check engine NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1076 of 3171

EC-96

DTC P0102, P0103 MAF SENSOR

3.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E9, F4

lHarness for open or short between IPDM E/R and mass air flow sensor

lHarness for open or short between ECM and mass air flow sensor

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK MAFS GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between MAF sensor terminal 4 and ECM terminal 73.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK MAFS INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between MAF sensor terminal 3 and ECM terminal 54.

Refer to Wiring Diagram.

2. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 6.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK MASS AIR FLOW SENSOR

Refer toEC-96, "

Component Inspection".

OK or NG

OK >> GO TO 7.

NG >> Replace mass air flow sensor.

7.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

Component InspectionEBS01KE2

MASS AIR FLOW SENSOR

With CONSULT-II

1. Reconnect all harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Connect CONSULT-II and select “DATA MONITOR” mode.Continuity should exist.

Continuity should exist.

Page 1077 of 3171

DTC P0102, P0103 MAF SENSOR

EC-97

C

D

E

F

G

H

I

J

K

L

MA

EC

4. Select “MAS AIR/FL SE” and check indication under the follow-

ing conditions.

*: Check for linear voltage rise in response to engine being increased to about

4,000 rpm.

5. If the voltage is out of specification, proceed the following.

a. Check for the cause of uneven air flow through mass air flow sensor. Refer to following.

lCrushed air ducts

lMalfunctioning seal of air cleaner element

lUneven dirt of air cleaner element

lImproper specification of intake air system parts

b. If NG, repair or replace malfunctioning part and perform step 2 to 4 again.

IfOK,gotonextstep.

6. Turn ignition switch OFF.

7. Disconnect mass air flow sensor harness connector and reconnect it again.

8. Performstep2to4again.

9. If NG, clean or replace mass air flow sensor.

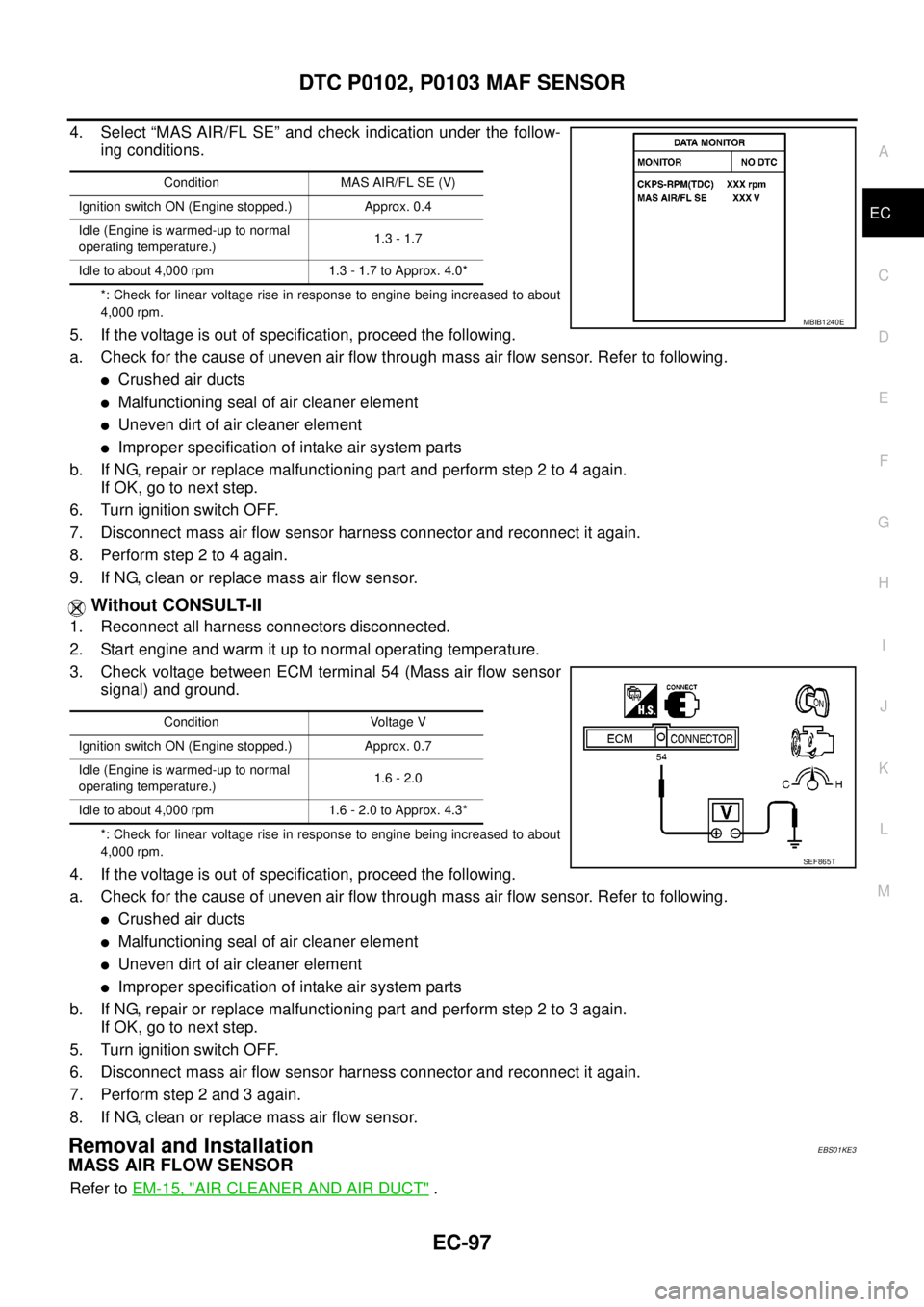

Without CONSULT-II

1. Reconnect all harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Check voltage between ECM terminal 54 (Mass air flow sensor

signal) and ground.

*: Check for linear voltage rise in response to engine being increased to about

4,000 rpm.

4. If the voltage is out of specification, proceed the following.

a. Check for the cause of uneven air flow through mass air flow sensor. Refer to following.

lCrushed air ducts

lMalfunctioning seal of air cleaner element

lUneven dirt of air cleaner element

lImproper specification of intake air system parts

b. If NG, repair or replace malfunctioning part and perform step 2 to 3 again.

IfOK,gotonextstep.

5. Turn ignition switch OFF.

6. Disconnect mass air flow sensor harness connector and reconnect it again.

7. Perform step 2 and 3 again.

8. If NG, clean or replace mass air flow sensor.

Removal and InstallationEBS01KE3

MASS AIR FLOW SENSOR

Refer toEM-15, "AIR CLEANER AND AIR DUCT".

Condition MAS AIR/FL SE (V)

Ignition switch ON (Engine stopped.) Approx. 0.4

Idle (Engine is warmed-up to normal

operating temperature.)1.3 - 1.7

Idle to about 4,000 rpm 1.3 - 1.7 to Approx. 4.0*

MBIB1240E

Condition Voltage V

Ignition switch ON (Engine stopped.) Approx. 0.7

Idle (Engine is warmed-up to normal

operating temperature.)1.6 - 2.0

Idle to about 4,000 rpm 1.6 - 2.0 to Approx. 4.3*

SEF865T

Page 1086 of 3171

EC-106

DTC P0117, P0118 ECT SENSOR

Diagnostic Procedure

EBS01KEF

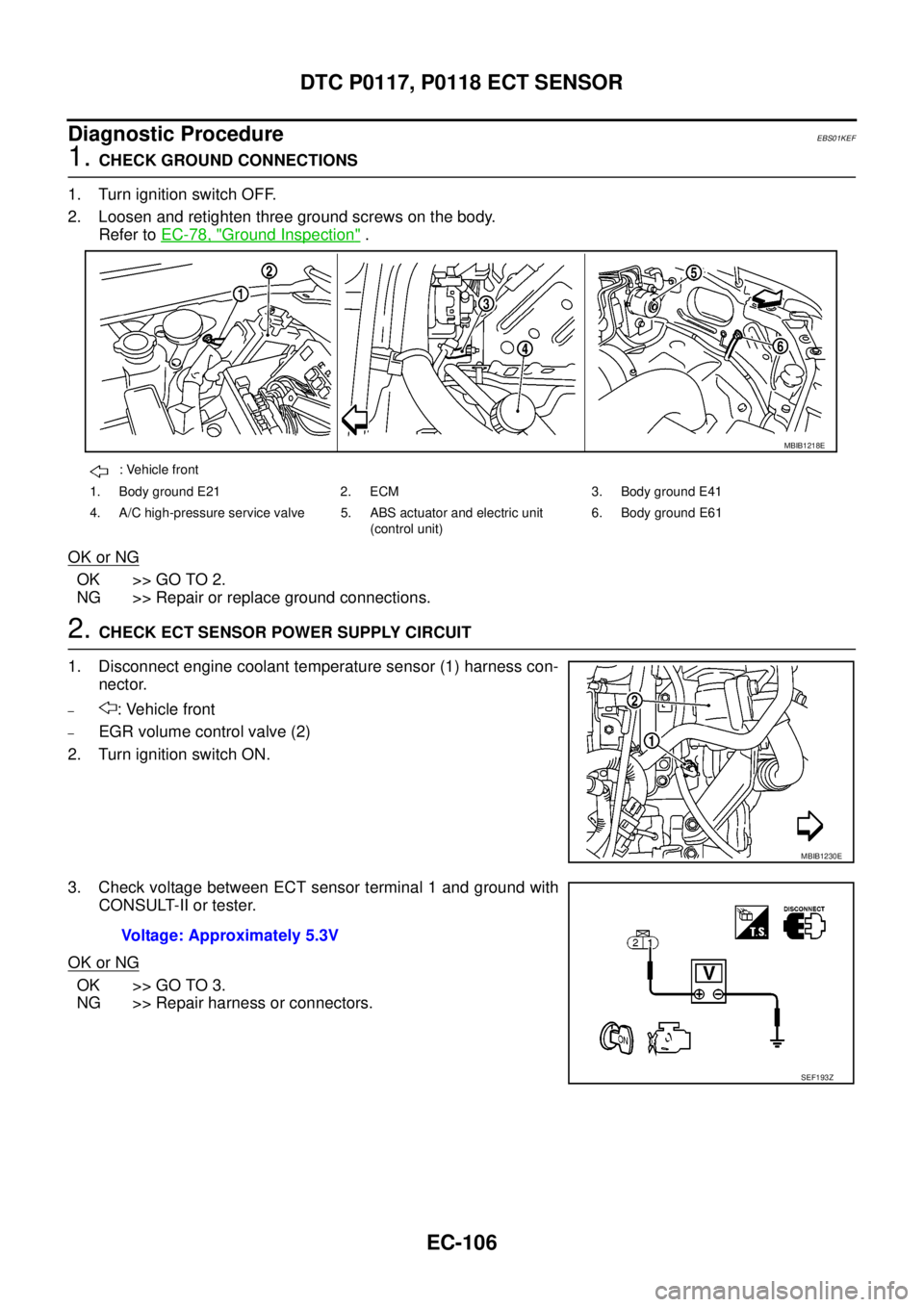

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer toEC-78, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.CHECK ECT SENSOR POWER SUPPLY CIRCUIT

1. Disconnect engine coolant temperature sensor (1) harness con-

nector.

–: Vehicle front

–EGR volume control valve (2)

2. Turn ignition switch ON.

3. Check voltage between ECT sensor terminal 1 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connectors.

: Vehicle front

1. Body ground E21 2. ECM 3. Body ground E41

4. A/C high-pressure service valve 5. ABS actuator and electric unit

(control unit)6. Body ground E61

MBIB1218E

MBIB1230E

Voltage: Approximately 5.3V

SEF193Z

Page 1087 of 3171

DTC P0117, P0118 ECT SENSOR

EC-107

C

D

E

F

G

H

I

J

K

L

MA

EC

3.CHECK ECT SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECT sensor terminal 2 and ECM terminal 70. Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK ENGINE COOLANT TEMPERATURE SENSOR

Refer toEC-107, "

Component Inspection".

OK or NG

OK >> GO TO 5.

NG >> Replace engine coolant temperature sensor.

5.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

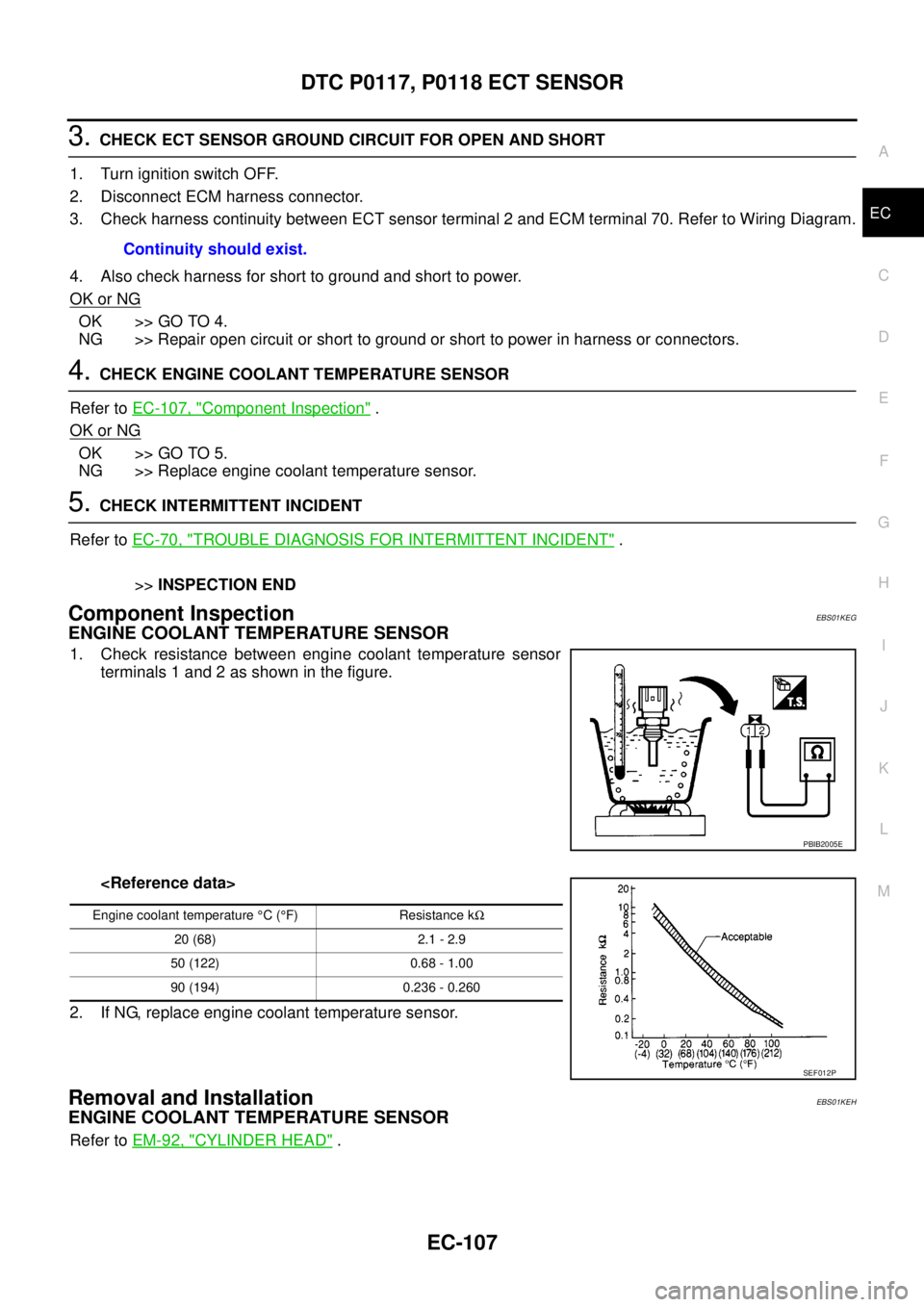

Component InspectionEBS01KEG

ENGINE COOLANT TEMPERATURE SENSOR

1. Check resistance between engine coolant temperature sensor

terminals 1 and 2 as shown in the figure.

2. If NG, replace engine coolant temperature sensor.

Removal and InstallationEBS01KEH

ENGINE COOLANT TEMPERATURE SENSOR

Refer toEM-92, "CYLINDER HEAD". Continuity should exist.

PBIB2005E

Engine coolant temperature°C(°F) Resistance kW

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

SEF012P

Page 1102 of 3171

EC-122

DTC P0192, P0193 FRP SENSOR

3.CHECK FUEL RAIL PRESSURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between fuel rail pressure sensor terminal 3 and ECM terminal 68.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK FUEL RAIL PRESSURE SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminals 48, 49 and fuel rail pressure sensor terminal 2.

Refer to Wiring Diagram.

2. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness connectors.

5.CHECK FUEL RAIL PRESSURE SENSOR

Refer toEC-122, "

Component Inspection".

OK or NG

OK >> GO TO 6.

NG >> Replace fuel rail.

6.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

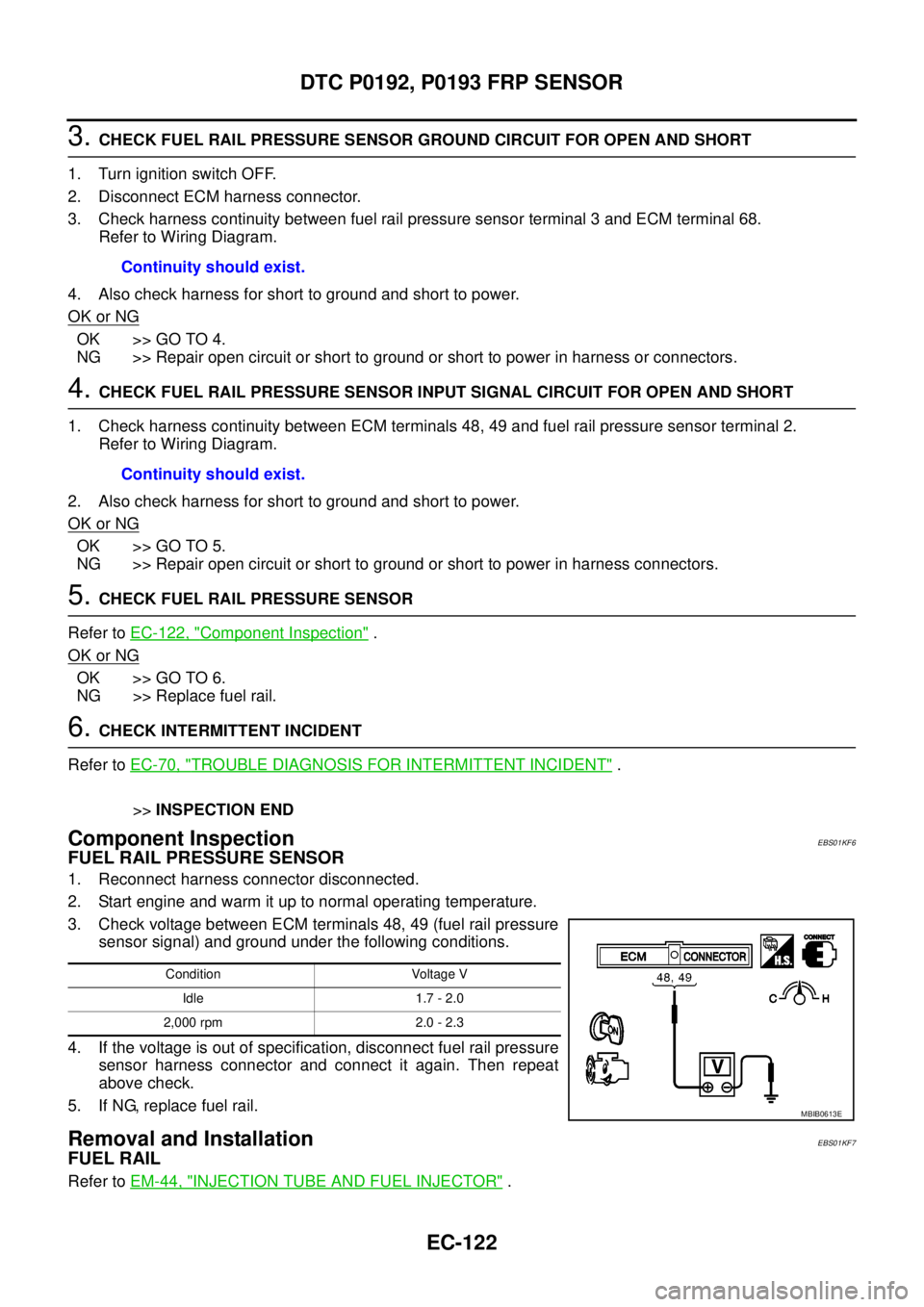

Component InspectionEBS01KF6

FUEL RAIL PRESSURE SENSOR

1. Reconnect harness connector disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Check voltage between ECM terminals 48, 49 (fuel rail pressure

sensor signal) and ground under the following conditions.

4. If the voltage is out of specification, disconnect fuel rail pressure

sensor harness connector and connect it again. Then repeat

above check.

5. If NG, replace fuel rail.

Removal and InstallationEBS01KF7

FUEL RAIL

Refer toEM-44, "INJECTION TUBE AND FUEL INJECTOR". Continuity should exist.

Continuity should exist.

Condition Voltage V

Idle 1.7 - 2.0

2,000 rpm 2.0 - 2.3

MBIB0613E

Page 1113 of 3171

DTC P0217 ENGINE OVER TEMPERATURE

EC-133

C

D

E

F

G

H

I

J

K

L

MA

EC

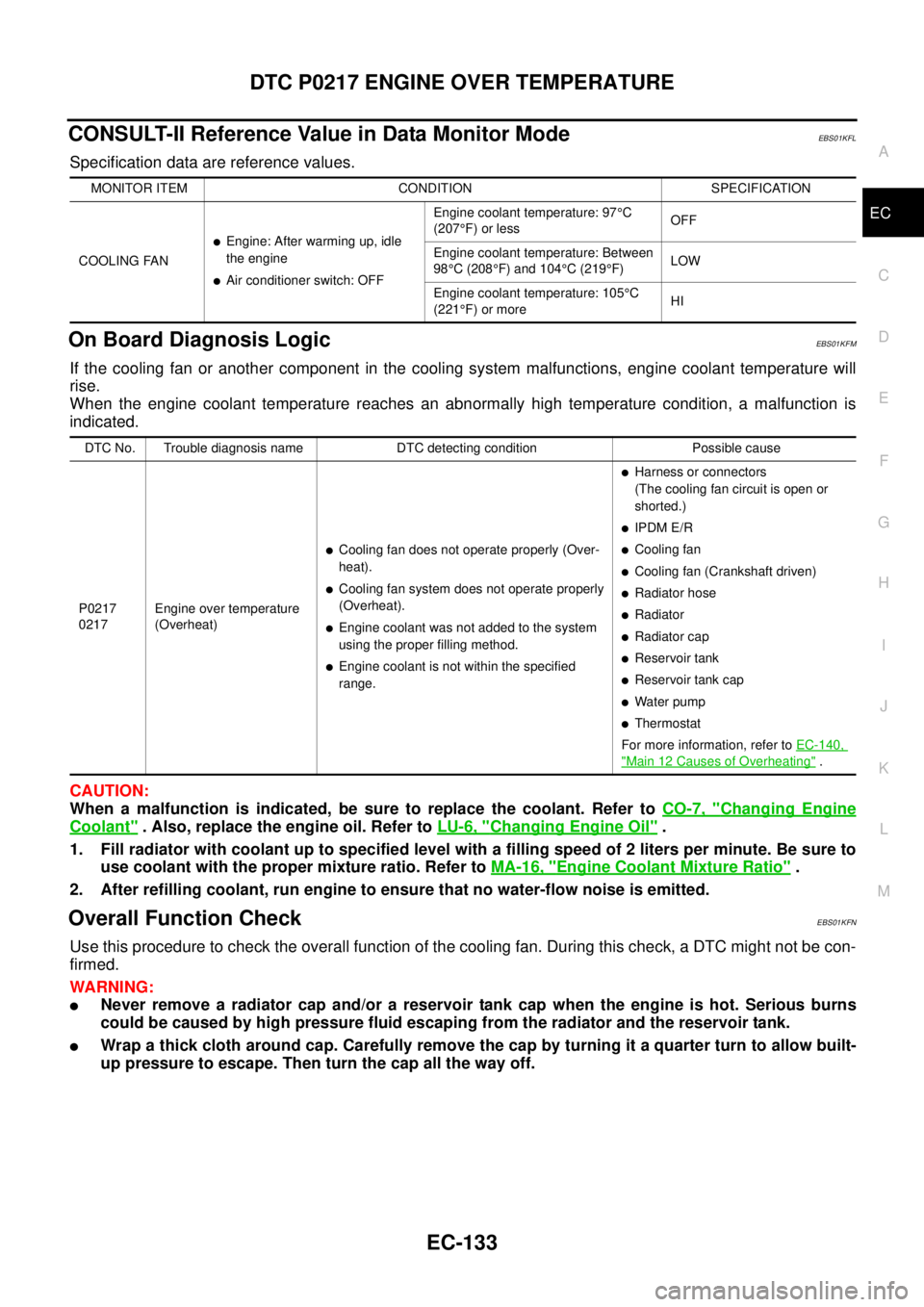

CONSULT-II Reference Value in Data Monitor ModeEBS01KFL

Specification data are reference values.

On Board Diagnosis LogicEBS01KFM

If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant. Refer toCO-7, "

Changing Engine

Coolant". Also, replace the engine oil. Refer toLU-6, "Changing Engine Oil".

1. Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to

use coolant with the proper mixture ratio. Refer toMA-16, "

Engine Coolant Mixture Ratio".

2. After refilling coolant, run engine to ensure that no water-flow noise is emitted.

Overall Function CheckEBS01KFN

Use this procedure to check the overall function of the cooling fan. During this check, a DTC might not be con-

firmed.

WARNING:

lNever remove a radiator cap and/or a reservoir tank cap when the engine is hot. Serious burns

could be caused by high pressure fluid escaping from the radiator and the reservoir tank.

lWrap a thick cloth around cap. Carefully remove the cap by turning it a quarter turn to allow built-

up pressure to escape. Then turn the cap all the way off.

MONITOR ITEM CONDITION SPECIFICATION

COOLING FAN

lEngine: After warming up, idle

the engine

lAir conditioner switch: OFFEngine coolant temperature: 97°C

(207°F) or lessOFF

Engine coolant temperature: Between

98°C (208°F) and 104°C(219°F)LOW

Engine coolant temperature: 105°C

(221°F) or moreHI

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0217

0217Engine over temperature

(Overheat)

lCooling fan does not operate properly (Over-

heat).

lCooling fan system does not operate properly

(Overheat).

lEngine coolant was not added to the system

using the proper filling method.

lEngine coolant is not within the specified

range.

lHarness or connectors

(The cooling fan circuit is open or

shorted.)

lIPDM E/R

lCooling fan

lCooling fan (Crankshaft driven)

lRadiator hose

lRadiator

lRadiator cap

lReservoir tank

lReservoir tank cap

lWater pump

lThermostat

For more information, refer toEC-140,

"Main 12 Causes of Overheating".

Page 1114 of 3171

EC-134

DTC P0217 ENGINE OVER TEMPERATURE

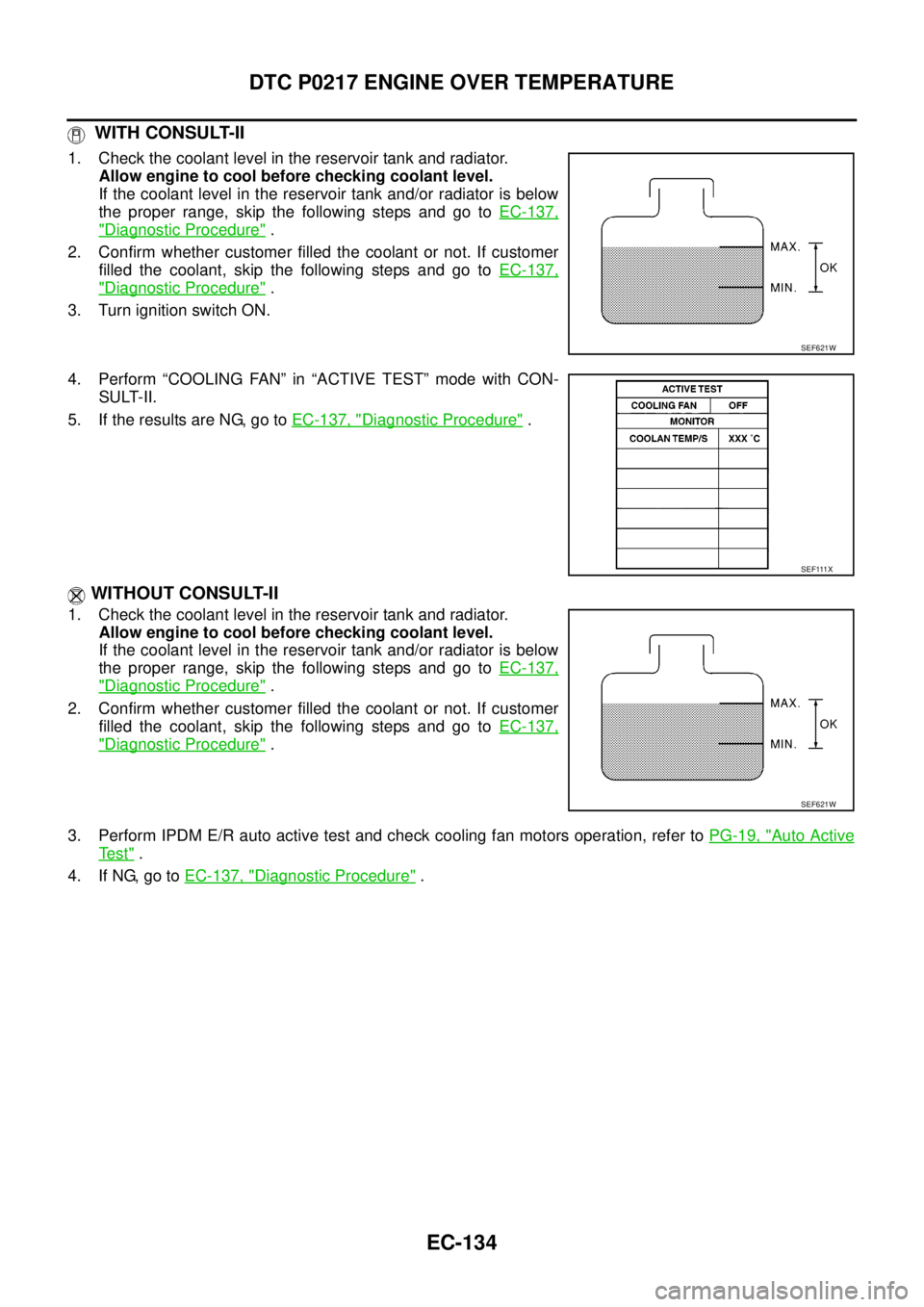

WITH CONSULT-II

1. Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go toEC-137,

"Diagnostic Procedure".

2. Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go toEC-137,

"Diagnostic Procedure".

3. Turn ignition switch ON.

4. Perform “COOLING FAN” in “ACTIVE TEST” mode with CON-

SULT-II.

5. If the results are NG, go toEC-137, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go toEC-137,

"Diagnostic Procedure".

2. Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go toEC-137,

"Diagnostic Procedure".

3. Perform IPDM E/R auto active test and check cooling fan motors operation, refer toPG-19, "

Auto Active

Te s t".

4. If NG, go toEC-137, "

Diagnostic Procedure".

SEF621W

SEF111X

SEF621W

Page 1117 of 3171

DTC P0217 ENGINE OVER TEMPERATURE

EC-137

C

D

E

F

G

H

I

J

K

L

MA

EC

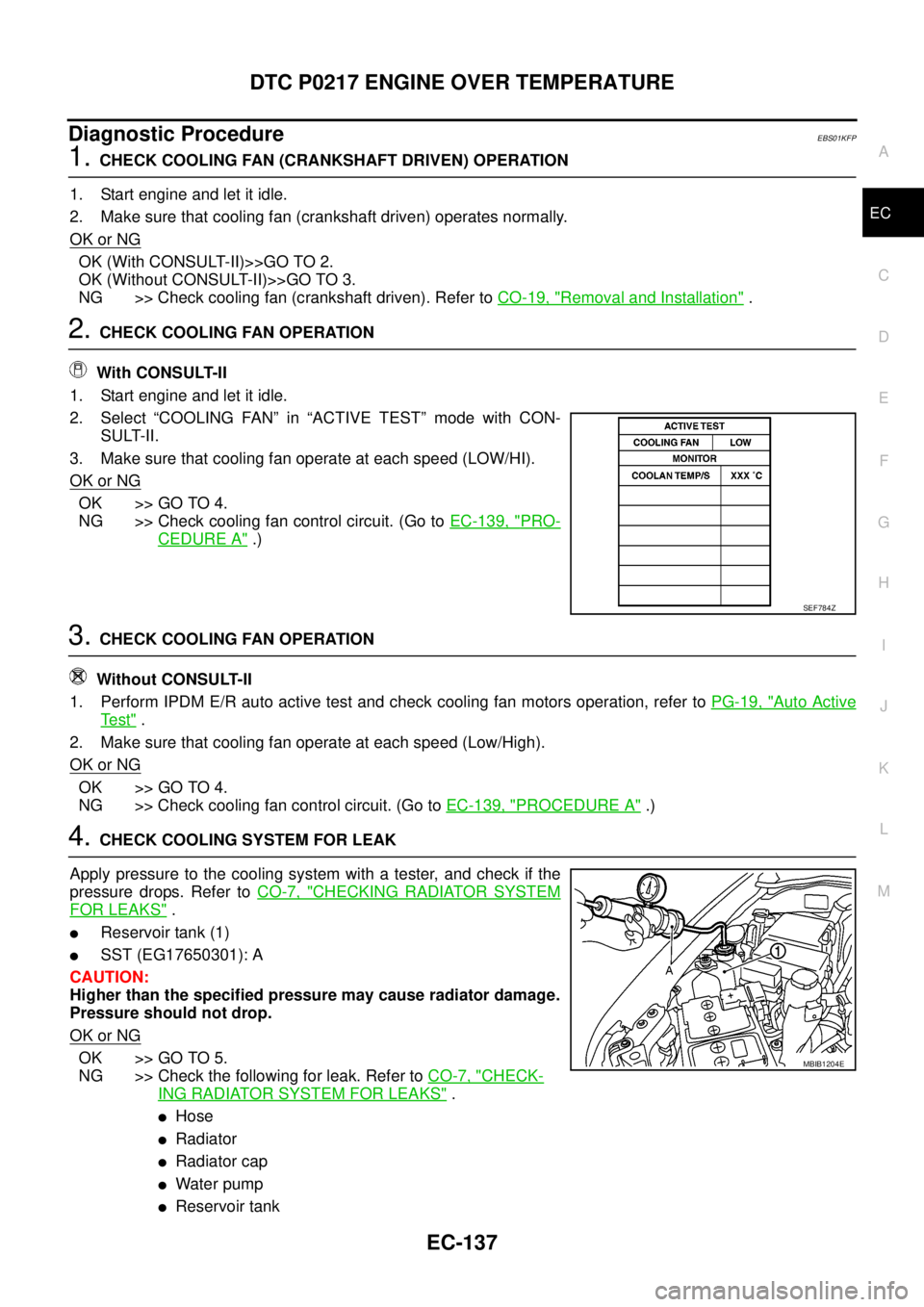

Diagnostic ProcedureEBS01KFP

1.CHECK COOLING FAN (CRANKSHAFT DRIVEN) OPERATION

1. Start engine and let it idle.

2. Make sure that cooling fan (crankshaft driven) operates normally.

OK or NG

OK (With CONSULT-II)>>GO TO 2.

OK (Without CONSULT-II)>>GO TO 3.

NG >> Check cooling fan (crankshaft driven). Refer toCO-19, "

Removal and Installation".

2.CHECK COOLING FAN OPERATION

With CONSULT-II

1. Start engine and let it idle.

2. Select “COOLING FAN” in “ACTIVE TEST” mode with CON-

SULT-II.

3. Make sure that cooling fan operate at each speed (LOW/HI).

OK or NG

OK >> GO TO 4.

NG >> Check cooling fan control circuit. (Go toEC-139, "

PRO-

CEDURE A".)

3.CHECK COOLING FAN OPERATION

Without CONSULT-II

1. Perform IPDM E/R auto active test and check cooling fan motors operation, refer toPG-19, "

Auto Active

Te s t".

2. Make sure that cooling fan operate at each speed (Low/High).

OK or NG

OK >> GO TO 4.

NG >> Check cooling fan control circuit. (Go toEC-139, "

PROCEDURE A".)

4.CHECK COOLING SYSTEM FOR LEAK

Apply pressure to the cooling system with a tester, and check if the

pressure drops. Refer toCO-7, "

CHECKING RADIATOR SYSTEM

FOR LEAKS".

lReservoir tank (1)

lSST (EG17650301): A

CAUTION:

Higher than the specified pressure may cause radiator damage.

Pressure should not drop.

OK or NG

OK >> GO TO 5.

NG >> Check the following for leak. Refer toCO-7, "

CHECK-

ING RADIATOR SYSTEM FOR LEAKS".

lHose

lRadiator

lRadiator cap

lWater pump

lReservoir tank

SEF784Z

MBIB1204E

Page 1118 of 3171

EC-138

DTC P0217 ENGINE OVER TEMPERATURE

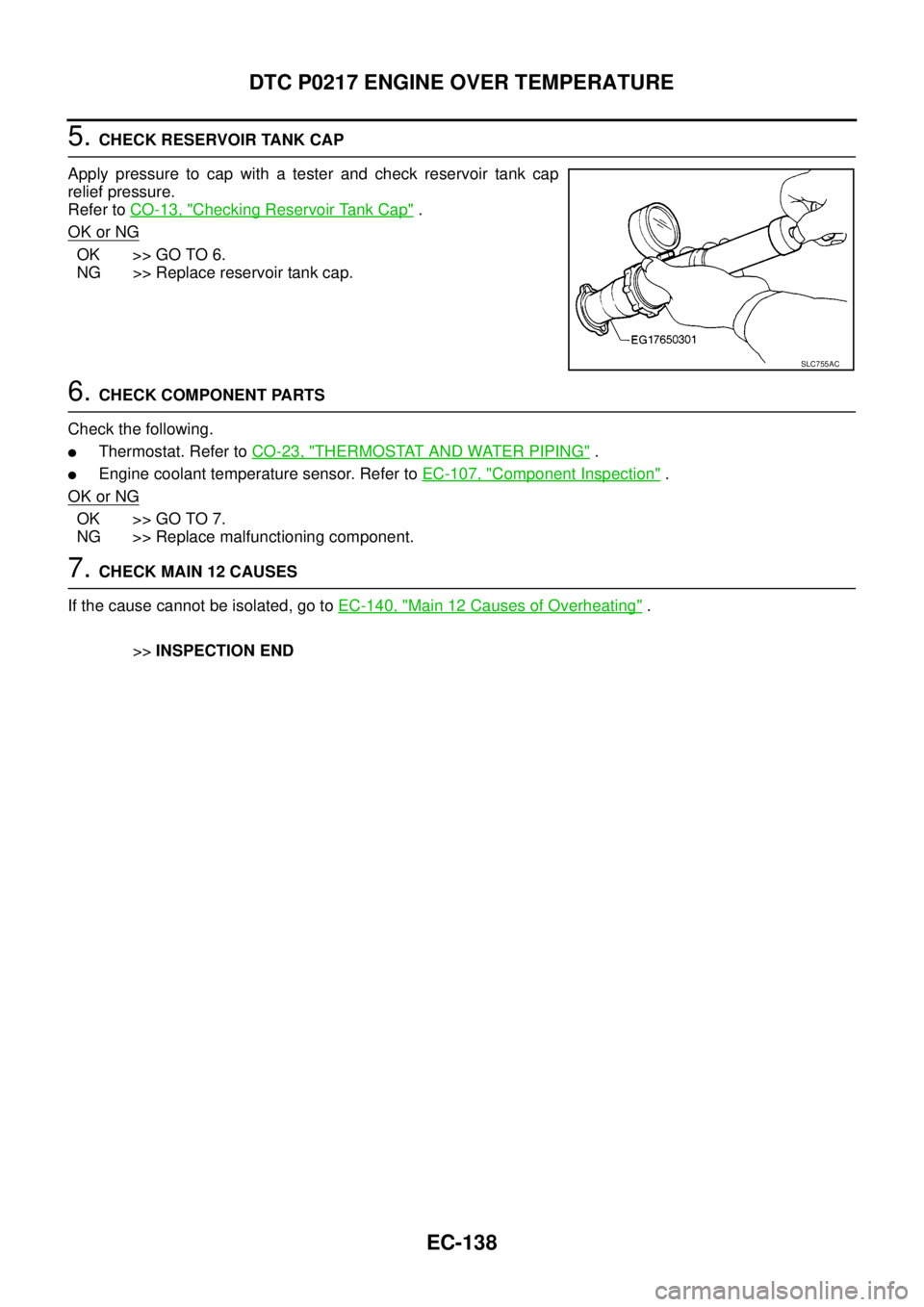

5.CHECK RESERVOIR TANK CAP

Apply pressure to cap with a tester and check reservoir tank cap

relief pressure.

Refer toCO-13, "

Checking Reservoir Tank Cap".

OK or NG

OK >> GO TO 6.

NG >> Replace reservoir tank cap.

6.CHECK COMPONENT PARTS

Check the following.

lThermostat. Refer toCO-23, "THERMOSTAT AND WATER PIPING".

lEngine coolant temperature sensor. Refer toEC-107, "Component Inspection".

OK or NG

OK >> GO TO 7.

NG >> Replace malfunctioning component.

7.CHECK MAIN 12 CAUSES

If the cause cannot be isolated, go toEC-140, "

Main 12 Causes of Overheating".

>>INSPECTION END

SLC755AC

Page 1119 of 3171

DTC P0217 ENGINE OVER TEMPERATURE

EC-139

C

D

E

F

G

H

I

J

K

L

MA

EC

PROCEDURE A

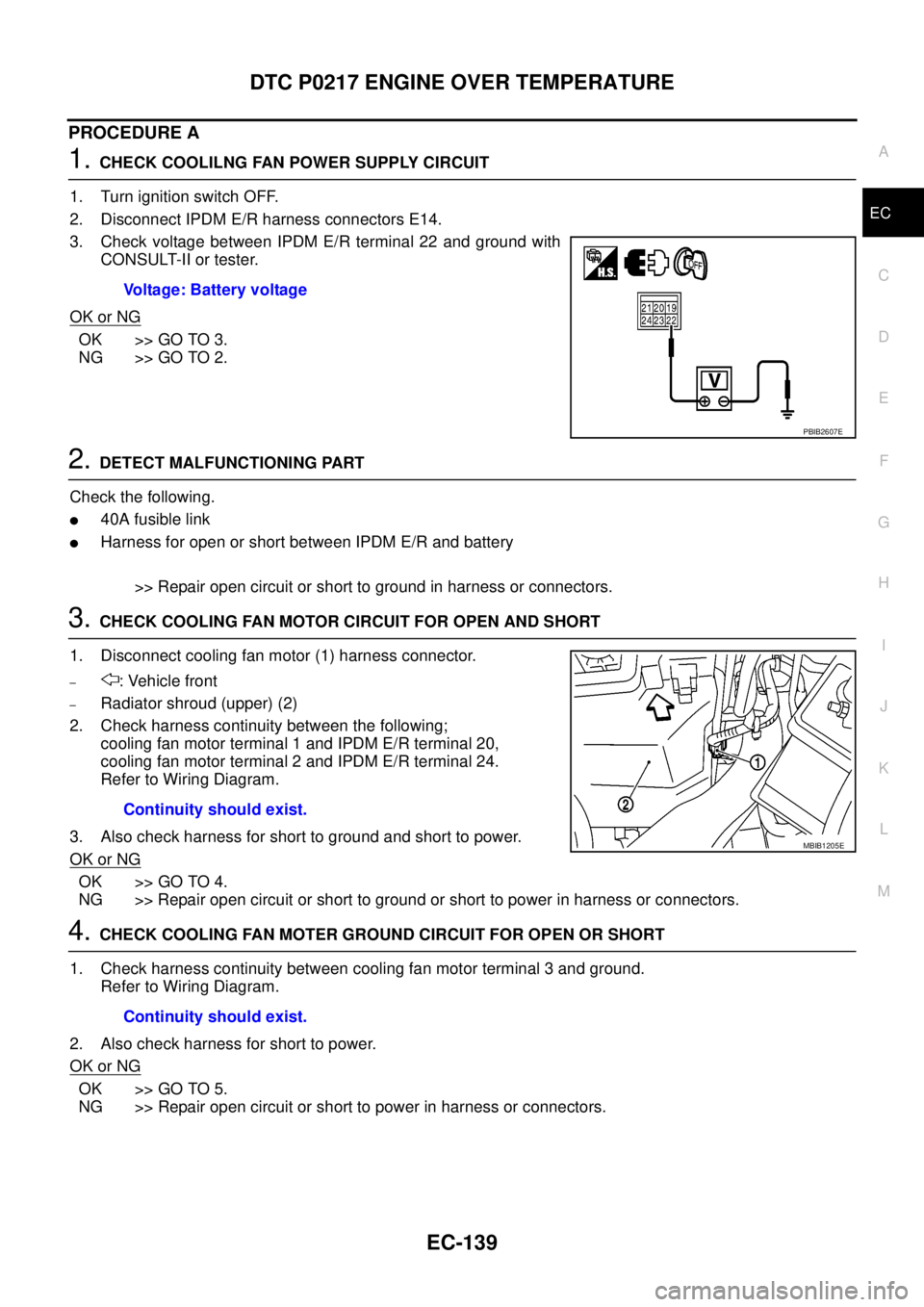

1.CHECK COOLILNG FAN POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connectors E14.

3. Check voltage between IPDM E/R terminal 22 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.DETECT MALFUNCTIONING PART

Check the following.

l40A fusible link

lHarness for open or short between IPDM E/R and battery

>> Repair open circuit or short to ground in harness or connectors.

3.CHECK COOLING FAN MOTOR CIRCUIT FOR OPEN AND SHORT

1. Disconnect cooling fan motor (1) harness connector.

–: Vehicle front

–Radiator shroud (upper) (2)

2. Check harness continuity between the following;

cooling fan motor terminal 1 and IPDM E/R terminal 20,

cooling fan motor terminal 2 and IPDM E/R terminal 24.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK COOLING FAN MOTER GROUND CIRCUIT FOR OPEN OR SHORT

1. Check harness continuity between cooling fan motor terminal 3 and ground.

Refer to Wiring Diagram.

2. Also check harness for short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to power in harness or connectors.Voltage: Battery voltage

PBIB2607E

Continuity should exist.

MBIB1205E

Continuity should exist.