service NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1623 of 3171

GI-1

GENERAL INFORMATION

A GENERAL INFORMATION

CONTENTS

C

D

E

F

G

H

I

J

K

L

MB

GI

SECTIONGI

GENERAL INFORMATION

PRECAUTIONS .......................................................... 3

Description ............................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Precautions for NATS (NISSAN ANTI-THEFT SYS-

TEM) ........................................................................ 3

Precautions Necessary for Steering Wheel Rotation

After Battery Disconnect .......................................... 3

OPERATION PROCEDURE ................................. 4

General Precautions ................................................ 4

Precautions for Three Way Catalyst ......................... 5

Precautions for Fuel ................................................. 5

GASOLINE ENGINE ............................................. 5

DIESEL ENGINE ................................................... 6

Precautions for Multiport Fuel Injection System or

Engine Control System ............................................ 6

Precautions for Turbocharger (If Equipped) ............. 6

Precautions for Hoses .............................................. 6

HOSE REMOVAL AND INSTALLATION ............... 6

HOSE CLAMPING ................................................ 7

Precautions for Engine Oils ...................................... 7

HEALTH PROTECTION PRECAUTIONS ............. 7

ENVIRONMENTAL PROTECTION PRECAU-

TIONS ................................................................... 8

Precautions for Air Conditioning ............................... 8

HOW TO USE THIS MANUAL ................................... 9

Description ............................................................... 9

Terms ....................................................................... 9

Units ......................................................................... 9

Contents ................................................................... 9

Components ........................................................... 10

SYMBOLS ........................................................... 10

How to Follow Trouble Diagnoses ........................... 11

DESCRIPTION ..................................................... 11

HOW TO FOLLOW TEST GROUPS IN TROU-

BLE DIAGNOSES ................................................ 11

HARNESS WIRE COLOR AND CONNECTOR

NUMBER INDICATION ....................................... 12

KEY TO SYMBOLS SIGNIFYING MEASURE-MENTS OR PROCEDURES ............................... 13

How to Read Wiring Diagrams ............................... 15

CONNECTOR SYMBOLS ................................... 15

SAMPLE/WIRING DIAGRAM - EXAMPL - .......... 16

DESCRIPTION .................................................... 17

Abbreviations .......................................................... 23

SERVICE INFORMATION FOR ELECTRICAL INCI-

DENT ......................................................................... 24

How to Perform Efficient Diagnosis for an Electrical

Incident ................................................................... 24

WORK FLOW ...................................................... 24

INCIDENT SIMULATION TESTS ........................ 24

CIRCUIT INSPECTION ....................................... 27

Control Units and Electrical Parts ........................... 32

PRECAUTIONS .................................................. 32

CONTROL UNIT CONFIGURATION PROCEDURE... 34

Description .............................................................. 34

Part Replacement procedure Reference Table ...... 34

Work Procedure ...................................................... 36

Configuration (BCM) ............................................... 37

DESCRIPTION .................................................... 37

READ CONFIGURATION PROCEDURE ............ 37

WRITE CONFIGURATION PROCEDURE .......... 41

CONSULT-II CHECKING SYSTEM .......................... 47

Description .............................................................. 47

Function and System Application ........................... 47

Nickel Metal Hydride Battery Replacement ............ 48

Checking Equipment .............................................. 49

CONSULT-II Start Procedure .................................. 49

CONSULT-II Data Link Connector (DLC) Circuit .... 50

INSPECTION PROCEDURE .............................. 51

LIFTING POINT ......................................................... 52

Pantograph Jack, Garage Jack and Safety Stand... 52

2-Pole Lift ............................................................... 52

TOW TRUCK TOWING ............................................. 53

Tow Truck Towing ................................................... 53

4X2 MODEL ........................................................ 53

4X4 MODEL ........................................................ 54

TOWING POINT .................................................. 54

Vehicle Recovery (Freeing a Stuck Vehicle) ........... 54

Page 1625 of 3171

PRECAUTIONS

GI-3

C

D

E

F

G

H

I

J

K

L

MB

GI

PRECAUTIONSPFP:00001

DescriptionEAS001GG

Observe the following precautions to ensure safe and proper servicing. These precautions are not

described in each individual section.

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EAS001GH

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for NATS (NISSAN ANTI-THEFT SYSTEM)EAS001GI

NATS will immobilize the engine if someone tries to start it without the registered key of NATS.

Both of the originally supplied ignition key IDs have been NATS registered.

The security indicator is located on the instrument panel. The indicator blinks when the immobilizer system is

functioning.

Therefore, NATS warns outsiders that the vehicle is equipped with the anti-theft system.

lWhen NATS detects trouble, the security indicator lamp lights up while ignition switch is in "ON" position.

This lighting up indicates that the anti-theft is not functioning, so prompt service is required.

lWhen servicing NATS (trouble diagnoses, system initialization and additional registration of other NATS

ignition key IDs), CONSULT-II hardware and CONSULT-II NATS software is necessary.

Regarding the procedures of NATS initialization and NATS ignition key ID registration, refer to CONSULT-

II operation manual, NATS.

Therefore, CONSULT-II NATS software (program card and operation manual) must be kept strictly con-

fidential to maintain the integrity of the anti-theft function.

lWhen servicing NATS (trouble diagnoses, system initialization and additional registration of other NATS

ignition key IDs), it may be necessary to re-register original key identification. Therefore, be sure to

receive all keys from vehicle owner. A maximum of four or five key IDs can be registered into NATS.

lWhen failing to start the engine first time using the key of NATS, start as follows.

1. Leave the ignition key in "ON" position for approximately 5 seconds.

2. Turn ignition key to "OFF" or "LOCK" position and wait approximately 5 seconds.

3. Repeat step 1 and 2 again.

4. Restart the engine while keeping the key separate from any others on key-chain.

Precautions Necessary for Steering Wheel Rotation After Battery DisconnectEAS001HY

NOTE:

lThis Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT

SYSTEM).

lRemove and install all control units after disconnecting both battery cables with the ignition knob in the

²LOCK²position.

lAlways use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing

work. If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

Page 1627 of 3171

PRECAUTIONS

GI-5

C

D

E

F

G

H

I

J

K

L

MB

GI

lTo prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

lDispose of drained oil or the solvent used for cleaning parts in

an appropriate manner.

lDo not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel

spray and possibly a fire.

lClean all disassembled parts in the designated liquid or solvent

prior to inspection or assembly.

lReplace oil seals, gaskets, packings, O-rings, locking washers, cotter pins, self-locking nuts, etc. with new

ones.

lReplace inner and outer races of tapered roller bearings and needle bearings as a set.

lArrange the disassembled parts in accordance with their assembled locations and sequence.

lDo not touch the terminals of electrical components which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

lAfter disconnecting vacuum or air hoses, attach a tag to indicate the proper connection.

lUse only the fluids and lubricants specified in this manual.

lUse approved bonding agent, sealants or their equivalents when required.

lUse tools and recommended special tools where specified for safe and efficient service repairs.

lWhen repairing the fuel, oil, water, vacuum or exhaust systems, check all affected lines for leaks.

lBefore servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate cov-

ers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do not carelessly disconnect the harness

connectors which are related to the engine control system and TCM (transmission control module)

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

Precautions for Three Way CatalystEAS001GL

If a large amount of unburned fuel flows into the catalyst, the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

lUse unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

lWhen checking for ignition spark or measuring engine compression, make tests quickly and only when

necessary.

lDo not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to

the catalyst.

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

Precautions for FuelEAS001GM

GASOLINE ENGINE

Use unleaded gasoline with an octane rating of at least 95 (RON).

SGI233

SGI234

Page 1630 of 3171

GI-8

PRECAUTIONS

lWhere there is a risk of eye contact, eye protection should be worn, for example, chemical goggles or face

shields; in addition an eye wash facility should be provided.

ENVIRONMENTAL PROTECTION PRECAUTIONS

Dispose of used oil and used oil filters through authorized waste disposal contractors to licensed waste dis-

posal sites, or to the waste oil reclamation trade. If in doubt, contact the local authority for advice on disposal

facilities.

It is illegal to pour used oil on to the ground, down sewers or drains, or into water sources.

The regulations concerning pollution vary between regions.

Precautions for Air ConditioningEAS001GR

Use an approved refrigerant recovery unit any time the air conditioning system must be discharged. Refer to

ATC/MTC section “HFC-134a (R-134a) Service Procedure”, “REFRIGERANT LINES” for specific instructions.

Page 1632 of 3171

GI-10

HOW TO USE THIS MANUAL

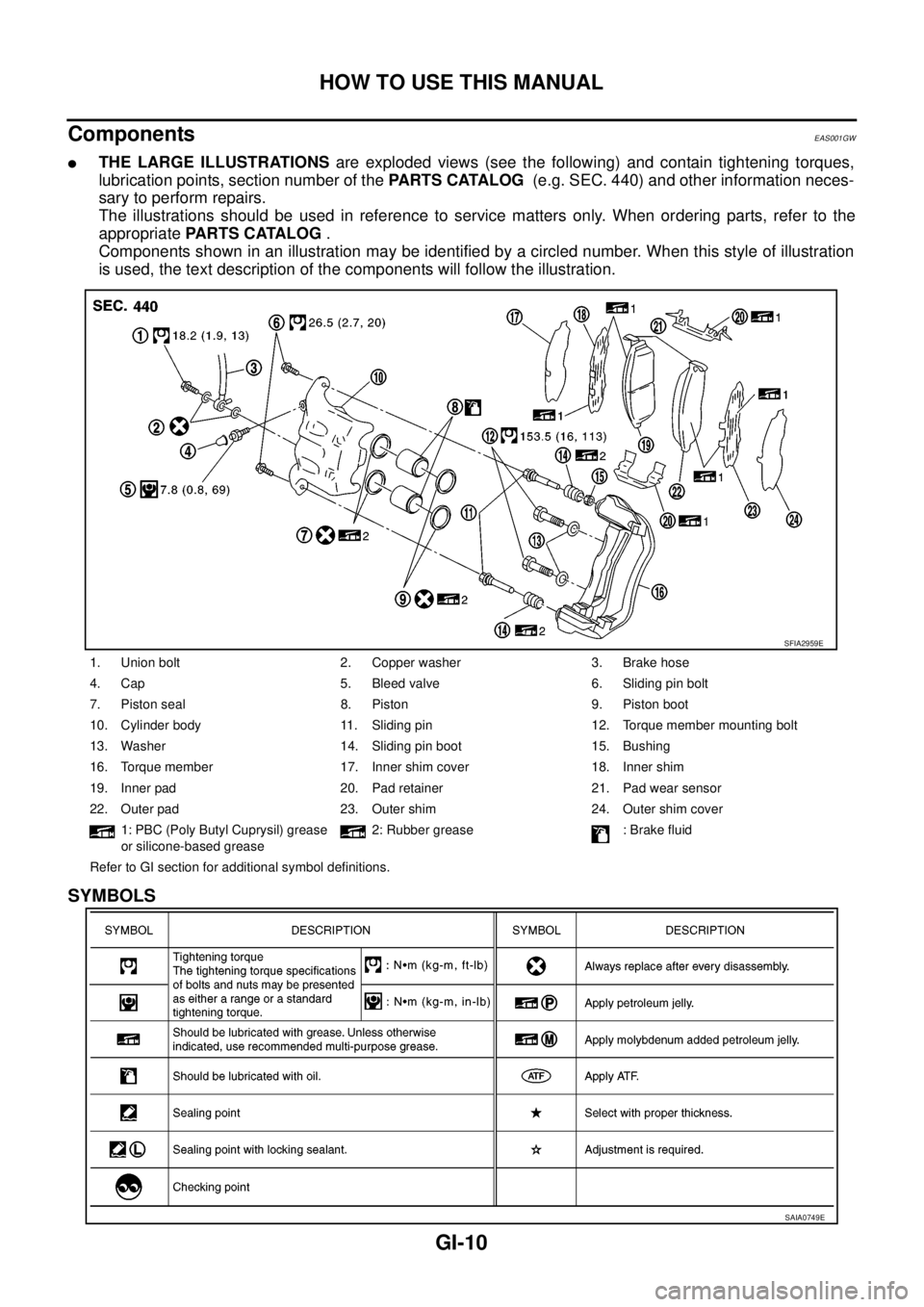

Components

EAS001GW

lTHE LARGE ILLUSTRATIONSare exploded views (see the following) and contain tightening torques,

lubrication points, section number of thePARTS CATALOG(e.g. SEC. 440) and other information neces-

sary to perform repairs.

The illustrations should be used in reference to service matters only. When ordering parts, refer to the

appropriatePARTS CATALOG.

Components shown in an illustration may be identified by a circled number. When this style of illustration

is used, the text description of the components will follow the illustration.

SYMBOLS

1. Union bolt 2. Copper washer 3. Brake hose

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Piston seal 8. Piston 9. Piston boot

10. Cylinder body 11. Sliding pin 12. Torque member mounting bolt

13. Washer 14. Sliding pin boot 15. Bushing

16. Torque member 17. Inner shim cover 18. Inner shim

19. Inner pad 20. Pad retainer 21. Pad wear sensor

22. Outer pad 23. Outer shim 24. Outer shim cover

1: PBC (Poly Butyl Cuprysil) grease

or silicone-based grease2: Rubber grease : Brake fluid

Refer to GI section for additional symbol definitions.

SFIA2959E

SAIA0749E

Page 1645 of 3171

HOW TO USE THIS MANUAL

GI-23

C

D

E

F

G

H

I

J

K

L

MB

GI

AbbreviationsEAS001GZ

The followingABBREVIATIONSare used:

ABBREVIATION DESCRIPTION

A/C Air Conditioner

A/T Automatic Transaxle/Transmission

ATF Automatic Transmission Fluid

D

1Drive range 1st gear

D

2Drive range 2nd gear

D

3Drive range 3rd gear

D

4Drive range 4th gear

FR, RR Front, Rear

LH, RH Left-Hand, Right-Hand

M/T Manual Transaxle/Transmission

OD Overdrive

P/S Power Steering

SAE Society of Automotive Engineers, Inc.

SDS Service Data and Specifications

SST Special Service Tools

2WD 2-Wheel Drive

2

22nd range 2nd gear

2

12nd range 1st gear

1

21st range 2nd gear

1

11st range 1st gear

Page 1646 of 3171

GI-24

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

PFP:00000

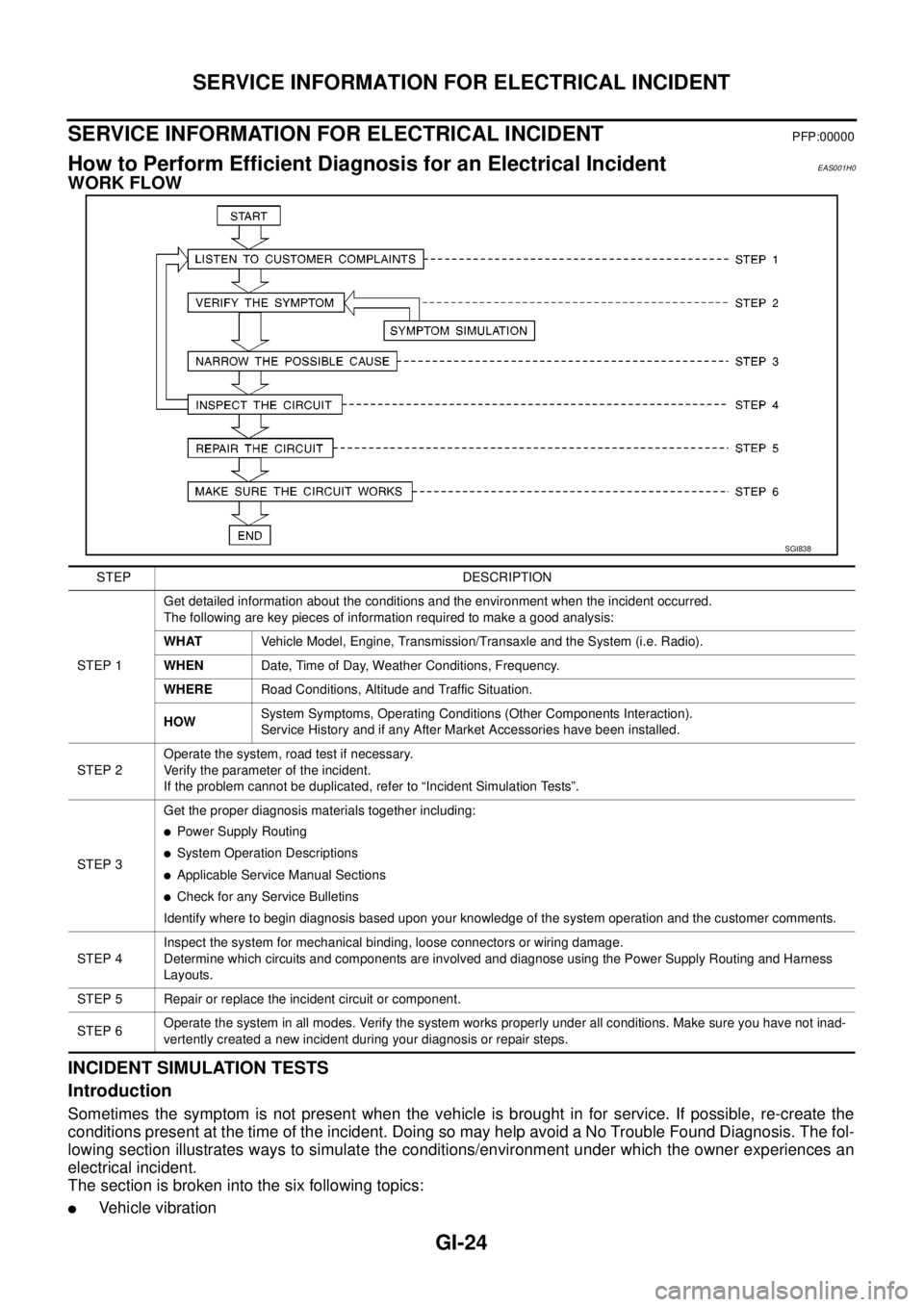

How to Perform Efficient Diagnosis for an Electrical IncidentEAS001H0

WORK FLOW

INCIDENT SIMULATION TESTS

Introduction

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No Trouble Found Diagnosis. The fol-

lowing section illustrates ways to simulate the conditions/environment under which the owner experiences an

electrical incident.

The section is broken into the six following topics:

lVehicle vibration

SGI838

STEP DESCRIPTION

STEP 1Get detailed information about the conditions and the environment when the incident occurred.

The following are key pieces of information required to make a good analysis:

WHATVehicle Model, Engine, Transmission/Transaxle and the System (i.e. Radio).

WHENDate, Time of Day, Weather Conditions, Frequency.

WHERERoad Conditions, Altitude and Traffic Situation.

HOWSystem Symptoms, Operating Conditions (Other Components Interaction).

Service History and if any After Market Accessories have been installed.

STEP 2Operate the system, road test if necessary.

Verify the parameter of the incident.

If the problem cannot be duplicated, refer to “Incident Simulation Tests”.

STEP 3Get the proper diagnosis materials together including:

lPower Supply Routing

lSystem Operation Descriptions

lApplicable Service Manual Sections

lCheck for any Service Bulletins

Identify where to begin diagnosis based upon your knowledge of the system operation and the customer comments.

STEP 4Inspect the system for mechanical binding, loose connectors or wiring damage.

Determine which circuits and components are involved and diagnose using the Power Supply Routing and Harness

Layouts.

STEP 5 Repair or replace the incident circuit or component.

STEP 6Operate the system in all modes. Verify the system works properly under all conditions. Make sure you have not inad-

vertently created a new incident during your diagnosis or repair steps.

Page 1647 of 3171

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

GI-25

C

D

E

F

G

H

I

J

K

L

MB

GI

lHeat sensitive

lFreezing

lWater intrusion

lElectrical load

lCold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of the

problem.

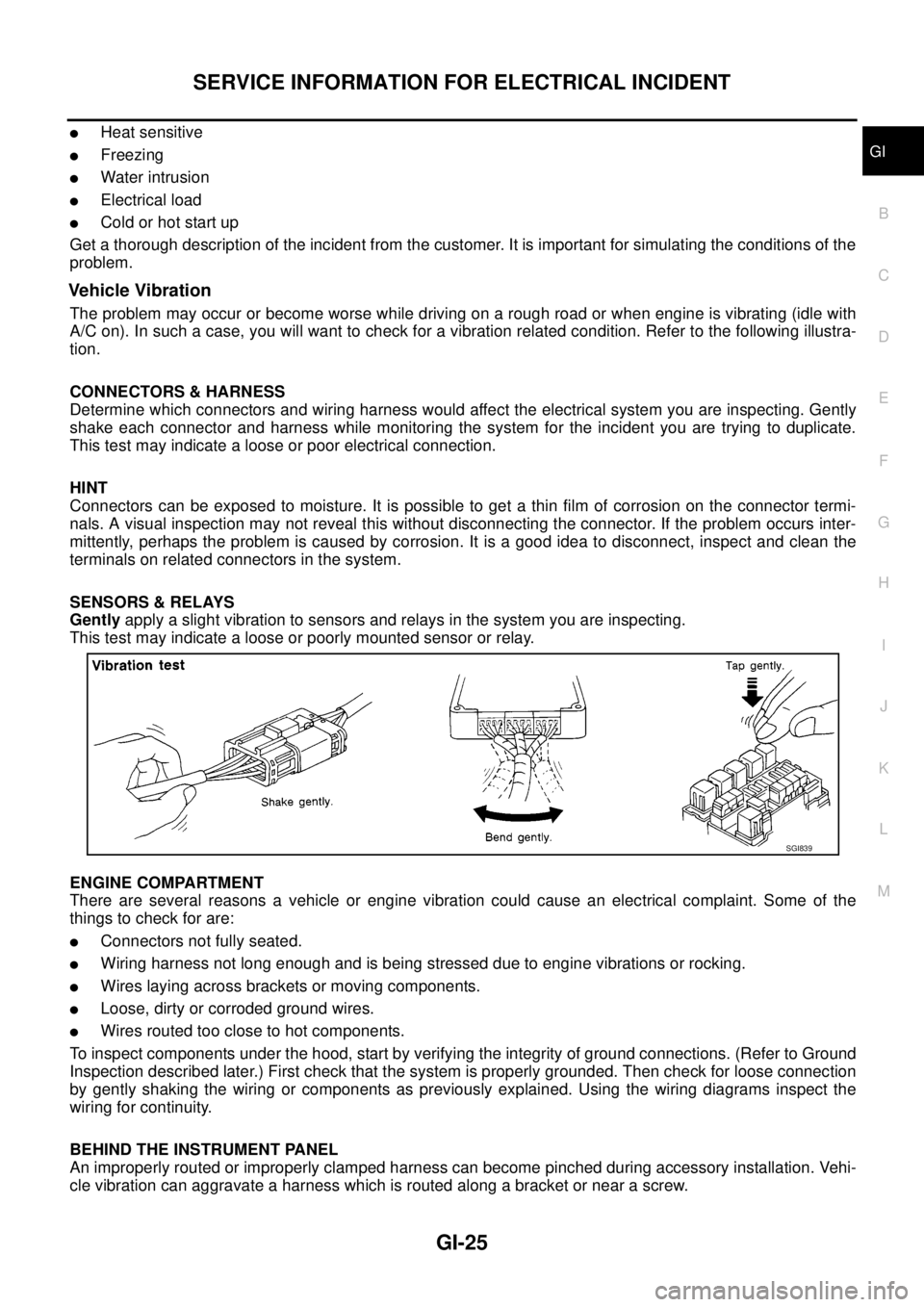

Vehicle Vibration

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vibration related condition. Refer to the following illustra-

tion.

CONNECTORS & HARNESS

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gently

shake each connector and harness while monitoring the system for the incident you are trying to duplicate.

This test may indicate a loose or poor electrical connection.

HINT

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs inter-

mittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean the

terminals on related connectors in the system.

SENSORS & RELAYS

Gentlyapply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

ENGINE COMPARTMENT

There are several reasons a vehicle or engine vibration could cause an electrical complaint. Some of the

things to check for are:

lConnectors not fully seated.

lWiring harness not long enough and is being stressed due to engine vibrations or rocking.

lWires laying across brackets or moving components.

lLoose, dirty or corroded ground wires.

lWires routed too close to hot components.

To inspect components under the hood, start by verifying the integrity of ground connections. (Refer to Ground

Inspection described later.) First check that the system is properly grounded. Then check for loose connection

by gently shaking the wiring or components as previously explained. Using the wiring diagrams inspect the

wiring for continuity.

BEHIND THE INSTRUMENT PANEL

An improperly routed or improperly clamped harness can become pinched during accessory installation. Vehi-

cle vibration can aggravate a harness which is routed along a bracket or near a screw.

SGI839

Page 1648 of 3171

GI-26

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

UNDER SEATING AREAS

An unclamped or loose harness can cause wiring to be pinched by seat components (such as slide guides)

during vehicle vibration. If the wiring runs under seating areas, inspect wire routing for possible damage or

pinching.

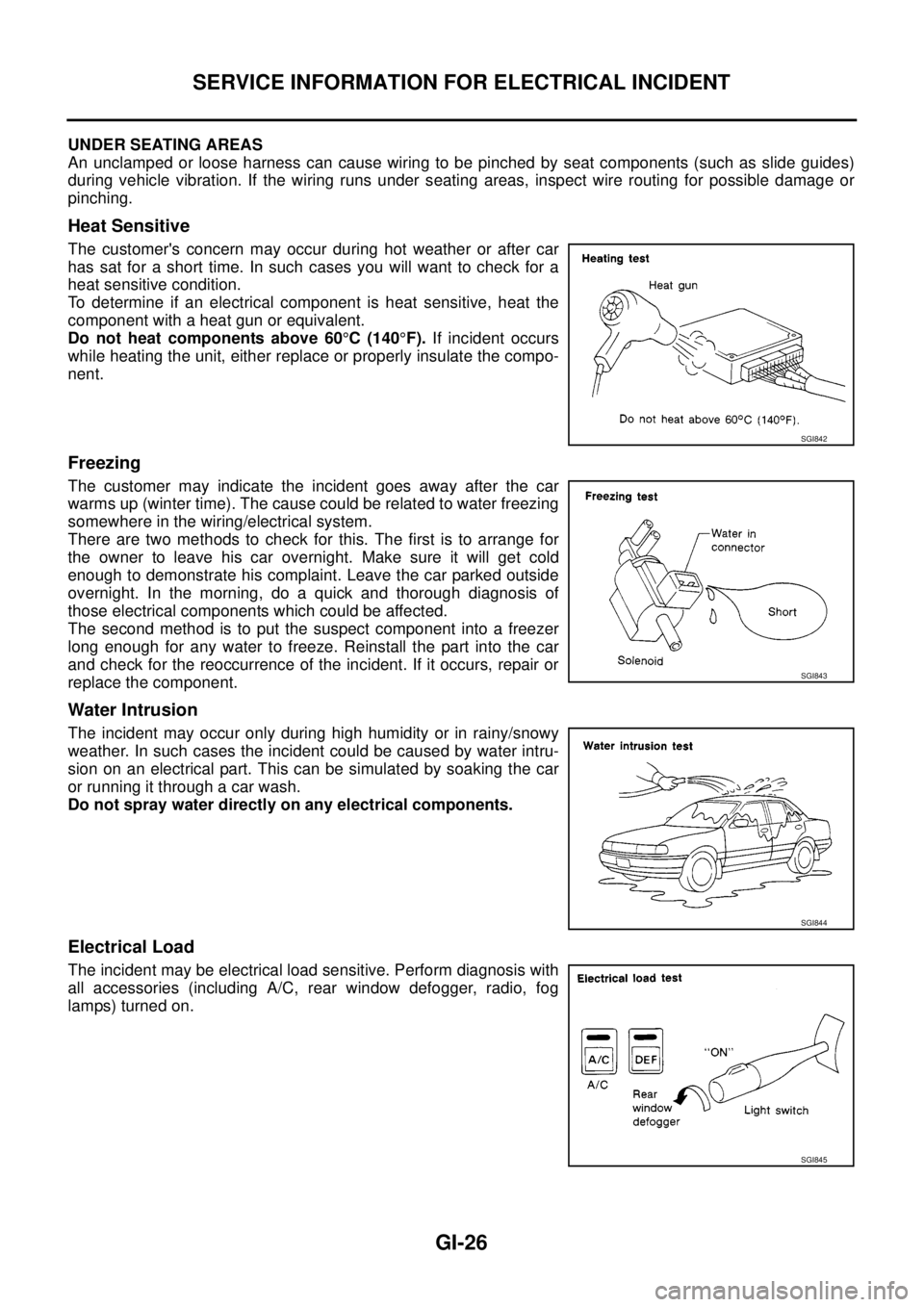

Heat Sensitive

The customer's concern may occur during hot weather or after car

has sat for a short time. In such cases you will want to check for a

heat sensitive condition.

To determine if an electrical component is heat sensitive, heat the

component with a heat gun or equivalent.

Do not heat components above 60°C(140°F).If incident occurs

while heating the unit, either replace or properly insulate the compo-

nent.

Freezing

The customer may indicate the incident goes away after the car

warms up (winter time). The cause could be related to water freezing

somewhere in the wiring/electrical system.

There are two methods to check for this. The first is to arrange for

the owner to leave his car overnight. Make sure it will get cold

enough to demonstrate his complaint. Leave the car parked outside

overnight. In the morning, do a quick and thorough diagnosis of

those electrical components which could be affected.

The second method is to put the suspect component into a freezer

long enough for any water to freeze. Reinstall the part into the car

and check for the reoccurrence of the incident. If it occurs, repair or

replace the component.

Water Intrusion

The incident may occur only during high humidity or in rainy/snowy

weather. In such cases the incident could be caused by water intru-

sion on an electrical part. This can be simulated by soaking the car

or running it through a car wash.

Do not spray water directly on any electrical components.

Electrical Load

The incident may be electrical load sensitive. Perform diagnosis with

all accessories (including A/C, rear window defogger, radio, fog

lamps) turned on.

SGI842

SGI843

SGI844

SGI845

Page 1649 of 3171

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

GI-27

C

D

E

F

G

H

I

J

K

L

MB

GI

Cold or Hot Start Up

On some occasions an electrical incident may occur only when the car is started cold, or it may occur when

the car is restarted hot shortly after being turned off. In these cases you may have to keep the car overnight to

make a proper diagnosis.

CIRCUIT INSPECTION

Introduction

In general, testing electrical circuits is an easy task if it is approached in a logical and organized method.

Before beginning it is important to have all available information on the system to be tested. Also, get a thor-

ough understanding of system operation. Then you will be able to use the appropriate equipment and follow

the correct test procedure.

You may have to simulate vehicle vibrations while testing electrical components. Gently shake the wiring har-

ness or electrical component to do this.

NOTE:

Refer to “How to Check Terminal” to probe or check terminal.

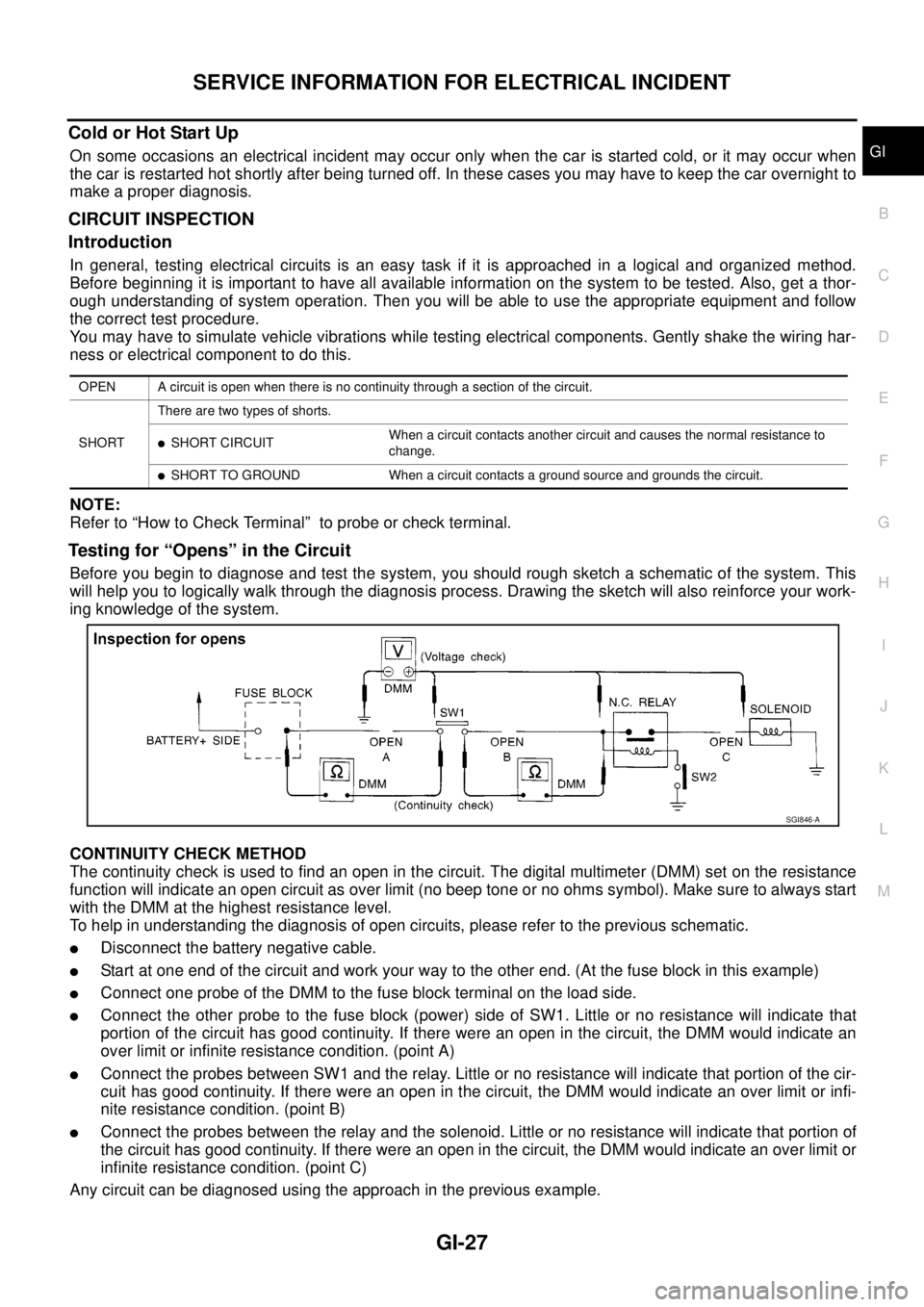

Testing for “Opens” in the Circuit

Before you begin to diagnose and test the system, you should rough sketch a schematic of the system. This

will help you to logically walk through the diagnosis process. Drawing the sketch will also reinforce your work-

ing knowledge of the system.

CONTINUITY CHECK METHOD

The continuity check is used to find an open in the circuit. The digital multimeter (DMM) set on the resistance

function will indicate an open circuit as over limit (no beep tone or no ohms symbol). Make sure to always start

with the DMM at the highest resistance level.

To help in understanding the diagnosis of open circuits, please refer to the previous schematic.

lDisconnect the battery negative cable.

lStart at one end of the circuit and work your way to the other end. (At the fuse block in this example)

lConnect one probe of the DMM to the fuse block terminal on the load side.

lConnect the other probe to the fuse block (power) side of SW1. Little or no resistance will indicate that

portion of the circuit has good continuity. If there were an open in the circuit, the DMM would indicate an

over limit or infinite resistance condition. (point A)

lConnect the probes between SW1 and the relay. Little or no resistance will indicate that portion of the cir-

cuit has good continuity. If there were an open in the circuit, the DMM would indicate an over limit or infi-

nite resistance condition. (point B)

lConnect the probes between the relay and the solenoid. Little or no resistance will indicate that portion of

the circuit has good continuity. If there were an open in the circuit, the DMM would indicate an over limit or

infinite resistance condition. (point C)

Any circuit can be diagnosed using the approach in the previous example.

OPEN A circuit is open when there is no continuity through a section of the circuit.

SHORTThere are two types of shorts.

lSHORT CIRCUITWhen a circuit contacts another circuit and causes the normal resistance to

change.

lSHORT TO GROUND When a circuit contacts a ground source and grounds the circuit.

SGI846-A