ECO mode NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2544 of 3171

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-15

C

D

E

F

G

H

I

J

L

MA

B

PG

IPDM E/R STATUS CONTROL

In order to save power, IPDM E/R switches status by itself based on each operating condition.

1. CAN communication status

lCAN communication is normally performed with other control units.

lIndividual unit control by IPDM E/R is normally performed.

lA status is changed into sleep transient status when receiving a sleep request signal from BCM while

all the systems controlled by IPDM E/R under suspension.

2. Sleep transient status

lProcess to stop CAN communication is activated.

lAll systems controlled by IPDM E/R are stopped. When 3 second has elapsed after CAN communica-

tion with other control units is stopped, status switches to sleep status.

3. Sleep status

lIPDM E/R operates in low power mode.

lCAN communication is stopped.

lWhen a change in CAN communication signal is detected, status switches to CAN communication sta-

tus.

lWhen a change in ignition switch signal is detected, status switches to CAN communication status.

CAN Communication System DescriptionEKS00PA9

Refer toLAN-23, "CAN COMMUNICATION".

Function of Detecting Ignition Relay MalfunctionEKS00PAA

lWhen the integrated ignition relay is stuck in a “closed contact” position and cannot be turned OFF, IPDM

E/R turns ON tail and parking lamps for 10 minutes to indicate IPDM E/R malfunction.

lWhen the state of the integrated ignition relay does not agree with the state of the ignition switch signal

received with CAN communication, the IPDM E/R activates the tail lamp relay.

NOTE:

When the ignition switch is turned ON, the tail lamps are OFF.

Ignition switch signal Ignition relay status Tail lamp relay

ON ON —

OFF OFF —

ON OFF —

OFF ON ON (10 minutes)

Page 2547 of 3171

PG-18

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

5. Touch “RECORD” while monitoring to record the status of the item being monitored. To stop recording,

touch “STOP”.

All Signals, Main Signals, Selection From Menu

NOTE:

Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is in ACC position,

display may not be correct.

CAN DIAG SUPPORT MNTR

Refer toLAN-15, "CAN Diagnostic Support Monitor".

ACTIVE TEST

Operation Procedure

1. Touch “ACTIVE TEST” on “SELECT DIAG-MODE” screen.

2. Touch item to be tested, and check operation.

3. Touch “START”.

4. Touch “STOP” while testing to stop the operation.

Item nameCONSULT-II

screen displayDisplay or unitMonitor item selection

Description

ALL

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

Motor fan requestMOTOR FAN

REQ1/2/3/4 X X X Signal status input from ECM

A/C compressor

requestAC COMP REQ ON/OFF X X X Signal status input from ECM

Tail & clear

requestTAIL & CLR REQ ON/OFF X X X Signal status input from BCM

Headlamp LO

requestHL LO REQ ON/OFF X X X Signal status input from BCM

Headlamp HI

requestHL HI REQ ON/OFF X X X Signal status input from BCM

Front fog lamp

requestFR FOG REQ ON/OFF X X X Signal status input from BCM

Headlamp washer

requestHL WASHER

REQON/OFF X X Signal from input from BCM

Front wiper

requestFR WIP REQSTOP/1LOW/

LOW/HIX X X Signal status input from BCM

Wiper auto stopWIP AUTO

STOPACT P/STOP P X X X Output status of IPDM E/R

Wiper protection WIP PROT OFF/BLOCK X X X Control status of IPDM E/R

Starter request ST RLY REQ ON/OFF X X

Status of input signal

NOTE

Ignition relay

statusIGN RLY ON/OFF X X XIgnition relay status monitored

with IPDM E/R

Rear defogger

requestRR DEF REQ ON/OFF X X X Signal status input from BCM

Oil pressure

switchOIL P SW OPEN/CLOSE X XSignal status input from IPDM

E/R

Hood switch HOOD SW OFF XSignal status input from IPDM

E/R (function is not enabled)

Theft warning

horn requestTHFT HRN REQ ON/OFF X X Signal status input from BCM

Horn chirp HORN CHIRP ON/OFF X X Output status of IPDM E/R

Page 2548 of 3171

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-19

C

D

E

F

G

H

I

J

L

MA

B

PG

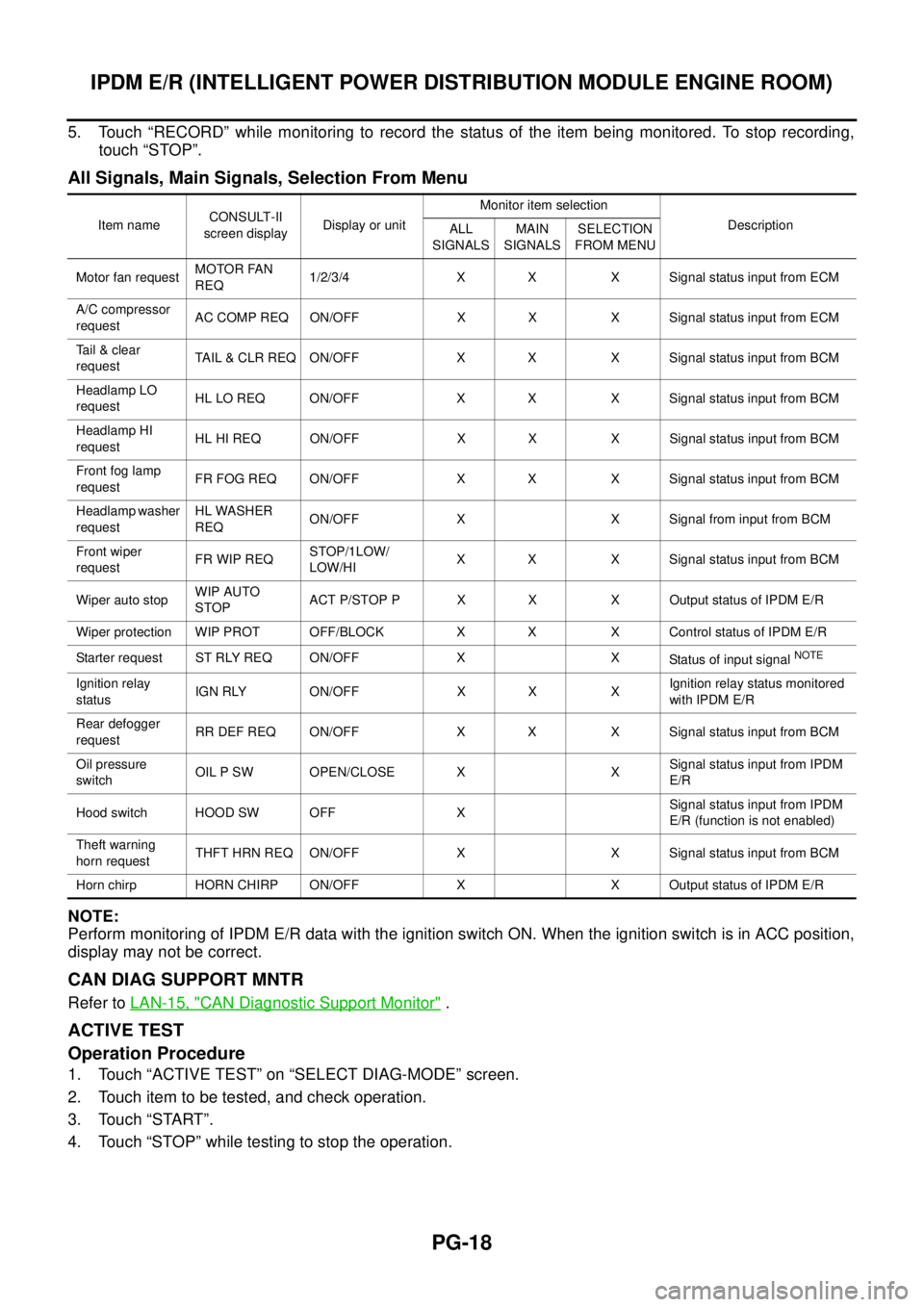

Auto Active TestEKS00PAC

DESCRIPTION

lIn auto active test mode, operation inspection can be performed when IPDM E/R sends a drive signal to

the following systems:

–Rear window defogger

–Front wiper

–Tail lamps, front fog lamps, parking lamps and license plate lamps

–Headlamps (HI, LO)

–A/C compressor (magnetic clutch)

–Cooling fan

–Oil pressure warning lamp

OPERATION PROCEDURE

1. Close hood and front door passenger side, and then lift wiper arms away from windshield (to prevent

glass damage by wiper operation).

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn ignition switch OFF.

3. Turn ignition switch ON and, within 20 seconds, press driver's door switch 10 times (close other doors).

Then turn ignition switch OFF.

4. Turn ignition switch ON within 10 seconds after ignition switch OFF.

5. When auto active test mode is actuated, oil pressure warning lamp starts blinking.

6. After a series of operations is repeated three times, auto active test is completed.

NOTE:

When auto active test mode has to be cancelled halfway, turn ignition switch OFF.

CAUTION:

Be sure to performBL-39, "

Check Door Switch"when the auto active test cannot be performed.

Test name CONSULT-II screen display Description

Rear defogger output REAR DEFOGGERWith a certain ON-OFF operation, the rear defogger relay can be oper-

ated.

Front wiper (HI, LO) output FRONT WIPERWith a certain operation (OFF, HI ON, LO ON), the front wiper relay

(Lo, Hi) can be operated.

Cooling fan output MOTOR FAN With a certain operation (1, 2, 3, 4), the cooling fan can be operated.

Lamp (HI, LO, TAIL, FOG)

outputEXTERNAL LAMPSWith a certain operation (OFF, HI ON, LO ON, TAIL ON, FOG ON), the

lamp relay (Low, High, Tail, Fog) can be operated.

Horn output HORN With a certain ON-OFF operation, the horn relay can be operated.

Page 2549 of 3171

PG-20

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

INSPECTION IN AUTO ACTIVE TEST MODE

When auto active test mode is actuated, the following six steps are repeated three times.

A: Oil pressure warning lamp is blinking when the auto active test operating.

Operation steps

Concept of Auto Active Test

lIPDM E/R actuates auto active test mode when it receives door switch signal from BCM via CAN commu-

nication line. Therefore, when auto active test mode is activated successfully, CAN communication

between IPDM E/R and BCM is normal.

lIf any of the systems controlled by IPDM E/R cannot be operated, possible cause can be easily diagnosed

using auto active test.

SKIB6851E

Step Test item Operation time/ frequency

1 Rear window defogger 10 seconds

2 Front wiper LO 5 seconds®HI 5 seconds

3 Tail lamps, front fog lamps, parking lamps, license plate lamps 10 seconds

4 Headlamps LO 10 seconds®HI ON-OFF 5 times

5 A/C compressor ON-OFF 5 times

6 Cooling fan LO 5 seconds®HI 5 seconds

PKIC1721E

Page 2736 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual PRECAUTIONS

RFD-33

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH ELECTRONIC LOCKING DIFFERENTIAL]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “A NISSAN NAVARA 2005 Repair Workshop Manual PRECAUTIONS

RFD-33

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH ELECTRONIC LOCKING DIFFERENTIAL]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “A](/img/5/57362/w960_57362-2735.png)

PRECAUTIONS

RFD-33

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH ELECTRONIC LOCKING DIFFERENTIAL]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EDS003IE

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Differential Case Assembly and Differential Lock Control Unit

Replacement

EDS003AG

lWhen replacing differential case assembly or differential lock control unit, check the DIFF LOCK indicator

pattern and adjustment of the position between differential case assembly and differential lock control unit

if necessary.

CHECK DIFF LOCK INDICATOR LAMP

1. Start engine. Run engine for at least 10 seconds.

2. Turn 4WD shift switch to “4LO” and confirm 4LO indicator lamp is turned on. Refer toTF-16, "

4WD SHIFT

SWITCH AND INDICATOR LAMP".

3. Stop vehicle and turn differential lock mode switch to “ON”.

4. Drive vehicle at 7 km/h (4 MPH) or less.

NOTE:

Differential case assembly must be given a rotation from rear left wheel and rear right wheel.

5. Check if DIFF LOCK indicator lamp flashes to turn on.

6. Check if DIFF LOCK indicator lamp and 4LO indicator lamp are changed properly as follows.

lIf each indication and state is OK, rear final drive assembly and differential lock control unit is working cor-

rectly.

lIf each indication and state is NG, rear final drive assembly and differential lock control unit is not working

correctly. Refer toRFD-34, "

METHOD FOR ADJUSTMENT".

Differential lock mode

switch4LO indicator lamp Vehicle speed (VSS)Differential case assem-

bly stateDIFF LOCK indicator

lamp

ONOFF7 km/h (4 MPH) < VSS

Disengage Flash VSS£7km/h(4MPH)

ON7 km/h (4 MPH) < VSS

VSS£7 km/h (4 MPH) Disengage®Engage Flash®ON

OFFOFF7 km/h (4 MPH) < VSS

Disengage OFF VSS£7km/h(4MPH)

ON7 km/h (4 MPH) < VSS

VSS£7km/h(4MPH)

Page 2745 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-42

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

DIFFERENTIAL LOCK SYSTEM

Differential Lock Operation

EDS003AQ

1. Differential lock solenoid operates pressure plate.

2. Pressure plate presses cam ring.

3 NISSAN NAVARA 2005 Repair Workshop Manual RFD-42

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

DIFFERENTIAL LOCK SYSTEM

Differential Lock Operation

EDS003AQ

1. Differential lock solenoid operates pressure plate.

2. Pressure plate presses cam ring.

3](/img/5/57362/w960_57362-2744.png)

RFD-42

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

DIFFERENTIAL LOCK SYSTEM

Differential Lock Operation

EDS003AQ

1. Differential lock solenoid operates pressure plate.

2. Pressure plate presses cam ring.

3. Engage cam ring and side gear, and then differential is locked.

System DescriptionEDS003AR

DIFFERENTIAL LOCK SOLENOID

It is operated by signal from differential lock control unit, and it operates pressure plate so as to switch lock/

unlock.

DIFFERENTIAL LOCK POSITION SWITCH

It detects that differential is in lock or unlock by pressure plate position, and sends it to differential lock control

unit.

DIFFERENTIAL LOCK CONTROL UNIT

lDifferential lock control unit controls differential lock solenoid by input signals of each sensor and each

switch.

lAs a fail-safe function, differential lock disengages, if malfunction is detected in differential lock system.

lSelf-diagnosis can be done with CONSULT-II.

DIFFERENTIAL LOCK MODE SWITCH

Able to select differential lock and unlock.

DIFF LOCK INDICATOR LAMP

The following is the indications of indicator lamp.

NOTE:

Differential lock standby condition is the condition that differential lock mode switch is ON and differential is unlocked.

SDIA2498E

Condition DIFF LOCK indicator lamp

Differential lock/unlock ON/OFF

Differential lock standby condition Flashing: 1 time/2 seconds

Differential lock system malfunction OFF (Even if differential lock mode switch is turned ON)

Lamp checkTurns ON when ignition switch is turned ON.

Turns OFF after engine start.

Page 2759 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-56

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYSTEM

3.CHECK DIFFERENTIAL LOCK CONTROL UNIT

Check differential lock control unit input/output signal. Refer toRFD-48, "

Differenti NISSAN NAVARA 2005 Repair Workshop Manual RFD-56

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYSTEM

3.CHECK DIFFERENTIAL LOCK CONTROL UNIT

Check differential lock control unit input/output signal. Refer toRFD-48, "

Differenti](/img/5/57362/w960_57362-2758.png)

RFD-56

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYSTEM

3.CHECK DIFFERENTIAL LOCK CONTROL UNIT

Check differential lock control unit input/output signal. Refer toRFD-48, "

Differential Lock Control Unit Input/

Output Signal Reference Values".

OK or NG

OK >> GO TO 4.

NG >> Check differential lock control unit pin terminals for damage or loose connection with harness con-

nector. If any items are damaged, repair or replace damaged parts.

4.CHECK DTC

Perform the self-diagnosis, after driving the vehicle for a while.

OK or NG

OK >>INSPECTION END

NG >> Replace differential lock control unit. Refer toRFD-76, "

Removal and Installation".

Differential Lock Control UnitEDS003B2

DIAGNOSTIC PROCEDURE

1.PERFORM SELF-DIAGNOSIS

With CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “SELF-DIAG RESULTS” mode for “DIFF LOCK” with CONSULT-II.

3. Touch “ERASE”.

4. Turn ignition switch “OFF” and wait at least 10 seconds.

5. Perform the self-diagnosis again.

Is the

“CONTROL UNIT 1 [P1834]”,“CONTROL UNIT 2 [P1835]”,“CONTROL UNIT 3 [P1836]”or“CONTROL

UNIT 4 [P1837]”displayed?

YES >> Replace differential lock control unit. Refer toRFD-76, "Removal and Installation".

NO >>INSPECTION END

Differential Lock Mode SwitchEDS003B3

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

DIFFERENTIAL LOCK CONTROL UNIT TERMINALS AND REFERENCE VALUE

Data are reference value and are measured between each terminal and ground.

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.

Monitor item [Unit] Content Condition Display value

D-LOCK SW SIG [ON/

OFF]Condition of differential

lock mode switchDifferential lock mode switch: ON ON

Differential lock mode switch: OFF OFF

Te r m i n a lWire

colorItem Condition Data (Approx.)

9YDifferential lock mode switch

(ON)Ignition switch: ONDifferential lock mode switch: ON Battery voltage

Differential lock mode switch: OFF 0V

22 GDifferential lock mode switch

(OFF)Ignition switch: ONDifferential lock mode switch: ON 0V

Differential lock mode switch: OFF Battery voltage

Page 2773 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-70

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYMPTOMS

TROUBLE DIAGNOSIS FOR SYMPTOMS

PFP:00007

DIFF LOCK Indicator Lamp Does Not Turn ONEDS003B9

SYMPTOM:

DIFF LOCK indicator lam NISSAN NAVARA 2005 Repair Workshop Manual RFD-70

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYMPTOMS

TROUBLE DIAGNOSIS FOR SYMPTOMS

PFP:00007

DIFF LOCK Indicator Lamp Does Not Turn ONEDS003B9

SYMPTOM:

DIFF LOCK indicator lam](/img/5/57362/w960_57362-2772.png)

RFD-70

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYMPTOMS

TROUBLE DIAGNOSIS FOR SYMPTOMS

PFP:00007

DIFF LOCK Indicator Lamp Does Not Turn ONEDS003B9

SYMPTOM:

DIFF LOCK indicator lamp does not turn ON for approx. 1 second when turning ignition switch to

“ON”.

DIAGNOSTIC PROCEDURE

1.CHECK SYSTEM FOR CAN COMMUNICATION LINE

Perform self-diagnosis. Refer toRFD-51, "

SELF-DIAG RESULTS MODE".

Is

“CAN COMM CIRCUIT”displayed?

YES >> Perform trouble diagnosis for CAN communication line. Refer toRFD-69, "CAN Communication

Line".

NO >> GO TO 2.

2.CHECK DIFFERENTIAL LOCK CONTROL UNIT POWER SUPPLY

1. Turn ignition switch “OFF”.

2. Disconnect differential lock control unit harness connector.

3. Check voltage between differential lock control unit harness

connector terminals and ground.

4. Turn ignition switch “ON”. (Do not start engine.)

5. Check voltage between differential lock control unit harness

connector terminals and ground.

OK or NG

OK >> GO TO 3.

NG >> Check the following. If any items are damaged, repair or

replace damaged parts.

l10A fuse [No. 3 or 19, located in fuse block (J/B)]

lHarness for short or open between battery and differential lock control unit harness connector

terminal 15

lHarness for short or open between ignition switch and differential lock control unit harness con-

nector terminals 1 and 2

lBattery and ignition switch. Refer toPG-4, "POWER SUPPLY ROUTING CIRCUIT".

Connector Terminal Voltage (Approx.)

M1071 - Ground 0V

2 - Ground 0V

15 - Ground Battery voltage

SDIA2562E

Connector Terminal Voltage (Approx.)

M1071 - Ground

Battery voltage 2 - Ground

15 - Ground

SDIA2563E

Page 2925 of 3171

SRS-16

TROUBLE DIAGNOSIS

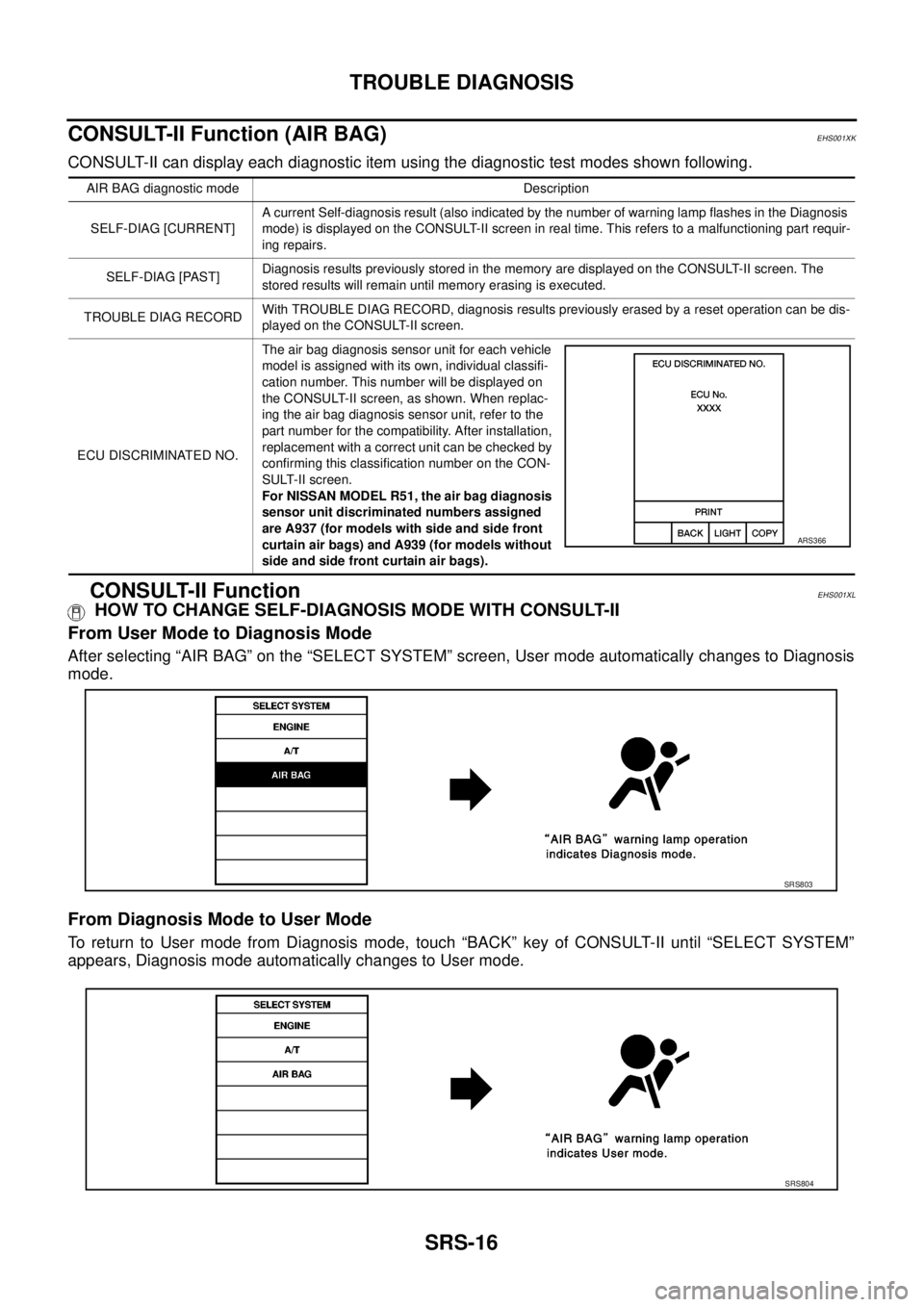

CONSULT-II Function (AIR BAG)

EHS001XK

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II FunctionEHS001XL

HOW TO CHANGE SELF-DIAGNOSIS MODE WITH CONSULT-II

From User Mode to Diagnosis Mode

After selecting “AIR BAG” on the “SELECT SYSTEM” screen, User mode automatically changes to Diagnosis

mode.

From Diagnosis Mode to User Mode

To return to User mode from Diagnosis mode, touch “BACK” key of CONSULT-II until “SELECT SYSTEM”

appears, Diagnosis mode automatically changes to User mode.

AIR BAG diagnostic mode Description

SELF-DIAG [CURRENT]A current Self-diagnosis result (also indicated by the number of warning lamp flashes in the Diagnosis

mode) is displayed on the CONSULT-II screen in real time. This refers to a malfunctioning part requir-

ing repairs.

SELF-DIAG [PAST]Diagnosis results previously stored in the memory are displayed on the CONSULT-II screen. The

stored results will remain until memory erasing is executed.

TROUBLE DIAG RECORDWith TROUBLE DIAG RECORD, diagnosis results previously erased by a reset operation can be dis-

played on the CONSULT-II screen.

ECU DISCRIMINATED NO.The air bag diagnosis sensor unit for each vehicle

model is assigned with its own, individual classifi-

cation number. This number will be displayed on

the CONSULT-II screen, as shown. When replac-

ing the air bag diagnosis sensor unit, refer to the

part number for the compatibility. After installation,

replacement with a correct unit can be checked by

confirming this classification number on the CON-

SULT-II screen.

For NISSAN MODEL R51, the air bag diagnosis

sensor unit discriminated numbers assigned

are A937 (for models with side and side front

curtain air bags) and A939 (for models without

side and side front curtain air bags).

ARS366

SRS803

SRS804

Page 2926 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS

SRS-17

C

D

E

F

G

I

J

K

L

MA

B

SRS

HOW TO ERASE SELF-DIAGNOSIS RESULTS

l“SELF-DIAG [CURRENT]”

A current self-diagnosis result is displayed on the CONSULT-II

screen in real time.

A NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS

SRS-17

C

D

E

F

G

I

J

K

L

MA

B

SRS

HOW TO ERASE SELF-DIAGNOSIS RESULTS

l“SELF-DIAG [CURRENT]”

A current self-diagnosis result is displayed on the CONSULT-II

screen in real time.

A](/img/5/57362/w960_57362-2925.png)

TROUBLE DIAGNOSIS

SRS-17

C

D

E

F

G

I

J

K

L

MA

B

SRS

HOW TO ERASE SELF-DIAGNOSIS RESULTS

l“SELF-DIAG [CURRENT]”

A current self-diagnosis result is displayed on the CONSULT-II

screen in real time.

After the malfunction is repaired completely, no malfunction is

detected on “SELF-DIAG [CURRENT]”.

l“SELF-DIAG [PAST]”

Return to the “SELF-DIAG [CURRENT]” CONSULT-II screen by

touching “BACK” key of CONSULT-II and select “SELF-DIAG

[PAST]” in SELECT DIAG MODE. Touch “ERASE” in “SELF-

DIAG [PAST]” mode.

NOTE:

If the memory of the malfunction in “SELF-DIAG [PAST]” is

not erased, the User mode will continue to show the system

malfunction by the operation of the warning lamp even if

the malfunction is repaired completely.

l“TROUBLE DIAG RECORD”

The memory of “TROUBLE DIAG RECORD” cannot be erased.

Self-Diagnosis Function (Without CONSULT-II)EHS001XM

lThe reading of these results is accomplished using one of two modes — “User mode” and “Diagnosis

mode”.

lAfter a malfunction is repaired, turn the ignition switch OFF for at least one second, then back ON. Diag-

nosis mode returns to the User mode. At that time, the self-diagnostic result is cleared.

HOW TO CHANGE SELF-DIAGNOSIS MODE

SRS701

SRS702

SHIA0183E