wheel NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1 of 3171

MODELD40 SERIES

2005 NISSAN EUROPE S.A.S.

All rights reserved. No part of this Electronic Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan

Europe S.A.S., Paris, France.

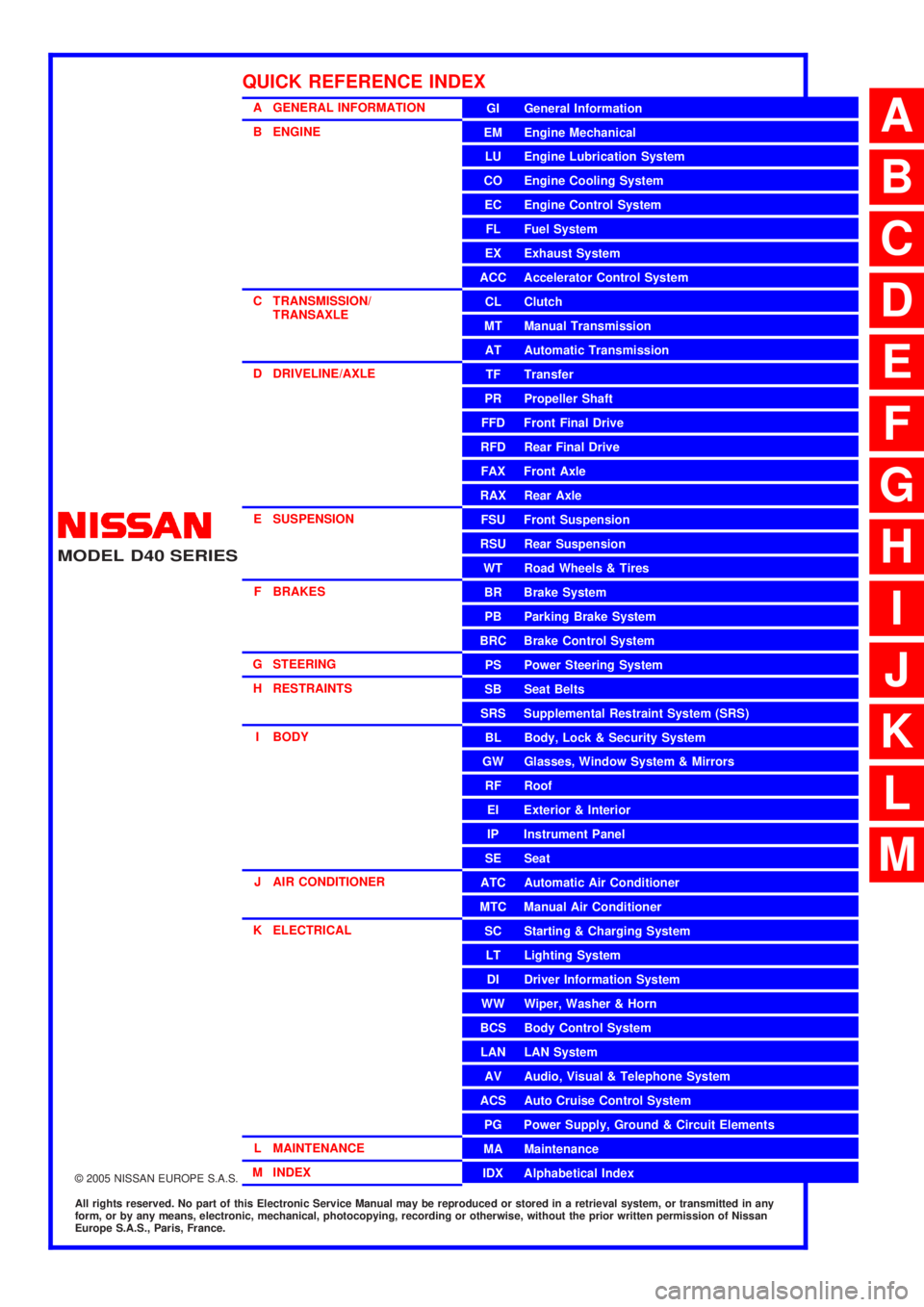

A GENERAL INFORMATION

B ENGINE

C TRANSMISSION/TRANSAXLE

D DRIVELINE/AXLE

E SUSPENSION F BRAKES

G STEERING H RESTRAINTS

I BODY

J AIR CONDITIONER

K ELECTRICAL

L MAINTENANCE

M INDEXGI General Information

EM Engine Mechanical

LU Engine Lubrication System

CO Engine Cooling System

EC Engine Control System

FL Fuel System

EX Exhaust System

ACC Accelerator Control System

CL Clutch

MTManualTransmission

AT Automatic Transmission

TF Transfer

PR Propeller Shaft

FFD Front Final Drive

RFD Rear Final Drive

FAX Front Axle

RAX Rear Axle

FSU Front Suspension

RSU Rear Suspension

WT Road Wheels & Tires

BR Brake System

PB Parking Brake System

BRC Brake Control System

PS Power Steering System

SB Seat Belts

SRS Supplemental Restraint System (SRS)

BL Body, Lock & Security System

GW Glasses, Window System & Mirrors

RF Roof

EI Exterior & Interior

IP Instrument Panel

SE Seat

ATC Automatic Air Conditioner

MTC Manual Air Conditioner

SC Starting & Charging System

LT Lighting System

DI Driver Information System

WW Wiper, Washer & Horn

BCS Body Control System

LAN LAN System

AV Audio, Visual & Telephone System

ACS Auto Cruise Control System

PG Power Supply, Ground & Circuit Elements

MA Maintenance

IDX Alphabetical Index

QUICK REFERENCE INDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

Page 40 of 3171

AT-32

A/T CONTROL SYSTEM

Lock-up Applied

In the lock-up applied state, the torque converter clutch control valve is set into the locked state by the torque

converter clutch solenoid and lock-up apply pressure is generated.

In this way, the torque converter clutch piston is pressed and coupled.

SMOOTH LOCK-UP CONTROL

When shifting from the lock-up released state to the lock-up applied state, the current output to the torque con-

verter clutch solenoid is controlled with the TCM. In this way, when shifting to the lock-up applied state, the

torque converter clutch is temporarily set to the half-clutched state to reduce the shock.

Half-clutched State

The current output from the TCM to the torque converter clutch solenoid is varied to gradually increase the

torque converter clutch solenoid pressure.

In this way, the lock-up apply pressure gradually rises and while the torque converter clutch piston is put into

half-clutched status, the torque converter clutch piston operating pressure is increased and the coupling is

completed smoothly.

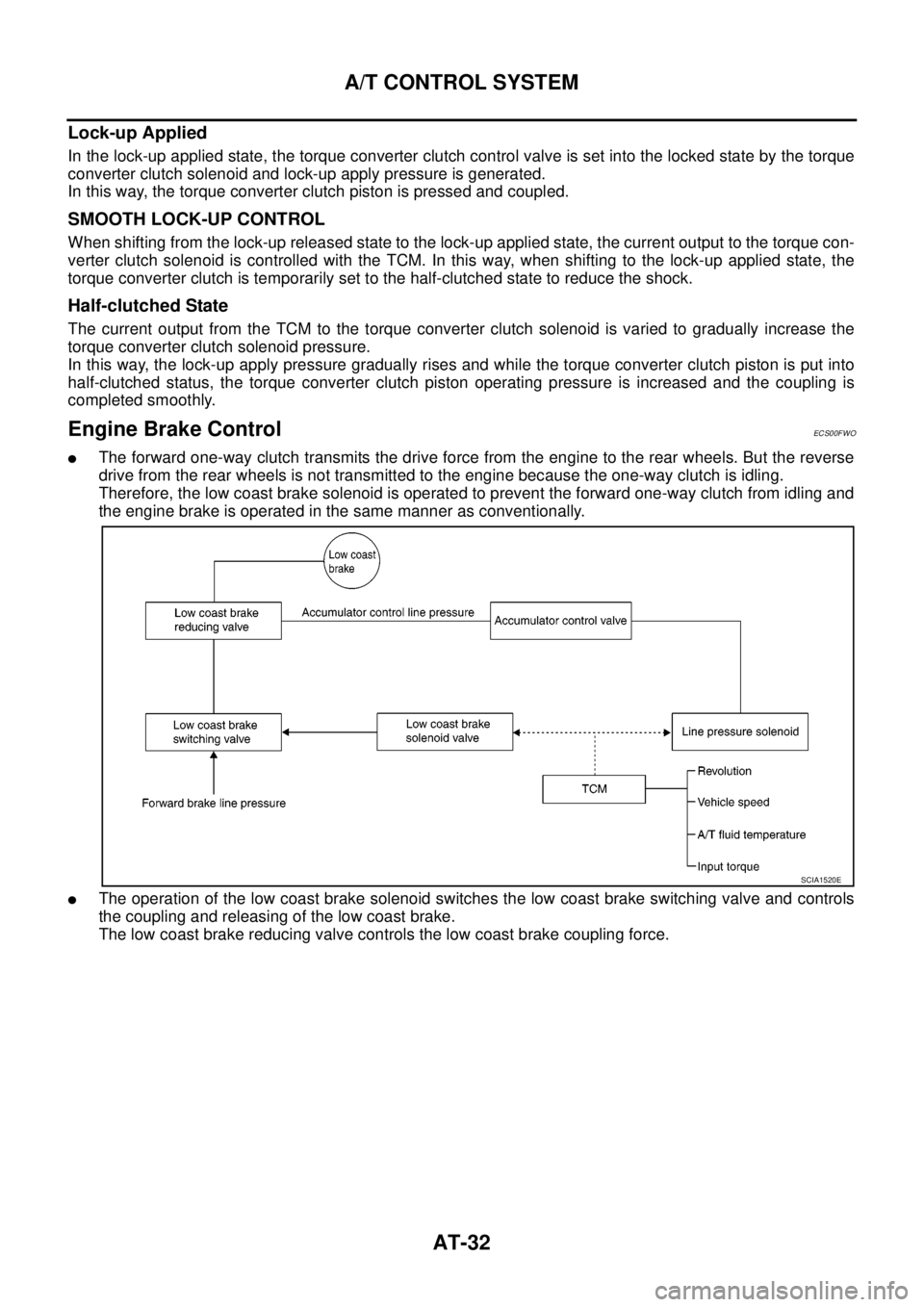

Engine Brake ControlECS00FWO

lThe forward one-way clutch transmits the drive force from the engine to the rear wheels. But the reverse

drive from the rear wheels is not transmitted to the engine because the one-way clutch is idling.

Therefore, the low coast brake solenoid is operated to prevent the forward one-way clutch from idling and

the engine brake is operated in the same manner as conventionally.

lThe operation of the low coast brake solenoid switches the low coast brake switching valve and controls

the coupling and releasing of the low coast brake.

The low coast brake reducing valve controls the low coast brake coupling force.

SCIA1520E

Page 42 of 3171

AT-34

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

PFP:00004

DTC Inspection Priority ChartECS00FWV

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

NOTE:

If DTC “U1000 CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis

for “DTC U1000 CAN COMMUNICATION LINE”. Refer toAT-91

.

Fail-safeECS00FWW

The TCM has an electrical fail-safe mode. This mode makes it possible to operate even if there is an error in a

main electronic control input/output signal circuit. In fail-safe mode A/T is fixed in 2nd, 4th or 5th (depending

on the breakdown position), so the customer should feel “slipping” or “poor acceleration”.

Even when the electronic circuits are normal, under special conditions (for example, when slamming on the

brake with the wheels spinning drastically and stopping the tire rotation), the transmission can go into fail-safe

mode. If this happens, switch OFF the ignition switch for 10 seconds, then switch it ON again to return to the

normal shift pattern. Therefore, the customer's vehicle has returned to normal, so handle according toAT- 3 7 ,

"WORK FLOW".

FAIL-SAFE FUNCTION

If any malfunction occurs in a sensor or solenoid, this function controls the A/T to mark driving possible.

Vehicle Speed Sensor

Signals are input from two systems - from vehicle speed sensor A/T (revolution sensor) installed on the A/T

and from combination meter so normal driving is possible even if there is a malfunction in one of the systems.

And if vehicle speed sensor A/T (revolution sensor) has unusual cases, 5th gear is prohibited.

Accelerator Pedal Position Sensor

If there is a malfunction in one of the systems, the accelerator opening angle is controlled by ECM according

to a pre-determined accelerator angle to make driving possible. And if there are malfunctions in tow systems,

the engine speed is fixed by ECM to a pre-determined engine speed to make driving possible.

PNP Switch

In the unlikely event that a malfunction signal enters the TCM, the position indicator is switched OFF, the

starter relay is switched OFF (starter starting is disabled), the back-up lamp relay switched OFF (back-up lamp

is OFF) and the position is fixed to the “D” position to make driving possible.

Starter Relay

The starter relay is switched OFF. (Starter starting is disabled.)

Priority Detected items (DTC)

1 U1000 CAN communication line

2 Except above

Page 476 of 3171

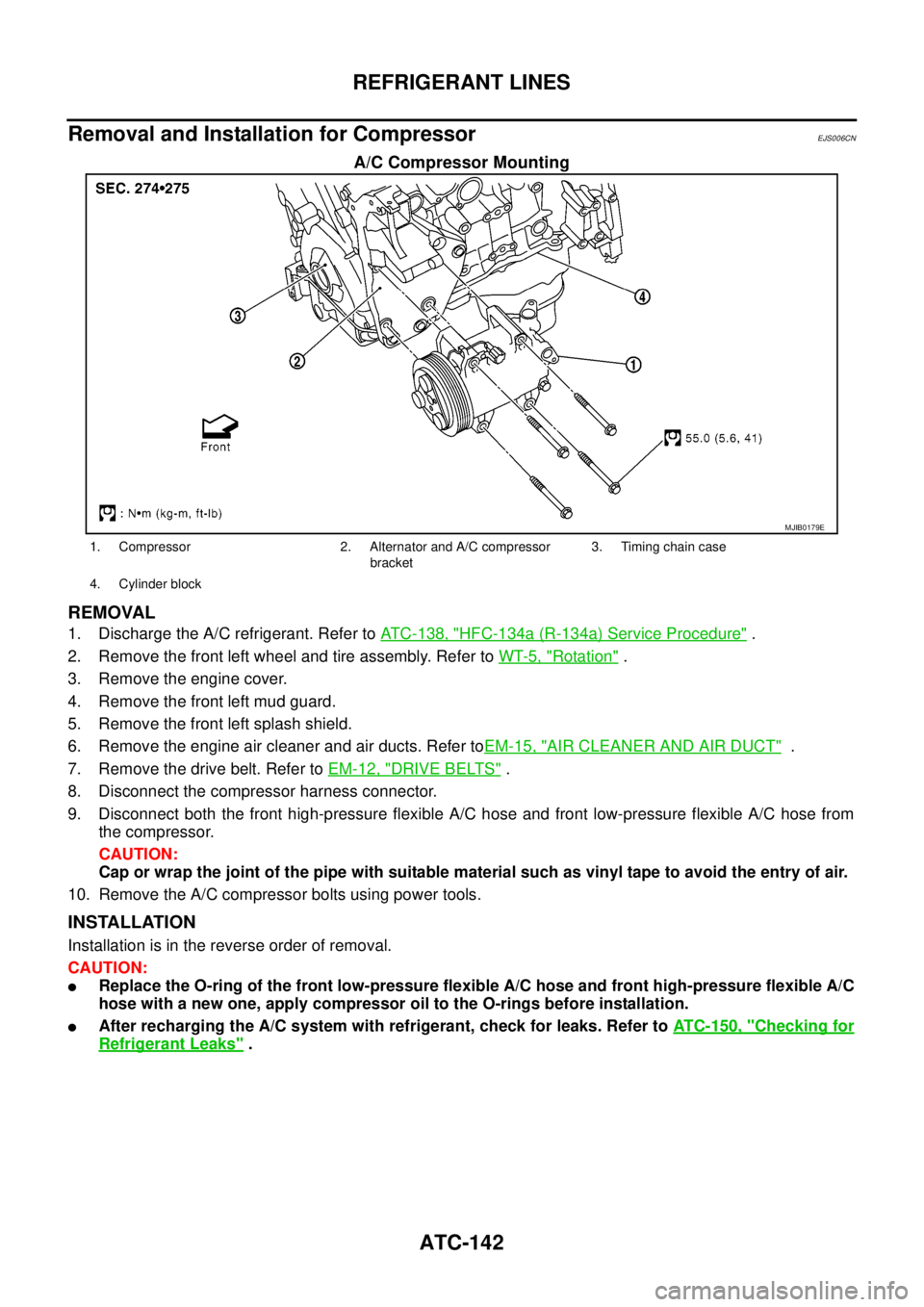

ATC-142

REFRIGERANT LINES

Removal and Installation for Compressor

EJS006CN

A/C Compressor Mounting

REMOVAL

1. Discharge the A/C refrigerant. Refer toATC-138, "HFC-134a (R-134a) Service Procedure".

2. Remove the front left wheel and tire assembly. Refer toWT-5, "

Rotation".

3. Remove the engine cover.

4. Remove the front left mud guard.

5. Remove the front left splash shield.

6. Remove the engine air cleaner and air ducts. Refer toEM-15, "

AIR CLEANER AND AIR DUCT".

7. Remove the drive belt. Refer toEM-12, "

DRIVE BELTS".

8. Disconnect the compressor harness connector.

9. Disconnect both the front high-pressure flexible A/C hose and front low-pressure flexible A/C hose from

the compressor.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

10. Remove the A/C compressor bolts using power tools.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

lReplace the O-ring of the front low-pressure flexible A/C hose and front high-pressure flexible A/C

hose with a new one, apply compressor oil to the O-rings before installation.

lAfter recharging the A/C system with refrigerant, check for leaks. Refer toATC-150, "Checking for

Refrigerant Leaks".

MJIB0179E

1. Compressor 2. Alternator and A/C compressor

bracket3. Timing chain case

4. Cylinder block

Page 480 of 3171

ATC-146

REFRIGERANT LINES

BREAK-IN OPERATION

When replacing compressor clutch assembly, always conduct the break-in operation. This is done by engag-

ing and disengaging the clutch about 30 times. Break-in operation raises the level of transmitted torque.

Removal and Installation for High-pressure Flexible A/C HoseEJS006CP

REMOVAL

1. Remove the front left wheel and tire assembly. Refer toWT-5, "Rotation".

2. Remove the front left mud guard.

3. Remove the front left splash shield.

4. Discharge the refrigerant. Refer toATC-138, "

HFC-134a (R-134a) Service Procedure".

5. Remove the high-pressure flexible A/C hose. Refer toATC-140, "

Components".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer toATC-140, "

Components".

CAUTION:

lReplace the O-ring of the high-pressure flexible A/C hose with a new one, then apply compressor

oil to it for installation.

lAfter charging refrigerant, check for leaks.

Removal and Installation for High-pressure A/C PipeEJS006CQ

REMOVAL

1. Remove the front right wheel and tire assembly. Refer toWT-5, "Rotation".

2. Remove the front right mud guard.

3. Remove the front right splash shield.

4. Discharge the refrigerant. Refer toATC-138, "

HFC-134a (R-134a) Service Procedure".

5. Remove the low pressure A/C pipe. Refer toATC-147, "

Removal and Installation for Low-pressure A/C

Pipe".

6. Remove the high-pressure A/C pipe. Refer toATC-146, "

Removal and Installation for High-pressure A/C

Pipe".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer toATC-140, "

Components".

CAUTION:

lReplace the O-ring of the high-pressure A/C pipe with a new one, then apply compressor oil to it

for installation.

lAfter charging refrigerant, check for leaks.

Removal and Installation for Low-pressure Flexible A/C HoseEJS006CR

REMOVAL

1. Remove the front right wheel and tire assembly. Refer toWT-5, "Rotation".

2. Remove the front right mud guard.

3. Remove the front right splash shield.

4. Discharge the refrigerant. Refer toATC-138, "

HFC-134a (R-134a) Service Procedure".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

5. Remove the low-pressure flexible A/C hose. Refer toATC-140, "

Components".

INSTALLATION

Installation is in the reverse order of removal.

Refer toATC-140, "

Components".

Page 489 of 3171

AV-1

AUDIO-VISUAL SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTIONAV

A

B

AV

AUDIO-VISUAL SYSTEM

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Wiring Diagrams and Trouble Diagnosis .................. 3

SYSTEM DESCRIPTION ............................................ 4

System Functions ..................................................... 4

AUDIO ................................................................... 4

NATS AUDIO LINK (WITHOUT NAVIGATION

SYSTEM) .............................................................. 4

VEHICLE INFORMATION SYSTEM ..................... 5

NAVIGATION SYSTEM ......................................... 5

HANDS-FREE PHONE ......................................... 7

Component Description ............................................ 8

AUDIO UNIT ......................................................... 8

NAVI CONTROL UNIT .......................................... 8

GPS ANTENNA .................................................... 9

DISPLAY UNIT ...................................................... 9

AV SWITCH .......................................................... 9

Component Parts Location ..................................... 10

Location Of Antenna .............................................. 10

Schematic — AUDIO — / With 1CD Player Type... 12

Wiring Diagram — AUDIO — / With 1CD Player Type

... 13

Schematic — AUDIO — / With 6CD Player Type... 16

Wiring Diagram — AUDIO — / With 6CD Player Type

... 17

Schematic — NAVI — ............................................ 20

Wiring Diagram — NAVI — .................................... 21

Schematic — NAVI — / COMM .............................. 28

Wiring Diagram — NAVI — / COMM ...................... 29

Wiring Diagram — TELEPHONE (PRE WIRE) —

/ Without NAVI ........................................................ 32

CAN Communication .............................................. 33

SYSTEM DESCRIPTION .................................... 33

TERMINALS AND REFERENCE VALUE FOR CON-

TROL UNIT ............................................................... 34

Audio Unit (1CD Player Type) ................................ 34

Audio Unit (6CD Player Type) Without NAVI .......... 35Audio Unit (With NAVI) ........................................... 37

NAVI Control Unit ................................................... 38

Display Unit ............................................................ 41

DIAGNOSIS SYSTEM ............................................... 44

Navigation System Diagnosis Function .................. 44

On Bord Self-Diagnosis Function ........................... 44

DESCRIPTION .................................................... 44

DIAGNOSIS ITEM ............................................... 44

OPERATION PROCEDURE ................................ 45

Self Diagnosis Mode ............................................... 46

ERROR DETECTION RANGE OF SELF-DIAG-

NOSIS MODE ..................................................... 47

DIAGNOSIS RESULTS ....................................... 47

Confirmation/Adjustment Mode .............................. 48

SCREEN TROUBLE DIAGNOSIS ...................... 49

VEHICLE SIGNALS ............................................ 49

SPEAKER TEST ................................................. 50

NAVIGATION ....................................................... 50

ERROR HISTORY ............................................... 51

VEHICLE CAN DIAGNOSIS ............................... 53

AV COMM DIAGNOSIS ....................................... 54

HANDSFREE PHONE ........................................ 54

BLUETOOTH ....................................................... 54

DELETE UNIT CONNECTION LOG ................... 55

CONSULT-II Functions ........................................... 56

CONSULT-II FUNCTIONS ................................... 56

CONSULT-II BASIC OPERATION PROCEDURE

... 56

SELF-DIAG RESULTS ........................................ 56

DATA MONITOR ................................................. 58

AV COMM MONITOR .......................................... 59

ECU PART NUMBER .......................................... 60

TROUBLE DIAGNOSIS ............................................ 61

Navigation System .................................................. 61

RGB Image ............................................................. 61

Voice Activated Control System ............................. 62

Steering Wheel Switch ............................................ 63

Component Parts Inspection .................................. 63

STEERING WHEEL SWITCH UNIT INSPEC-

Page 494 of 3171

AV-6

SYSTEM DESCRIPTION

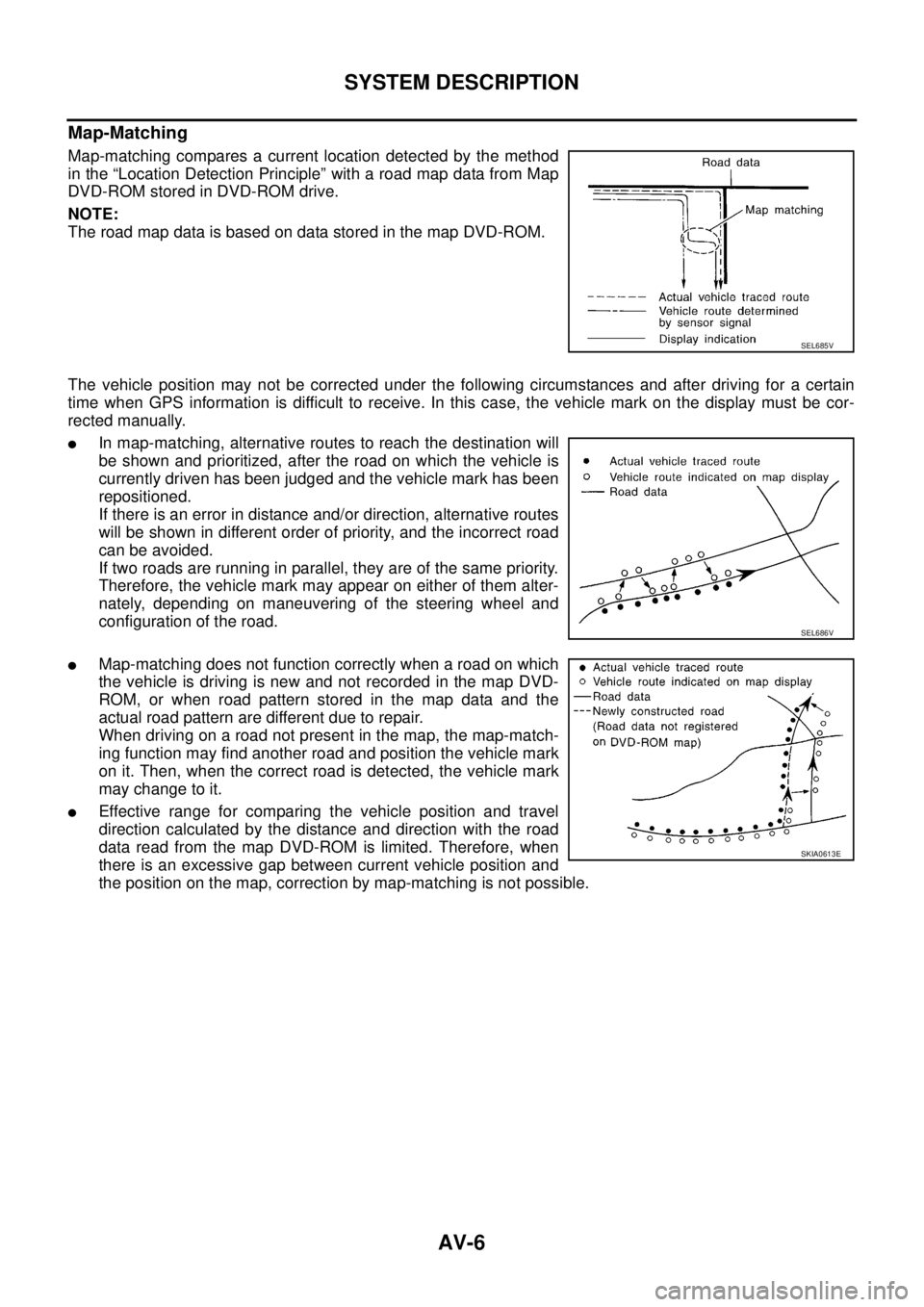

Map-Matching

Map-matching compares a current location detected by the method

in the “Location Detection Principle” with a road map data from Map

DVD-ROM stored in DVD-ROM drive.

NOTE:

TheroadmapdataisbasedondatastoredinthemapDVD-ROM.

The vehicle position may not be corrected under the following circumstances and after driving for a certain

time when GPS information is difficult to receive. In this case, the vehicle mark on the display must be cor-

rected manually.

lIn map-matching, alternative routes to reach the destination will

be shown and prioritized, after the road on which the vehicle is

currently driven has been judged and the vehicle mark has been

repositioned.

If there is an error in distance and/or direction, alternative routes

will be shown in different order of priority, and the incorrect road

can be avoided.

If two roads are running in parallel, they are of the same priority.

Therefore, the vehicle mark may appear on either of them alter-

nately, depending on maneuvering of the steering wheel and

configuration of the road.

lMap-matching does not function correctly when a road on which

the vehicle is driving is new and not recorded in the map DVD-

ROM, or when road pattern stored in the map data and the

actual road pattern are different due to repair.

When driving on a road not present in the map, the map-match-

ing function may find another road and position the vehicle mark

on it. Then, when the correct road is detected, the vehicle mark

may change to it.

lEffective range for comparing the vehicle position and travel

direction calculated by the distance and direction with the road

data read from the map DVD-ROM is limited. Therefore, when

there is an excessive gap between current vehicle position and

the position on the map, correction by map-matching is not possible.

SEL685V

SEL686V

SKIA0613E

Page 550 of 3171

AV-62

TROUBLE DIAGNOSIS

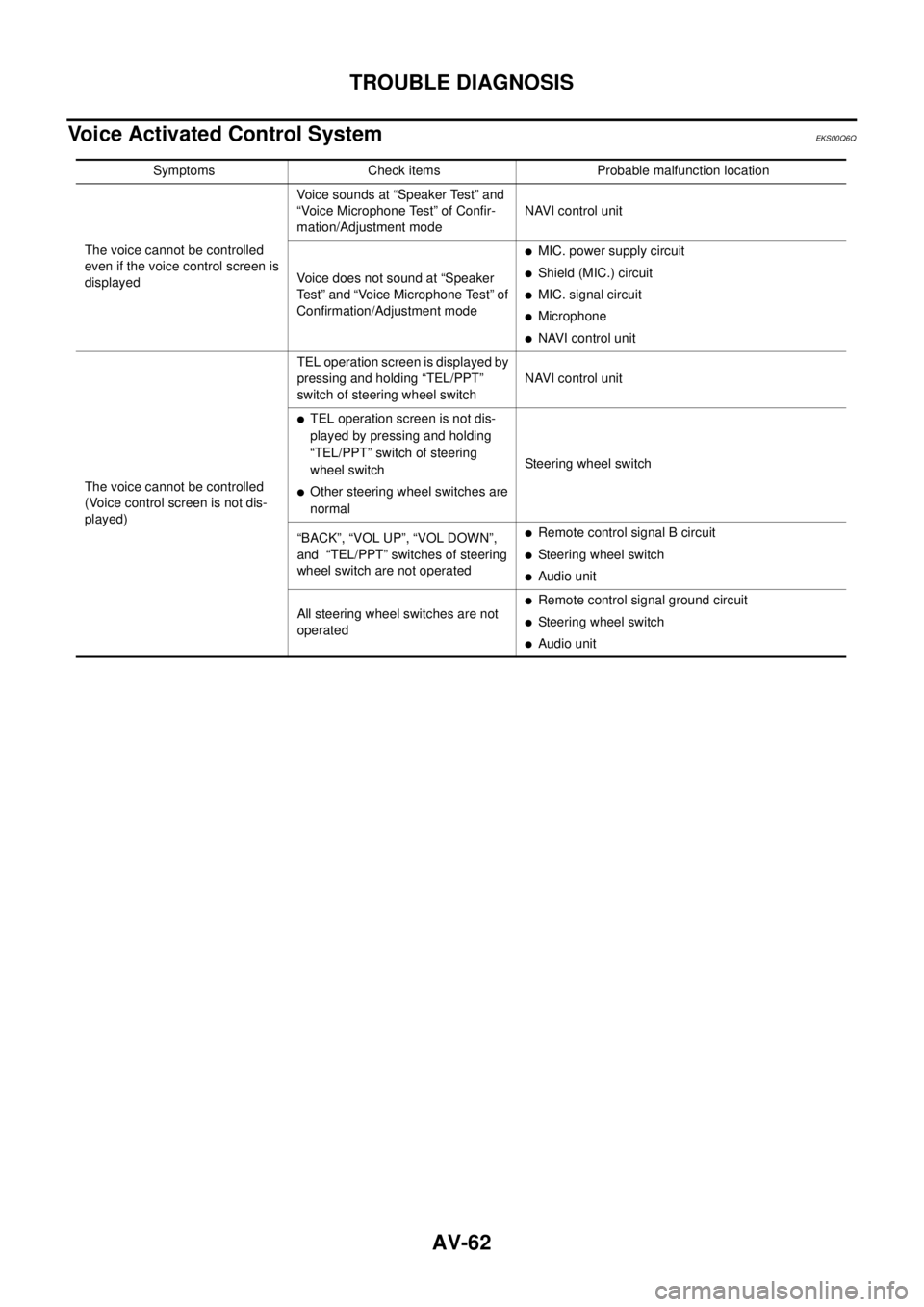

Voice Activated Control System

EKS00Q6Q

Symptoms Check items Probable malfunction location

The voice cannot be controlled

even if the voice control screen is

displayedVoice sounds at “Speaker Test” and

“Voice Microphone Test” of Confir-

mation/Adjustment modeNAVI control unit

Voice does not sound at “Speaker

Test” and “Voice Microphone Test” of

Confirmation/Adjustment mode

lMIC. power supply circuit

lShield (MIC.) circuit

lMIC. signal circuit

lMicrophone

lNAVI control unit

The voice cannot be controlled

(Voice control screen is not dis-

played)TEL operation screen is displayed by

pressing and holding “TEL/PPT”

switch of steering wheel switchNAVI control unit

lTEL operation screen is not dis-

played by pressing and holding

“TEL/PPT” switch of steering

wheel switch

lOther steering wheel switches are

normalSteering wheel switch

“BACK”, “VOL UP”, “VOL DOWN”,

and “TEL/PPT” switches of steering

wheel switch are not operated

lRemote control signal B circuit

lSteering wheel switch

lAudio unit

All steering wheel switches are not

operated

lRemote control signal ground circuit

lSteering wheel switch

lAudio unit

Page 551 of 3171

TROUBLE DIAGNOSIS

AV-63

C

D

E

F

G

H

I

J

L

MA

B

AV

Steering Wheel SwitchEKS00Q6R

Without NAVI

With NAVI

Component Parts InspectionEKS00Q6S

STEERING WHEEL SWITCH UNIT INSPECTION

lCheck continuity between combination switch harness connector M302 terminal 15 and terminal 16.

lCheck continuity between combination switch harness connector M302 terminal 14 and terminal 16.

Symptoms Probable malfunction location

All steering wheel switches are not operated

lRemote control signal ground circuit

lSteering wheel switch

lAudio unit

Only specified switch cannot be operated Steering wheel switch

“MODE”, “SEEK UP”, and “VOL UP” switches are not oper-

ated

lRemote control signal A circuit

lSteering wheel switch

lAudio unit

“SEEK DOWN”, and “VOL DOWN” switches are not oper-

ated

lRemote control signal B circuit

lSteering wheel switch

lAudio unit

Symptoms Probable malfunction location

All steering wheel switches are not operated

lRemote control signal ground circuit

lSteering wheel switch

lAudio unit

Only specified switch cannot be operated Steering wheel switch

“ENTER”, “MENU UP”, “MENU DOWN”, and “SOURCE”

switches are not operated

lRemote control signal A circuit

lSteering wheel switch

lAudio unit

“BACK”, “TEL /PPT”, “VOL UP”, and “VOL DOWN” switches

are not operated

lRemote control signal B circuit

lSteering wheel switch

lAudio unit

Page 558 of 3171

AV-70

TROUBLE DIAGNOSIS

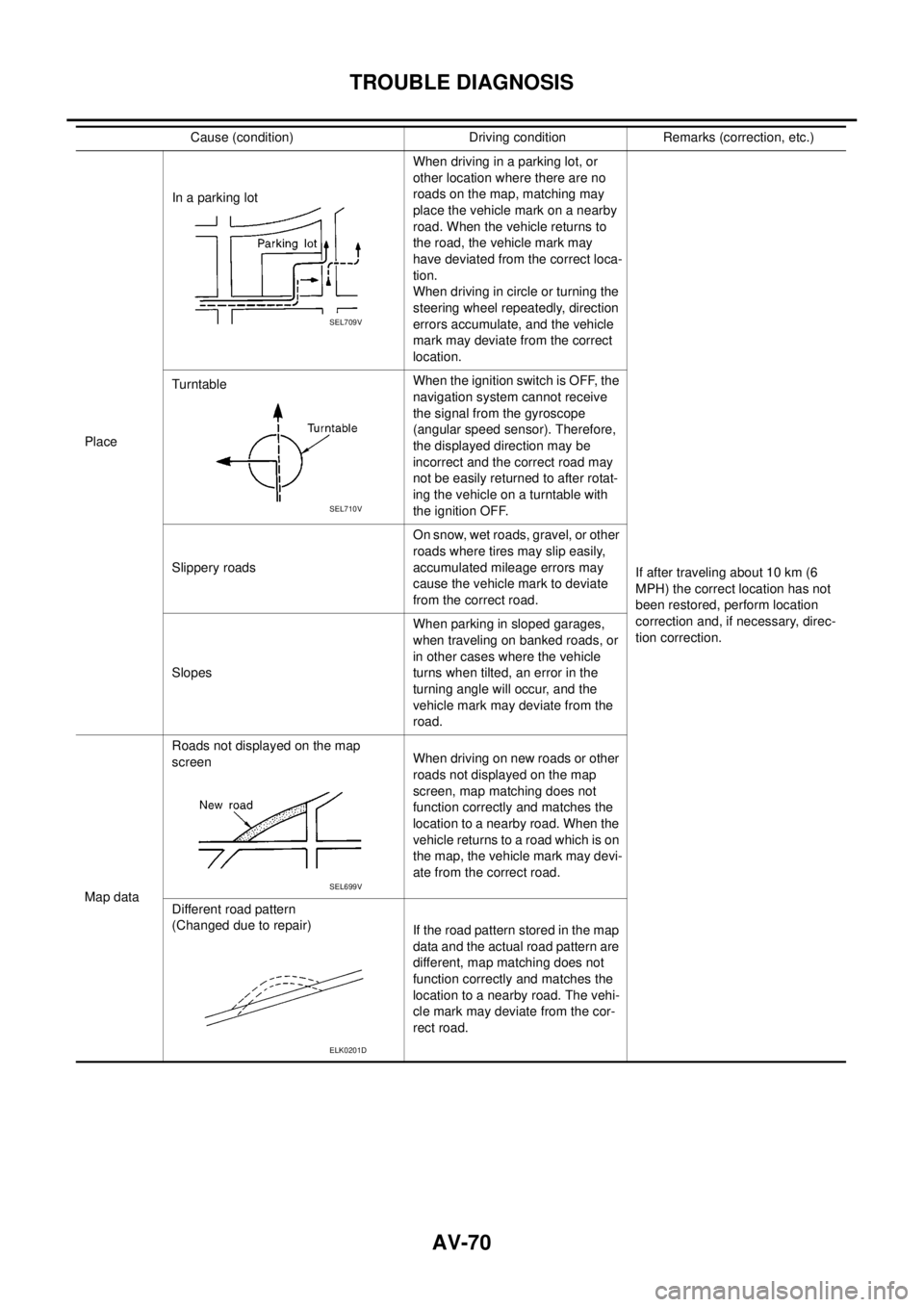

PlaceIn a parking lotWhen driving in a parking lot, or

other location where there are no

roads on the map, matching may

place the vehicle mark on a nearby

road. When the vehicle returns to

the road, the vehicle mark may

have deviated from the correct loca-

tion.

When driving in circle or turning the

steering wheel repeatedly, direction

errors accumulate, and the vehicle

mark may deviate from the correct

location.

If after traveling about 10 km (6

MPH) the correct location has not

been restored, perform location

correction and, if necessary, direc-

tion correction. TurntableWhentheignitionswitchisOFF,the

navigation system cannot receive

the signal from the gyroscope

(angular speed sensor). Therefore,

the displayed direction may be

incorrect and the correct road may

not be easily returned to after rotat-

ing the vehicle on a turntable with

the ignition OFF.

Slippery roadsOn snow, wet roads, gravel, or other

roads where tires may slip easily,

accumulated mileage errors may

cause the vehicle mark to deviate

from the correct road.

SlopesWhen parking in sloped garages,

when traveling on banked roads, or

in other cases where the vehicle

turns when tilted, an error in the

turning angle will occur, and the

vehicle mark may deviate from the

road.

Map dataRoads not displayed on the map

screenWhen driving on new roads or other

roads not displayed on the map

screen, map matching does not

function correctly and matches the

location to a nearby road. When the

vehicle returns to a road which is on

the map, the vehicle mark may devi-

ate from the correct road.

Different road pattern

(Changed due to repair)

If the road pattern stored in the map

data and the actual road pattern are

different, map matching does not

function correctly and matches the

location to a nearby road. The vehi-

cle mark may deviate from the cor-

rect road. Cause (condition) Driving condition Remarks (correction, etc.)

SEL709V

SEL710V

SEL699V

ELK0201D