check engine NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1235 of 3171

DTC P1273 FUEL PUMP

EC-255

C

D

E

F

G

H

I

J

K

L

MA

EC

Diagnostic ProcedureEBS01KJW

1.CHECK INJECTOR ADJUSTMENT VALUE

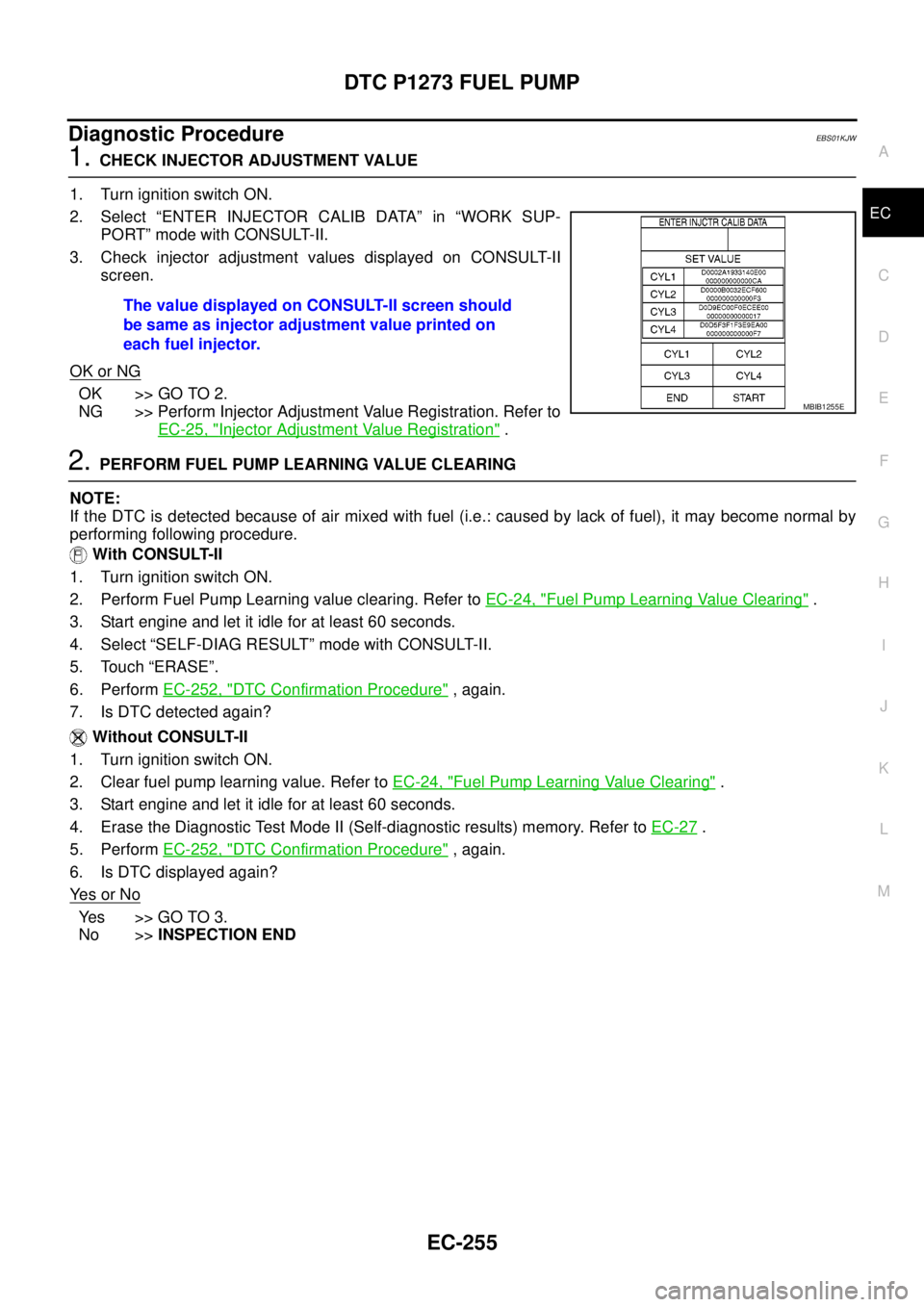

1. Turn ignition switch ON.

2. Select “ENTER INJECTOR CALIB DATA” in “WORK SUP-

PORT” mode with CONSULT-II.

3. Check injector adjustment values displayed on CONSULT-II

screen.

OK or NG

OK >> GO TO 2.

NG >> Perform Injector Adjustment Value Registration. Refer to

EC-25, "

Injector Adjustment Value Registration".

2.PERFORM FUEL PUMP LEARNING VALUE CLEARING

NOTE:

If the DTC is detected because of air mixed with fuel (i.e.: caused by lack of fuel), it may become normal by

performing following procedure.

With CONSULT-II

1. Turn ignition switch ON.

2. Perform Fuel Pump Learning value clearing. Refer toEC-24, "

Fuel Pump Learning Value Clearing".

3. Start engine and let it idle for at least 60 seconds.

4. Select “SELF-DIAG RESULT” mode with CONSULT-II.

5. Touch “ERASE”.

6. PerformEC-252, "

DTC Confirmation Procedure", again.

7. Is DTC detected again?

Without CONSULT-II

1. Turn ignition switch ON.

2. Clear fuel pump learning value. Refer toEC-24, "

Fuel Pump Learning Value Clearing".

3. Start engine and let it idle for at least 60 seconds.

4. Erase the Diagnostic Test Mode II (Self-diagnostic results) memory. Refer toEC-27

.

5. PerformEC-252, "

DTC Confirmation Procedure", again.

6. Is DTC displayed again?

Ye s o r N o

Ye s > > G O T O 3 .

No >>INSPECTION END The value displayed on CONSULT-II screen should

be same as injector adjustment value printed on

each fuel injector.

MBIB1255E

Page 1277 of 3171

GLOW CONTROL SYSTEM

EC-297

C

D

E

F

G

H

I

J

K

L

MA

EC

Diagnostic ProcedureEBS01KLO

1.INSPECTION START

Check fuel level, fuel supplying system, starter motor, etc.

OK or NG

OK >> GO TO 2.

NG >> Correct.

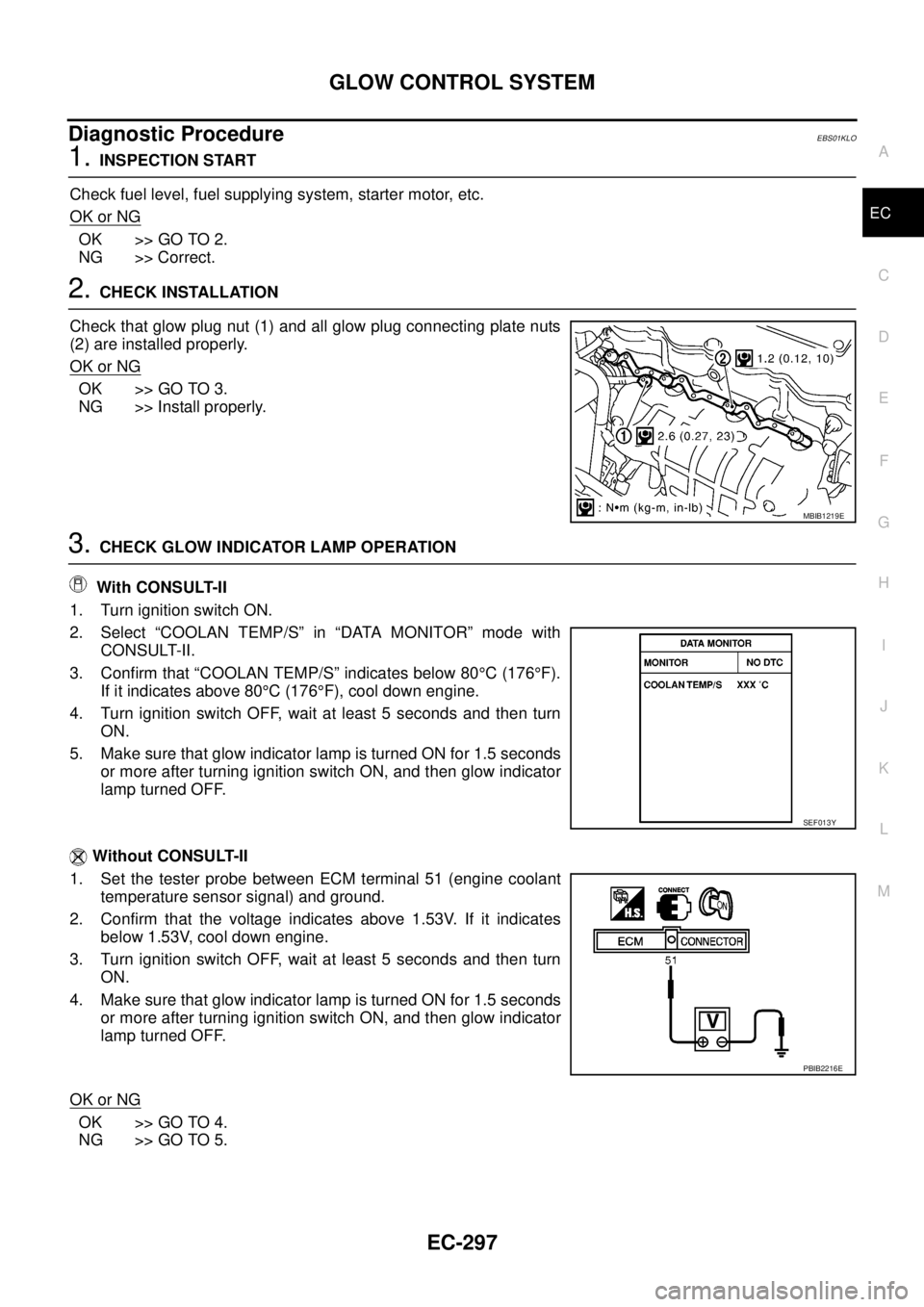

2.CHECK INSTALLATION

Check that glow plug nut (1) and all glow plug connecting plate nuts

(2) are installed properly.

OK or NG

OK >> GO TO 3.

NG >> Install properly.

3.CHECK GLOW INDICATOR LAMP OPERATION

With CONSULT-II

1. Turn ignition switch ON.

2. Select “COOLAN TEMP/S” in “DATA MONITOR” mode with

CONSULT-II.

3. Confirm that “COOLAN TEMP/S” indicates below 80°C(176°F).

If it indicates above 80°C(176°F), cool down engine.

4. Turn ignition switch OFF, wait at least 5 seconds and then turn

ON.

5. Make sure that glow indicator lamp is turned ON for 1.5 seconds

or more after turning ignition switch ON, and then glow indicator

lamp turned OFF.

Without CONSULT-II

1. Set the tester probe between ECM terminal 51 (engine coolant

temperature sensor signal) and ground.

2. Confirm that the voltage indicates above 1.53V. If it indicates

below 1.53V, cool down engine.

3. Turn ignition switch OFF, wait at least 5 seconds and then turn

ON.

4. Make sure that glow indicator lamp is turned ON for 1.5 seconds

or more after turning ignition switch ON, and then glow indicator

lamp turned OFF.

OK or NG

OK >> GO TO 4.

NG >> GO TO 5.

MBIB1219E

SEF013Y

PBIB2216E

Page 1278 of 3171

EC-298

GLOW CONTROL SYSTEM

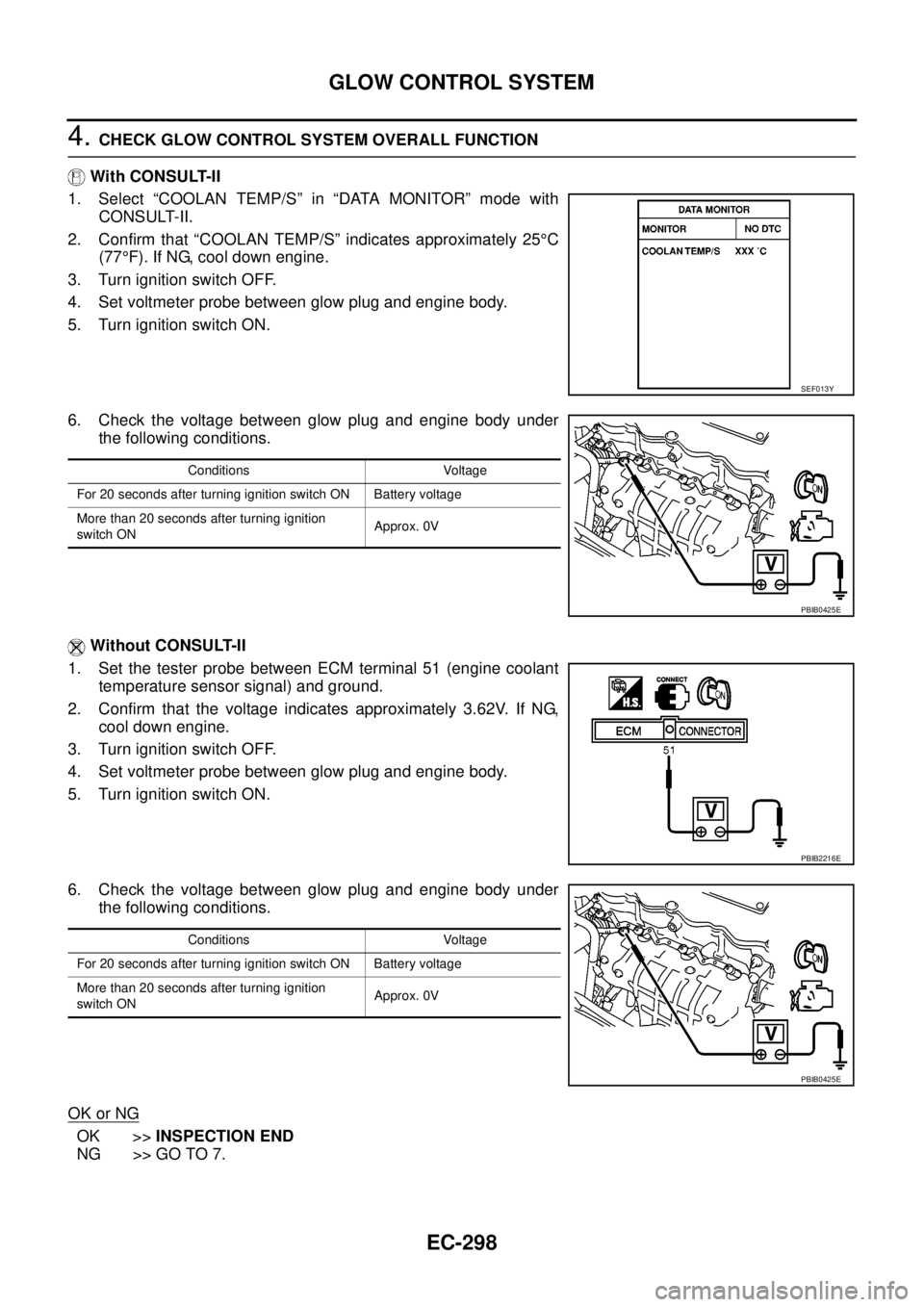

4.CHECK GLOW CONTROL SYSTEM OVERALL FUNCTION

With CONSULT-II

1. Select “COOLAN TEMP/S” in “DATA MONITOR” mode with

CONSULT-II.

2. Confirm that “COOLAN TEMP/S” indicates approximately 25°C

(77°F). If NG, cool down engine.

3. Turn ignition switch OFF.

4. Set voltmeter probe between glow plug and engine body.

5. Turn ignition switch ON.

6. Check the voltage between glow plug and engine body under

the following conditions.

Without CONSULT-II

1. Set the tester probe between ECM terminal 51 (engine coolant

temperature sensor signal) and ground.

2. Confirm that the voltage indicates approximately 3.62V. If NG,

cool down engine.

3. Turn ignition switch OFF.

4. Set voltmeter probe between glow plug and engine body.

5. Turn ignition switch ON.

6. Check the voltage between glow plug and engine body under

the following conditions.

OK or NG

OK >>INSPECTION END

NG >> GO TO 7.

SEF013Y

Conditions Voltage

For 20 seconds after turning ignition switch ON Battery voltage

More than 20 seconds after turning ignition

switch ONApprox. 0V

PBIB0425E

PBIB2216E

Conditions Voltage

For 20 seconds after turning ignition switch ON Battery voltage

More than 20 seconds after turning ignition

switch ONApprox. 0V

PBIB0425E

Page 1285 of 3171

EGR VOLUME CONTROL SYSTEM

EC-305

C

D

E

F

G

H

I

J

K

L

MA

EC

Diagnostic ProcedureEBS01KLV

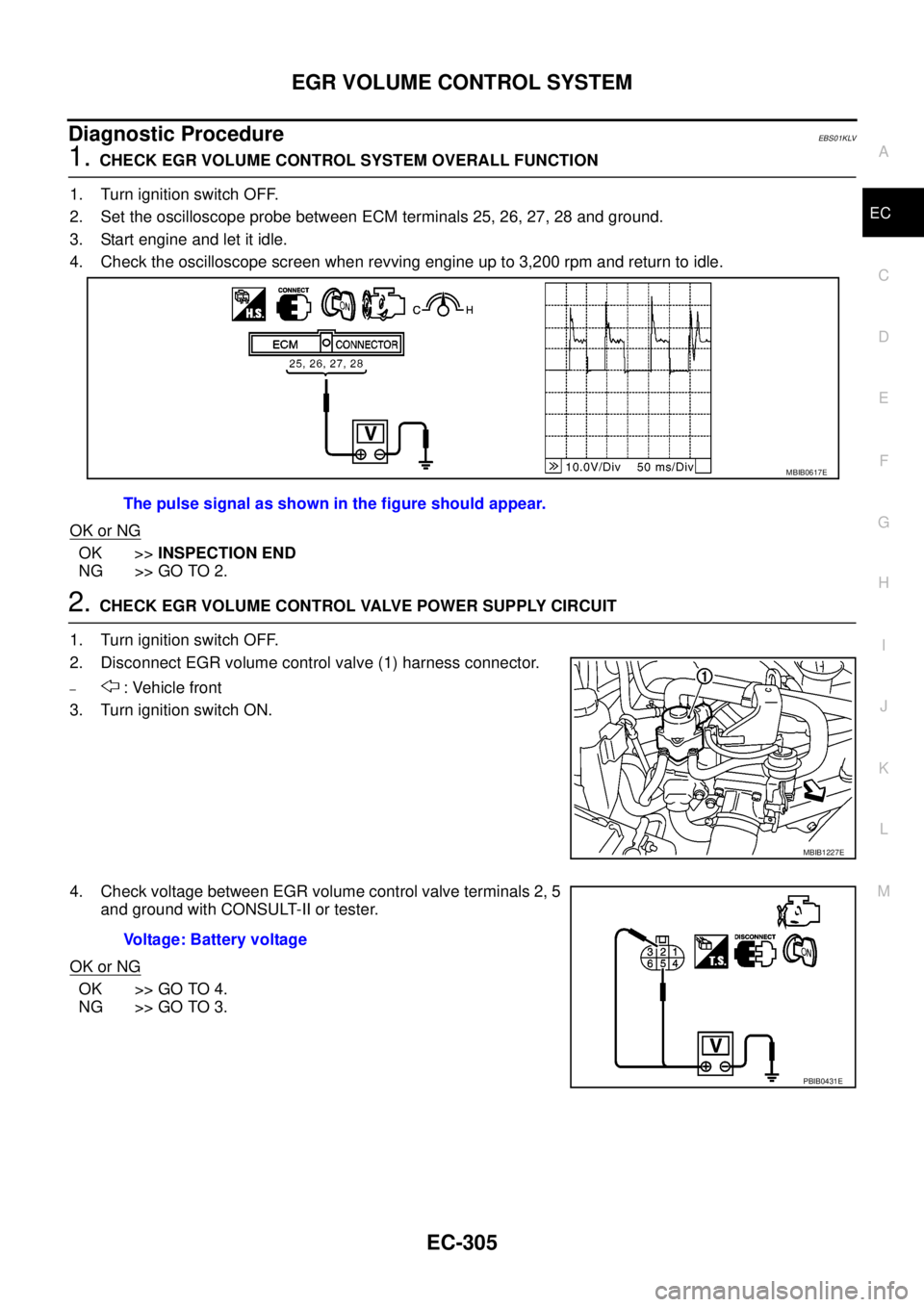

1.CHECK EGR VOLUME CONTROL SYSTEM OVERALL FUNCTION

1. Turn ignition switch OFF.

2. Set the oscilloscope probe between ECM terminals 25, 26, 27, 28 and ground.

3. Start engine and let it idle.

4. Check the oscilloscope screen when revving engine up to 3,200 rpm and return to idle.

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

2.CHECK EGR VOLUME CONTROL VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect EGR volume control valve (1) harness connector.

–: Vehicle front

3. Turn ignition switch ON.

4. Check voltage between EGR volume control valve terminals 2, 5

and ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.The pulse signal as shown in the figure should appear.

MBIB0617E

MBIB1227E

Voltage: Battery voltage

PBIB0431E

Page 1292 of 3171

EC-312

TC BOOST CONTROL SOLENOID VALVE

Diagnostic Procedure

EBS01KM2

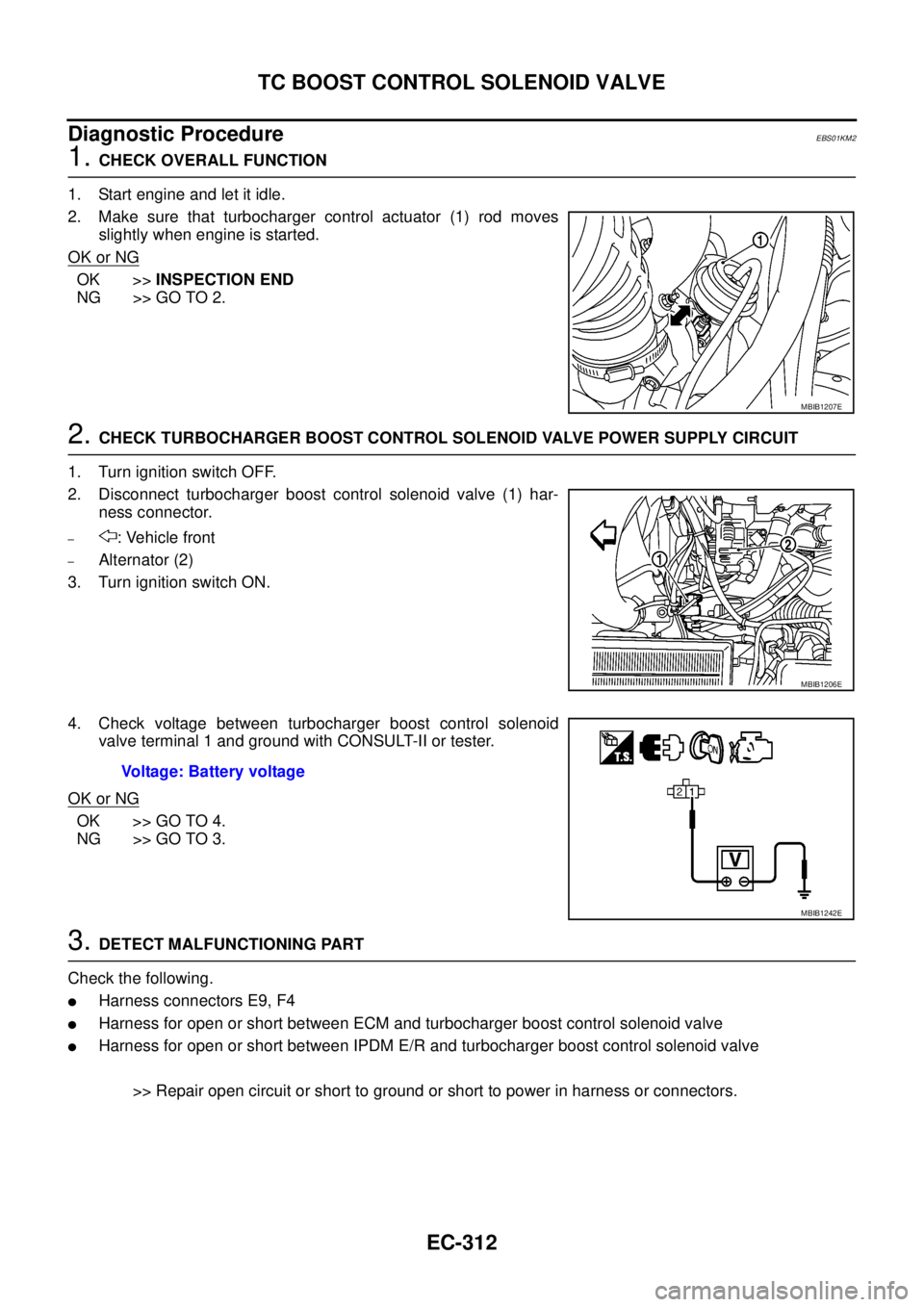

1.CHECK OVERALL FUNCTION

1. Start engine and let it idle.

2. Make sure that turbocharger control actuator (1) rod moves

slightly when engine is started.

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

2.CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect turbocharger boost control solenoid valve (1) har-

ness connector.

–: Vehicle front

–Alternator (2)

3. Turn ignition switch ON.

4. Check voltage between turbocharger boost control solenoid

valve terminal 1 and ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E9, F4

lHarness for open or short between ECM and turbocharger boost control solenoid valve

lHarness for open or short between IPDM E/R and turbocharger boost control solenoid valve

>> Repair open circuit or short to ground or short to power in harness or connectors.

MBIB1207E

MBIB1206E

Voltage: Battery voltage

MBIB1242E

Page 1296 of 3171

EC-316

INTAKE AIR CONTROL VALVE CONTROL SOLENOID VALVE

Diagnostic Procedure

EBS01KM8

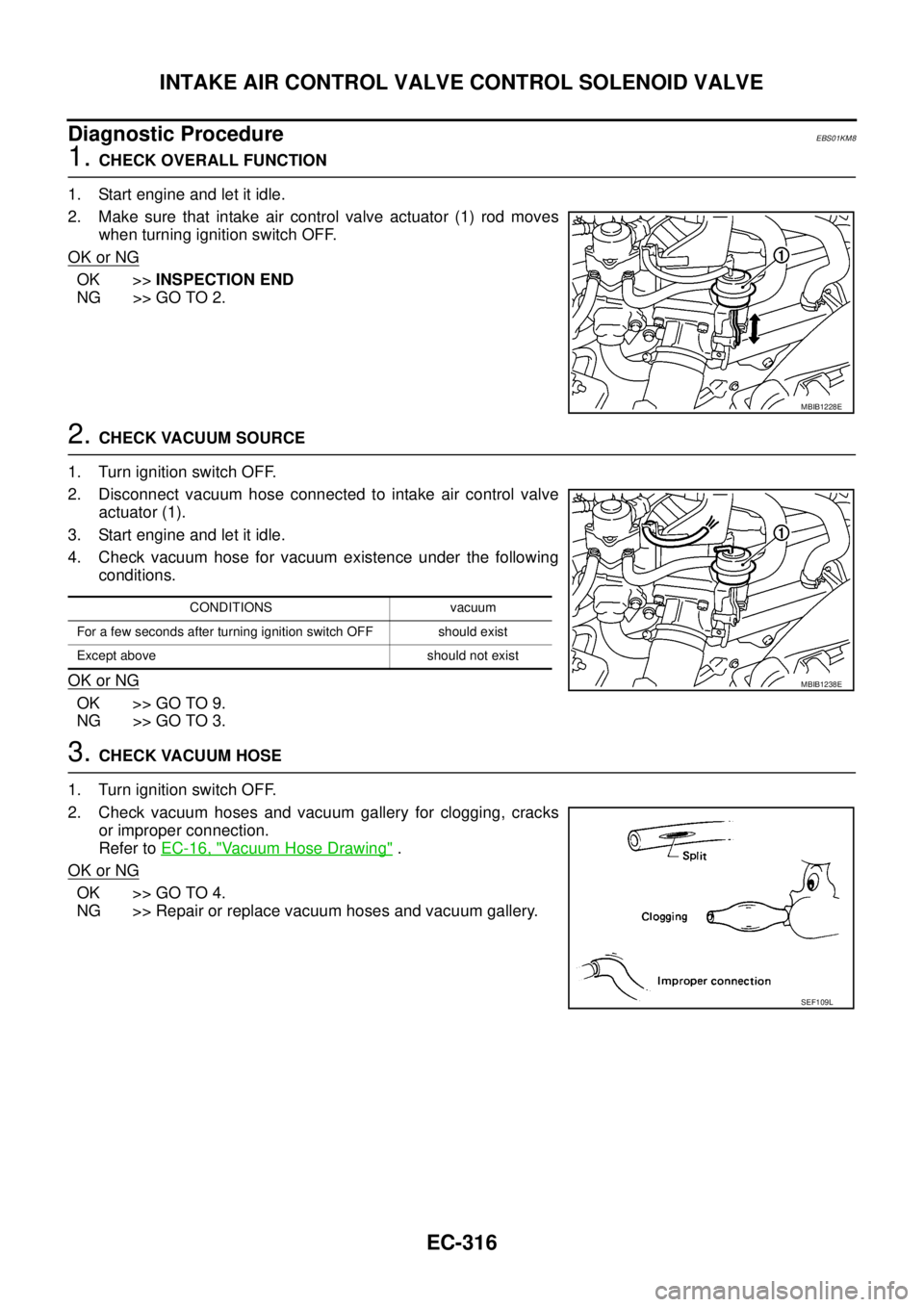

1.CHECK OVERALL FUNCTION

1. Start engine and let it idle.

2. Make sure that intake air control valve actuator (1) rod moves

when turning ignition switch OFF.

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

2.CHECK VACUUM SOURCE

1. Turn ignition switch OFF.

2. Disconnect vacuum hose connected to intake air control valve

actuator (1).

3. Start engine and let it idle.

4. Check vacuum hose for vacuum existence under the following

conditions.

OK or NG

OK >> GO TO 9.

NG >> GO TO 3.

3.CHECK VACUUM HOSE

1. Turn ignition switch OFF.

2. Check vacuum hoses and vacuum gallery for clogging, cracks

or improper connection.

Refer toEC-16, "

Vacuum Hose Drawing".

OK or NG

OK >> GO TO 4.

NG >> Repair or replace vacuum hoses and vacuum gallery.

MBIB1228E

CONDITIONS vacuum

For a few seconds after turning ignition switch OFF should exist

Except above should not exist

MBIB1238E

SEF109L

Page 1297 of 3171

INTAKE AIR CONTROL VALVE CONTROL SOLENOID VALVE

EC-317

C

D

E

F

G

H

I

J

K

L

MA

EC

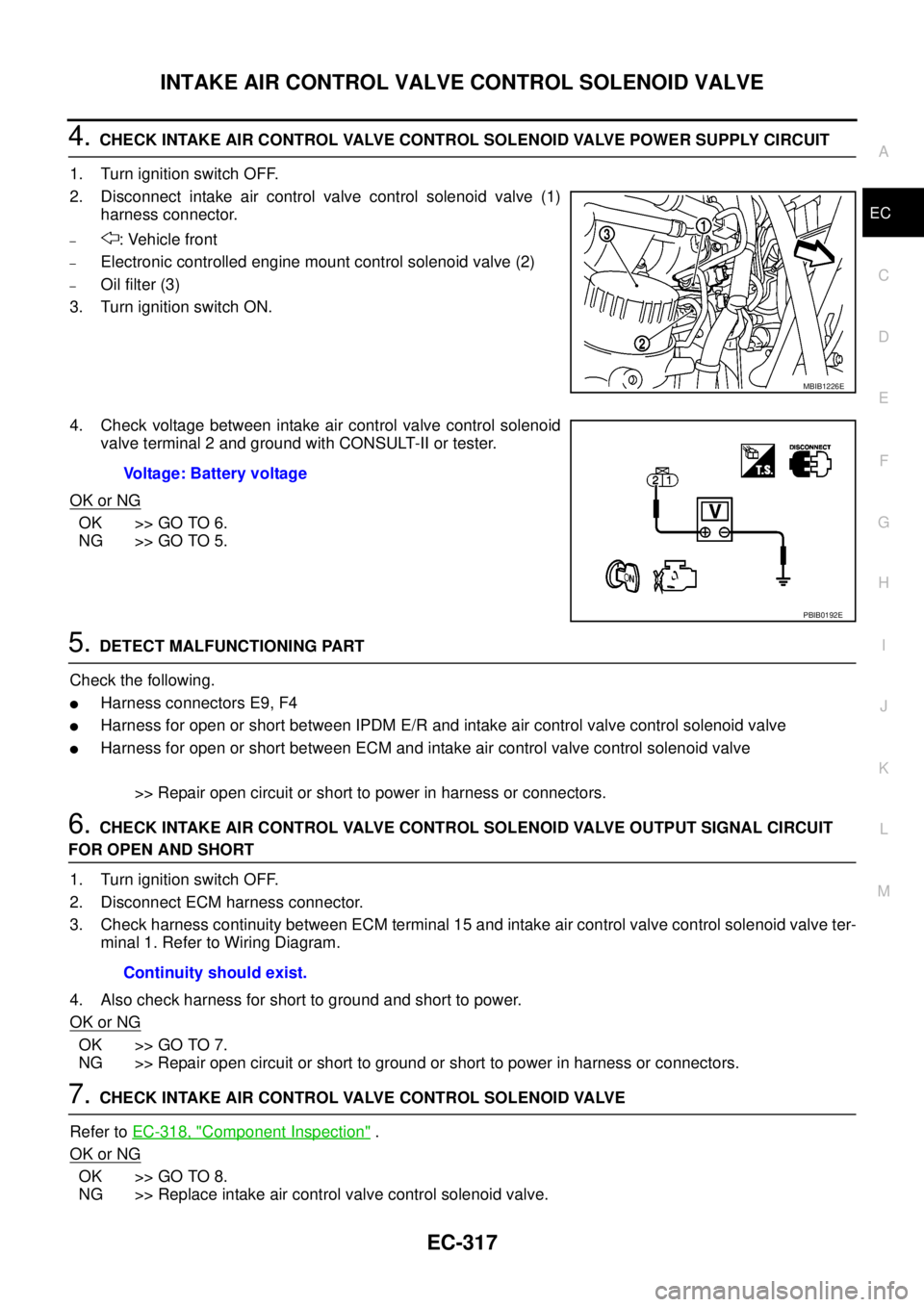

4.CHECK INTAKE AIR CONTROL VALVE CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect intake air control valve control solenoid valve (1)

harness connector.

–: Vehicle front

–Electronic controlled engine mount control solenoid valve (2)

–Oil filter (3)

3. Turn ignition switch ON.

4. Check voltage between intake air control valve control solenoid

valve terminal 2 and ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E9, F4

lHarness for open or short between IPDM E/R and intake air control valve control solenoid valve

lHarness for open or short between ECM and intake air control valve control solenoid valve

>> Repair open circuit or short to power in harness or connectors.

6.CHECK INTAKE AIR CONTROL VALVE CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT

FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 15 and intake air control valve control solenoid valve ter-

minal 1. Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 7.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

7.CHECK INTAKE AIR CONTROL VALVE CONTROL SOLENOID VALVE

Refer toEC-318, "

Component Inspection".

OK or NG

OK >> GO TO 8.

NG >> Replace intake air control valve control solenoid valve.

MBIB1226E

Voltage: Battery voltage

PBIB0192E

Continuity should exist.

Page 1298 of 3171

EC-318

INTAKE AIR CONTROL VALVE CONTROL SOLENOID VALVE

8.CHECK VACUUM PUMP

Refer toEM-42, "

VACUUM PUMP".

OK or NG

OK >> GO TO 9.

NG >> Replace vacuum pump assembly.

9.CHECK INTAKE AIR CONTROL VALVE ACTUATOR

1. Turn ignition switch OFF.

2. Install a vacuum pump A to intake air control valve actuator (1).

3. Make sure that the intake air control valve actuator rod moves

smoothly when applying vacuum of -53.3 kPa (-533 mbar, -400

mmHg, -15.75 inHg) and releasing it.

OK or NG

OK >> GO TO 10.

NG >> Replace intake air control valve actuator.

10.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

Component InspectionEBS01KM9

INTAKE AIR CONTROL VALVE CONTROL SOLENOID VALVE

1. Disconnect intake air control valve control solenoid valve (1)

harness connector.

l: Vehicle front

lElectronic controlled engine mount control solenoid valve (2)

lOil filter (3)

2. Apply 12V direct current between turbocharger boost control

solenoid valve terminals.

3. Check air passage continuity of intake air control valve control

solenoid valve under the following conditions.

Operation takes less than 1 second.

If NG, replace intake air control valve control solenoid valve.

MBIB1239E

MBIB1226E

CONDITIONSAir passage continuity

between (A) and (B)Air passage continuity

between (A) and (C)

12V direct current supply

between terminals (1) and (2)Ye s N o

No supply No Yes

MEC488B

Page 1307 of 3171

REFRIGERANT PRESSURE SENSOR

EC-327

C

D

E

F

G

H

I

J

K

L

MA

EC

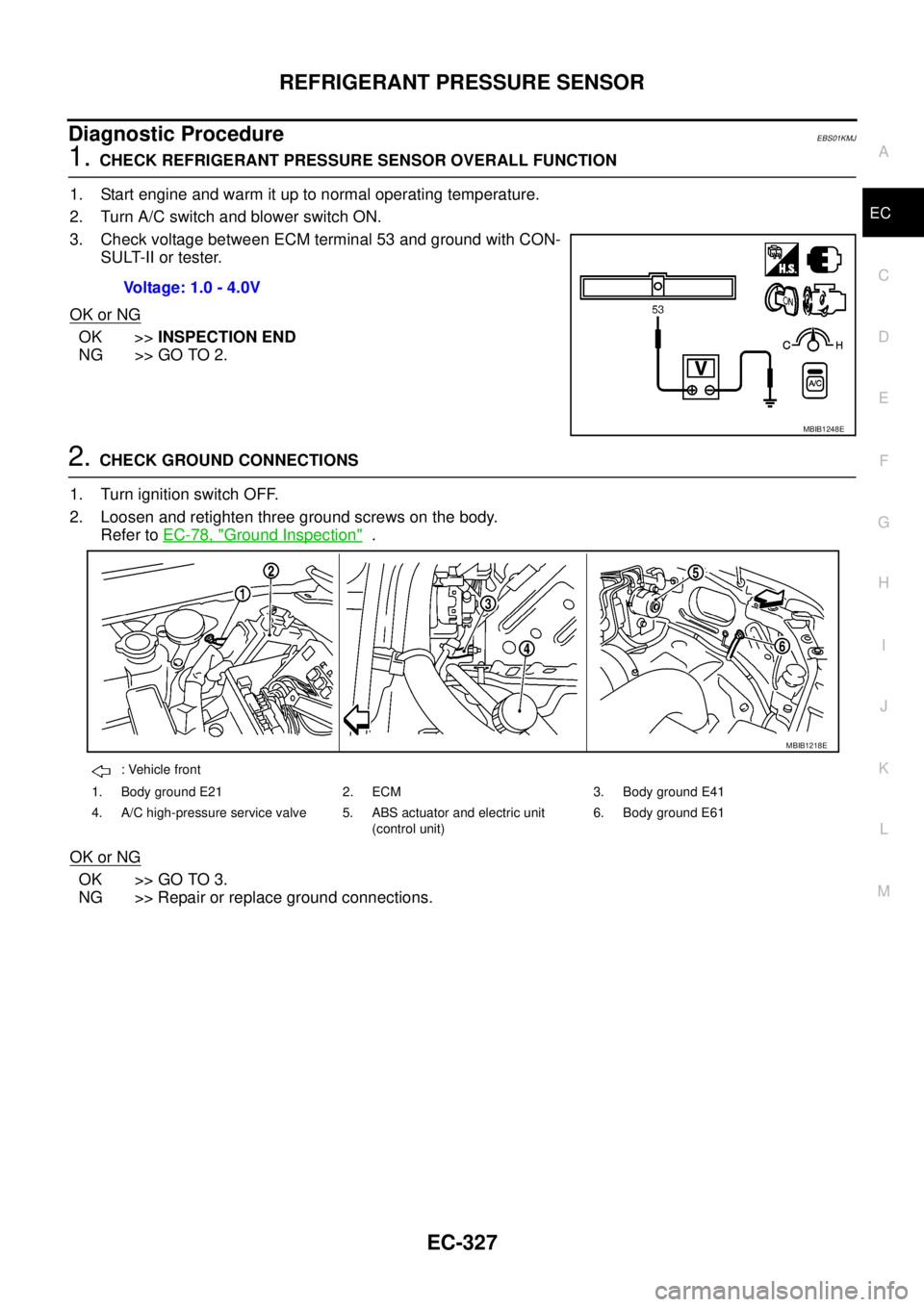

Diagnostic ProcedureEBS01KMJ

1.CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Turn A/C switch and blower switch ON.

3. Check voltage between ECM terminal 53 and ground with CON-

SULT-II or tester.

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

2.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer toEC-78, "

Ground Inspection".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace ground connections.Voltage: 1.0 - 4.0V

MBIB1248E

: Vehicle front

1. Body ground E21 2. ECM 3. Body ground E41

4. A/C high-pressure service valve 5. ABS actuator and electric unit

(control unit)6. Body ground E61

MBIB1218E

Page 1345 of 3171

SQUEAK AND RATTLE TROUBLE DIAGNOSES

EI-7

C

D

E

F

G

H

J

K

L

MA

B

EI

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

6) Raisethevehicleonahoistandhitatirewitharubberhammer.

lDrive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

lIf it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area.To help pinpoint the source of the noise, use a listening tool

(Engine Ear and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

lremoving the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be bro-

ken or lost during the repair, resulting in the creation of new noise.

ltapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only

temporarily.

lfeeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

lplacing a piece of paper between components that you suspect are causing the noise.

llooking for loose components and contact marks.

Refer toEI-7, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

lIf the cause is a loose component, tighten the component securely.

lIf the cause is insufficient clearance between components:

–separate components by repositioning or loosening and retightening the component, if possible.

–insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingEIS00DY6

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing