stop start NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2865 of 3171

SC-32

STARTING SYSTEM

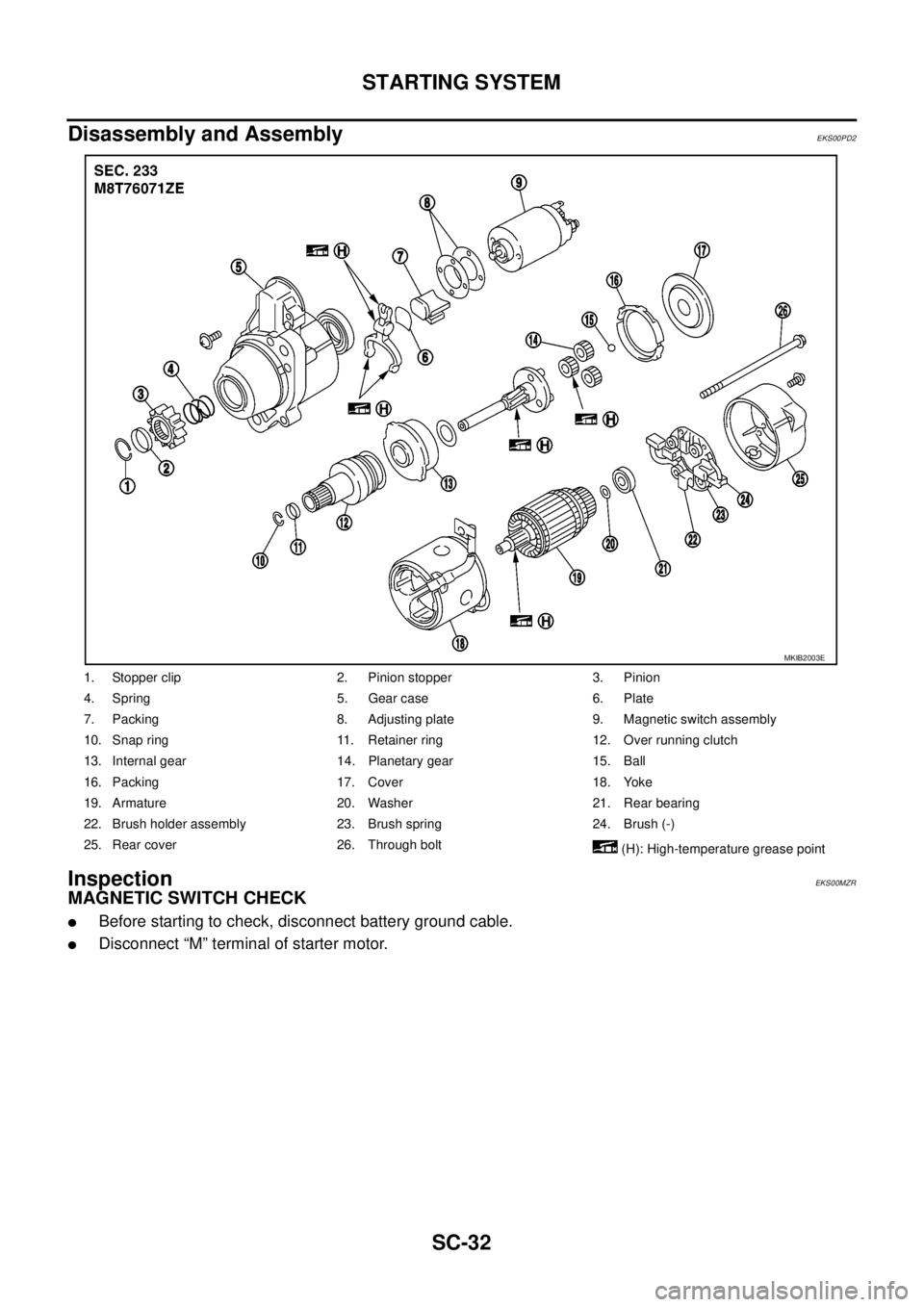

Disassembly and Assembly

EKS00PD2

InspectionEKS00MZR

MAGNETIC SWITCH CHECK

lBefore starting to check, disconnect battery ground cable.

lDisconnect “M” terminal of starter motor.

1. Stopper clip 2. Pinion stopper 3. Pinion

4. Spring 5. Gear case 6. Plate

7. Packing 8. Adjusting plate 9. Magnetic switch assembly

10. Snap ring 11. Retainer ring 12. Over running clutch

13. Internal gear 14. Planetary gear 15. Ball

16. Packing 17. Cover 18. Yoke

19. Armature 20. Washer 21. Rear bearing

22. Brush holder assembly 23. Brush spring 24. Brush (-)

25. Rear cover 26. Through bolt

(H): High-temperature grease point

MKIB2003E

Page 2869 of 3171

SC-36

STARTING SYSTEM

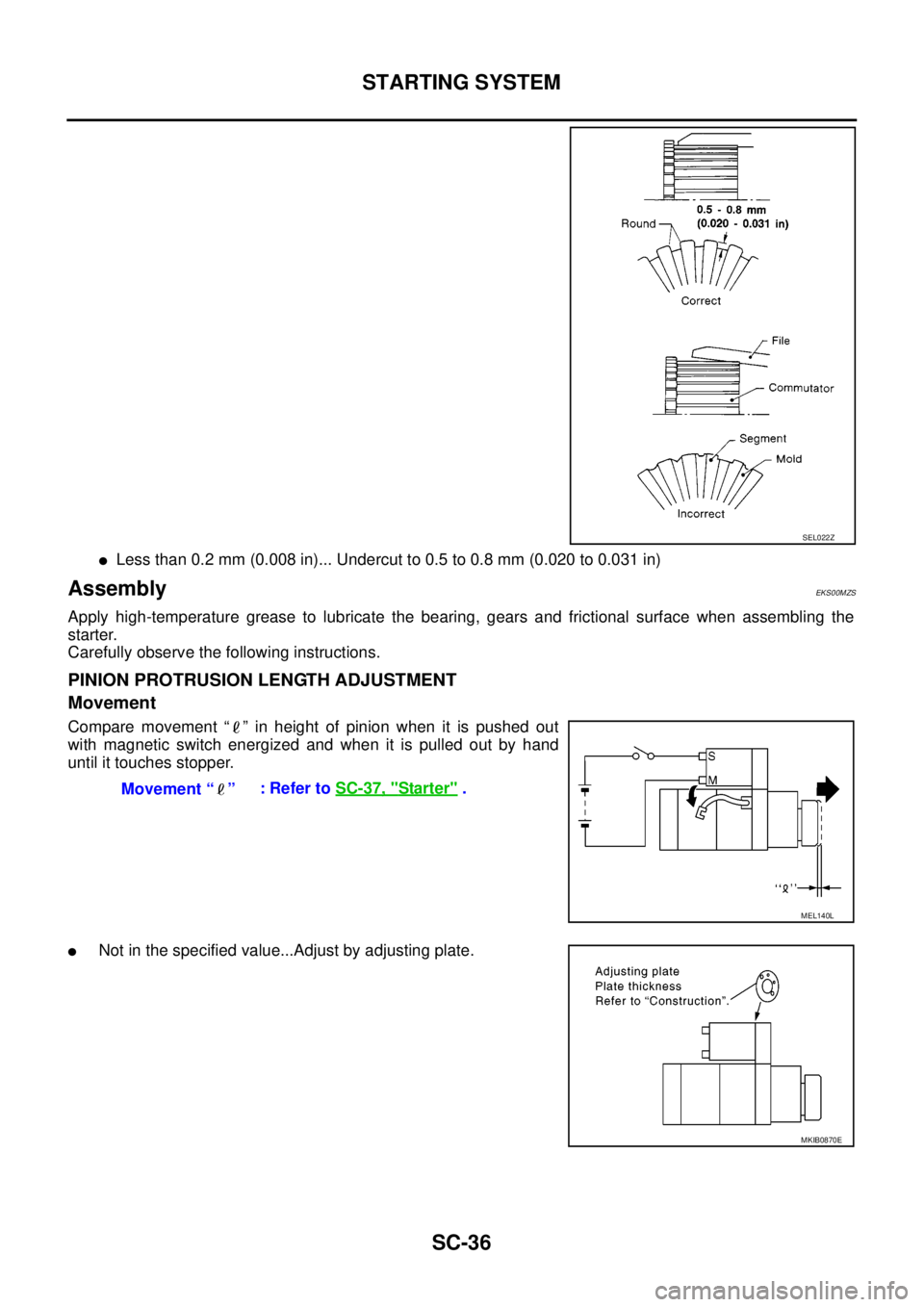

lLess than 0.2 mm (0.008 in)... Undercut to 0.5 to 0.8 mm (0.020 to 0.031 in)

AssemblyEKS00MZS

Apply high-temperature grease to lubricate the bearing, gears and frictional surface when assembling the

starter.

Carefully observe the following instructions.

PINION PROTRUSION LENGTH ADJUSTMENT

Movement

Compare movement “ ” in height of pinion when it is pushed out

with magnetic switch energized and when it is pulled out by hand

until it touches stopper.

lNot in the specified value...Adjust by adjusting plate.

SEL022Z

Movement “ ”:RefertoSC-37, "Starter".

MEL140L

MKIB0870E

Page 2870 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

SC-37

C

D

E

F

G

H

I

J

L

MA

B

SC

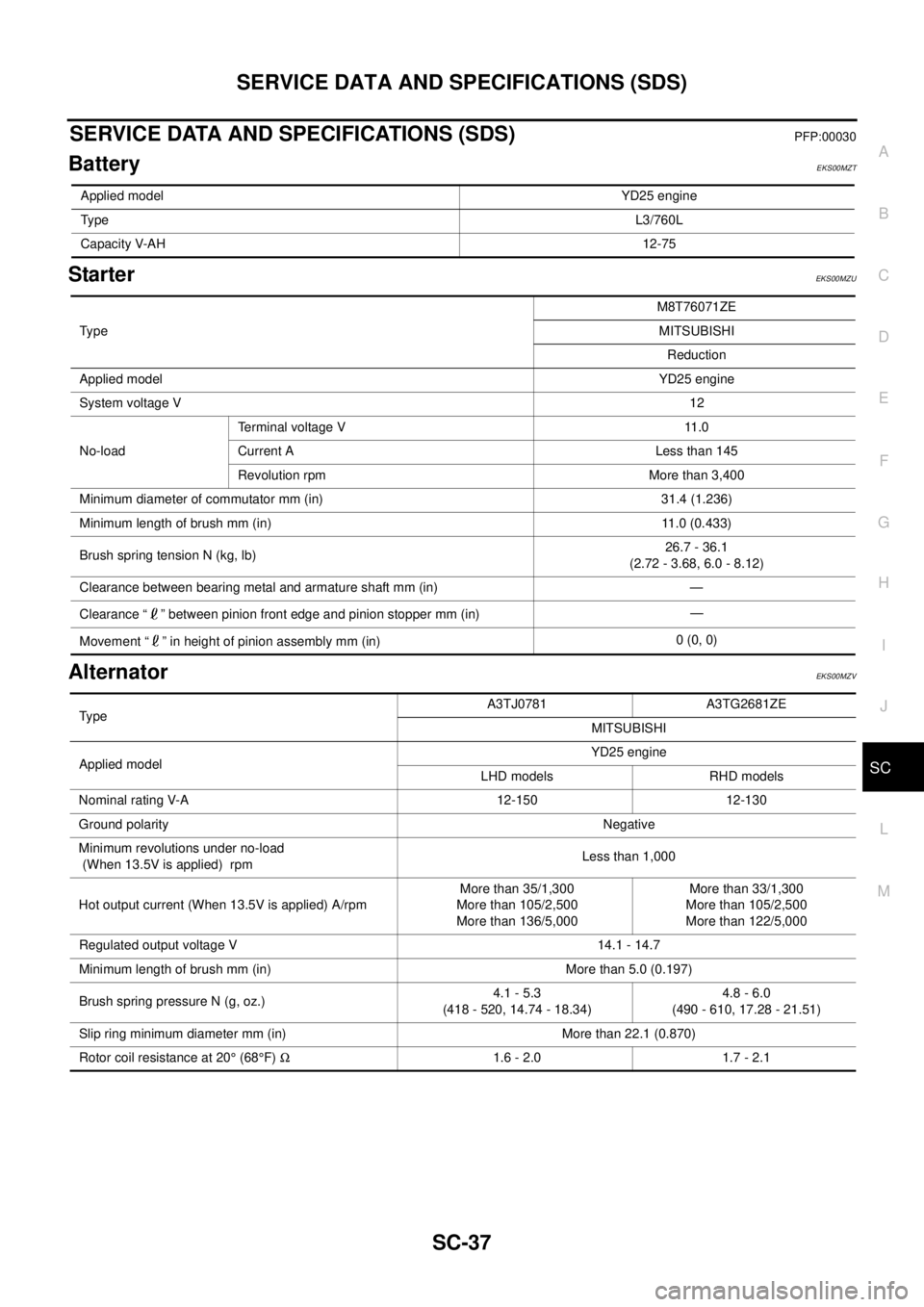

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

BatteryEKS00MZT

StarterEKS00MZU

AlternatorEKS00MZV

Applied modelYD25 engine

TypeL3/760L

Capacity V-AH12-75

Ty p eM8T76071ZE

MITSUBISHI

Reduction

Applied modelYD25 engine

System voltage V12

No-loadTerminal voltage V 11.0

Current A Less than 145

Revolution rpm More than 3,400

Minimum diameter of commutator mm (in) 31.4 (1.236)

Minimum length of brush mm (in) 11.0 (0.433)

Brush spring tension N (kg, lb)26.7 - 36.1

(2.72 - 3.68, 6.0 - 8.12)

Clearance between bearing metal and armature shaft mm (in) —

Clearance “ ” between pinion front edge and pinion stopper mm (in)—

Movement “ ” in height of pinion assembly mm (in)0 (0, 0)

TypeA3TJ0781 A3TG2681ZE

MITSUBISHI

Applied modelYD25 engine

LHD models RHD models

Nominal rating V-A 12-150 12-130

Ground polarityNegative

Minimum revolutions under no-load

(When 13.5V is applied) rpmLess than 1,000

Hot output current (When 13.5V is applied) A/rpmMore than 35/1,300

More than 105/2,500

More than 136/5,000More than 33/1,300

More than 105/2,500

More than 122/5,000

Regulated output voltage V 14.1 - 14.7

Minimum length of brush mm (in) More than 5.0 (0.197)

Brush spring pressure N (g, oz.)4.1 - 5.3

(418 - 520, 14.74 - 18.34)4.8 - 6.0

(490 - 610, 17.28 - 21.51)

Slip ring minimum diameter mm (in) More than 22.1 (0.870)

Rotor coil resistance at 20°(68°F)W1.6 - 2.0 1.7 - 2.1

Page 2877 of 3171

SE-6

SQUEAK AND RATTLE TROUBLE DIAGNOSES

FELT CLOTHTAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15´25 mm (0.59´0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll

The following materials, not available through NISSAN Parts Department, can also be used to repair squeaks

and rattles.

UHMW(TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingEIS00CEI

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks to

repair the noise.

Page 2972 of 3171

PRECAUTIONS

TF-5

C

E

F

G

H

I

J

K

L

MA

B

TF

METHODFORADJUSTMENTWITH4WDSHIFTSWITCHAT“2WD”

Select Adjustment Pattern

1. Start engine. Run engine for at least 10 seconds.

2. Check 4WD shift indicator lamp and 4LO indicator lamp.

Pattern A

1. Stay in the below for at least 2 seconds.

lFor A/T models, stop the vehicle and move A/T selector lever to “N” position with the brake pedal

depressed.

lFor M/T models, stop the vehicle and move M/T shift lever to the neutral position with the brake and

clutch pedal depressed.

2. Turn 4WD shift switch to “4LO” position. Stay in "4LO" for at least 2 seconds.

3. Turn ignition switch “OFF”.

4. Start engine.

5. Erase self-diagnosis. Refer toTF-46, "

How to Erase Self-diagnostic Results"(with CONSULT-II) orTF-

51, "ERASE SELF-DIAGNOSIS"(without CONSULT-II).

6. Check 4WD shift indicator lamp and 4LO indicator lamp again. Refer toTF-4, "

CHECK 4WD SHIFT INDI-

CATOR PATTERN".

If 4WD shift indicator lamp and 4LO indicator lamp do not indicate proper pattern, install new transfer con-

trol unit and retry the above check.

Pattern B

1. Stay in the below for at least 2 seconds.

lFor A/T models, stop the vehicle and move A/T selector lever to “N” position with the brake pedal

depressed.

lFor M/T models, stop the vehicle and move M/T shift lever to the neutral position with the brake and

clutch pedal depressed.

2. Turn ignition switch “OFF”.

3. Start engine.

4. Erase self-diagnosis. Refer toTF-46, "

How to Erase Self-diagnostic Results"(with CONSULT-II) orTF-

51, "ERASE SELF-DIAGNOSIS"(without CONSULT-II).

5. Check 4WD shift indicator lamp and 4LO indicator lamp again. Refer toTF-4, "

CHECK 4WD SHIFT INDI-

CATOR PATTERN".

If 4WD shift indicator lamp and 4LO indicator lamp do not indicate proper pattern, install new transfer con-

trol unit and retry the above check.

METHODFORADJUSTMENTWITH4WDSHIFTSWITCHAT“4H”OR“4LO”

1. Start engine. Run the engine for at least 10 seconds.

2. Stay in the below for at least 2 seconds.

lFor A/T models, stop the vehicle and move A/T selector lever to “N” position with the brake pedal

depressed.

lFor M/T models, stop the vehicle and move M/T shift lever to the neutral position with the brake and

clutch pedal depressed.

3. Turn 4WD shift switch to “2WD” position. Stay in "2WD" for at least 2 seconds.

4. Turn ignition switch “OFF”.

5. Start engine.

6. Erase self-diagnosis. Refer toTF-46, "

How to Erase Self-diagnostic Results"(with CONSULT-II) orTF-

51, "ERASE SELF-DIAGNOSIS"(without CONSULT-II).

7. Check 4WD shift indicator lamp and 4LO indicator lamp again. Refer toTF-4, "

CHECK 4WD SHIFT INDI-

CATOR PATTERN".

Indicator lamp condition Refer procedure

When 4WD shift indicator lamp or 4LO indicator lamp is flashing.TF-5, "

Pattern A"

Except for above.TF-5, "Pattern B"

Page 2979 of 3171

TF-12

TRANSFER FLUID

TRANSFER FLUID

PFP:31001

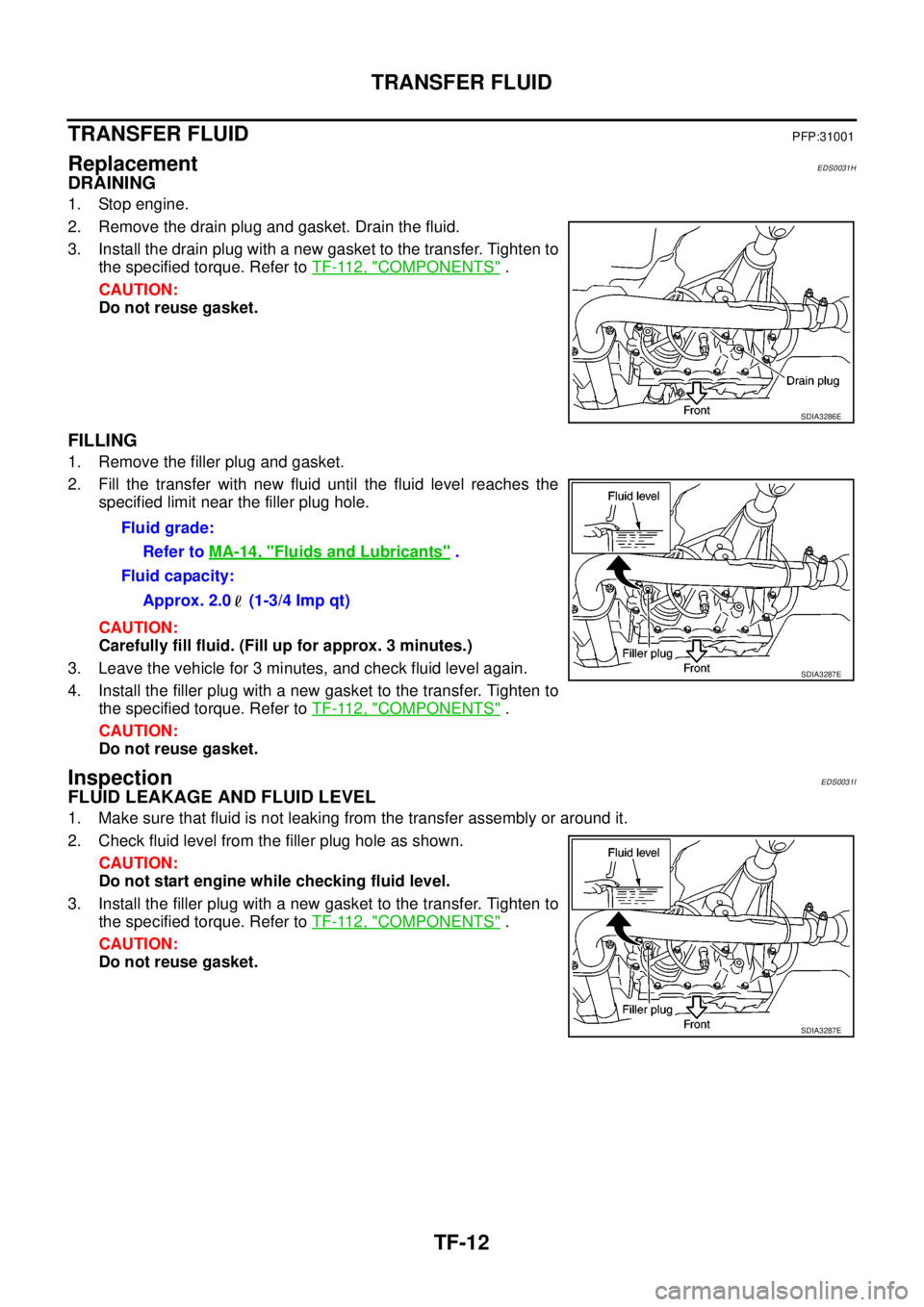

ReplacementEDS0031H

DRAINING

1. Stop engine.

2. Remove the drain plug and gasket. Drain the fluid.

3. Install the drain plug with a new gasket to the transfer. Tighten to

the specified torque. Refer toTF-112, "

COMPONENTS".

CAUTION:

Do not reuse gasket.

FILLING

1. Remove the filler plug and gasket.

2. Fill the transfer with new fluid until the fluid level reaches the

specified limit near the filler plug hole.

CAUTION:

Carefully fill fluid. (Fill up for approx. 3 minutes.)

3. Leave the vehicle for 3 minutes, and check fluid level again.

4. Install the filler plug with a new gasket to the transfer. Tighten to

the specified torque. Refer toTF-112, "

COMPONENTS".

CAUTION:

Do not reuse gasket.

InspectionEDS0031I

FLUID LEAKAGE AND FLUID LEVEL

1. Make sure that fluid is not leaking from the transfer assembly or around it.

2. Check fluid level from the filler plug hole as shown.

CAUTION:

Do not start engine while checking fluid level.

3. Install the filler plug with a new gasket to the transfer. Tighten to

the specified torque. Refer toTF-112, "

COMPONENTS".

CAUTION:

Do not reuse gasket.

SDIA3286E

Fluid grade:

Refer toMA-14, "

Fluids and Lubricants".

Fluid capacity:

Approx. 2.0 (1-3/4 Imp qt)

SDIA3287E

SDIA3287E

Page 3024 of 3171

TROUBLE DIAGNOSIS FOR SYSTEM

TF-57

C

E

F

G

H

I

J

K

L

MA

B

TF

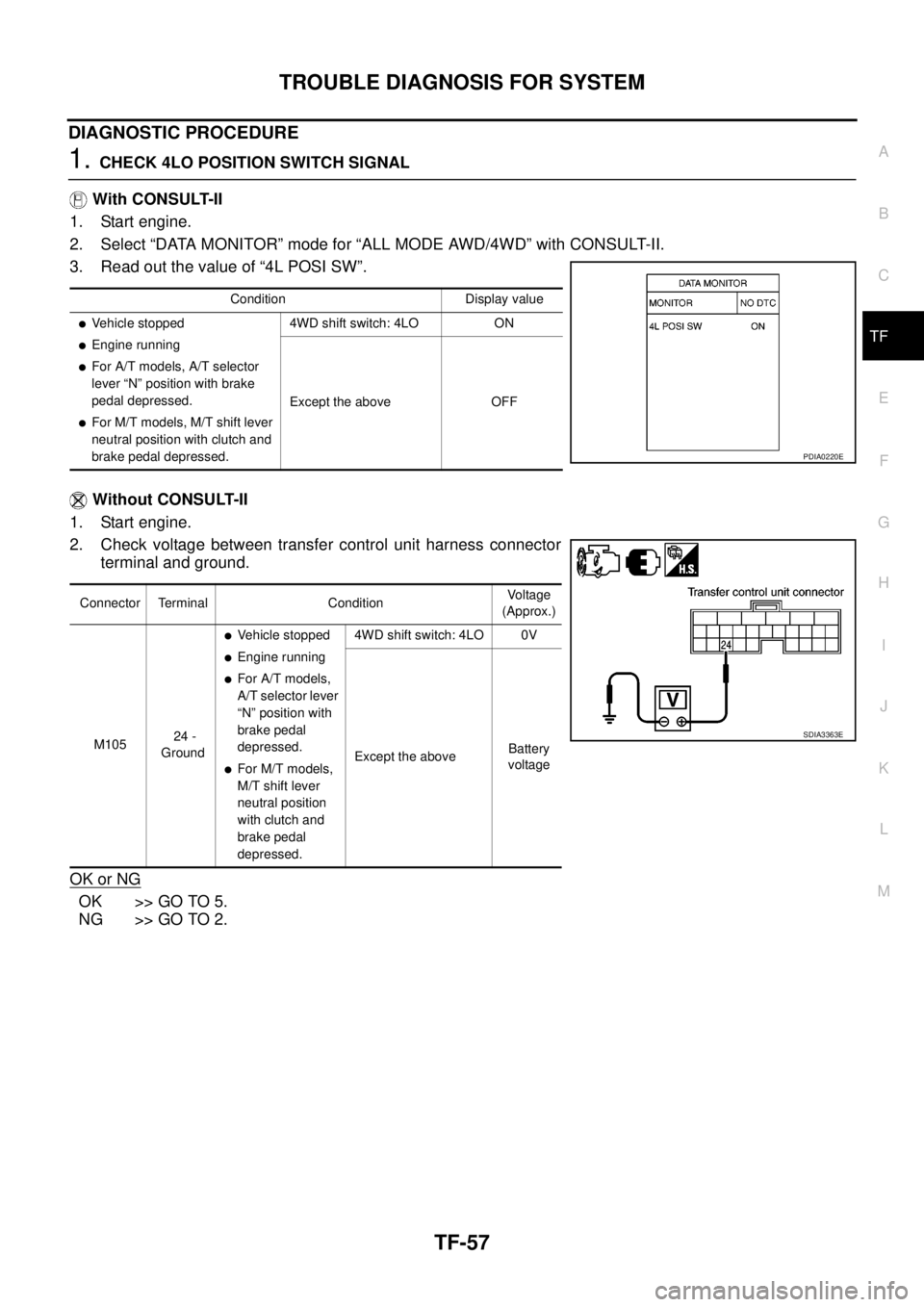

DIAGNOSTIC PROCEDURE

1.CHECK 4LO POSITION SWITCH SIGNAL

With CONSULT-II

1. Start engine.

2. Select “DATA MONITOR” mode for “ALL MODE AWD/4WD” with CONSULT-II.

3. Read out the value of “4L POSI SW”.

Without CONSULT-II

1. Start engine.

2. Check voltage between transfer control unit harness connector

terminal and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

Condition Display value

lVehicle stopped

lEngine running

lFor A/T models, A/T selector

lever “N” position with brake

pedal depressed.

lFor M/T models, M/T shift lever

neutral position with clutch and

brake pedal depressed.4WD shift switch: 4LO ON

Except the above OFF

PDIA0220E

Connector Terminal ConditionVo l ta g e

(Approx.)

M10524 -

Ground

lVehicle stopped

lEngine running

lFor A/T models,

A/T selector lever

“N” position with

brake pedal

depressed.

lFor M/T models,

M/T shift lever

neutral position

with clutch and

brake pedal

depressed.4WD shift switch: 4LO 0V

Except the aboveBattery

voltage

SDIA3363E

Page 3031 of 3171

TF-64

TROUBLE DIAGNOSIS FOR SYSTEM

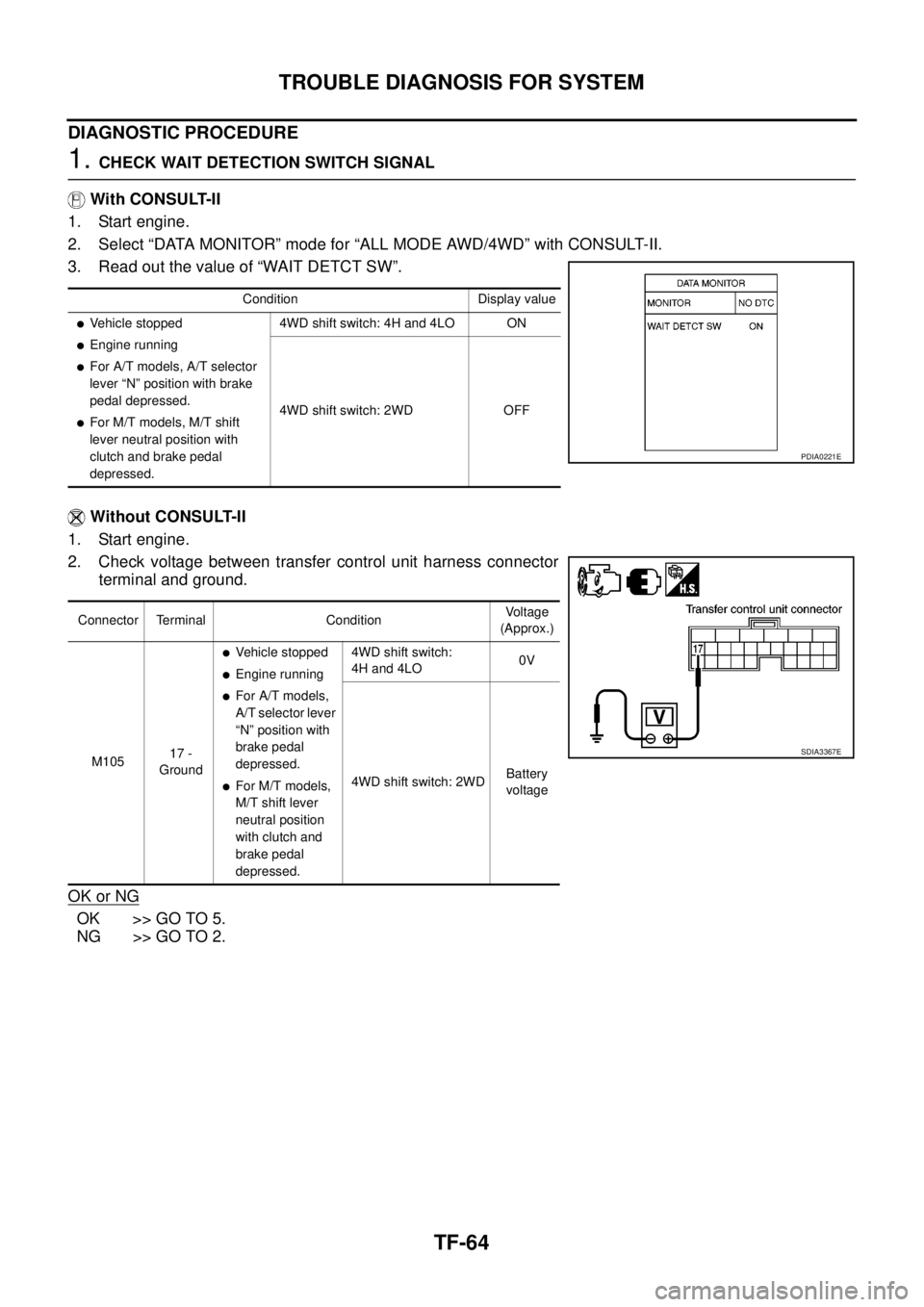

DIAGNOSTIC PROCEDURE

1.CHECK WAIT DETECTION SWITCH SIGNAL

With CONSULT-II

1. Start engine.

2. Select “DATA MONITOR” mode for “ALL MODE AWD/4WD” with CONSULT-II.

3. Read out the value of “WAIT DETCT SW”.

Without CONSULT-II

1. Start engine.

2. Check voltage between transfer control unit harness connector

terminal and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

Condition Display value

lVehicle stopped

lEngine running

lFor A/T models, A/T selector

lever “N” position with brake

pedal depressed.

lFor M/T models, M/T shift

lever neutral position with

clutch and brake pedal

depressed.4WD shift switch: 4H and 4LO ON

4WD shift switch: 2WD OFF

PDIA0221E

Connector Terminal ConditionVoltage

(Approx.)

M10517 -

Ground

lVehicle stopped

lEngine running

lFor A/T models,

A/T selector lever

“N” position with

brake pedal

depressed.

lFor M/T models,

M/T shift lever

neutral position

withclutchand

brake pedal

depressed.4WD shift switch:

4H and 4LO0V

4WD shift switch: 2WDBattery

voltage

SDIA3367E

Page 3035 of 3171

TF-68

TROUBLE DIAGNOSIS FOR SYSTEM

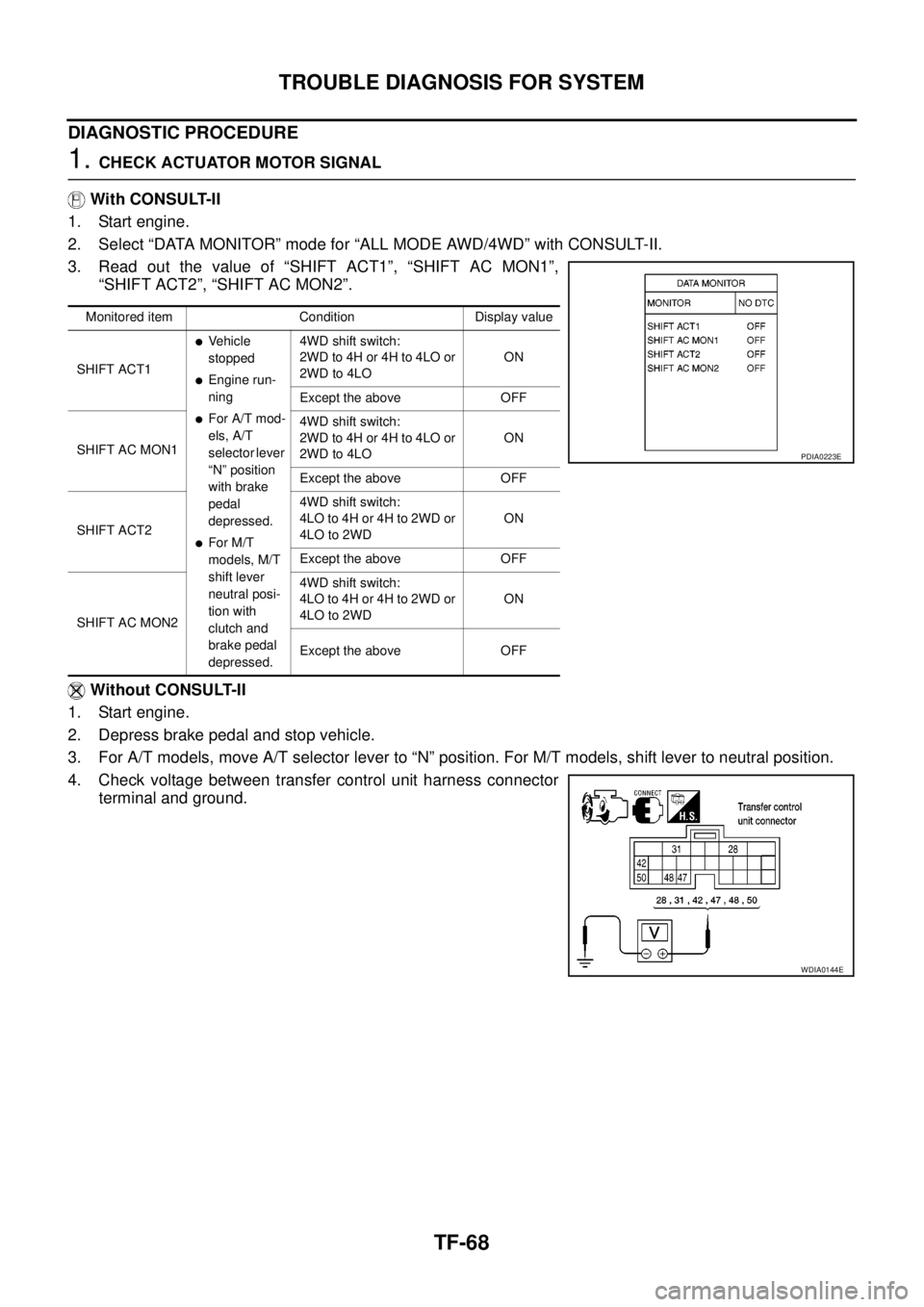

DIAGNOSTIC PROCEDURE

1.CHECK ACTUATOR MOTOR SIGNAL

With CONSULT-II

1. Start engine.

2. Select “DATA MONITOR” mode for “ALL MODE AWD/4WD” with CONSULT-II.

3. Read out the value of “SHIFT ACT1”, “SHIFT AC MON1”,

“SHIFT ACT2”, “SHIFT AC MON2”.

Without CONSULT-II

1. Start engine.

2. Depress brake pedal and stop vehicle.

3. For A/T models, move A/T selector lever to “N” position. For M/T models, shift lever to neutral position.

4. Check voltage between transfer control unit harness connector

terminal and ground.

Monitored item Condition Display value

SHIFT ACT1

lVehicle

stopped

lEngine run-

ning

lFor A/T mod-

els, A/T

selector lever

“N” position

with brake

pedal

depressed.

lFor M/T

models, M/T

shift lever

neutral posi-

tion with

clutch and

brake pedal

depressed.4WD shift switch:

2WD to 4H or 4H to 4LO or

2WD to 4LOON

Except the above OFF

SHIFT AC MON14WD shift switch:

2WD to 4H or 4H to 4LO or

2WD to 4LOON

Except the above OFF

SHIFT ACT24WD shift switch:

4LOto4Hor4Hto2WDor

4LO to 2WDON

Except the above OFF

SHIFT AC MON24WD shift switch:

4LOto4Hor4Hto2WDor

4LO to 2WDON

Except the above OFF

PDIA0223E

WDIA0144E

Page 3043 of 3171

TF-76

TROUBLE DIAGNOSIS FOR SYSTEM

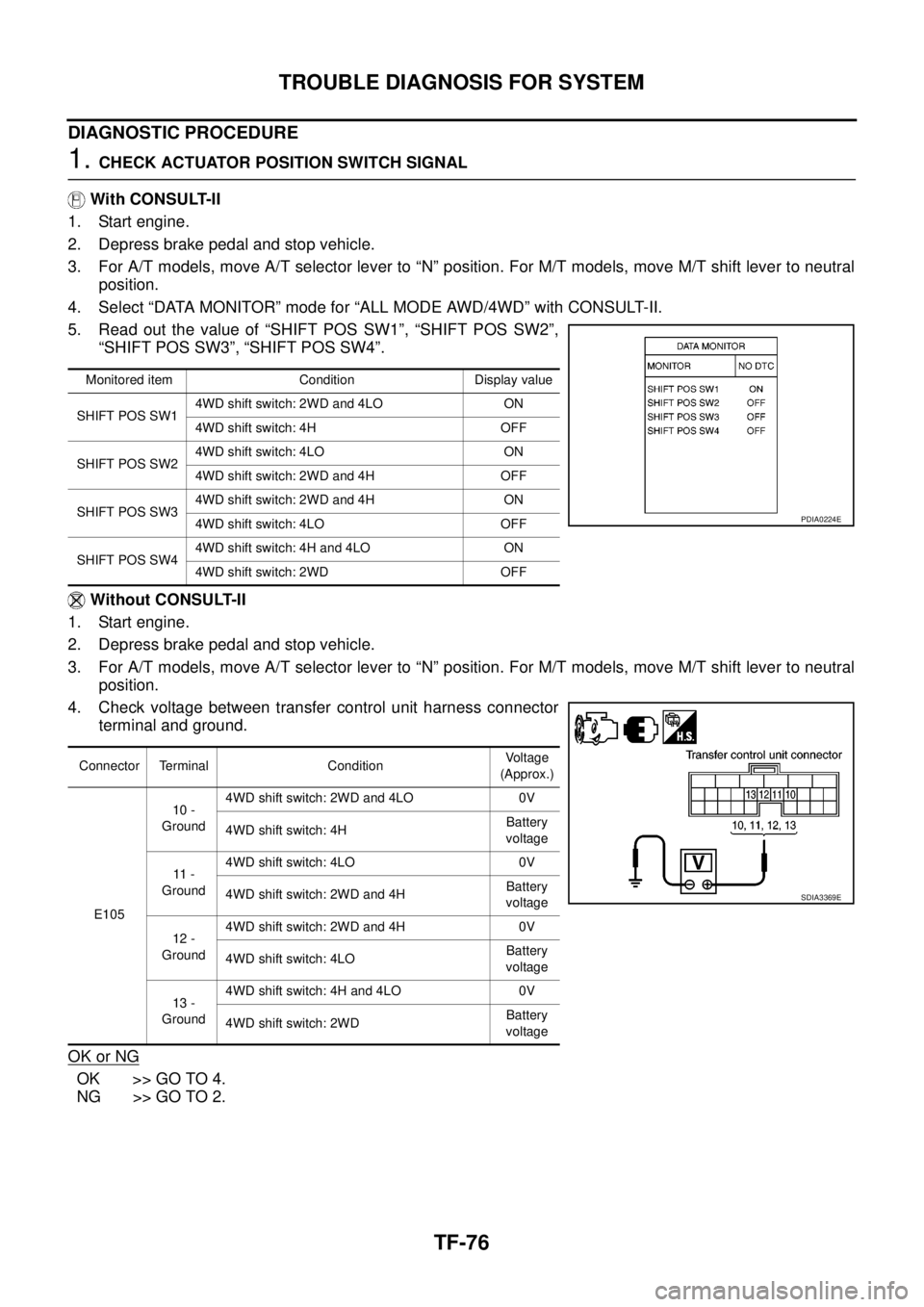

DIAGNOSTIC PROCEDURE

1.CHECK ACTUATOR POSITION SWITCH SIGNAL

With CONSULT-II

1. Start engine.

2. Depress brake pedal and stop vehicle.

3. For A/T models, move A/T selector lever to “N” position. For M/T models, move M/T shift lever to neutral

position.

4. Select “DATA MONITOR” mode for “ALL MODE AWD/4WD” with CONSULT-II.

5. Read out the value of “SHIFT POS SW1”, “SHIFT POS SW2”,

“SHIFT POS SW3”, “SHIFT POS SW4”.

Without CONSULT-II

1. Start engine.

2. Depress brake pedal and stop vehicle.

3. For A/T models, move A/T selector lever to “N” position. For M/T models, move M/T shift lever to neutral

position.

4. Check voltage between transfer control unit harness connector

terminal and ground.

OK or NG

OK >> GO TO 4.

NG >> GO TO 2.

Monitored item Condition Display value

SHIFT POS SW14WD shift switch: 2WD and 4LO ON

4WD shift switch: 4H OFF

SHIFT POS SW24WD shift switch: 4LO ON

4WD shift switch: 2WD and 4H OFF

SHIFT POS SW34WD shift switch: 2WD and 4H ON

4WD shift switch: 4LO OFF

SHIFT POS SW44WD shift switch: 4H and 4LO ON

4WD shift switch: 2WD OFF

Connector Terminal ConditionVoltage

(Approx.)

E10510 -

Ground4WD shift switch: 2WD and 4LO 0V

4WD shift switch: 4HBattery

voltage

11 -

Ground4WD shift switch: 4LO 0V

4WD shift switch: 2WD and 4HBattery

voltage

12 -

Ground4WD shift switch: 2WD and 4H 0V

4WD shift switch: 4LOBattery

voltage

13 -

Ground4WD shift switch: 4H and 4LO 0V

4WD shift switch: 2WDBattery

voltage

PDIA0224E

SDIA3369E