cooling NISSAN NAVARA 2005 Repair Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 467 of 3171

VARIABLE BLOWER CONTROL

ATC-133

C

D

E

F

G

H

I

K

L

MA

B

AT C

VARIABLE BLOWER CONTROLPFP:27200

ComponentsEJS006CH

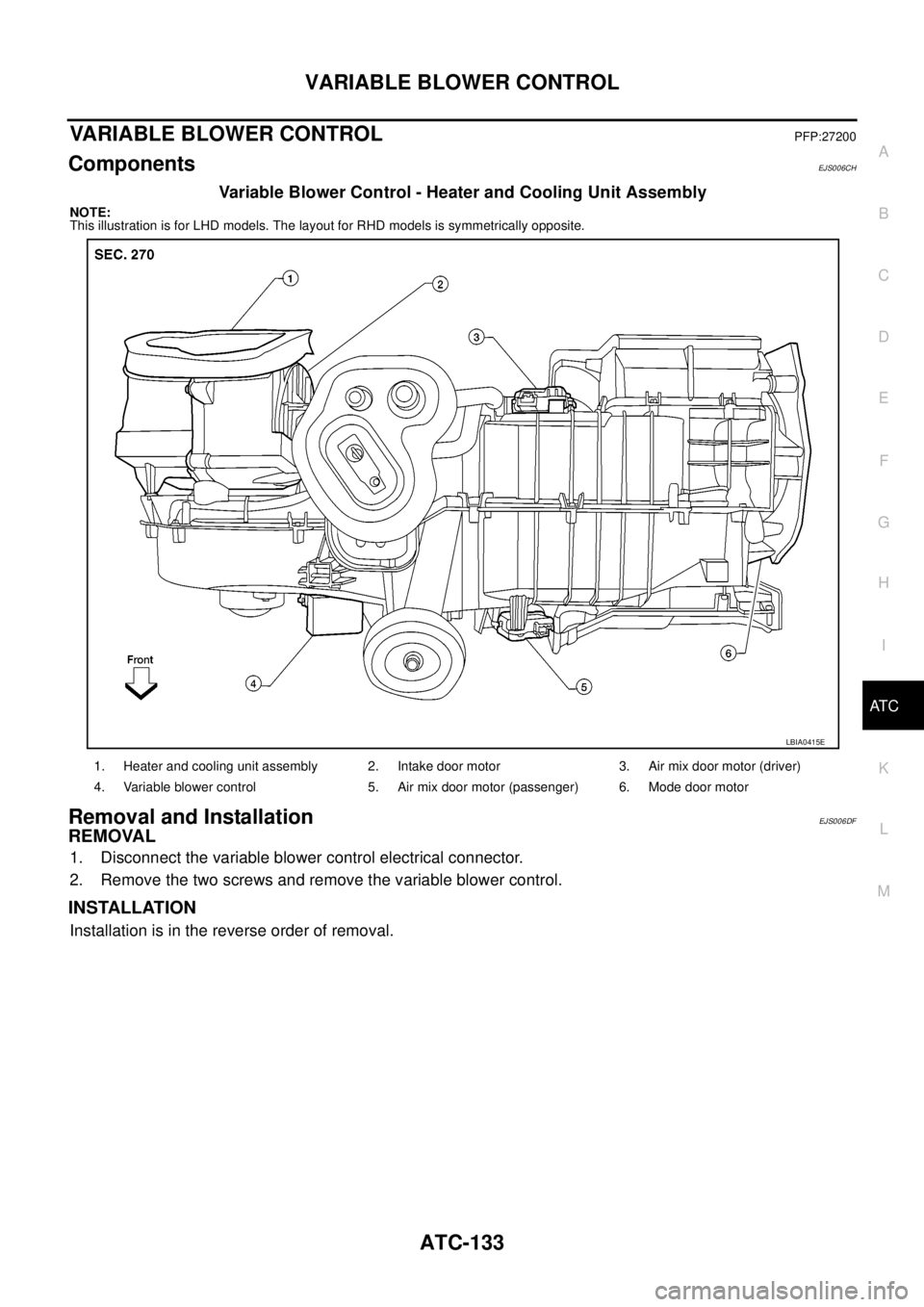

Variable Blower Control - Heater and Cooling Unit Assembly

NOTE:

This illustration is for LHD models. The layout for RHD models is symmetrically opposite.

Removal and InstallationEJS006DF

REMOVAL

1. Disconnect the variable blower control electrical connector.

2. Remove the two screws and remove the variable blower control.

INSTALLATION

Installation is in the reverse order of removal.

1. Heater and cooling unit assembly 2. Intake door motor 3. Air mix door motor (driver)

4. Variable blower control 5. Air mix door motor (passenger) 6. Mode door motor

LBIA0415E

Page 468 of 3171

ATC-134

DUCTS AND GRILLES

DUCTS AND GRILLES

PFP:27860

ComponentsEJS006CJ

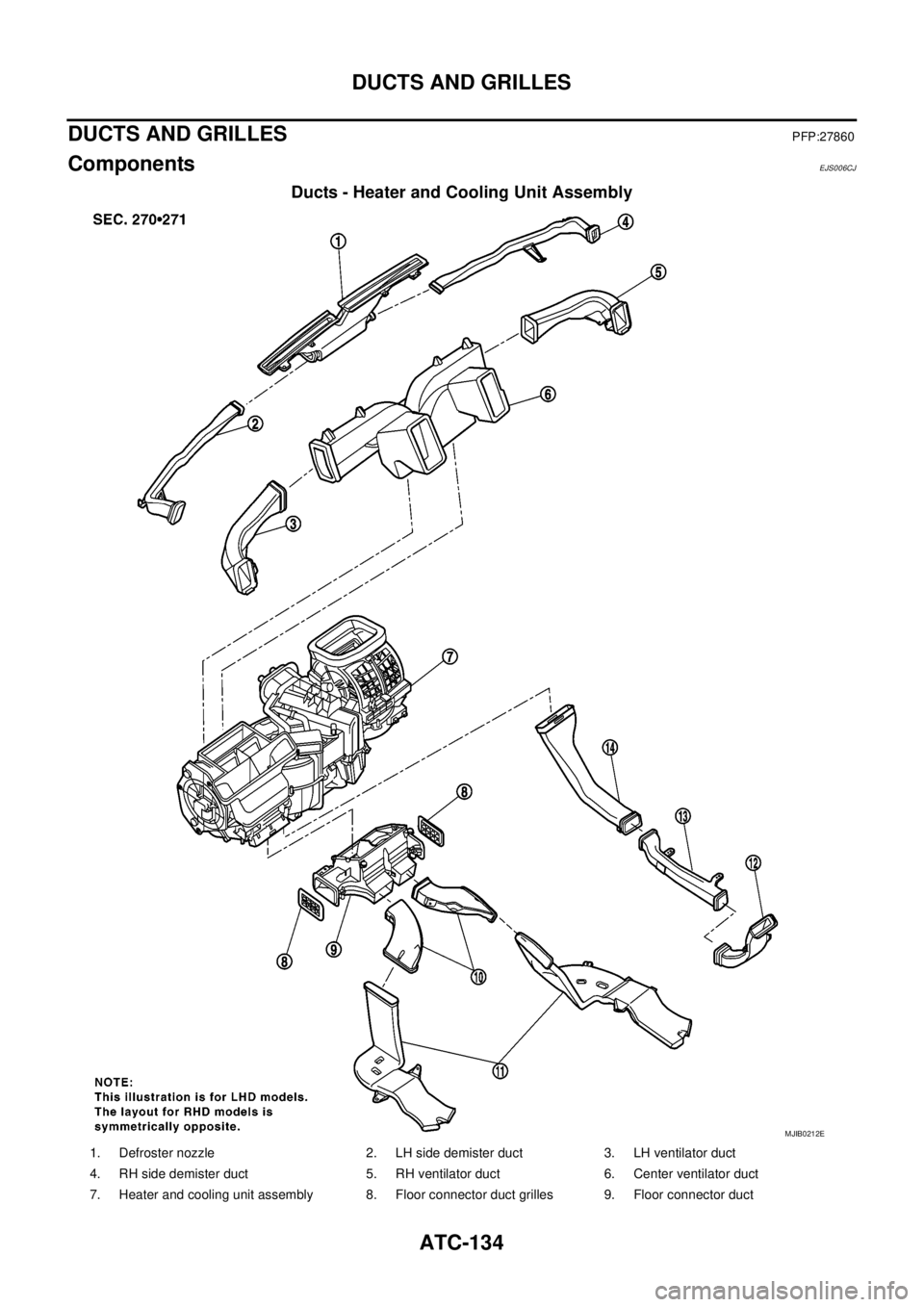

Ducts - Heater and Cooling Unit Assembly

MJIB0212E

1. Defroster nozzle 2. LH side demister duct 3. LH ventilator duct

4. RH side demister duct 5. RH ventilator duct 6. Center ventilator duct

7. Heater and cooling unit assembly 8. Floor connector duct grilles 9. Floor connector duct

Page 470 of 3171

ATC-136

DUCTS AND GRILLES

Removal and Installation

EJS006CK

CONSOLE DUCTS AND CONSOLE GRILLE

Removal

The center console must be removed and disassembled to remove the console ducts and the console grille.

Refer toIP-16, "

CENTER CONSOLE".

Installation

Installation is in the reverse order of removal.

DEFROSTER NOZZLE

Removal

1. Remove the instrument panel trim. Refer toIP-10, "Removal and Installation".

2. Remove the defroster nozzle.

Installation

Installation is in the reverse order of removal.

RH AND LH SIDE DEMISTER DUCT

Removal

1. Remove the instrument panel trim. Refer toIP-10, "Removal and Installation".

2. Remove the center console. Refer toIP-16, "

CENTER CONSOLE".

3. Remove the RH or LH side demister duct.

Installation

Installation is in the reverse order of removal.

RH AND LH VENTILATOR DUCT

Removal

1. Remove the instrument panel trim. Refer toIP-10, "Removal and Installation".

2. Remove the center console. Refer toIP-16, "

CENTER CONSOLE".

3. Remove the RH or LH ventilator duct.

Installation

Installation is in the reverse order of removal.

CENTER VENTILATOR DUCT

Removal

1. Remove the heater and cooling unit assembly. Refer toATC-126, "REMOVAL".

2. Remove the center console. Refer toIP-16, "

CENTER CONSOLE".

3. Remove the defroster nozzle.

4. Remove the RH and LH ventilator ducts.

5. Remove the RH and LH side demister ducts.

6. Remove the center ventilator duct.

Installation

Installation is in the reverse order of removal.

FLOOR CONNECTOR DUCT

Removal

1. Remove the heater and cooling unit assembly. Refer toATC-126, "REMOVAL".

2. Remove the center console. Refer toIP-16, "

CENTER CONSOLE".

3. Remove the floor connector duct.

Installation

Installation is in the reverse order of removal.

Page 483 of 3171

REFRIGERANT LINES

ATC-149

C

D

E

F

G

H

I

K

L

MA

B

AT C

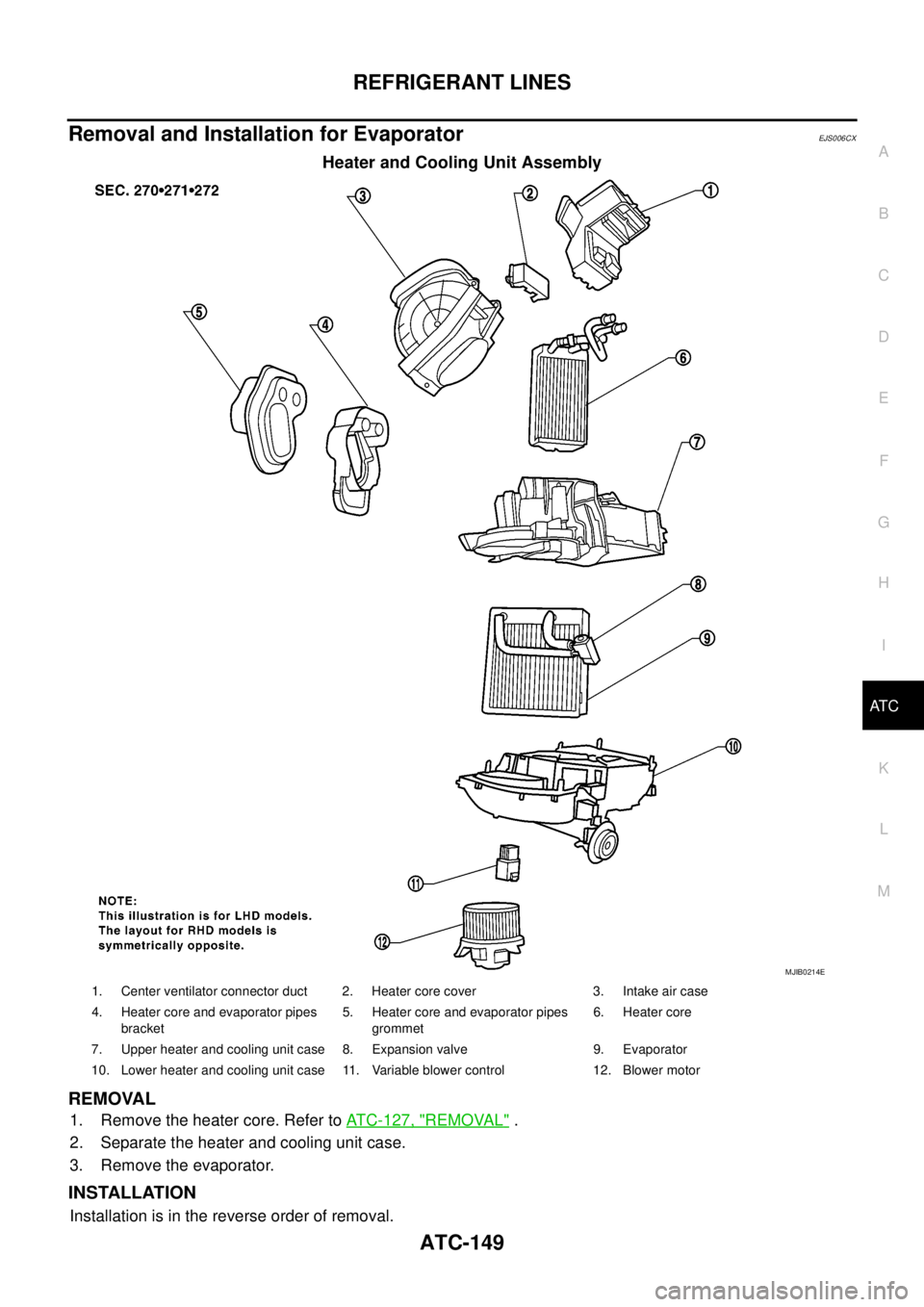

Removal and Installation for EvaporatorEJS006CX

Heater and Cooling Unit Assembly

REMOVAL

1. Remove the heater core. Refer toATC-127, "REMOVAL".

2. Separate the heater and cooling unit case.

3. Remove the evaporator.

INSTALLATION

Installation is in the reverse order of removal.

MJIB0214E

1. Center ventilator connector duct 2. Heater core cover 3. Intake air case

4. Heater core and evaporator pipes

bracket5. Heater core and evaporator pipes

grommet6. Heater core

7. Upper heater and cooling unit case 8. Expansion valve 9. Evaporator

10. Lower heater and cooling unit case 11. Variable blower control 12. Blower motor

Page 484 of 3171

ATC-150

REFRIGERANT LINES

CAUTION:

Replace the O-rings on the A/C low-pressure flexible A/C hose and the high-pressure A/C pipe with

new ones. Apply compressor oil to the O-rings for installation.

Removal and Installation for Expansion ValveEJS006CZ

REMOVAL

1. Discharge the refrigerant. Refer toATC-138, "HFC-134a (R-134a) Service Procedure".

2. Remove the heater and cooling unit assembly. Refer toATC-126, "

REMOVAL".

3. Remove the heater core and evaporator pipes grommet.

4. Remove the expansion valve.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

lReplace the O-rings on then expansion valve and the A/C refrigerant pipes with new ones, then

apply compressor oil to them for installation.

lAfter charging refrigerant, check for leaks.

Checking for Refrigerant LeaksEJS006D1

Perform a visual inspection of all refrigeration parts, fittings, hoses and components for signs of A/C lubricant

leakage, damage and corrosion. A/C lubricant leakage may indicate an area of refrigerant leakage. Allow

extra inspection time in these areas when using either an electronic refrigerant leak detector or fluorescent

dye leak detector.

If dye is observed, confirm the leak with an electronic refrigerant leak detector. It is possible a prior leak was

repaired and not properly cleaned.

When searching for leaks, do not stop when one leak is found but continue to check for additional leaks at all

system components and connections.

When searching for refrigerant leaks using an electronic leak detector, move the probe along the suspected

leak area at 1 to 2 inches per second and no further than 1/4 inch from the component.

CAUTION:

Moving the electronic leak detector probe slower and closer to the suspected leak area will improve

the chances of finding a leak.

Checking System for Leaks Using the Fluorescent Leak DetectorEJS006D2

1. Check A/C system for leaks using the UV lamp and safety goggles [SST: J-42220] in a low sunlight area

(area without windows preferable). Illuminate all components, fittings and lines. The dye will appear as a

bright green/yellow area at the point of leakage. Fluorescent dye observed at the evaporator drain open-

ing indicates an evaporator core assembly (tubes, core or expansion valve) leak.

2. If the suspected area is difficult to see, use an adjustable mirror or wipe the area with a clean shop rag or

cloth, with the UV lamp for dye residue.

3. After the leak is repaired, remove any residual dye using dye cleaner [SST: J-43872] to prevent future mis-

diagnosis.

4. Perform a system performance check and verify the leak repair with an approved electronic refrigerant

leak detector.

NOTE:

Other gases in the work area or substances on the A/C components, for example, anti-freeze, windshield

washer fluid, solvents and lubricants, may falsely trigger the leak detector. Make sure the surfaces to be

checked are clean.

Cleanwithadryclothorblowoffwithshopair.

Do not allow the sensor tip of the detector to contact with any substance. This can also cause false readings

and may damage the detector.Expansion valve bolts : 4 N·m (0.41 kg-m, 35 in-lb)

A/C refrigerant pipe to expansion valve bolt : Refer toATC-140, "

Components"

.

Page 486 of 3171

ATC-152

REFRIGERANT LINES

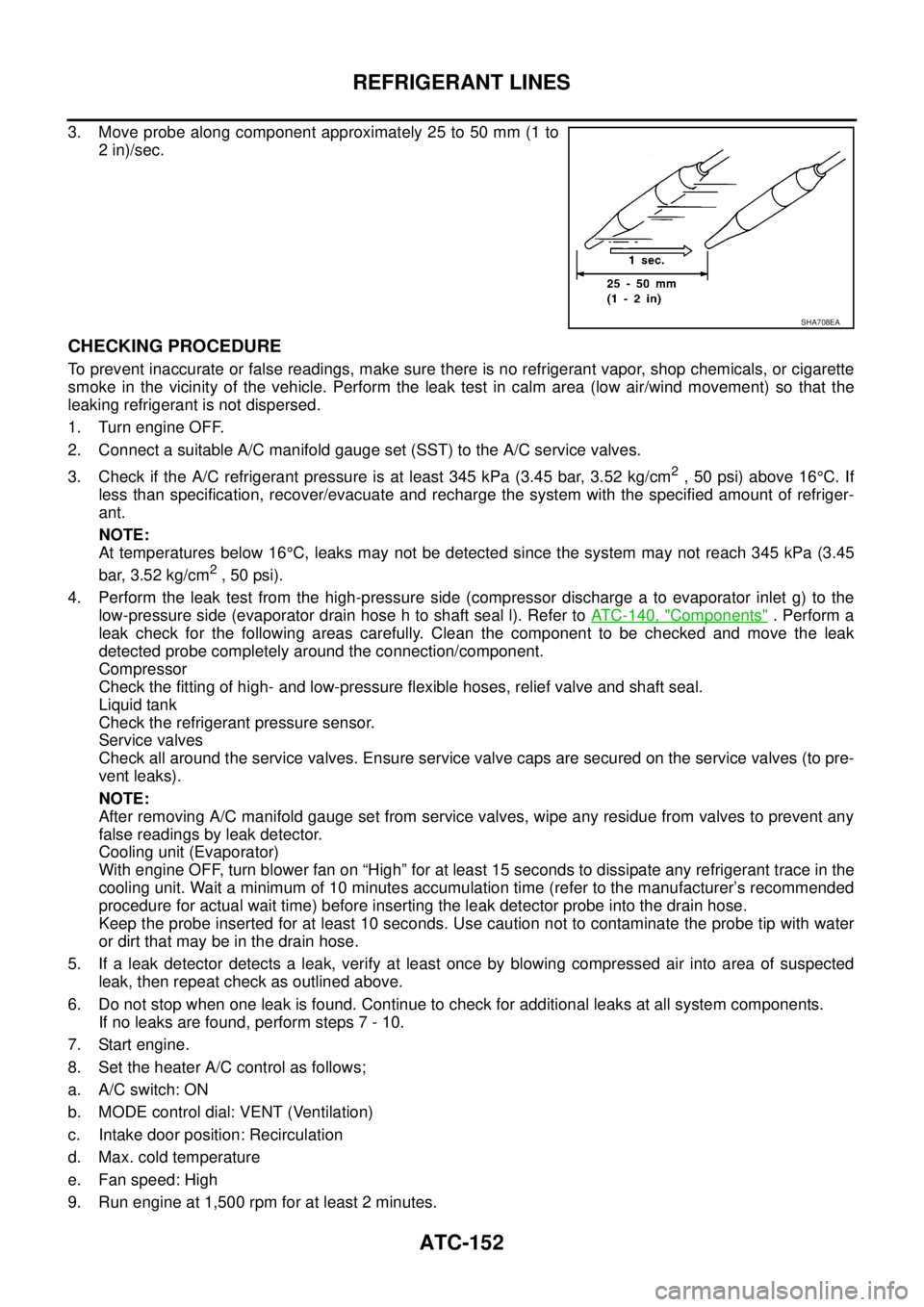

3. Move probe along component approximately 25 to 50 mm (1 to

2 in)/sec.

CHECKING PROCEDURE

To prevent inaccurate or false readings, make sure there is no refrigerant vapor, shop chemicals, or cigarette

smoke in the vicinity of the vehicle. Perform the leak test in calm area (low air/wind movement) so that the

leaking refrigerant is not dispersed.

1. Turn engine OFF.

2. Connect a suitable A/C manifold gauge set (SST) to the A/C service valves.

3. Check if the A/C refrigerant pressure is at least 345 kPa (3.45 bar, 3.52 kg/cm

2,50psi)above16°C. If

less than specification, recover/evacuate and recharge the system with the specified amount of refriger-

ant.

NOTE:

At temperatures below 16°C, leaks may not be detected since the system may not reach 345 kPa (3.45

bar, 3.52 kg/cm

2,50psi).

4. Perform the leak test from the high-pressure side (compressor discharge a to evaporator inlet g) to the

low-pressure side (evaporator drain hose h to shaft seal l). Refer toATC-140, "

Components". Perform a

leak check for the following areas carefully. Clean the component to be checked and move the leak

detected probe completely around the connection/component.

Compressor

Check the fitting of high- and low-pressure flexible hoses, relief valve and shaft seal.

Liquid tank

Check the refrigerant pressure sensor.

Service valves

Check all around the service valves. Ensure service valve caps are secured on the service valves (to pre-

vent leaks).

NOTE:

After removing A/C manifold gauge set from service valves, wipe any residue from valves to prevent any

false readings by leak detector.

Cooling unit (Evaporator)

With engine OFF, turn blower fan on “High” for at least 15 seconds to dissipate any refrigerant trace in the

cooling unit. Wait a minimum of 10 minutes accumulation time (refer to the manufacturer’s recommended

procedure for actual wait time) before inserting the leak detector probe into the drain hose.

Keep the probe inserted for at least 10 seconds. Use caution not to contaminate the probe tip with water

or dirt that may be in the drain hose.

5. If a leak detector detects a leak, verify at least once by blowing compressed air into area of suspected

leak, then repeat check as outlined above.

6. Do not stop when one leak is found. Continue to check for additional leaks at all system components.

If no leaks are found, perform steps 7 - 10.

7. Start engine.

8. Set the heater A/C control as follows;

a. A/C switch: ON

b. MODE control dial: VENT (Ventilation)

c. Intake door position: Recirculation

d. Max. cold temperature

e. Fan speed: High

9. Run engine at 1,500 rpm for at least 2 minutes.

SHA708EA

Page 885 of 3171

CO-1

ENGINE COOLING SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTIONCO

A

CO

ENGINE COOLING SYSTEM

PRECAUTIONS .......................................................... 2

Precautions For Liquid Gasket ................................. 2

LIQUID GASKET APPLICATION PROCEDURE..... 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 3

OVERHEATING CAUSE ANALYSIS .......................... 4

Troubleshooting Chart .............................................. 4

COOLING SYSTEM .................................................... 6

Cooling Circuit .......................................................... 6

ENGINE COOLANT .................................................... 7

Inspection ................................................................. 7

LEVEL CHECK ..................................................... 7

CHECKING RADIATOR SYSTEM FOR LEAKS..... 7

Changing Engine Coolant ........................................ 7

DRAINING ENGINE COOLANT ........................... 8

REFILLING ENGINE COOLANT .......................... 8

FLUSHING COOLING SYSTEM ........................... 9

RADIATOR .................................................................11

Components ............................................................ 11

Removal and Installation ......................................... 11

REMOVAL ............................................................ 11

INSPECTION AFTER REMOVAL ....................... 13

INSTALLATION ................................................... 14

INSPECTION AFTER INSTALLATION ............... 14

RADIATOR (ALUMINUM TYPE) .............................. 15

Components ........................................................... 15

Disassembly and Assembly ................................... 15

PREPARATION ................................................... 15

DISASSEMBLY ................................................... 15

ASSEMBLY ......................................................... 16

INSPECTION ...................................................... 18COOLING FAN .......................................................... 19

Components (Crankshaft Driven Type) .................. 19

Removal and Installation ........................................ 19

REMOVAL ........................................................... 19

INSPECTION AFTER REMOVAL ....................... 19

INSTALLATION ................................................... 19

Removal and Installation (Motor Driven Type) (Mod-

els with A/C) ........................................................... 19

REMOVAL ........................................................... 19

INSTALLATION ................................................... 20

WATER PUMP .......................................................... 21

Components ........................................................... 21

Removal and Installation ........................................ 21

REMOVAL ........................................................... 21

INSPECTION AFTER REMOVAL ....................... 22

INSTALLATION ................................................... 22

INSPECTION AFTER INSTALLATION ................ 22

THERMOSTAT AND WATER PIPING ...................... 23

Components ........................................................... 23

Removal and Installation ........................................ 24

REMOVAL ........................................................... 24

INSPECTION AFTER REMOVAL ....................... 24

INSTALLATION ................................................... 24

INSPECTION AFTER INSTALLATION ................ 25

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 26

Standard and Limit .................................................. 26

ENGINE COOLANT CAPACITY .......................... 26

THERMOSTAT .................................................... 26

RESERVOIR TANK ............................................. 26

Page 888 of 3171

CO-4

OVERHEATING CAUSE ANALYSIS

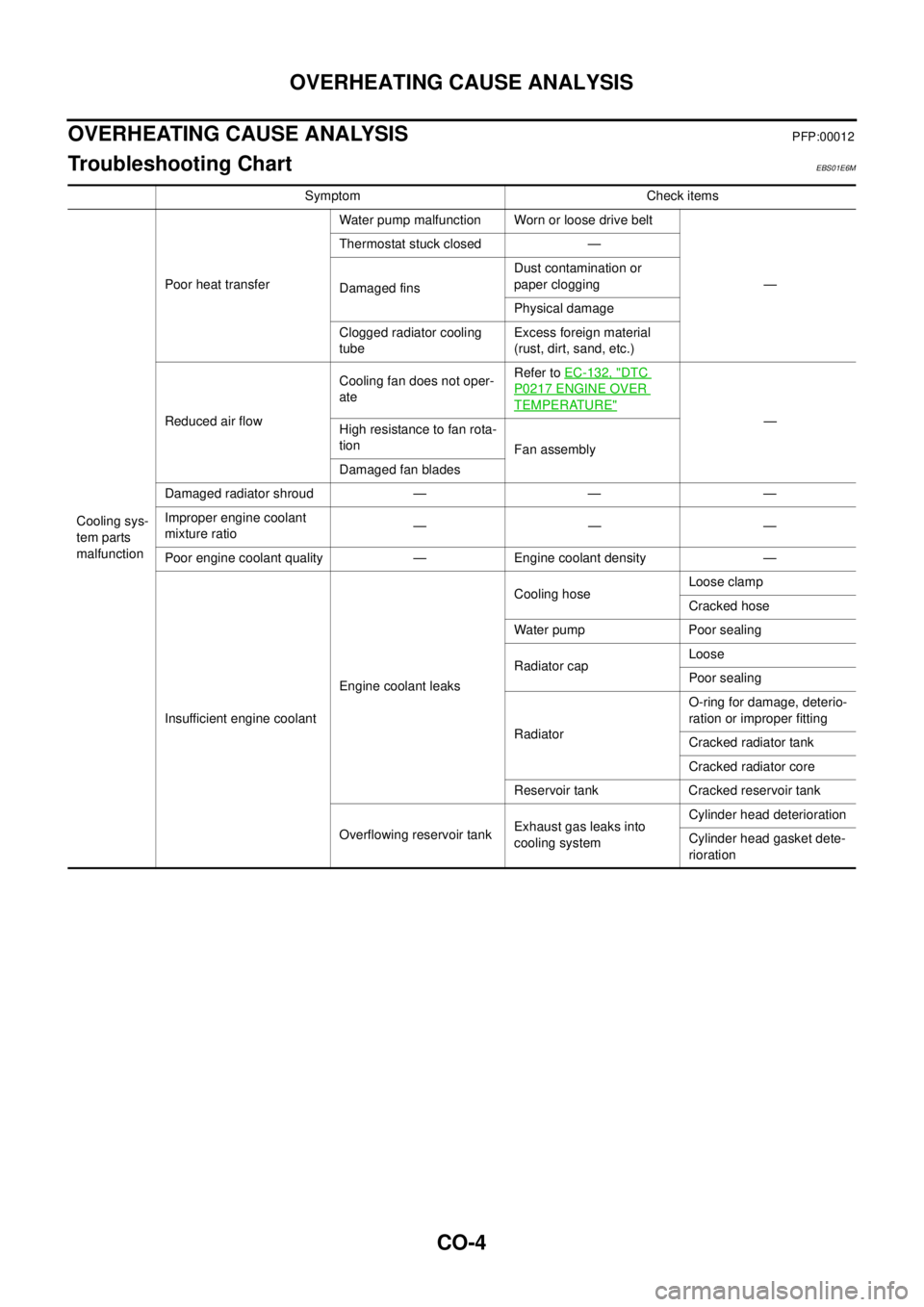

OVERHEATING CAUSE ANALYSIS

PFP:00012

Troubleshooting ChartEBS01E6M

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

— Thermostat stuck closed —

Damaged finsDust contamination or

paper clogging

Physical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not oper-

ateRefer toEC-132, "

DTC

P0217 ENGINE OVER

TEMPERATURE"

—

Highresistancetofanrota-

tion

Fan assembly

Damaged fan blades

Damaged radiator shroud — — —

Improper engine coolant

mixture ratio—— —

Poor engine coolant quality — Engine coolant density —

Insufficient engine coolantEngine coolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into

cooling systemCylinder head deterioration

Cylinder head gasket dete-

rioration

Page 890 of 3171

CO-6

COOLING SYSTEM

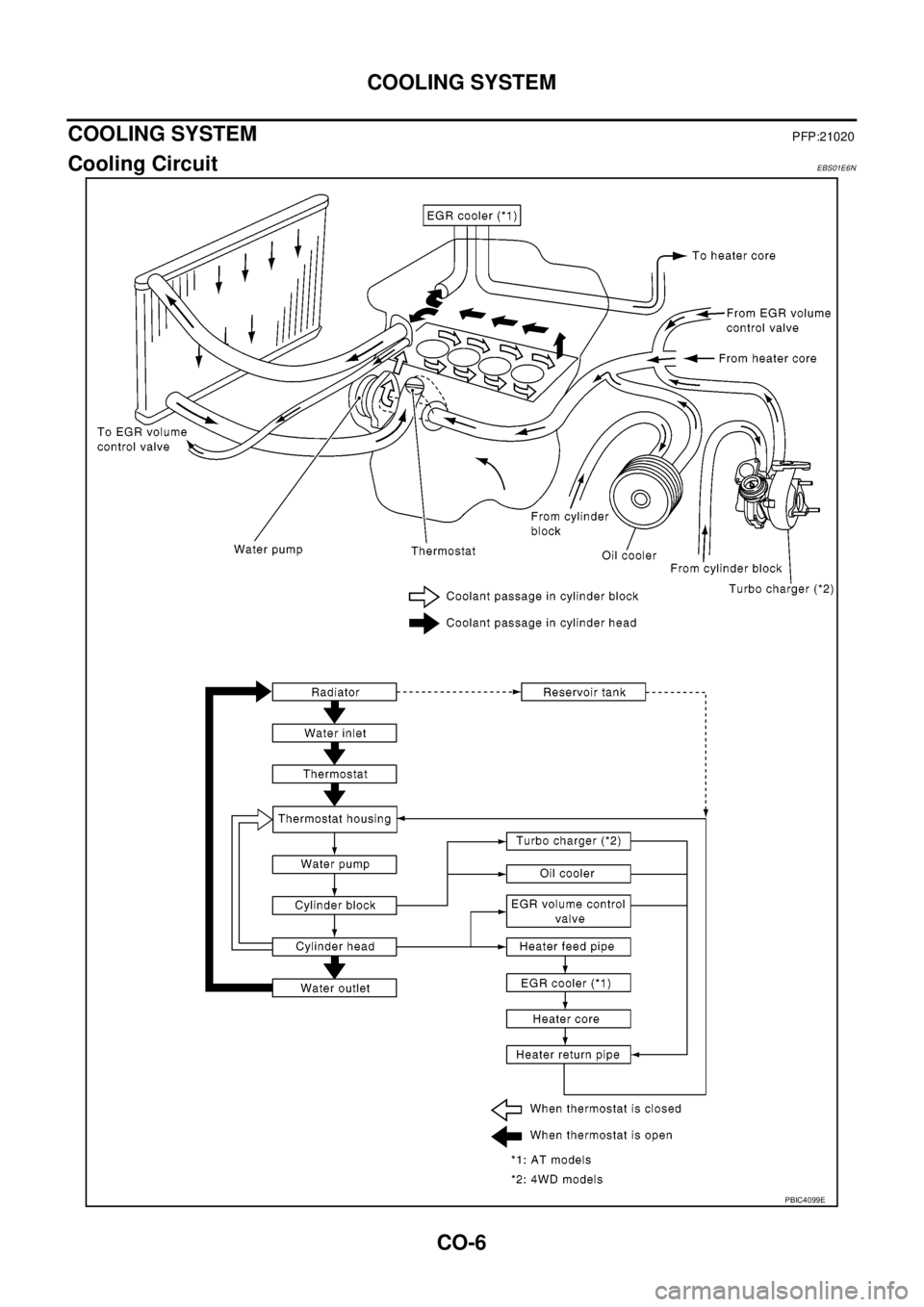

COOLING SYSTEM

PFP:21020

Cooling CircuitEBS01E6N

PBIC4099E

Page 891 of 3171

ENGINE COOLANT

CO-7

C

D

E

F

G

H

I

J

K

L

MA

CO

ENGINE COOLANTPFP:KQ100

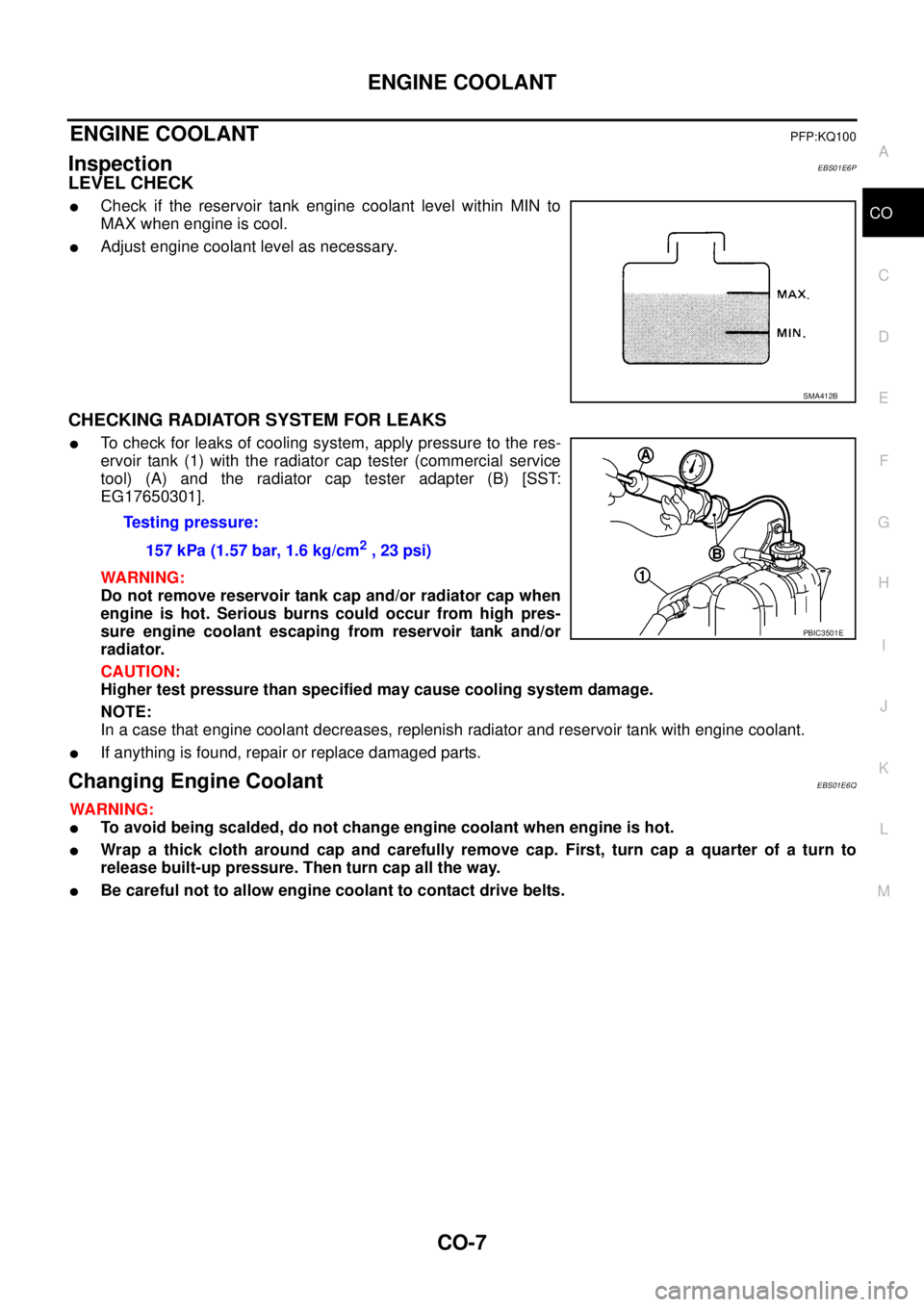

InspectionEBS01E6P

LEVEL CHECK

lCheck if the reservoir tank engine coolant level within MIN to

MAX when engine is cool.

lAdjust engine coolant level as necessary.

CHECKING RADIATOR SYSTEM FOR LEAKS

lTo check for leaks of cooling system, apply pressure to the res-

ervoir tank (1) with the radiator cap tester (commercial service

tool) (A) and the radiator cap tester adapter (B) [SST:

EG17650301].

WARNING:

Do not remove reservoir tank cap and/or radiator cap when

engine is hot. Serious burns could occur from high pres-

sure engine coolant escaping from reservoir tank and/or

radiator.

CAUTION:

Higher test pressure than specified may cause cooling system damage.

NOTE:

In a case that engine coolant decreases, replenish radiator and reservoir tank with engine coolant.

lIf anything is found, repair or replace damaged parts.

Changing Engine CoolantEBS01E6Q

WARNING:

lTo avoid being scalded, do not change engine coolant when engine is hot.

lWrap a thick cloth around cap and carefully remove cap. First, turn cap a quarter of a turn to

release built-up pressure. Then turn cap all the way.

lBe careful not to allow engine coolant to contact drive belts.

SMA412B

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2,23psi)

PBIC3501E