engine NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 591 of 3171

SQUEAK AND RATTLE TROUBLE DIAGNOSES

BL-7

C

D

E

F

G

H

J

K

L

MA

B

BL

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T models, drive position on A/T models).

6) Raisethevehicleonahoistandhitatirewitharubberhammer.

lDrive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

lIf it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool

(Engine Ear or mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

lremoving the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fastener can be broken

or lost during the repair, resulting in the creation of new noise.

ltapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only

temporarily.

lfeeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

lplacing a piece of paper between components that you suspect are causing the noise.

llooking for loose components and contact marks.

Refer toBL-8, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

lIf the cause is a loose component, tighten the component securely.

lIf the cause is insufficient clearance between components:

–separate components by repositioning or loosening and retightening the component, if possible.

–insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape are available through your authorized Nissan Parts Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Department for the latest parts information.

Each item can be ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100´135 mm (3.94´5.31 in)/76884-71L01: 60´85 mm (2.36´3.35 in)/76884-71L02: 15´

25 mm (0.59´0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50´50 mm (1.97´1.97 in)/73982-50Y00: 10 mm (0.39 in) thick, 50

´50 mm (1.97´1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30´50 mm (1.18´1.97 in)

Page 593 of 3171

SQUEAK AND RATTLE TROUBLE DIAGNOSES

BL-9

C

D

E

F

G

H

J

K

L

MA

B

BL

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 600 of 3171

BL-16

HOOD

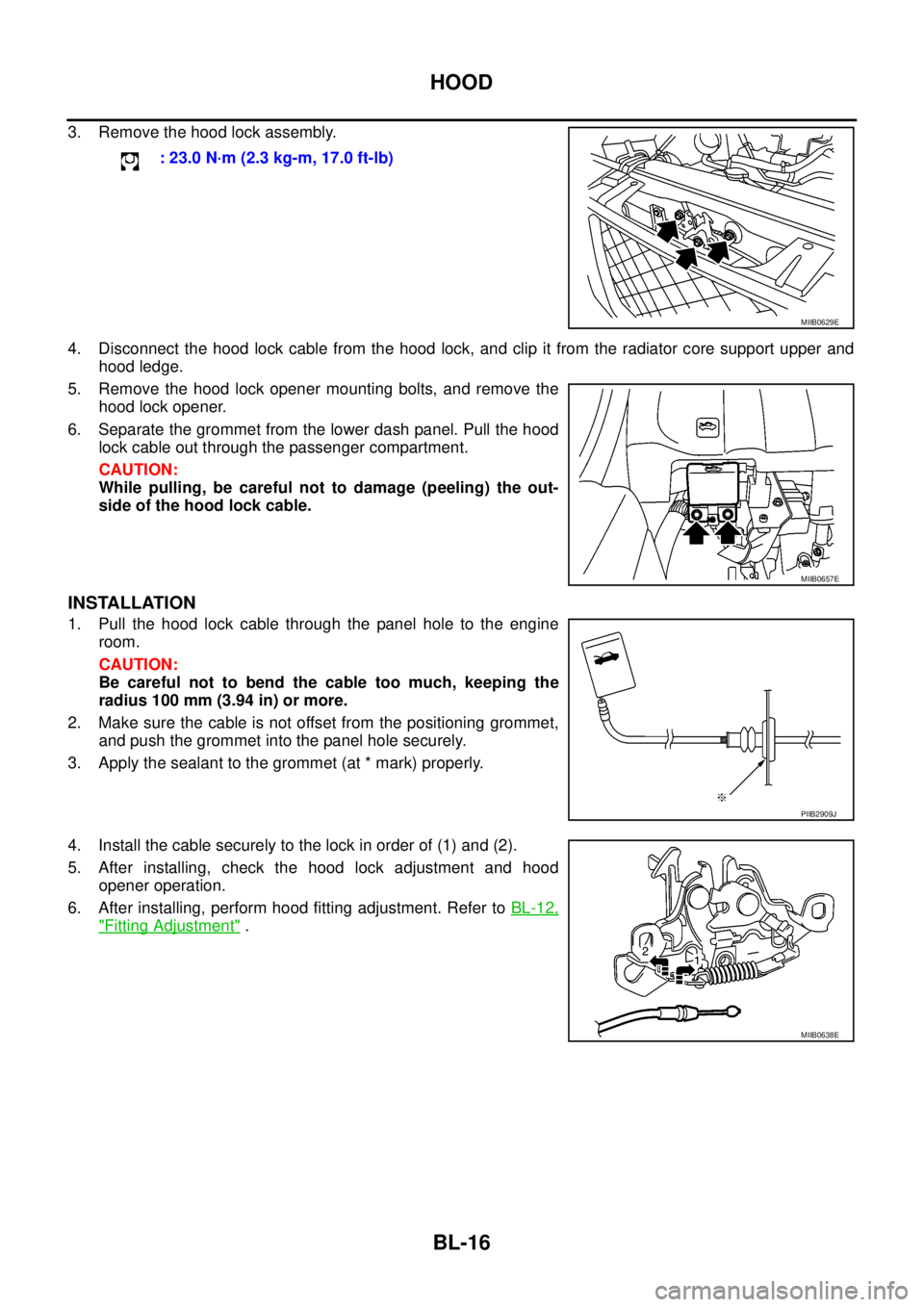

3. Remove the hood lock assembly.

4. Disconnect the hood lock cable from the hood lock, and clip it from the radiator core support upper and

hood ledge.

5. Remove the hood lock opener mounting bolts, and remove the

hood lock opener.

6. Separate the grommet from the lower dash panel. Pull the hood

lock cable out through the passenger compartment.

CAUTION:

While pulling, be careful not to damage (peeling) the out-

side of the hood lock cable.

INSTALLATION

1. Pull the hood lock cable through the panel hole to the engine

room.

CAUTION:

Be careful not to bend the cable too much, keeping the

radius 100 mm (3.94 in) or more.

2. Make sure the cable is not offset from the positioning grommet,

and push the grommet into the panel hole securely.

3. Apply the sealant to the grommet (at * mark) properly.

4. Install the cable securely to the lock in order of (1) and (2).

5. After installing, check the hood lock adjustment and hood

opener operation.

6. After installing, perform hood fitting adjustment. Refer toBL-12,

"Fitting Adjustment". : 23.0 N·m (2.3 kg-m, 17.0 ft-lb)

MIIB0629E

MIIB0657E

PIIB2909J

MIIB0638E

Page 602 of 3171

BL-18

RADIATOR CORE SUPPORT

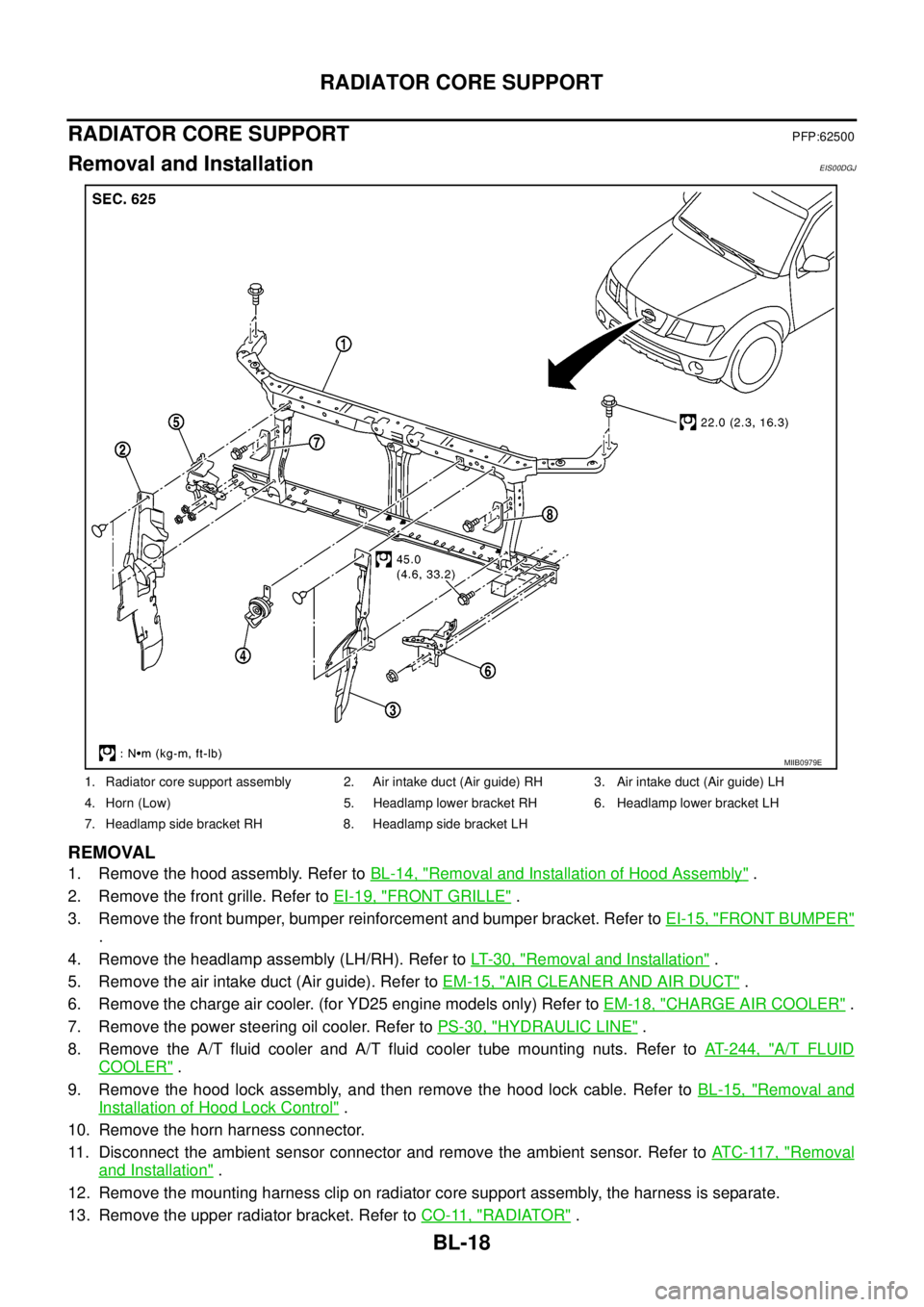

RADIATOR CORE SUPPORT

PFP:62500

Removal and InstallationEIS00DGJ

REMOVAL

1. Remove the hood assembly. Refer toBL-14, "Removal and Installation of Hood Assembly".

2. Remove the front grille. Refer toEI-19, "

FRONT GRILLE".

3. Remove the front bumper, bumper reinforcement and bumper bracket. Refer toEI-15, "

FRONT BUMPER"

.

4. Remove the headlamp assembly (LH/RH). Refer toLT-30, "

Removal and Installation".

5. Remove the air intake duct (Air guide). Refer toEM-15, "

AIR CLEANER AND AIR DUCT".

6. Remove the charge air cooler. (for YD25 engine models only) Refer toEM-18, "

CHARGE AIR COOLER".

7. Remove the power steering oil cooler. Refer toPS-30, "

HYDRAULIC LINE".

8. Remove the A/T fluid cooler and A/T fluid cooler tube mounting nuts. Refer toAT- 2 4 4 , "

A/T FLUID

COOLER".

9. Remove the hood lock assembly, and then remove the hood lock cable. Refer toBL-15, "

Removal and

Installation of Hood Lock Control".

10. Remove the horn harness connector.

11. Disconnect the ambient sensor connector and remove the ambient sensor. Refer toAT C - 11 7 , "

Removal

and Installation".

12. Remove the mounting harness clip on radiator core support assembly, the harness is separate.

13. Remove the upper radiator bracket. Refer toCO-11, "

RADIATOR".

1. Radiator core support assembly 2. Air intake duct (Air guide) RH 3. Air intake duct (Air guide) LH

4. Horn (Low) 5. Headlamp lower bracket RH 6. Headlamp lower bracket LH

7. Headlamp side bracket RH 8. Headlamp side bracket LH

MIIB0979E

Page 724 of 3171

BL-140

THEFT WARNING SYSTEM

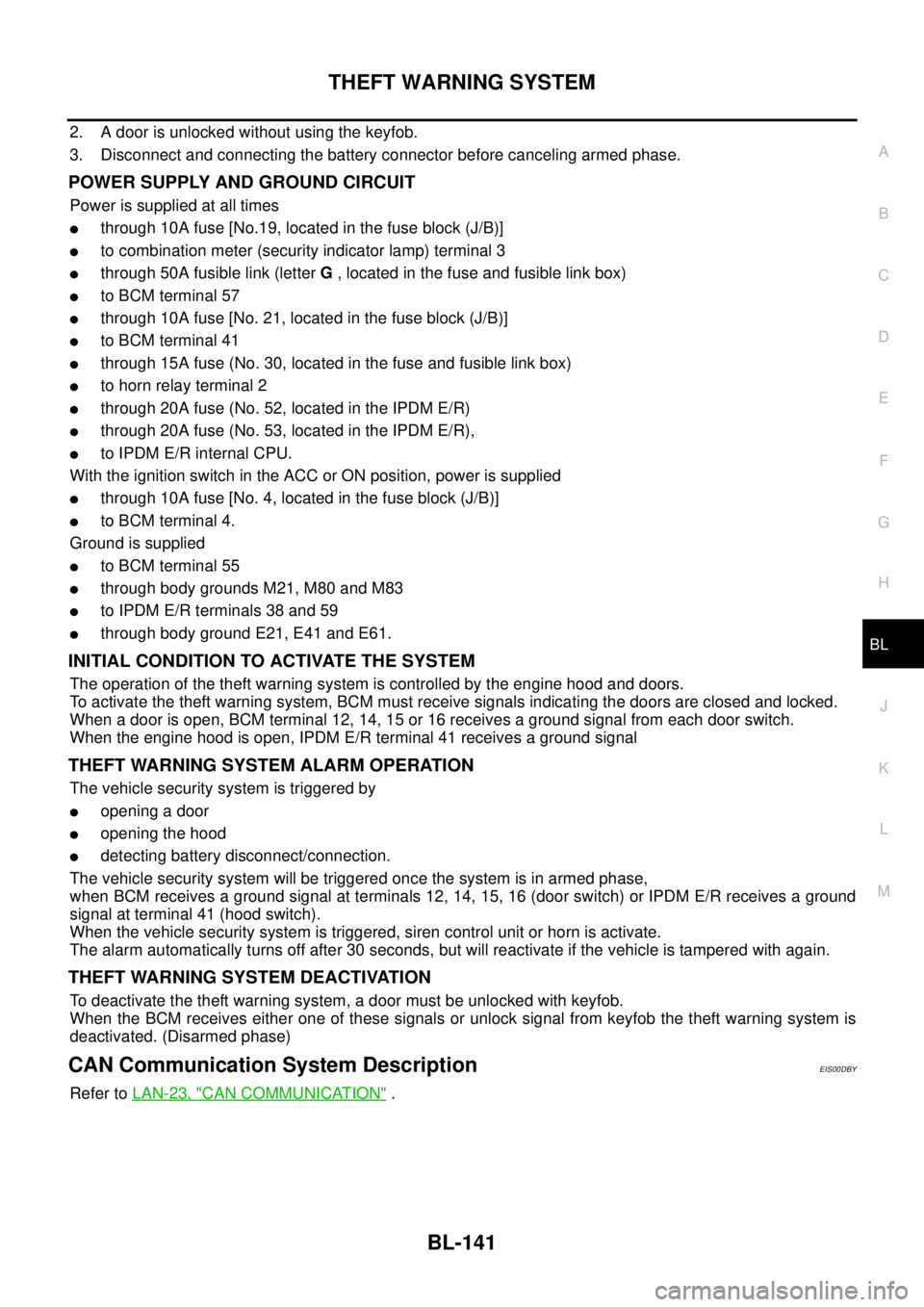

System Description

EIS00DBX

DESCRIPTION

Operation Flow

Setting the theft warning system

Initial condition

lIgnition switch is in OFF position.

Disarmed phase

lWhen the vehicle is being driven or when doors are open, the theft warning system is set in the disarmed

phase on the assumption that the owner is inside or near the vehicle.

Pre-armed phase and armed phase

lThe theft warning system turns into the “pre-armed” phase when all doors are closed and locked. The

security indicator lamp illuminates for 20 seconds. Then, the system automatically shifts into the “armed”

phase.

Canceling the set theft warning system

When one of the following operations is performed, the armed phase is canceled.

1. Unlock the doors with the keyfob.

2. Unlock the doors with the ignition key.

Activating the alarm operation of the theft warning system

Make sure the system is in the armed phase.

When any of the following operation 1, 2 or 3 is performed, the system sounds the siren control unit or horn

and flashes the turn signal lamps for about 30 seconds.

1. Engine hood or any doors is opened before unlocking door with keyfob.

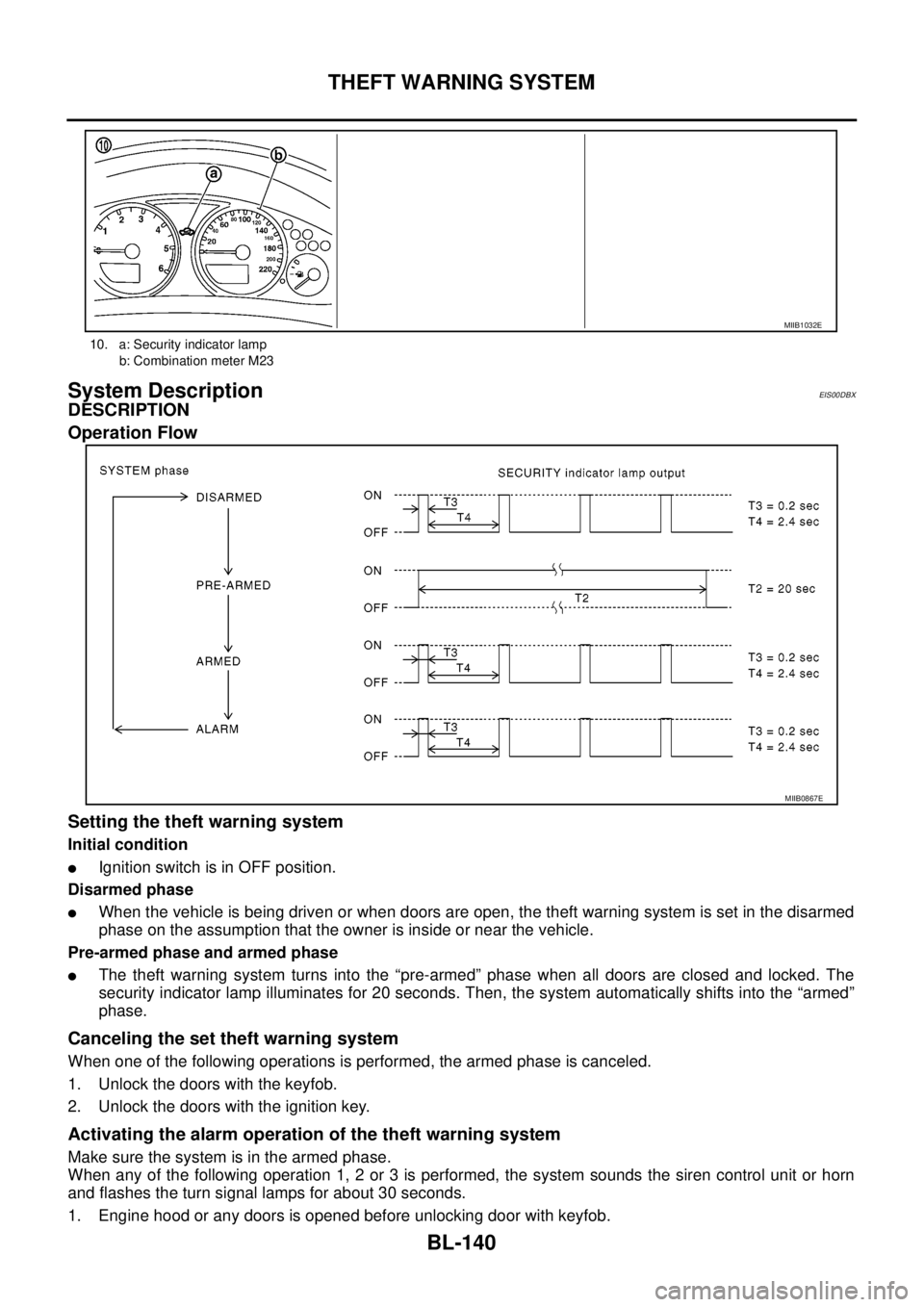

10. a: Security indicator lamp

b: Combination meter M23

MIIB1032E

MIIB0867E

Page 725 of 3171

THEFT WARNING SYSTEM

BL-141

C

D

E

F

G

H

J

K

L

MA

B

BL

2. A door is unlocked without using the keyfob.

3. Disconnect and connecting the battery connector before canceling armed phase.

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

lthrough 10A fuse [No.19, located in the fuse block (J/B)]

lto combination meter (security indicator lamp) terminal 3

lthrough 50A fusible link (letterG, located in the fuse and fusible link box)

lto BCM terminal 57

lthrough 10A fuse [No. 21, located in the fuse block (J/B)]

lto BCM terminal 41

lthrough 15A fuse (No. 30, located in the fuse and fusible link box)

lto horn relay terminal 2

lthrough 20A fuse (No. 52, located in the IPDM E/R)

lthrough 20A fuse (No. 53, located in the IPDM E/R),

lto IPDM E/R internal CPU.

With the ignition switch in the ACC or ON position, power is supplied

lthrough 10A fuse [No. 4, located in the fuse block (J/B)]

lto BCM terminal 4.

Ground is supplied

lto BCM terminal 55

lthrough body grounds M21, M80 and M83

lto IPDM E/R terminals 38 and 59

lthrough body ground E21, E41 and E61.

INITIAL CONDITION TO ACTIVATE THE SYSTEM

The operation of the theft warning system is controlled by the engine hood and doors.

To activate the theft warning system, BCM must receive signals indicating the doors are closed and locked.

When a door is open, BCM terminal 12, 14, 15 or 16 receives a ground signal from each door switch.

When the engine hood is open, IPDM E/R terminal 41 receives a ground signal

THEFT WARNING SYSTEM ALARM OPERATION

The vehicle security system is triggered by

lopening a door

lopening the hood

ldetecting battery disconnect/connection.

The vehicle security system will be triggered once the system is in armed phase,

when BCM receives a ground signal at terminals 12, 14, 15, 16 (door switch) or IPDM E/R receives a ground

signal at terminal 41 (hood switch).

When the vehicle security system is triggered, siren control unit or horn is activate.

The alarm automatically turns off after 30 seconds, but will reactivate if the vehicle is tampered with again.

THEFT WARNING SYSTEM DEACTIVATION

To deactivate the theft warning system, a door must be unlocked with keyfob.

When the BCM receives either one of these signals or unlock signal from keyfob the theft warning system is

deactivated. (Disarmed phase)

CAN Communication System DescriptionEIS00DBY

Refer toLAN-23, "CAN COMMUNICATION".

Page 740 of 3171

BL-156

THEFT WARNING SYSTEM

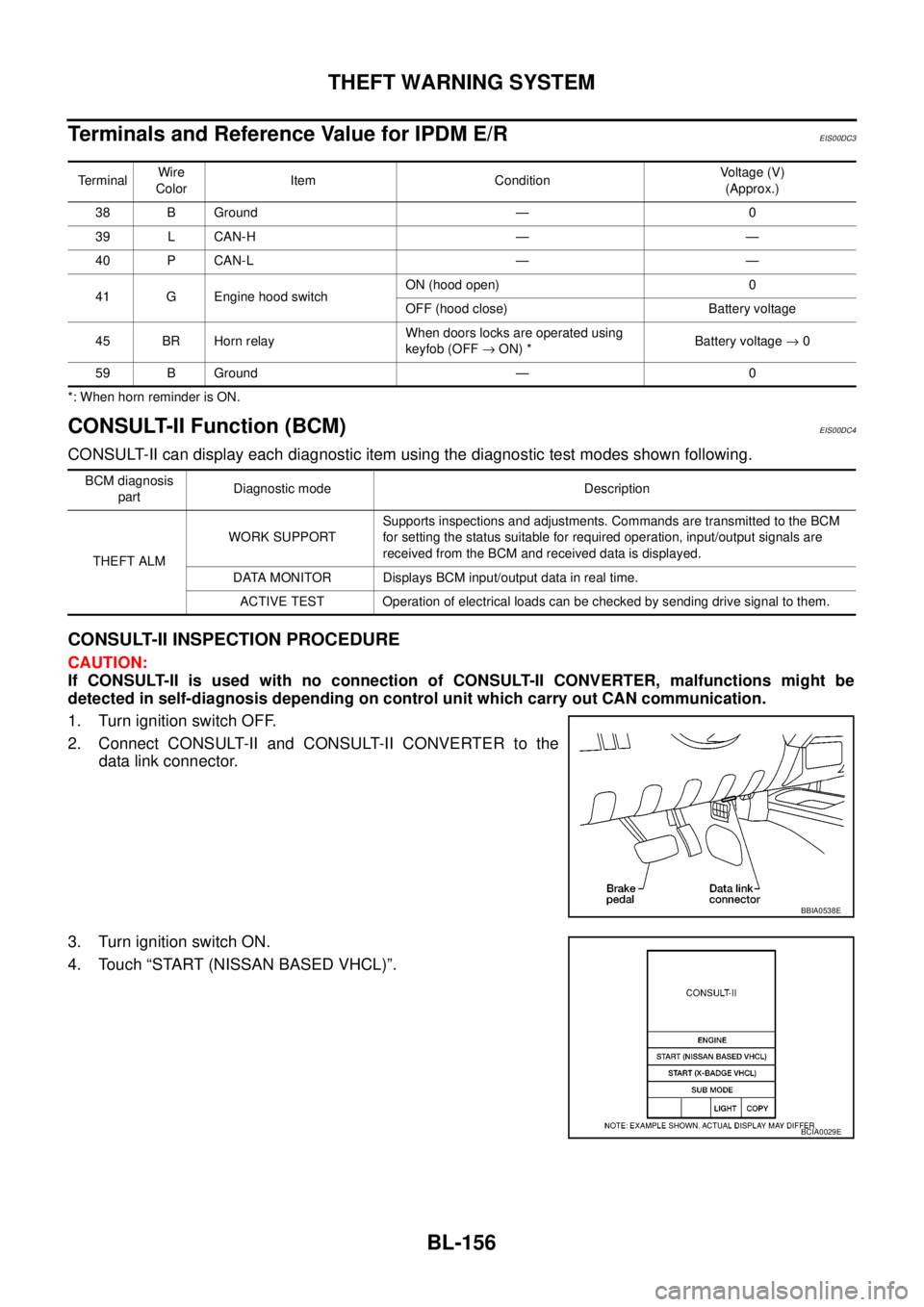

TerminalsandReferenceValueforIPDME/R

EIS00DC3

*: When horn reminder is ON.

CONSULT-II Function (BCM)EIS00DC4

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II INSPECTION PROCEDURE

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. Turn ignition switch OFF.

2. Connect CONSULT-II and CONSULT-II CONVERTER to the

data link connector.

3. Turn ignition switch ON.

4. Touch “START (NISSAN BASED VHCL)”.

TerminalWire

ColorItem ConditionVoltage (V)

(Approx.)

38 B Ground — 0

39 L CAN-H — —

40 P CAN-L — —

41 G Engine hood switchON (hood open) 0

OFF (hood close) Battery voltage

45 BR Horn relayWhen doors locks are operated using

keyfob (OFF®ON) *Battery voltage®0

59 B Ground — 0

BCM diagnosis

partDiagnostic mode Description

THEFT ALMWORK SUPPORTSupports inspections and adjustments. Commands are transmitted to the BCM

for setting the status suitable for required operation, input/output signals are

received from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

BBIA0538E

BCIA0029E

Page 754 of 3171

BL-170

NATS(NISSAN ANTI-THEFT SYSTEM)

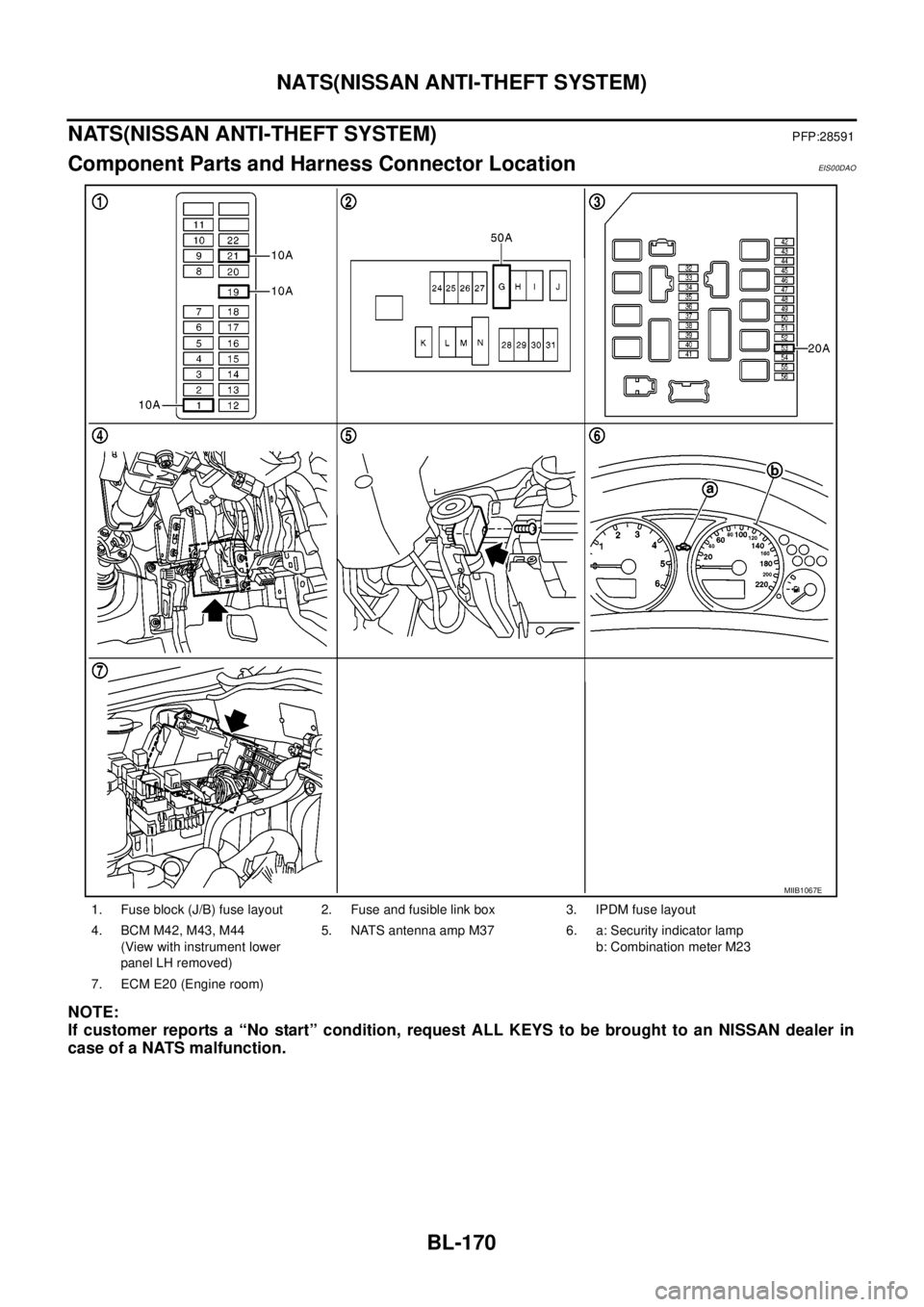

NATS(NISSAN ANTI-THEFT SYSTEM)

PFP:28591

Component Parts and Harness Connector LocationEIS00DAO

NOTE:

If customer reports a “No start” condition, request ALL KEYS to be brought to an NISSAN dealer in

case of a NATS malfunction.

1. Fuse block (J/B) fuse layout 2. Fuse and fusible link box 3. IPDM fuse layout

4. BCM M42, M43, M44

(View with instrument lower

panel LH removed)5. NATS antenna amp M37 6. a: Security indicator lamp

b: Combination meter M23

7. ECM E20 (Engine room)

MIIB1067E

Page 755 of 3171

NATS(NISSAN ANTI-THEFT SYSTEM)

BL-171

C

D

E

F

G

H

J

K

L

MA

B

BL

System DescriptionEIS00DAP

NATS (Nissan Anti-Theft System) has the following immobilizer functions:

lSince only NATS ignition keys, whose ID No. s have been registered into the ECM and IMMU of NATS,

allow the engine to run, a vehicle operation without a registered key in NATS is prevented by NATS.

That is to say, NATS will immobilize the engine if someone tries to start it without the registered key of

NATS.

lThis version of NATS has dongle unit to improve its anti-theft performance (RHD models). Dongle unit has

its own ID which is registered into NATS IMMU. So if dongle unit is replaced, initialization must be per-

formed.

lWhen malfunction of dongle unit is detected:

The security indicator lamp illuminates for about 15 minutes after ignition switch is turned to ON.

–When dongle unit has a malfunction and the indicator lamp is illuminated, engine cannot be started. How-

ever engine can be started only one time when security indicator lamp turns off in about 15 minutes after

ignition switch is turned to ON.

lAll of the originally supplied ignition key IDs have been NATS registered in NATS.

If the vehicle owner requests, a maximum of four key IDs can be registered into the NATS components.

lThe security indicator blinks when the ignition switch is in “OFF” or “ACC” position. Therefore, NATS

warns outsiders that the vehicle is equipped with the anti-theft system.

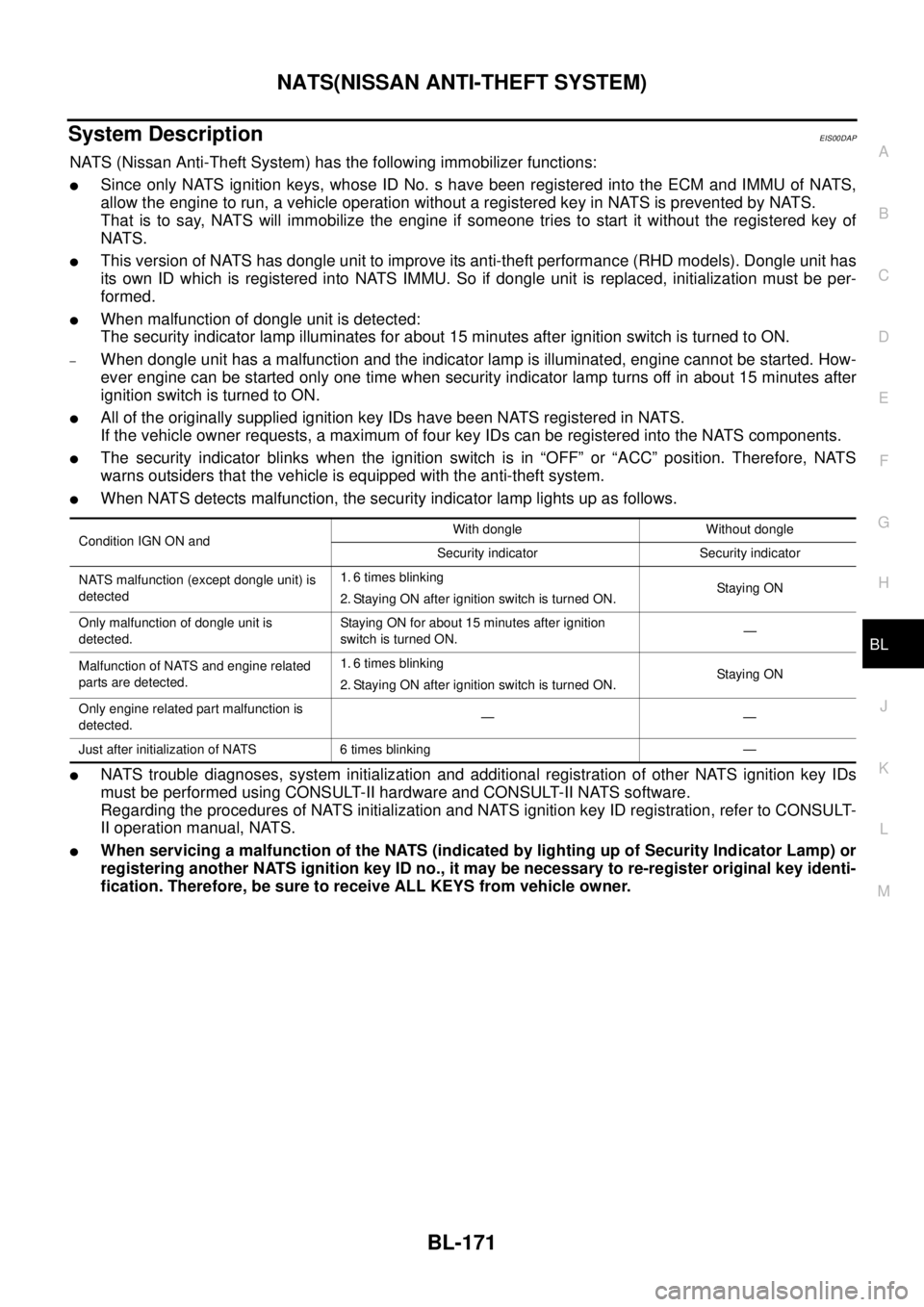

lWhen NATS detects malfunction, the security indicator lamp lights up as follows.

lNATS trouble diagnoses, system initialization and additional registration of other NATS ignition key IDs

must be performed using CONSULT-II hardware and CONSULT-II NATS software.

Regarding the procedures of NATS initialization and NATS ignition key ID registration, refer to CONSULT-

II operation manual, NATS.

lWhen servicing a malfunction of the NATS (indicated by lighting up of Security Indicator Lamp) or

registering another NATS ignition key ID no., it may be necessary to re-register original key identi-

fication. Therefore, be sure to receive ALL KEYS from vehicle owner.

Condition IGN ON andWith dongle Without dongle

Security indicator Security indicator

NATS malfunction (except dongle unit) is

detected1. 6 times blinking

2. Staying ON after ignition switch is turned ON.Staying ON

Only malfunction of dongle unit is

detected.Staying ON for about 15 minutes after ignition

switch is turned ON.—

Malfunction of NATS and engine related

parts are detected.1. 6 times blinking

2. Staying ON after ignition switch is turned ON.Staying ON

Only engine related part malfunction is

detected.——

Just after initialization of NATS 6 times blinking —

Page 756 of 3171

BL-172

NATS(NISSAN ANTI-THEFT SYSTEM)

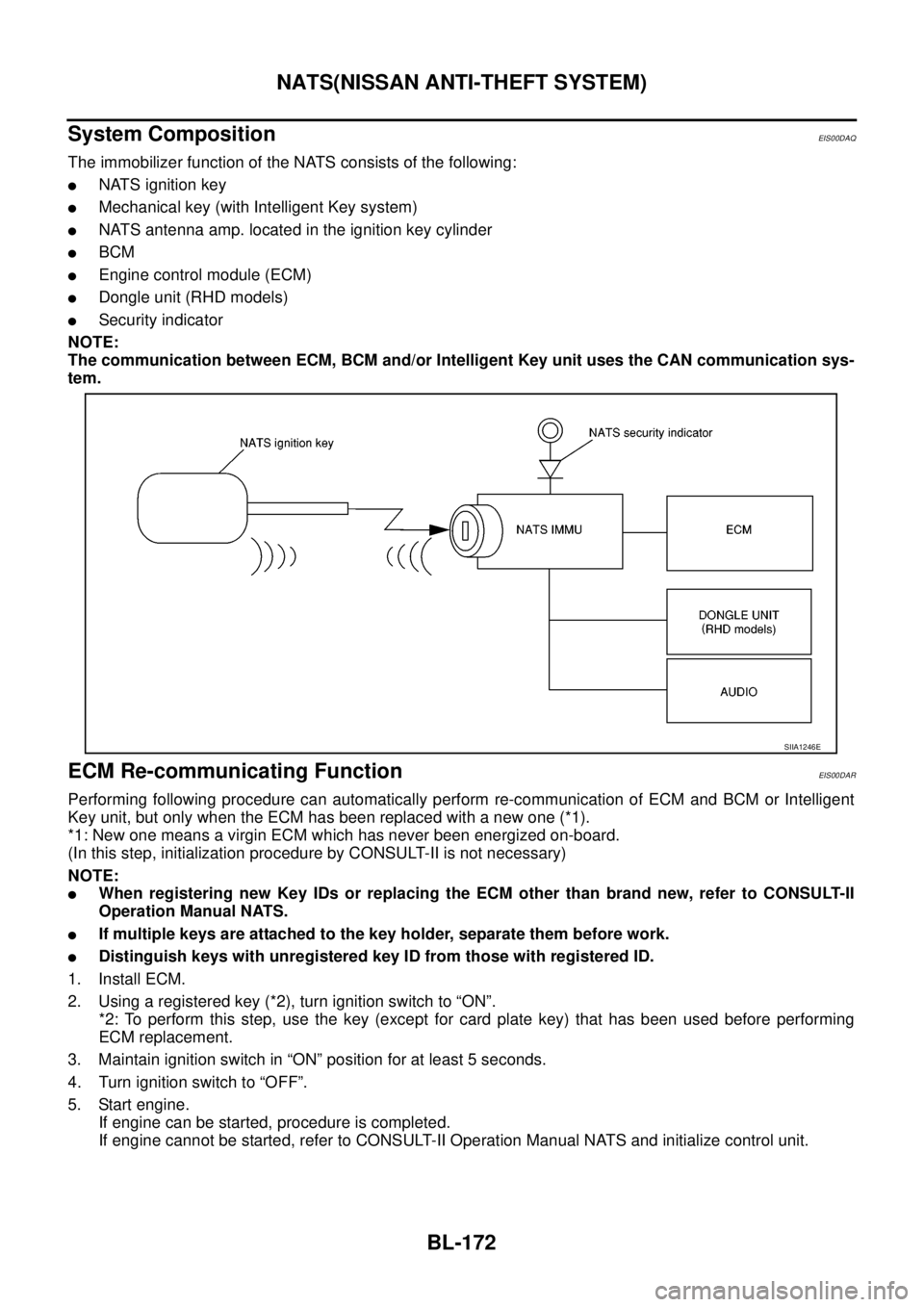

System Composition

EIS00DAQ

The immobilizer function of the NATS consists of the following:

lNATS ignition key

lMechanical key (with Intelligent Key system)

lNATS antenna amp. located in the ignition key cylinder

lBCM

lEngine control module (ECM)

lDongle unit (RHD models)

lSecurity indicator

NOTE:

The communication between ECM, BCM and/or Intelligent Key unit uses the CAN communication sys-

tem.

ECM Re-communicating FunctionEIS00DAR

Performing following procedure can automatically perform re-communication of ECM and BCM or Intelligent

Key unit, but only when the ECM has been replaced with a new one (*1).

*1: New one means a virgin ECM which has never been energized on-board.

(In this step, initialization procedure by CONSULT-II is not necessary)

NOTE:

lWhen registering new Key IDs or replacing the ECM other than brand new, refer to CONSULT-II

Operation Manual NATS.

lIf multiple keys are attached to the key holder, separate them before work.

lDistinguish keys with unregistered key ID from those with registered ID.

1. Install ECM.

2. Usingaregisteredkey(*2),turnignitionswitchto“ON”.

*2: To perform this step, use the key (except for card plate key) that has been used before performing

ECM replacement.

3. Maintain ignition switch in “ON” position for at least 5 seconds.

4. Turn ignition switch to “OFF”.

5. Start engine.

If engine can be started, procedure is completed.

If engine cannot be started, refer to CONSULT-II Operation Manual NATS and initialize control unit.

SIIA1246E