check engine NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 56 of 3171

AT-48

TROUBLE DIAGNOSIS

6.CHECK “R” POSITION FUNCTIONS

1. Engage the brake.

2. Move selector lever to “R” position.

3. Release the brake for 4 to 5 seconds.

Does the vehicle creep backward?

YES >> GO TO 7.

NO >> Enter a check mark at “Vehicle Does Not Creep Backward in “R” Position” onAT-38, "

DIAGNOS-

TIC WORKSHEET", then continue the road test.

7.CHECK “D” POSITION FUNCTIONS

Inspect whether the vehicle creep forward when the A/T is put into the “D” position.

Does the vehicle creep forward in

“D”position?

YES >> Go toAT-48, "Cruise Test - Part 1",AT-50, "Cruise Test - Part 2"andAT-51, "Cruise Test - Part 3"

.

NO >> Enter a check mark at “Vehicle Does Not Creep Forward in “D” Position” onAT-38, "

DIAGNOSTIC

WORKSHEET", then continue the road test. Go toAT-48, "Cruise Test - Part 1",AT-50, "Cruise

Te s t - P a r t 2"andAT-51, "Cruise Test - Part 3".

CruiseTest-Part1ECS00FX3

1.CHECK STARTING OUT FROM D1

1. Drive the vehicle for about 10 minutes to warm up the engine oil and ATF.

Appropriate temperature for the ATF: 50 - 80°C (122 - 176°F)

2. Park the vehicle on a level surface.

3. Move selector lever to “P” position.

4. Start engine.

5. Move selector lever to “D” position.

6. Press accelerator pedal about half-way down to accelerate the vehicle.

With CONSULT-II

Read the gear position. Refer toAT-83, "

DATA MONITOR MODE".

Starts from D

1?

YES >> GO TO 2.

NO >> Enter a check mark at “Vehicle Cannot Be Started from D

1”onAT-38, "DIAGNOSTIC WORK-

SHEET", then continue the road test.

2.CHECK SHIFT-UP D1®D2

Press down accelerator pedal about half-way and inspect if the vehicle shifts up (D1®D2) at the appropriate

speed. Refer toAT-52, "

Vehicle Speed at Which Gear Shifting Occurs".

With CONSULT-II

Read the gear position, throttle degree and vehicle speed. Refer toAT-83, "

DATA MONITOR MODE".

Does the A/T shift-up D

1®D2at the correct speed?

YES >> GO TO 3.

NO >> Enter a check mark at “A/T Does Not Shift: D

1®D2”onAT-38, "DIAGNOSTIC WORKSHEET",

then continue the road test.

Page 58 of 3171

AT-50

TROUBLE DIAGNOSIS

8.CHECK LOCK-UP RELEASE

Check lock-up cancellation by depressing brake pedal lightly to decelerate.

With CONSULT-II

Select “TCC SOLENOID” with “MAIN SIGNALS” mode for “A/T”. Refer toAT-77, "

CONSULT-II REFERENCE

VA L U E".

Does lock-up cancel?

YES >> GO TO 9.

NO >> Enter a check mark at “Lock-up Is Not Released” onAT-38, "

DIAGNOSTIC WORKSHEET",then

continue the road test.

9.CHECK SHIFT-DOWN D5®D4

Decelerate by pressing lightly on brake pedal.

With CONSULT-II

Read the gear position and engine speed. Refer toAT-83, "

DATA MONITOR MODE".

When the A/T shift-down D

5®D4, does the engine speed drop smoothly back to idle?

YES >> 1. Stop the vehicle.

2. Go toAT-50, "

Cruise Test - Part 2".

NO >> Enter a check mark at “Engine Speed Does Not Return to Idle” onAT-38, "

DIAGNOSTIC WORK-

SHEET", then continue the road test. Go toAT-50, "Cruise Test - Part 2".

CruiseTest-Part2ECS00FX4

1.CHECK STARTING FROM D1

1. Move selector lever to “D” position.

2. Accelerate at half throttle.

With CONSULT-II

Read the gear position. Refer toAT-83, "

DATA MONITOR MODE".

Does it start from D

1?

YES >> GO TO 2.

NO >> Enter a check mark at “Vehicle Cannot Be Started from D

1”onAT-38, "DIAGNOSTIC WORK-

SHEET", then continue the road test.

2.CHECK SHIFT-UP D1®D2

Press accelerator pedal down all the way and inspect whether or not the A/T shifts up (D1®D2)atthecor-

rect speed. Refer toAT-52, "

Vehicle Speed at Which Gear Shifting Occurs".

With CONSULT-II

Read the gear position, throttle degree and vehicle speed. Refer toAT-83, "

DATA MONITOR MODE".

Does the A/T shift-up D

1®D2at the correct speed?

YES >> GO TO 3.

NO >> Enter a check mark at “A/T Does Not Shift: D

1®D2”onAT-38, "DIAGNOSTIC WORKSHEET",

then continue the road test.

3.CHECK SHIFT-UP D2®D3

Press accelerator pedal down all the way and inspect whether or not the A/T shifts up (D2®D3)atthecor-

rect speed. Refer toAT-52, "

Vehicle Speed at Which Gear Shifting Occurs".

With CONSULT-II

Read the gear position, throttle degree and vehicle speed. Refer toAT-83, "

DATA MONITOR MODE".

Does the A/T shift-up D

2®D3at the correct speed?

YES >> GO TO 4.

NO >> Enter a check mark at “A/T Does Not Shift: D

2®D3”onAT-38, "DIAGNOSTIC WORKSHEET",

then continue the road test.

Page 59 of 3171

TROUBLE DIAGNOSIS

AT-51

D

E

F

G

H

I

J

K

L

MA

B

AT

4.CHECK SHIFT-UP D3®D4AND ENGINE BRAKE

When the A/T changes speed D

3®D4, return accelerator pedal.

With CONSULT-II

Read the gear position. Refer toAT-83, "

DATA MONITOR MODE".

Does the A/T shift-up D

3®D4and apply the engine brake?

YES >> 1. Stop the vehicle.

2. Go toAT-51, "

Cruise Test - Part 3".

NO >> Enter a check mark at “A/T Does Not Shift: D

3®D4”onAT-38, "DIAGNOSTIC WORKSHEET",

then continue the road test. Go toAT-51, "

Cruise Test - Part 3".

Cruise Test - Part 3ECS00FX5

1.CHECK SHIFT-DOWN

1. Confirm overdrive control switch is ON position.

2. Confirm gear selector lever is in “D” position.

3. Accelerate vehicle using half-throttle to D

5.

4. Release accelerator pedal.

5. Set overdrive control switch to OFF position while driving in D

5.

With CONSULT-II

Read the gear position. Refer toAT-83, "

DATA MONITOR MODE".

Does A/T shift from D

5to D4(OD OFF)?

YES >> GO TO 2.

NO >> Enter a check mark at “A/T does not shift: 5th gear®4th gear” on theAT-38, "

DIAGNOSTIC

WORKSHEET", then continue the road test.

2.CHECK SHIFT-DOWN

During D

4driving, is downshift from “D”®“3”®“2”®“1” performed?

With CONSULT-II

Read the gear position. Refer toAT-83, "

DATA MONITOR MODE".

Is downshifting correctly performed?

YES >> GO TO 3.

NO >> Enter a check mark at “A/T does not shift” at the corresponding position (4th®3rd, 3rd®2nd,

2nd®1st) on theAT-38, "

DIAGNOSTIC WORKSHEET", then continue the road test.

3.CHECK ENGINE BRAKE

Check engine brake.

Does engine braking effectively reduce speed in 1

1position?

YES >> 1. Stop the vehicle.

2. Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diag-

nostic Procedure Without CONSULT-II".

NO >> Enter a check mark at “Vehicle Does Not Decelerate by Engine Brake” on theAT-38, "

DIAGNOS-

TIC WORKSHEET", then continue trouble diagnosis.

Page 61 of 3171

TROUBLE DIAGNOSIS

AT-53

D

E

F

G

H

I

J

K

L

MA

B

AT

Symptom ChartECS00FX8

lThe diagnostic item numbers show the sequence for inspection. Inspect in order from item 1.

lOverhaul and inspect inside the A/T only if A/T fluid condition is NG. Refer toAT-43, "A/T Fluid Con-

dition Check".

No. Items Symptom Condition Diagnostic ItemReference

page

1

Shift

ShockLarge shock. (“N”®“D”

position)

Refer toAT-180,

"Large Shock (“N”to

“D”Position)".ON vehicle1. Engine idle speedEC-38

2. Engine speed signalAT-108

3. Accelerator pedal position sensorAT- 11 6

4. Control cable adjustmentAT- 2 11

5. A/T fluid temperature sensorAT- 11 8

6. ATF pressure switch 1 and front brake solenoid valveAT-156,

AT-137

7. CAN communication lineAT- 9 1

8. A/T fluid level and stateAT- 4 3

9. Line pressure testAT- 4 4

10. Control valve with TCMAT-218

OFF vehicle11. Forward brake (Parts behind drum support is impossible

to perform inspection by disassembly. Refer toAT- 1 4 , "Cross-

Sectional View (2WD Models)",AT- 1 5 , "Cross-Sectional View

(4WD Models)".)AT-263

2Shock is too large

when changing D1

®D2.ON vehicle1. Accelerator pedal position sensorAT- 11 6

2. Control cable adjustmentAT- 2 11

3. ATF pressure switch 5 and direct clutch solenoid valveAT-160,

AT-142

4. CAN communication lineAT- 9 1

5. Engine speed signalAT-108

6. Turbine revolution sensorAT-123

7. Vehicle speed sensor A/T and vehicle speed sensor MTRAT-103,

AT-125

8. A/T fluid level and stateAT- 4 3

9. Control valve with TCMAT-218

OFF vehicle 10. Direct clutchAT-298

3Shock is too large

when changing D2

®D3.ON vehicle1. Accelerator pedal position sensorAT- 11 6

2. Control cable adjustmentAT- 2 11

3. ATF pressure switch 6 and high and low reverse clutch

solenoid valveAT-162,

AT-147

4. CAN communication lineAT- 9 1

5. Engine speed signalAT-108

6. Turbine revolution sensorAT-123

7. Vehicle speed sensor A/T and vehicle speed sensor MTRAT-103,

AT-125

8. A/T fluid level and stateAT- 4 3

9. Control valve with TCMAT-218

OFF vehicle 10. High and low reverse clutchAT-296

Page 85 of 3171

TROUBLE DIAGNOSIS

AT-77

D

E

F

G

H

I

J

K

L

MA

B

AT

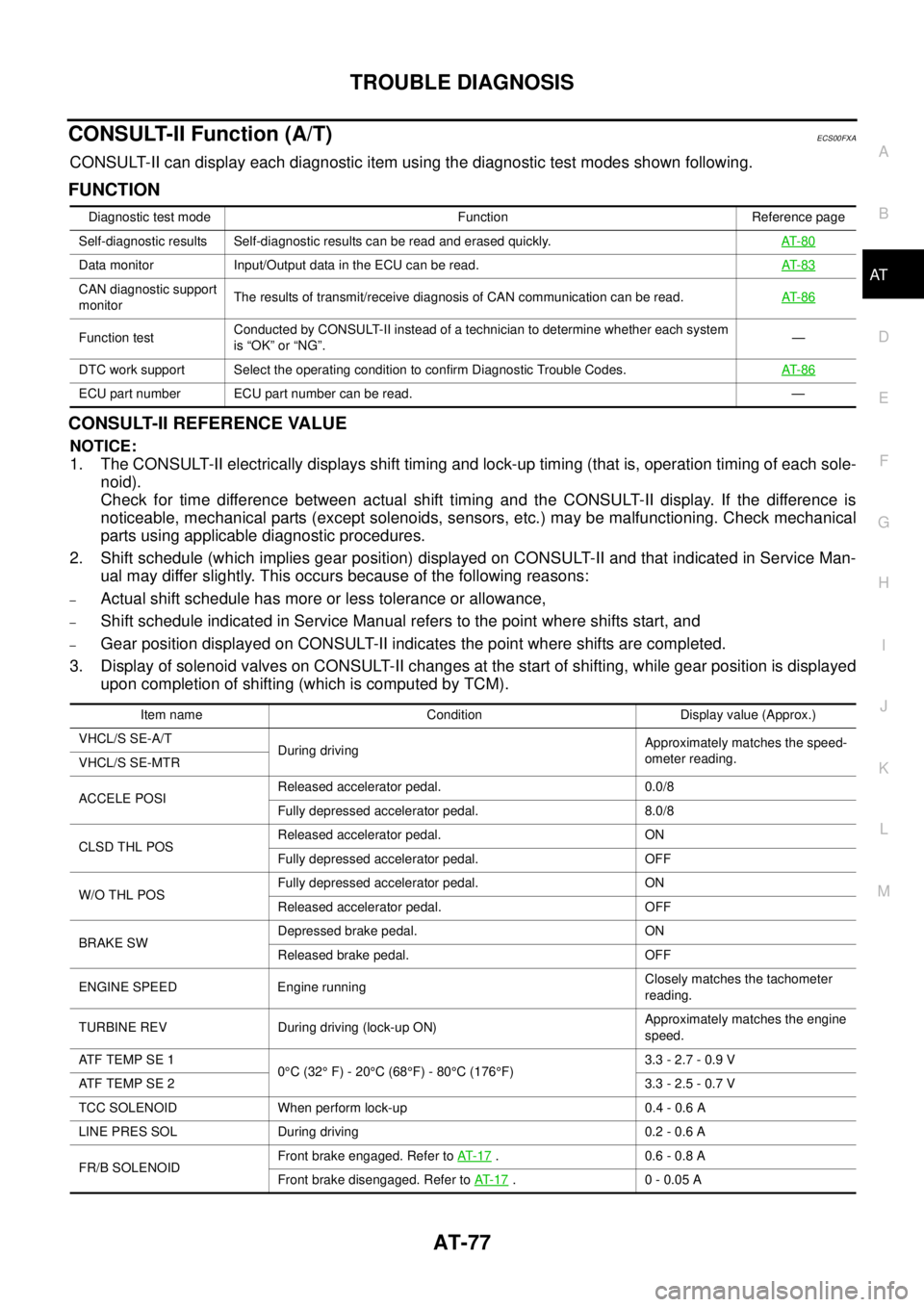

CONSULT-II Function (A/T)ECS00FXA

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

FUNCTION

CONSULT-II REFERENCE VALUE

NOTICE:

1. The CONSULT-II electrically displays shift timing and lock-up timing (that is, operation timing of each sole-

noid).

Check for time difference between actual shift timing and the CONSULT-II display. If the difference is

noticeable, mechanical parts (except solenoids, sensors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) displayed on CONSULT-II and that indicated in Service Man-

ual may differ slightly. This occurs because of the following reasons:

–Actual shift schedule has more or less tolerance or allowance,

–Shift schedule indicated in Service Manual refers to the point where shifts start, and

–Gear position displayed on CONSULT-II indicates the point where shifts are completed.

3. Display of solenoid valves on CONSULT-II changes at the start of shifting, while gear position is displayed

upon completion of shifting (which is computed by TCM).

Diagnostic test mode Function Reference page

Self-diagnostic results Self-diagnostic results can be read and erased quickly.AT- 8 0

Data monitor Input/Output data in the ECU can be read.AT- 8 3

CAN diagnostic support

monitorThe results of transmit/receive diagnosis of CAN communication can be read.AT- 8 6

Function testConducted by CONSULT-II instead of a technician to determine whether each system

is “OK” or “NG”.—

DTC work support Select the operating condition to confirm Diagnostic Trouble Codes.AT- 8 6

ECU part number ECU part number can be read. —

Item name Condition Display value (Approx.)

VHCL/S SE-A/T

During drivingApproximately matches the speed-

ometer reading.

VHCL/S SE-MTR

ACCELE POSIReleased accelerator pedal. 0.0/8

Fully depressed accelerator pedal. 8.0/8

CLSD THL POSReleased accelerator pedal. ON

Fully depressed accelerator pedal. OFF

W/O THL POSFully depressed accelerator pedal. ON

Released accelerator pedal. OFF

BRAKE SWDepressed brake pedal. ON

Released brake pedal. OFF

ENGINE SPEED Engine runningClosely matches the tachometer

reading.

TURBINE REV During driving (lock-up ON)Approximately matches the engine

speed.

ATFTEMPSE1

0°C(32°F)-20°C(68°F)-80°C (176°F)3.3 - 2.7 - 0.9 V

ATFTEMPSE23.3 - 2.5 - 0.7 V

TCC SOLENOID When perform lock-up 0.4 - 0.6 A

LINE PRES SOL During driving 0.2 - 0.6 A

FR/B SOLENOIDFront brake engaged. Refer toAT- 1 7

. 0.6 - 0.8 A

Front brake disengaged. Refer toAT- 1 7

.0-0.05A

Page 88 of 3171

AT-80

TROUBLE DIAGNOSIS

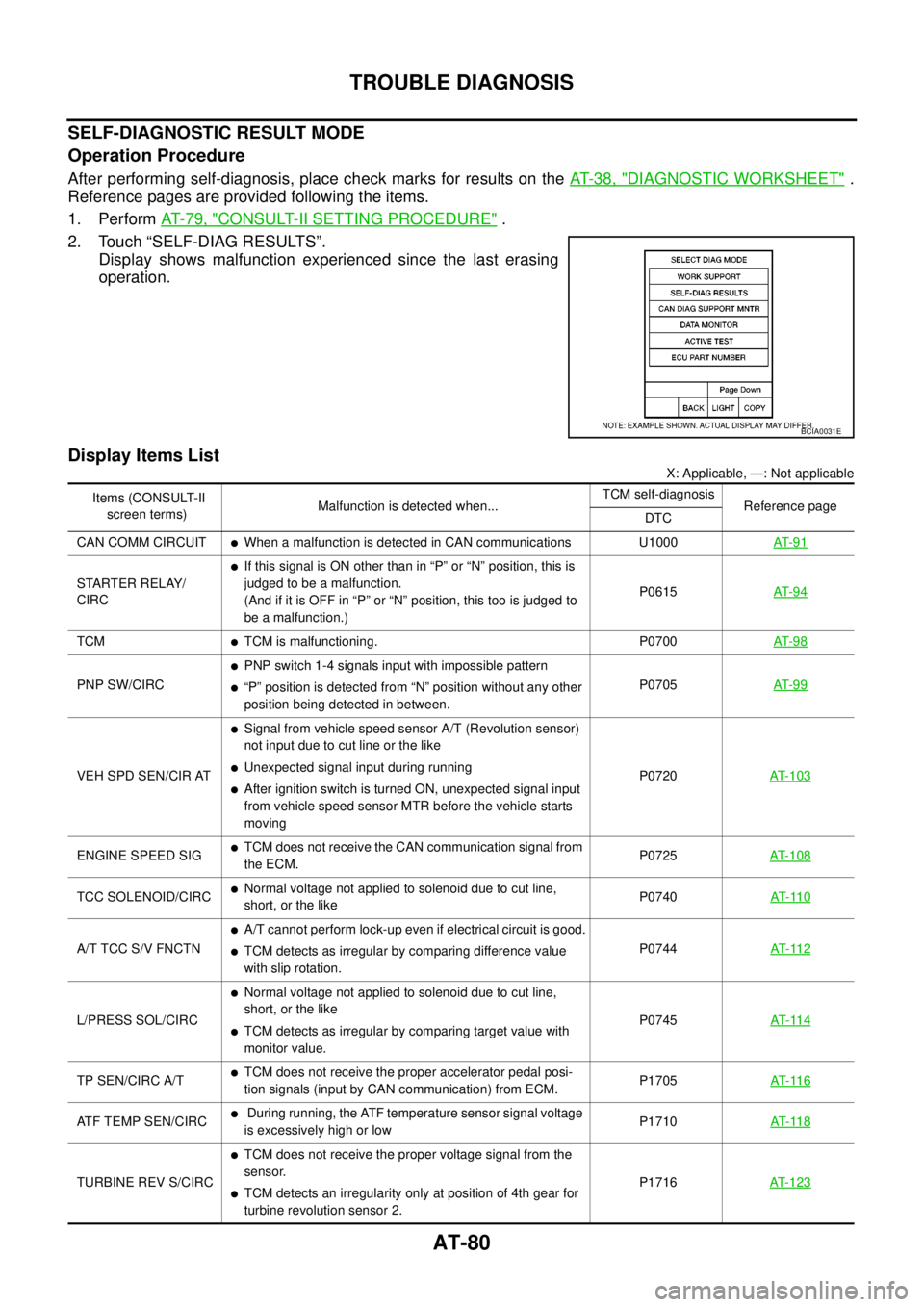

SELF-DIAGNOSTIC RESULT MODE

Operation Procedure

After performing self-diagnosis, place check marks for results on theAT-38, "DIAGNOSTIC WORKSHEET".

Reference pages are provided following the items.

1. PerformAT- 7 9 , "

CONSULT-II SETTING PROCEDURE".

2. Touch “SELF-DIAG RESULTS”.

Display shows malfunction experienced since the last erasing

operation.

Display Items List

X: Applicable, —: Not applicable

BCIA0031E

Items (CONSULT-II

screen terms)Malfunction is detected when...TCM self-diagnosis

Reference page

DTC

CAN COMM CIRCUIT

lWhen a malfunction is detected in CAN communications U1000AT- 9 1

STARTER RELAY/

CIRC

lIf this signal is ON other than in “P” or “N” position, this is

judged to be a malfunction.

(And if it is OFF in “P” or “N” position, this too is judged to

be a malfunction.)P0615AT- 9 4

TCMlTCM is malfunctioning. P0700AT- 9 8

PNP SW/CIRC

lPNP switch 1-4 signals input with impossible pattern

l“P” position is detected from “N” position without any other

position being detected in between.P0705AT- 9 9

VEH SPD SEN/CIR AT

lSignal from vehicle speed sensor A/T (Revolution sensor)

not input due to cut line or the like

lUnexpected signal input during running

lAfter ignition switch is turned ON, unexpected signal input

from vehicle speed sensor MTR before the vehicle starts

movingP0720AT- 1 0 3

ENGINE SPEED SIGlTCM does not receive the CAN communication signal from

the ECM.P0725AT- 1 0 8

TCC SOLENOID/CIRClNormal voltage not applied to solenoid due to cut line,

short, or the likeP0740AT- 11 0

A/T TCC S/V FNCTN

lA/T cannot perform lock-up even if electrical circuit is good.

lTCM detects as irregular by comparing difference value

with slip rotation.P0744AT- 11 2

L/PRESS SOL/CIRC

lNormal voltage not applied to solenoid due to cut line,

short, or the like

lTCM detects as irregular by comparing target value with

monitor value.P0745AT- 11 4

TP SEN/CIRC A/TlTCM does not receive the proper accelerator pedal posi-

tion signals (input by CAN communication) from ECM.P1705AT- 11 6

ATF TEMP SEN/CIRClDuring running, the ATF temperature sensor signal voltage

is excessively high or lowP1710AT- 11 8

TURBINE REV S/CIRC

lTCM does not receive the proper voltage signal from the

sensor.

lTCM detects an irregularity only at position of 4th gear for

turbine revolution sensor 2.P1716AT- 1 2 3

Page 97 of 3171

TROUBLE DIAGNOSIS

AT-89

D

E

F

G

H

I

J

K

L

MA

B

AT

Diagnostic Procedure Without CONSULT-IIECS00FXB

TCM SELF-DIAGNOSTIC PROCEDURE (WITHOUT CONSULT-II)

Description

In the unlikely event of a malfunction in the electrical system, when the ignition switch is switched ON, the OD

OFF indicator lamp lights up for 2 seconds. If there is no malfunction, when the ignition switch is turned ON,

the indicator lamp lights up for 2 seconds. As a method for locating the suspect circuit, when the self-diagnos-

tics start signal is input, the memory for the malfunction location is output and OD OFF indicator lamp flashes

to display the corresponding DTC.

Diagnostic Procedure

1.CHECK OD OFF INDICATOR LAMP

1. Start the engine with selector lever in “P” position. Warm engine to normal operating temperature.

2. Turn ignition switch ON and OFF at least twice, then leave it in the OFF position.

3. Wait 10 seconds.

4. Turn ignition switch ON. (Do not start engine.)

Does OD OFF indicator lamp come on for about 2 seconds?

YES >> GO TO 2.

NO >> GO TOAT- 1 7 7 , "

OD OFF Indicator Lamp Does Not Come On".

2.JUDGEMENT PROCEDURE

1. Turn ignition switch OFF.

2. Keep pressing shift lock release button.

3. Move selector lever from “P” to “D” position.

4. Release accelerator pedal. (Set the closed throttle position signal ON.)

5. Depress brake pedal. (Stop lamp switch signal ON.)

6. Turn ignition switch ON.

7. Wait 3 seconds.

8. Move selector lever from “D” to “3” position.

9. Release brake pedal. (Stop lamp switch signal OFF.)

10. Move selector lever from “3” to “2” position.

11. Depress brake pedal. (Stop lamp switch signal ON.)

12. Release brake pedal. (Stop lamp switch signal OFF.)

13. Depress accelerator pedal fully and release it.

>> GO TO 3.

3.CHECK SELF-DIAGNOSIS CODE

Check OD OFF indicator lamp. Refer toAT-90, "

Judgement Self-diagnosis Code".

If the system does not go into self-diagnosis. Refer toAT-99, "

DTC P0705 PARK/NEUTRAL POSITION

SWITCH",AT- 1 6 8 , "CLOSED THROTTLE POSITION AND WIDE OPEN THROTTLE POSITION CIRCUIT",

AT- 1 6 9 , "

BRAKE SIGNAL CIRCUIT".

>>DIAGNOSIS END

Page 101 of 3171

DTC U1000 CAN COMMUNICATION LINE

AT-93

D

E

F

G

H

I

J

K

L

MA

B

AT

Data are reference value and are measured between each terminal and ground.

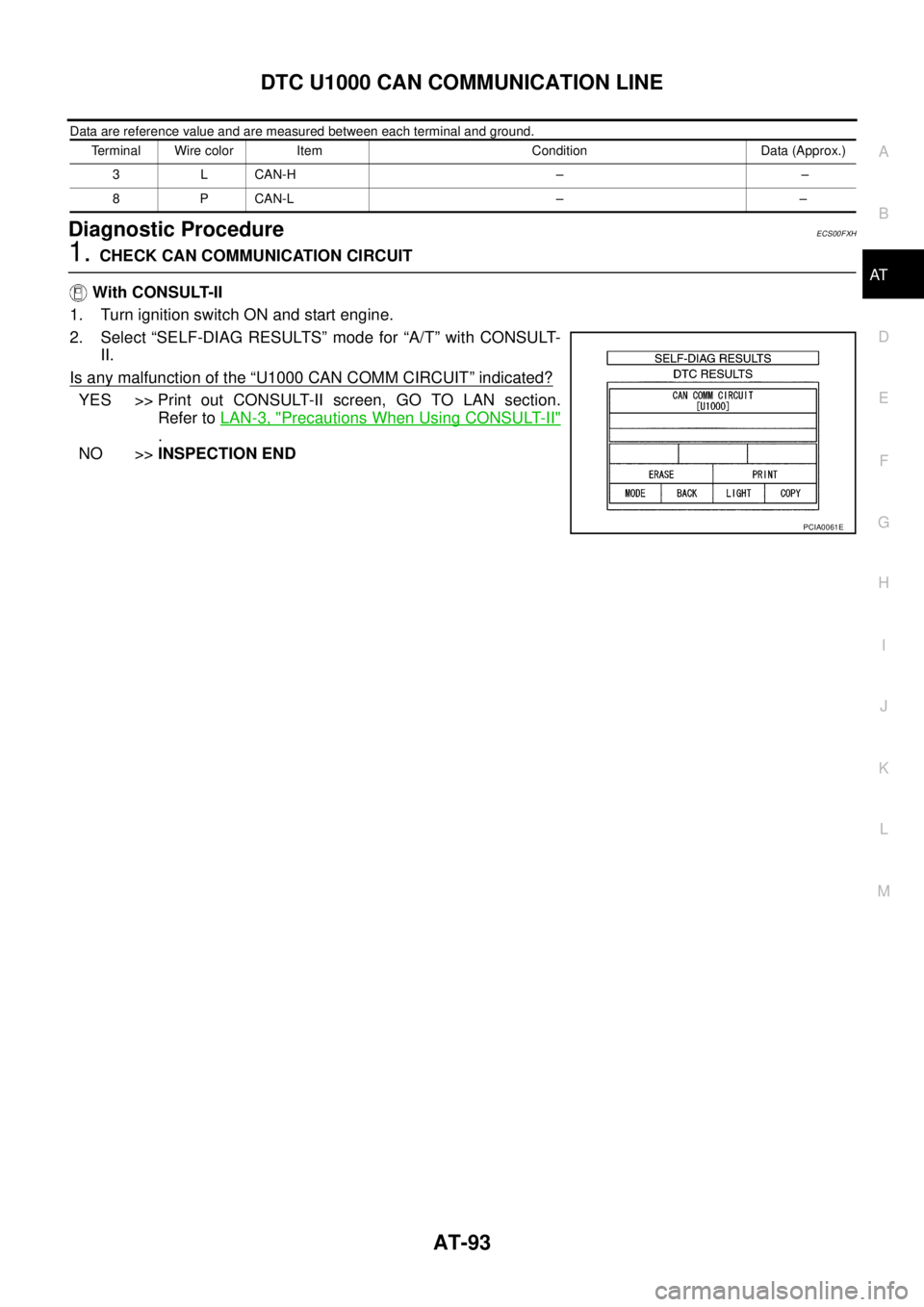

Diagnostic ProcedureECS00FXH

1.CHECK CAN COMMUNICATION CIRCUIT

With CONSULT-II

1. Turn ignition switch ON and start engine.

2. Select “SELF-DIAG RESULTS” mode for “A/T” with CONSULT-

II.

Is any malfunction of the

“U1000 CAN COMM CIRCUIT”indicated?

YES >> Print out CONSULT-II screen, GO TO LAN section.

Refer toLAN-3, "

Precautions When Using CONSULT-II"

.

NO >>INSPECTION END

Terminal Wire color Item Condition Data (Approx.)

3 L CAN-H – –

8 P CAN-L – –

PCIA0061E

Page 102 of 3171

AT-94

DTC P0615 START SIGNAL CIRCUIT

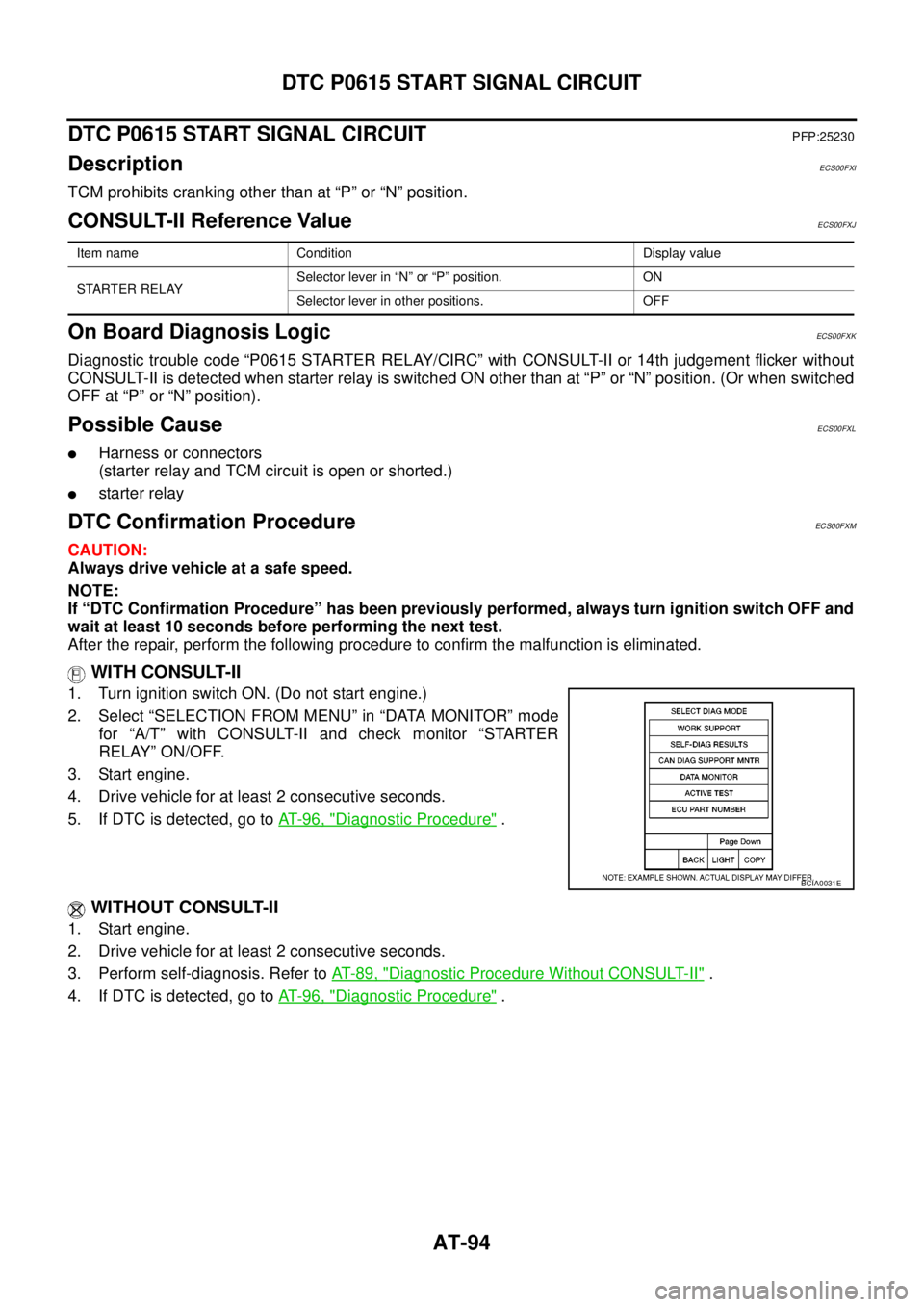

DTC P0615 START SIGNAL CIRCUIT

PFP:25230

DescriptionECS00FXI

TCM prohibits cranking other than at “P” or “N” position.

CONSULT-II Reference ValueECS00FXJ

On Board Diagnosis LogicECS00FXK

Diagnostic trouble code “P0615 STARTER RELAY/CIRC” with CONSULT-II or 14th judgement flicker without

CONSULT-II is detected when starter relay is switched ON other than at “P” or “N” position. (Or when switched

OFF at “P” or “N” position).

Possible CauseECS00FXL

lHarness or connectors

(starter relay and TCM circuit is open or shorted.)

lstarter relay

DTC Confirmation ProcedureECS00FXM

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “SELECTION FROM MENU” in “DATA MONITOR” mode

for “A/T” with CONSULT-II and check monitor “STARTER

RELAY” ON/OFF.

3. Start engine.

4. Drive vehicle for at least 2 consecutive seconds.

5. If DTC is detected, go toAT-96, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Start engine.

2. Drive vehicle for at least 2 consecutive seconds.

3. Perform self-diagnosis. Refer toAT-89, "

Diagnostic Procedure Without CONSULT-II".

4. If DTC is detected, go toAT-96, "

Diagnostic Procedure".

Item name Condition Display value

STARTER RELAYSelector lever in “N” or “P” position. ON

Selector lever in other positions. OFF

BCIA0031E

Page 104 of 3171

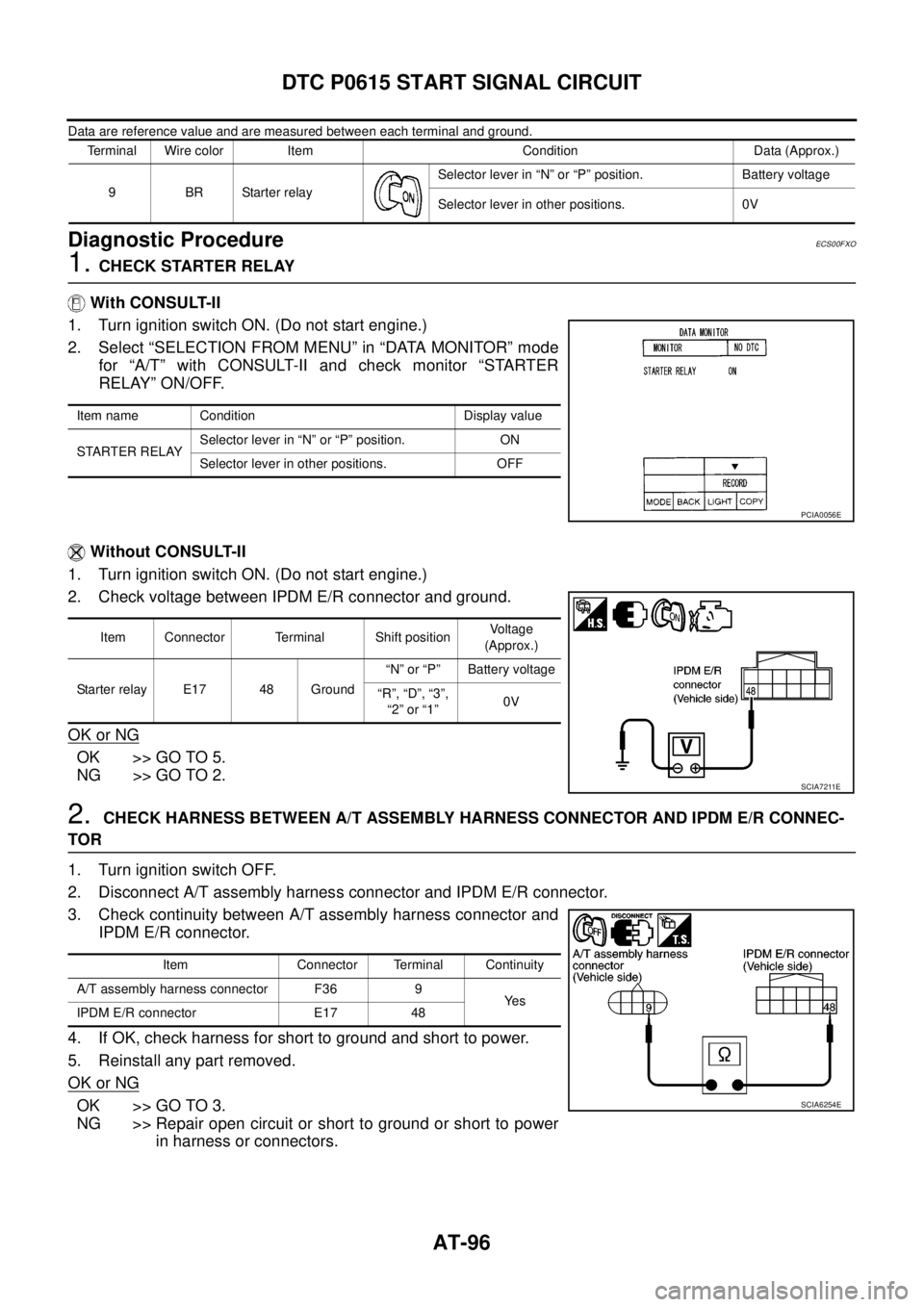

AT-96

DTC P0615 START SIGNAL CIRCUIT

Data are reference value and are measured between each terminal and ground.

Diagnostic ProcedureECS00FXO

1.CHECK STARTER RELAY

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “SELECTION FROM MENU” in “DATA MONITOR” mode

for “A/T” with CONSULT-II and check monitor “STARTER

RELAY” ON/OFF.

Without CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between IPDM E/R connector and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

2.CHECK HARNESS BETWEEN A/T ASSEMBLY HARNESS CONNECTOR AND IPDM E/R CONNEC-

TOR

1. Turn ignition switch OFF.

2. Disconnect A/T assembly harness connector and IPDM E/R connector.

3. Check continuity between A/T assembly harness connector and

IPDM E/R connector.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors.

Terminal Wire color Item Condition Data (Approx.)

9BRStarterrelaySelector lever in “N” or “P” position. Battery voltage

Selector lever in other positions. 0V

Item name Condition Display value

STARTER RELAYSelector lever in “N” or “P” position. ON

Selector lever in other positions. OFF

PCIA0056E

Item Connector Terminal Shift positionVoltage

(Approx.)

Starter relay E17 48 Ground“N” or “P” Battery voltage

“R”, “D”, “3”,

“2”or“1”0V

SCIA7211E

Item Connector Terminal Continuity

A/T assembly harness connector F36 9

Ye s

IPDM E/R connector E17 48

SCIA6254E