ABS NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2898 of 3171

FRONT SEAT

SE-27

C

D

E

F

G

H

J

K

L

MA

B

SE

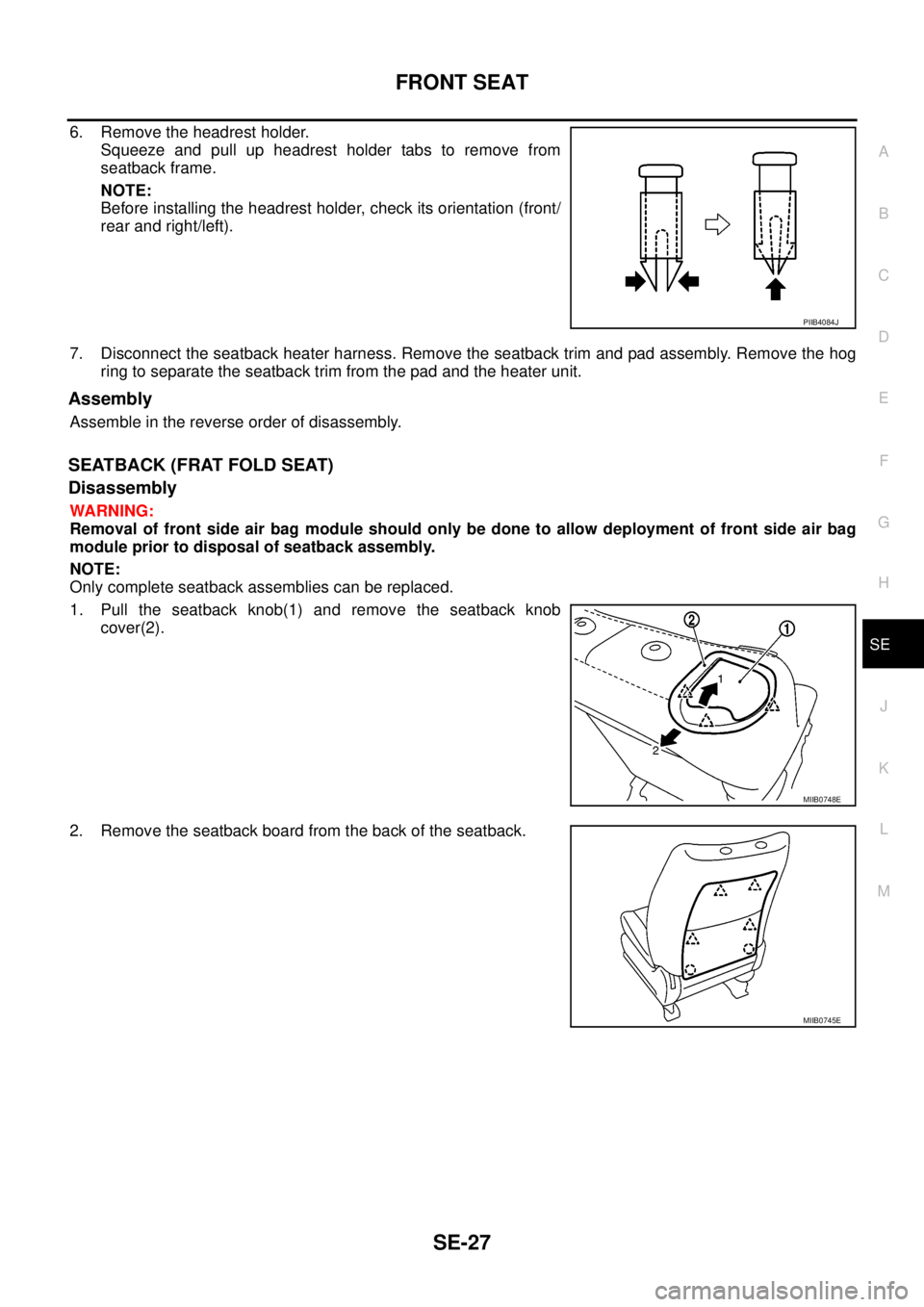

6. Remove the headrest holder.

Squeeze and pull up headrest holder tabs to remove from

seatback frame.

NOTE:

Before installing the headrest holder, check its orientation (front/

rear and right/left).

7. Disconnect the seatback heater harness. Remove the seatback trim and pad assembly. Remove the hog

ring to separate the seatback trim from the pad and the heater unit.

Assembly

Assemble in the reverse order of disassembly.

SEATBACK (FRAT FOLD SEAT)

Disassembly

WARNING:

Removal of front side air bag module should only be done to allow deployment of front side air bag

module prior to disposal of seatback assembly.

NOTE:

Only complete seatback assemblies can be replaced.

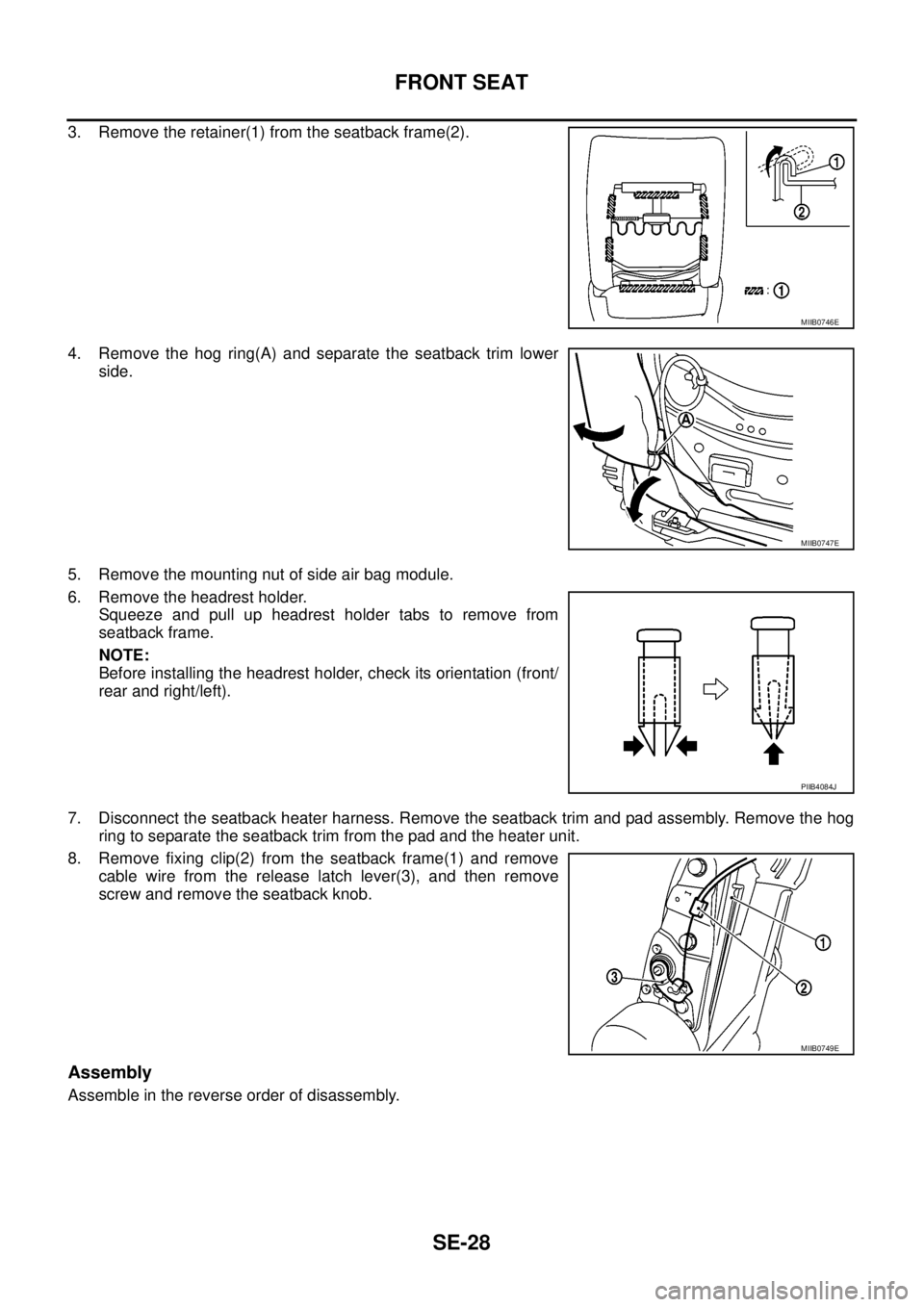

1. Pull the seatback knob(1) and remove the seatback knob

cover(2).

2. Remove the seatback board from the back of the seatback.

PIIB4084J

MIIB0748E

MIIB0745E

Page 2899 of 3171

SE-28

FRONT SEAT

3. Remove the retainer(1) from the seatback frame(2).

4. Remove the hog ring(A) and separate the seatback trim lower

side.

5. Remove the mounting nut of side air bag module.

6. Remove the headrest holder.

Squeeze and pull up headrest holder tabs to remove from

seatback frame.

NOTE:

Before installing the headrest holder, check its orientation (front/

rear and right/left).

7. Disconnect the seatback heater harness. Remove the seatback trim and pad assembly. Remove the hog

ring to separate the seatback trim from the pad and the heater unit.

8. Remove fixing clip(2) from the seatback frame(1) and remove

cablewirefromthereleaselatchlever(3),andthenremove

screw and remove the seatback knob.

Assembly

Assemble in the reverse order of disassembly.

MIIB0746E

MIIB0747E

PIIB4084J

MIIB0749E

Page 2947 of 3171

SRS-38

SPIRAL CABLE

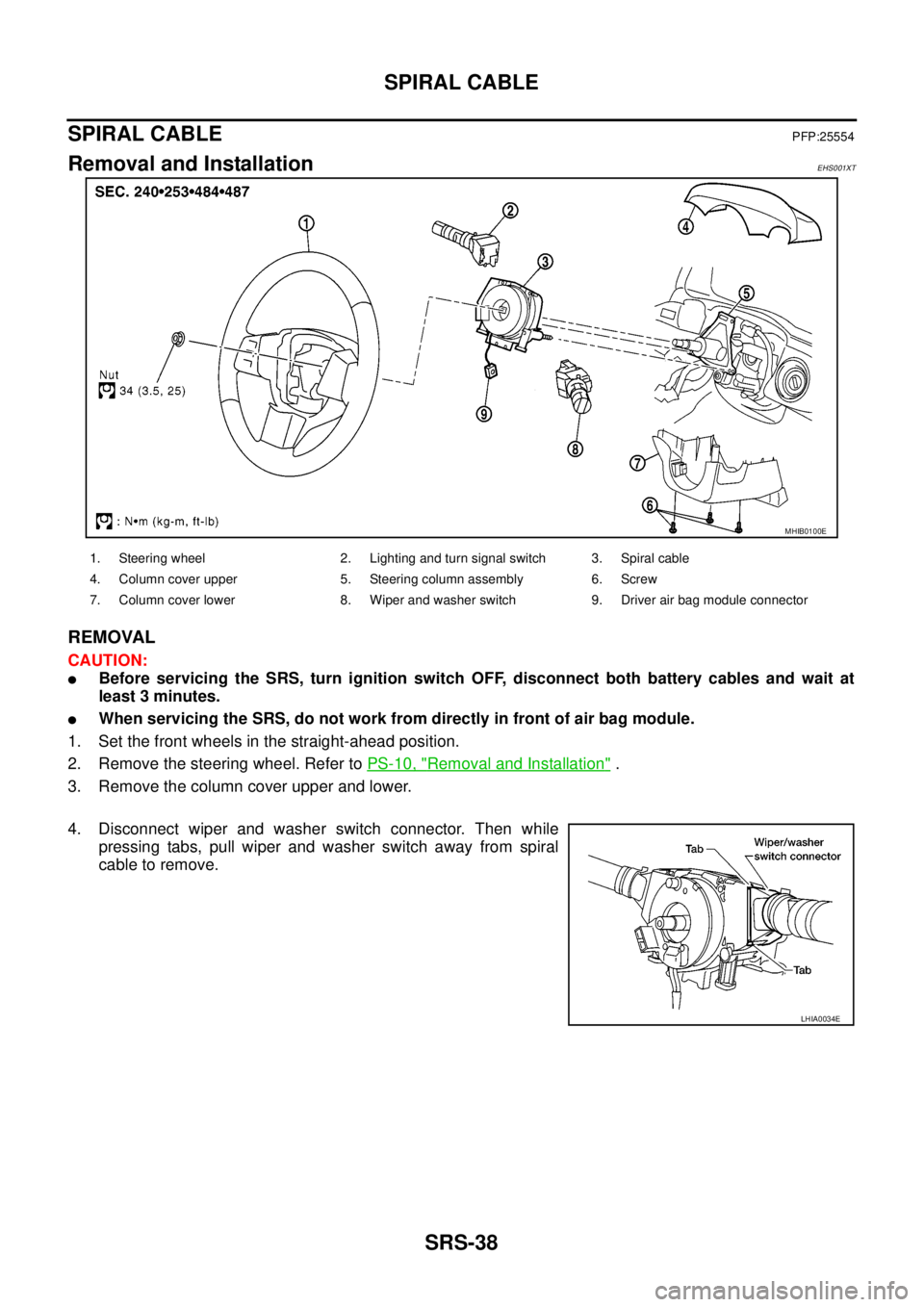

SPIRAL CABLE

PFP:25554

Removal and InstallationEHS001XT

REMOVAL

CAUTION:

lBefore servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at

least 3 minutes.

lWhen servicing the SRS, do not work from directly in front of air bag module.

1. Set the front wheels in the straight-ahead position.

2. Remove the steering wheel. Refer toPS-10, "

Removal and Installation".

3. Remove the column cover upper and lower.

4. Disconnect wiper and washer switch connector. Then while

pressing tabs, pull wiper and washer switch away from spiral

cable to remove.

MHIB0100E

1. Steering wheel 2. Lighting and turn signal switch 3. Spiral cable

4. Column cover upper 5. Steering column assembly 6. Screw

7. Column cover lower 8. Wiper and washer switch 9. Driver air bag module connector

LHIA0034E

Page 2948 of 3171

SPIRAL CABLE

SRS-39

C

D

E

F

G

I

J

K

L

MA

B

SRS

5. Disconnect lighting and turn signal switch connector. Then while

pressing tabs, pull lighting and turn signal switch toward driver

door to remove.

6. Remove the screws. Then while pressing the tab, pull the spiral

cable away from steering column assembly.

CAUTION:

lDo not disassemble spiral cable.

lDo not apply lubricant to the spiral cable.

7. Disconnect the spiral cable connectors.

CAUTION:

With the steering linkage disconnected, the spiral cable

may snap by turning the steering wheel beyond the limited

number of turns. The spiral cable can be turned counter-

clockwise about 2.5 turns from the right end position.

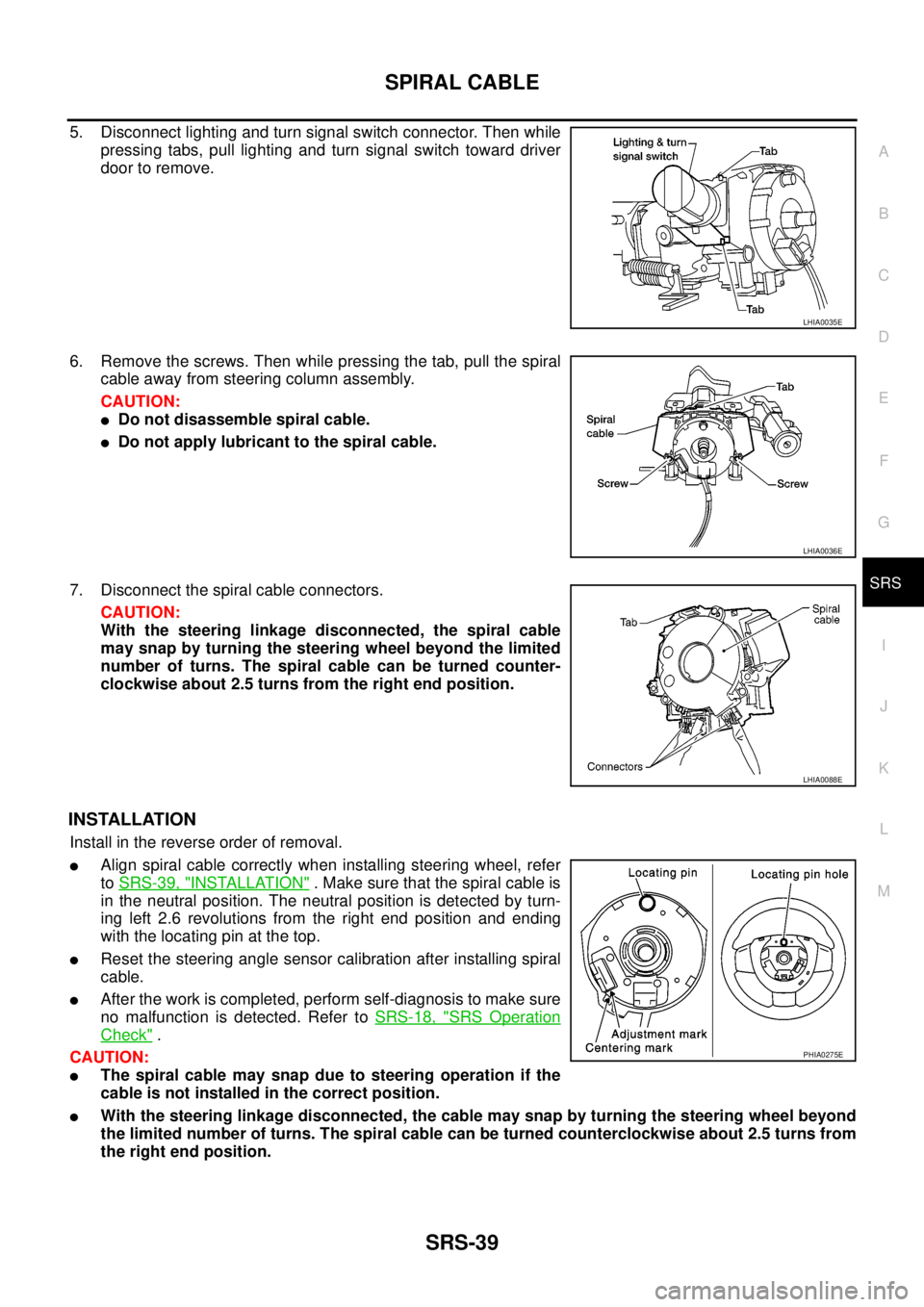

INSTALLATION

Install in the reverse order of removal.

lAlign spiral cable correctly when installing steering wheel, refer

toSRS-39, "

INSTALLATION". Make sure that the spiral cable is

in the neutral position. The neutral position is detected by turn-

ing left 2.6 revolutions from the right end position and ending

with the locating pin at the top.

lReset the steering angle sensor calibration after installing spiral

cable.

lAfter the work is completed, perform self-diagnosis to make sure

no malfunction is detected. Refer toSRS-18, "

SRS Operation

Check".

CAUTION:

lThe spiral cable may snap due to steering operation if the

cable is not installed in the correct position.

lWith the steering linkage disconnected, the cable may snap by turning the steering wheel beyond

the limited number of turns. The spiral cable can be turned counterclockwise about 2.5 turns from

the right end position.

LHIA0035E

LHIA0036E

LHIA0088E

PHIA0275E

Page 2969 of 3171

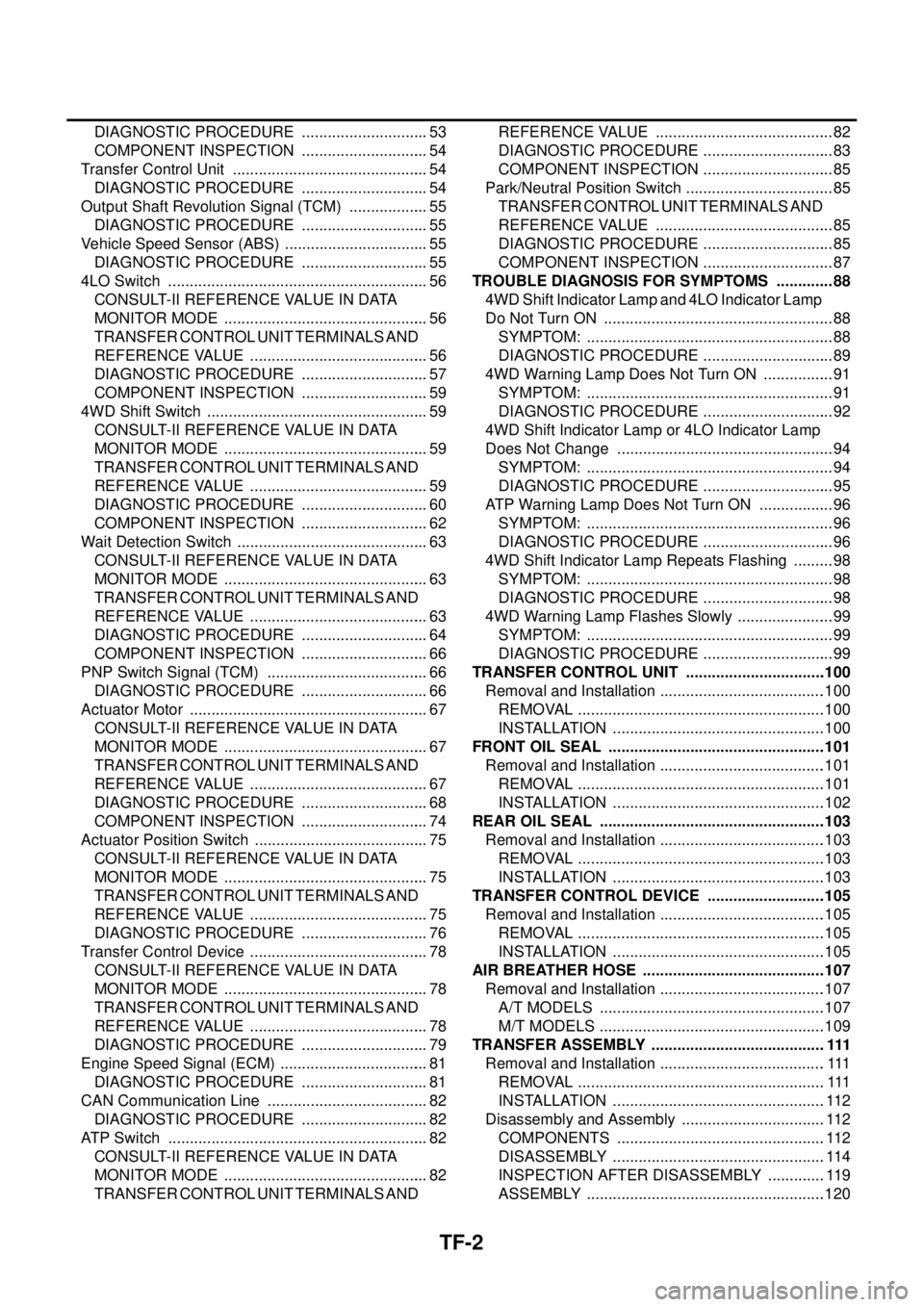

TF-2

DIAGNOSTIC PROCEDURE .............................. 53

COMPONENT INSPECTION .............................. 54

Transfer Control Unit .............................................. 54

DIAGNOSTIC PROCEDURE .............................. 54

Output Shaft Revolution Signal (TCM) ................... 55

DIAGNOSTIC PROCEDURE .............................. 55

Vehicle Speed Sensor (ABS) .................................. 55

DIAGNOSTIC PROCEDURE .............................. 55

4LO Switch ............................................................. 56

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 56

TRANSFER CONTROL UNIT TERMINALS AND

REFERENCE VALUE .......................................... 56

DIAGNOSTIC PROCEDURE .............................. 57

COMPONENT INSPECTION .............................. 59

4WD Shift Switch .................................................... 59

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 59

TRANSFER CONTROL UNIT TERMINALS AND

REFERENCE VALUE .......................................... 59

DIAGNOSTIC PROCEDURE .............................. 60

COMPONENT INSPECTION .............................. 62

Wait Detection Switch ............................................. 63

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 63

TRANSFER CONTROL UNIT TERMINALS AND

REFERENCE VALUE .......................................... 63

DIAGNOSTIC PROCEDURE .............................. 64

COMPONENT INSPECTION .............................. 66

PNP Switch Signal (TCM) ...................................... 66

DIAGNOSTIC PROCEDURE .............................. 66

Actuator Motor ........................................................ 67

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 67

TRANSFER CONTROL UNIT TERMINALS AND

REFERENCE VALUE .......................................... 67

DIAGNOSTIC PROCEDURE .............................. 68

COMPONENT INSPECTION .............................. 74

Actuator Position Switch ......................................... 75

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 75

TRANSFER CONTROL UNIT TERMINALS AND

REFERENCE VALUE .......................................... 75

DIAGNOSTIC PROCEDURE .............................. 76

Transfer Control Device .......................................... 78

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 78

TRANSFER CONTROL UNIT TERMINALS AND

REFERENCE VALUE .......................................... 78

DIAGNOSTIC PROCEDURE .............................. 79

Engine Speed Signal (ECM) ................................... 81

DIAGNOSTIC PROCEDURE .............................. 81

CAN Communication Line ...................................... 82

DIAGNOSTIC PROCEDURE .............................. 82

ATP Switch ............................................................. 82

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 82

TRANSFER CONTROL UNIT TERMINALS ANDREFERENCE VALUE .......................................... 82

DIAGNOSTIC PROCEDURE ............................... 83

COMPONENT INSPECTION ............................... 85

Park/Neutral Position Switch ................................... 85

TRANSFER CONTROL UNIT TERMINALS AND

REFERENCE VALUE .......................................... 85

DIAGNOSTIC PROCEDURE ............................... 85

COMPONENT INSPECTION ............................... 87

TROUBLE DIAGNOSIS FOR SYMPTOMS .............. 88

4WD Shift Indicator Lamp and 4LO Indicator Lamp

Do Not Turn ON ...................................................... 88

SYMPTOM: .......................................................... 88

DIAGNOSTIC PROCEDURE ............................... 89

4WD Warning Lamp Does Not Turn ON ................. 91

SYMPTOM: .......................................................... 91

DIAGNOSTIC PROCEDURE ............................... 92

4WD Shift Indicator Lamp or 4LO Indicator Lamp

Does Not Change ................................................... 94

SYMPTOM: .......................................................... 94

DIAGNOSTIC PROCEDURE ............................... 95

ATP Warning Lamp Does Not Turn ON .................. 96

SYMPTOM: .......................................................... 96

DIAGNOSTIC PROCEDURE ............................... 96

4WD Shift Indicator Lamp Repeats Flashing .......... 98

SYMPTOM: .......................................................... 98

DIAGNOSTIC PROCEDURE ............................... 98

4WD Warning Lamp Flashes Slowly ....................... 99

SYMPTOM: .......................................................... 99

DIAGNOSTIC PROCEDURE ............................... 99

TRANSFER CONTROL UNIT .................................100

Removal and Installation .......................................100

REMOVAL ..........................................................100

INSTALLATION ..................................................100

FRONT OIL SEAL ...................................................101

Removal and Installation .......................................101

REMOVAL ..........................................................101

INSTALLATION ..................................................102

REAR OIL SEAL .....................................................103

Removal and Installation .......................................103

REMOVAL ..........................................................103

INSTALLATION ..................................................103

TRANSFER CONTROL DEVICE ............................105

Removal and Installation .......................................105

REMOVAL ..........................................................105

INSTALLATION ..................................................105

AIR BREATHER HOSE ...........................................107

Removal and Installation .......................................107

A/T MODELS .....................................................107

M/T MODELS .....................................................109

TRANSFER ASSEMBLY ......................................... 111

Removal and Installation ....................................... 111

REMOVAL .......................................................... 111

INSTALLATION ..................................................112

Disassembly and Assembly ..................................112

COMPONENTS .................................................112

DISASSEMBLY ..................................................114

INSPECTION AFTER DISASSEMBLY ..............119

ASSEMBLY ........................................................120

Page 2984 of 3171

4WD SYSTEM

TF-17

C

E

F

G

H

I

J

K

L

MA

B

TF

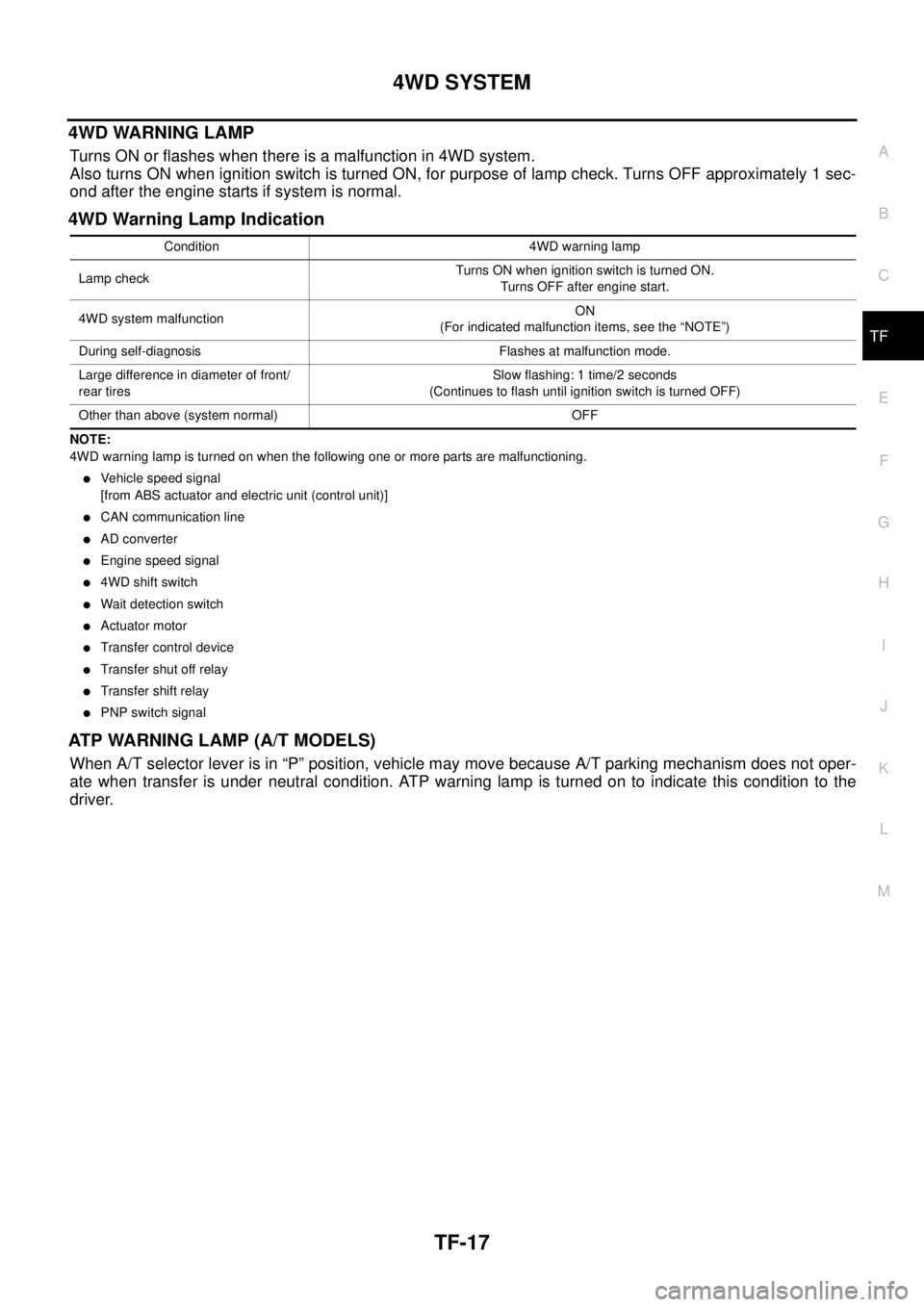

4WD WARNING LAMP

Turns ON or flashes when there is a malfunction in 4WD system.

Also turns ON when ignition switch is turned ON, for purpose of lamp check. Turns OFF approximately 1 sec-

ond after the engine starts if system is normal.

4WD Warning Lamp Indication

NOTE:

4WD warning lamp is turned on when the following one or more parts are malfunctioning.

lVehicle speed signal

[from ABS actuator and electric unit (control unit)]

lCAN communication line

lAD converter

lEngine speed signal

l4WD shift switch

lWait detection switch

lActuator motor

lTransfer control device

lTransfer shut off relay

lTransfer shift relay

lPNP switch signal

ATP WARNING LAMP (A/T MODELS)

When A/T selector lever is in “P” position, vehicle may move because A/T parking mechanism does not oper-

ate when transfer is under neutral condition. ATP warning lamp is turned on to indicate this condition to the

driver.

Condition 4WD warning lamp

Lamp checkTurns ON when ignition switch is turned ON.

Turns OFF after engine start.

4WD system malfunctionON

(For indicated malfunction items, see the “NOTE”)

During self-diagnosis Flashes at malfunction mode.

Large difference in diameter of front/

rear tiresSlow flashing: 1 time/2 seconds

(Continues to flash until ignition switch is turned OFF)

Other than above (system normal) OFF

Page 2985 of 3171

TF-18

4WD SYSTEM

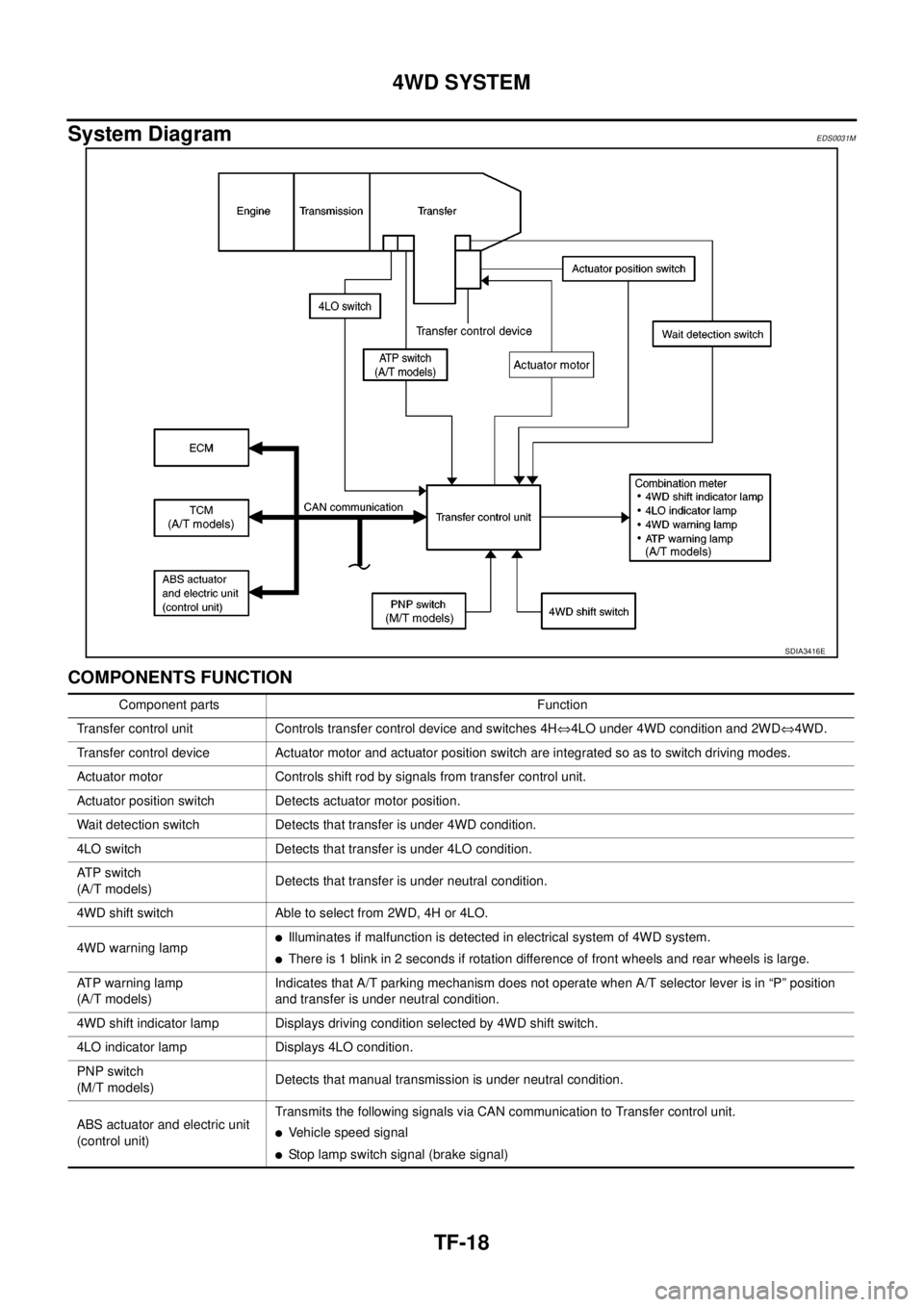

System Diagram

EDS0031M

COMPONENTS FUNCTION

SDIA3416E

Component parts Function

Transfer control unit Controls transfer control device and switches 4HÛ4LO under 4WD condition and 2WDÛ4WD.

Transfer control device Actuator motor and actuator position switch are integrated so as to switch driving modes.

Actuator motor Controls shift rod by signals from transfer control unit.

Actuator position switch Detects actuator motor position.

Wait detection switch Detects that transfer is under 4WD condition.

4LO switch Detects that transfer is under 4LO condition.

AT P s w i t c h

(A/T models)Detects that transfer is under neutral condition.

4WD shift switch Able to select from 2WD, 4H or 4LO.

4WD warning lamp

lIlluminates if malfunction is detected in electrical system of 4WD system.

lThere is 1 blink in 2 seconds if rotation difference of front wheels and rear wheels is large.

ATP warning lamp

(A/T models)Indicates that A/T parking mechanism does not operate when A/T selector lever is in “P” position

and transfer is under neutral condition.

4WD shift indicator lamp Displays driving condition selected by 4WD shift switch.

4LO indicator lamp Displays 4LO condition.

PNP switch

(M/T models)Detects that manual transmission is under neutral condition.

ABS actuator and electric unit

(control unit)Transmits the following signals via CAN communication to Transfer control unit.

lVehicle speed signal

lStop lamp switch signal (brake signal)

Page 3012 of 3171

TROUBLE DIAGNOSIS

TF-45

C

E

F

G

H

I

J

K

L

MA

B

TF

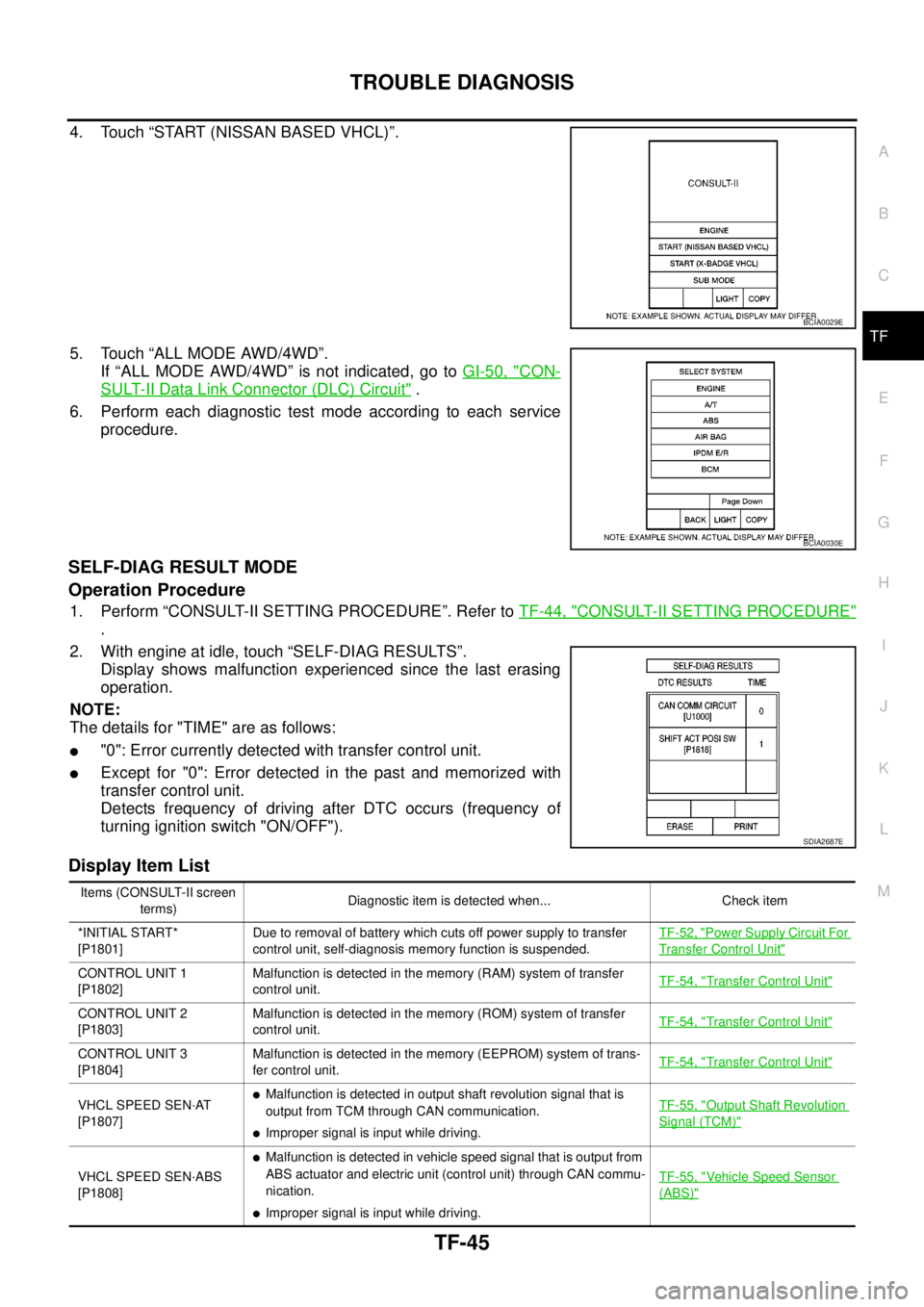

4. Touch “START (NISSAN BASED VHCL)”.

5. Touch “ALL MODE AWD/4WD”.

If “ALL MODE AWD/4WD” is not indicated, go toGI-50, "

CON-

SULT-II Data Link Connector (DLC) Circuit".

6. Perform each diagnostic test mode according to each service

procedure.

SELF-DIAG RESULT MODE

Operation Procedure

1. Perform “CONSULT-II SETTING PROCEDURE”. Refer toTF-44, "CONSULT-II SETTING PROCEDURE"

.

2. With engine at idle, touch “SELF-DIAG RESULTS”.

Display shows malfunction experienced since the last erasing

operation.

NOTE:

The details for "TIME" are as follows:

l"0": Error currently detected with transfer control unit.

lExcept for "0": Error detected in the past and memorized with

transfer control unit.

Detects frequency of driving after DTC occurs (frequency of

turning ignition switch "ON/OFF").

Display Item List

BCIA0029E

BCIA0030E

SDIA2687E

Items (CONSULT-II screen

terms)Diagnostic item is detected when... Check item

*INITIAL START*

[P1801]Due to removal of battery which cuts off power supply to transfer

control unit, self-diagnosis memory function is suspended.TF-52, "

Power Supply Circuit For

Transfer Control Unit"

CONTROL UNIT 1

[P1802]Malfunction is detected in the memory (RAM) system of transfer

control unit.TF-54, "Transfer Control Unit"

CONTROL UNIT 2

[P1803]Malfunction is detected in the memory (ROM) system of transfer

control unit.TF-54, "Transfer Control Unit"

CONTROL UNIT 3

[P1804]Malfunction is detected in the memory (EEPROM) system of trans-

fer control unit.TF-54, "Transfer Control Unit"

VHCL SPEED SEN·AT

[P1807]lMalfunction is detected in output shaft revolution signal that is

output from TCM through CAN communication.

lImproper signal is input while driving.TF-55, "

Output Shaft Revolution

Signal (TCM)"

VHCL SPEED SEN·ABS

[P1808]

lMalfunction is detected in vehicle speed signal that is output from

ABS actuator and electric unit (control unit) through CAN commu-

nication.

lImproper signal is input while driving.TF-55, "

Vehicle Speed Sensor

(ABS)"

Page 3014 of 3171

TROUBLE DIAGNOSIS

TF-47

C

E

F

G

H

I

J

K

L

MA

B

TF

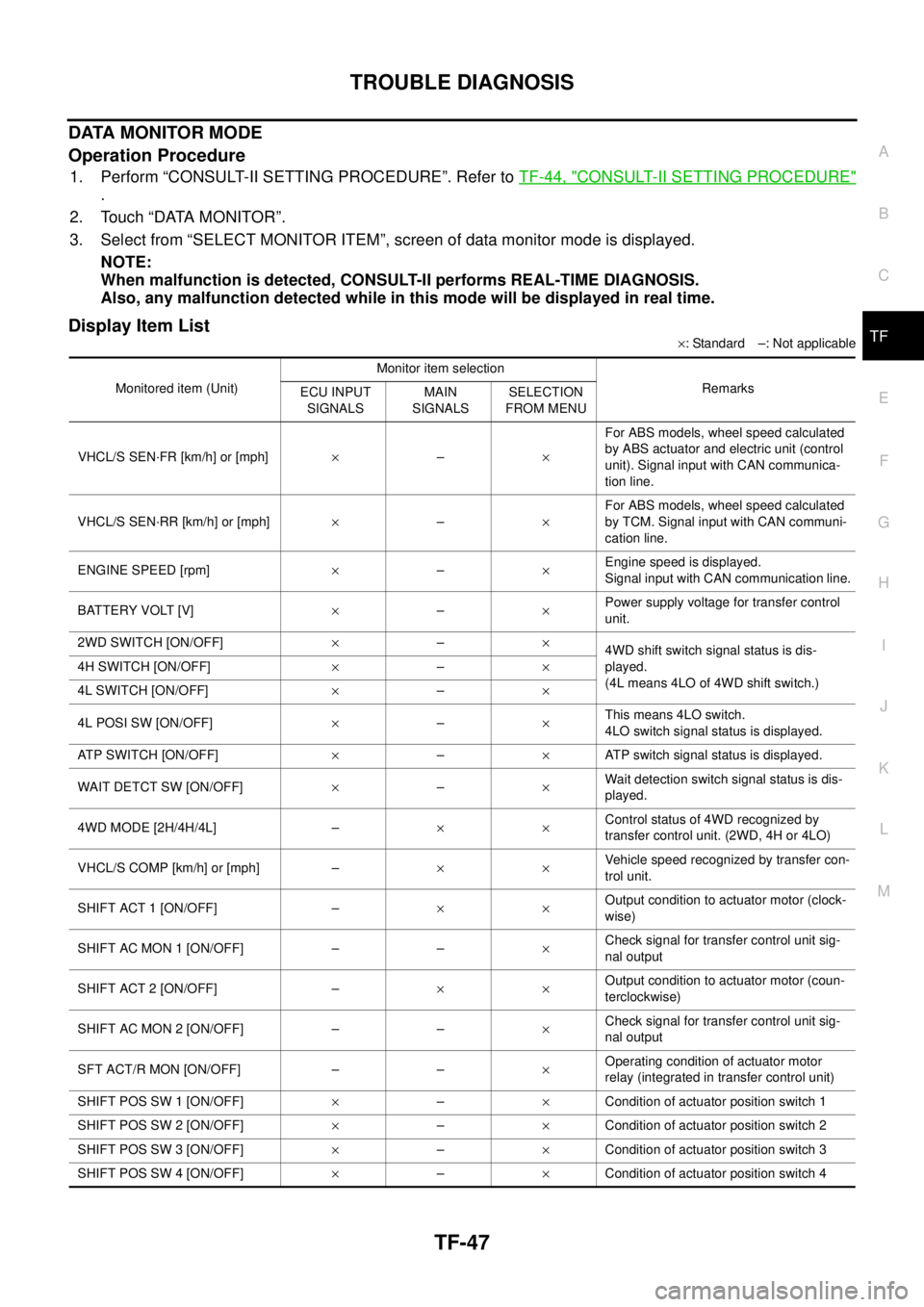

DATA MONITOR MODE

Operation Procedure

1. Perform “CONSULT-II SETTING PROCEDURE”. Refer toTF-44, "CONSULT-II SETTING PROCEDURE"

.

2. Touch “DATA MONITOR”.

3. Select from “SELECT MONITOR ITEM”, screen of data monitor mode is displayed.

NOTE:

When malfunction is detected, CONSULT-II performs REAL-TIME DIAGNOSIS.

Also, any malfunction detected while in this mode will be displayed in real time.

Display Item List

´: Standard –: Not applicable

Monitored item (Unit)Monitor item selection

Remarks

ECU INPUT

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

VHCL/S SEN·FR [km/h] or [mph]´–´For ABS models, wheel speed calculated

by ABS actuator and electric unit (control

unit). Signal input with CAN communica-

tion line.

VHCL/S SEN·RR [km/h] or [mph]´–´For ABS models, wheel speed calculated

by TCM. Signal input with CAN communi-

cation line.

ENGINE SPEED [rpm]´–´Engine speed is displayed.

Signal input with CAN communication line.

BATTERY VOLT [V]´–´Power supply voltage for transfer control

unit.

2WD SWITCH [ON/OFF]´–´

4WD shift switch signal status is dis-

played.

(4L means 4LO of 4WD shift switch.) 4H SWITCH [ON/OFF]´–´

4L SWITCH [ON/OFF]´–´

4L POSI SW [ON/OFF]´–´This means 4LO switch.

4LO switch signal status is displayed.

ATP SWITCH [ON/OFF]´–´ATP switch signal status is displayed.

WAIT DETCT SW [ON/OFF]´–´Wait detection switch signal status is dis-

played.

4WD MODE [2H/4H/4L] –´´Control status of 4WD recognized by

transfer control unit. (2WD, 4H or 4LO)

VHCL/S COMP [km/h] or [mph] –´´Vehicle speed recognized by transfer con-

trol unit.

SHIFT ACT 1 [ON/OFF] –´´Output condition to actuator motor (clock-

wise)

SHIFT AC MON 1 [ON/OFF] – –´Check signal for transfer control unit sig-

nal output

SHIFT ACT 2 [ON/OFF] –´´Output condition to actuator motor (coun-

terclockwise)

SHIFT AC MON 2 [ON/OFF] – –´Check signal for transfer control unit sig-

nal output

SFT ACT/R MON [ON/OFF] – –´Operating condition of actuator motor

relay (integrated in transfer control unit)

SHIFT POS SW 1 [ON/OFF]´–´Condition of actuator position switch 1

SHIFT POS SW 2 [ON/OFF]´–´Condition of actuator position switch 2

SHIFT POS SW 3 [ON/OFF]´–´Condition of actuator position switch 3

SHIFT POS SW 4 [ON/OFF]´–´Condition of actuator position switch 4

Page 3017 of 3171

TF-50

TROUBLE DIAGNOSIS

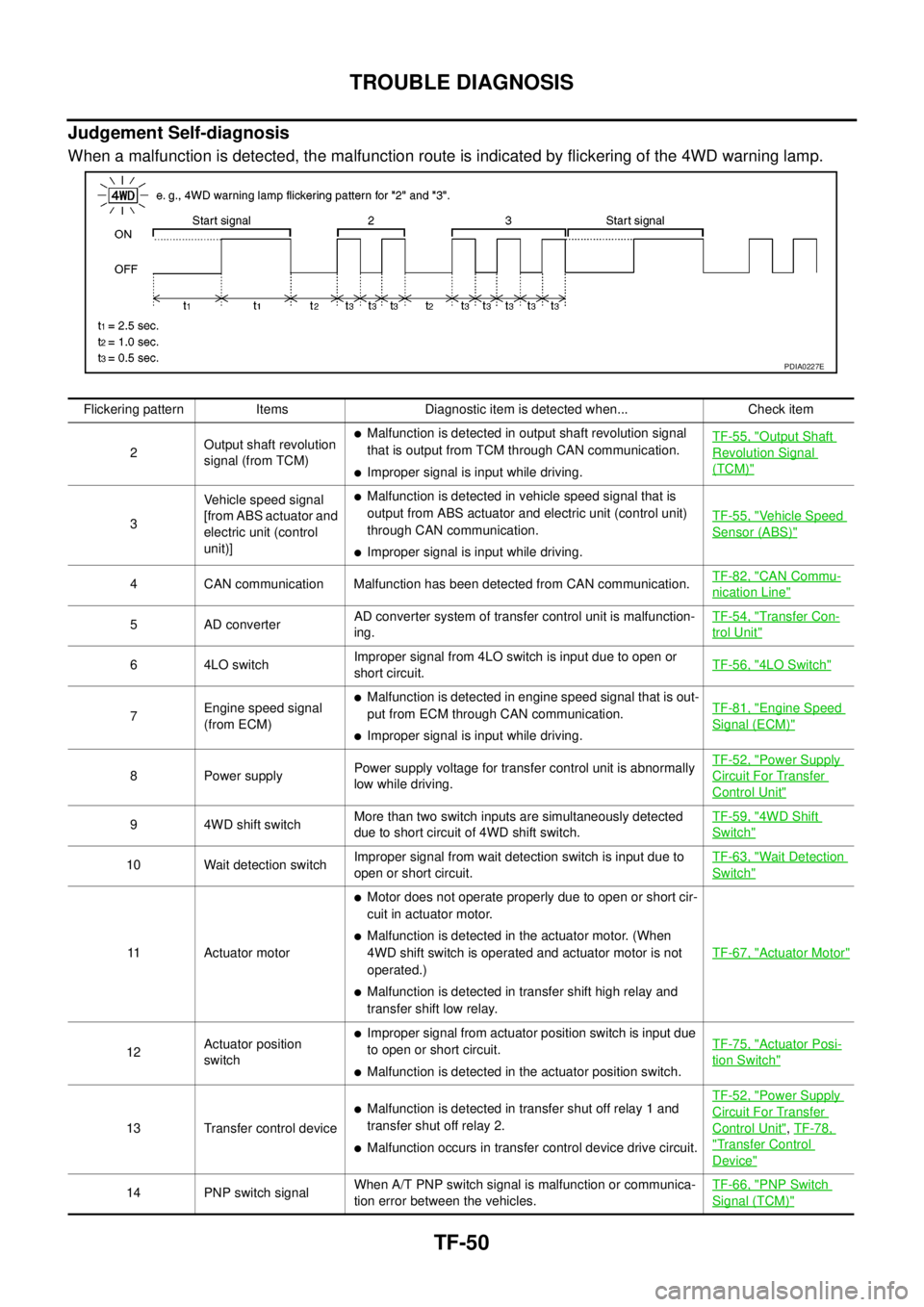

Judgement Self-diagnosis

When a malfunction is detected, the malfunction route is indicated by flickering of the 4WD warning lamp.

PDIA0227E

Flickering pattern Items Diagnostic item is detected when... Check item

2Output shaft revolution

signal (from TCM)

lMalfunction is detected in output shaft revolution signal

that is output from TCM through CAN communication.

lImproper signal is input while driving.TF-55, "

Output Shaft

Revolution Signal

(TCM)"

3Vehicle speed signal

[from ABS actuator and

electric unit (control

unit)]

lMalfunction is detected in vehicle speed signal that is

output from ABS actuator and electric unit (control unit)

through CAN communication.

lImproper signal is input while driving.TF-55, "

Vehicle Speed

Sensor (ABS)"

4 CAN communication Malfunction has been detected from CAN communication.TF-82, "CAN Commu-

nication Line"

5 AD converterAD converter system of transfer control unit is malfunction-

ing.TF-54, "Transfer Con-

trol Unit"

6 4LO switchImproper signal from 4LO switch is input due to open or

short circuit.TF-56, "4LO Switch"

7Engine speed signal

(from ECM)

lMalfunction is detected in engine speed signal that is out-

put from ECM through CAN communication.

lImproper signal is input while driving.TF-81, "

Engine Speed

Signal (ECM)"

8 Power supplyPower supply voltage for transfer control unit is abnormally

low while driving.TF-52, "

Power Supply

Circuit For Transfer

Control Unit"

9 4WD shift switchMore than two switch inputs are simultaneously detected

due to short circuit of 4WD shift switch.TF-59, "4WD Shift

Switch"

10 Wait detection switchImproper signal from wait detection switch is input due to

open or short circuit.TF-63, "Wait Detection

Switch"

11 Actuator motor

lMotor does not operate properly due to open or short cir-

cuit in actuator motor.

lMalfunction is detected in the actuator motor. (When

4WD shift switch is operated and actuator motor is not

operated.)

lMalfunction is detected in transfer shift high relay and

transfer shift low relay.TF-67, "

Actuator Motor"

12Actuator position

switch

lImproper signal from actuator position switch is input due

to open or short circuit.

lMalfunction is detected in the actuator position switch.TF-75, "

Actuator Posi-

tion Switch"

13 Transfer control device

lMalfunction is detected in transfer shut off relay 1 and

transfer shut off relay 2.

lMalfunction occurs in transfer control device drive circuit.TF-52, "

Power Supply

Circuit For Transfer

Control Unit",TF-78,

"Transfer Control

Device"

14 PNP switch signalWhen A/T PNP switch signal is malfunction or communica-

tion error between the vehicles.TF-66, "PNP Switch

Signal (TCM)"