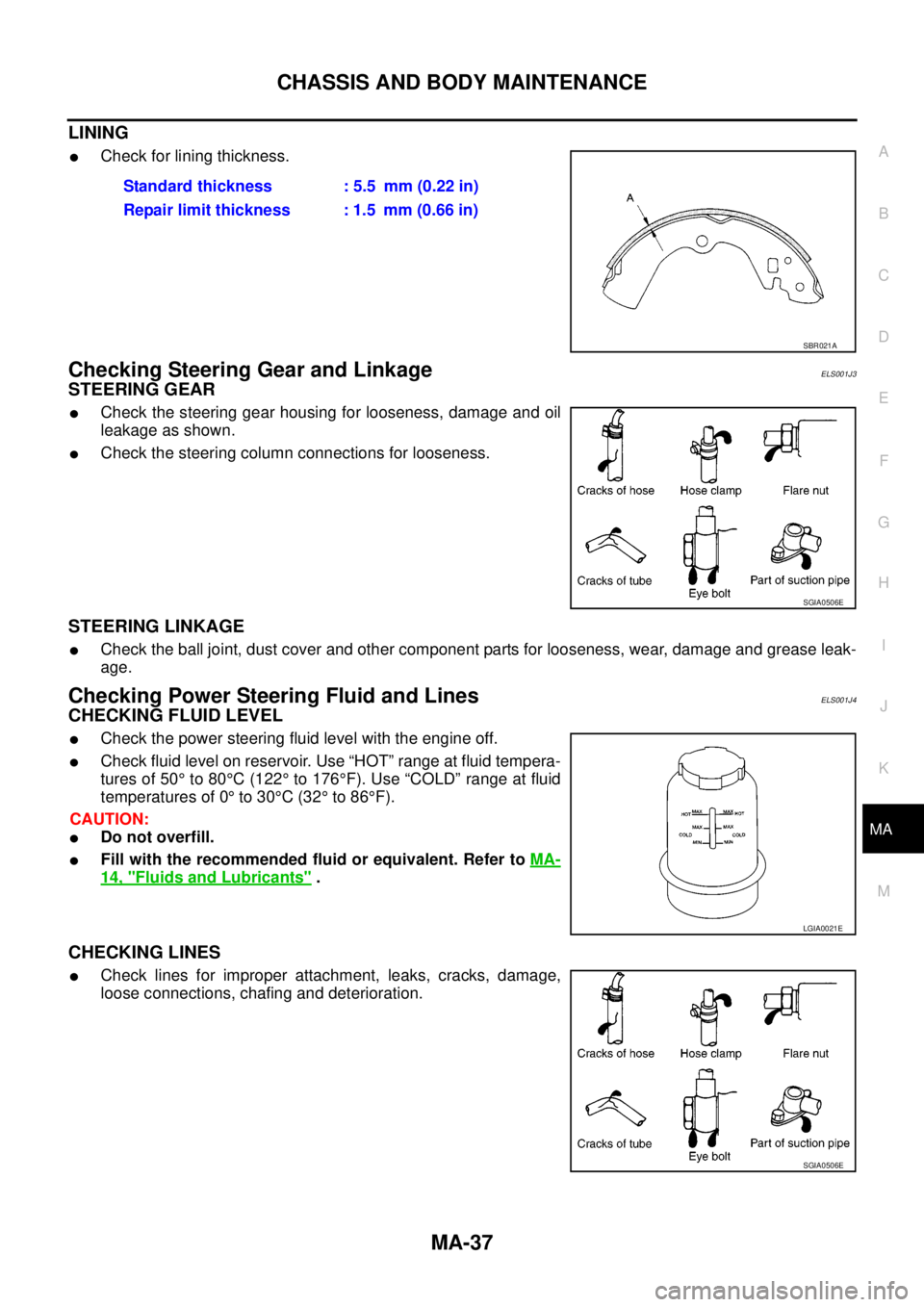

LINING

lCheck for lining thickness.

Checking Steering Gear and LinkageELS001J3

STEERING GEAR

lCheck the steering gear housing for looseness, damage and oil

leakage as shown.

lCheck the steering column connections for looseness.

STEERING LINKAGE

lCheck the ball joint, dust cover and other component parts for looseness, wear, damage and grease leak-

age.

Checking Power Steering Fluid and LinesELS001J4

CHECKING FLUID LEVEL

lCheck the power steering fluid level with the engine off.

lCheck fluid level on reservoir. Use “HOT” range at fluid tempera-

tures of 50°to 80°C(122°to 176°F). Use “COLD” range at fluid

temperatures of 0°to 30°C(32°to 86°F).

CAUTION:

lDo not overfill.

lFill with the recommended fluid or equivalent. Refer toMA-

14, "Fluids and Lubricants".

CHECKING LINES

lCheck lines for improper attachment, leaks, cracks, damage,

loose connections, chafing and deterioration.Standard thickness : 5.5 mm (0.22 in)

Repair limit thickness : 1.5 mm (0.66 in)

SBR021A

SGIA0506E

LGIA0021E

SGIA0506E

Page 2316 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

MA-41

C

D

E

F

G

H

I

J

K

MA

B

MA

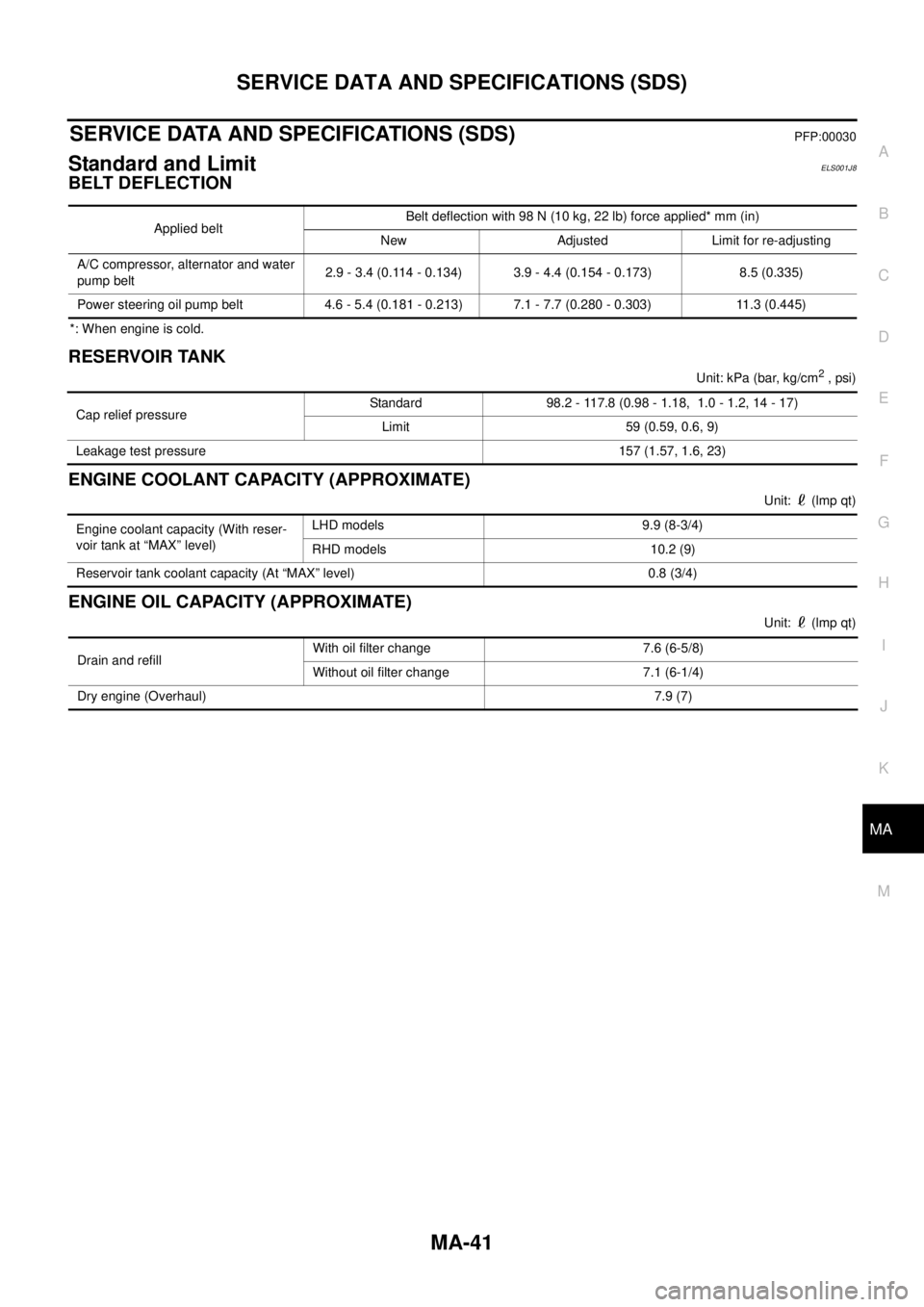

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Standard and LimitELS001J8

BELT DEFLECTION

*: When engine is cold.

RESERVOIR TANK

Unit:kPa(bar,kg/cm2, psi)

ENGINE COOLANT CAPACITY (APPROXIMATE)

Unit: (lmp qt)

ENGINE OIL CAPACITY (APPROXIMATE)

Unit: (lmp qt) Applied beltBelt deflection with 98 N (10 kg, 22 lb) force applied* mm (in)

New Adjusted Limit for re-adjusting

A/C compressor, alternator and water

pump belt2.9 - 3.4 (0.114 - 0.134) 3.9 - 4.4 (0.154 - 0.173) 8.5 (0.335)

Power steering oil pump belt 4.6 - 5.4 (0.181 - 0.213) 7.1 - 7.7 (0.280 - 0.303) 11.3 (0.445)

Cap relief pressureStandard 98.2 - 117.8 (0.98 - 1.18, 1.0 - 1.2, 14 - 17)

Limit 59 (0.59, 0.6, 9)

Leakage test pressure 157 (1.57, 1.6, 23)

Engine coolant capacity (With reser-

voir tank at “MAX” level)LHD models 9.9 (8-3/4)

RHD models 10.2 (9)

Reservoir tank coolant capacity (At “MAX” level) 0.8 (3/4)

Drain and refillWith oil filter change 7.6 (6-5/8)

Without oil filter change 7.1 (6-1/4)

Dry engine (Overhaul)7.9 (7)

Page 2492 of 3171

HEATER & COOLING UNIT ASSEMBLY

MTC-105

C

D

E

F

G

H

I

K

L

MA

B

MTC

Removal and InstallationEJS005GY

REMOVAL

1. Discharge the refrigerant from the A/C system. Refer toMTC-118, "Discharging Refrigerant".

2. Drain the coolant from the engine cooling system. Refer toCO-8, "

DRAINING ENGINE COOLANT".

3. Remove the cowl top extension. Refer toEI-20, "

Removal and Installation".

4. Remove the exhaust system. Refer toEX-3, "

Removal and Installation".

5. Disconnect the heater hoses from the heater core.

6. Disconnect the high/low pressure pipes from the expansion valve.

7. Move the two front seats to the rearmost position on the seat track.

8. Remove the instrument panel and console panel. Refer toIP-10, "

Removal and Installation".

9. Remove the steering column. Refer toPS-11, "

Removal and Installation".

10. Disconnect the instrument panel wire harness at the RH and LH in-line connector brackets, and the fuse

block (J/B) electrical connectors. Refer toPG-38, "

Harness Layout".

11. Disconnect the steering member from each side of the vehicle body.

12. Remove the heater and cooling unit assembly with it attached to the steering member, from the vehicle.

CAUTION:

Use care not to damage the seats and interior trim panels when removing the heater and cooling

unit assembly with it attached to the steering member.

13. Remove the heater and cooling unit assembly from the steering member.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

lReplace the O-ring of the low-pressure pipe and high-pressure pipe with a new one, and apply

compressor oil to it when installing it.

lAfter charging the refrigerant, check for leaks.

NOTE:

lFill the engine cooling system with the specified coolant mixture. Refer toCO-8, "REFILLING ENGINE

COOLANT".

lRecharge the A/C system. Refer toMTC-118, "Evacuating System and Charging Refrigerant".

Page 2495 of 3171

MTC-108

DEFROSTERDOORMOTOR

DEFROSTER DOOR MOTOR

PFP:27733

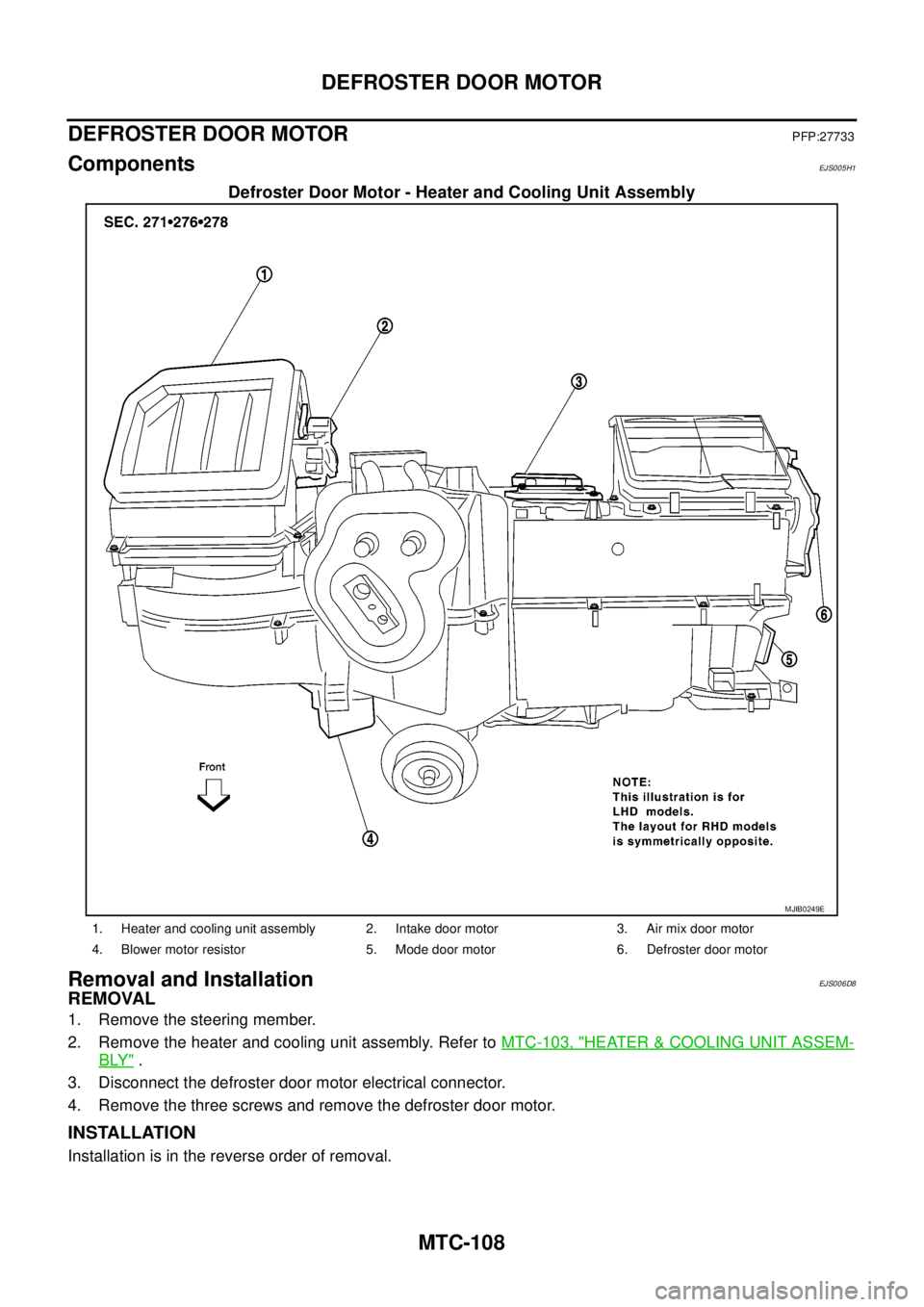

ComponentsEJS005H1

Defroster Door Motor - Heater and Cooling Unit Assembly

Removal and InstallationEJS006D8

REMOVAL

1. Remove the steering member.

2. Remove the heater and cooling unit assembly. Refer toMTC-103, "

HEATER&COOLING UNIT ASSEM-

BLY".

3. Disconnect the defroster door motor electrical connector.

4. Remove the three screws and remove the defroster door motor.

INSTALLATION

Installation is in the reverse order of removal.

MJIB0249E

1. Heater and cooling unit assembly 2. Intake door motor 3. Air mix door motor

4. Blower motor resistor 5. Mode door motor 6. Defroster door motor

Page 2496 of 3171

INTAKE DOOR MOTOR

MTC-109

C

D

E

F

G

H

I

K

L

MA

B

MTC

INTAKE DOOR MOTORPFP:27730

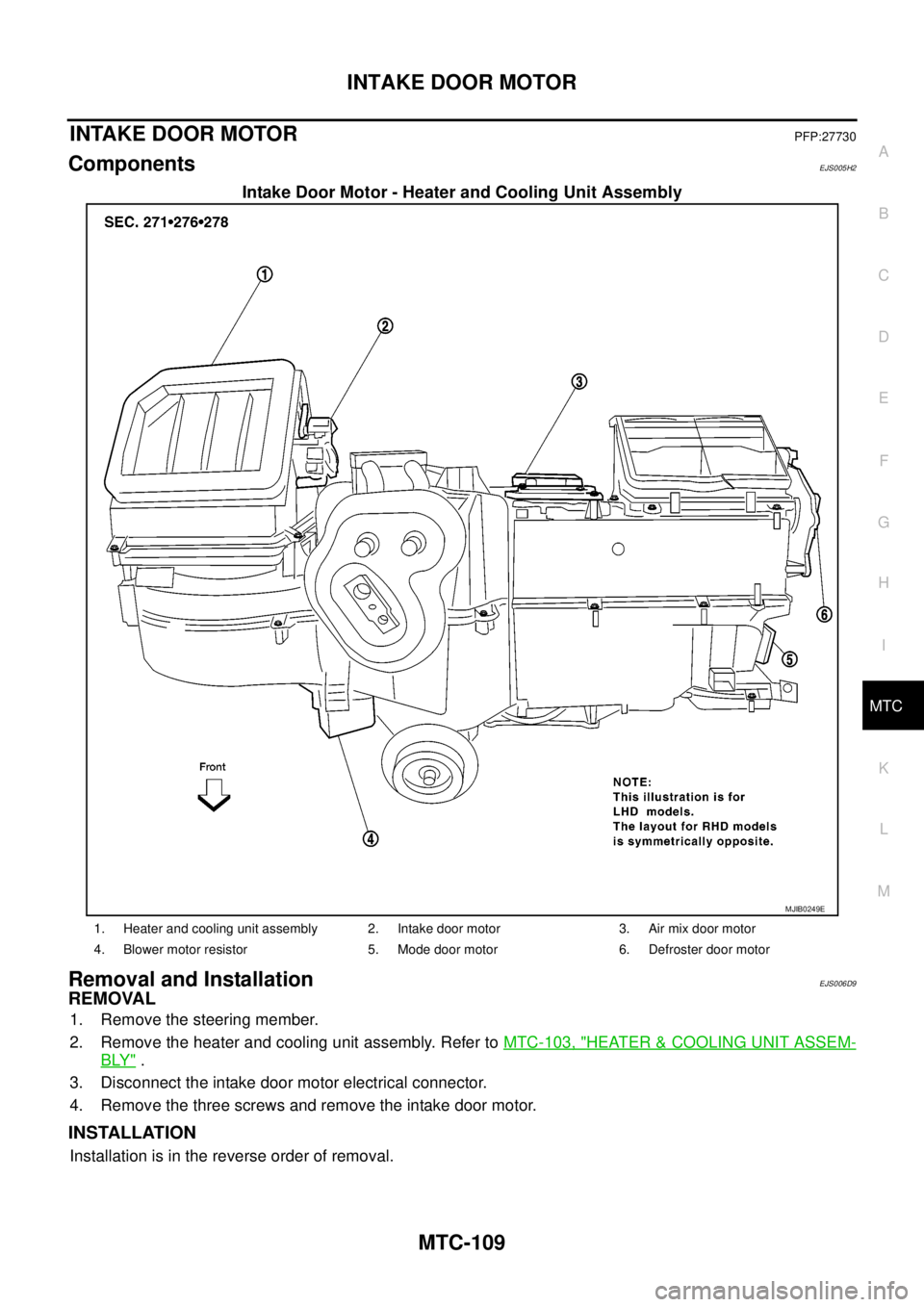

ComponentsEJS005H2

Intake Door Motor - Heater and Cooling Unit Assembly

Removal and InstallationEJS006D9

REMOVAL

1. Remove the steering member.

2. Remove the heater and cooling unit assembly. Refer toMTC-103, "

HEATER&COOLING UNIT ASSEM-

BLY".

3. Disconnect the intake door motor electrical connector.

4. Remove the three screws and remove the intake door motor.

INSTALLATION

Installation is in the reverse order of removal.

MJIB0249E

1. Heater and cooling unit assembly 2. Intake door motor 3. Air mix door motor

4. Blower motor resistor 5. Mode door motor 6. Defroster door motor

Page 2497 of 3171

MTC-110

MODE DOOR MOTOR

MODE DOOR MOTOR

PFP:27731

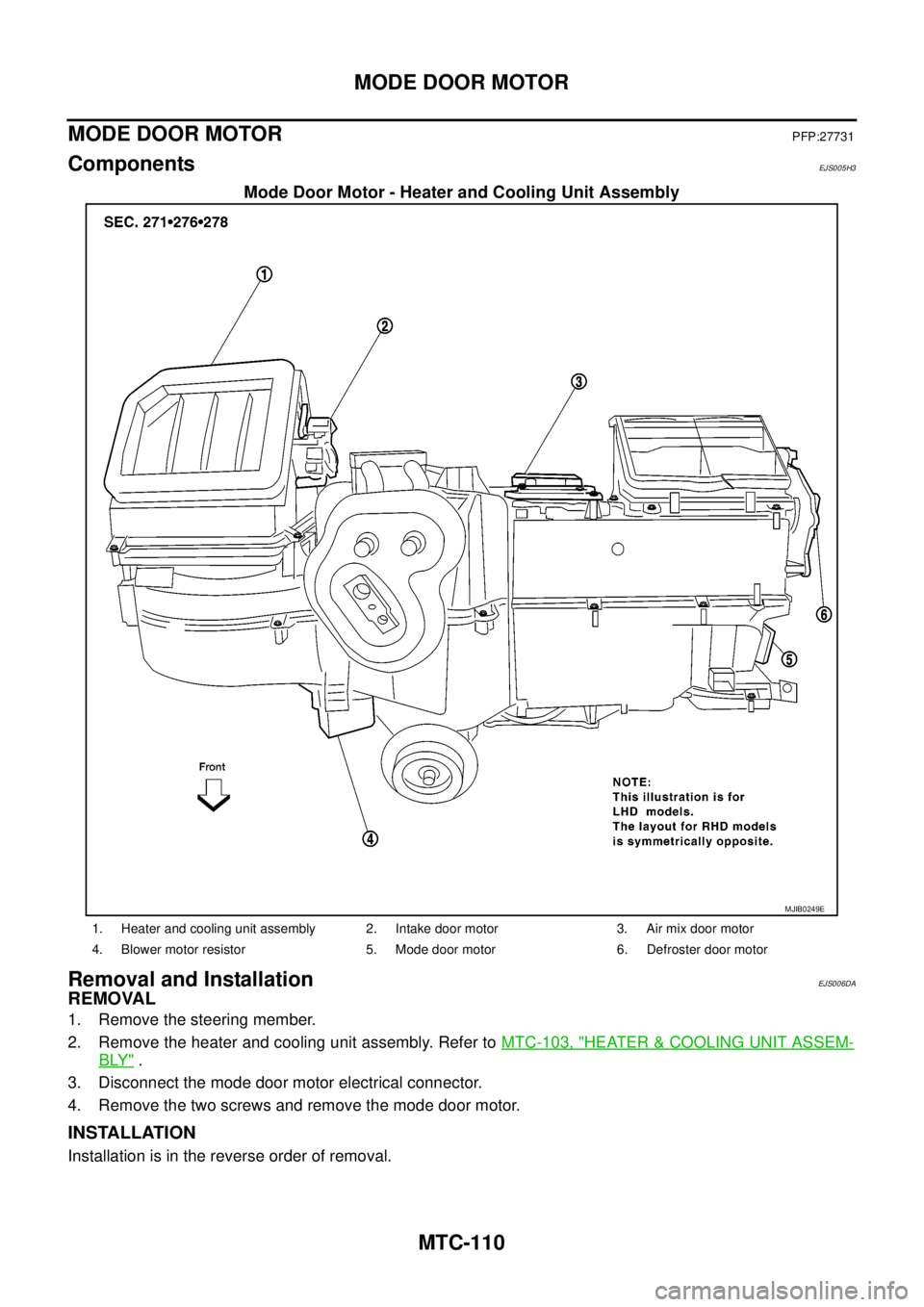

ComponentsEJS005H3

Mode Door Motor - Heater and Cooling Unit Assembly

Removal and InstallationEJS006DA

REMOVAL

1. Remove the steering member.

2. Remove the heater and cooling unit assembly. Refer toMTC-103, "

HEATER&COOLING UNIT ASSEM-

BLY".

3. Disconnect the mode door motor electrical connector.

4. Remove the two screws and remove the mode door motor.

INSTALLATION

Installation is in the reverse order of removal.

MJIB0249E

1. Heater and cooling unit assembly 2. Intake door motor 3. Air mix door motor

4. Blower motor resistor 5. Mode door motor 6. Defroster door motor

Page 2498 of 3171

AIR MIX DOOR MOTOR

MTC-111

C

D

E

F

G

H

I

K

L

MA

B

MTC

AIR MIX DOOR MOTORPFP:27732

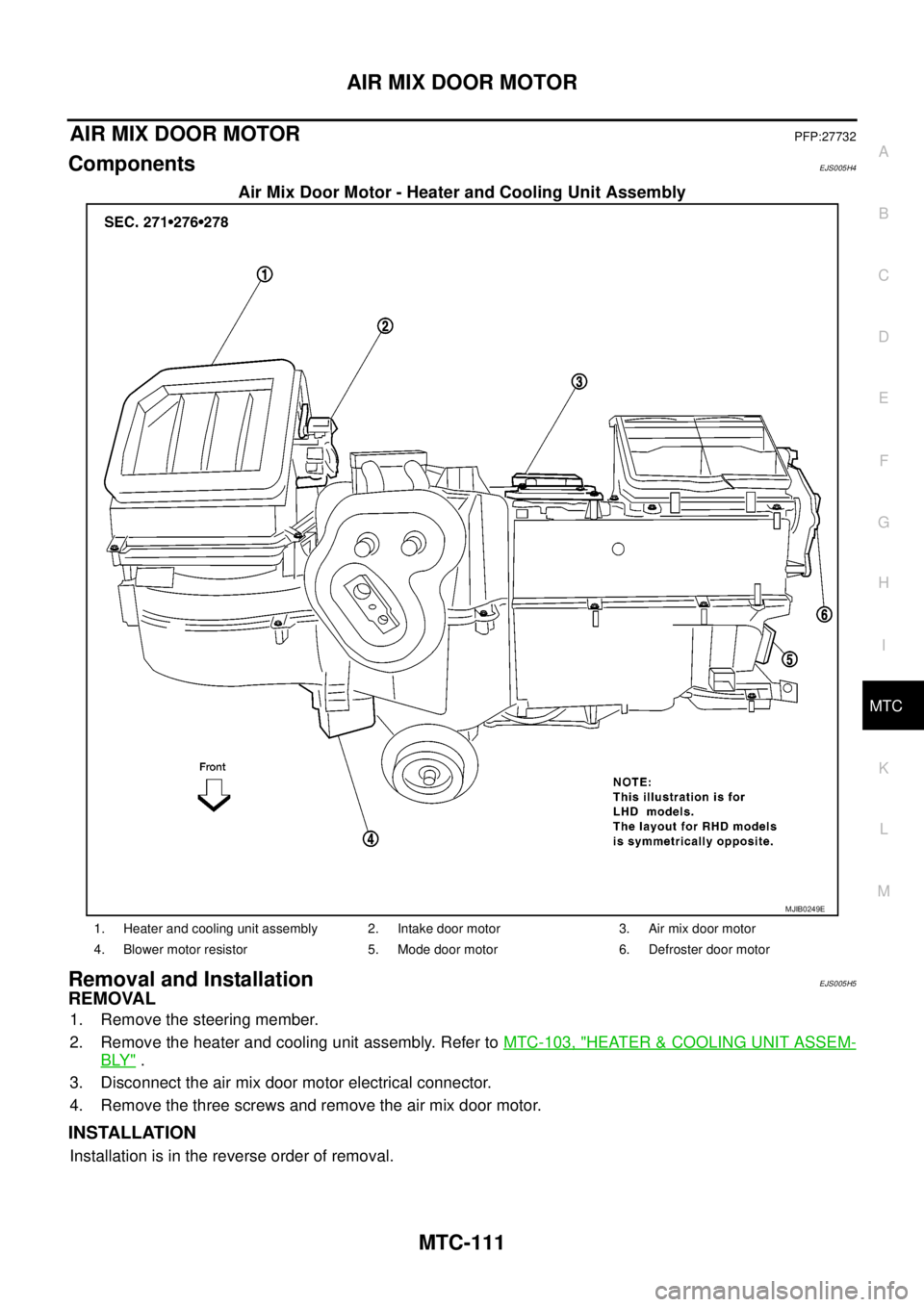

ComponentsEJS005H4

Air Mix Door Motor - Heater and Cooling Unit Assembly

Removal and InstallationEJS005H5

REMOVAL

1. Remove the steering member.

2. Remove the heater and cooling unit assembly. Refer toMTC-103, "

HEATER&COOLING UNIT ASSEM-

BLY".

3. Disconnect the air mix door motor electrical connector.

4. Remove the three screws and remove the air mix door motor.

INSTALLATION

Installation is in the reverse order of removal.

MJIB0249E

1. Heater and cooling unit assembly 2. Intake door motor 3. Air mix door motor

4. Blower motor resistor 5. Mode door motor 6. Defroster door motor

Page 2499 of 3171

MTC-112

BLOWER MOTOR RESISTOR

BLOWER MOTOR RESISTOR

PFP:27077

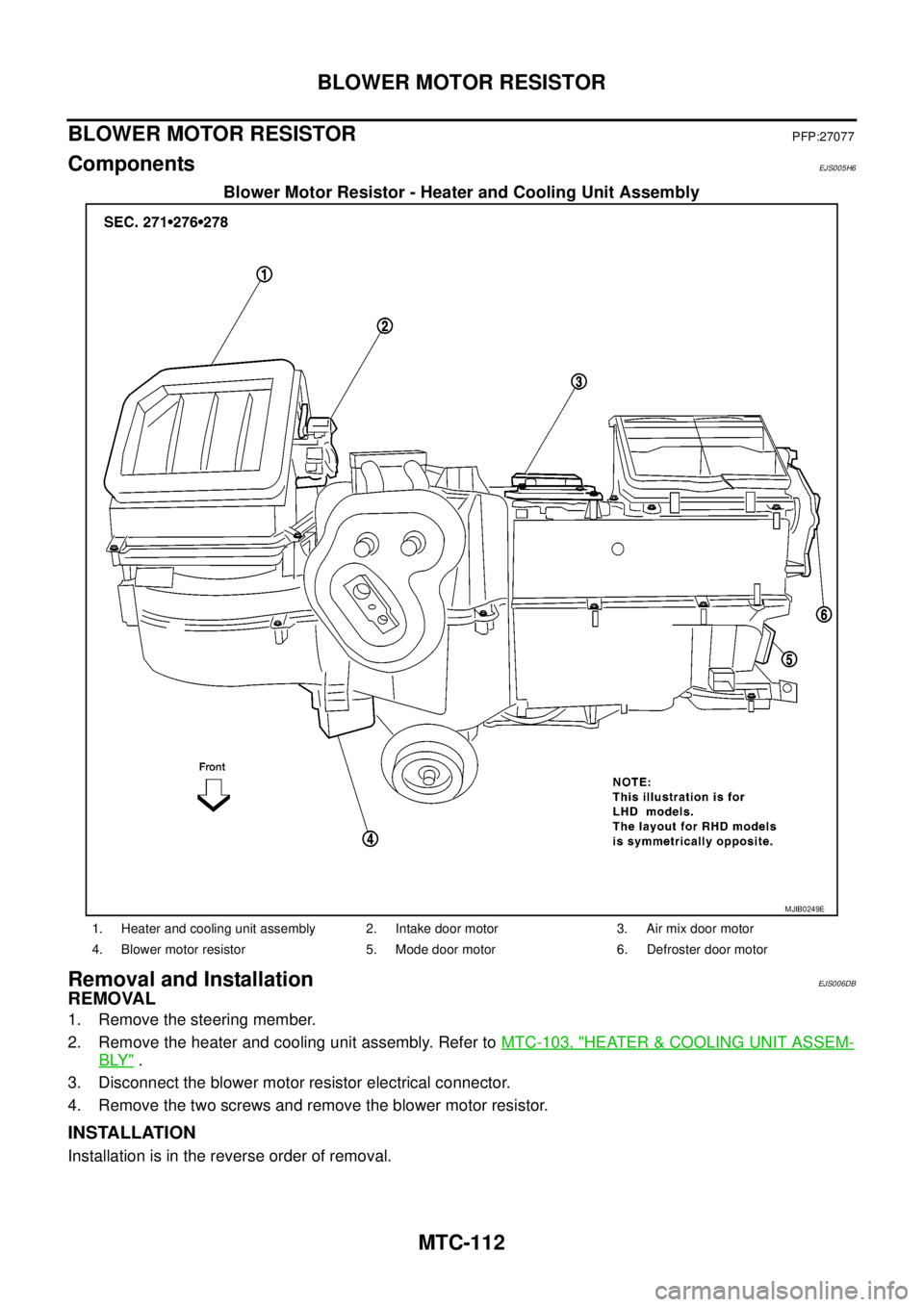

ComponentsEJS005H6

Blower Motor Resistor - Heater and Cooling Unit Assembly

Removal and InstallationEJS006DB

REMOVAL

1. Remove the steering member.

2. Remove the heater and cooling unit assembly. Refer toMTC-103, "

HEATER&COOLING UNIT ASSEM-

BLY".

3. Disconnect the blower motor resistor electrical connector.

4. Remove the two screws and remove the blower motor resistor.

INSTALLATION

Installation is in the reverse order of removal.

MJIB0249E

1. Heater and cooling unit assembly 2. Intake door motor 3. Air mix door motor

4. Blower motor resistor 5. Mode door motor 6. Defroster door motor

Page 2597 of 3171

PG-68

HARNESS

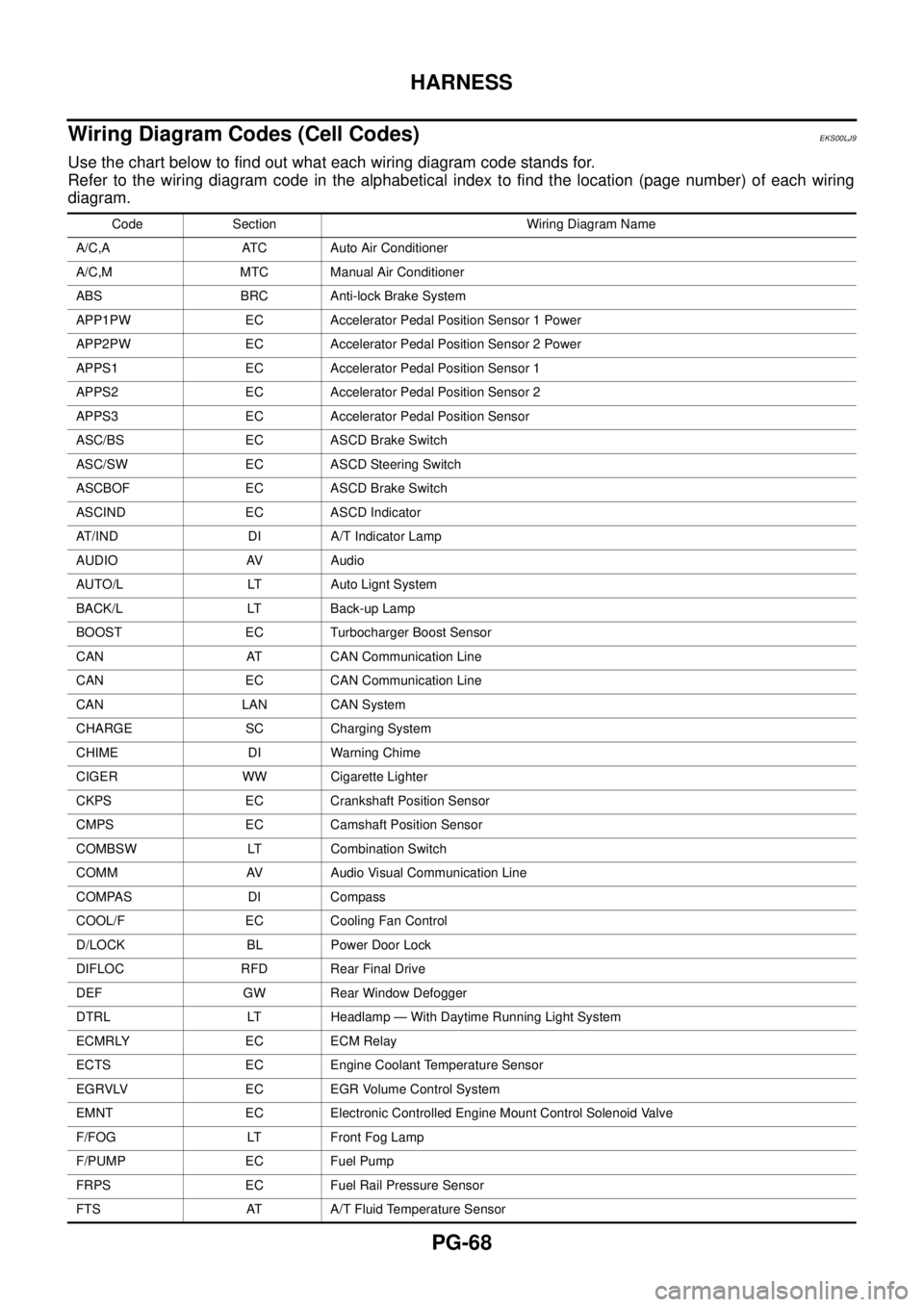

Wiring Diagram Codes (Cell Codes)

EKS00LJ9

Use the chart below to find out what each wiring diagram code stands for.

Refer to the wiring diagram code in the alphabetical index to find the location (page number) of each wiring

diagram.

Code Section Wiring Diagram Name

A/C,A ATC Auto Air Conditioner

A/C,M MTC Manual Air Conditioner

ABS BRC Anti-lock Brake System

APP1PW EC Accelerator Pedal Position Sensor 1 Power

APP2PW EC Accelerator Pedal Position Sensor 2 Power

APPS1 EC Accelerator Pedal Position Sensor 1

APPS2 EC Accelerator Pedal Position Sensor 2

APPS3 EC Accelerator Pedal Position Sensor

ASC/BS EC ASCD Brake Switch

ASC/SW EC ASCD Steering Switch

ASCBOF EC ASCD Brake Switch

ASCIND EC ASCD Indicator

AT/IND DI A/T Indicator Lamp

AUDIO AV Audio

AUTO/L LT Auto Lignt System

BACK/L LT Back-up Lamp

BOOST EC Turbocharger Boost Sensor

CAN AT CAN Communication Line

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

CIGER WW Cigarette Lighter

CKPS EC Crankshaft Position Sensor

CMPS EC Camshaft Position Sensor

COMBSW LT Combination Switch

COMM AV Audio Visual Communication Line

COMPAS DI Compass

COOL/F EC Cooling Fan Control

D/LOCK BL Power Door Lock

DIFLOC RFD Rear Final Drive

DEF GW Rear Window Defogger

DTRL LT Headlamp — With Daytime Running Light System

ECMRLY EC ECM Relay

ECTS EC Engine Coolant Temperature Sensor

EGRVLV EC EGR Volume Control System

EMNT EC Electronic Controlled Engine Mount Control Solenoid Valve

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

FRPS EC Fuel Rail Pressure Sensor

FTS AT A/T Fluid Temperature Sensor