check engine NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1480 of 3171

EM-98

CYLINDER HEAD

lBefore installing, remove carbon depositing on mounting hole of glow plug with a reamer.

6. Install engine coolant temperature sensor.

7. Install in the reverse order of removal.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

lBefore starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer toMA-14, "

RECOMMENDED FLUIDS AND LUBRICANTS".

lUse procedure below to check for fuel leakage.

–Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel

leakage at connection points.

–Start engine. With engine speed increased, check again for fuel leakage at connection points.

lRun engine to check for unusual noise and vibration.

lWarm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids

including engine oil and engine coolant.

lBleed air from lines and hoses of applicable lines, such as in cooling system.

lAfter cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*1: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

*2: Check engine oil level 10 minutes after engine stopped.Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level (*2)

Other oils and fluid (*1) Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 1482 of 3171

EM-100

CYLINDER HEAD

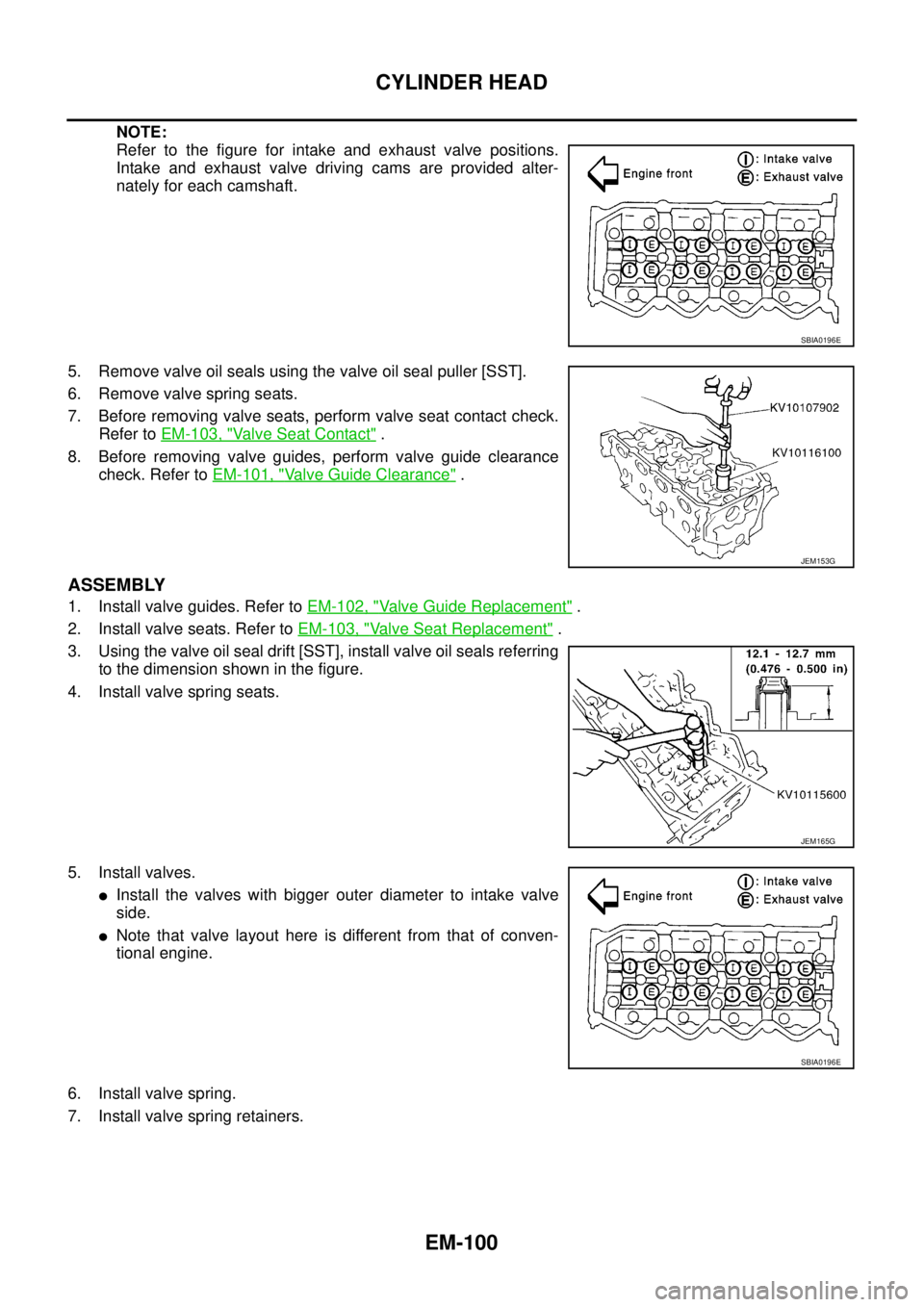

NOTE:

Refer to the figure for intake and exhaust valve positions.

Intake and exhaust valve driving cams are provided alter-

nately for each camshaft.

5. Remove valve oil seals using the valve oil seal puller [SST].

6. Remove valve spring seats.

7. Before removing valve seats, perform valve seat contact check.

Refer toEM-103, "

Va l v e S e a t C o n t a c t".

8. Before removing valve guides, perform valve guide clearance

check. Refer toEM-101, "

Valve Guide Clearance".

ASSEMBLY

1. Install valve guides. Refer toEM-102, "Valve Guide Replacement".

2. Install valve seats. Refer toEM-103, "

Valve Seat Replacement".

3. Using the valve oil seal drift [SST], install valve oil seals referring

to the dimension shown in the figure.

4. Install valve spring seats.

5. Install valves.

lInstall the valves with bigger outer diameter to intake valve

side.

lNote that valve layout here is different from that of conven-

tional engine.

6. Install valve spring.

7. Install valve spring retainers.

SBIA0196E

JEM153G

JEM165G

SBIA0196E

Page 1490 of 3171

EM-108

ENGINE ASSEMBLY

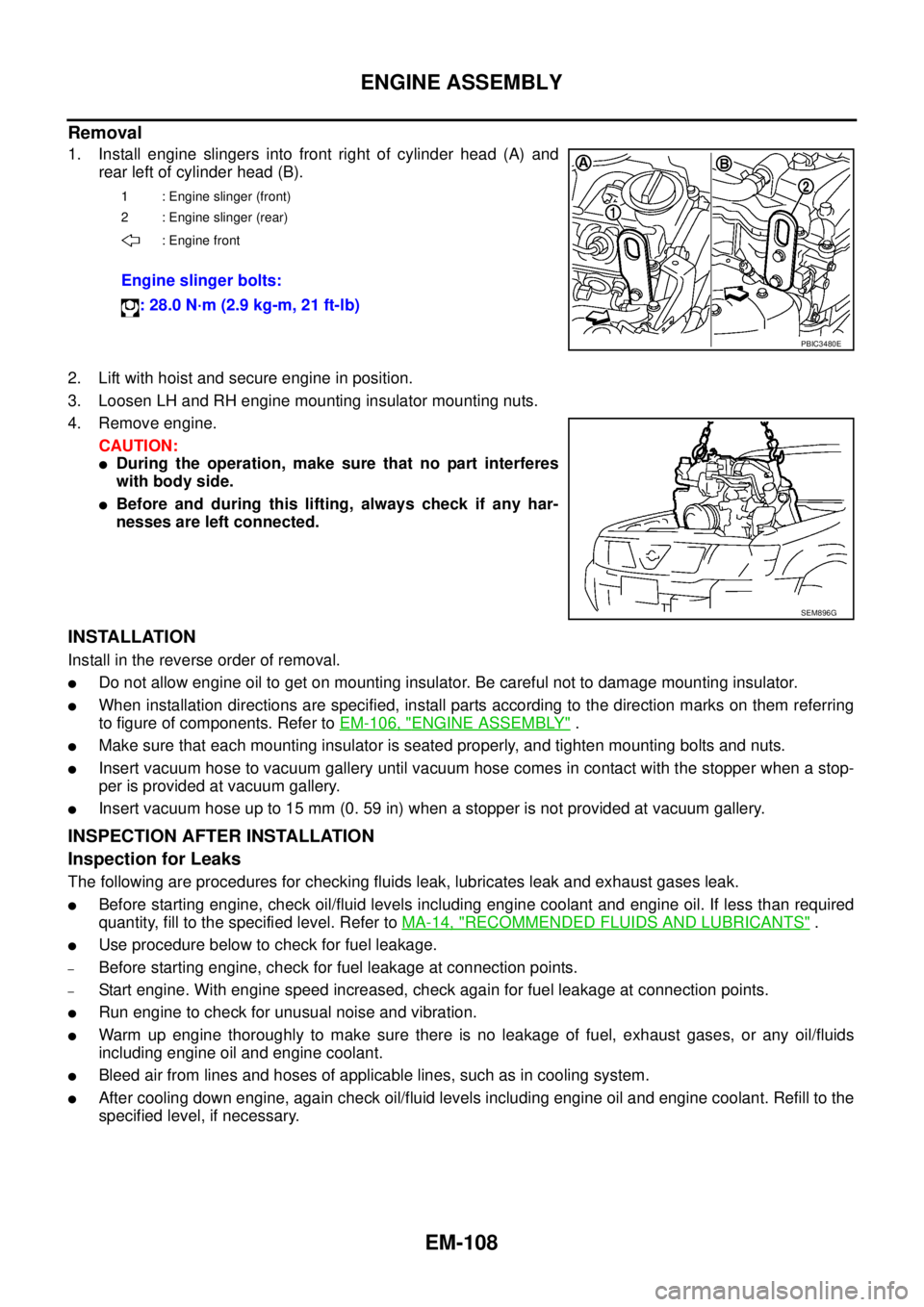

Removal

1. Install engine slingers into front right of cylinder head (A) and

rear left of cylinder head (B).

2. Lift with hoist and secure engine in position.

3. Loosen LH and RH engine mounting insulator mounting nuts.

4. Remove engine.

CAUTION:

lDuring the operation, make sure that no part interferes

with body side.

lBefore and during this lifting, always check if any har-

nesses are left connected.

INSTALLATION

Install in the reverse order of removal.

lDo not allow engine oil to get on mounting insulator. Be careful not to damage mounting insulator.

lWhen installation directions are specified, install parts according to the direction marks on them referring

to figure of components. Refer toEM-106, "

ENGINE ASSEMBLY".

lMake sure that each mounting insulator is seated properly, and tighten mounting bolts and nuts.

lInsert vacuum hose to vacuum gallery until vacuum hose comes in contact with the stopper when a stop-

per is provided at vacuum gallery.

lInsert vacuum hose up to 15 mm (0. 59 in) when a stopper is not provided at vacuum gallery.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

lBefore starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer toMA-14, "

RECOMMENDED FLUIDS AND LUBRICANTS".

lUse procedure below to check for fuel leakage.

–Before starting engine, check for fuel leakage at connection points.

–Start engine. With engine speed increased, check again for fuel leakage at connection points.

lRun engine to check for unusual noise and vibration.

lWarm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids

including engine oil and engine coolant.

lBleed air from lines and hoses of applicable lines, such as in cooling system.

lAfter cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

1 : Engine slinger (front)

2 : Engine slinger (rear)

: Engine front

Engine slinger bolts:

: 28.0 N·m (2.9 kg-m, 21 ft-lb)

PBIC3480E

SEM896G

Page 1491 of 3171

ENGINE ASSEMBLY

EM-109

C

D

E

F

G

H

I

J

K

L

MA

EM

Summary of the inspection items:

*1: Transmission/transaxle/AT fluid, power steering fluid, brake fluid, etc.

*2: Check engine oil level 10 minutes after engine stopped.Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level (*2)

Other oils and fluid (*1) Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 1496 of 3171

EM-114

CYLINDER BLOCK

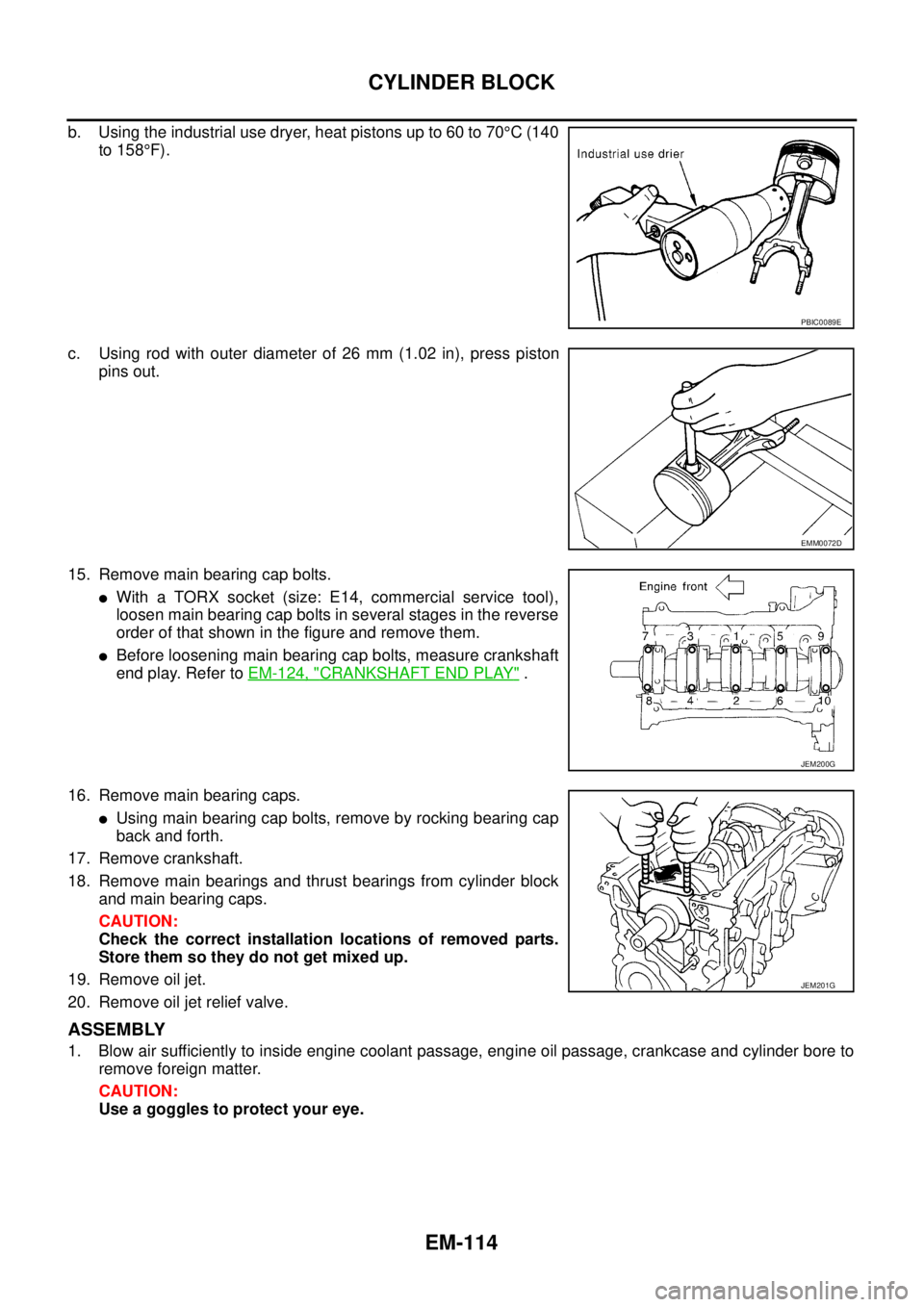

b. Using the industrial use dryer, heat pistons up to 60 to 70°C(140

to 158°F).

c. Using rod with outer diameter of 26 mm (1.02 in), press piston

pins out.

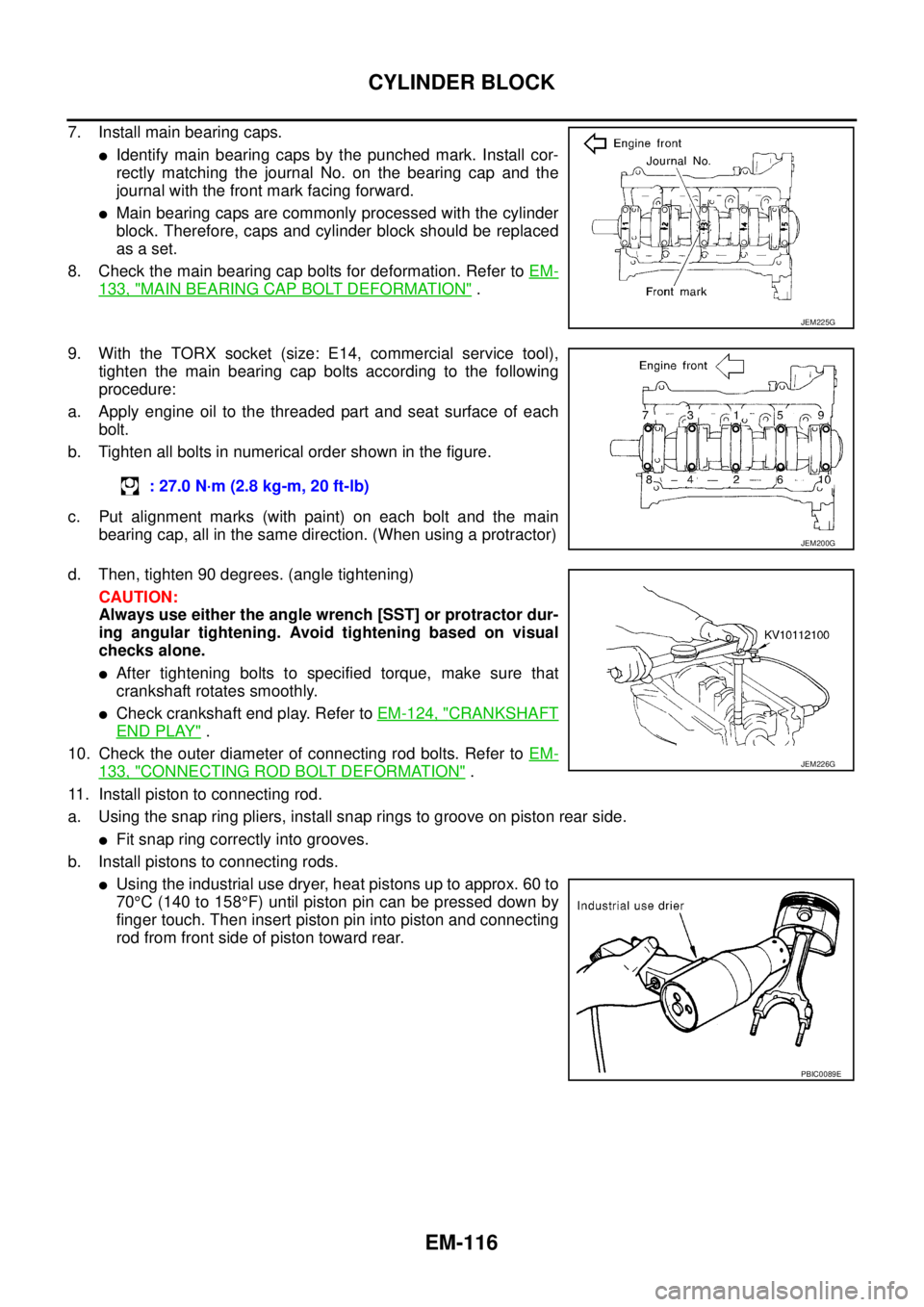

15. Remove main bearing cap bolts.

lWith a TORX socket (size: E14, commercial service tool),

loosen main bearing cap bolts in several stages in the reverse

order of that shown in the figure and remove them.

lBefore loosening main bearing cap bolts, measure crankshaft

end play. Refer toEM-124, "

CRANKSHAFT END PLAY".

16. Remove main bearing caps.

lUsing main bearing cap bolts, remove by rocking bearing cap

back and forth.

17. Remove crankshaft.

18. Remove main bearings and thrust bearings from cylinder block

andmainbearingcaps.

CAUTION:

Check the correct installation locations of removed parts.

Store them so they do not get mixed up.

19. Remove oil jet.

20. Remove oil jet relief valve.

ASSEMBLY

1. Blow air sufficiently to inside engine coolant passage, engine oil passage, crankcase and cylinder bore to

remove foreign matter.

CAUTION:

Use a goggles to protect your eye.

PBIC0089E

EMM0072D

JEM200G

JEM201G

Page 1498 of 3171

EM-116

CYLINDER BLOCK

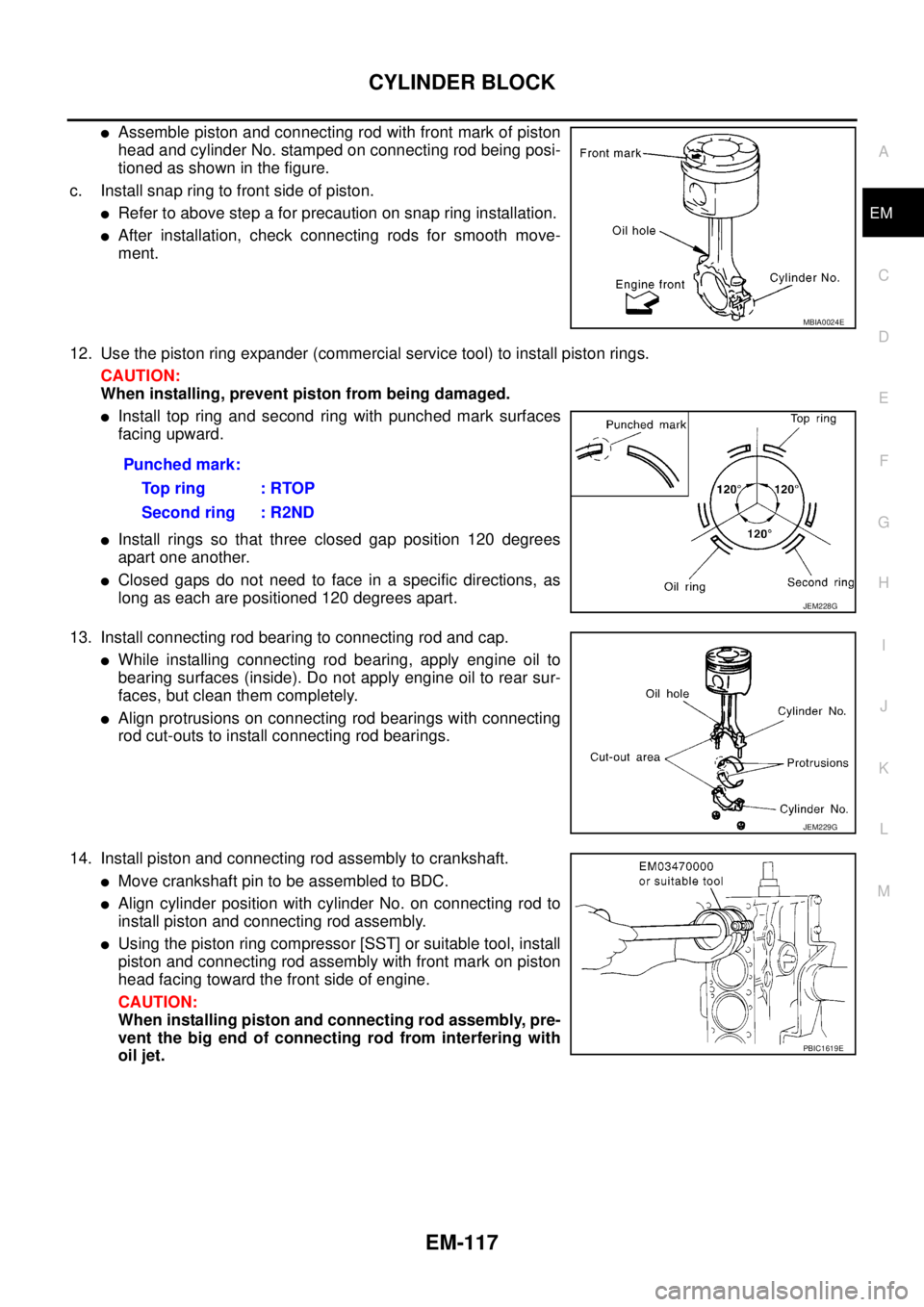

7. Install main bearing caps.

lIdentify main bearing caps by the punched mark. Install cor-

rectly matching the journal No. on the bearing cap and the

journal with the front mark facing forward.

lMain bearing caps are commonly processed with the cylinder

block. Therefore, caps and cylinder block should be replaced

as a set.

8. Check the main bearing cap bolts for deformation. Refer toEM-

133, "MAIN BEARING CAP BOLT DEFORMATION".

9. With the TORX socket (size: E14, commercial service tool),

tighten the main bearing cap bolts according to the following

procedure:

a. Apply engine oil to the threaded part and seat surface of each

bolt.

b. Tighten all bolts in numerical order shown in the figure.

c. Put alignment marks (with paint) on each bolt and the main

bearing cap, all in the same direction. (When using a protractor)

d. Then, tighten 90 degrees. (angle tightening)

CAUTION:

Always use either the angle wrench [SST] or protractor dur-

ing angular tightening. Avoid tightening based on visual

checks alone.

lAfter tightening bolts to specified torque, make sure that

crankshaft rotates smoothly.

lCheck crankshaft end play. Refer toEM-124, "CRANKSHAFT

END PLAY".

10. Check the outer diameter of connecting rod bolts. Refer toEM-

133, "CONNECTING ROD BOLT DEFORMATION".

11. Install piston to connecting rod.

a. Using the snap ring pliers, install snap rings to groove on piston rear side.

lFit snap ring correctly into grooves.

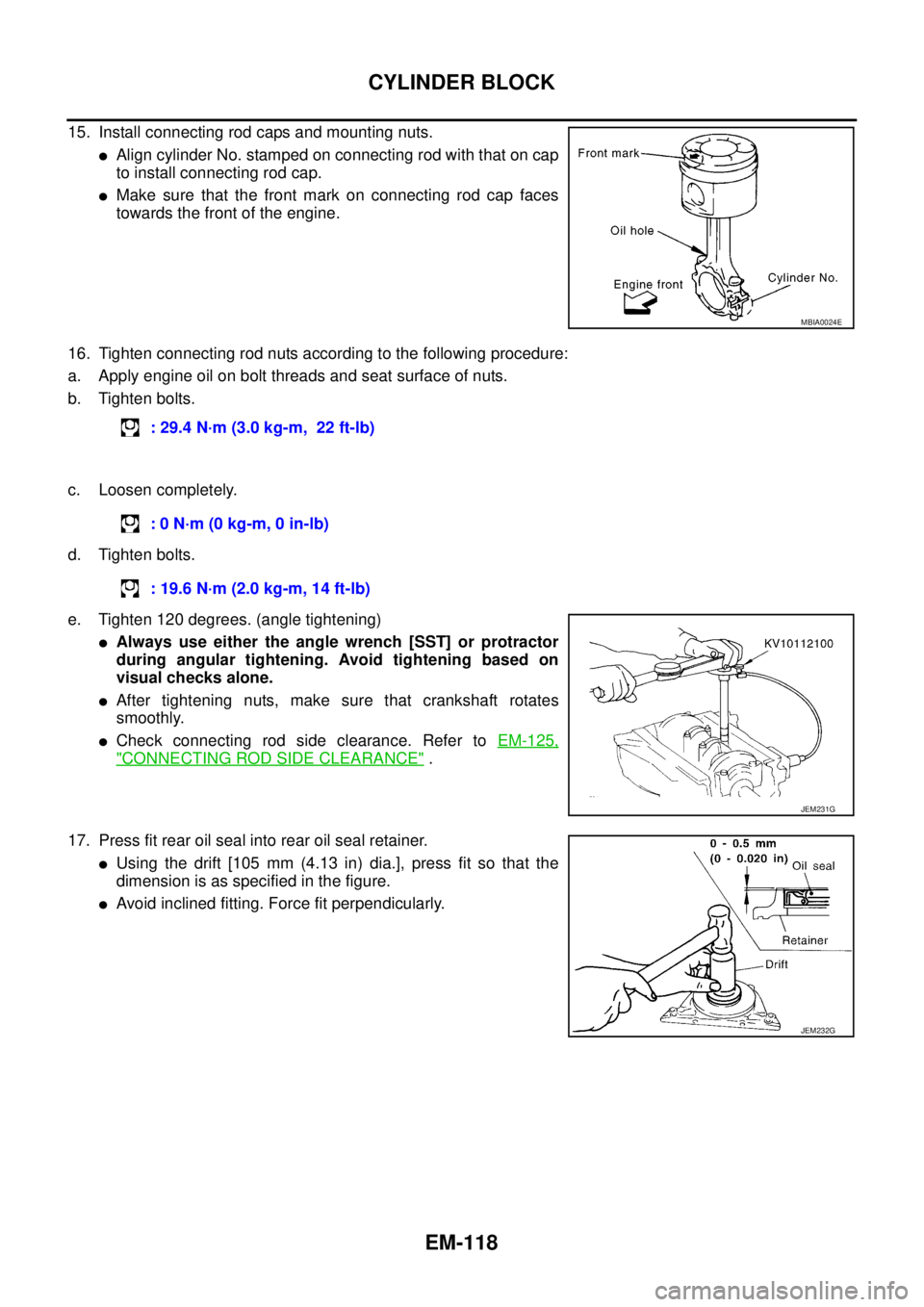

b. Install pistons to connecting rods.

lUsing the industrial use dryer, heat pistons up to approx. 60 to

70°C(140to158°F) until piston pin can be pressed down by

finger touch. Then insert piston pin into piston and connecting

rod from front side of piston toward rear.

JEM225G

: 27.0 N·m (2.8 kg-m, 20 ft-lb)

JEM200G

JEM226G

PBIC0089E

Page 1499 of 3171

CYLINDER BLOCK

EM-117

C

D

E

F

G

H

I

J

K

L

MA

EM

lAssemble piston and connecting rod with front mark of piston

head and cylinder No. stamped on connecting rod being posi-

tioned as shown in the figure.

c. Install snap ring to front side of piston.

lRefer to above step a for precaution on snap ring installation.

lAfter installation, check connecting rods for smooth move-

ment.

12. Use the piston ring expander (commercial service tool) to install piston rings.

CAUTION:

When installing, prevent piston from being damaged.

lInstall top ring and second ring with punched mark surfaces

facing upward.

lInstall rings so that three closed gap position 120 degrees

apart one another.

lClosed gaps do not need to face in a specific directions, as

long as each are positioned 120 degrees apart.

13. Install connecting rod bearing to connecting rod and cap.

lWhile installing connecting rod bearing, apply engine oil to

bearing surfaces (inside). Do not apply engine oil to rear sur-

faces, but clean them completely.

lAlign protrusions on connecting rod bearings with connecting

rod cut-outs to install connecting rod bearings.

14. Install piston and connecting rod assembly to crankshaft.

lMove crankshaft pin to be assembled to BDC.

lAlign cylinder position with cylinder No. on connecting rod to

install piston and connecting rod assembly.

lUsing the piston ring compressor [SST] or suitable tool, install

piston and connecting rod assembly with front mark on piston

head facing toward the front side of engine.

CAUTION:

When installing piston and connecting rod assembly, pre-

vent the big end of connecting rod from interfering with

oil jet.

MBIA0024E

Punched mark:

To p r i n g : R TO P

Second ring : R2ND

JEM228G

JEM229G

PBIC1619E

Page 1500 of 3171

EM-118

CYLINDER BLOCK

15. Install connecting rod caps and mounting nuts.

lAlign cylinder No. stamped on connecting rod with that on cap

to install connecting rod cap.

lMake sure that the front mark on connecting rod cap faces

towards the front of the engine.

16. Tighten connecting rod nuts according to the following procedure:

a. Apply engine oil on bolt threads and seat surface of nuts.

b. Tighten bolts.

c. Loosen completely.

d. Tighten bolts.

e. Tighten 120 degrees. (angle tightening)

lAlways use either the angle wrench [SST] or protractor

during angular tightening. Avoid tightening based on

visual checks alone.

lAfter tightening nuts, make sure that crankshaft rotates

smoothly.

lCheck connecting rod side clearance. Refer toEM-125,

"CONNECTING ROD SIDE CLEARANCE".

17. Press fit rear oil seal into rear oil seal retainer.

lUsing the drift [105 mm (4.13 in) dia.], press fit so that the

dimension is as specified in the figure.

lAvoid inclined fitting. Force fit perpendicularly.

MBIA0024E

: 29.4 N·m (3.0 kg-m, 22 ft-lb)

:0N·m(0kg-m,0in-lb)

: 19.6 N·m (2.0 kg-m, 14 ft-lb)

JEM231G

JEM232G

Page 1508 of 3171

EM-126

CYLINDER BLOCK

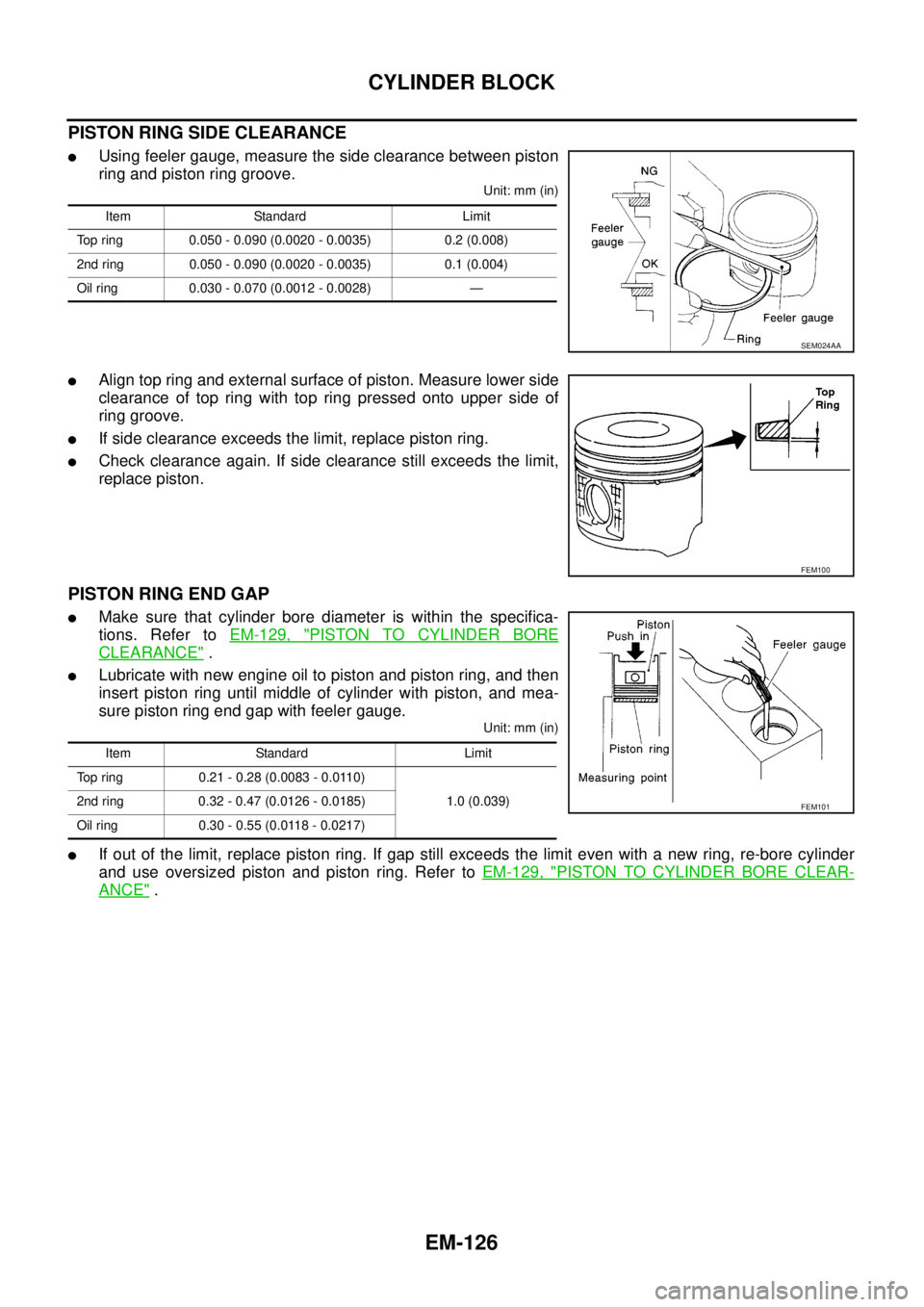

PISTON RING SIDE CLEARANCE

lUsing feeler gauge, measure the side clearance between piston

ringandpistonringgroove.

Unit: mm (in)

lAlign top ring and external surface of piston. Measure lower side

clearance of top ring with top ring pressed onto upper side of

ring groove.

lIf side clearance exceeds the limit, replace piston ring.

lCheck clearance again. If side clearance still exceeds the limit,

replace piston.

PISTON RING END GAP

lMake sure that cylinder bore diameter is within the specifica-

tions. Refer toEM-129, "

PISTON TO CYLINDER BORE

CLEARANCE".

lLubricate with new engine oil to piston and piston ring, and then

insert piston ring until middle of cylinder with piston, and mea-

sure piston ring end gap with feeler gauge.

Unit: mm (in)

lIf out of the limit, replace piston ring. If gap still exceeds the limit even with a new ring, re-bore cylinder

and use oversized piston and piston ring. Refer toEM-129, "

PISTON TO CYLINDER BORE CLEAR-

ANCE".

Item Standard Limit

Top ring 0.050 - 0.090 (0.0020 - 0.0035) 0.2 (0.008)

2nd ring 0.050 - 0.090 (0.0020 - 0.0035) 0.1 (0.004)

Oil ring 0.030 - 0.070 (0.0012 - 0.0028) —

SEM024AA

FEM100

Item Standard Limit

Top ring 0.21 - 0.28 (0.0083 - 0.0110)

1.0 (0.039) 2nd ring 0.32 - 0.47 (0.0126 - 0.0185)

Oil ring 0.30 - 0.55 (0.0118 - 0.0217)

FEM101

Page 1510 of 3171

EM-128

CYLINDER BLOCK

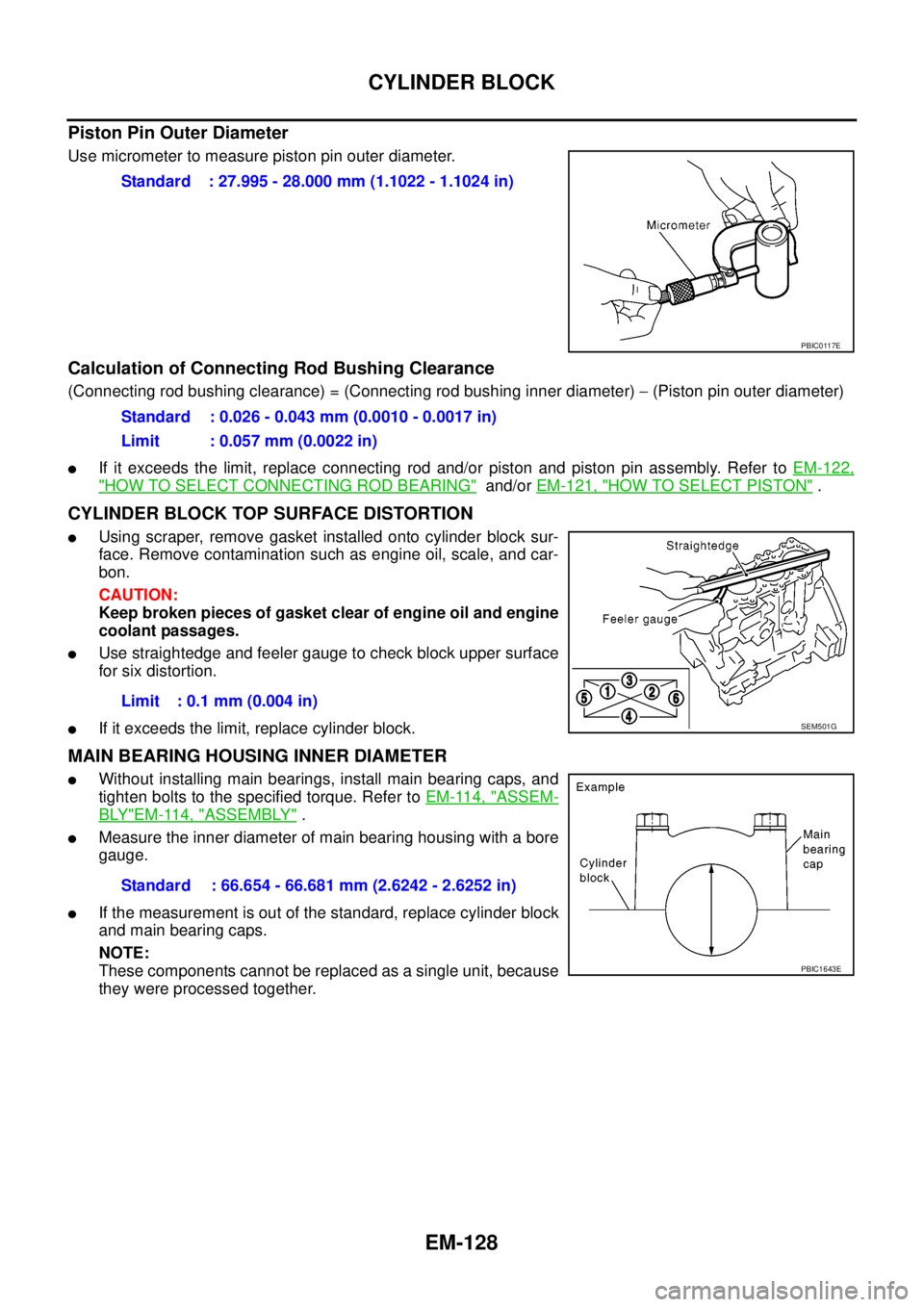

Piston Pin Outer Diameter

Use micrometer to measure piston pin outer diameter.

Calculation of Connecting Rod Bushing Clearance

(Connecting rod bushing clearance) = (Connecting rod bushing inner diameter)-(Piston pin outer diameter)

lIf it exceeds the limit, replace connecting rod and/or piston and piston pin assembly. Refer toEM-122,

"HOW TO SELECT CONNECTING ROD BEARING"and/orEM-121, "HOW TO SELECT PISTON".

CYLINDER BLOCK TOP SURFACE DISTORTION

lUsing scraper, remove gasket installed onto cylinder block sur-

face. Remove contamination such as engine oil, scale, and car-

bon.

CAUTION:

Keep broken pieces of gasket clear of engine oil and engine

coolant passages.

lUse straightedge and feeler gauge to check block upper surface

for six distortion.

lIf it exceeds the limit, replace cylinder block.

MAIN BEARING HOUSING INNER DIAMETER

lWithout installing main bearings, install main bearing caps, and

tighten bolts to the specified torque. Refer toEM-114, "

ASSEM-

BLY"EM-114, "ASSEMBLY".

lMeasure the inner diameter of main bearing housing with a bore

gauge.

lIf the measurement is out of the standard, replace cylinder block

andmainbearingcaps.

NOTE:

These components cannot be replaced as a single unit, because

they were processed together.Standard : 27.995 - 28.000 mm (1.1022 - 1.1024 in)

PBIC0117E

Standard : 0.026 - 0.043 mm (0.0010 - 0.0017 in)

Limit : 0.057 mm (0.0022 in)

Limit : 0.1 mm (0.004 in)

SEM501G

Standard : 66.654 - 66.681 mm (2.6242 - 2.6252 in)

PBIC1643E