cooling NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1 of 3171

MODELD40 SERIES

2005 NISSAN EUROPE S.A.S.

All rights reserved. No part of this Electronic Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan

Europe S.A.S., Paris, France.

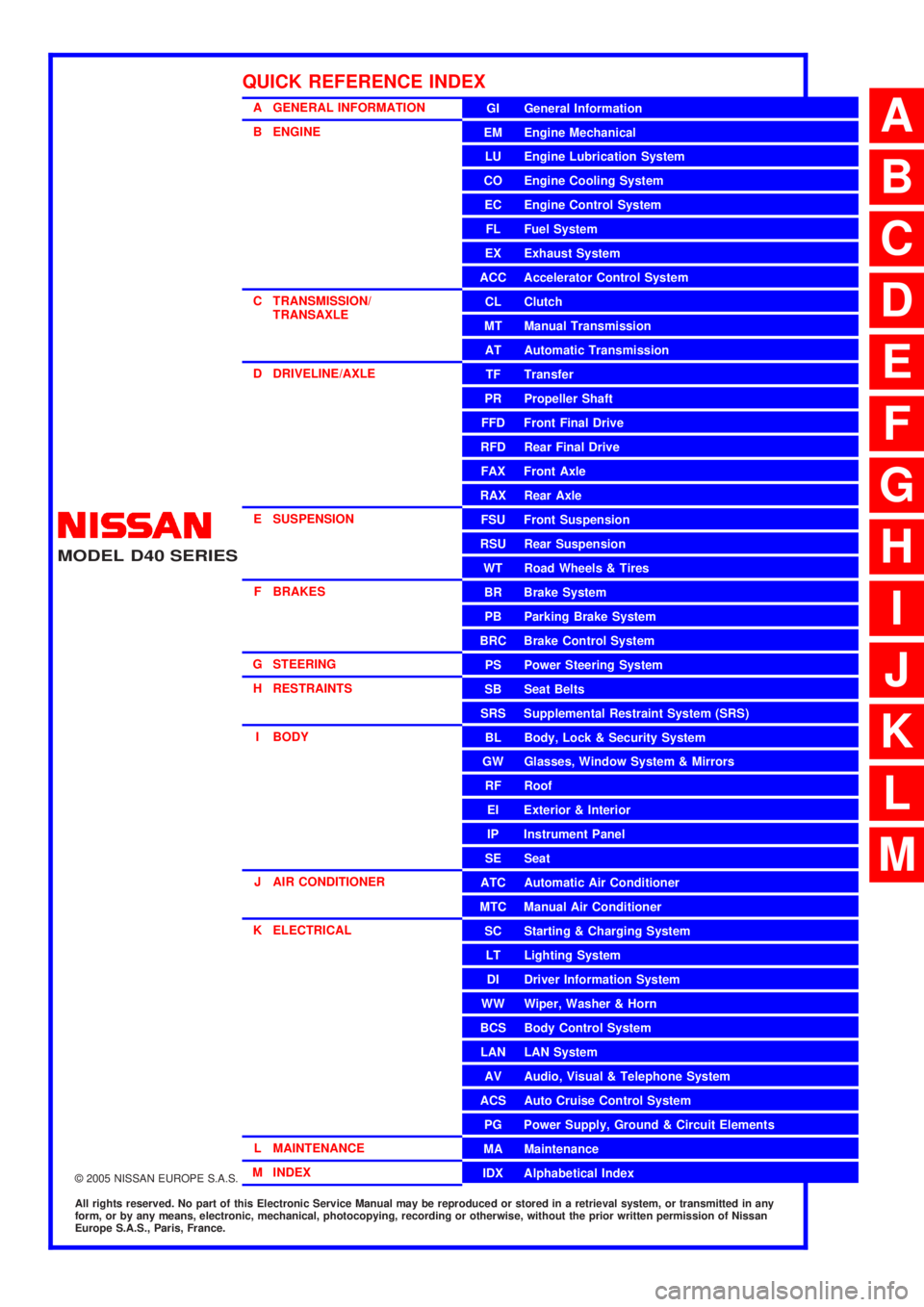

A GENERAL INFORMATION

B ENGINE

C TRANSMISSION/TRANSAXLE

D DRIVELINE/AXLE

E SUSPENSION F BRAKES

G STEERING H RESTRAINTS

I BODY

J AIR CONDITIONER

K ELECTRICAL

L MAINTENANCE

M INDEXGI General Information

EM Engine Mechanical

LU Engine Lubrication System

CO Engine Cooling System

EC Engine Control System

FL Fuel System

EX Exhaust System

ACC Accelerator Control System

CL Clutch

MTManualTransmission

AT Automatic Transmission

TF Transfer

PR Propeller Shaft

FFD Front Final Drive

RFD Rear Final Drive

FAX Front Axle

RAX Rear Axle

FSU Front Suspension

RSU Rear Suspension

WT Road Wheels & Tires

BR Brake System

PB Parking Brake System

BRC Brake Control System

PS Power Steering System

SB Seat Belts

SRS Supplemental Restraint System (SRS)

BL Body, Lock & Security System

GW Glasses, Window System & Mirrors

RF Roof

EI Exterior & Interior

IP Instrument Panel

SE Seat

ATC Automatic Air Conditioner

MTC Manual Air Conditioner

SC Starting & Charging System

LT Lighting System

DI Driver Information System

WW Wiper, Washer & Horn

BCS Body Control System

LAN LAN System

AV Audio, Visual & Telephone System

ACS Auto Cruise Control System

PG Power Supply, Ground & Circuit Elements

MA Maintenance

IDX Alphabetical Index

QUICK REFERENCE INDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

Page 15 of 3171

PRECAUTIONS

AT-7

D

E

F

G

H

I

J

K

L

MA

B

AT

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

ECS00IPT

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

PrecautionsECS00IPR

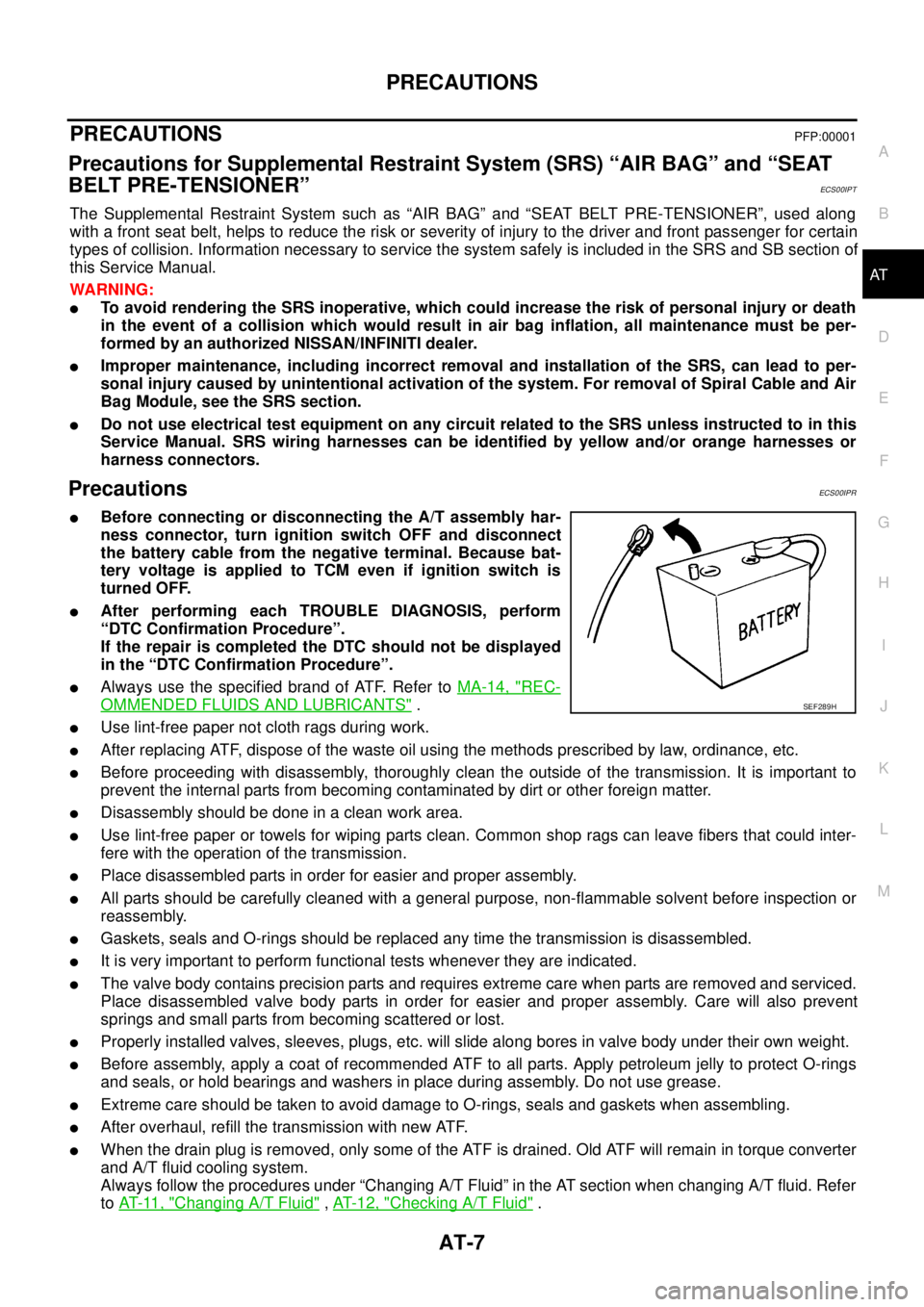

lBefore connecting or disconnecting the A/T assembly har-

ness connector, turn ignition switch OFF and disconnect

the battery cable from the negative terminal. Because bat-

tery voltage is applied to TCM even if ignition switch is

turned OFF.

lAfter performing each TROUBLE DIAGNOSIS, perform

“DTC Confirmation Procedure”.

If the repair is completed the DTC should not be displayed

in the “DTC Confirmation Procedure”.

lAlways use the specified brand of ATF. Refer toMA-14, "REC-

OMMENDED FLUIDS AND LUBRICANTS".

lUse lint-free paper not cloth rags during work.

lAfter replacing ATF, dispose of the waste oil using the methods prescribed by law, ordinance, etc.

lBefore proceeding with disassembly, thoroughly clean the outside of the transmission. It is important to

prevent the internal parts from becoming contaminated by dirt or other foreign matter.

lDisassembly should be done in a clean work area.

lUse lint-free paper or towels for wiping parts clean. Common shop rags can leave fibers that could inter-

fere with the operation of the transmission.

lPlace disassembled parts in order for easier and proper assembly.

lAll parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

lGaskets, seals and O-rings should be replaced any time the transmission is disassembled.

lIt is very important to perform functional tests whenever they are indicated.

lThe valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent

springs and small parts from becoming scattered or lost.

lProperly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

lBefore assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, or hold bearings and washers in place during assembly. Do not use grease.

lExtreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

lAfter overhaul, refill the transmission with new ATF.

lWhen the drain plug is removed, only some of the ATF is drained. Old ATF will remain in torque converter

and A/T fluid cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer

toAT-11, "

Changing A/T Fluid",AT-12, "Checking A/T Fluid".

SEF289H

Page 21 of 3171

A/T FLUID

AT-13

D

E

F

G

H

I

J

K

L

MA

B

AT

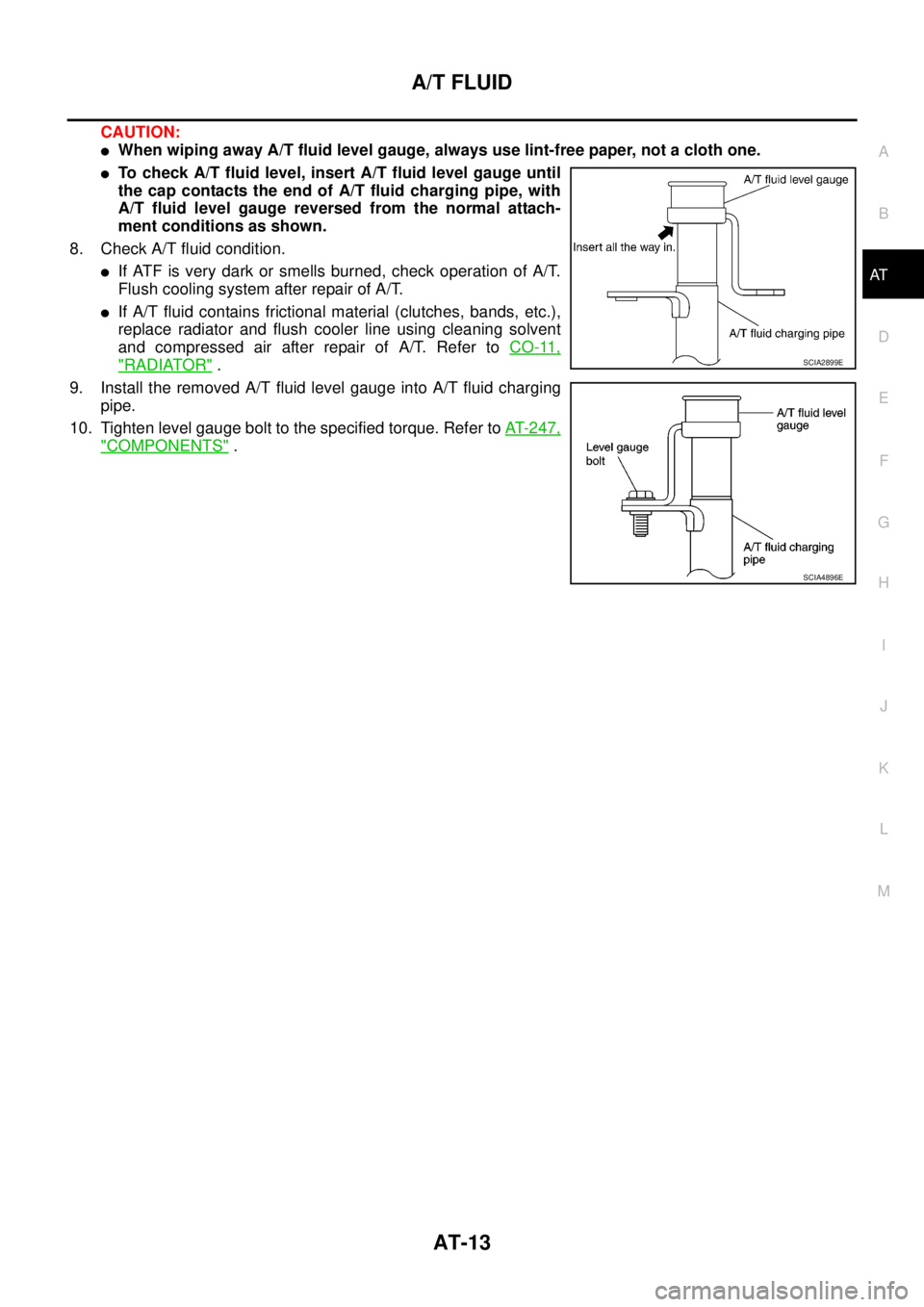

CAUTION:

lWhen wiping away A/T fluid level gauge, always use lint-free paper, not a cloth one.

lTo check A/T fluid level, insert A/T fluid level gauge until

the cap contacts the end of A/T fluid charging pipe, with

A/T fluid level gauge reversed from the normal attach-

ment conditions as shown.

8. Check A/T fluid condition.

lIf ATF is very dark or smells burned, check operation of A/T.

Flush cooling system after repair of A/T.

lIf A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer toCO-11,

"RADIATOR".

9. Install the removed A/T fluid level gauge into A/T fluid charging

pipe.

10. Tighten level gauge bolt to the specified torque. Refer toAT-247,

"COMPONENTS".

SCIA2899E

SCIA4896E

Page 41 of 3171

A/T CONTROL SYSTEM

AT-33

D

E

F

G

H

I

J

K

L

MA

B

AT

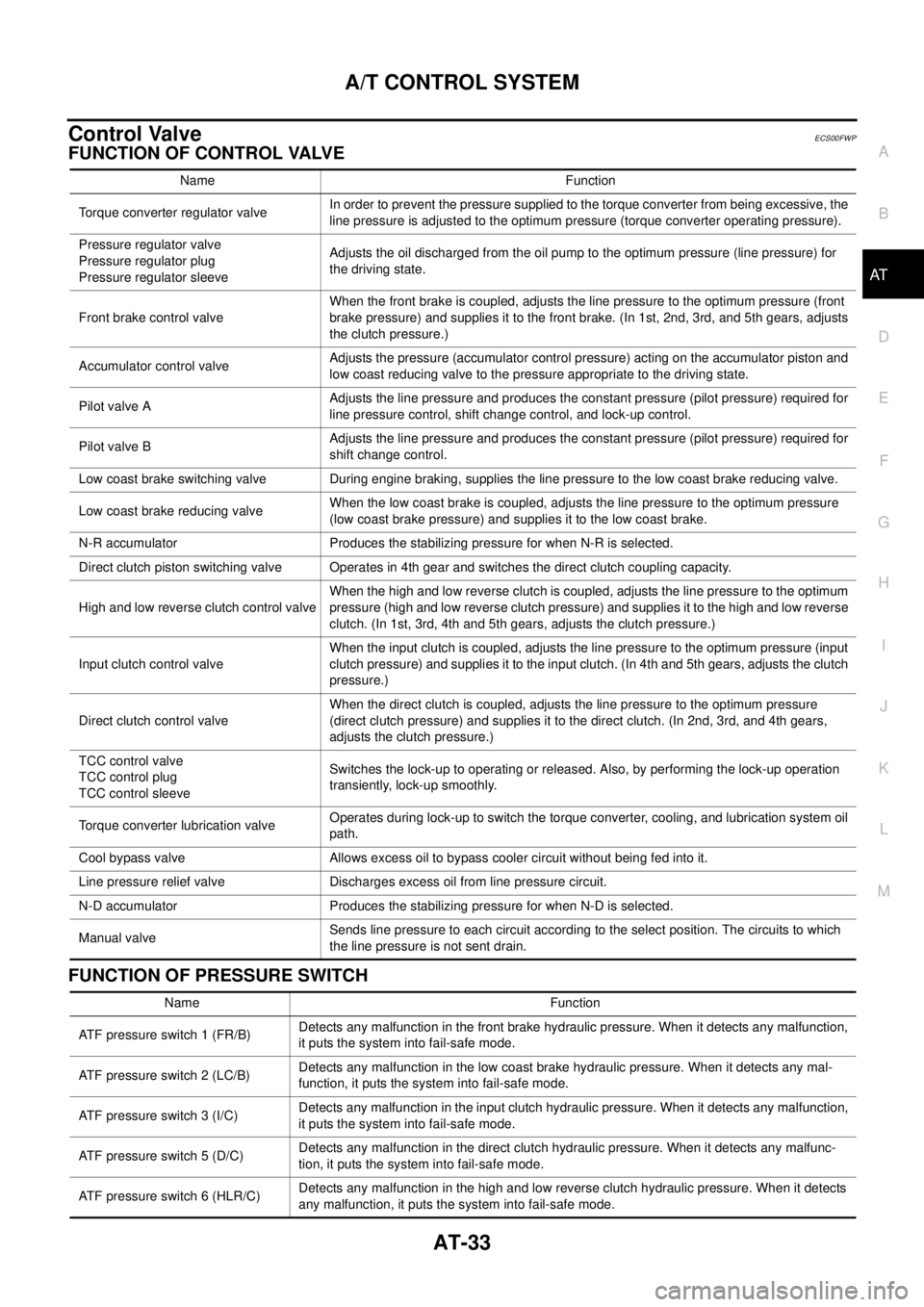

Control ValveECS00FWP

FUNCTION OF CONTROL VALVE

FUNCTION OF PRESSURE SWITCH

Name Function

Torque converter regulator valveIn order to prevent the pressure supplied to the torque converter from being excessive, the

line pressure is adjusted to the optimum pressure (torque converter operating pressure).

Pressure regulator valve

Pressure regulator plug

Pressure regulator sleeveAdjusts the oil discharged from the oil pump to the optimum pressure (line pressure) for

the driving state.

Front brake control valveWhen the front brake is coupled, adjusts the line pressure to the optimum pressure (front

brake pressure) and supplies it to the front brake. (In 1st, 2nd, 3rd, and 5th gears, adjusts

theclutchpressure.)

Accumulator control valveAdjusts the pressure (accumulator control pressure) acting on the accumulator piston and

low coast reducing valve to the pressure appropriate to the driving state.

Pilot valve AAdjusts the line pressure and produces the constant pressure (pilot pressure) required for

line pressure control, shift change control, and lock-up control.

Pilot valve BAdjusts the line pressure and produces the constant pressure (pilot pressure) required for

shift change control.

Low coast brake switching valve During engine braking, supplies the line pressure to the low coast brake reducing valve.

Low coast brake reducing valveWhen the low coast brake is coupled, adjusts the line pressure to the optimum pressure

(low coast brake pressure) and supplies it to the low coast brake.

N-R accumulator Produces the stabilizing pressure for when N-R is selected.

Direct clutch piston switching valve Operates in 4th gear and switches the direct clutch coupling capacity.

High and low reverse clutch control valveWhen the high and low reverse clutch is coupled, adjusts the line pressure to the optimum

pressure (high and low reverse clutch pressure) and supplies it to the high and low reverse

clutch. (In 1st, 3rd, 4th and 5th gears, adjusts the clutch pressure.)

Input clutch control valveWhen the input clutch is coupled, adjusts the line pressure to the optimum pressure (input

clutch pressure) and supplies it to the input clutch. (In 4th and 5th gears, adjusts the clutch

pressure.)

Direct clutch control valveWhen the direct clutch is coupled, adjusts the line pressure to the optimum pressure

(direct clutch pressure) and supplies it to the direct clutch. (In 2nd, 3rd, and 4th gears,

adjusts the clutch pressure.)

TCC control valve

TCC control plug

TCC control sleeveSwitches the lock-up to operating or released. Also, by performing the lock-up operation

transiently, lock-up smoothly.

Torque converter lubrication valveOperates during lock-up to switch the torque converter, cooling, and lubrication system oil

path.

Cool bypass valve Allows excess oil to bypass cooler circuit without being fed into it.

Line pressure relief valve Discharges excess oil from line pressure circuit.

N-D accumulator Produces the stabilizing pressure for when N-D is selected.

Manual valveSends line pressure to each circuit according to the select position. The circuits to which

the line pressure is not sent drain.

Name Function

ATFpressureswitch1(FR/B)Detects any malfunction in the front brake hydraulic pressure. When it detects any malfunction,

it puts the system into fail-safe mode.

ATFpressureswitch2(LC/B)Detects any malfunction in the low coast brake hydraulic pressure. When it detects any mal-

function, it puts the system into fail-safe mode.

ATFpressureswitch3(I/C)Detects any malfunction in the input clutch hydraulic pressure. When it detects any malfunction,

it puts the system into fail-safe mode.

ATF pressure switch 5 (D/C)Detects any malfunction in the direct clutch hydraulic pressure. When it detects any malfunc-

tion, it puts the system into fail-safe mode.

ATF pressure switch 6 (HLR/C)Detects any malfunction in the high and low reverse clutch hydraulic pressure. When it detects

any malfunction, it puts the system into fail-safe mode.

Page 336 of 3171

ATC-2

DATA MONITOR .................................................. 34

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ...................................................... 35

WORK FLOW ...................................................... 35

SYMPTOM TABLE .............................................. 35

Component Parts and Harness Connector Location... 36

ENGINE COMPARTMENT .................................. 36

FRONT PASSENGER COMPARTMENT ............ 37

Schematic —LHD MODELS— ............................... 38

Wiring Diagram —A/C— —LHD MODELS— ......... 39

Schematic —RHD MODELS— ............................... 46

Wiring Diadram —A/C— —RHD MODELS— ......... 47

Front Air Control Terminals and Reference Value... 53

PIN CONNECTOR TERMINAL LAYOUT ............ 53

TERMINALS AND REFERENCE VALUE FOR

FRONT AIR CONTROL ....................................... 53

A/C System Self-diagnosis Function ...................... 55

DESCRIPTION .................................................... 55

Operational Check .................................................. 57

CHECKING MEMORY FUNCTION ..................... 57

CHECKING BLOWER ......................................... 57

CHECKING DISCHARGE AIR ............................ 58

CHECKING RECIRCULATION ............................ 58

CHECKING TEMPERATURE DECREASE ......... 58

CHECKING TEMPERATURE INCREASE .......... 59

CHECK A/C SWITCH .......................................... 59

CHECKING AUTO MODE ................................... 59

Power Supply and Ground Circuit for Front Air Con-

trol ........................................................................... 60

INSPECTION FLOW ........................................... 60

COMPONENT DESCRIPTION ............................ 61

DIAGNOSTIC PROCEDURE FOR A/C SYSTEM... 61

Mode Door Motor Circuit ........................................ 63

INSPECTION FLOW ........................................... 63

SYSTEM DESCRIPTION .................................... 64

COMPONENT DESCRIPTION ............................ 65

DIAGNOSTIC PROCEDURE FOR MODE

DOOR MOTOR ................................................... 65

Air Mix Door Motor Circuit ...................................... 68

INSPECTION FLOW ........................................... 68

SYSTEM DESCRIPTION .................................... 69

COMPONENT DESCRIPTION ............................ 70

DIAGNOSTIC PROCEDURE FOR AIR MIX

DOOR MOTOR (DRIVER) ................................... 71

DIAGNOSTIC PROCEDURE FOR AIR MIX

DOOR MOTOR (PASSENGER) .......................... 73

Intake Door Motor Circuit ........................................ 77

INSPECTION FLOW ........................................... 77

SYSTEM DESCRIPTION .................................... 78

COMPONENT DESCRIPTION ............................ 79

DIAGNOSTIC PROCEDURE FOR INTAKE

DOOR MOTOR ................................................... 79

Blower Motor Circuit ............................................... 80

INSPECTION FLOW ........................................... 80

SYSTEM DESCRIPTION .................................... 81

COMPONENT DESCRIPTION ............................ 82

DIAGNOSTIC PROCEDURE FOR BLOWER

MOTOR ............................................................... 82

COMPONENT INSPECTION .............................. 86Magnet Clutch Circuit .............................................. 87

INSPECTION FLOW ............................................ 87

SYSTEM DESCRIPTION ..................................... 88

DIAGNOSTIC PROCEDURE FOR MAGNET

CLUTCH .............................................................. 88

COMPONENT INSPECTION ............................... 92

Insufficient Cooling .................................................. 93

INSPECTION FLOW ............................................ 93

PERFORMANCE TEST DIAGNOSES ................ 94

PERFORMANCE CHART .................................... 96

TROUBLE DIAGNOSES FOR UNUSUAL PRES-

SURE ................................................................... 97

Insufficient Heating ...............................................100

INSPECTION FLOW ..........................................100

Noise .....................................................................101

INSPECTION FLOW ..........................................101

Self-diagnosis .......................................................103

INSPECTION FLOW ..........................................103

Memory Function ..................................................104

INSPECTION FLOW ..........................................104

Ambient Sensor Circuit .........................................105

COMPONENT DESCRIPTION ..........................105

AMBIENT TEMPERATURE INPUT PROCESS.105

DIAGNOSTIC PROCEDURE FOR AMBIENT

SENSOR ............................................................105

COMPONENT INSPECTION .............................107

In-vehicle Sensor Circuit .......................................108

COMPONENT DESCRIPTION ..........................108

DIAGNOSTIC PROCEDURE FOR IN-VEHICLE

SENSOR ............................................................109

COMPONENT INSPECTION ............................. 111

Optical Sensor Circuit ...........................................112

COMPONENT DESCRIPTION ..........................112

OPTICAL INPUT PROCESS .............................112

DIAGNOSTIC PROCEDURE FOR SUNLOAD

SENSOR ............................................................112

Intake Sensor Circuit .............................................114

COMPONENT DESCRIPTION ..........................114

DIAGNOSTIC PROCEDURE FOR INTAKE SEN-

SOR ...................................................................114

COMPONENT INSPECTION .............................115

CONTROL UNIT ......................................................116

Removal and Installation .......................................116

REMOVAL ..........................................................116

INSTALLATION ..................................................116

AMBIENT SENSOR ................................................117

Removal and Installation .......................................117

REMOVAL ..........................................................117

INSTALLATION ..................................................117

IN-VEHICLE SENSOR ............................................118

Removal and Installation .......................................118

REMOVAL ..........................................................118

INSTALLATION ..................................................118

OPTICAL SENSOR .................................................119

Removal and Installation .......................................119

INTAKE SENSOR ....................................................120

Removal and Installation .......................................120

REMOVAL ..........................................................120

INSTALLATION ..................................................120

Page 337 of 3171

ATC-3

C

D

E

F

G

H

I

K

L

MA

B

AT C BLOWER MOTOR .................................................. 121

Components ......................................................... 121

Removal and Installation ...................................... 121

REMOVAL ......................................................... 121

INSTALLATION ................................................. 121

AIR CONDITIONER FILTER ................................... 122

Removal and Installation ...................................... 122

FUNCTION ........................................................ 122

REPLACEMENT TIMING .................................. 122

REPLACEMENT PROCEDURE ....................... 122

HEATER & COOLING UNIT ASSEMBLY .............. 124

Components ......................................................... 124

Removal and Installation ...................................... 126

REMOVAL ......................................................... 126

INSTALLATION ................................................. 126

HEATER CORE ...................................................... 127

Components ......................................................... 127

Removal and Installation ...................................... 127

REMOVAL ......................................................... 127

INSTALLATION ................................................. 127

HEATER PUMP ...................................................... 128

Components ......................................................... 128

Removal and Installation ...................................... 128

REMOVAL ......................................................... 128

INSTALLATION ................................................. 128

INTAKE DOOR MOTOR ......................................... 129

Components ......................................................... 129

Removal and Installation ...................................... 129

REMOVAL ......................................................... 129

INSTALLATION ................................................. 129

MODE DOOR MOTOR ........................................... 130

Components ......................................................... 130

Removal and Installation ...................................... 130

REMOVAL ......................................................... 130

INSTALLATION ................................................. 130

AIR MIX DOOR MOTOR ......................................... 131

Components ......................................................... 131

Removal and Installation ...................................... 131

AIR MIX DOOR MOTOR (DRIVER) .................. 131

AIR MIX DOOR MOTOR (PASSENGER) ......... 131

VARIABLE BLOWER CONTROL .......................... 133

Components ......................................................... 133

Removal and Installation ...................................... 133

REMOVAL ......................................................... 133

INSTALLATION ................................................. 133

DUCTS AND GRILLES .......................................... 134

Components ......................................................... 134

Removal and Installation ...................................... 136

CONSOLE DUCTS AND CONSOLE GRILLE .. 136

DEFROSTER NOZZLE ..................................... 136

RH AND LH SIDE DEMISTER DUCT ............... 136

RH AND LH VENTILATOR DUCT ..................... 136

CENTER VENTILATOR DUCT ......................... 136

FLOOR CONNECTOR DUCT ........................... 136

FRONT AND REAR FLOOR DUCTS ............... 137

REAR OVERHEAD DUCTS .............................. 137

SIDE REAR FLOOR DUCT .............................. 137

GRILLES ........................................................... 137REFRIGERANT LINES ...........................................138

HFC-134a (R-134a) Service Procedure ...............138

SETTING OF SERVICE TOOLS AND EQUIP-

MENT ................................................................138

Components .........................................................140

Removal and Installation for Compressor ............142

REMOVAL .........................................................142

INSTALLATION .................................................142

Removal and Installation for Compressor Clutch . 143

REMOVAL .........................................................143

INSPECTION ....................................................144

INSTALLATION .................................................144

BREAK-IN OPERATION ....................................146

Removal and Installation for High-pressure Flexible

A/C Hose ..............................................................146

REMOVAL .........................................................146

INSTALLATION .................................................146

Removal and Installation for High-pressure A/C

Pipe ......................................................................146

REMOVAL .........................................................146

INSTALLATION .................................................146

Removal and Installation for Low-pressure Flexible

A/C Hose ..............................................................146

REMOVAL .........................................................146

INSTALLATION .................................................146

Removal and Installation for Low-pressure A/C Pipe.147

REMOVAL .........................................................147

INSTALLATION .................................................147

Removal and Installation for Refrigerant Pressure

Sensor ..................................................................147

REMOVAL .........................................................147

INSTALLATION .................................................147

Removal and Installation for Condenser ..............147

REMOVAL .........................................................147

INSTALLATION .................................................148

Removal and Installation for Evaporator ..............149

REMOVAL .........................................................149

INSTALLATION .................................................149

Removal and Installation for Expansion Valve ......150

REMOVAL .........................................................150

INSTALLATION .................................................150

Checking for Refrigerant Leaks ............................150

Checking System for Leaks Using the Fluorescent

Leak Detector .......................................................150

Dye Injection .........................................................151

Electronic Refrigerant Leak Detector ....................151

PRECAUTIONS FOR HANDLING LEAK

DETECTOR .......................................................151

CHECKING PROCEDURE ...............................152

SERVICE DATA AND SPECIFICATIONS (SDS) ....154

Service Data and Specifications (SDS) ................154

COMPRESSOR ................................................154

LUBRICANT ......................................................154

REFRIGERANT .................................................154

ENGINE IDLING SPEED ..................................154

BELT TENSION .................................................154

Page 339 of 3171

PRECAUTIONS

ATC-5

C

D

E

F

G

H

I

K

L

MA

B

AT C

lIf the vehicle is within the warranty period, the air conditioner warranty is void. Please contact NISSAN

Customer Affairs for further assistance.

General Refrigerant PrecautionsEJS006AN

WARNING:

lDo not release refrigerant into the air. Use approved recovery/recycling equipment to capture the

refrigerant every time an air conditioning system is discharged.

lAlways wear eye and hand protection (goggles and gloves) when working with any refrigerant or

air conditioning system.

lDo not store or heat refrigerant containers above 52°C.

lDo not heat a refrigerant container with an open flame; if container warming is required, place the

bottom of the container in a warm pail of water.

lDo not intentionally drop, puncture, or incinerate refrigerant containers.

lKeep refrigerant away from open flames: poisonous gas will be produced if refrigerant burns.

lRefrigerant will displace oxygen, therefore be certain to work in well ventilated areas to prevent

suffocation.

lDo not pressure test or leak test HFC-134a (R-134a) service equipment and/or vehicle air condi-

tioning systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a)

have been shown to be combustible at elevated pressures. These mixtures, if ignited, may cause

injury or property damage. Additional health and safety information may be obtained from refriger-

ant manufacturers.

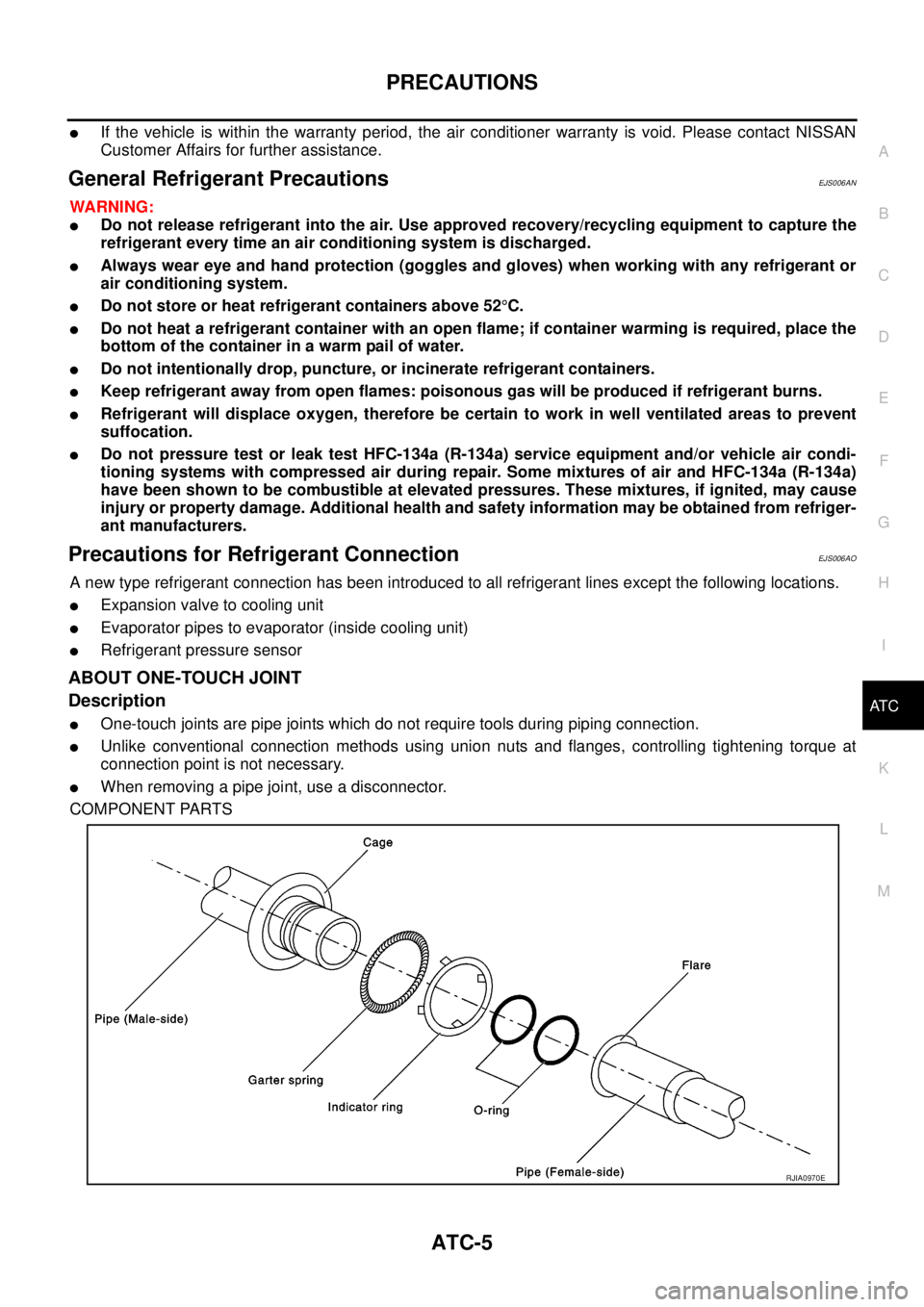

Precautions for Refrigerant ConnectionEJS006AO

A new type refrigerant connection has been introduced to all refrigerant lines except the following locations.

lExpansion valve to cooling unit

lEvaporator pipes to evaporator (inside cooling unit)

lRefrigerant pressure sensor

ABOUT ONE-TOUCH JOINT

Description

lOne-touch joints are pipe joints which do not require tools during piping connection.

lUnlike conventional connection methods using union nuts and flanges, controlling tightening torque at

connection point is not necessary.

lWhen removing a pipe joint, use a disconnector.

COMPONENT PARTS

RJIA0970E

Page 357 of 3171

REFRIGERATION SYSTEM

ATC-23

C

D

E

F

G

H

I

K

L

MA

B

AT C

1. Defroster nozzle 2. LH side demister duct 3. LH ventilator duct

4. RH side demister duct 5. RH ventilator duct 6. Center ventilation duct

7. Heater and cooling unit assembly 8. Floor connector duct grilles 9. Floor connector duct

10. Front floor duct 11. Rear floor duct

Page 358 of 3171

ATC-24

LUBRICANT

LUBRICANT

PFP:KLG00

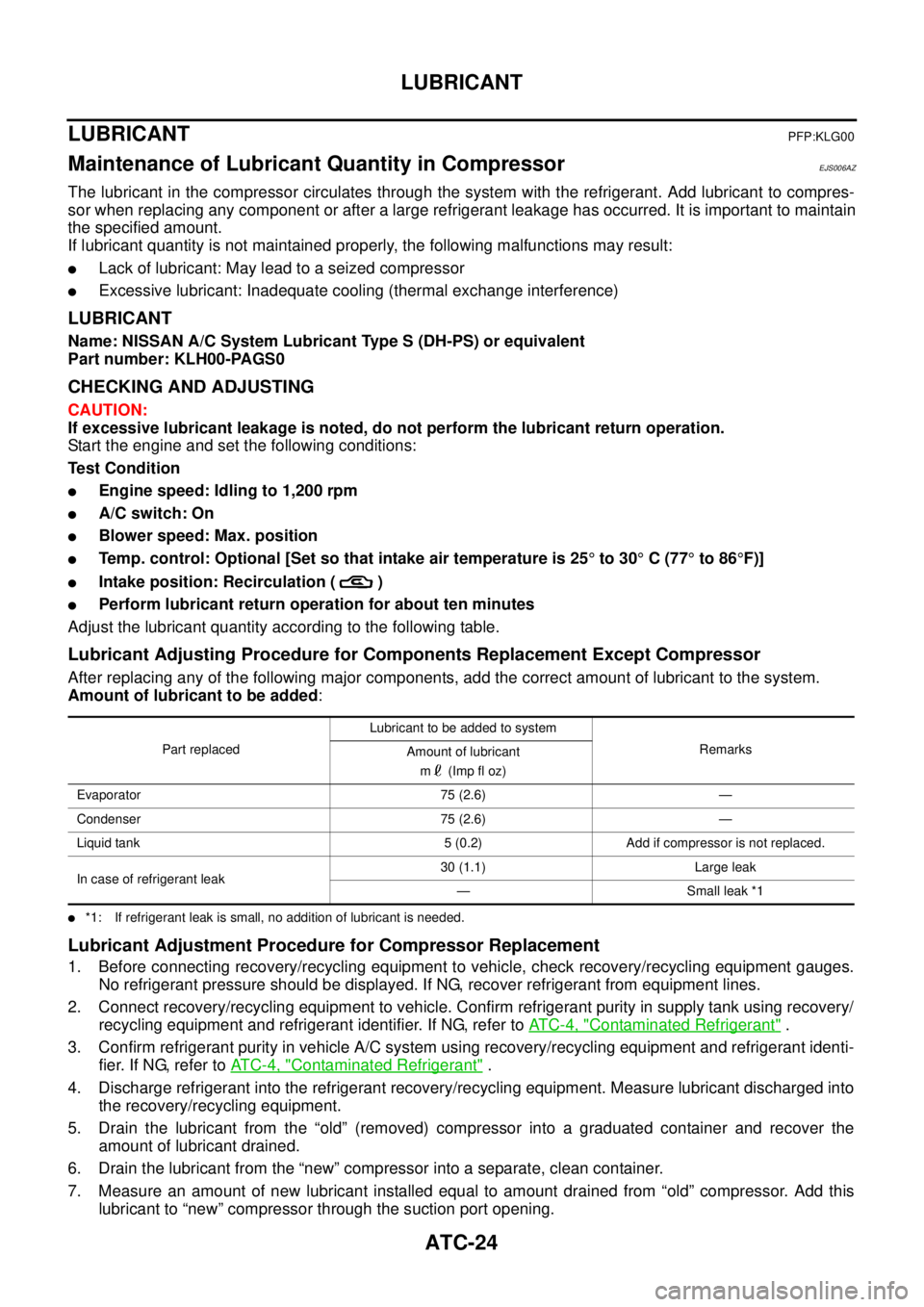

Maintenance of Lubricant Quantity in CompressorEJS006AZ

The lubricant in the compressor circulates through the system with the refrigerant. Add lubricant to compres-

sor when replacing any component or after a large refrigerant leakage has occurred. It is important to maintain

the specified amount.

If lubricant quantity is not maintained properly, the following malfunctions may result:

lLack of lubricant: May lead to a seized compressor

lExcessive lubricant: Inadequate cooling (thermal exchange interference)

LUBRICANT

Name: NISSAN A/C System Lubricant Type S (DH-PS) or equivalent

Part number: KLH00-PAGS0

CHECKING AND ADJUSTING

CAUTION:

If excessive lubricant leakage is noted, do not perform the lubricant return operation.

Start the engine and set the following conditions:

Test Condition

lEngine speed: Idling to 1,200 rpm

lA/C switch: On

lBlower speed: Max. position

lTemp. control: Optional [Set so that intake air temperature is 25°to 30°C(77°to 86°F)]

lIntake position: Recirculation ( )

lPerform lubricant return operation for about ten minutes

Adjust the lubricant quantity according to the following table.

Lubricant Adjusting Procedure for Components Replacement Except Compressor

After replacing any of the following major components, add the correct amount of lubricant to the system.

Amount of lubricant to be added:

l*1: If refrigerant leak is small, no addition of lubricant is needed.

Lubricant Adjustment Procedure for Compressor Replacement

1. Before connecting recovery/recycling equipment to vehicle, check recovery/recycling equipment gauges.

No refrigerant pressure should be displayed. If NG, recover refrigerant from equipment lines.

2. Connect recovery/recycling equipment to vehicle. Confirm refrigerant purity in supply tank using recovery/

recycling equipment and refrigerant identifier. If NG, refer toAT C - 4 , "

Contaminated Refrigerant".

3. Confirm refrigerant purity in vehicle A/C system using recovery/recycling equipment and refrigerant identi-

fier. If NG, refer toAT C - 4 , "

Contaminated Refrigerant".

4. Discharge refrigerant into the refrigerant recovery/recycling equipment. Measure lubricant discharged into

the recovery/recycling equipment.

5. Drain the lubricant from the “old” (removed) compressor into a graduated container and recover the

amount of lubricant drained.

6. Drain the lubricant from the “new” compressor into a separate, clean container.

7. Measure an amount of new lubricant installed equal to amount drained from “old” compressor. Add this

lubricant to “new” compressor through the suction port opening.

Part replacedLubricant to be added to system

Remarks

Amount of lubricant

m(Impfloz)

Evaporator 75 (2.6) —

Condenser 75 (2.6) —

Liquid tank 5 (0.2) Add if compressor is not replaced.

In case of refrigerant leak30 (1.1) Large leak

— Small leak *1

Page 369 of 3171

TROUBLE DIAGNOSIS

ATC-35

C

D

E

F

G

H

I

K

L

MA

B

AT C

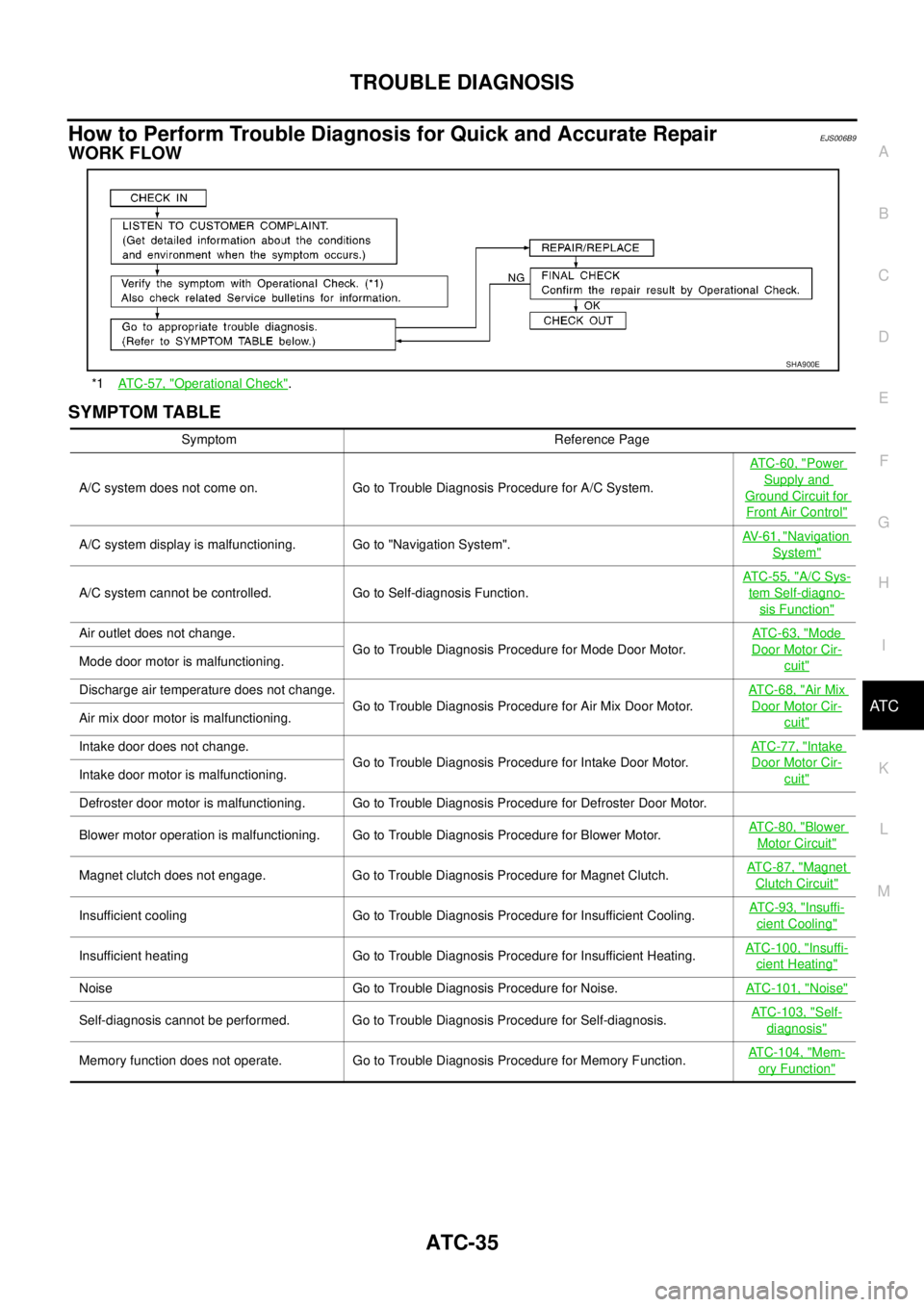

How to Perform Trouble Diagnosis for Quick and Accurate RepairEJS006B9

WORK FLOW

SYMPTOM TABLE

*1AT C - 5 7 , "Operational Check".

SHA900E

Symptom Reference Page

A/C system does not come on. Go to Trouble Diagnosis Procedure for A/C System.ATC-60, "

Power

Supply and

Ground Circuit for

Front Air Control"

A/C system display is malfunctioning. Go to "Navigation System".AV-61, "Navigation

System"

A/C system cannot be controlled. Go to Self-diagnosis Function.AT C - 5 5 , "

A/C Sys-

tem Self-diagno-

sis Function"

Air outlet does not change.

Go to Trouble Diagnosis Procedure for Mode Door Motor.AT C - 6 3 , "Mode

Door Motor Cir-

cuit"Mode door motor is malfunctioning.

Discharge air temperature does not change.

Go to Trouble Diagnosis Procedure for Air Mix Door Motor.ATC-68, "

Air Mix

Door Motor Cir-

cuit"Air mix door motor is malfunctioning.

Intake door does not change.

Go to Trouble Diagnosis Procedure for Intake Door Motor.AT C - 7 7 , "

Intake

Door Motor Cir-

cuit"Intake door motor is malfunctioning.

Defroster door motor is malfunctioning. Go to Trouble Diagnosis Procedure for Defroster Door Motor.

Blower motor operation is malfunctioning. Go to Trouble Diagnosis Procedure for Blower Motor.ATC-80, "

Blower

Motor Circuit"

Magnet clutch does not engage. Go to Trouble Diagnosis Procedure for Magnet Clutch.AT C - 8 7 , "Magnet

Clutch Circuit"

Insufficient cooling Go to Trouble Diagnosis Procedure for Insufficient Cooling.AT C - 9 3 , "Insuffi-

cient Cooling"

Insufficient heating Go to Trouble Diagnosis Procedure for Insufficient Heating.ATC-100, "Insuffi-

cient Heating"

Noise Go to Trouble Diagnosis Procedure for Noise.ATC-101, "Noise"

Self-diagnosis cannot be performed. Go to Trouble Diagnosis Procedure for Self-diagnosis.ATC-103, "Self-

diagnosis"

Memory function does not operate. Go to Trouble Diagnosis Procedure for Memory Function.ATC-104, "Mem-

ory Function"