cooling NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 392 of 3171

ATC-58

TROUBLE DIAGNOSIS

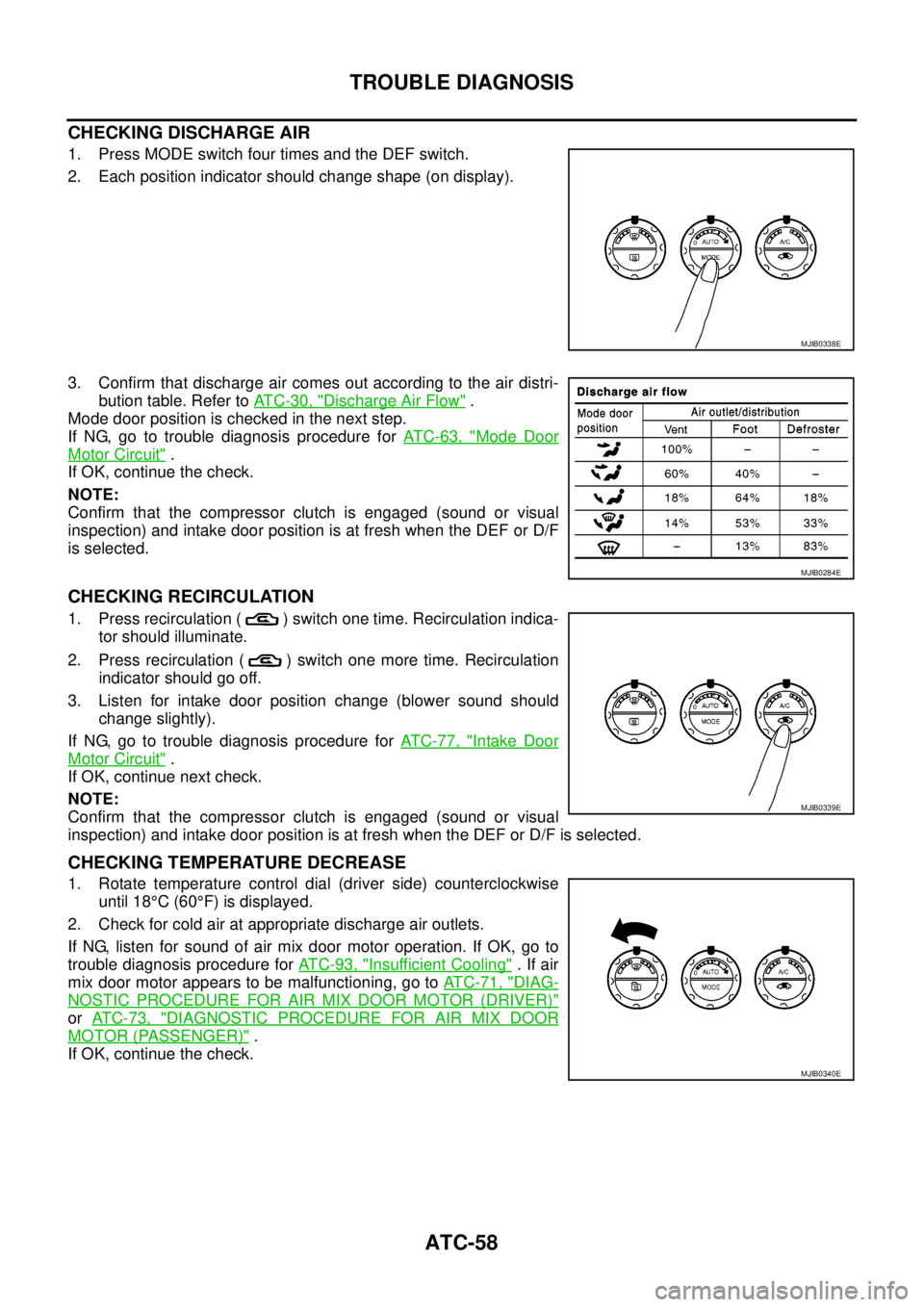

CHECKING DISCHARGE AIR

1. Press MODE switch four times and the DEF switch.

2. Each position indicator should change shape (on display).

3. Confirm that discharge air comes out according to the air distri-

bution table. Refer toAT C - 3 0 , "

Discharge Air Flow".

Mode door position is checked in the next step.

If NG, go to trouble diagnosis procedure forAT C - 6 3 , "

Mode Door

Motor Circuit".

If OK, continue the check.

NOTE:

Confirm that the compressor clutch is engaged (sound or visual

inspection) and intake door position is at fresh when the DEF or D/F

is selected.

CHECKING RECIRCULATION

1. Press recirculation ( ) switch one time. Recirculation indica-

tor should illuminate.

2. Press recirculation ( ) switch one more time. Recirculation

indicator should go off.

3. Listen for intake door position change (blower sound should

change slightly).

If NG, go to trouble diagnosis procedure forAT C - 7 7 , "

Intake Door

Motor Circuit".

If OK, continue next check.

NOTE:

Confirm that the compressor clutch is engaged (sound or visual

inspection) and intake door position is at fresh when the DEF or D/F is selected.

CHECKING TEMPERATURE DECREASE

1. Rotate temperature control dial (driver side) counterclockwise

until 18°C(60°F) is displayed.

2. Check for cold air at appropriate discharge air outlets.

If NG, listen for sound of air mix door motor operation. If OK, go to

trouble diagnosis procedure forAT C - 9 3 , "

Insufficient Cooling".Ifair

mix door motor appears to be malfunctioning, go toAT C - 7 1 , "

DIAG-

NOSTIC PROCEDURE FOR AIR MIX DOOR MOTOR (DRIVER)"

orAT C - 7 3 , "DIAGNOSTIC PROCEDURE FOR AIR MIX DOOR

MOTOR (PASSENGER)".

If OK, continue the check.

MJIB0338E

MJIB0284E

MJIB0339E

MJIB0340E

Page 399 of 3171

TROUBLE DIAGNOSIS

ATC-65

C

D

E

F

G

H

I

K

L

MA

B

AT C

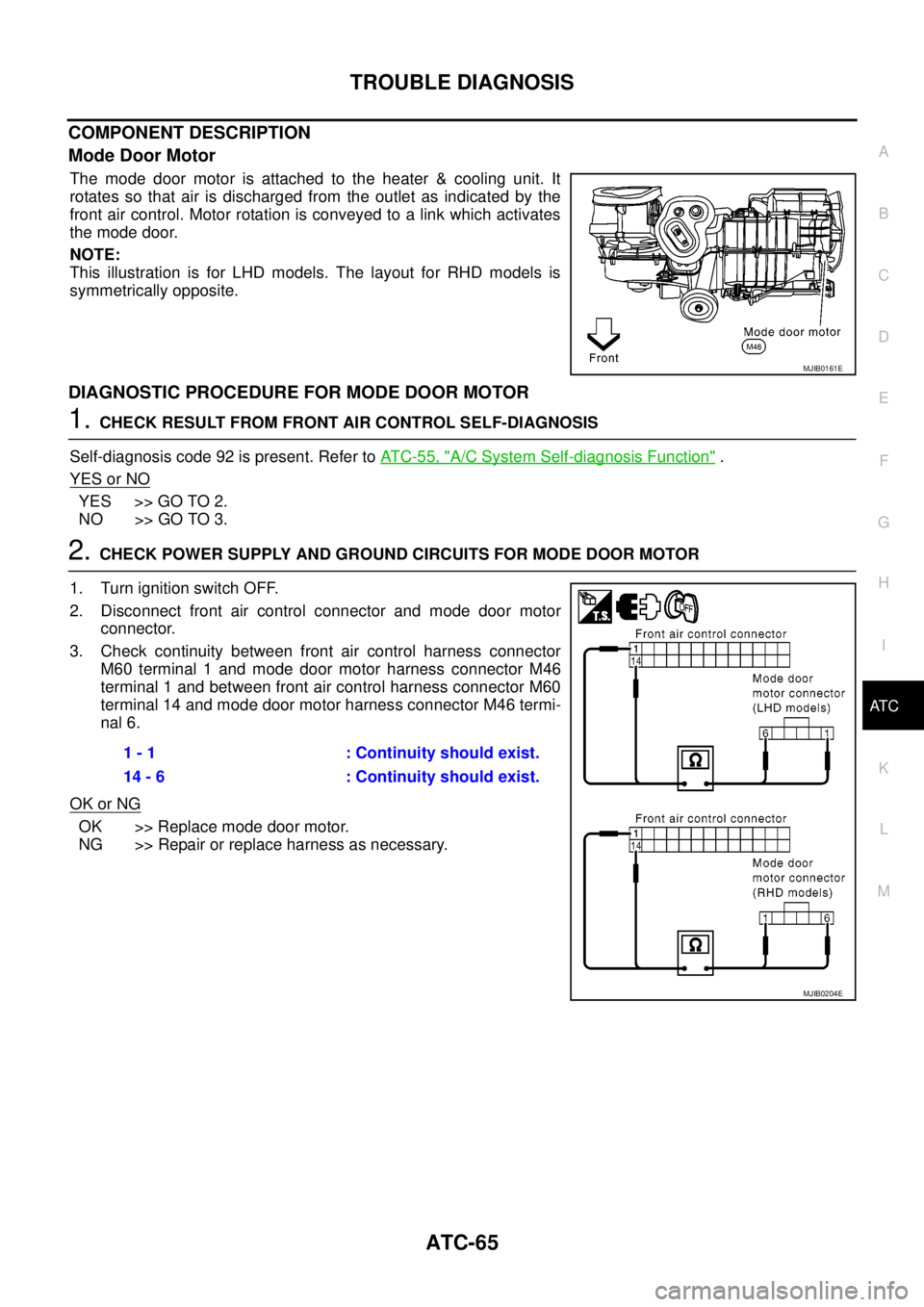

COMPONENT DESCRIPTION

Mode Door Motor

The mode door motor is attached to the heater & cooling unit. It

rotates so that air is discharged from the outlet as indicated by the

front air control. Motor rotation is conveyed to a link which activates

themodedoor.

NOTE:

This illustration is for LHD models. The layout for RHD models is

symmetrically opposite.

DIAGNOSTIC PROCEDURE FOR MODE DOOR MOTOR

1.CHECK RESULT FROM FRONT AIR CONTROL SELF-DIAGNOSIS

Self-diagnosis code 92 is present. Refer toAT C - 5 5 , "

A/C System Self-diagnosis Function".

YES or NO

YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK POWER SUPPLY AND GROUND CIRCUITS FOR MODE DOOR MOTOR

1. Turn ignition switch OFF.

2. Disconnect front air control connector and mode door motor

connector.

3. Check continuity between front air control harness connector

M60 terminal 1 and mode door motor harness connector M46

terminal 1 and between front air control harness connector M60

terminal 14 and mode door motor harness connector M46 termi-

nal 6.

OK or NG

OK >> Replace mode door motor.

NG >> Repair or replace harness as necessary.

MJIB0161E

1 - 1 : Continuity should exist.

14 - 6 : Continuity should exist.

MJIB0204E

Page 404 of 3171

ATC-70

TROUBLE DIAGNOSIS

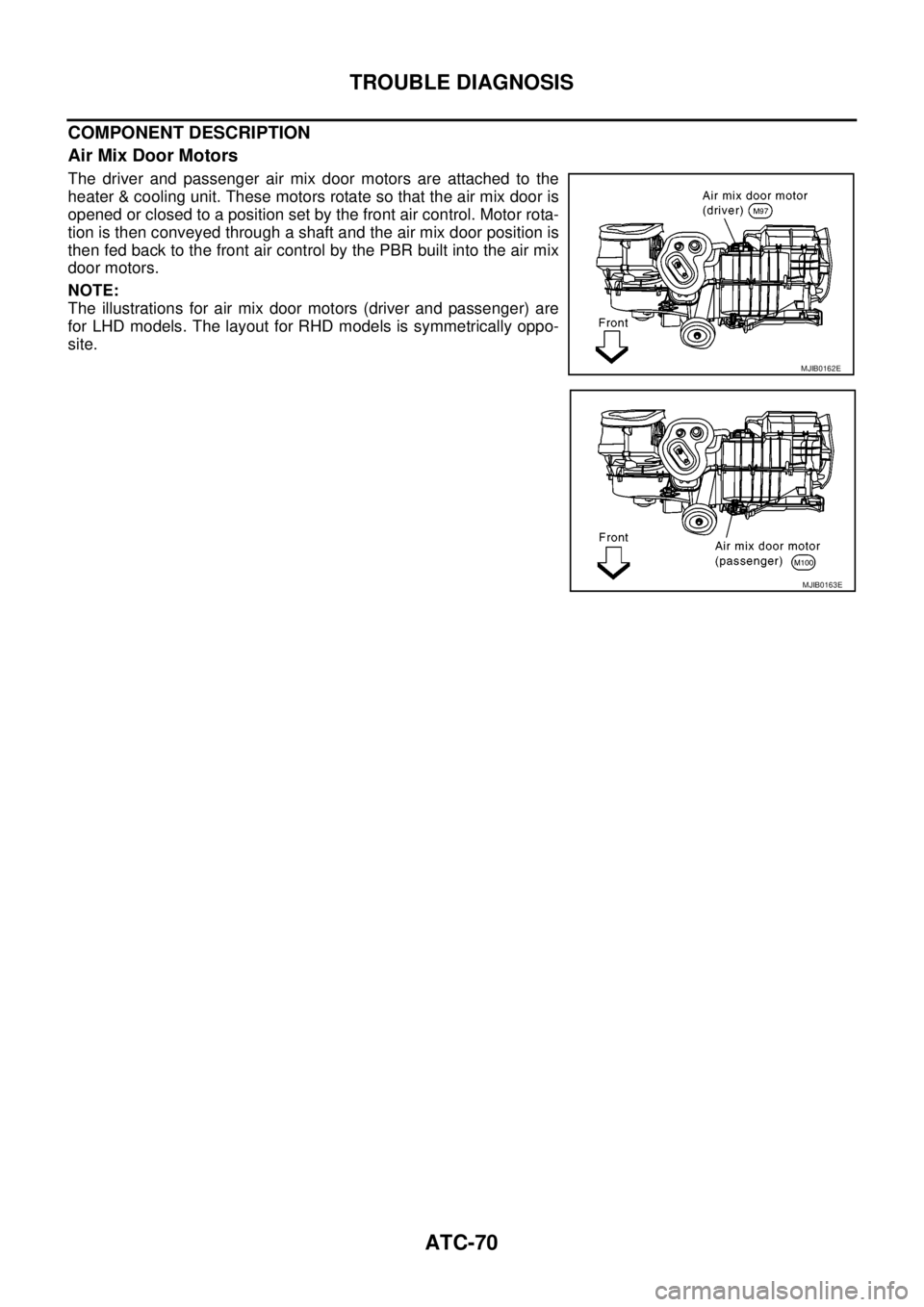

COMPONENT DESCRIPTION

Air Mix Door Motors

The driver and passenger air mix door motors are attached to the

heater & cooling unit. These motors rotate so that the air mix door is

opened or closed to a position set by the front air control. Motor rota-

tion is then conveyed through a shaft and the air mix door position is

then fed back to the front air control by the PBR built into the air mix

door motors.

NOTE:

The illustrations for air mix door motors (driver and passenger) are

for LHD models. The layout for RHD models is symmetrically oppo-

site.

MJIB0162E

MJIB0163E

Page 416 of 3171

ATC-82

TROUBLE DIAGNOSIS

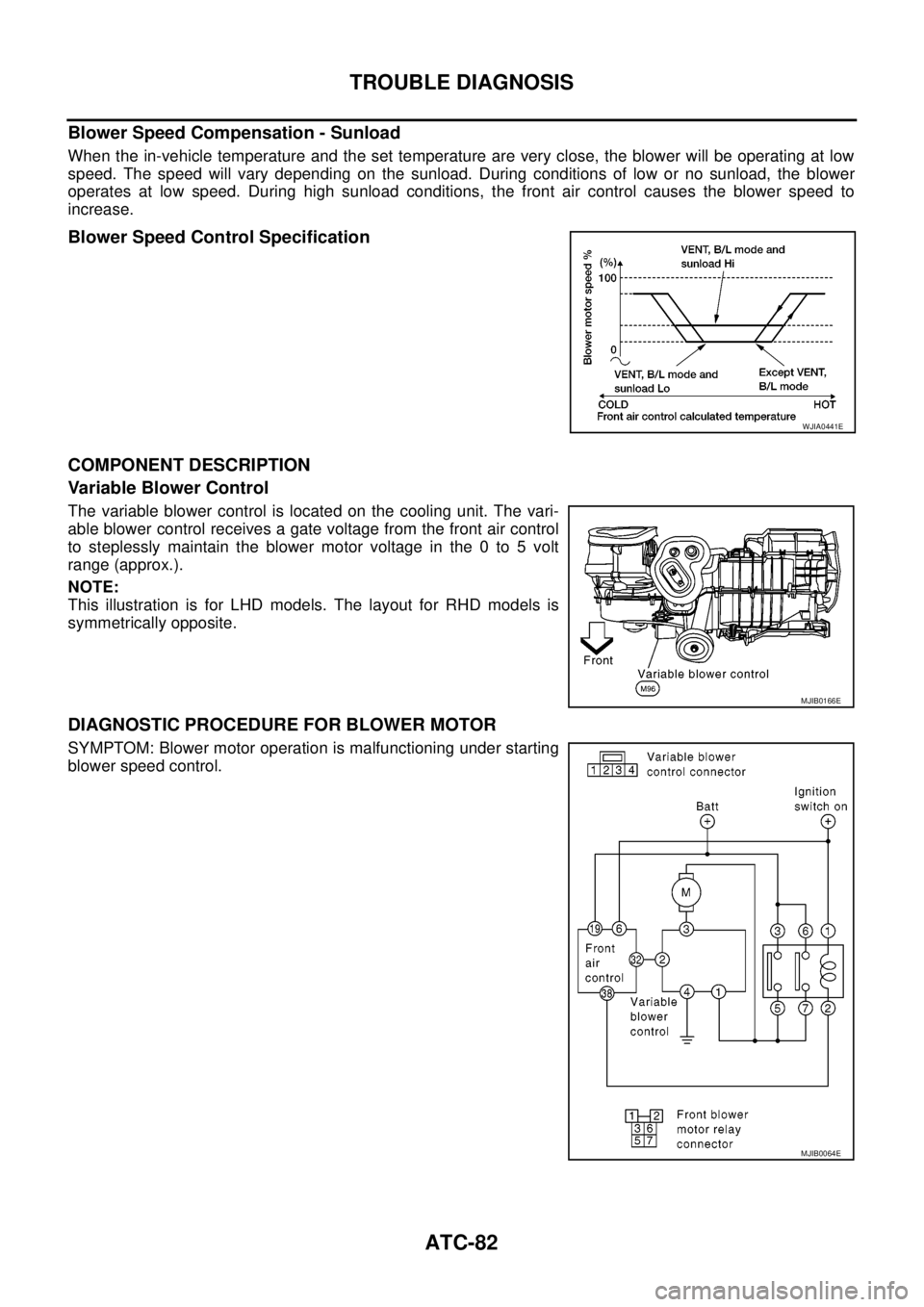

Blower Speed Compensation - Sunload

When the in-vehicle temperature and the set temperature are very close, the blower will be operating at low

speed. The speed will vary depending on the sunload. During conditions of low or no sunload, the blower

operates at low speed. During high sunload conditions, the front air control causes the blower speed to

increase.

Blower Speed Control Specification

COMPONENT DESCRIPTION

Variable Blower Control

The variable blower control is located on the cooling unit. The vari-

able blower control receives a gate voltage from the front air control

to steplessly maintain the blower motor voltage in the 0 to 5 volt

range (approx.).

NOTE:

This illustration is for LHD models. The layout for RHD models is

symmetrically opposite.

DIAGNOSTIC PROCEDURE FOR BLOWER MOTOR

SYMPTOM: Blower motor operation is malfunctioning under starting

blower speed control.

WJIA0441E

MJIB0166E

MJIB0064E

Page 427 of 3171

TROUBLE DIAGNOSIS

ATC-93

C

D

E

F

G

H

I

K

L

MA

B

AT C

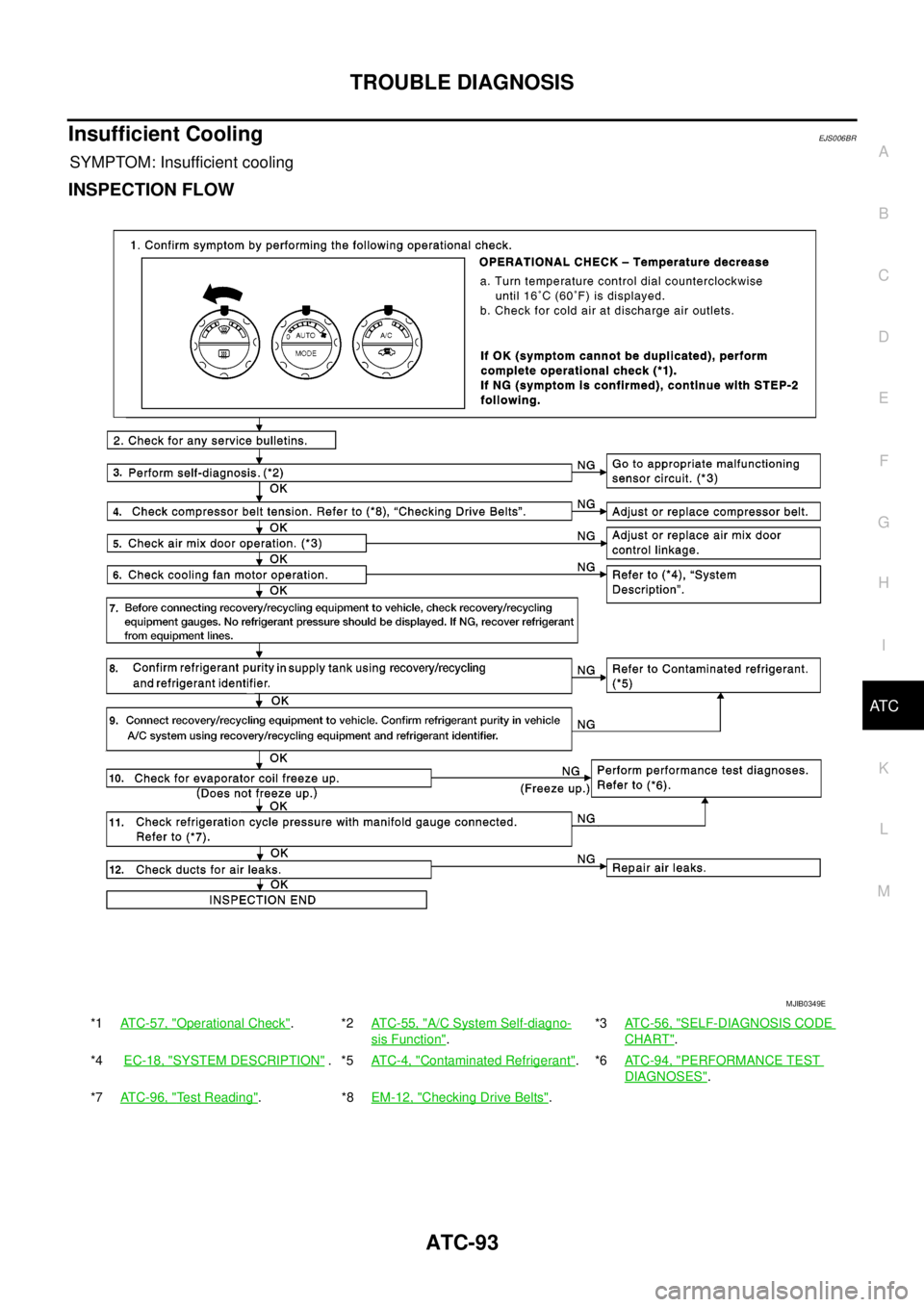

Insufficient CoolingEJS006BR

SYMPTOM: Insufficient cooling

INSPECTION FLOW

*1ATC-57, "Operational Check".*2ATC-55, "A/C System Self-diagno-

sis Function".*3AT C - 5 6 , "

SELF-DIAGNOSIS CODE

CHART".

*4EC-18, "

SYSTEM DESCRIPTION".*5AT C - 4 , "Contaminated Refrigerant".*6AT C - 9 4 , "PERFORMANCE TEST

DIAGNOSES".

*7ATC-96, "

Test Reading".*8EM-12, "Checking Drive Belts".

MJIB0349E

Page 431 of 3171

TROUBLE DIAGNOSIS

ATC-97

C

D

E

F

G

H

I

K

L

MA

B

AT C

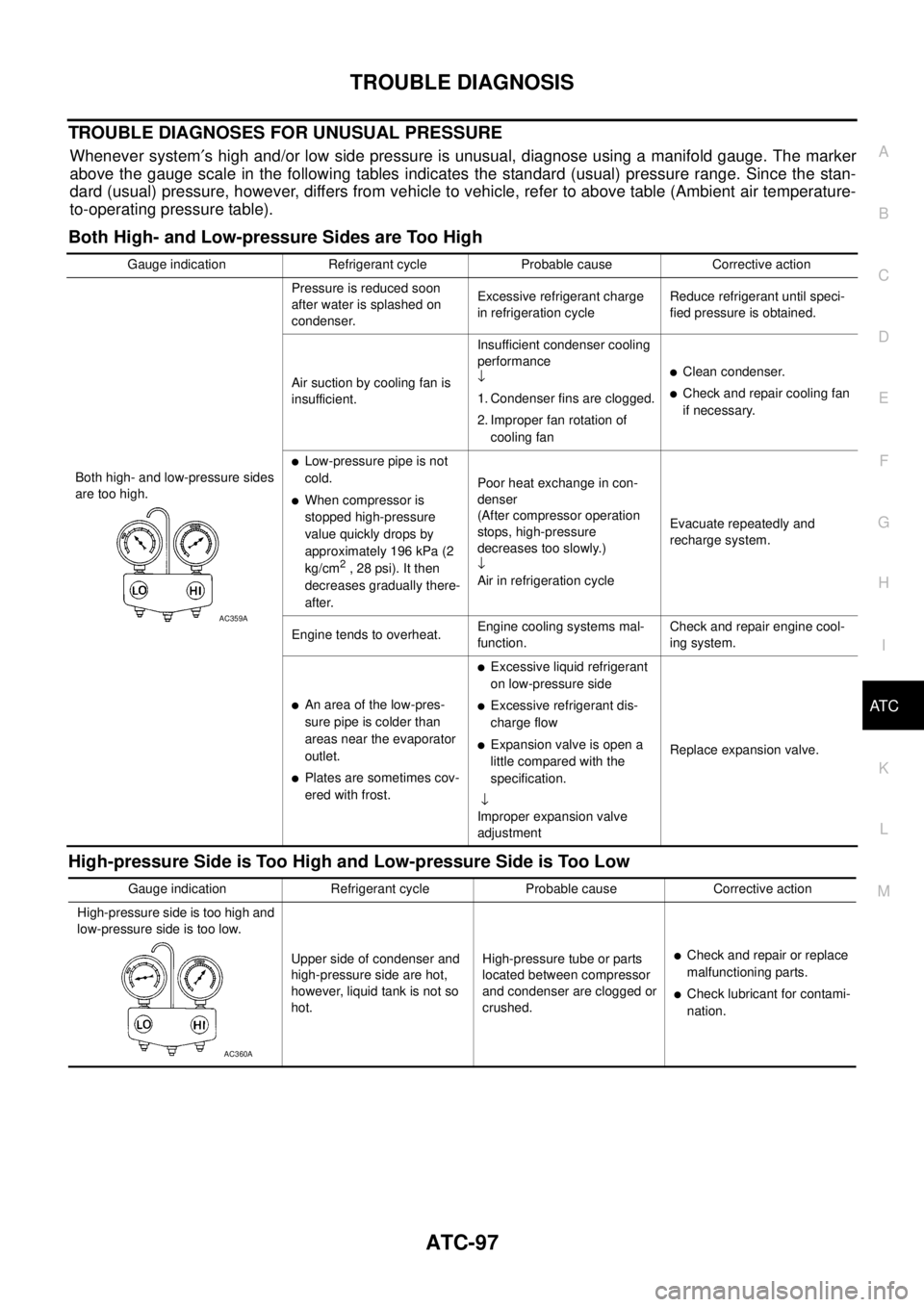

TROUBLE DIAGNOSES FOR UNUSUAL PRESSURE

Whenever system¢s high and/or low side pressure is unusual, diagnose using a manifold gauge. The marker

above the gauge scale in the following tables indicates the standard (usual) pressure range. Since the stan-

dard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air temperature-

to-operating pressure table).

Both High- and Low-pressure Sides are Too High

High-pressure Side is Too High and Low-pressure Side is Too Low

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure sides

are too high.Pressure is reduced soon

after water is splashed on

condenser.Excessive refrigerant charge

in refrigeration cycleReduce refrigerant until speci-

fied pressure is obtained.

Air suction by cooling fan is

insufficient.Insufficient condenser cooling

performance

¯

1. Condenser fins are clogged.

2. Improper fan rotation of

cooling fan

lClean condenser.

lCheck and repair cooling fan

if necessary.

lLow-pressure pipe is not

cold.

lWhen compressor is

stopped high-pressure

value quickly drops by

approximately 196 kPa (2

kg/cm

2, 28 psi). It then

decreases gradually there-

after.Poor heat exchange in con-

denser

(After compressor operation

stops, high-pressure

decreases too slowly.)

¯

Air in refrigeration cycleEvacuate repeatedly and

recharge system.

Engine tends to overheat.Engine cooling systems mal-

function.Check and repair engine cool-

ing system.

lAn area of the low-pres-

sure pipe is colder than

areas near the evaporator

outlet.

lPlates are sometimes cov-

ered with frost.

lExcessive liquid refrigerant

on low-pressure side

lExcessive refrigerant dis-

charge flow

lExpansion valve is open a

little compared with the

specification.

¯

Improper expansion valve

adjustmentReplace expansion valve.

AC359A

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too high and

low-pressure side is too low.

Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tube or parts

located between compressor

and condenser are clogged or

crushed.

lCheck and repair or replace

malfunctioning parts.

lCheck lubricant for contami-

nation.

AC360A

Page 433 of 3171

TROUBLE DIAGNOSIS

ATC-99

C

D

E

F

G

H

I

K

L

MA

B

AT C

Low-pressure Side Sometimes Becomes Negative

Low-pressure Side Becomes Negative

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side sometimes

becomes negative.

lAir conditioning system

does not function and does

not cyclically cool the com-

partment air.

lThe system constantly func-

tions for a certain period of

time after compressor is

stopped and restarted.Refrigerant does not dis-

charge cyclically.

¯

Moisture is frozen at expan-

sion valve outlet and inlet.

¯

Water is mixed with refriger-

ant.

lDrain water from refrigerant

or replace refrigerant.

lReplace liquid tank.

AC354A

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side becomes nega-

tive.

Liquid tank or front/rear side of

expansion valve¢spipeis

frosted or dewed.High-pressure side is closed

and refrigerant does not flow.

¯

Expansion valve or liquid tank

is frosted.Leave the system at rest until

no frost is present. Start it

again to check whether or not

the malfunction is caused by

water or foreign particles.

lIf water is the cause, initially

cooling is okay. Then the

water freezes causing a

blockage. Drain water from

refrigerant or replace refrig-

erant.

lIf due to foreign particles,

remove expansion valve

and remove the particles

with dry and compressed air

(not shop air).

lIf either of the above meth-

ods cannot correct the mal-

function, replace expansion

valve.

lReplace liquid tank.

lCheck lubricant for contami-

nation.

AC362A

Page 448 of 3171

ATC-114

TROUBLE DIAGNOSIS

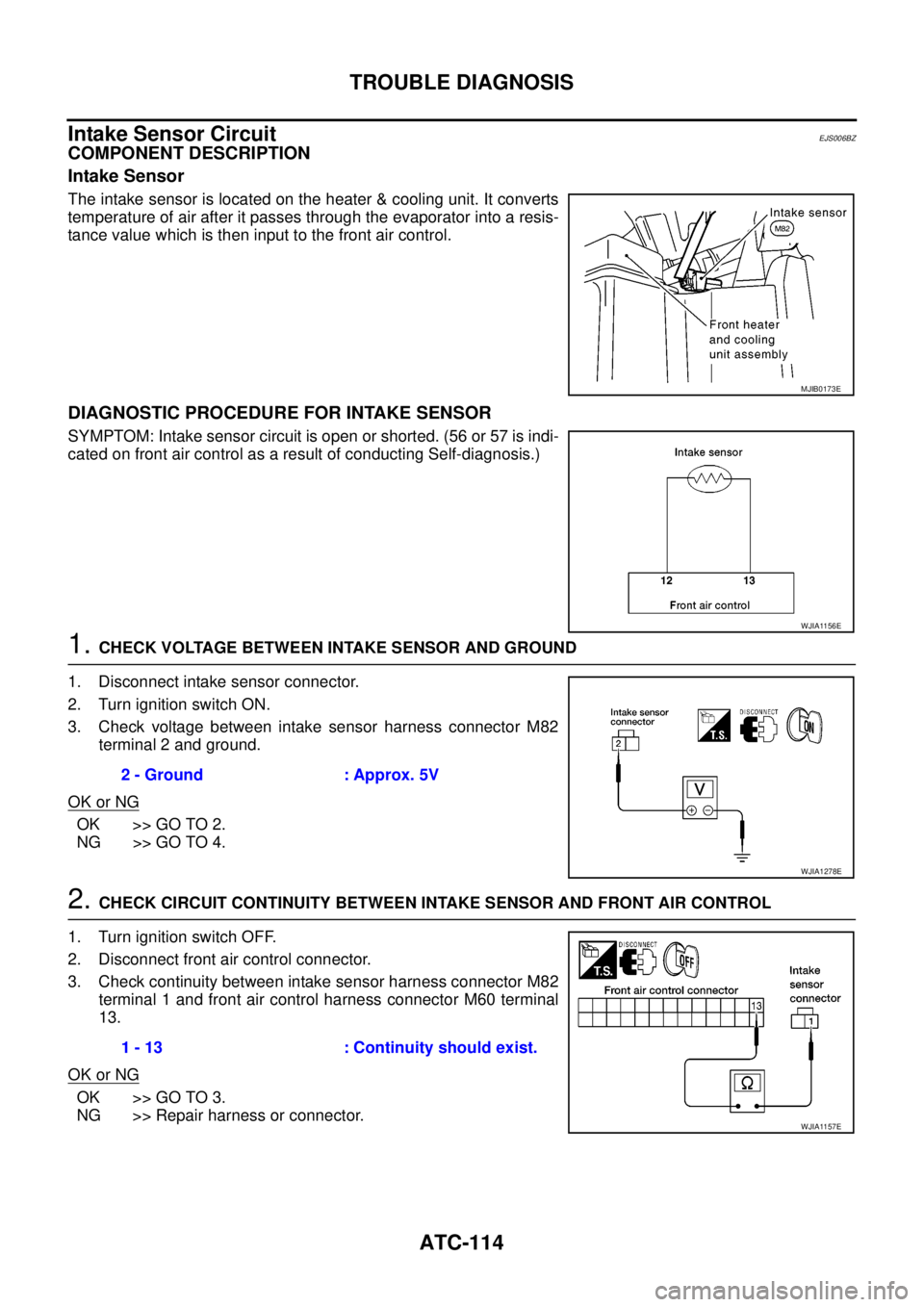

Intake Sensor Circuit

EJS006BZ

COMPONENT DESCRIPTION

Intake Sensor

The intake sensor is located on the heater & cooling unit. It converts

temperature of air after it passes through the evaporator into a resis-

tance value which is then input to the front air control.

DIAGNOSTIC PROCEDURE FOR INTAKE SENSOR

SYMPTOM: Intake sensor circuit is open or shorted. (56 or 57 is indi-

cated on front air control as a result of conducting Self-diagnosis.)

1.CHECK VOLTAGE BETWEEN INTAKE SENSOR AND GROUND

1. Disconnect intake sensor connector.

2. Turn ignition switch ON.

3. Check voltage between intake sensor harness connector M82

terminal 2 and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2.CHECK CIRCUIT CONTINUITY BETWEEN INTAKE SENSOR AND FRONT AIR CONTROL

1. Turn ignition switch OFF.

2. Disconnect front air control connector.

3. Check continuity between intake sensor harness connector M82

terminal 1 and front air control harness connector M60 terminal

13.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

MJIB0173E

WJIA1156E

2 - Ground : Approx. 5V

WJIA1278E

1 - 13 : Continuity should exist.

WJIA1157E

Page 454 of 3171

ATC-120

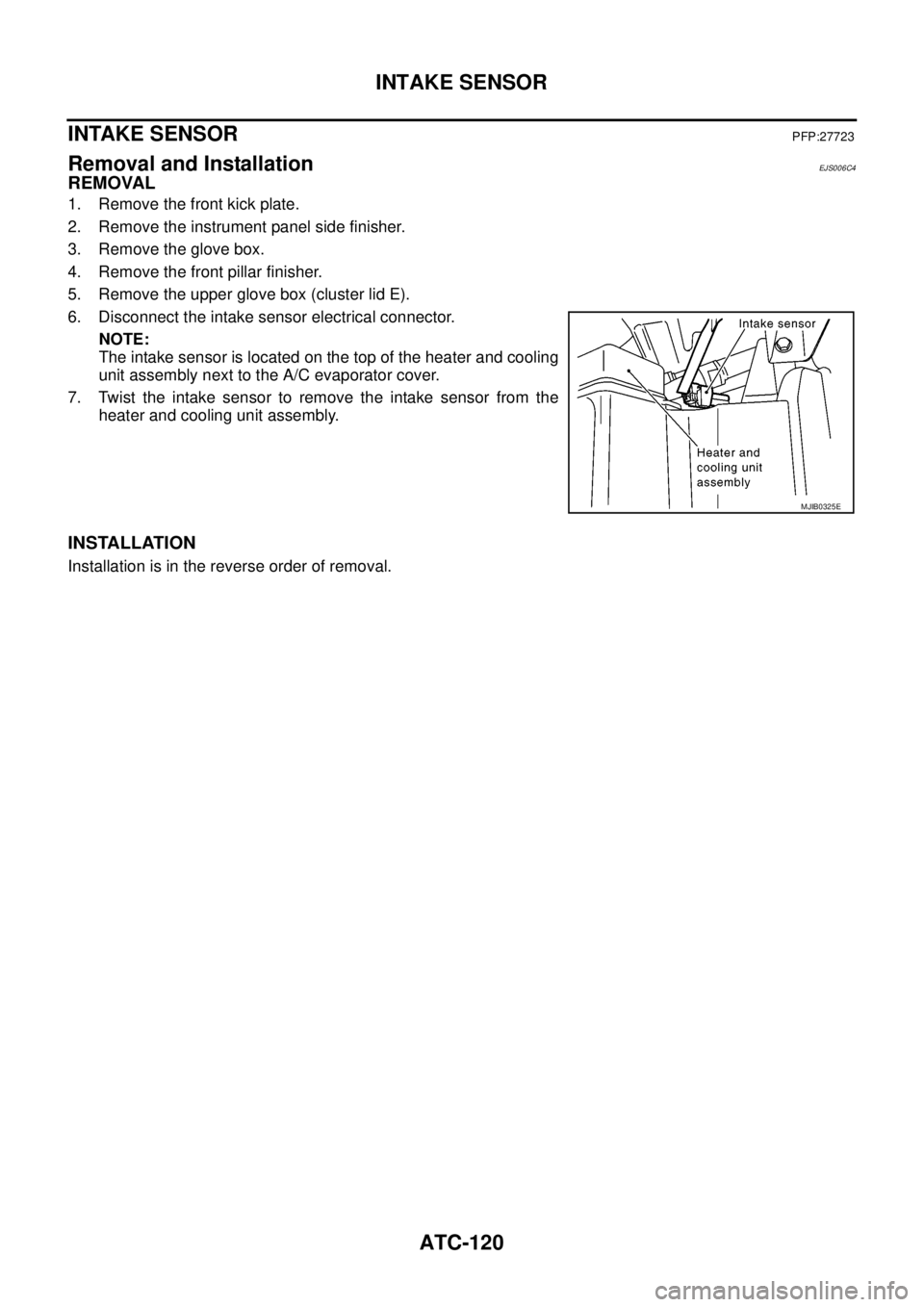

INTAKE SENSOR

INTAKE SENSOR

PFP:27723

Removal and InstallationEJS006C4

REMOVAL

1. Remove the front kick plate.

2. Remove the instrument panel side finisher.

3. Remove the glove box.

4. Remove the front pillar finisher.

5. Remove the upper glove box (cluster lid E).

6. Disconnect the intake sensor electrical connector.

NOTE:

The intake sensor is located on the top of the heater and cooling

unit assembly next to the A/C evaporator cover.

7. Twist the intake sensor to remove the intake sensor from the

heater and cooling unit assembly.

INSTALLATION

Installation is in the reverse order of removal.

MJIB0325E

Page 455 of 3171

BLOWER MOTOR

ATC-121

C

D

E

F

G

H

I

K

L

MA

B

AT C

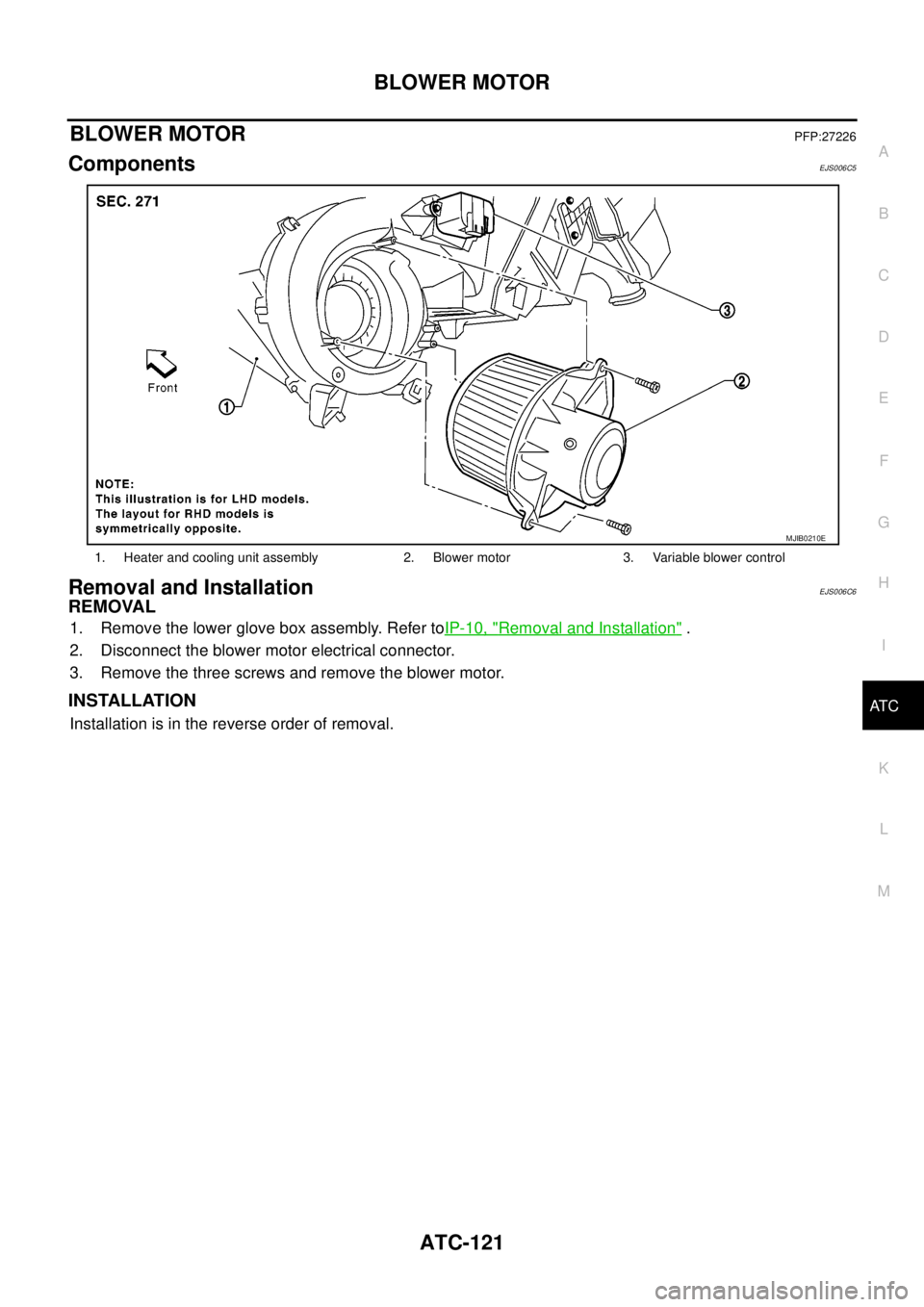

BLOWER MOTORPFP:27226

ComponentsEJS006C5

Removal and InstallationEJS006C6

REMOVAL

1. Remove the lower glove box assembly. Refer toIP-10, "Removal and Installation".

2. Disconnect the blower motor electrical connector.

3. Remove the three screws and remove the blower motor.

INSTALLATION

Installation is in the reverse order of removal.

1. Heater and cooling unit assembly 2. Blower motor 3. Variable blower control

MJIB0210E