ABS NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2053 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual LAN-276

[CAN]

CAN SYSTEM (TYPE 16)

Case 7

Check ABS actuator and electric unit (control unit) circuit. Refer toLAN-302, "ABS Actuator and Electric Unit

(Control Unit) Circuit Inspection".

PKIC1965E

PK NISSAN NAVARA 2005 Repair Workshop Manual LAN-276

[CAN]

CAN SYSTEM (TYPE 16)

Case 7

Check ABS actuator and electric unit (control unit) circuit. Refer toLAN-302, "ABS Actuator and Electric Unit

(Control Unit) Circuit Inspection".

PKIC1965E

PK](/img/5/57362/w960_57362-2052.png)

LAN-276

[CAN]

CAN SYSTEM (TYPE 16)

Case 7

Check ABS actuator and electric unit (control unit) circuit. Refer toLAN-302, "ABS Actuator and Electric Unit

(Control Unit) Circuit Inspection".

PKIC1965E

PKIC1580E

Page 2059 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual LAN-282

[CAN]

CAN SYSTEM (TYPE 17)

CHECK SHEET RESULTS (EXAMPLE)

NOTE:

If a check mark is put on “NG” on “INITIAL DIAG (Initial diagnosis)”, replace the control unit.

Case 1

Check harness betw NISSAN NAVARA 2005 Repair Workshop Manual LAN-282

[CAN]

CAN SYSTEM (TYPE 17)

CHECK SHEET RESULTS (EXAMPLE)

NOTE:

If a check mark is put on “NG” on “INITIAL DIAG (Initial diagnosis)”, replace the control unit.

Case 1

Check harness betw](/img/5/57362/w960_57362-2058.png)

LAN-282

[CAN]

CAN SYSTEM (TYPE 17)

CHECK SHEET RESULTS (EXAMPLE)

NOTE:

If a check mark is put on “NG” on “INITIAL DIAG (Initial diagnosis)”, replace the control unit.

Case 1

Check harness between data link connector and ABS actuator and electric unit (control unit) circuit. Refer to

LAN-296, "

Inspection Between Data Link Connector and ABS Actuator and Electric Unit (Control Unit) Circuit"

.

PKIC1970E

PKIC1582E

Page 2066 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual CAN SYSTEM (TYPE 17)

LAN-289

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Case 8

Check ABS actuator and electric unit (control unit) circuit. Refer toLAN-302, "ABS Actuator and Electric Unit

(Control Unit) Circui NISSAN NAVARA 2005 Repair Workshop Manual CAN SYSTEM (TYPE 17)

LAN-289

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Case 8

Check ABS actuator and electric unit (control unit) circuit. Refer toLAN-302, "ABS Actuator and Electric Unit

(Control Unit) Circui](/img/5/57362/w960_57362-2065.png)

CAN SYSTEM (TYPE 17)

LAN-289

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Case 8

Check ABS actuator and electric unit (control unit) circuit. Refer toLAN-302, "ABS Actuator and Electric Unit

(Control Unit) Circuit Inspection".

PKIC1977E

PKIC1589E

Page 2073 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual LAN-296

[CAN]

TROUBLE DIAGNOSIS FOR SYSTEM

Inspection Between Data Link Connector and ABS Actuator and Electric Unit

(Control Unit) Circuit

EKS00O4X

1.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. D NISSAN NAVARA 2005 Repair Workshop Manual LAN-296

[CAN]

TROUBLE DIAGNOSIS FOR SYSTEM

Inspection Between Data Link Connector and ABS Actuator and Electric Unit

(Control Unit) Circuit

EKS00O4X

1.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. D](/img/5/57362/w960_57362-2072.png)

LAN-296

[CAN]

TROUBLE DIAGNOSIS FOR SYSTEM

Inspection Between Data Link Connector and ABS Actuator and Electric Unit

(Control Unit) Circuit

EKS00O4X

1.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check following terminals and connectors for damage, bend and loose connection (connector side and

harness side).

–Harness connector M3

–Harness connector E112

OK or NG

OK >> GO TO 2.

NG >> Repair terminal or connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect harness connector M3.

2. Check continuity between data link connector M45 terminals 6,

14 and harness connector M3 terminals 11, 10.

OK or NG

OK >> GO TO 3.

NG >> Repair harness.

3.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect ABS actuator and electric unit (control unit) connector.

2. Check continuity between harness connector E112 terminals 11,

10 and ABS actuator and electric unit (control unit) harness con-

nector E63 terminals 11, 15.

OK or NG

OK >> Connect all the connectors and diagnose again. Refer to

LAN-5, "

TROUBLE DIAGNOSES WORK FLOW".

NG >> Repair harness.6 – 11 : Continuity should exist.

14 – 10 : Continuity should exist.

SKIB2812E

11 – 11 : Continuity should exist.

10 – 15 : Continuity should exist.

SKIB2813E

Page 2079 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual LAN-302

[CAN]

TROUBLE DIAGNOSIS FOR SYSTEM

Transfer Control Unit Circuit Inspection

EKS00O56

1.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

NISSAN NAVARA 2005 Repair Workshop Manual LAN-302

[CAN]

TROUBLE DIAGNOSIS FOR SYSTEM

Transfer Control Unit Circuit Inspection

EKS00O56

1.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.](/img/5/57362/w960_57362-2078.png)

LAN-302

[CAN]

TROUBLE DIAGNOSIS FOR SYSTEM

Transfer Control Unit Circuit Inspection

EKS00O56

1.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check terminals and connector of transfer control unit for damage, bend and loose connection (control

unit side and harness side).

OK or NG

OK >> GO TO 2.

NG >> Repair terminal or connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect transfer control unit connector.

2. Check resistance between transfer control unit harness connec-

tor terminals.

OK or NG

OK >> Replace transfer control unit.

NG >> Repair harness between transfer control unit and data

link connector.

ABS Actuator and Electric Unit (Control Unit) Circuit InspectionEKS00O59

1.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check terminals and connector of ABS actuator and electric unit (control unit) for damage, bend and loose

connection (control unit side and harness side).

OK or NG

OK >> GO TO 2.

NG >> Repair terminal or connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect ABS actuator and electric unit (control unit) connector.

2. Check resistance between ABS actuator and electric unit (con-

trol unit) harness connector E63 terminals 11 and 15.

OK or NG

OK >> Replace ABS actuator and electric unit (control unit).

NG >> Repair harness between ABS actuator and electric unit

(control unit) and IPDM E/R.

Transfer control

unit connectorTerminalResistance

(Approx.)

M105 1 2 54 – 66W

PKIC1656E

11 – 15 : Approx. 54 – 66W

SKIA6872E

Page 2195 of 3171

LT-112

LIGHTING AND TURN SIGNAL SWITCH

LIGHTING AND TURN SIGNAL SWITCH

PFP:25540

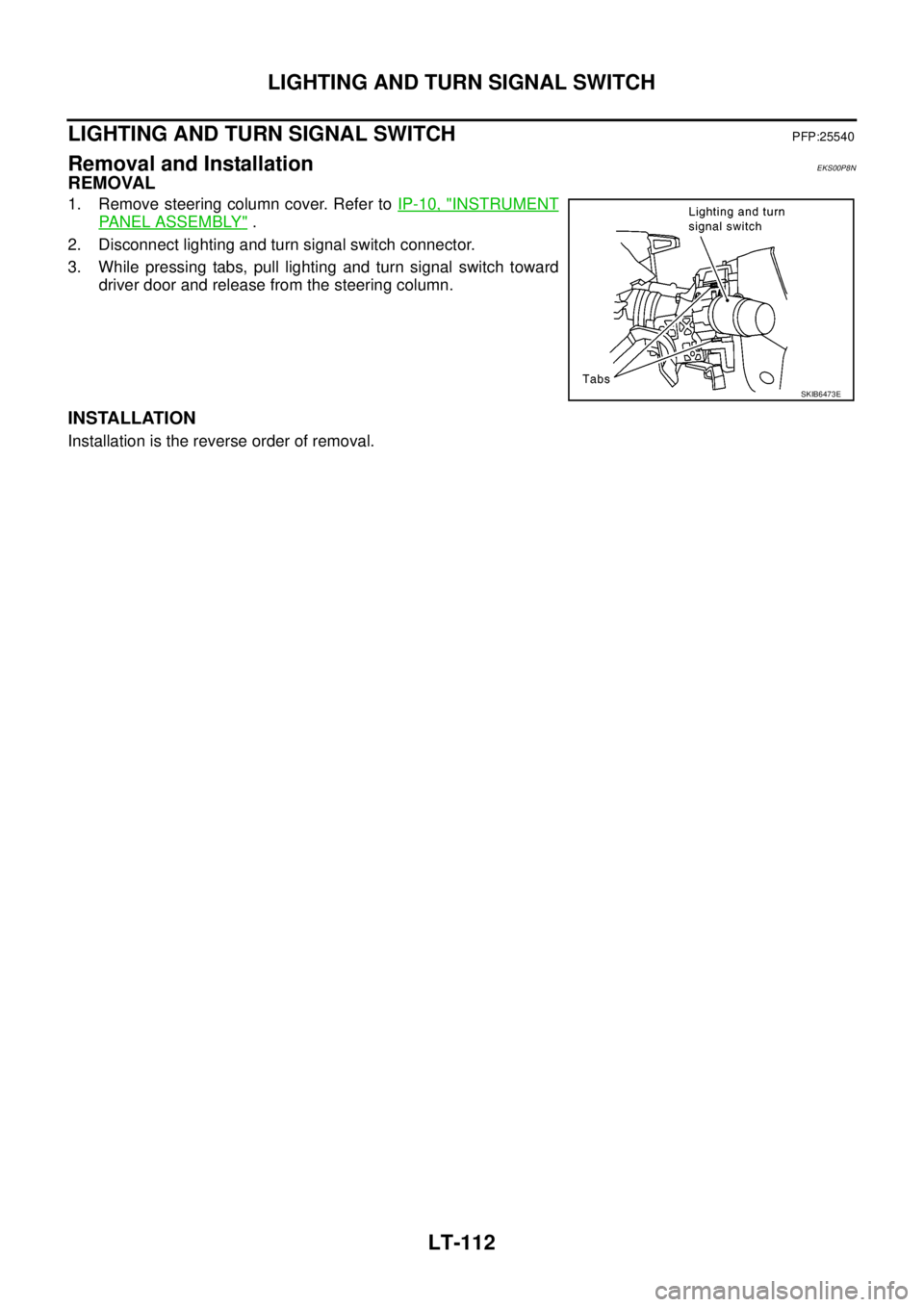

Removal and InstallationEKS00P8N

REMOVAL

1. Remove steering column cover. Refer toIP-10, "INSTRUMENT

PANEL ASSEMBLY".

2. Disconnect lighting and turn signal switch connector.

3. While pressing tabs, pull lighting and turn signal switch toward

driver door and release from the steering column.

INSTALLATION

Installation is the reverse order of removal.

SKIB6473E

Page 2265 of 3171

LU-8

OIL FILTER

OIL FILTER

PFP:15208

Removal and InstallationEBS01E58

REMOVAL

1. Remove engine undercover middle.

2. Place a pan to catch the engine oil under the lower part of drain hose outlet before removing oil filter.

3. Using the oil filter wrench, remove oil filter.

CAUTION:

lBe careful not to get burned when engine and engine oil are hot.

lWhen removing, prepare a shop cloth to absorb any engine oil leakage or spillage.

lDo not allow engine oil to adhere to drive belts.

lCompletely wipe off any engine oil that adhere to engine and vehicle.

lOil filter is provided with a relief valve. Use Genuine Nissan Oil Filter or equivalent.

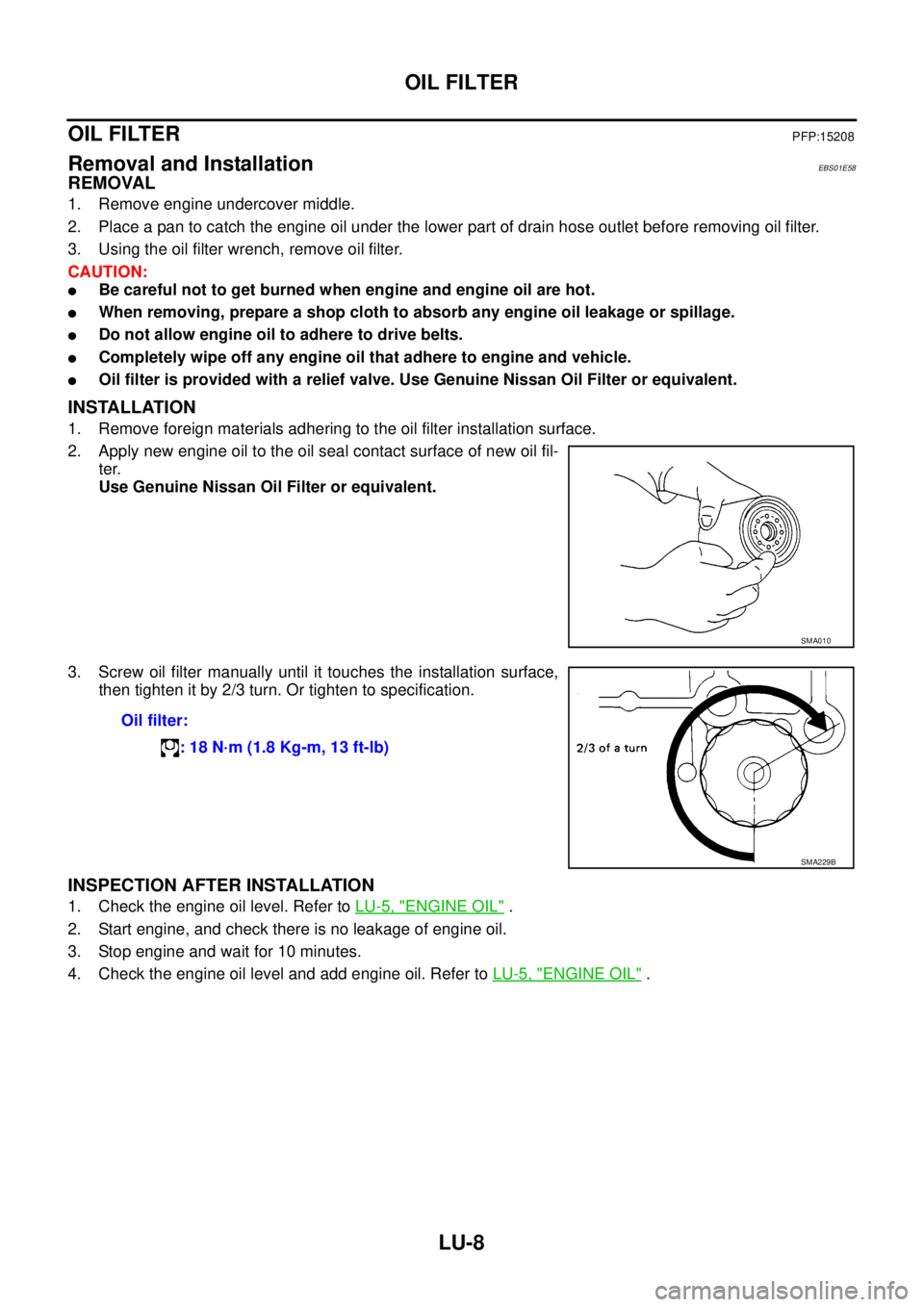

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply new engine oil to the oil seal contact surface of new oil fil-

ter.

Use Genuine Nissan Oil Filter or equivalent.

3. Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn. Or tighten to specification.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer toLU-5, "ENGINE OIL".

2. Start engine, and check there is no leakage of engine oil.

3. Stop engine and wait for 10 minutes.

4. Check the engine oil level and add engine oil. Refer toLU-5, "

ENGINE OIL".

SMA010

Oil filter:

: 18 N·m (1.8 Kg-m, 13 ft-lb)

SMA229B

Page 2268 of 3171

OIL COOLER

LU-11

C

D

E

F

G

H

I

J

K

L

MA

LU

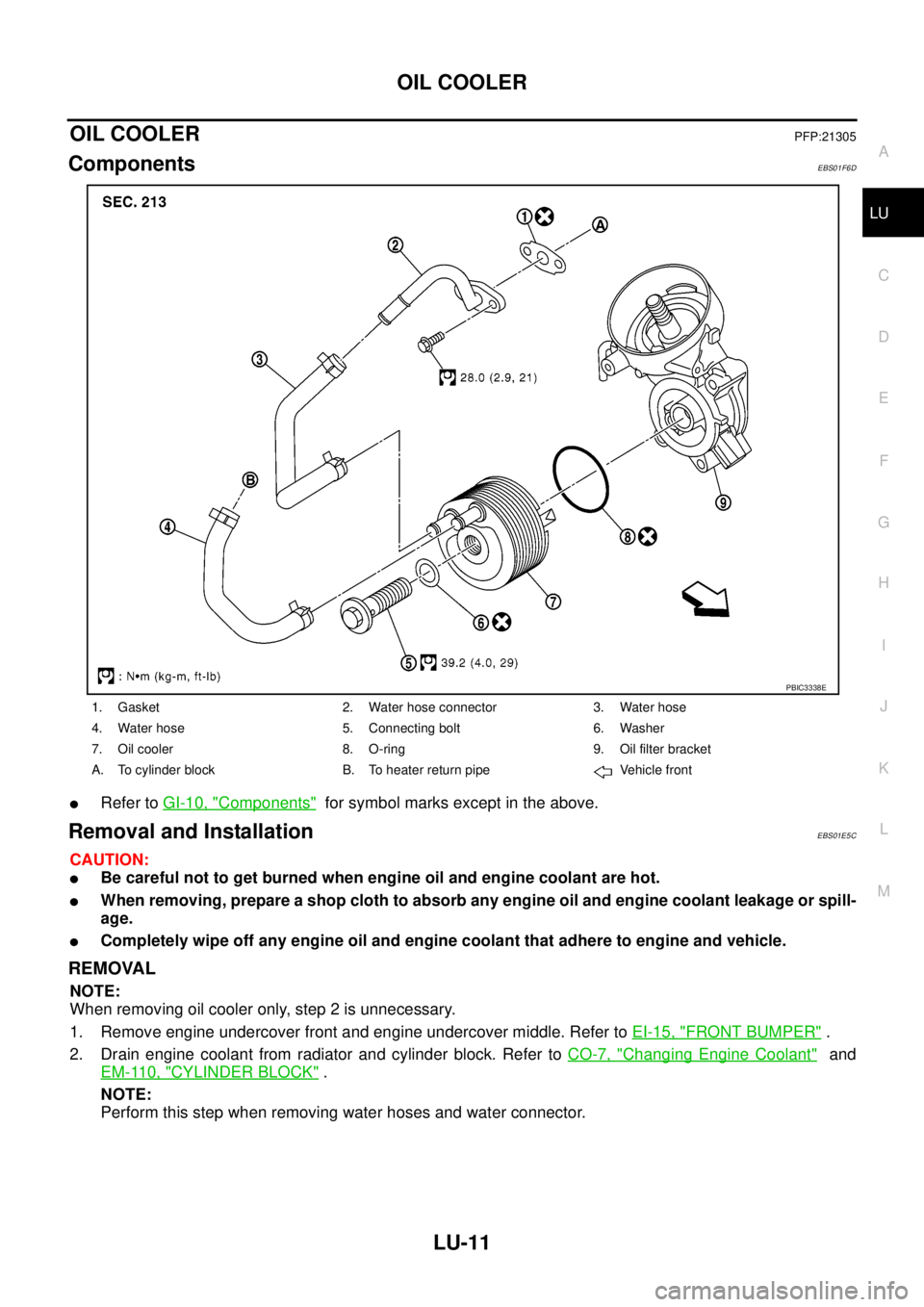

OIL COOLERPFP:21305

ComponentsEBS01F6D

lRefer toGI-10, "Components"for symbol marks except in the above.

Removal and InstallationEBS01E5C

CAUTION:

lBe careful not to get burned when engine oil and engine coolant are hot.

lWhen removing, prepare a shop cloth to absorb any engine oil and engine coolant leakage or spill-

age.

lCompletely wipe off any engine oil and engine coolant that adhere to engine and vehicle.

REMOVAL

NOTE:

When removing oil cooler only, step 2 is unnecessary.

1. Remove engine undercover front and engine undercover middle. Refer toEI-15, "

FRONT BUMPER".

2. Drain engine coolant from radiator and cylinder block. Refer toCO-7, "

Changing Engine Coolant"and

EM-110, "

CYLINDER BLOCK".

NOTE:

Perform this step when removing water hoses and water connector.

1. Gasket 2. Water hose connector 3. Water hose

4. Water hose 5. Connecting bolt 6. Washer

7. Oil cooler 8. O-ring 9. Oil filter bracket

A. To cylinder block B. To heater return pipe Vehicle front

PBIC3338E

Page 2301 of 3171

MA-26

ENGINE MAINTENANCE

CAUTION:

Be sure to clean drain plug and install with new washer.

6. Refill with new engine oil.

Engine oil specification and viscosity:

Refer toMA-14, "

RECOMMENDED FLUIDS AND LUBRICANTS".

Engine oil capacity (Approximate):

Unit: (lmp qt)

CAUTION:

lWhen filling engine oil, do not pull out oil level gauge.

lThe refill capacity depends on the engine oil temperature and drain time. Use these specifica-

tions for reference only.

lAlways use the oil level gauge to determine when the proper amount of engine oil is in the

engine.

7. Warm up engine and check area around drain plug and oil filter for oil leakage.

8. Stop engine and wait for 10 minutes.

9. Check the engine oil level. Refer toLU-5, "

ENGINE OIL LEVEL".

Changing Oil FilterELS001JY

REMOVAL

1. Remove engine undercover middle.

2. Place a pan to catch the engine oil under the lower part of drain hose outlet before removing oil filter.

3. Using the oil filter wrench, remove oil filter.

CAUTION:

lBe careful not to get burned when engine and engine oil are hot.

lWhen removing, prepare a shop cloth to absorb any engine oil leakage or spillage.

lDo not allow engine oil to adhere to drive belts.

lCompletely wipe off any engine oil that adhere to engine and vehicle.

lOil filter is provided with a relief valve. Use Genuine NISSAN Oil Filter or equivalent.

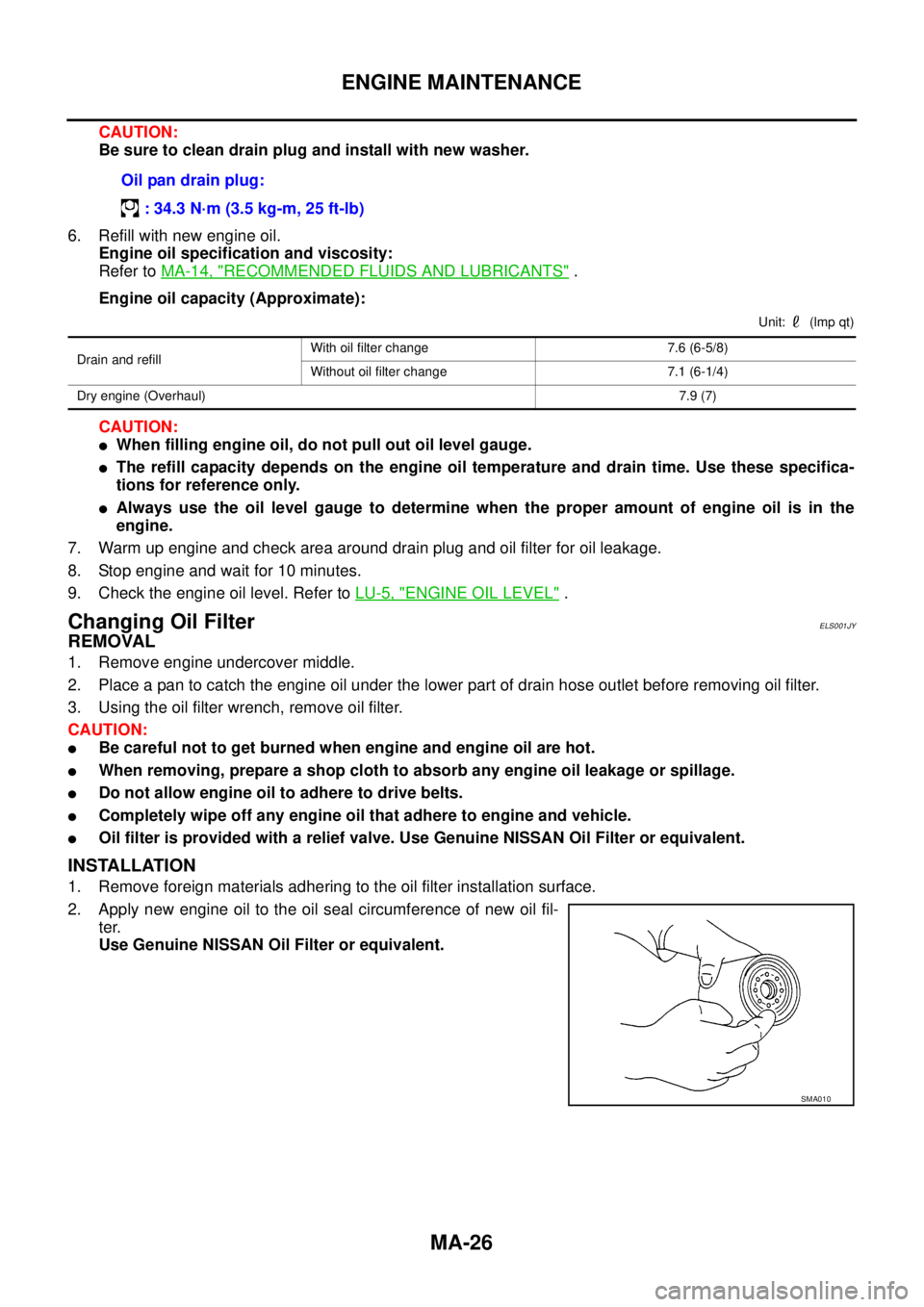

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply new engine oil to the oil seal circumference of new oil fil-

ter.

Use Genuine NISSAN Oil Filter or equivalent.Oil pan drain plug:

: 34.3 N·m (3.5 kg-m, 25 ft-lb)

Drain and refillWith oil filter change 7.6 (6-5/8)

Without oil filter change 7.1 (6-1/4)

Dry engine (Overhaul)7.9 (7)

SMA010

Page 2313 of 3171

MA-38

CHASSIS AND BODY MAINTENANCE

Checking Axle and Suspension Parts

ELS001J5

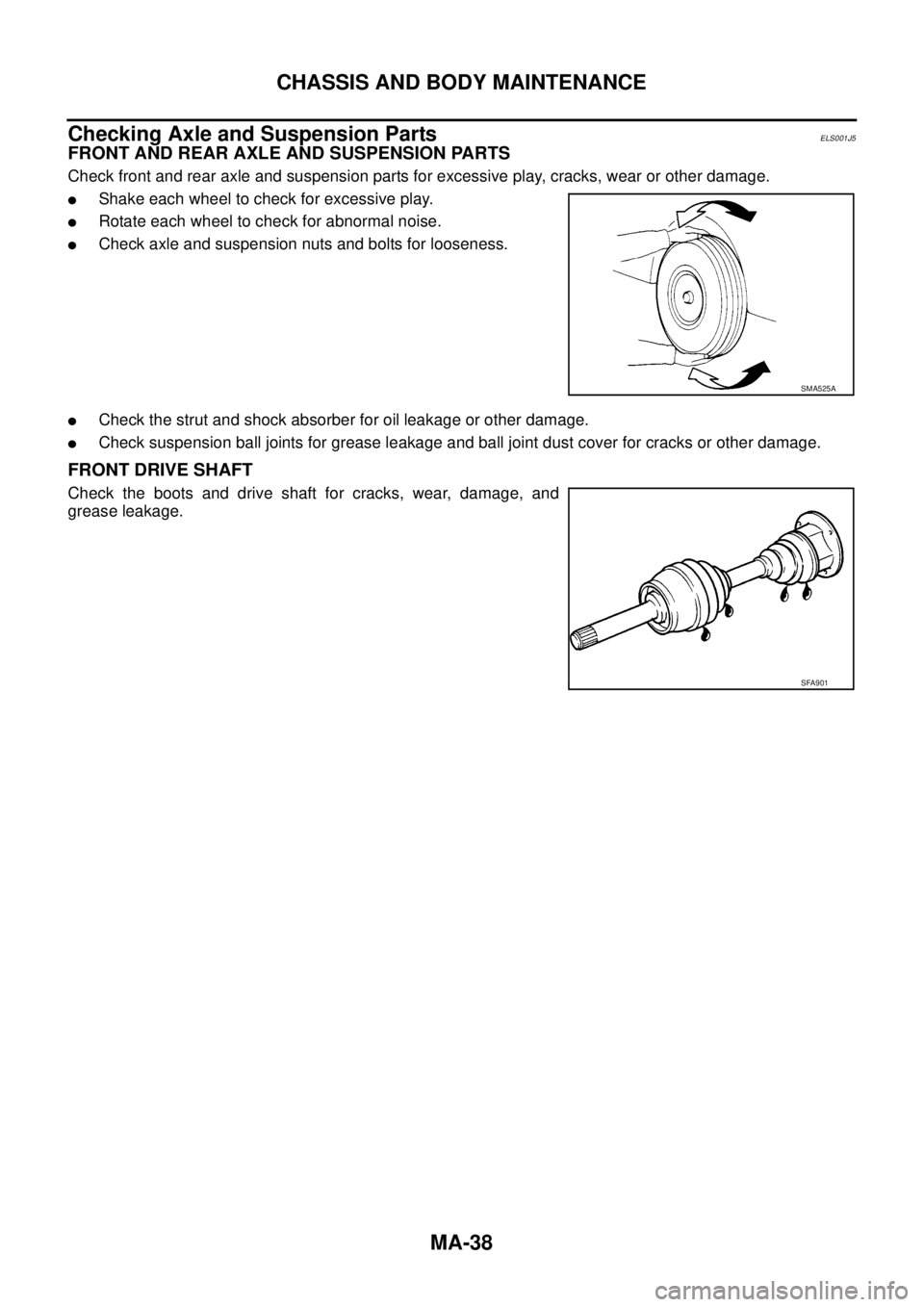

FRONT AND REAR AXLE AND SUSPENSION PARTS

Check front and rear axle and suspension parts for excessive play, cracks, wear or other damage.

lShake each wheel to check for excessive play.

lRotate each wheel to check for abnormal noise.

lCheck axle and suspension nuts and bolts for looseness.

lCheck the strut and shock absorber for oil leakage or other damage.

lCheck suspension ball joints for grease leakage and ball joint dust cover for cracks or other damage.

FRONT DRIVE SHAFT

Check the boots and drive shaft for cracks, wear, damage, and

grease leakage.

SMA525A

SFA901