FL- NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1587 of 3171

FUEL SYSTEM

FL-3

C

D

E

F

G

H

I

J

K

L

MA

FL

FUEL SYSTEMPFP:17503

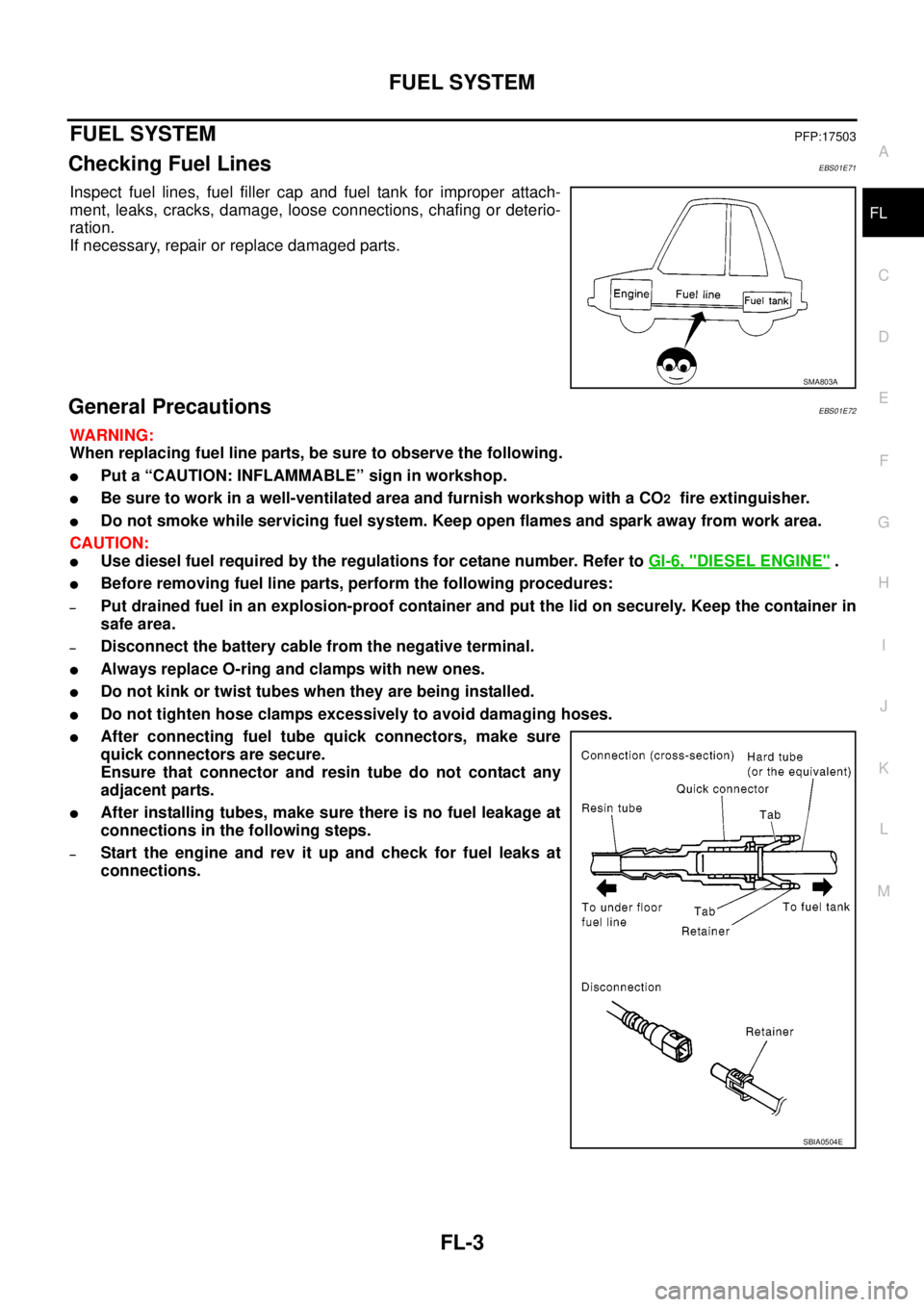

Checking Fuel LinesEBS01E71

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loose connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

General PrecautionsEBS01E72

WARNING:

When replacing fuel line parts, be sure to observe the following.

lPut a “CAUTION: INFLAMMABLE” sign in workshop.

lBe sure to work in a well-ventilated area and furnish workshop with a CO2fire extinguisher.

lDo not smoke while servicing fuel system. Keep open flames and spark away from work area.

CAUTION:

lUse diesel fuel required by the regulations for cetane number. Refer toGI-6, "DIESEL ENGINE".

lBefore removing fuel line parts, perform the following procedures:

–Put drained fuel in an explosion-proof container and put the lid on securely. Keep the container in

safe area.

–Disconnect the battery cable from the negative terminal.

lAlways replace O-ring and clamps with new ones.

lDo not kink or twist tubes when they are being installed.

lDo not tighten hose clamps excessively to avoid damaging hoses.

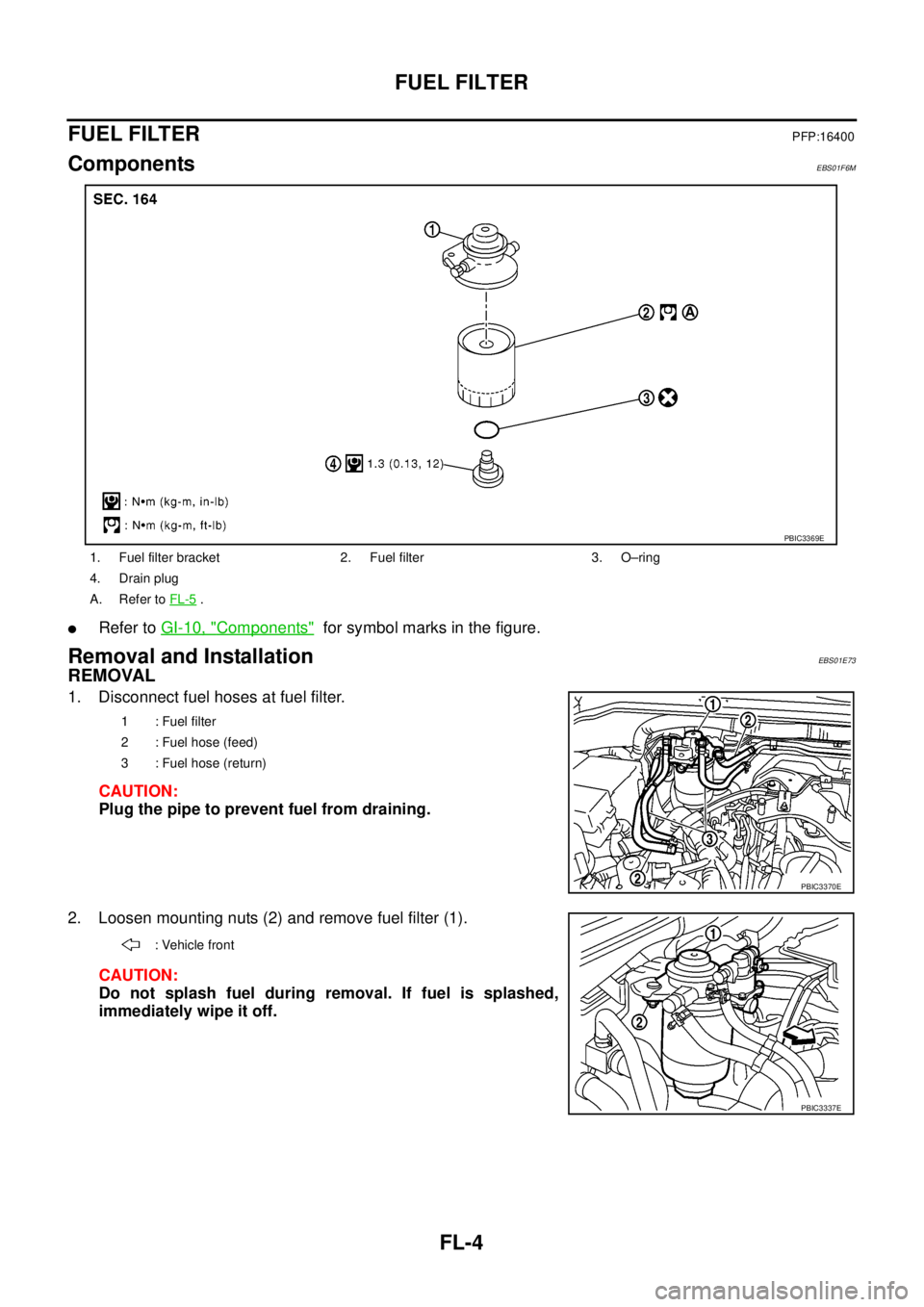

lAfter connecting fuel tube quick connectors, make sure

quick connectors are secure.

Ensure that connector and resin tube do not contact any

adjacent parts.

lAfter installing tubes, make sure there is no fuel leakage at

connections in the following steps.

–Start the engine and rev it up and check for fuel leaks at

connections.

SMA803A

SBIA0504E

Page 1588 of 3171

FL-4

FUEL FILTER

FUEL FILTER

PFP:16400

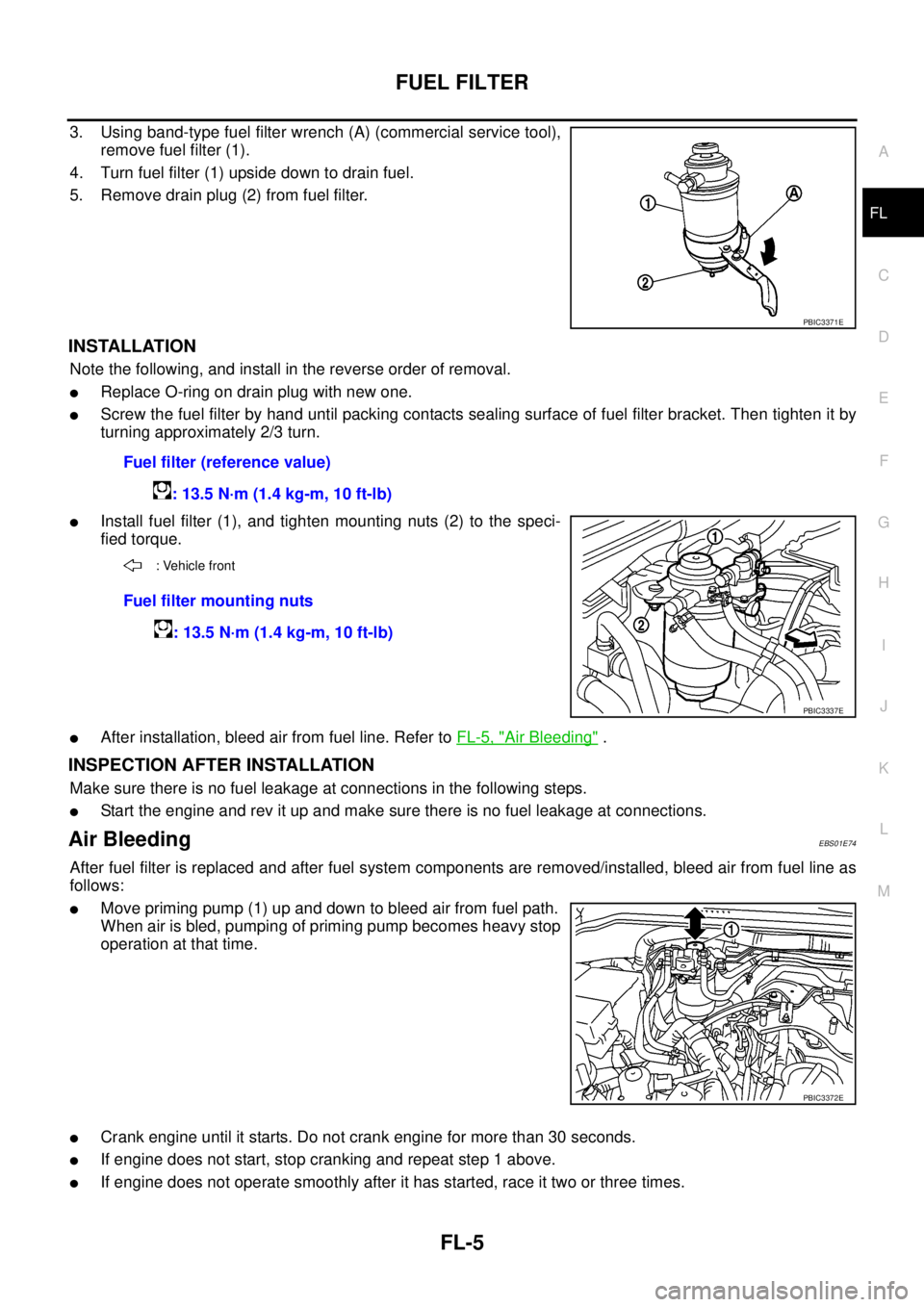

ComponentsEBS01F6M

lRefer toGI-10, "Components"for symbol marks in the figure.

Removal and InstallationEBS01E73

REMOVAL

1. Disconnect fuel hoses at fuel filter.

CAUTION:

Plug the pipe to prevent fuel from draining.

2. Loosen mounting nuts (2) and remove fuel filter (1).

CAUTION:

Do not splash fuel during removal. If fuel is splashed,

immediately wipe it off.

1. Fuel filter bracket 2. Fuel filter 3. O–ring

4. Drain plug

A. Refer toFL-5

.

PBIC3369E

1 : Fuel filter

2 : Fuel hose (feed)

3 : Fuel hose (return)

PBIC3370E

: Vehicle front

PBIC3337E

Page 1589 of 3171

FUEL FILTER

FL-5

C

D

E

F

G

H

I

J

K

L

MA

FL

3. Using band-type fuel filter wrench (A) (commercial service tool),

remove fuel filter (1).

4. Turn fuel filter (1) upside down to drain fuel.

5. Remove drain plug (2) from fuel filter.

INSTALLATION

Note the following, and install in the reverse order of removal.

lReplace O-ring on drain plug with new one.

lScrew the fuel filter by hand until packing contacts sealing surface of fuel filter bracket. Then tighten it by

turning approximately 2/3 turn.

lInstall fuel filter (1), and tighten mounting nuts (2) to the speci-

fied torque.

lAfter installation, bleed air from fuel line. Refer toFL-5, "Air Bleeding".

INSPECTION AFTER INSTALLATION

Make sure there is no fuel leakage at connections in the following steps.

lStart the engine and rev it up and make sure there is no fuel leakage at connections.

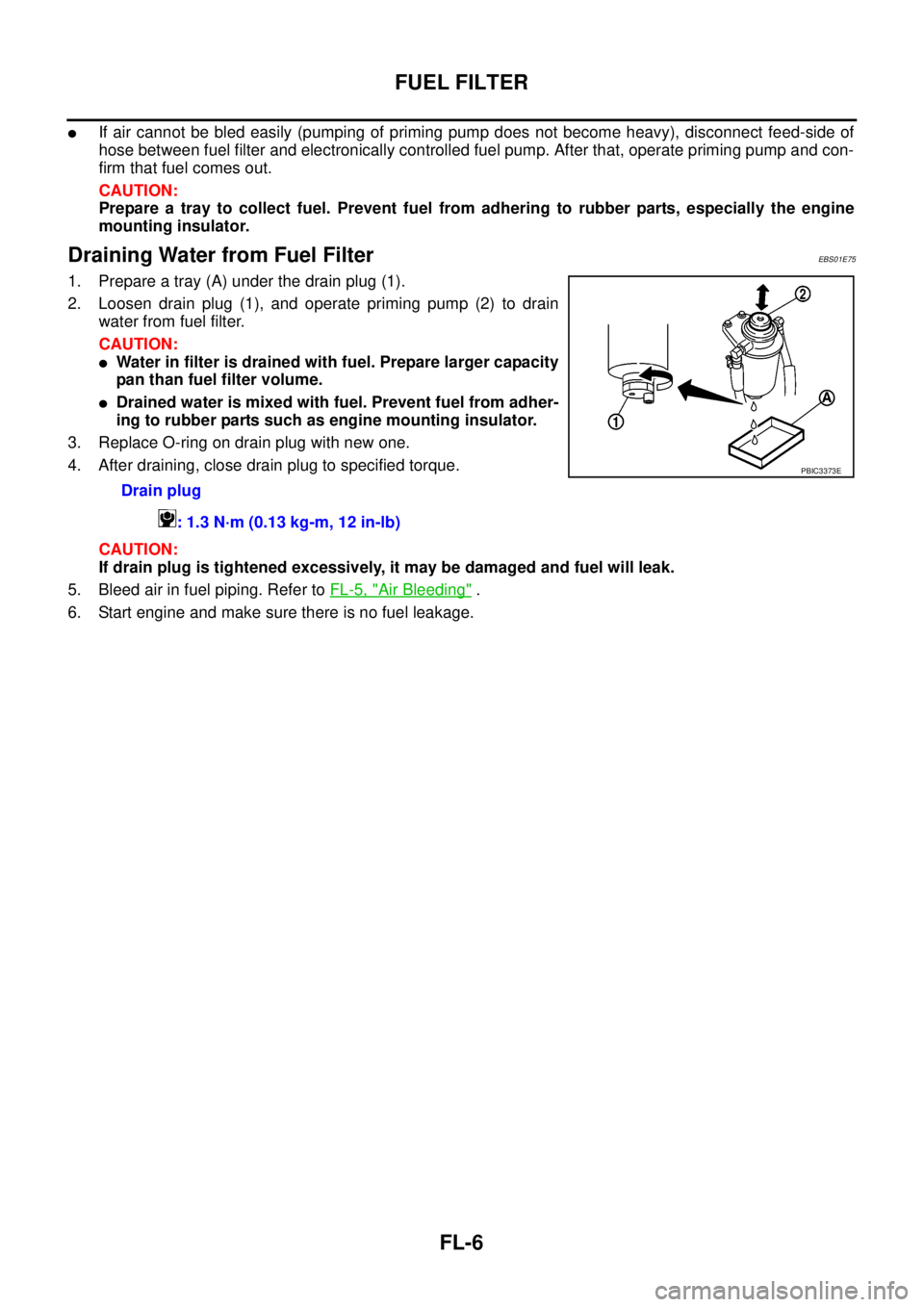

Air BleedingEBS01E74

After fuel filter is replaced and after fuel system components are removed/installed, bleed air from fuel line as

follows:

lMove priming pump (1) up and down to bleed air from fuel path.

When air is bled, pumping of priming pump becomes heavy stop

operation at that time.

lCrank engine until it starts. Do not crank engine for more than 30 seconds.

lIf engine does not start, stop cranking and repeat step 1 above.

lIf engine does not operate smoothly after it has started, race it two or three times.

PBIC3371E

Fuel filter (reference value)

: 13.5 N·m (1.4 kg-m, 10 ft-lb)

: Vehicle front

Fuel filter mounting nuts

: 13.5 N·m (1.4 kg-m, 10 ft-lb)

PBIC3337E

PBIC3372E

Page 1590 of 3171

FL-6

FUEL FILTER

lIf air cannot be bled easily (pumping of priming pump does not become heavy), disconnect feed-side of

hose between fuel filter and electronically controlled fuel pump. After that, operate priming pump and con-

firm that fuel comes out.

CAUTION:

Prepare a tray to collect fuel. Prevent fuel from adhering to rubber parts, especially the engine

mounting insulator.

Draining Water from Fuel FilterEBS01E75

1. Prepare a tray (A) under the drain plug (1).

2. Loosen drain plug (1), and operate priming pump (2) to drain

water from fuel filter.

CAUTION:

lWater in filter is drained with fuel. Prepare larger capacity

pan than fuel filter volume.

lDrained water is mixed with fuel. Prevent fuel from adher-

ing to rubber parts such as engine mounting insulator.

3. Replace O-ring on drain plug with new one.

4. After draining, close drain plug to specified torque.

CAUTION:

If drain plug is tightened excessively, it may be damaged and fuel will leak.

5. Bleed air in fuel piping. Refer toFL-5, "

Air Bleeding".

6. Start engine and make sure there is no fuel leakage.Drain plug

: 1.3 N·m (0.13 kg-m, 12 in-lb)

PBIC3373E

Page 1591 of 3171

FUEL COOLER

FL-7

C

D

E

F

G

H

I

J

K

L

MA

FL

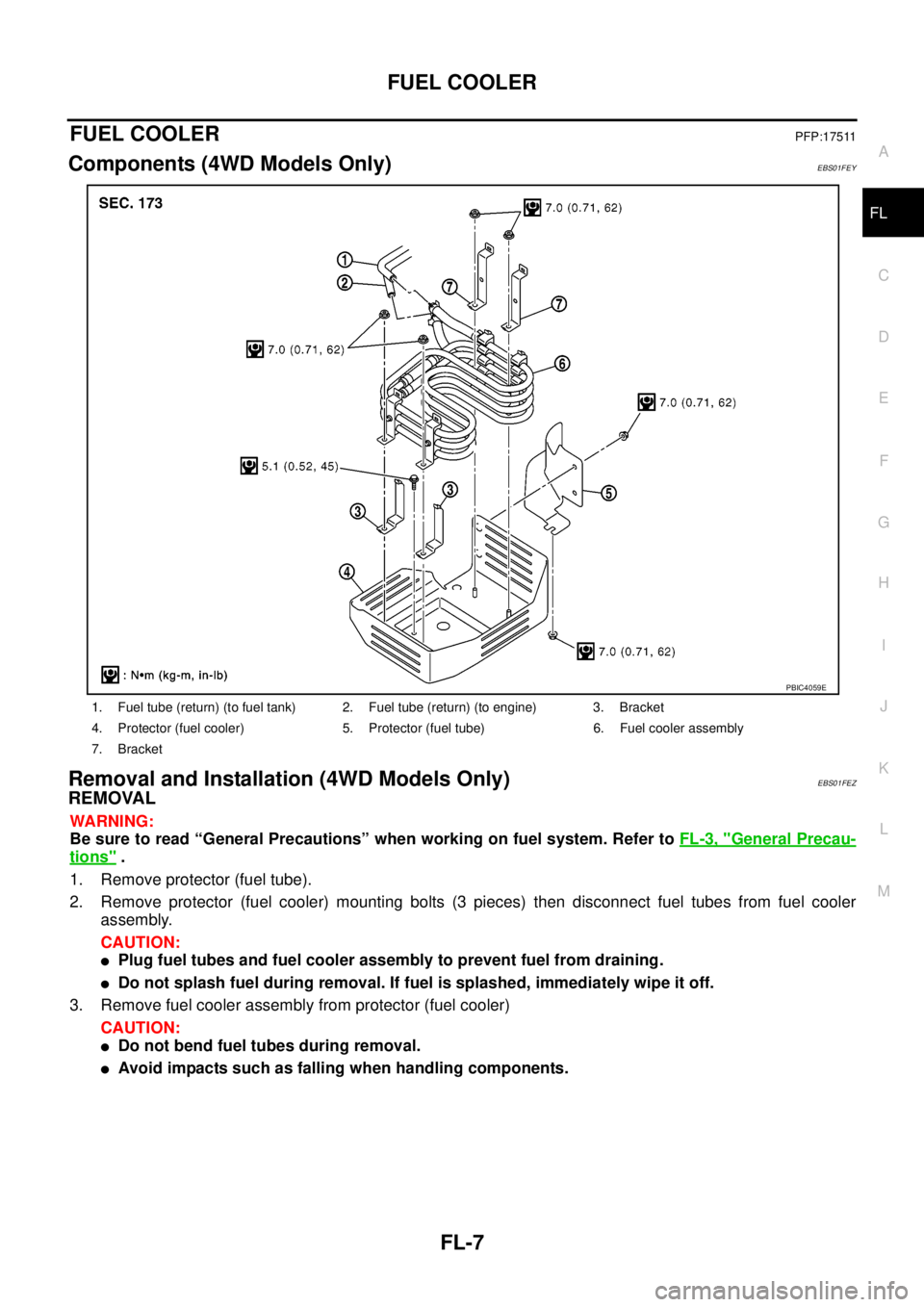

FUEL COOLERPFP:17511

Components (4WD Models Only)EBS01FEY

Removal and Installation (4WD Models Only)EBS01FEZ

REMOVAL

WARNING:

Be sure to read “General Precautions” when working on fuel system. Refer toFL-3, "

General Precau-

tions".

1. Remove protector (fuel tube).

2. Remove protector (fuel cooler) mounting bolts (3 pieces) then disconnect fuel tubes from fuel cooler

assembly.

CAUTION:

lPlug fuel tubes and fuel cooler assembly to prevent fuel from draining.

lDo not splash fuel during removal. If fuel is splashed, immediately wipe it off.

3. Remove fuel cooler assembly from protector (fuel cooler)

CAUTION:

lDo not bend fuel tubes during removal.

lAvoid impacts such as falling when handling components.

1. Fuel tube (return) (to fuel tank) 2. Fuel tube (return) (to engine) 3. Bracket

4. Protector (fuel cooler) 5. Protector (fuel tube) 6. Fuel cooler assembly

7. Bracket

PBIC4059E

Page 1592 of 3171

FL-8

FUEL COOLER

INSTALLATION

Note the following, and install in the reverse order of removal.

lInsert hose to the length below when there is no spool on the fuel tube and surely clamp fuel hoses.

lBe sure hose clamp is not positioned on swelled area of fuel tube.

INSPECTION AFTER INSTALLATION

Make sure there is no fuel leakage at connections in the following steps.

lStart engine and rev it up and make sure there is no fuel leakage at connections.Fuel hose : 25 mm (0.98 in)

Page 1593 of 3171

FUEL TANK

FL-9

C

D

E

F

G

H

I

J

K

L

MA

FL

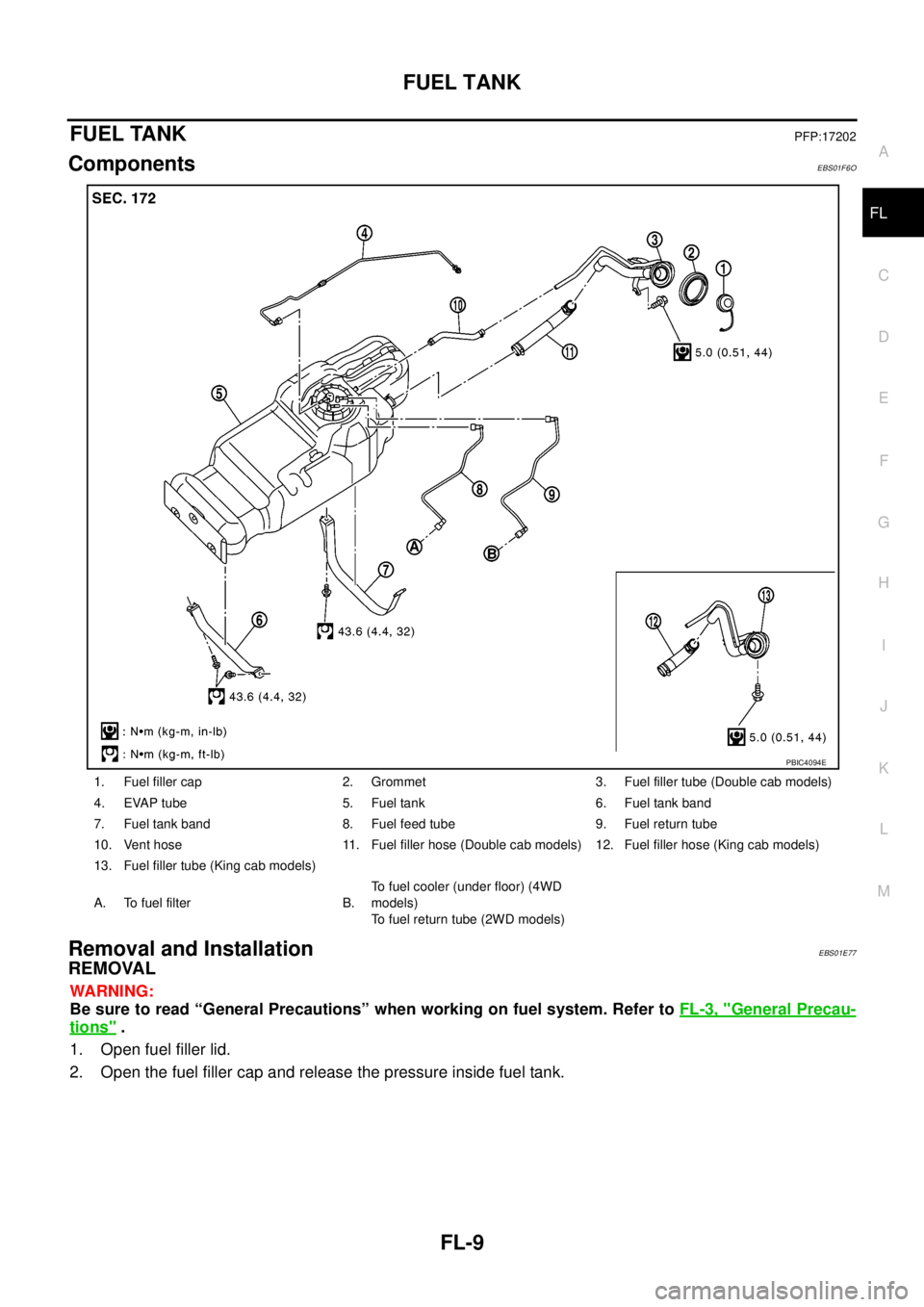

FUEL TANKPFP:17202

ComponentsEBS01F6O

Removal and InstallationEBS01E77

REMOVAL

WARNING:

Be sure to read “General Precautions” when working on fuel system. Refer toFL-3, "

General Precau-

tions".

1. Open fuel filler lid.

2. Open the fuel filler cap and release the pressure inside fuel tank.

1. Fuel filler cap 2. Grommet 3. Fuel filler tube (Double cab models)

4. EVAP tube 5. Fuel tank 6. Fuel tank band

7. Fuel tank band 8. Fuel feed tube 9. Fuel return tube

10. Vent hose 11. Fuel filler hose (Double cab models) 12. Fuel filler hose (King cab models)

13. Fuel filler tube (King cab models)

A. To fuel filter B.To fuel cooler (under floor) (4WD

models)

To fuel return tube (2WD models)

PBIC4094E

Page 1594 of 3171

FL-10

FUEL TANK

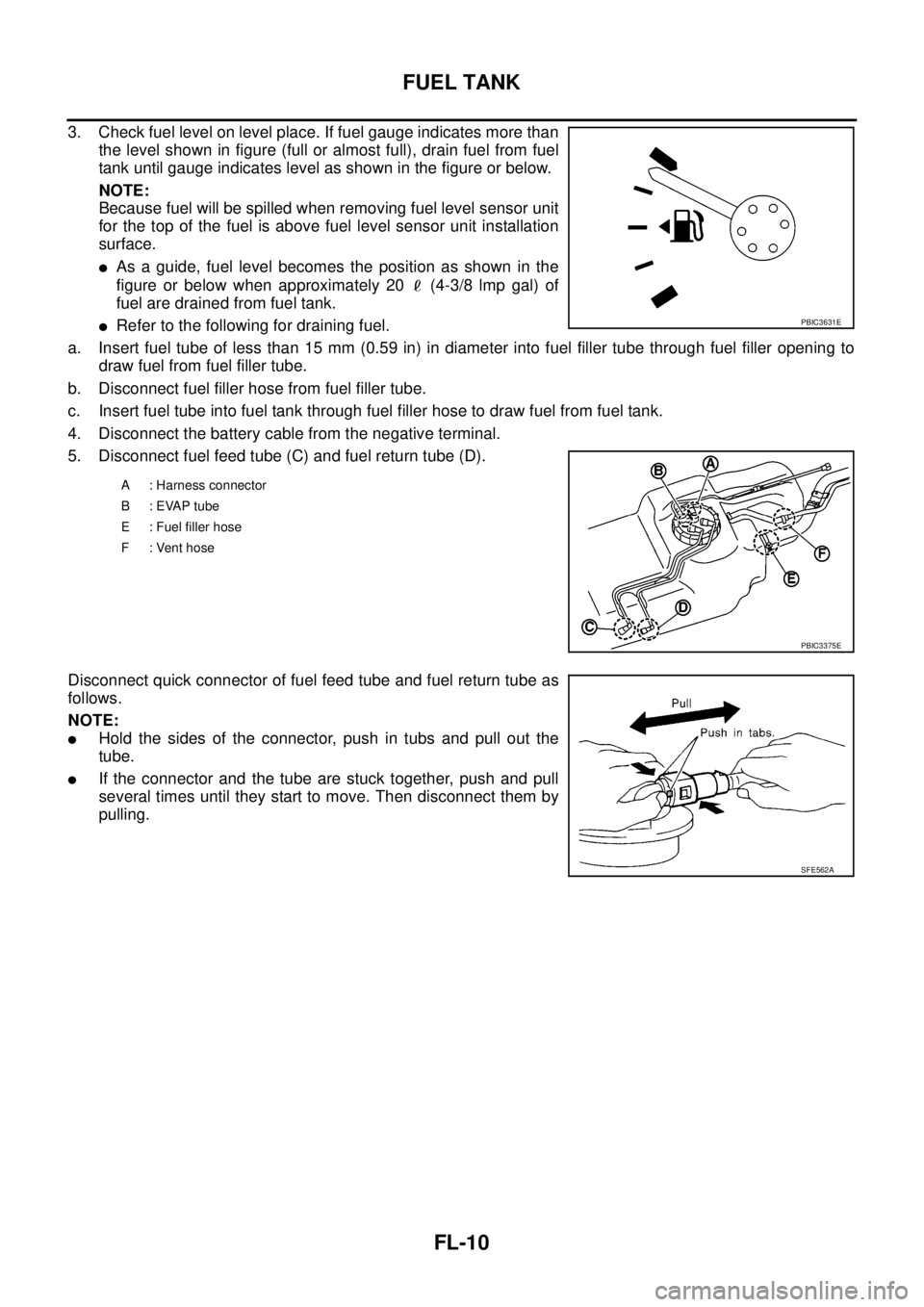

3. Check fuel level on level place. If fuel gauge indicates more than

the level shown in figure (full or almost full), drain fuel from fuel

tank until gauge indicates level as shown in the figure or below.

NOTE:

Because fuel will be spilled when removing fuel level sensor unit

for the top of the fuel is above fuel level sensor unit installation

surface.

lAs a guide, fuel level becomes the position as shown in the

figure or below when approximately 20 (4-3/8 lmp gal) of

fuel are drained from fuel tank.

lRefer to the following for draining fuel.

a. Insert fuel tube of less than 15 mm (0.59 in) in diameter into fuel filler tube through fuel filler opening to

draw fuel from fuel filler tube.

b. Disconnect fuel filler hose from fuel filler tube.

c. Insert fuel tube into fuel tank through fuel filler hose to draw fuel from fuel tank.

4. Disconnect the battery cable from the negative terminal.

5. Disconnect fuel feed tube (C) and fuel return tube (D).

Disconnect quick connector of fuel feed tube and fuel return tube as

follows.

NOTE:

lHold the sides of the connector, push in tubs and pull out the

tube.

lIf the connector and the tube are stuck together, push and pull

several times until they start to move. Then disconnect them by

pulling.

A : Harness connector

B : EVAP tube

E : Fuel filler hose

F : Vent hose

PBIC3631E

PBIC3375E

SFE562A

Page 1595 of 3171

FUEL TANK

FL-11

C

D

E

F

G

H

I

J

K

L

MA

FL

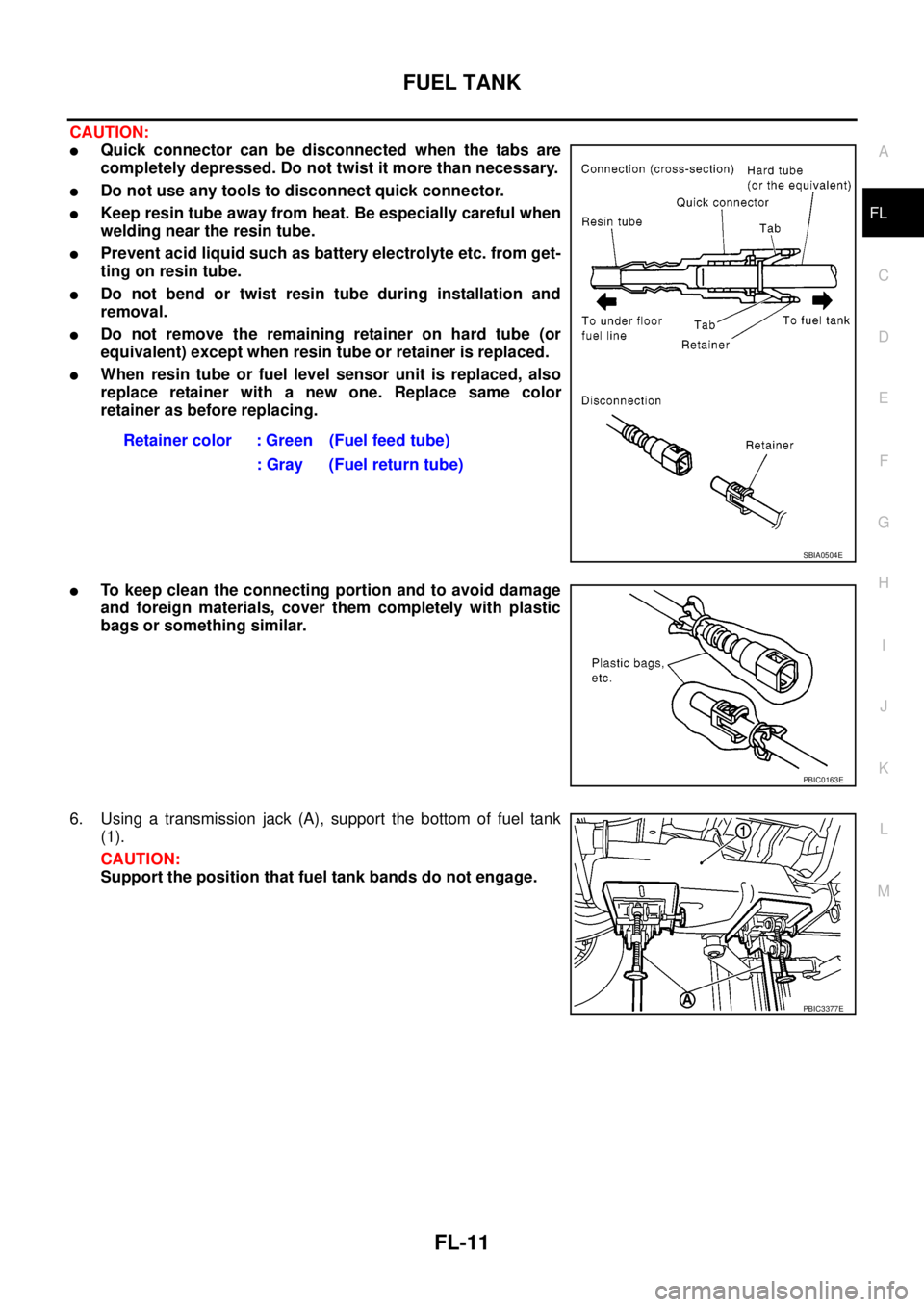

CAUTION:

lQuick connector can be disconnected when the tabs are

completely depressed. Do not twist it more than necessary.

lDo not use any tools to disconnect quick connector.

lKeep resin tube away from heat. Be especially careful when

welding near the resin tube.

lPrevent acid liquid such as battery electrolyte etc. from get-

ting on resin tube.

lDo not bend or twist resin tube during installation and

removal.

lDo not remove the remaining retainer on hard tube (or

equivalent) except when resin tube or retainer is replaced.

lWhen resin tube or fuel level sensor unit is replaced, also

replace retainer with a new one. Replace same color

retainer as before replacing.

lTo keep clean the connecting portion and to avoid damage

and foreign materials, cover them completely with plastic

bags or something similar.

6. Using a transmission jack (A), support the bottom of fuel tank

(1).

CAUTION:

Support the position that fuel tank bands do not engage.Retainer color : Green (Fuel feed tube)

: Gray (Fuel return tube)

SBIA0504E

PBIC0163E

PBIC3377E

Page 1596 of 3171

FL-12

FUEL TANK

7. Remove fuel tank bands, and lower the transmission jack care-

fully until harness connector (A), EVAP tube (B), fuel filler hose

(E) and vent hose (F) can be disconnected.

8. Disconnect harness connector (A), EVAP tube (B), fuel filler

hose (E) and vent hose (F).

9. Supporting with hands, lower transmission jack carefully, and remove fuel tank.

CAUTION:

lPay attention not to fall fuel tank.

lMake sure that all connection points have been disconnected.

lConfirm there is no interference with vehicle.

10. Remove fuel filler tubes, fuel filler hoses and vent hoses if necessary.

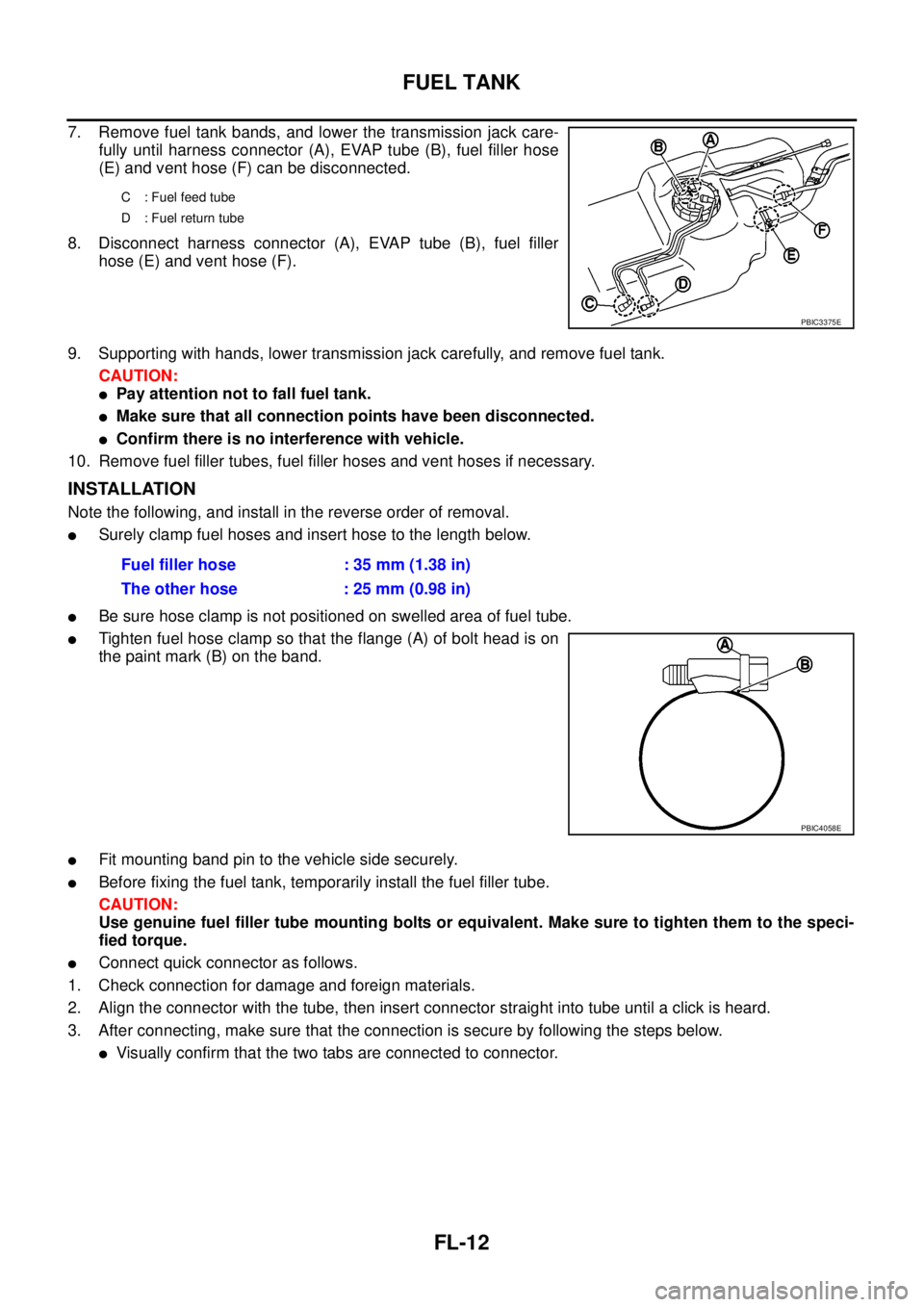

INSTALLATION

Note the following, and install in the reverse order of removal.

lSurely clamp fuel hoses and insert hose to the length below.

lBe sure hose clamp is not positioned on swelled area of fuel tube.

lTighten fuel hose clamp so that the flange (A) of bolt head is on

the paint mark (B) on the band.

lFit mounting band pin to the vehicle side securely.

lBefore fixing the fuel tank, temporarily install the fuel filler tube.

CAUTION:

Use genuine fuel filler tube mounting bolts or equivalent. Make sure to tighten them to the speci-

fied torque.

lConnect quick connector as follows.

1. Check connection for damage and foreign materials.

2. Align the connector with the tube, then insert connector straight into tube until a click is heard.

3. After connecting, make sure that the connection is secure by following the steps below.

lVisually confirm that the two tabs are connected to connector.

C : Fuel feed tube

D : Fuel return tube

PBIC3375E

Fuel filler hose : 35 mm (1.38 in)

The other hose : 25 mm (0.98 in)

PBIC4058E