ABS NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2391 of 3171

MTC-4

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EJS005QE

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Working with HFC-134a (R-134a)EJS00627

WARNING:

lCFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant are not compatible. These refrigerants

must never be mixed, even in the smallest amounts. If the refrigerants are mixed and compressor

malfunction is likely occur.

lUse only specified lubricant for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) compo-

nents. If lubricant other than that specified is used, compressor malfunction is likely to occur.

lThe specified HFC-134a (R-134a) lubricant rapidly absorbs moisture from the atmosphere. The fol-

lowing handling precautions must be observed:

–When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of moisture from the atmosphere.

–When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just

before connecting the components. Connect all refrigerant loop components as quickly as possi-

ble to minimize the entry of moisture into system.

–Only use the specified lubricant from a sealed container. Immediately reseal containers of lubri-

cant. Without proper sealing, lubricant will become moisture saturated and should not be used.

–Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose and

throat. Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a) refriger-

ant. If accidental system discharge occurs, ventilate work area before resuming service. Addi-

tional health and safety information may be obtained from refrigerant and lubricant

manufacturers.

–Do not allow lubricant (Nissan A/C System Oil Type S) to come in contact with styrofoam parts.

Damage may result.

Contaminated RefrigerantEJS0063C

If a refrigerant other than pure HFC-134a (R-134a) is identified in a vehicle, your options are:

lExplain to the customer that environmental regulations prohibit the release of contaminated refrigerant

into the atmosphere.

lExplain that recovery of the contaminated refrigerant could damage your service equipment and refriger-

ant supply.

lSuggest the customer return the vehicle to the location of previous service where the contamination may

have occurred.

lIf you choose to perform the repair, recover the refrigerant using onlydedicated equipment and contain-

ers. Do not recover contaminated refrigerant into your existing service equipment.If your facility

does not have dedicated recovery equipment, you may contact a local refrigerant product retailer for avail-

able service. This refrigerant must be disposed of in accordance with all federal and local regulations. In

addition, replacement of all refrigerant system components on the vehicle is recommended.

Page 2597 of 3171

PG-68

HARNESS

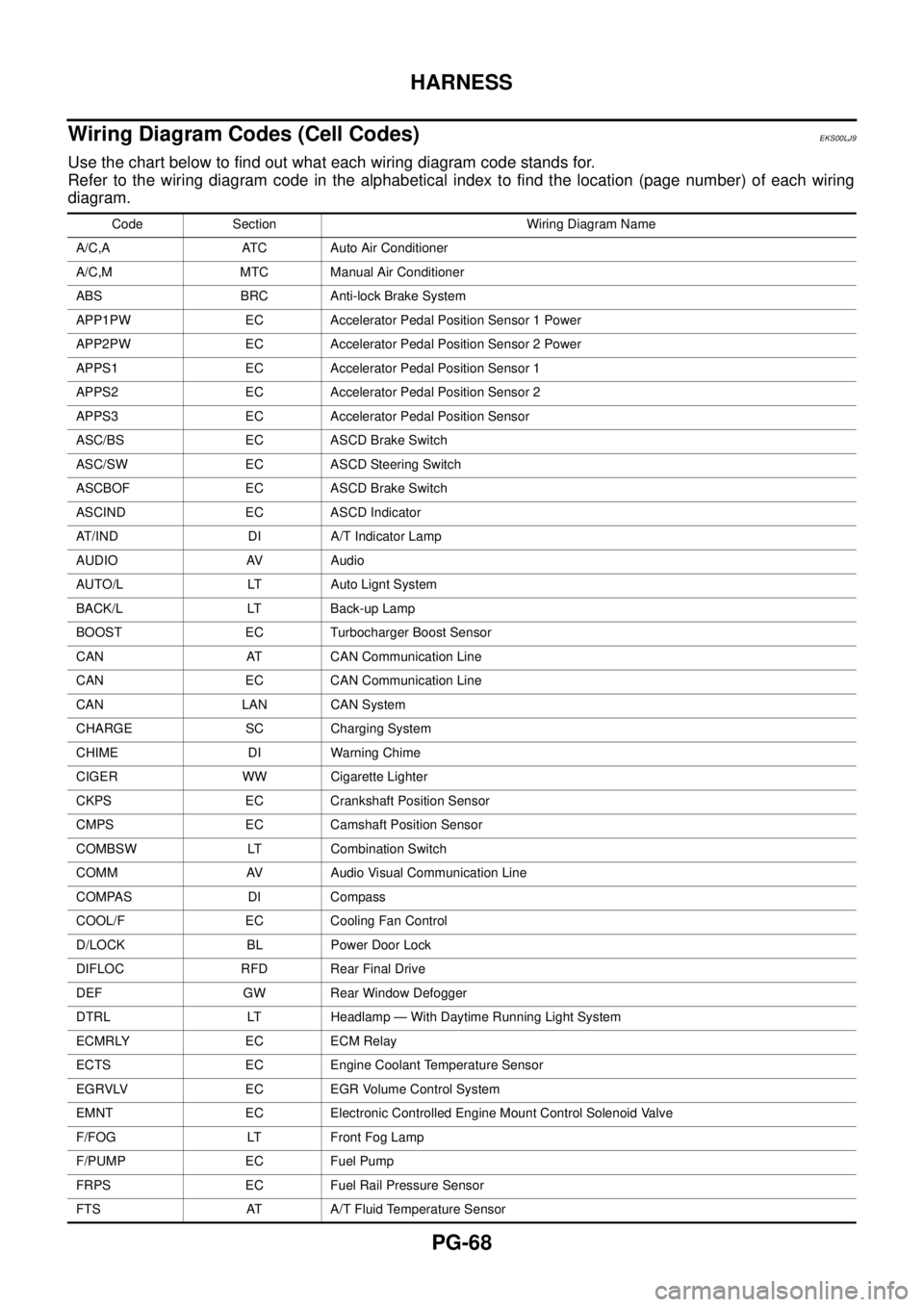

Wiring Diagram Codes (Cell Codes)

EKS00LJ9

Use the chart below to find out what each wiring diagram code stands for.

Refer to the wiring diagram code in the alphabetical index to find the location (page number) of each wiring

diagram.

Code Section Wiring Diagram Name

A/C,A ATC Auto Air Conditioner

A/C,M MTC Manual Air Conditioner

ABS BRC Anti-lock Brake System

APP1PW EC Accelerator Pedal Position Sensor 1 Power

APP2PW EC Accelerator Pedal Position Sensor 2 Power

APPS1 EC Accelerator Pedal Position Sensor 1

APPS2 EC Accelerator Pedal Position Sensor 2

APPS3 EC Accelerator Pedal Position Sensor

ASC/BS EC ASCD Brake Switch

ASC/SW EC ASCD Steering Switch

ASCBOF EC ASCD Brake Switch

ASCIND EC ASCD Indicator

AT/IND DI A/T Indicator Lamp

AUDIO AV Audio

AUTO/L LT Auto Lignt System

BACK/L LT Back-up Lamp

BOOST EC Turbocharger Boost Sensor

CAN AT CAN Communication Line

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

CIGER WW Cigarette Lighter

CKPS EC Crankshaft Position Sensor

CMPS EC Camshaft Position Sensor

COMBSW LT Combination Switch

COMM AV Audio Visual Communication Line

COMPAS DI Compass

COOL/F EC Cooling Fan Control

D/LOCK BL Power Door Lock

DIFLOC RFD Rear Final Drive

DEF GW Rear Window Defogger

DTRL LT Headlamp — With Daytime Running Light System

ECMRLY EC ECM Relay

ECTS EC Engine Coolant Temperature Sensor

EGRVLV EC EGR Volume Control System

EMNT EC Electronic Controlled Engine Mount Control Solenoid Valve

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

FRPS EC Fuel Rail Pressure Sensor

FTS AT A/T Fluid Temperature Sensor

Page 2670 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual AXLE SHAFT

RAX-7

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

AXLE SHAFTPFP:38164

Removal and InstallationEDS003HZ

1. Axle shaft 2. Grease catcher 3. Axle shaft retainer

4. Axle shaft seal lip 5. Axle shaft bear NISSAN NAVARA 2005 Repair Workshop Manual AXLE SHAFT

RAX-7

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

AXLE SHAFTPFP:38164

Removal and InstallationEDS003HZ

1. Axle shaft 2. Grease catcher 3. Axle shaft retainer

4. Axle shaft seal lip 5. Axle shaft bear](/img/5/57362/w960_57362-2669.png)

AXLE SHAFT

RAX-7

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

AXLE SHAFTPFP:38164

Removal and InstallationEDS003HZ

1. Axle shaft 2. Grease catcher 3. Axle shaft retainer

4. Axle shaft seal lip 5. Axle shaft bearing 6. Bearing ring retainer

7. Snap ring 8. ABS sensor rotor 9. Brake drum

MDIB9028E

Page 2672 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual AXLE SHAFT

RAX-9

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

INSPECTION AFTER REMOVAL

Axle Shaft Bearing and Cup

lCheck that the axle shaft bearing and cup roll freely and are free from noise, cracks, pitting a NISSAN NAVARA 2005 Repair Workshop Manual AXLE SHAFT

RAX-9

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

INSPECTION AFTER REMOVAL

Axle Shaft Bearing and Cup

lCheck that the axle shaft bearing and cup roll freely and are free from noise, cracks, pitting a](/img/5/57362/w960_57362-2671.png)

AXLE SHAFT

RAX-9

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

INSPECTION AFTER REMOVAL

Axle Shaft Bearing and Cup

lCheck that the axle shaft bearing and cup roll freely and are free from noise, cracks, pitting and wear.

Replace if necessary.

Axle Shaft Retainer

lCheck for deformation and cracks. Replace if necessary.

Rear Axle Case

lCheck the exterior and inner machined surfaces for deformation and cracks. Replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

When installing pay attention to following points:

lInstall a new shaft guide and a new oil seal into the rear axle case.

CAUTION:

lDo not reuse the axle oil seal. The axle oil seal must be replaced every time the axle shaft assem-

bly is removed from the axle shaft housing.

lWhen installing oil seals, apply multi-purpsose grease to oil seal lips.

lInstall four new lock nuts to secure the axle shaft assembly to the rear axle case, and tighten lock nuts to

the specified torque. Refer toRAX-7, "

Removal and Installation".

lReinstall the rear brake drum. Refer toBR-31, "Removal and Installation of Drum Brake Assembly".

lAdjust the differential gear oil level.

Refer toRFD-9, "

DIFFERENTIAL GEAR OIL", for M226 without LD.

Refer toRFD-9, "

DIFFERENTIAL GEAR OIL", for M226 with LD.

lReinstall the wheel. Refer toWT-5, "Rotation".

DISASSEMBLY

1. Remove the ABS sensor rotor. Refer toBRC-39, "SENSOR ROTOR".

2. Remove the snap ring from the axle shaft using a suitable snap ring pliers.

3. Secure the axle shaft in a suitable vise as shown, and use a

brass hammer to remove studs (4) from the axle shaft retainer.

CAUTION:

lMount the axle shaft using a soft jaw vise to avoid dam-

aging the axle shaft retainer.

MDIB9051E

Page 2674 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual AXLE SHAFT

RAX-11

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

INSPECTION AFTER DISASSEMBLY

Axle Shaft

lClean and remove all nicks and burrs.

lCheck for straightness and distortion. Replace if necessary.

lInspec NISSAN NAVARA 2005 Repair Workshop Manual AXLE SHAFT

RAX-11

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

INSPECTION AFTER DISASSEMBLY

Axle Shaft

lClean and remove all nicks and burrs.

lCheck for straightness and distortion. Replace if necessary.

lInspec](/img/5/57362/w960_57362-2673.png)

AXLE SHAFT

RAX-11

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

INSPECTION AFTER DISASSEMBLY

Axle Shaft

lClean and remove all nicks and burrs.

lCheck for straightness and distortion. Replace if necessary.

lInspect machined surfaces for evidence of overheating, damage and wear. Replace if necessary.

lMeasure the bearing ring retainer axle journal diameter. Replace if necessary.

ASSEMBLY

1. Install a new grease catcher onto the axle shaft.

2. Reinstall studs on the axle shaft retainer, and install the axle shaft retainer on the axle shaft.

3. Install a new seal lip onto the axle shaft.

CAUTION:

lSeal lip can not be reused. Do not attempt to reuse it.

lWhen installing oil seals, apply multi-purpose grease to oil seal lips.

4. Install a new bearing on the axle shaft.

CAUTION:

lWheel bearing can not be reused. Do not attempt to reuse it.

5. Using a bearing inserter, and a suitable press, press fit the axle

shaft to the new bearing ring retainer, until the snap ring groove.

CAUTION:

lMake sure the bearing ring retainer, axle shaft bearing,

axle shaft lip seal, and axle shaft retainer are installed

facing in the correct direction.

lBearing ring retainer can not be reused. Do not attempt to

reuse it.

6. Apply grease to the bearing cup, and install onto the axle shaft

bearing.

7. Install a new snap ring using a suitable snap ring pliers.

CAUTION:

Discard the old snap ring: replace with new ones.

8. Install the new ABS rotor sensor. Refer toBRC-39, "

SENSOR ROTOR".

CAUTION:

Discard the old sensor rotor; replace with a new one.Bearing ring retainer axle journal diameter (minimum)

: 45.027 mm (1.7727 in)

MDIB9047E

Page 2705 of 3171

RFD-2

DIFFERENTIAL LOCK CONTROL UNIT ............ 42

DIFFERENTIAL LOCK MODE SWITCH ............. 42

DIFF LOCK INDICATOR LAMP ........................... 42

System Diagram ..................................................... 43

COMPONENTS FUNCTION DESCRIPTION ...... 43

CAN Communication .............................................. 43

SYSTEM DESCRIPTION .................................... 43

TROUBLE DIAGNOSIS ............................................ 44

Fail-safe Function ................................................... 44

How to Perform Trouble Diagnosis ......................... 44

BASIC CONCEPT ............................................... 44

Location of Electrical Parts ..................................... 45

Wiring Diagram — DIFLOC — ................................ 46

Trouble Diagnosis Chart for Symptoms .................. 48

Differential Lock Control Unit Input/Output Signal

Reference Values ................................................... 48

DIFFERENTIAL LOCK CONTROL UNIT

INSPECTION TABLE .......................................... 48

CONSULT-II Function (DIFF LOCK) ....................... 50

FUNCTION .......................................................... 50

CONSULT-II SETTING PROCEDURE ................ 50

SELF-DIAG RESULTS MODE ............................. 51

DATA MONITOR MODE ...................................... 53

TROUBLE DIAGNOSIS FOR SYSTEM .................... 54

Power Supply Circuit For Differential Lock Control

Unit ......................................................................... 54

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 54

DIFFERENTIAL LOCK CONTROL UNIT TER-

MINALS AND REFERENCE VALUE ................... 54

DIAGNOSTIC PROCEDURE .............................. 55

Differential Lock Control Unit .................................. 56

DIAGNOSTIC PROCEDURE .............................. 56

Differential Lock Mode Switch ................................ 56

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 56

DIFFERENTIAL LOCK CONTROL UNIT TER-

MINALS AND REFERENCE VALUE ................... 56

DIAGNOSTIC PROCEDURE .............................. 57

COMPONENT INSPECTION .............................. 59

Differential Lock Position Switch ............................. 60

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 60

DIFFERENTIAL CONTROL UNIT TERMINALS

AND REFERENCE VALUE ................................. 60

DIAGNOSTIC PROCEDURE .............................. 61

COMPONENT INSPECTION .............................. 63

Differential Lock Solenoid Relay ............................. 63

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 63DIAGNOSTIC PROCEDURE ............................... 63

Differential Lock Solenoid ....................................... 64

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 64

DIFFERENTIAL LOCK CONTROL UNIT TER-

MINALS AND REFERENCE VALUE ................... 64

DIAGNOSTIC PROCEDURE ............................... 65

COMPONENT INSPECTION ............................... 68

ABS System ............................................................ 68

DIAGNOSTIC PROCEDURE ............................... 68

CAN Communication Line ....................................... 69

DIAGNOSTIC PROCEDURE ............................... 69

TROUBLE DIAGNOSIS FOR SYMPTOMS .............. 70

DIFF LOCK Indicator Lamp Does Not Turn ON ...... 70

DIAGNOSTIC PROCEDURE ............................... 70

DIFF LOCK Indicator Lamp Does Not Change ....... 73

DIAGNOSTIC PROCEDURE ............................... 73

DIFF LOCK Indicator Lamp Sometimes Flashes .... 74

DIAGNOSTIC PROCEDURE ............................... 74

DIFFERENTIAL LOCK CONTROL UNIT .................. 76

Removal and Installation ......................................... 76

REMOVAL ............................................................ 76

INSTALLATION .................................................... 76

FRONT OIL SEAL ..................................................... 77

Removal and Installation ......................................... 77

REMOVAL ............................................................ 77

INSTALLATION .................................................... 78

CARRIER COVER ..................................................... 80

Removal and Installation ......................................... 80

REMOVAL ............................................................ 80

INSTALLATION .................................................... 80

REAR FINAL DRIVE ASSEMBLY ............................. 81

Removal and Installation ......................................... 81

REMOVAL ............................................................ 81

INSTALLATION .................................................... 81

Disassembly and Assembly .................................... 82

COMPONENTS ................................................... 82

ASSEMBLY INSPECTION AND ADJUSTMENT...83

DISASSEMBLY .................................................... 86

INSPECTION AFTER DISASSEMBLY ................ 90

SELECTION ADJUSTING WASHERS ................ 90

ASSEMBLY .......................................................... 91

SERVICE DATA AND SPECIFICATIONS (SDS) ....100

General Specifications ..........................................100

Inspection and Adjustment ....................................100

PRELOAD TORQUE .........................................100

BACKLASH ........................................................100

COMPANION FLANGE RUNOUT .....................100

SELECTIVE PARTS ..........................................101

Page 2717 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-14

[WITH LIMITED SLIP DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

REAR FINAL DRIVE ASSEMBLY

PFP:38300

Removal and InstallationEDS00398

REMOVAL

1. Remove the rear propeller shaft. Refer toPR-8, "Remova NISSAN NAVARA 2005 Repair Workshop Manual RFD-14

[WITH LIMITED SLIP DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

REAR FINAL DRIVE ASSEMBLY

PFP:38300

Removal and InstallationEDS00398

REMOVAL

1. Remove the rear propeller shaft. Refer toPR-8, "Remova](/img/5/57362/w960_57362-2716.png)

RFD-14

[WITH LIMITED SLIP DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

REAR FINAL DRIVE ASSEMBLY

PFP:38300

Removal and InstallationEDS00398

REMOVAL

1. Remove the rear propeller shaft. Refer toPR-8, "Removal and Installation".

lPlug rear end of transmission or transfer.

2. Remove the axle shafts and back plate and torque members. Refer toRAX-7, "

Removal and Installation".

3. Disconnect the following components from the rear final drive.

lABS sensor wire harness

lRear cable (LH) and rear cable (RH)

lBrake hoses and brake tube

CAUTION:

Position the wire harness, cable and hoses away from the final drive assembly. Failure to do so

may result in components being damaged during rear axle assembly removal.

4. Support the rear final drive using a suitable jack.

5. Remove rear shock absorber lower bolts. Refer toRSU-6, "

Removal and Installation".

6. Remove leaf spring U-bolt nuts. Refer toRSU-7, "

Removal and Installation".

WARNING:

Support the rear final drive assembly using suitable jack before removing leaf spring U-bolt nuts.

7. Remove rear final drive assembly using suitable jack.

INSTALLATION

Installation is the reverse order of removal.

lWhen oil leaks while removing rear final drive assembly, check oil level after the installation. Refer to

RFD-9, "

Checking Differential Gear Oil".

lRefill brake fluid and bleed the air from the brake system. Refer toBR-11, "Bleeding Brake System".

Page 2746 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual DIFFERENTIAL LOCK SYSTEM

RFD-43

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

System DiagramEDS003AS

COMPONENTS FUNCTION DESCRIPTION

CAN CommunicationEDS003AT

SYSTEM DESCRIPTION

CA NISSAN NAVARA 2005 Repair Workshop Manual DIFFERENTIAL LOCK SYSTEM

RFD-43

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

System DiagramEDS003AS

COMPONENTS FUNCTION DESCRIPTION

CAN CommunicationEDS003AT

SYSTEM DESCRIPTION

CA](/img/5/57362/w960_57362-2745.png)

DIFFERENTIAL LOCK SYSTEM

RFD-43

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

System DiagramEDS003AS

COMPONENTS FUNCTION DESCRIPTION

CAN CommunicationEDS003AT

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

For details, refer toDI-65, "

CAN Communication Unit".

SDIA2500E

Component parts Function

Differential lock control unit

lControls differential lock solenoid and switches differential lock/unlock.

lAs a fail-safe function, differential lock disengages, if malfunction is detected in differential lock

system.

Differential lock solenoid Controls pressure plate by current from differential lock control unit.

Differential lock position switch Detects that differential is lock or unlock condition.

Differential lock mode switch Able to select differential lock or unlock.

DIFF LOCK indicator lamp Illuminates that differential is in lock or lock standby condition.

ABS actuator and electric unit

(control unit)Transmits the following signals via CAN communication to differential lock control unit.

lVehicle speed signal

Transfer control unitTransmits the following signal via CAN communication to differential lock control unit.

l4WD shift switch signal

Page 2755 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-52

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS

CAUTION:

If “CAN COMM CIRCUIT [U1000]” is displayed with other DTCs, first perform the trouble diagnosis for CAN communication

line. NISSAN NAVARA 2005 Repair Workshop Manual RFD-52

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS

CAUTION:

If “CAN COMM CIRCUIT [U1000]” is displayed with other DTCs, first perform the trouble diagnosis for CAN communication

line.](/img/5/57362/w960_57362-2754.png)

RFD-52

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS

CAUTION:

If “CAN COMM CIRCUIT [U1000]” is displayed with other DTCs, first perform the trouble diagnosis for CAN communication

line.

How to Erase Self-diagnostic Results

1. Perform applicable inspection of malfunctioning item and then repair or replace.

2. Start engine and select “SELF-DIAG RESULTS” mode for “DIFF LOCK” with CONSULT-II.

3. Touch “ERASE” on CONSULT-II screen to erase DTC memory.

CAUTION:

If memory cannot be erased, perform diagnosis.

POSI SW ON

[P1839]When differential lock position switch is ON, rotation difference

occurs in wheel speed (rear wheel right and left).RFD-60, "Differential Lock Posi-

tion Switch"

RELAY

[P1844]Differential lock control unit detects as irregular by comparing target

value with monitor value.RFD-63, "Differential Lock Sole-

noid Relay",RFD-64, "Differen-

tial Lock Solenoid"

SOL CIRCUIT

[P1847]Malfunction is detected in differential lock control unit internal circuit.RFD-64, "Differential Lock Sole-

noid"

SOL DISCONNECT

[P1848]lDifferential lock solenoid internal circuit or harness is open.

lDifferential lock solenoid relay does not switch to ON position.RFD-64, "

Differential Lock Sole-

noid"

SOL SHORT

[P1849]Differential lock solenoid internal circuit or harness is shorted.RFD-64, "Differential Lock Sole-

noid"

SOL CURRENT

[P1850]Differential lock solenoid relay does not switch to OFF position.RFD-64, "Differential Lock Sole-

noid"

ABS SYSTEM

[C1203]Malfunction related to wheel sensor has been detected by ABS

actuator and electric unit (control unit).RFD-68, "ABS System"

CAN COMM CIRCUIT

[U1000]Malfunction has been detected from CAN communication line.RFD-69, "CAN Communication

Line"

NO DTC IS DETECTED.

FURTHER TESTING MAY

BE REQUIRED.No NG item has been detected. — Items (CONSULT-II screen

terms)Diagnostic item is detected when... Check item

Page 2771 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-68

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYSTEM

COMPONENT INSPECTION

1. Turn ignition switch “OFF”.

2. Disconnect differential lock solenoid harness connector.

3. Check NISSAN NAVARA 2005 Repair Workshop Manual RFD-68

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYSTEM

COMPONENT INSPECTION

1. Turn ignition switch “OFF”.

2. Disconnect differential lock solenoid harness connector.

3. Check](/img/5/57362/w960_57362-2770.png)

RFD-68

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYSTEM

COMPONENT INSPECTION

1. Turn ignition switch “OFF”.

2. Disconnect differential lock solenoid harness connector.

3. Check resistance between differential lock solenoid harness

connector C23 terminals 1 and 2.

4. If NG, replace differential lock solenoid. Refer toRFD-86, "

Differ-

ential Assembly".

5. Check operation by applying battery voltage to differential lock

solenoid harness connector terminals.

CAUTION:

Be sure to apply the voltage of the correct polarity to the

respective terminals. Otherwise, the part may be damaged.

6. If NG, replace differential lock solenoid.

ABS SystemEDS003B7

DIAGNOSTIC PROCEDURE

1.CHECK DTC WITH ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

Perform self-diagnosis with ABS actuator and electric unit (control unit). Refer toBRC-18, "

Self-Diagnosis".

Is any malfunction detected by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 2.

2.CHECK DIFFERENTIAL LOCK CONTROL UNIT

Check differential lock control unit input/output signal. Refer toRFD-48, "

Differential Lock Control Unit Input/

Output Signal Reference Values".

OK or NG

OK >> GO TO 3.

NG >> Check differential lock control unit pin terminals for damage or loose connection with harness con-

nector. If any items are damaged, repair or replace damaged parts.

3.CHECK DTC

Perform the self-diagnosis, after driving the vehicle for a while.

OK or NG

OK >>INSPECTION END

NG >> Perform self-diagnosis with ABS actuator and electric unit (control unit) again. Refer toBRC-18,

"Self-Diagnosis". 1-2 :Approx.3.4W

SDIA3431E

Connector Terminal

C23 1 (Battery voltage) - 2 (Ground)

SDIA3432E