service NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1527 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-145

C

D

E

F

G

H

I

J

K

L

MA

EM

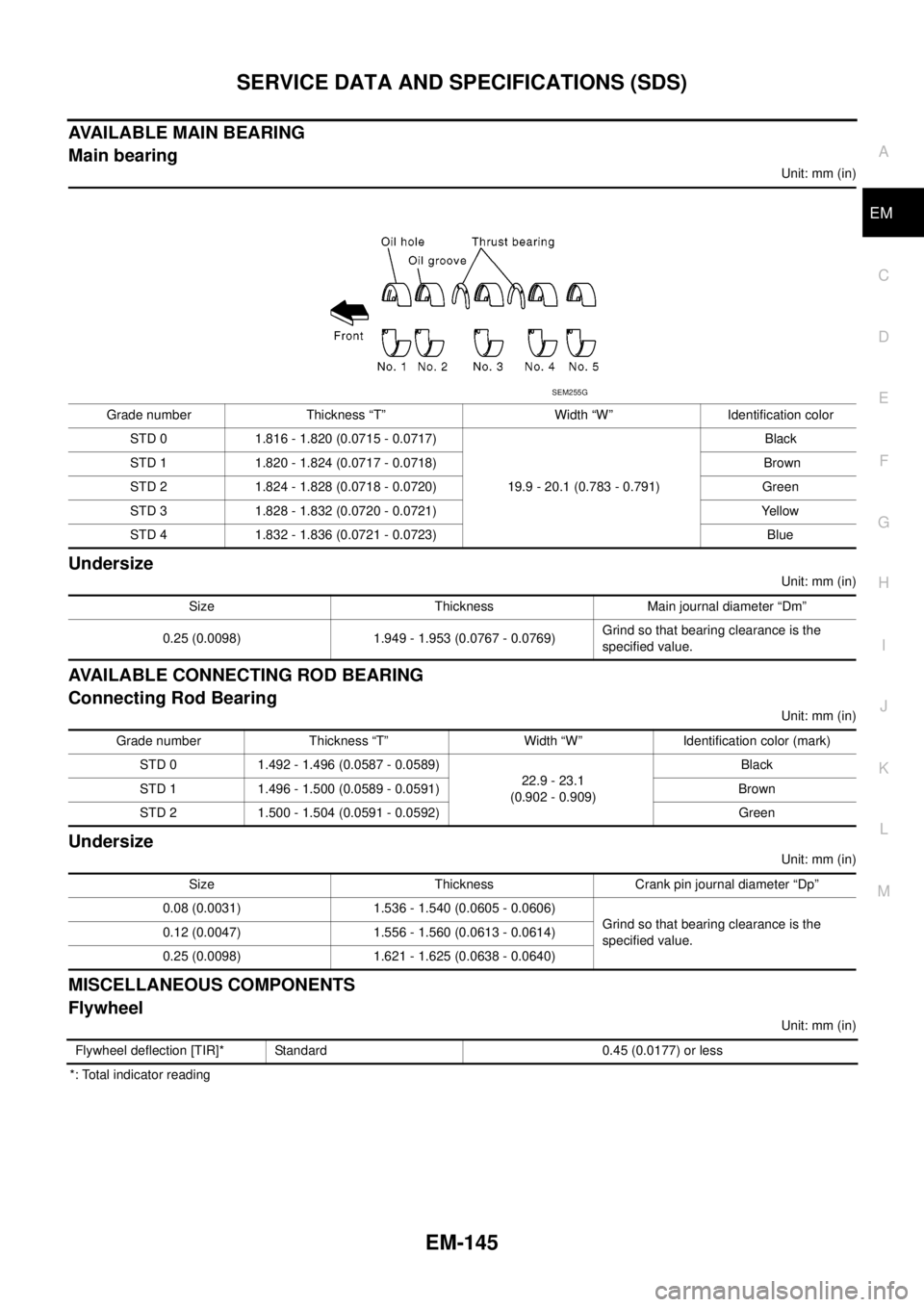

AVAILABLE MAIN BEARING

Main bearing

Unit: mm (in)

Undersize

Unit: mm (in)

AVAILABLE CONNECTING ROD BEARING

Connecting Rod Bearing

Unit: mm (in)

Undersize

Unit: mm (in)

MISCELLANEOUS COMPONENTS

Flywheel

Unit: mm (in)

*: Total indicator readingGrade number Thickness “T” Width “W” Identification color

STD 0 1.816 - 1.820 (0.0715 - 0.0717)

19.9 - 20.1 (0.783 - 0.791)Black

STD 1 1.820 - 1.824 (0.0717 - 0.0718) Brown

STD 2 1.824 - 1.828 (0.0718 - 0.0720) Green

STD 3 1.828 - 1.832 (0.0720 - 0.0721) Yellow

STD 4 1.832 - 1.836 (0.0721 - 0.0723) Blue

SEM255G

Size Thickness Main journal diameter “Dm”

0.25 (0.0098) 1.949 - 1.953 (0.0767 - 0.0769)Grind so that bearing clearance is the

specified value.

Grade number Thickness “T” Width “W” Identification color (mark)

STD 0 1.492 - 1.496 (0.0587 - 0.0589)

22.9 - 23.1

(0.902 - 0.909)Black

STD 1 1.496 - 1.500 (0.0589 - 0.0591) Brown

STD 2 1.500 - 1.504 (0.0591 - 0.0592) Green

Size Thickness Crank pin journal diameter “Dp”

0.08 (0.0031) 1.536 - 1.540 (0.0605 - 0.0606)

Grind so that bearing clearance is the

specified value. 0.12 (0.0047) 1.556 - 1.560 (0.0613 - 0.0614)

0.25 (0.0098) 1.621 - 1.625 (0.0638 - 0.0640)

Flywheel deflection [TIR]* Standard 0.45 (0.0177) or less

Page 1528 of 3171

EM-146

SERVICE DATA AND SPECIFICATIONS (SDS)

Bearing Clearance

Unit: mm (in)

Main bearing oil clearance Standard 0.047 - 0.077 (0.0019 - 0.0030)

Connecting rod bearing oil

clearanceStandard 0.039 - 0.070 (0.0015 - 0.0028)

Page 1533 of 3171

FAX-1

FRONT AXLE

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTIONFA X

A

B

FA X

FRONT AXLE

PRECAUTIONS .......................................................... 2

Precautions .............................................................. 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 3

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 4

NVH Troubleshooting Chart ..................................... 4

WHEEL HUB .............................................................. 5

On-Vehicle Inspection and Service .......................... 5

WHEEL BEARING INSPECTION ......................... 5

Removal and Installation .......................................... 5

REMOVAL ............................................................. 5

INSPECTION AFTER REMOVAL ......................... 6

INSTALLATION ..................................................... 6DRIVE SHAFT ............................................................. 7

Removal and Installation .......................................... 7

REMOVAL ............................................................. 7

INSPECTION AFTER REMOVAL ......................... 7

INSTALLATION ..................................................... 8

Disassembly and Assembly ...................................... 8

DISASSEMBLY ..................................................... 8

INSPECTION AFTER DISASSEMBLY .................. 9

ASSEMBLY ......................................................... 10

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 14

Wheel Bearing ........................................................ 14

Drive Shaft .............................................................. 14

Page 1535 of 3171

PREPARATION

FAX-3

C

E

F

G

H

I

J

K

L

MA

B

FA X

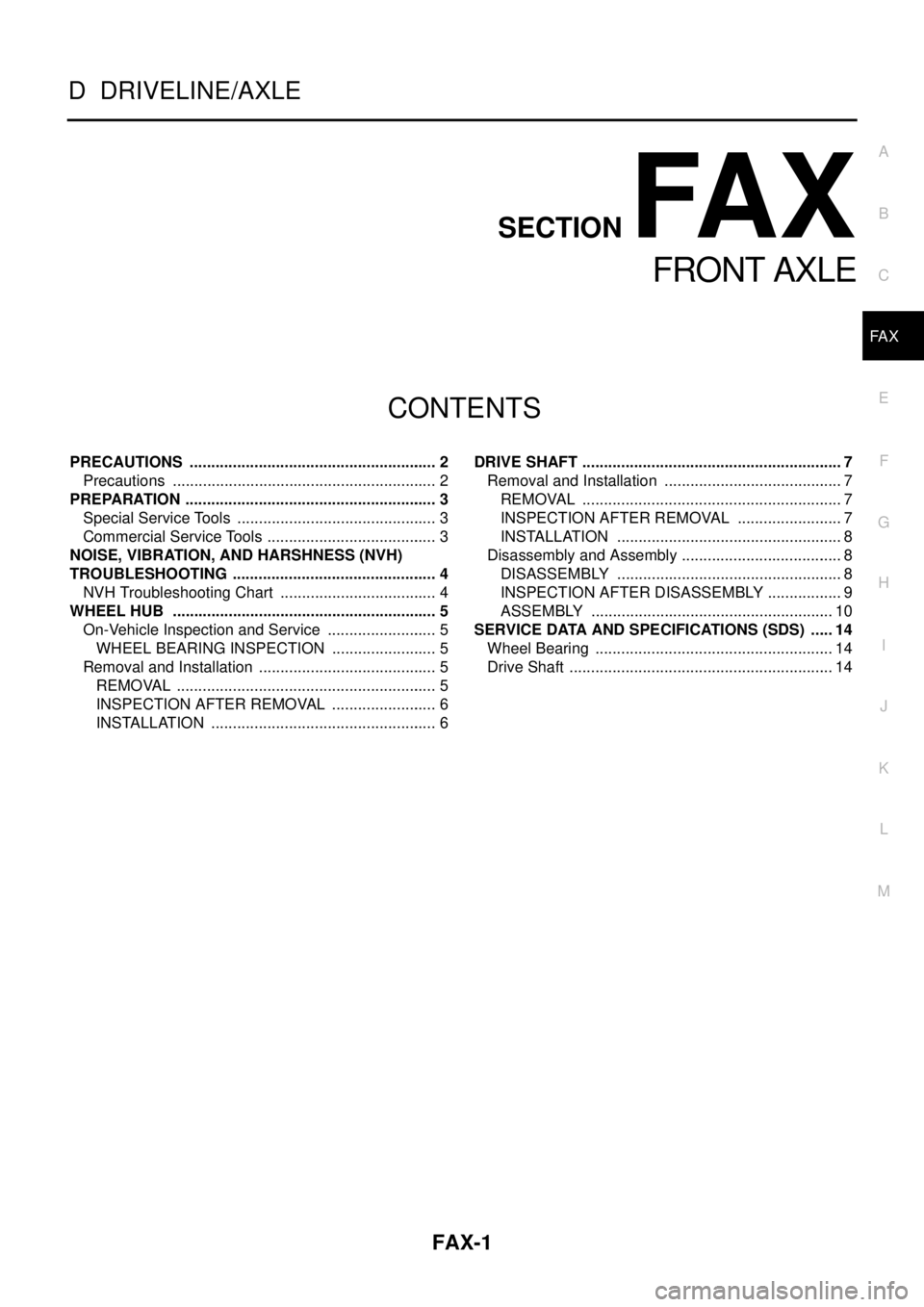

PREPARATIONPFP:00002

Special Service ToolsEDS003I4

Commercial Service ToolsEDS003I5

Tool number

Tool nameDescription

ST29020001

Gear arm pullerRemoving ball joint for steering knuckle

a: 34 mm (1.34 in)

b: 6.5 mm (0.256 in)

c: 61.5 mm (2.421 in)

KV38105500

ProtectorInstalling drive shaft

a: 40 mm (1.57 in) dia

KV40107300

BootbandcrimpingtoolInstalling boot bands

NT694

ZZA0835D

ZZA1229D

Tool nameDescription

PullerRemoving drive shaft

NT077

Page 1537 of 3171

WHEEL HUB

FAX-5

C

E

F

G

H

I

J

K

L

MA

B

FA X

WHEEL HUBPFP:43202

On-Vehicle Inspection and ServiceEDS003I7

Make sure the mounting conditions (looseness, backlash) of each component and component status (wear,

damage) are normal.

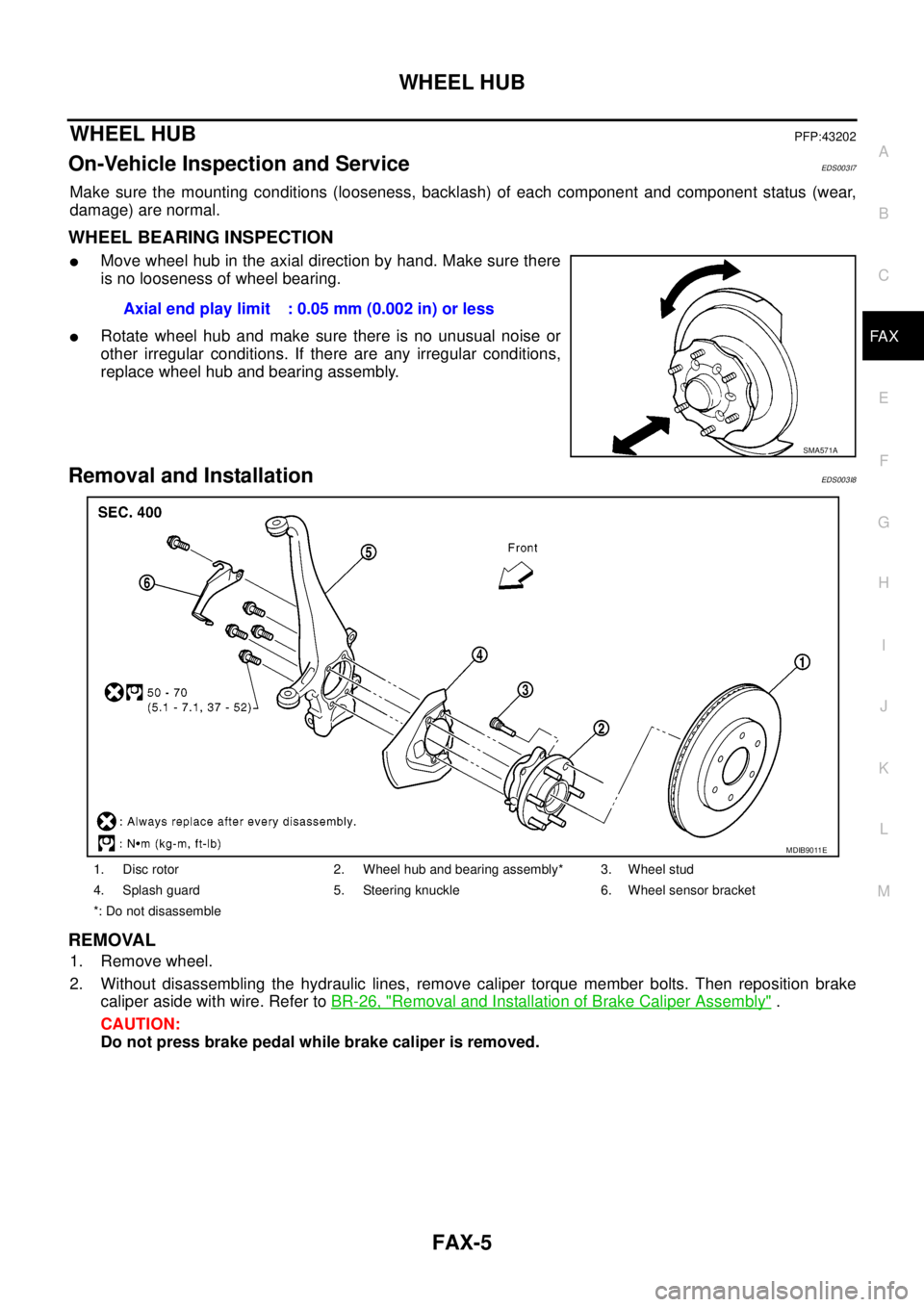

WHEEL BEARING INSPECTION

lMove wheel hub in the axial direction by hand. Make sure there

is no looseness of wheel bearing.

lRotate wheel hub and make sure there is no unusual noise or

other irregular conditions. If there are any irregular conditions,

replace wheel hub and bearing assembly.

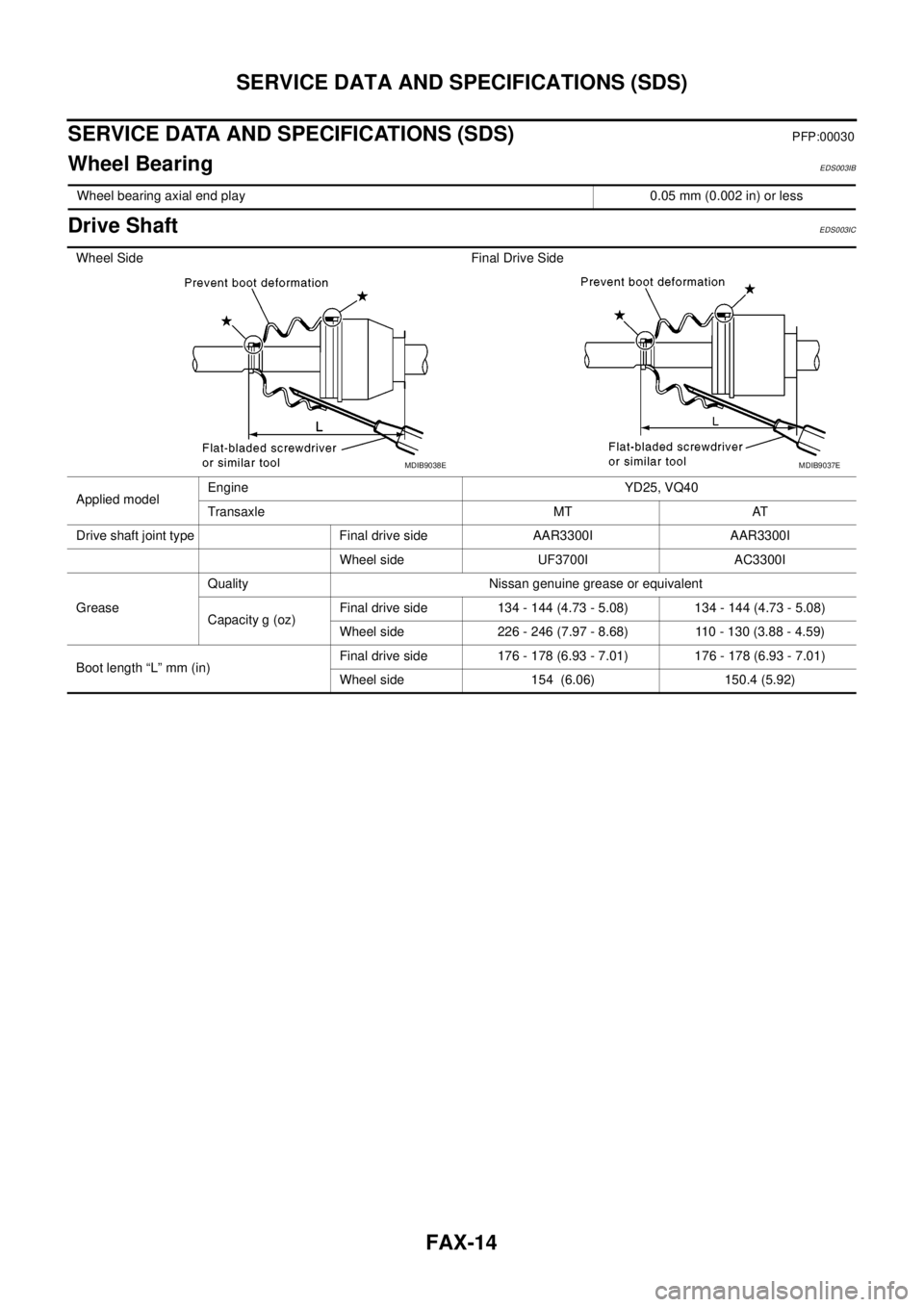

Removal and InstallationEDS003I8

REMOVAL

1. Remove wheel.

2. Without disassembling the hydraulic lines, remove caliper torque member bolts. Then reposition brake

caliper aside with wire. Refer toBR-26, "

Removal and Installation of Brake Caliper Assembly".

CAUTION:

Do not press brake pedal while brake caliper is removed.Axial end play limit : 0.05 mm (0.002 in) or less

SMA571A

1. Disc rotor 2. Wheel hub and bearing assembly* 3. Wheel stud

4. Splash guard 5. Steering knuckle 6. Wheel sensor bracket

*: Do not disassemble

MDIB9011E

Page 1546 of 3171

FAX-14

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

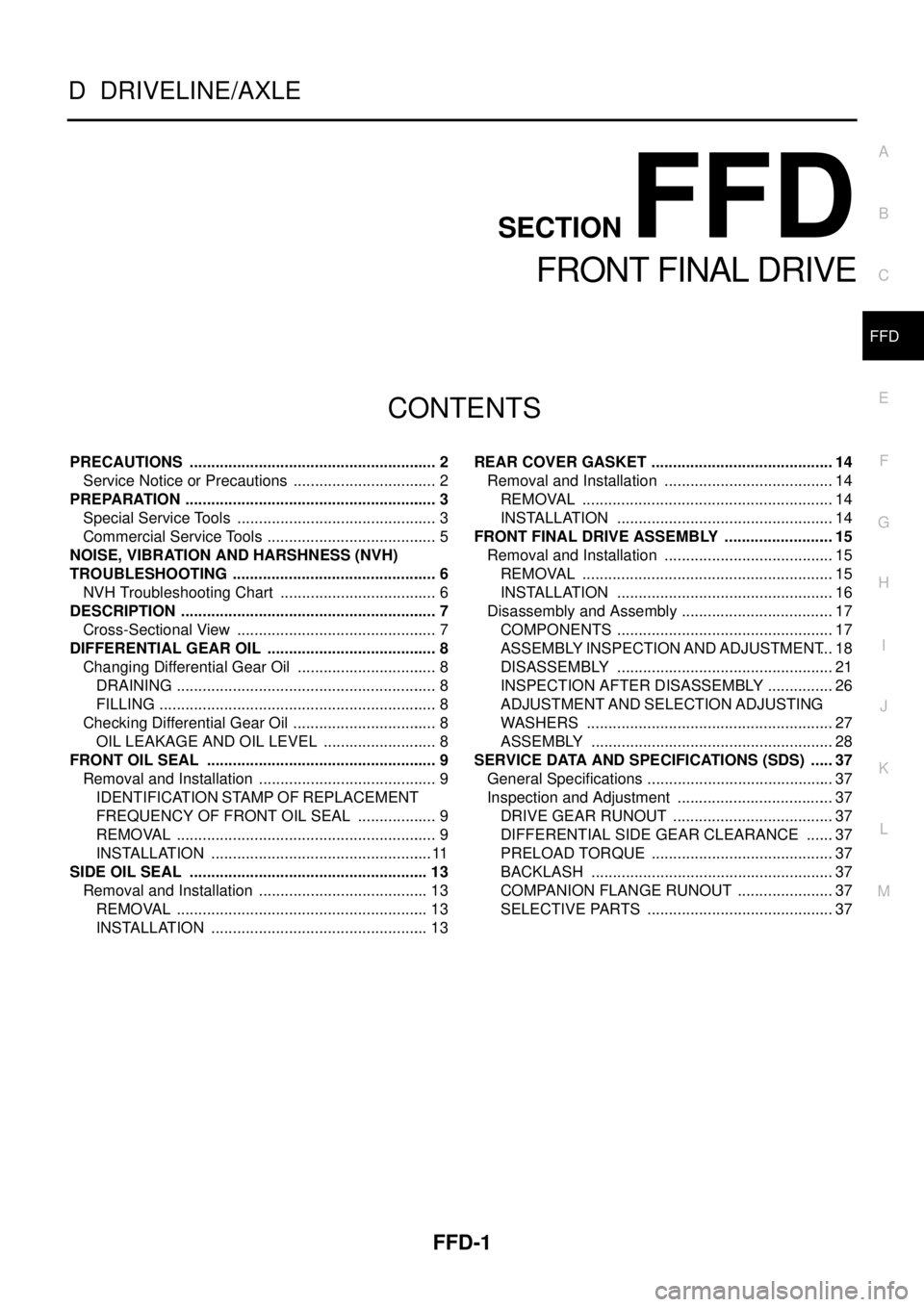

Wheel BearingEDS003IB

Drive ShaftEDS003IC

Wheel bearing axial end play 0.05 mm (0.002 in) or less

Wheel Side Final Drive Side

Applied modelEngine YD25, VQ40

Transaxle MT AT

Drive shaft joint type Final drive side AAR3300I AAR3300I

Wheel side UF3700I AC3300I

GreaseQuality Nissan genuine grease or equivalent

Capacity g (oz)Final drive side 134 - 144 (4.73 - 5.08) 134 - 144 (4.73 - 5.08)

Wheel side 226 - 246 (7.97 - 8.68) 110 - 130 (3.88 - 4.59)

Boot length “L” mm (in)Final drive side 176 - 178 (6.93 - 7.01) 176 - 178 (6.93 - 7.01)

Wheel side 154 (6.06) 150.4 (5.92)

MDIB9038EMDIB9037E

Page 1547 of 3171

FFD-1

FRONT FINAL DRIVE

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTIONFFD

A

B

FFD

FRONT FINAL DRIVE

PRECAUTIONS .......................................................... 2

Service Notice or Precautions .................................. 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 5

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 6

NVH Troubleshooting Chart ..................................... 6

DESCRIPTION ............................................................ 7

Cross-Sectional View ............................................... 7

DIFFERENTIAL GEAR OIL ........................................ 8

Changing Differential Gear Oil ................................. 8

DRAINING ............................................................. 8

FILLING ................................................................. 8

Checking Differential Gear Oil .................................. 8

OIL LEAKAGE AND OIL LEVEL ........................... 8

FRONT OIL SEAL ...................................................... 9

Removal and Installation .......................................... 9

IDENTIFICATION STAMP OF REPLACEMENT

FREQUENCY OF FRONT OIL SEAL ................... 9

REMOVAL ............................................................. 9

INSTALLATION .................................................... 11

SIDE OIL SEAL ........................................................ 13

Removal and Installation ........................................ 13

REMOVAL ........................................................... 13

INSTALLATION ................................................... 13REAR COVER GASKET ........................................... 14

Removal and Installation ........................................ 14

REMOVAL ........................................................... 14

INSTALLATION ................................................... 14

FRONT FINAL DRIVE ASSEMBLY .......................... 15

Removal and Installation ........................................ 15

REMOVAL ........................................................... 15

INSTALLATION ................................................... 16

Disassembly and Assembly .................................... 17

COMPONENTS ................................................... 17

ASSEMBLY INSPECTION AND ADJUSTMENT... 18

DISASSEMBLY ................................................... 21

INSPECTION AFTER DISASSEMBLY ................ 26

ADJUSTMENT AND SELECTION ADJUSTING

WASHERS .......................................................... 27

ASSEMBLY ......................................................... 28

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 37

General Specifications ............................................ 37

Inspection and Adjustment ..................................... 37

DRIVE GEAR RUNOUT ...................................... 37

DIFFERENTIAL SIDE GEAR CLEARANCE ....... 37

PRELOAD TORQUE ........................................... 37

BACKLASH ......................................................... 37

COMPANION FLANGE RUNOUT ....................... 37

SELECTIVE PARTS ............................................ 37

Page 1548 of 3171

FFD-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

ServiceNoticeorPrecautionsEDS0034W

lBefore starting diagnosis of the vehicle, understand the symptoms well. Perform correct and systematic

operations.

lCheck for the correct installation status prior to removal or disassembly. When matching marks are

required, be certain they do not interfere with the function of the parts they are applied to.

lOverhaul should be done in a clean work area, a dust proof area is recommended.

lBefore disassembly, completely remove sand and mud from the exterior of the unit, preventing them from

entering into the unit during disassembly or assembly.

lAlways use shop paper for cleaning the inside of components.

lAvoid using cotton gloves or a shop cloth to prevent the entering of lint.

lCheck appearance of the disassembled parts for damage, deformation, and unusual wear. Replace them

with new ones if necessary.

lGaskets, seals and O-rings should be replaced any time the unit is disassembled.

lClean and flush the parts sufficiently and blow them dry.

lBe careful not to damage sliding surfaces and mating surfaces.

lWhen applying sealant, remove the old sealant from the mating surface; then remove any moisture, oil,

and foreign materials from the application and mating surfaces.

lIn principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If a

tightening sequence is specified, observe it.

lDuring assembly, observe the specified tightening torque.

lAdd new differential gear oil, petroleum jelly, or multi-purpose grease, as specified.

Page 1549 of 3171

PREPARATION

FFD-3

C

E

F

G

H

I

J

K

L

MA

B

FFD

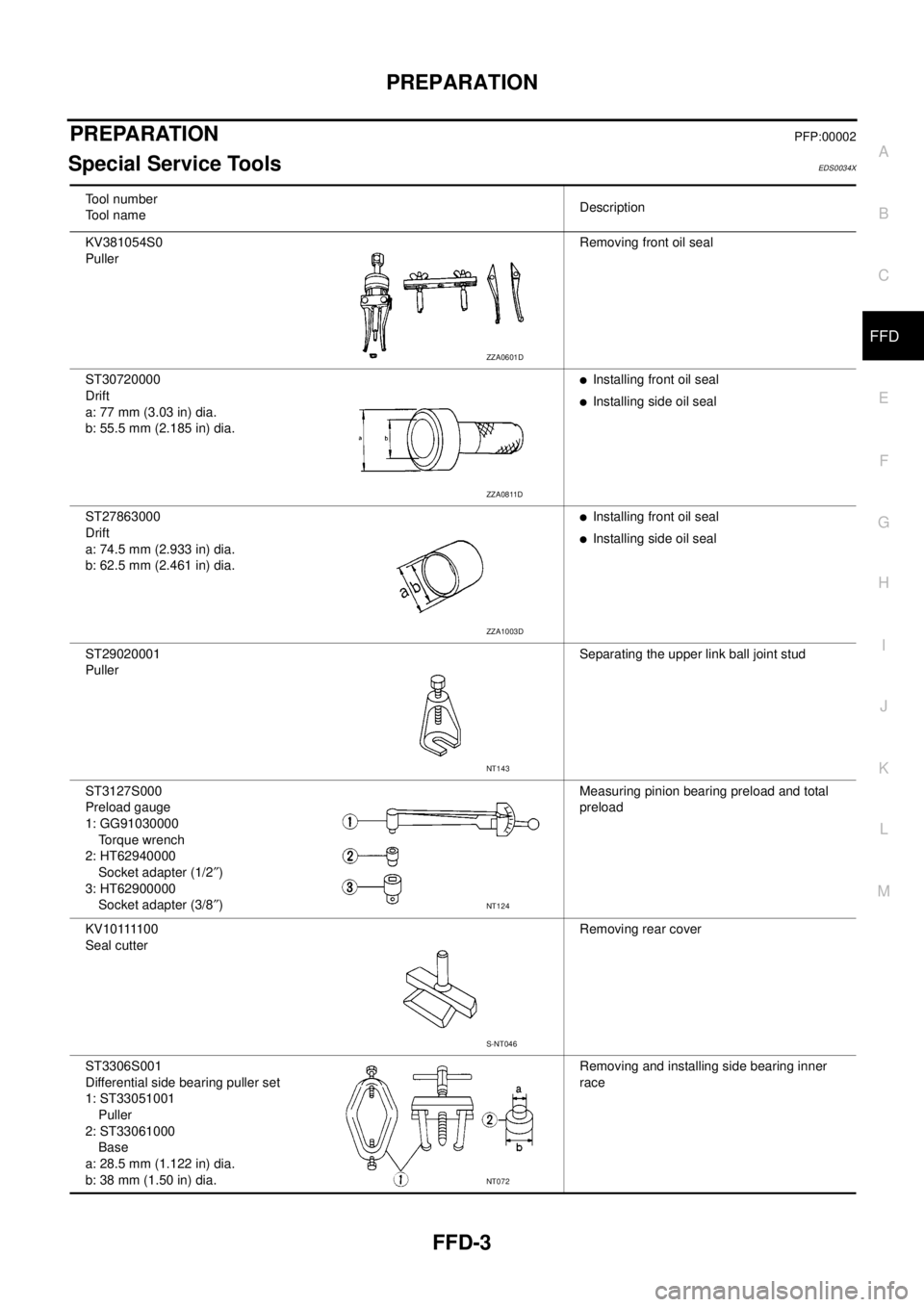

PREPARATIONPFP:00002

Special Service ToolsEDS0034X

Tool number

Tool nameDescription

KV381054S0

PullerRemoving front oil seal

ST30720000

Drift

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

lInstalling front oil seal

lInstalling side oil seal

ST27863000

Drift

a: 74.5 mm (2.933 in) dia.

b: 62.5 mm (2.461 in) dia.

lInstalling front oil seal

lInstalling side oil seal

ST29020001

PullerSeparating the upper link ball joint stud

ST3127S000

Preload gauge

1: GG91030000

Torque wrench

2: HT62940000

Socket adapter (1/2²)

3: HT62900000

Socket adapter (3/8²)Measuring pinion bearing preload and total

preload

K V 1 0 1111 0 0

Seal cutterRemoving rear cover

ST3306S001

Differential side bearing puller set

1: ST33051001

Puller

2: ST33061000

Base

a: 28.5 mm (1.122 in) dia.

b: 38 mm (1.50 in) dia.Removing and installing side bearing inner

race

ZZA0601D

ZZA0811D

ZZA1003D

NT143

NT124

S-NT046

NT072

Page 1551 of 3171

PREPARATION

FFD-5

C

E

F

G

H

I

J

K

L

MA

B

FFD

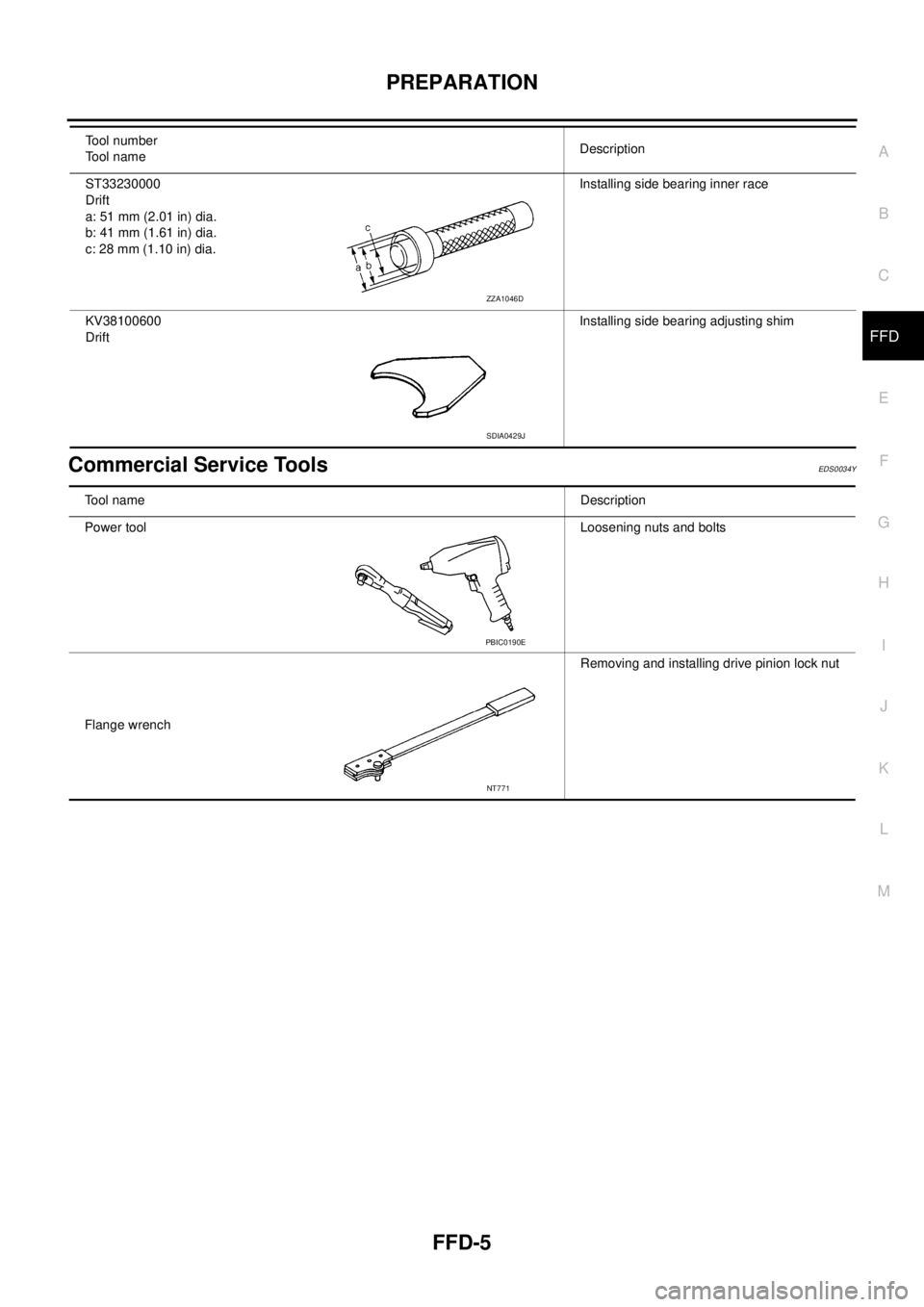

Commercial Service ToolsEDS0034Y

ST33230000

Drift

a: 51 mm (2.01 in) dia.

b: 41 mm (1.61 in) dia.

c: 28 mm (1.10 in) dia.Installing side bearing inner race

KV38100600

DriftInstalling side bearing adjusting shim Tool number

Tool nameDescription

ZZA1046D

SDIA0429J

Tool nameDescription

Power toolLoosening nuts and bolts

Flange wrenchRemoving and installing drive pinion lock nut

PBIC0190E

NT771