ECO mode NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 3014 of 3171

TROUBLE DIAGNOSIS

TF-47

C

E

F

G

H

I

J

K

L

MA

B

TF

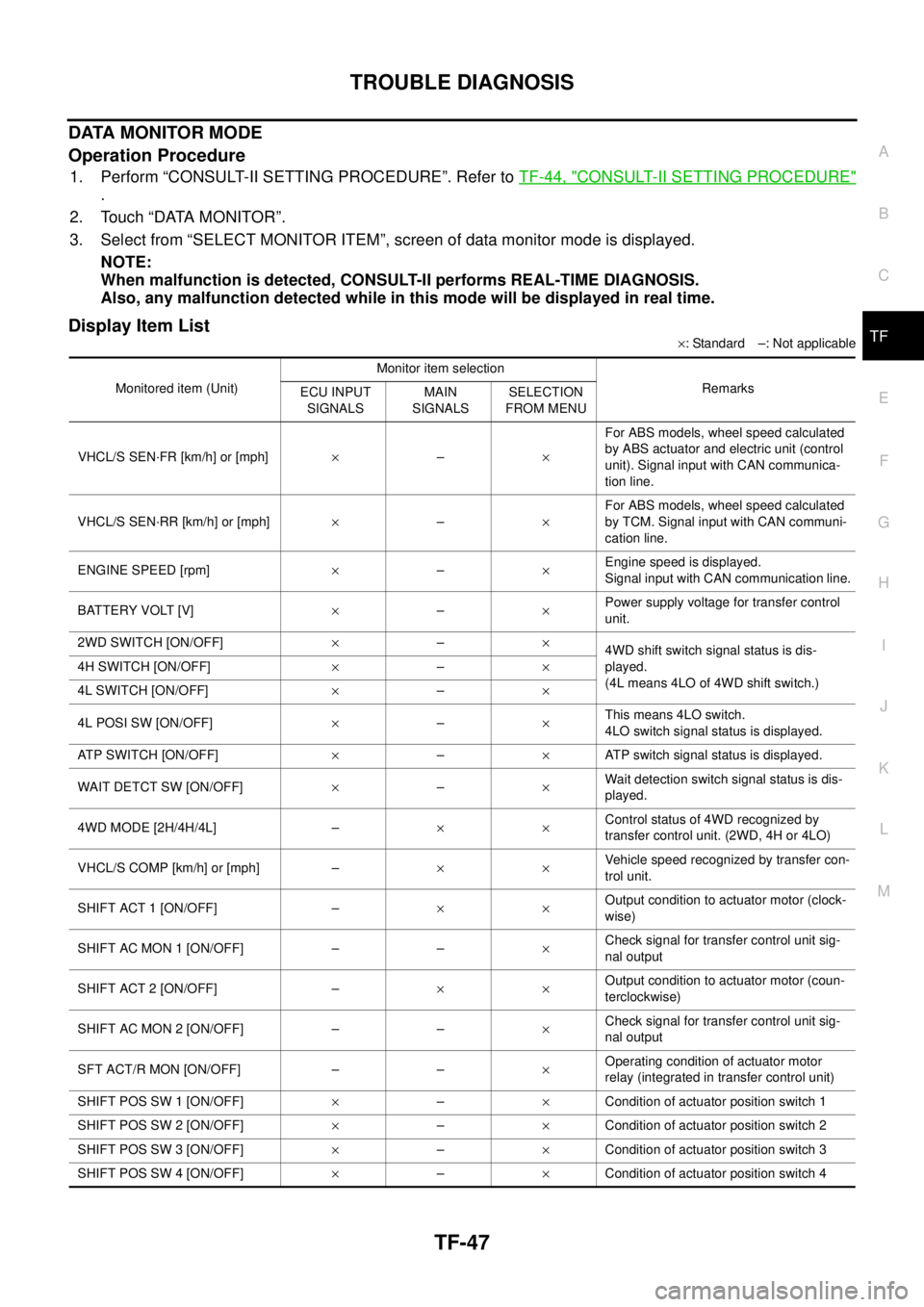

DATA MONITOR MODE

Operation Procedure

1. Perform “CONSULT-II SETTING PROCEDURE”. Refer toTF-44, "CONSULT-II SETTING PROCEDURE"

.

2. Touch “DATA MONITOR”.

3. Select from “SELECT MONITOR ITEM”, screen of data monitor mode is displayed.

NOTE:

When malfunction is detected, CONSULT-II performs REAL-TIME DIAGNOSIS.

Also, any malfunction detected while in this mode will be displayed in real time.

Display Item List

´: Standard –: Not applicable

Monitored item (Unit)Monitor item selection

Remarks

ECU INPUT

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

VHCL/S SEN·FR [km/h] or [mph]´–´For ABS models, wheel speed calculated

by ABS actuator and electric unit (control

unit). Signal input with CAN communica-

tion line.

VHCL/S SEN·RR [km/h] or [mph]´–´For ABS models, wheel speed calculated

by TCM. Signal input with CAN communi-

cation line.

ENGINE SPEED [rpm]´–´Engine speed is displayed.

Signal input with CAN communication line.

BATTERY VOLT [V]´–´Power supply voltage for transfer control

unit.

2WD SWITCH [ON/OFF]´–´

4WD shift switch signal status is dis-

played.

(4L means 4LO of 4WD shift switch.) 4H SWITCH [ON/OFF]´–´

4L SWITCH [ON/OFF]´–´

4L POSI SW [ON/OFF]´–´This means 4LO switch.

4LO switch signal status is displayed.

ATP SWITCH [ON/OFF]´–´ATP switch signal status is displayed.

WAIT DETCT SW [ON/OFF]´–´Wait detection switch signal status is dis-

played.

4WD MODE [2H/4H/4L] –´´Control status of 4WD recognized by

transfer control unit. (2WD, 4H or 4LO)

VHCL/S COMP [km/h] or [mph] –´´Vehicle speed recognized by transfer con-

trol unit.

SHIFT ACT 1 [ON/OFF] –´´Output condition to actuator motor (clock-

wise)

SHIFT AC MON 1 [ON/OFF] – –´Check signal for transfer control unit sig-

nal output

SHIFT ACT 2 [ON/OFF] –´´Output condition to actuator motor (coun-

terclockwise)

SHIFT AC MON 2 [ON/OFF] – –´Check signal for transfer control unit sig-

nal output

SFT ACT/R MON [ON/OFF] – –´Operating condition of actuator motor

relay (integrated in transfer control unit)

SHIFT POS SW 1 [ON/OFF]´–´Condition of actuator position switch 1

SHIFT POS SW 2 [ON/OFF]´–´Condition of actuator position switch 2

SHIFT POS SW 3 [ON/OFF]´–´Condition of actuator position switch 3

SHIFT POS SW 4 [ON/OFF]´–´Condition of actuator position switch 4

Page 3019 of 3171

TF-52

TROUBLE DIAGNOSIS FOR SYSTEM

TROUBLE DIAGNOSIS FOR SYSTEM

PFP:00000

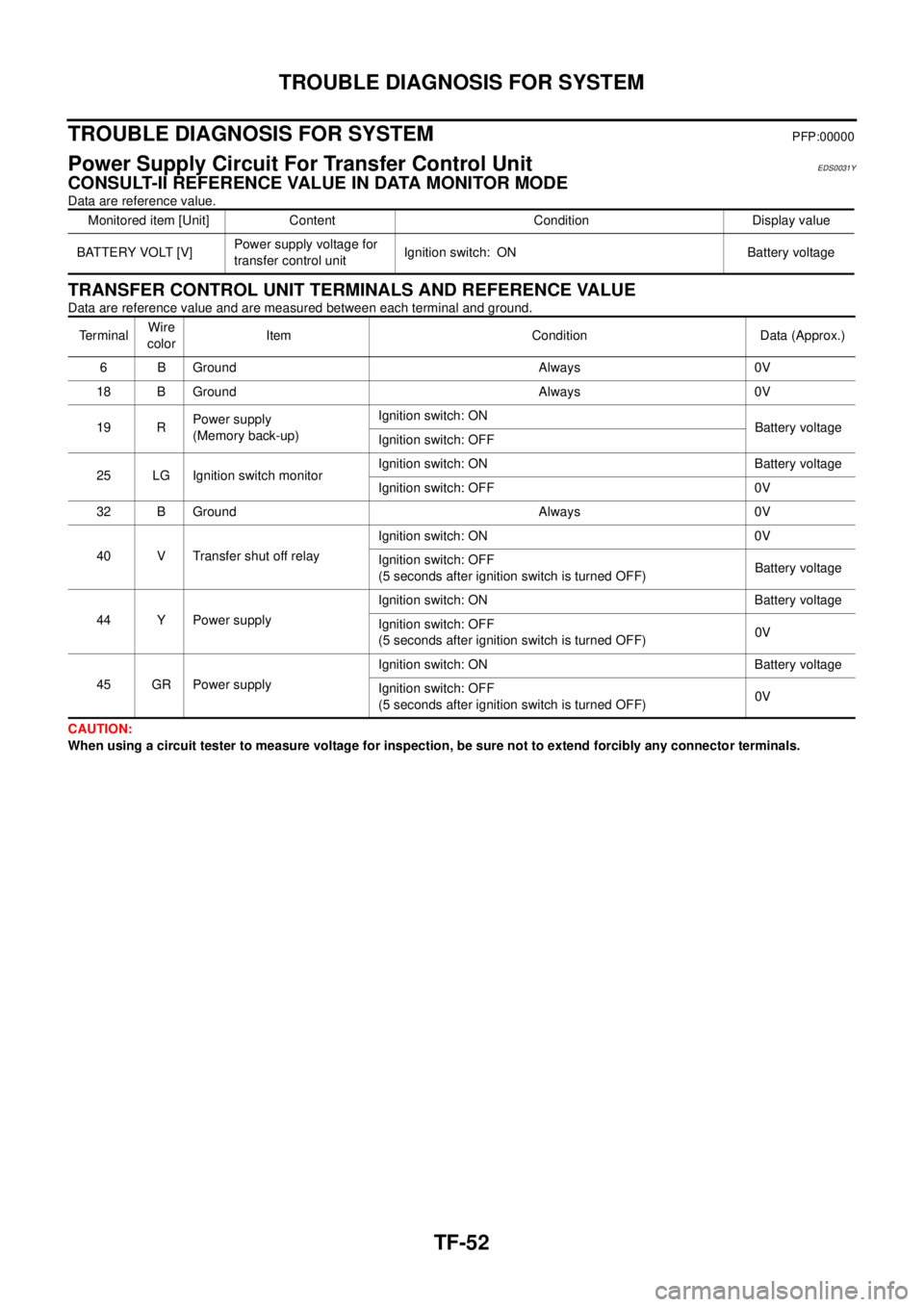

Power Supply Circuit For Transfer Control UnitEDS0031Y

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

TRANSFER CONTROL UNIT TERMINALS AND REFERENCE VALUE

Data are reference value and are measured between each terminal and ground.

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.Monitored item [Unit] Content Condition Display value

BATTERY VOLT [V]Power supply voltage for

transfer control unitIgnition switch: ON Battery voltage

Te r m i n a lWire

colorItem Condition Data (Approx.)

6 B Ground Always 0V

18 B Ground Always 0V

19 RPower supply

(Memory back-up)Ignition switch: ON

Battery voltage

Ignition switch: OFF

25 LG Ignition switch monitorIgnition switch: ON Battery voltage

Ignition switch: OFF 0V

32 B Ground Always 0V

40 V Transfer shut off relayIgnition switch: ON 0V

Ignition switch: OFF

(5 seconds after ignition switch is turned OFF)Battery voltage

44 Y Power supplyIgnition switch: ON Battery voltage

Ignition switch: OFF

(5 seconds after ignition switch is turned OFF)0V

45 GR Power supplyIgnition switch: ON Battery voltage

Ignition switch: OFF

(5 seconds after ignition switch is turned OFF)0V

Page 3022 of 3171

TROUBLE DIAGNOSIS FOR SYSTEM

TF-55

C

E

F

G

H

I

J

K

L

MA

B

TF

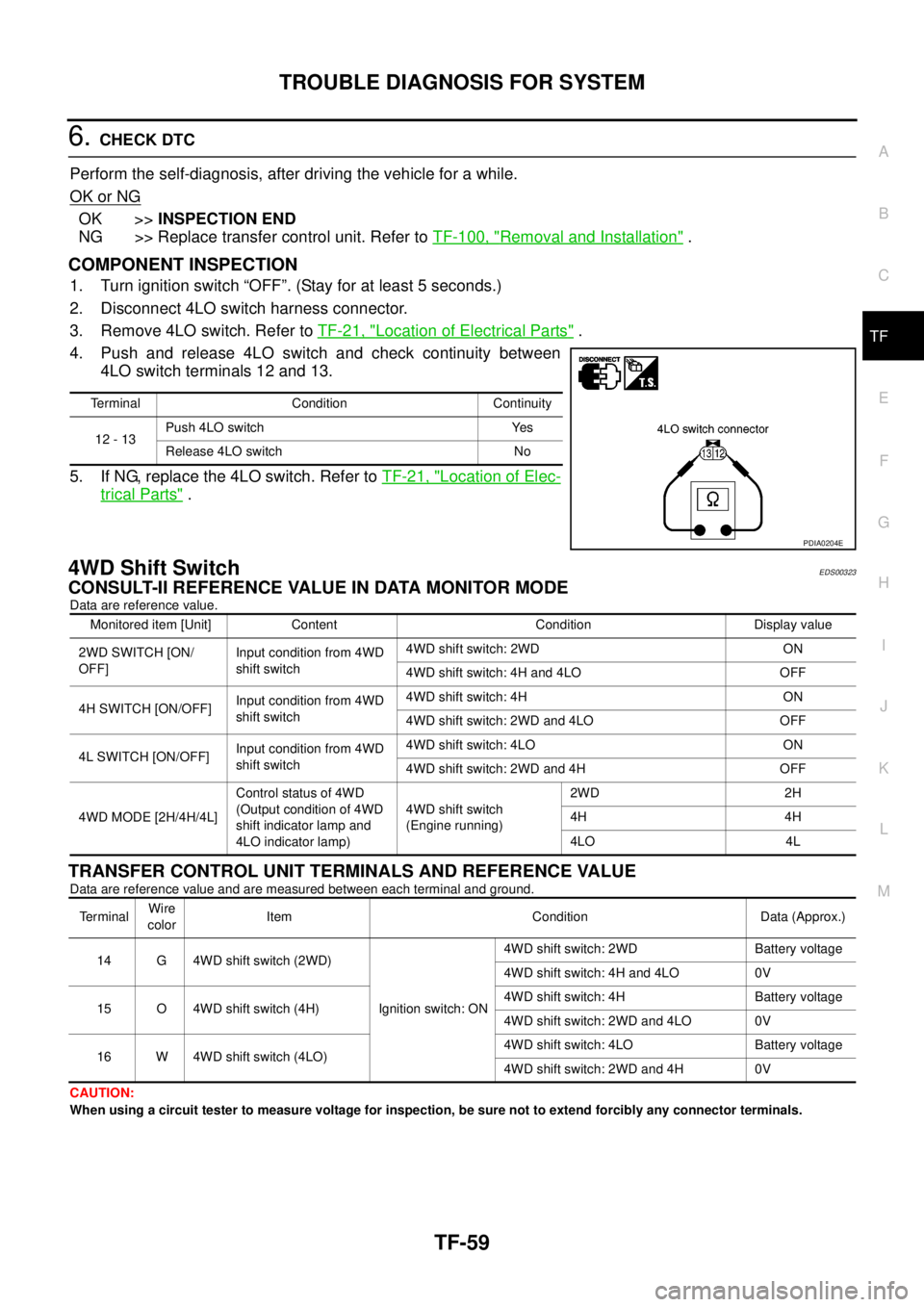

2.PERFORM SELF-DIAGNOSIS (WITH CONSULT-II)

With CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “SELF-DIAG RESULTS” mode for “ALL MODE AWD/4WD” with CONSULT-II.

3. Touch “ERASE”.

4. Turn ignition switch “OFF” and wait at least 10 seconds.

5. Perform the self-diagnosis again.

Is the

“CONTROL UNIT 1 [P1802]”,“CONTROL UNIT 2 [P1803]”,“CONTROL UNIT 3 [P1804]”or“CONTROL

UNIT 4 [P1809]”displayed?

YES >> Replace transfer control unit. Refer toTF-100, "Removal and Installation".

NO >>INSPECTION END

3.PERFORM SELF-DIAGNOSIS (WITHOUT CONSULT-II)

Without CONSULT-II

1. Perform the self-diagnosis and then erase self-diagnostic results. Refer toTF-49, "

SELF-DIAGNOSTIC

PROCEDURE (WITHOUT CONSULT-II)"andTF-51, "ERASE SELF-DIAGNOSIS".

2. Perform the self-diagnosis again.

Do the self-diagnostic results indicate AD converter?

YES >> Replace transfer control unit. Refer toTF-100, "Removal and Installation".

NO >>INSPECTION END

Output Shaft Revolution Signal (TCM)EDS00320

DIAGNOSTIC PROCEDURE

1.CHECK DTC WITH TCM

Perform self-diagnosis with TCM. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE".

Is any malfunction detected by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 2.

2.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer toTF-38, "

Transfer Control Unit Input/Output Signal Ref-

erence Values".

OK or NG

OK >> GO TO 3.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

3.CHECK DTC

Perform the self-diagnosis, after driving a vehicle for a while.

OK or NG

OK >>INSPECTION END

NG >> Perform self-diagnosis with TCM again. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE".

Vehicle Speed Sensor (ABS)EDS00321

DIAGNOSTIC PROCEDURE

1.CHECK DTC WITH ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

Perform self-diagnosis with ABS actuator and electric unit (control unit). Refer toBRC-18, "

Self-Diagnosis".

Is any malfunction detected by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 2.

Page 3026 of 3171

TROUBLE DIAGNOSIS FOR SYSTEM

TF-59

C

E

F

G

H

I

J

K

L

MA

B

TF

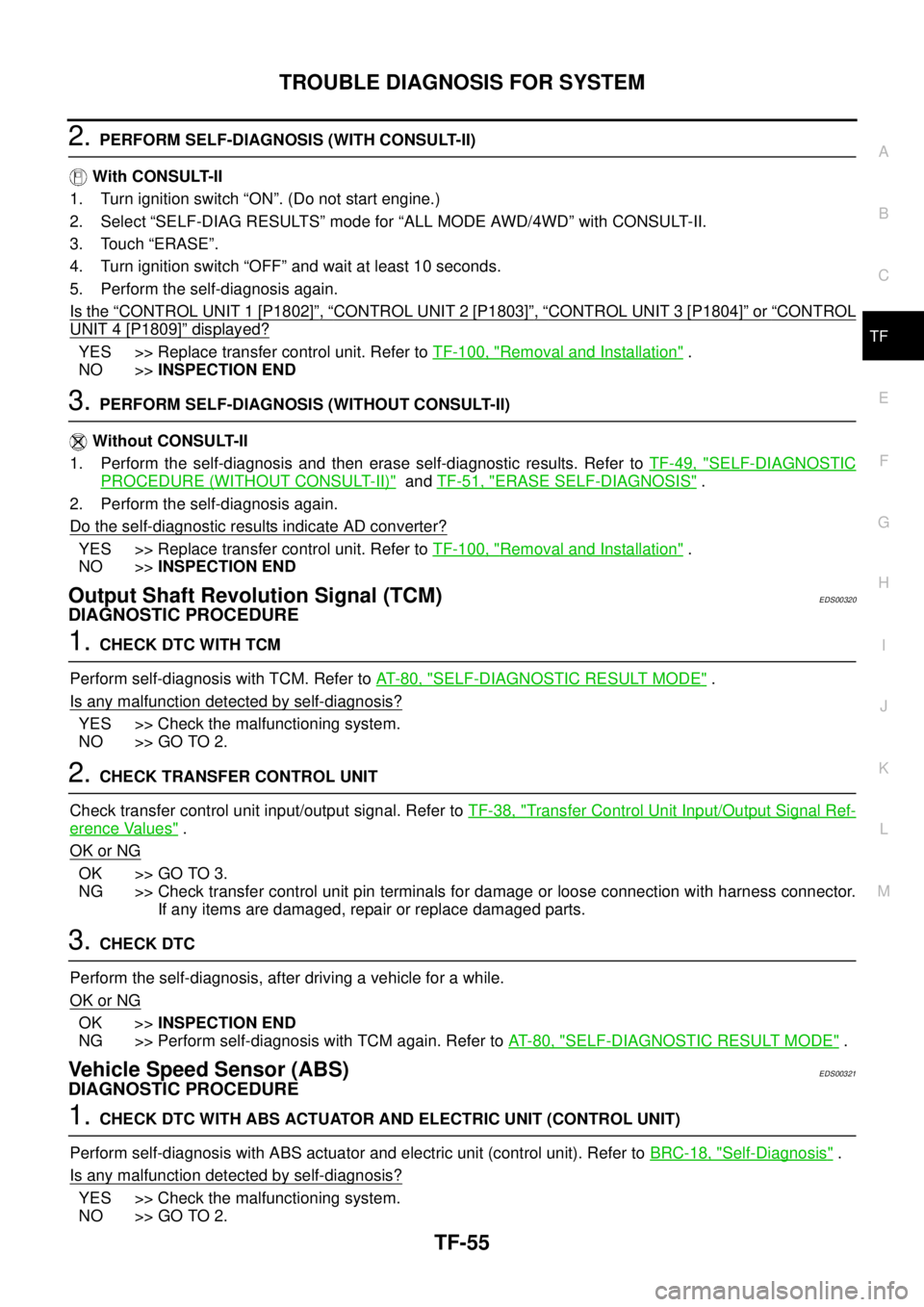

6.CHECK DTC

Perform the self-diagnosis, after driving the vehicle for a while.

OK or NG

OK >>INSPECTION END

NG >> Replace transfer control unit. Refer toTF-100, "

Removal and Installation".

COMPONENT INSPECTION

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect 4LO switch harness connector.

3. Remove 4LO switch. Refer toTF-21, "

Location of Electrical Parts".

4. Push and release 4LO switch and check continuity between

4LO switch terminals 12 and 13.

5. If NG, replace the 4LO switch. Refer toTF-21, "

Location of Elec-

trical Parts".

4WD Shift SwitchEDS00323

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

TRANSFER CONTROL UNIT TERMINALS AND REFERENCE VALUE

Data are reference value and are measured between each terminal and ground.

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.Terminal Condition Continuity

12 - 13Push 4LO switch Yes

Release 4LO switch No

PDIA0204E

Monitored item [Unit] Content Condition Display value

2WDSWITCH[ON/

OFF]Input condition from 4WD

shift switch4WD shift switch: 2WD ON

4WD shift switch: 4H and 4LO OFF

4H SWITCH [ON/OFF]Input condition from 4WD

shift switch4WD shift switch: 4H ON

4WD shift switch: 2WD and 4LO OFF

4L SWITCH [ON/OFF]Input condition from 4WD

shift switch4WD shift switch: 4LO ON

4WD shift switch: 2WD and 4H OFF

4WD MODE [2H/4H/4L]Control status of 4WD

(Output condition of 4WD

shift indicator lamp and

4LO indicator lamp)4WD shift switch

(Engine running)2WD 2H

4H 4H

4LO 4L

TerminalWire

colorItem Condition Data (Approx.)

14 G 4WD shift switch (2WD)

Ignition switch: ON4WD shift switch: 2WD Battery voltage

4WD shift switch: 4H and 4LO 0V

15 O 4WD shift switch (4H)4WD shift switch: 4H Battery voltage

4WD shift switch: 2WD and 4LO 0V

16 W 4WD shift switch (4LO)4WD shift switch: 4LO Battery voltage

4WD shift switch: 2WD and 4H 0V

Page 3033 of 3171

TF-66

TROUBLE DIAGNOSIS FOR SYSTEM

6.CHECK DTC

Perform the self-diagnosis, after driving a vehicle for a while.

OK or NG

OK >>INSPECTION END

NG >> Replace transfer control unit. Refer toTF-100, "

Removal and Installation".

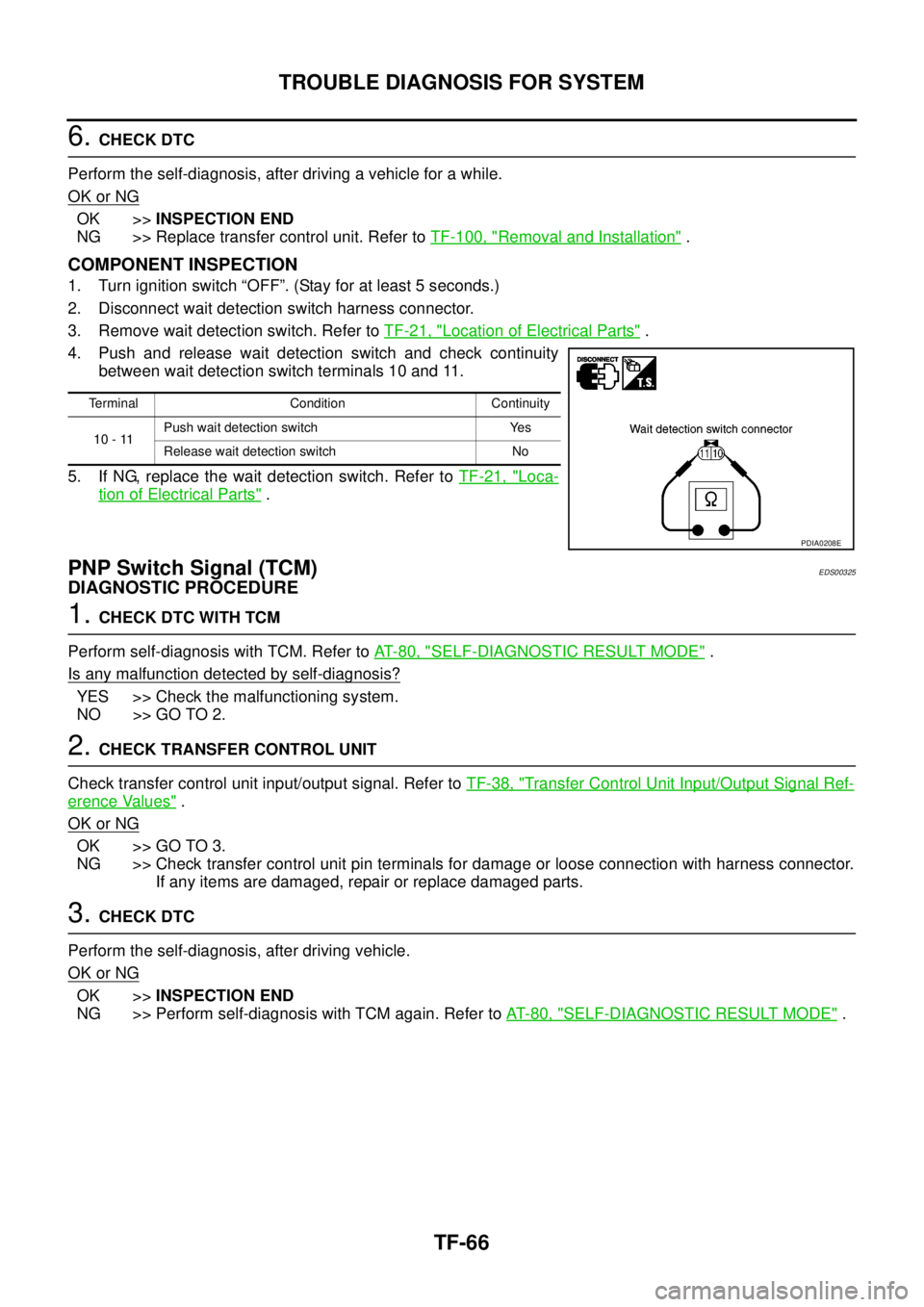

COMPONENT INSPECTION

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect wait detection switch harness connector.

3. Remove wait detection switch. Refer toTF-21, "

Location of Electrical Parts".

4. Push and release wait detection switch and check continuity

between wait detection switch terminals 10 and 11.

5. If NG, replace the wait detection switch. Refer toTF-21, "

Loca-

tion of Electrical Parts".

PNP Switch Signal (TCM)EDS00325

DIAGNOSTIC PROCEDURE

1.CHECK DTC WITH TCM

Perform self-diagnosis with TCM. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE".

Is any malfunction detected by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 2.

2.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer toTF-38, "

Transfer Control Unit Input/Output Signal Ref-

erence Values".

OK or NG

OK >> GO TO 3.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

3.CHECK DTC

Perform the self-diagnosis, after driving vehicle.

OK or NG

OK >>INSPECTION END

NG >> Perform self-diagnosis with TCM again. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE".

Terminal Condition Continuity

10 - 11Push wait detection switch Yes

Release wait detection switch No

PDIA0208E

Page 3034 of 3171

TROUBLE DIAGNOSIS FOR SYSTEM

TF-67

C

E

F

G

H

I

J

K

L

MA

B

TF

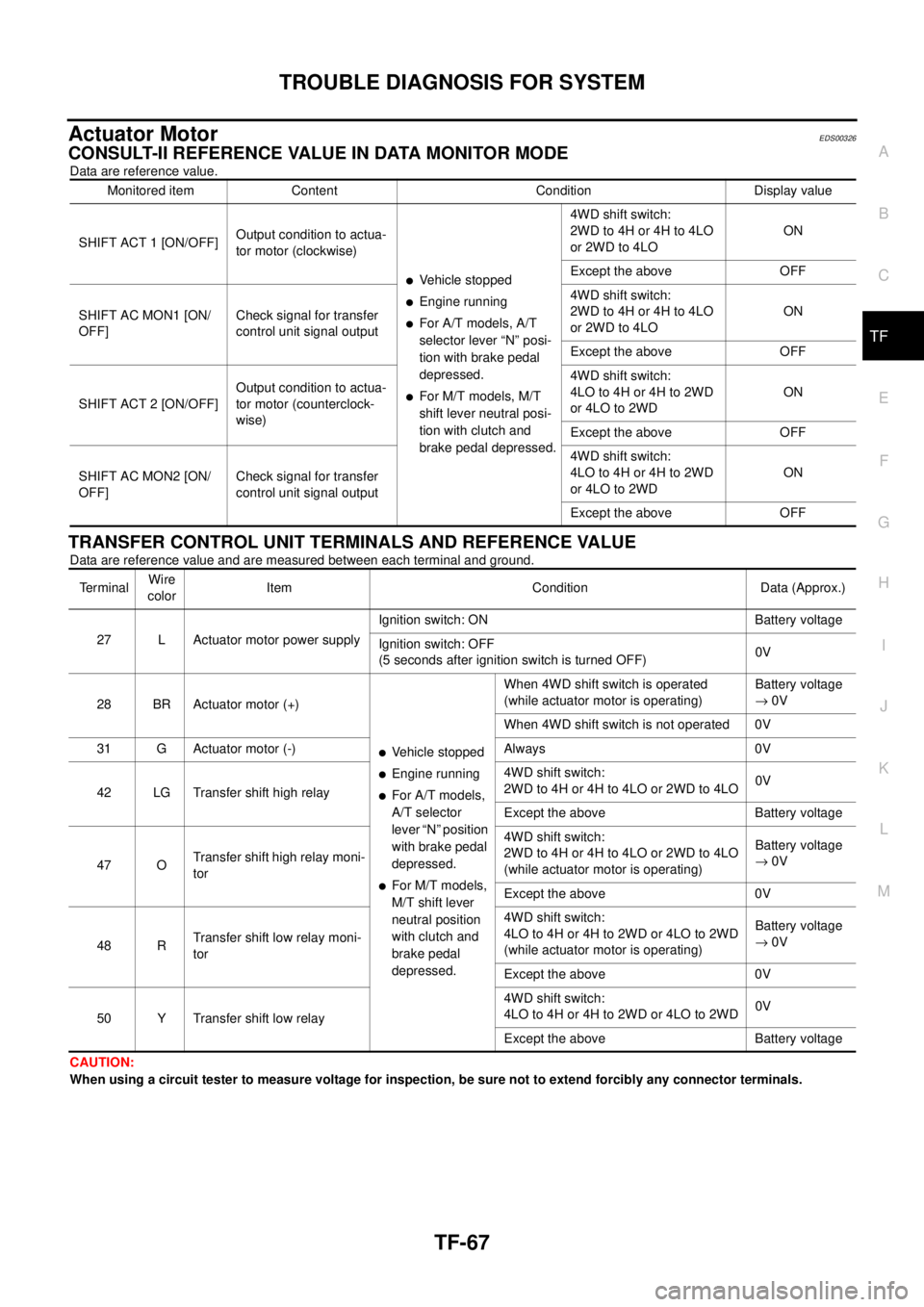

Actuator MotorEDS00326

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

TRANSFER CONTROL UNIT TERMINALS AND REFERENCE VALUE

Data are reference value and are measured between each terminal and ground.

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.Monitored item Content Condition Display value

SHIFT ACT 1 [ON/OFF]Output condition to actua-

tor motor (clockwise)

lVehicle stopped

lEngine running

lFor A/T models, A/T

selector lever “N” posi-

tion with brake pedal

depressed.

lFor M/T models, M/T

shift lever neutral posi-

tion with clutch and

brake pedal depressed.4WD shift switch:

2WDto4Hor4Hto4LO

or 2WD to 4LOON

Except the above OFF

SHIFT AC MON1 [ON/

OFF]Check signal for transfer

control unit signal output4WD shift switch:

2WDto4Hor4Hto4LO

or 2WD to 4LOON

Except the above OFF

SHIFT ACT 2 [ON/OFF]Output condition to actua-

tor motor (counterclock-

wise)4WD shift switch:

4LO to 4H or 4H to 2WD

or 4LO to 2WDON

Except the above OFF

SHIFT AC MON2 [ON/

OFF]Check signal for transfer

control unit signal output4WD shift switch:

4LO to 4H or 4H to 2WD

or 4LO to 2WDON

Except the above OFF

TerminalWire

colorItem Condition Data (Approx.)

27 L Actuator motor power supplyIgnition switch: ON Battery voltage

Ignition switch: OFF

(5 seconds after ignition switch is turned OFF)0V

28 BR Actuator motor (+)

lVehicle stopped

lEngine running

lFor A/T models,

A/T selector

lever “N” position

with brake pedal

depressed.

lFor M/T models,

M/T shift lever

neutral position

with clutch and

brake pedal

depressed.When 4WD shift switch is operated

(while actuator motor is operating)Battery voltage

®0V

When 4WD shift switch is not operated 0V

31 G Actuator motor (-) Always 0V

42 LG Transfer shift high relay4WD shift switch:

2WD to 4H or 4H to 4LO or 2WD to 4LO0V

Except the above Battery voltage

47 OTransfer shift high relay moni-

tor4WD shift switch:

2WD to 4H or 4H to 4LO or 2WD to 4LO

(while actuator motor is operating)Battery voltage

®0V

Except the above 0V

48 RTransfer shift low relay moni-

tor4WD shift switch:

4LO to 4H or 4H to 2WD or 4LO to 2WD

(while actuator motor is operating)Battery voltage

®0V

Except the above 0V

50 Y Transfer shift low relay4WD shift switch:

4LO to 4H or 4H to 2WD or 4LO to 2WD0V

Except the above Battery voltage

Page 3045 of 3171

TF-78

TROUBLE DIAGNOSIS FOR SYSTEM

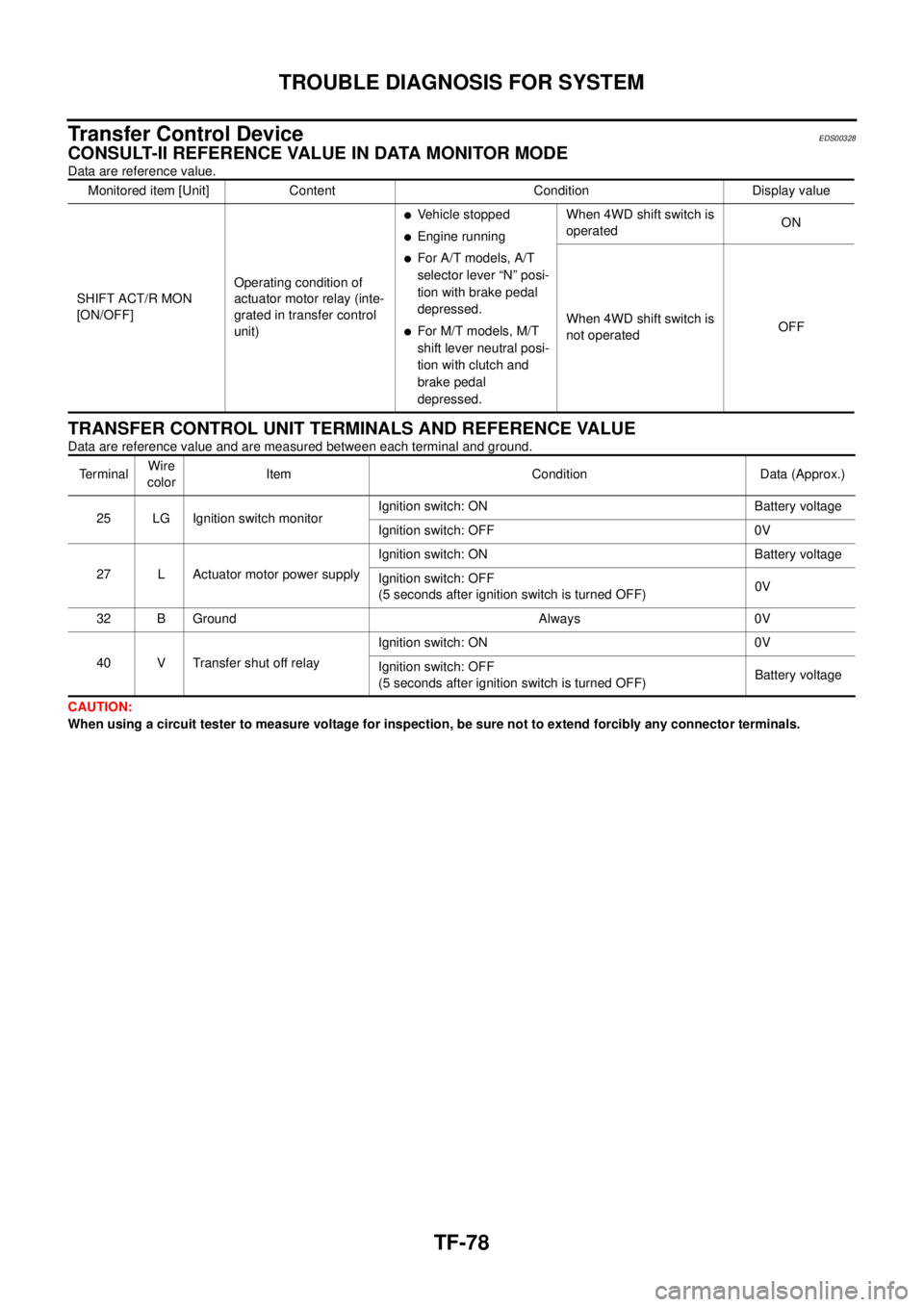

Transfer Control Device

EDS00328

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

TRANSFER CONTROL UNIT TERMINALS AND REFERENCE VALUE

Data are reference value and are measured between each terminal and ground.

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.Monitored item [Unit] Content Condition Display value

SHIFT ACT/R MON

[ON/OFF]Operating condition of

actuator motor relay (inte-

grated in transfer control

unit)

lVehicle stopped

lEngine running

lFor A/T models, A/T

selector lever “N” posi-

tion with brake pedal

depressed.

lFor M/T models, M/T

shift lever neutral posi-

tion with clutch and

brake pedal

depressed.When 4WD shift switch is

operatedON

When 4WD shift switch is

not operatedOFF

Te r m i n a lWire

colorItem Condition Data (Approx.)

25 LG Ignition switch monitorIgnition switch: ON Battery voltage

Ignition switch: OFF 0V

27 L Actuator motor power supplyIgnition switch: ON Battery voltage

Ignition switch: OFF

(5 seconds after ignition switch is turned OFF)0V

32 B Ground Always 0V

40 V Transfer shut off relayIgnition switch: ON 0V

Ignition switch: OFF

(5 seconds after ignition switch is turned OFF)Battery voltage

Page 3048 of 3171

TROUBLE DIAGNOSIS FOR SYSTEM

TF-81

C

E

F

G

H

I

J

K

L

MA

B

TF

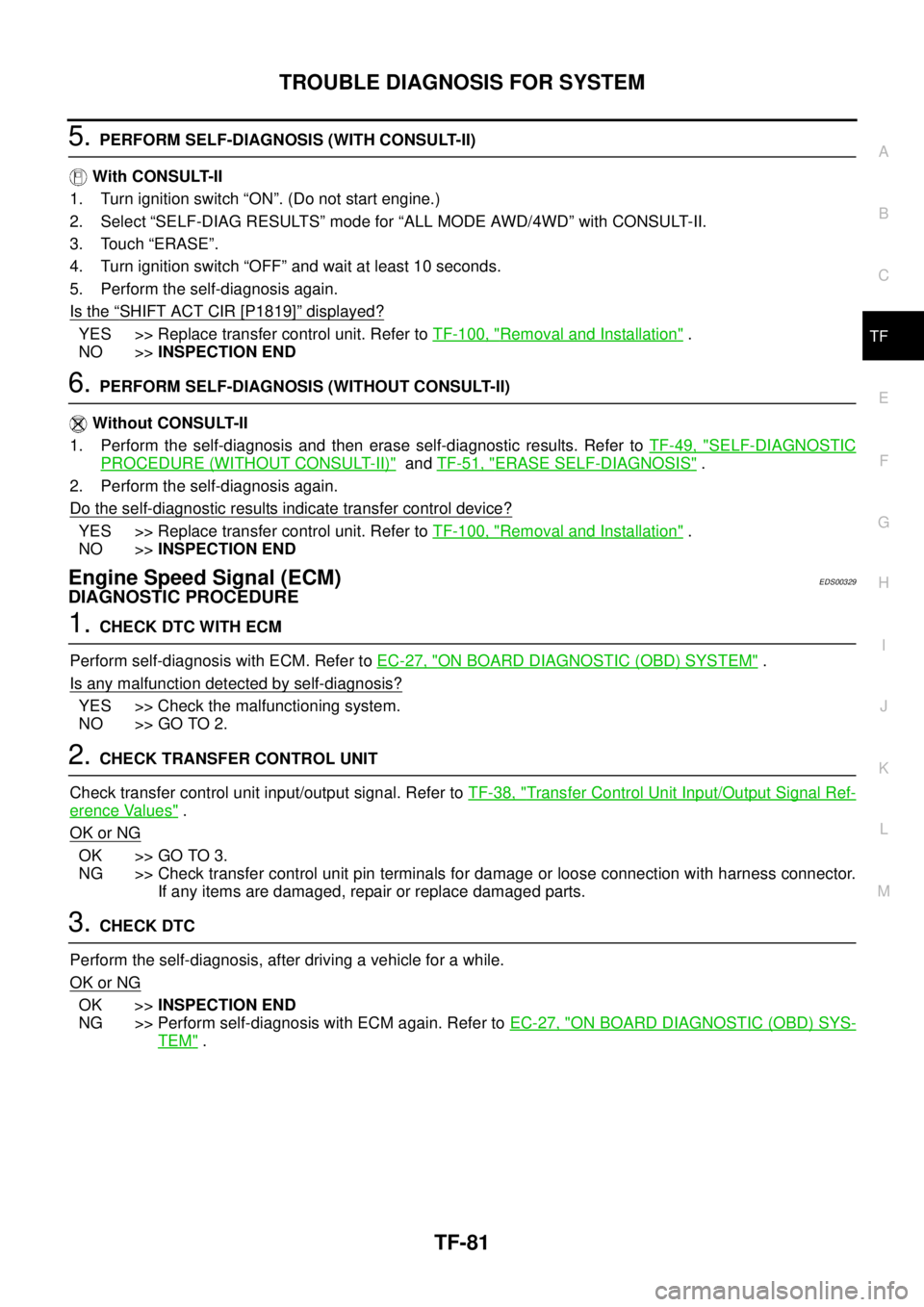

5.PERFORM SELF-DIAGNOSIS (WITH CONSULT-II)

With CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “SELF-DIAG RESULTS” mode for “ALL MODE AWD/4WD” with CONSULT-II.

3. Touch “ERASE”.

4. Turn ignition switch “OFF” and wait at least 10 seconds.

5. Perform the self-diagnosis again.

Is the

“SHIFT ACT CIR [P1819]”displayed?

YES >> Replace transfer control unit. Refer toTF-100, "Removal and Installation".

NO >>INSPECTION END

6.PERFORM SELF-DIAGNOSIS (WITHOUT CONSULT-II)

Without CONSULT-II

1. Perform the self-diagnosis and then erase self-diagnostic results. Refer toTF-49, "

SELF-DIAGNOSTIC

PROCEDURE (WITHOUT CONSULT-II)"andTF-51, "ERASE SELF-DIAGNOSIS".

2. Perform the self-diagnosis again.

Do the self-diagnostic results indicate transfer control device?

YES >> Replace transfer control unit. Refer toTF-100, "Removal and Installation".

NO >>INSPECTION END

Engine Speed Signal (ECM)EDS00329

DIAGNOSTIC PROCEDURE

1.CHECK DTC WITH ECM

Perform self-diagnosis with ECM. Refer toEC-27, "

ON BOARD DIAGNOSTIC (OBD) SYSTEM".

Is any malfunction detected by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 2.

2.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer toTF-38, "

Transfer Control Unit Input/Output Signal Ref-

erence Values".

OK or NG

OK >> GO TO 3.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

3.CHECK DTC

Perform the self-diagnosis, after driving a vehicle for a while.

OK or NG

OK >>INSPECTION END

NG >> Perform self-diagnosis with ECM again. Refer toEC-27, "

ON BOARD DIAGNOSTIC (OBD) SYS-

TEM".

Page 3050 of 3171

TROUBLE DIAGNOSIS FOR SYSTEM

TF-83

C

E

F

G

H

I

J

K

L

MA

B

TF

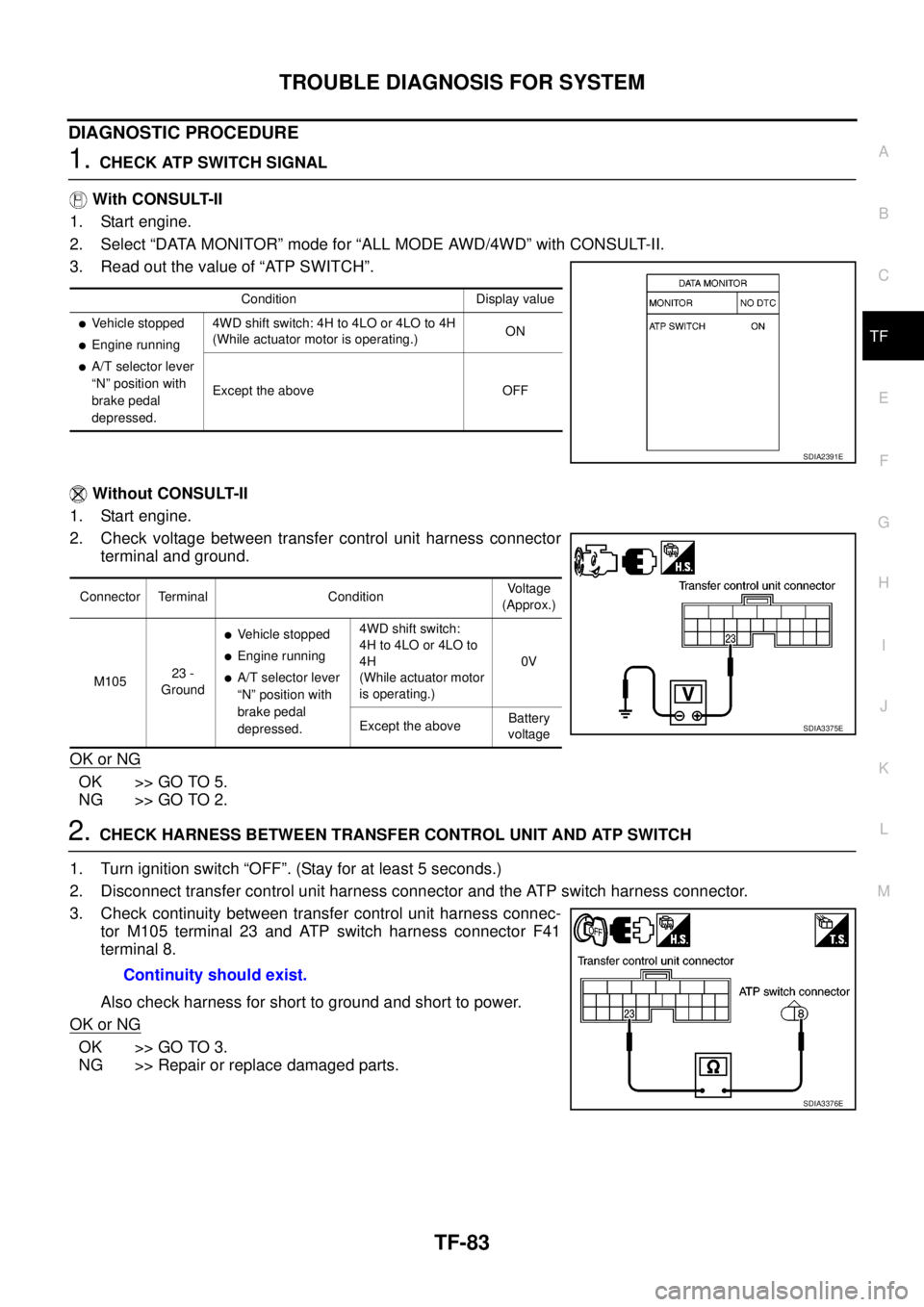

DIAGNOSTIC PROCEDURE

1.CHECK ATP SWITCH SIGNAL

With CONSULT-II

1. Start engine.

2. Select “DATA MONITOR” mode for “ALL MODE AWD/4WD” with CONSULT-II.

3. Read out the value of “ATP SWITCH”.

Without CONSULT-II

1. Start engine.

2. Check voltage between transfer control unit harness connector

terminal and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

2.CHECK HARNESS BETWEEN TRANSFER CONTROL UNIT AND ATP SWITCH

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector and the ATP switch harness connector.

3. Check continuity between transfer control unit harness connec-

tor M105 terminal 23 and ATP switch harness connector F41

terminal 8.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

Condition Display value

lVehicle stopped

lEngine running

lA/T selector lever

“N” position with

brake pedal

depressed.4WD shift switch: 4H to 4LO or 4LO to 4H

(While actuator motor is operating.)ON

Except the above OFF

SDIA2391E

Connector Terminal ConditionVoltage

(Approx.)

M10523 -

Ground

lVehicle stopped

lEngine running

lA/T selector lever

“N” position with

brake pedal

depressed.4WD shift switch:

4H to 4LO or 4LO to

4H

(While actuator motor

is operating.)0V

Except the aboveBattery

voltage

SDIA3375E

Continuity should exist.

SDIA3376E

Page 3091 of 3171

TF-124

TRANSFER ASSEMBLY

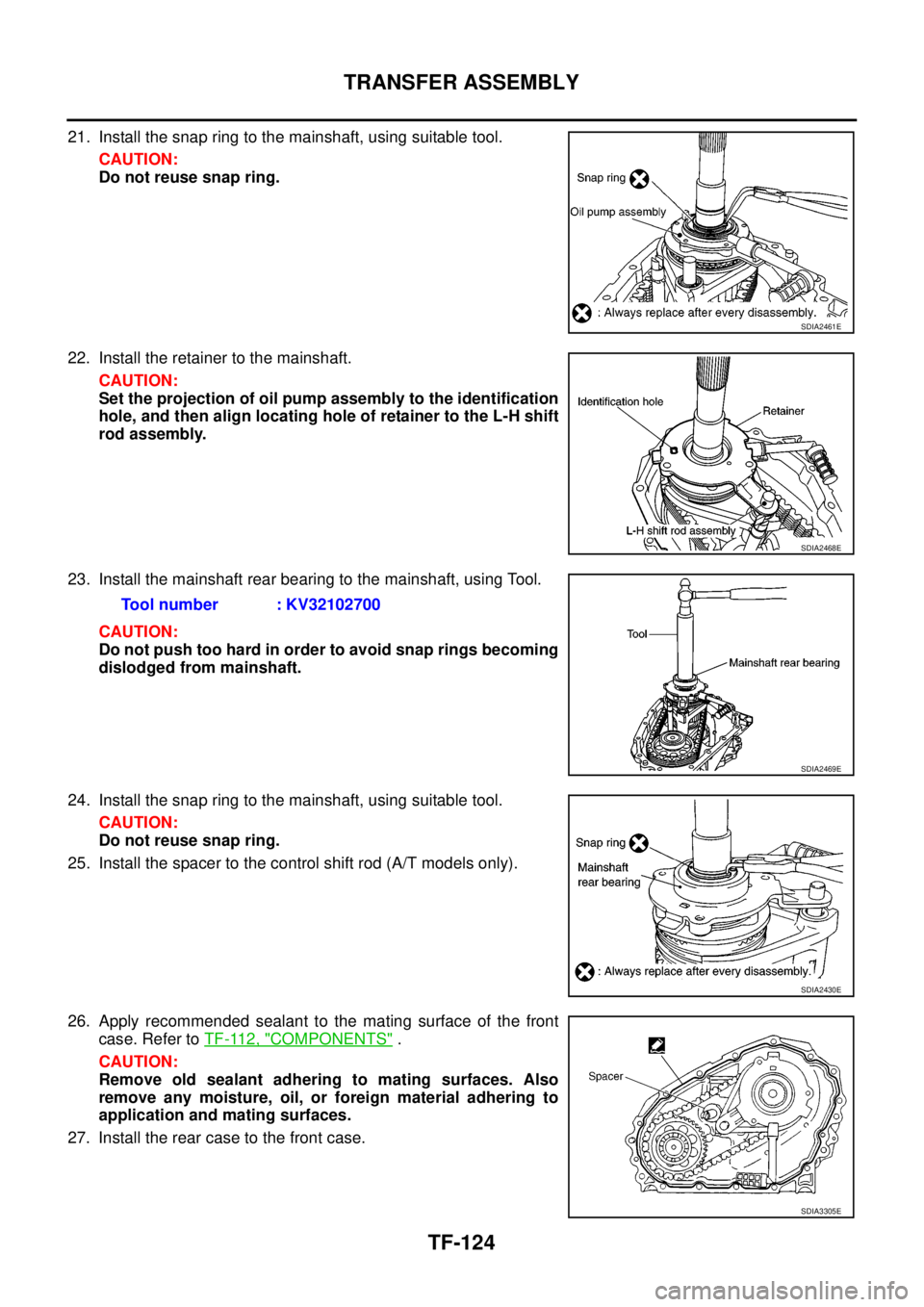

21. Install the snap ring to the mainshaft, using suitable tool.

CAUTION:

Do not reuse snap ring.

22. Install the retainer to the mainshaft.

CAUTION:

Set the projection of oil pump assembly to the identification

hole, and then align locating hole of retainer to the L-H shift

rod assembly.

23. Install the mainshaft rear bearing to the mainshaft, using Tool.

CAUTION:

Do not push too hard in order to avoid snap rings becoming

dislodged from mainshaft.

24. Install the snap ring to the mainshaft, using suitable tool.

CAUTION:

Do not reuse snap ring.

25. Install the spacer to the control shift rod (A/T models only).

26. Apply recommended sealant to the mating surface of the front

case. Refer toTF-112, "

COMPONENTS".

CAUTION:

Remove old sealant adhering to mating surfaces. Also

remove any moisture, oil, or foreign material adhering to

application and mating surfaces.

27. Install the rear case to the front case.

SDIA2461E

SDIA2468E

Tool number : KV32102700

SDIA2469E

SDIA2430E

SDIA3305E