diagnostic menu NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 163 of 3171

DTC P1774 LOW COAST BRAKE SOLENOID VALVE FUNCTION

AT-155

D

E

F

G

H

I

J

K

L

MA

B

AT

WITHOUT CONSULT-II

1. Start engine.

2. Accelerate vehicle to maintain the following conditions.

Selector lever position: “1” or “2” position

Gear position: “1” or “2” (LC/B ON/OFF)

3. Perform step 2 again.

4. Turn ignition switch OFF position, then perform step 1 to 3 again.

5. Perform self-diagnosis. Refer toAT-89, "

Diagnostic Procedure Without CONSULT-II".

6. If DTC is detected, go toAT- 1 5 5 , "

Diagnostic Procedure".

Diagnostic ProcedureECS00G1D

1.CHECK INPUT SIGNALS

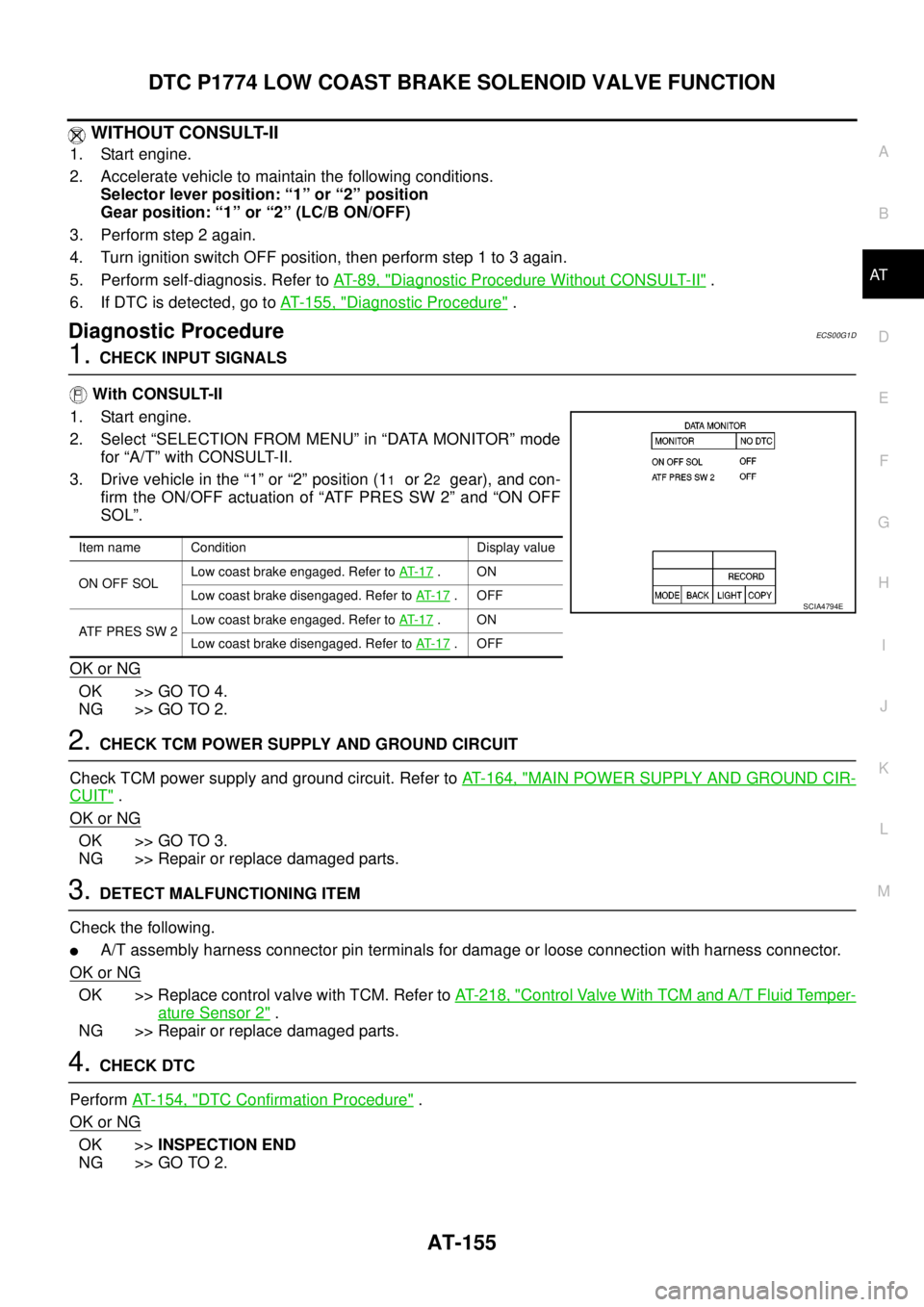

With CONSULT-II

1. Start engine.

2. Select “SELECTION FROM MENU” in “DATA MONITOR” mode

for “A/T” with CONSULT-II.

3. Drive vehicle in the “1” or “2” position (1

1or 22gear), and con-

firm the ON/OFF actuation of “ATF PRES SW 2” and “ON OFF

SOL”.

OK or NG

OK >> GO TO 4.

NG >> GO TO 2.

2.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer toAT- 1 6 4 , "

MAIN POWER SUPPLY AND GROUND CIR-

CUIT".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.DETECT MALFUNCTIONING ITEM

Check the following.

lA/T assembly harness connector pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> Replace control valve with TCM. Refer toAT- 2 1 8 , "Control Valve With TCM and A/T Fluid Temper-

ature Sensor 2".

NG >> Repair or replace damaged parts.

4.CHECK DTC

PerformAT- 1 5 4 , "

DTC Confirmation Procedure".

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

Item name Condition Display value

ON OFF SOLLow coast brake engaged. Refer toAT- 1 7

.ON

Low coast brake disengaged. Refer toAT- 1 7

.OFF

AT F P R E S S W 2Low coast brake engaged. Refer toAT- 1 7

.ON

Low coast brake disengaged. Refer toAT- 1 7

.OFF

SCIA4794E

Page 533 of 3171

DIAGNOSIS SYSTEM

AV-45

C

D

E

F

G

H

I

J

L

MA

B

AV

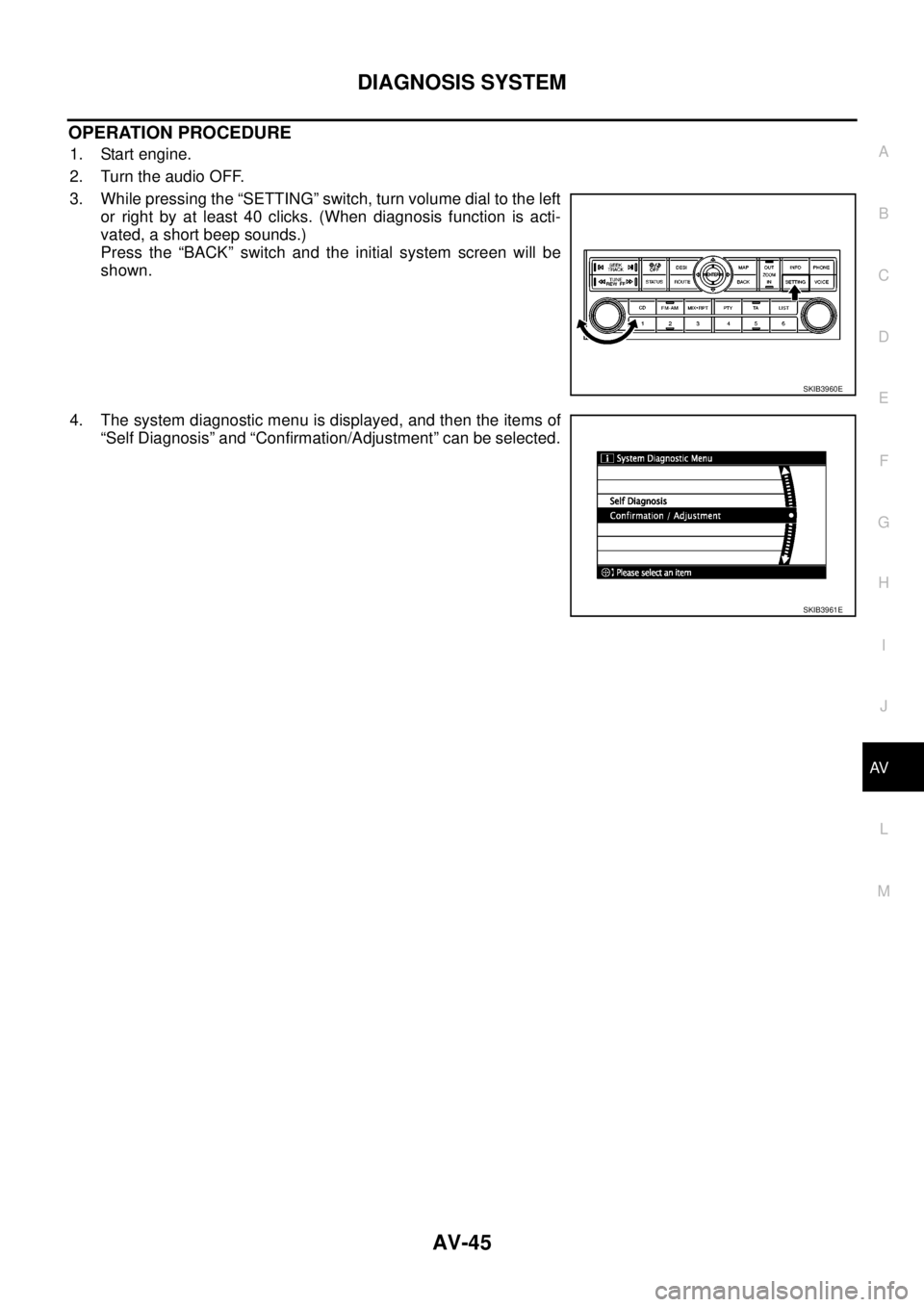

OPERATION PROCEDURE

1. Start engine.

2. Turn the audio OFF.

3. While pressing the “SETTING” switch, turn volume dial to the left

or right by at least 40 clicks. (When diagnosis function is acti-

vated, a short beep sounds.)

Press the “BACK” switch and the initial system screen will be

shown.

4. The system diagnostic menu is displayed, and then the items of

“Self Diagnosis” and “Confirmation/Adjustment” can be selected.

SKIB3960E

SKIB3961E

Page 2546 of 3171

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-17

C

D

E

F

G

H

I

J

L

MA

B

PG

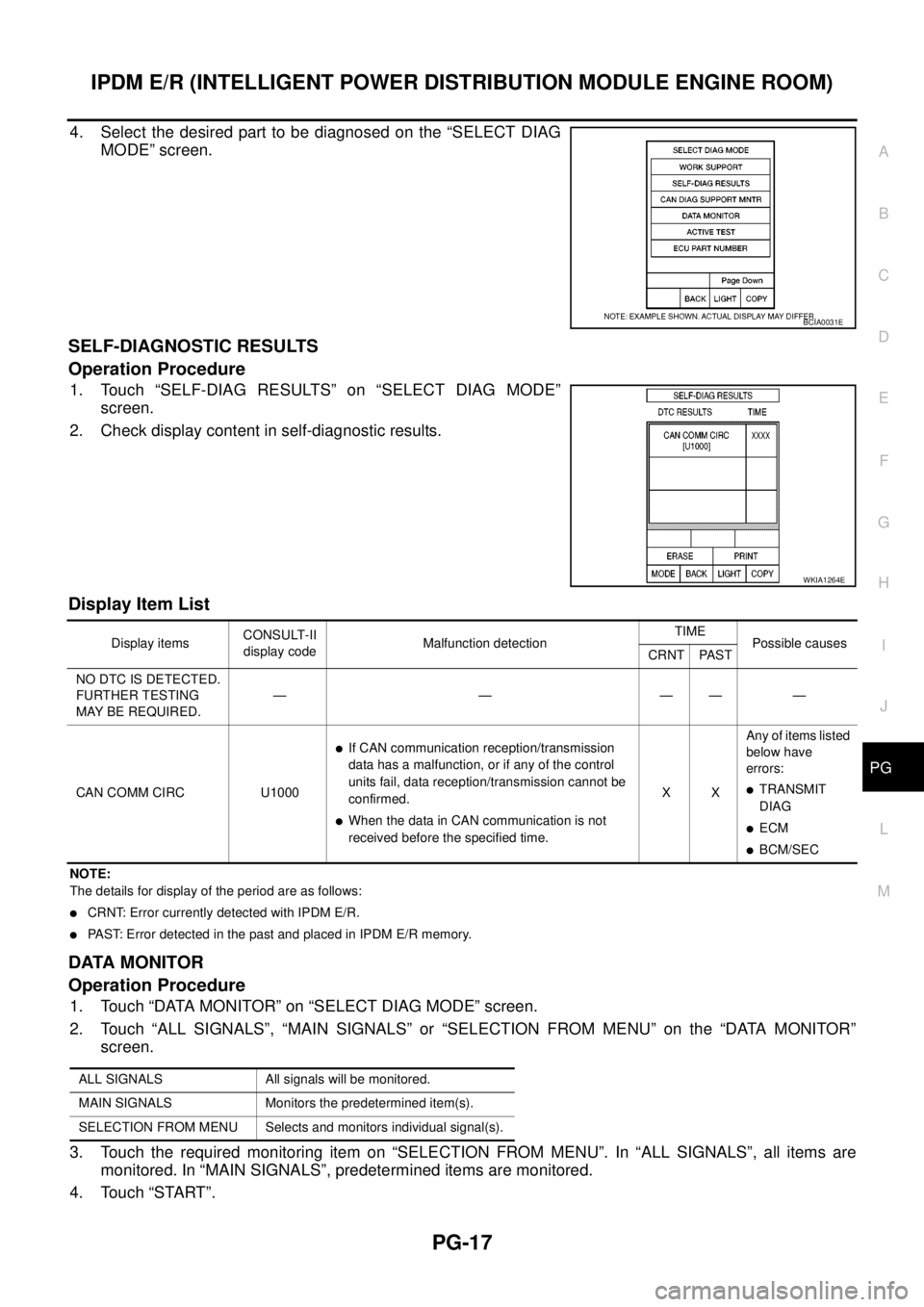

4. Select the desired part to be diagnosed on the “SELECT DIAG

MODE” screen.

SELF-DIAGNOSTIC RESULTS

Operation Procedure

1. Touch “SELF-DIAG RESULTS” on “SELECT DIAG MODE”

screen.

2. Check display content in self-diagnostic results.

Display Item List

NOTE:

The details for display of the period are as follows:

lCRNT: Error currently detected with IPDM E/R.

lPAST: Error detected in the past and placed in IPDM E/R memory.

DATA MONITOR

Operation Procedure

1. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

2. Touch “ALL SIGNALS”, “MAIN SIGNALS” or “SELECTION FROM MENU” on the “DATA MONITOR”

screen.

3. Touch the required monitoring item on “SELECTION FROM MENU”. In “ALL SIGNALS”, all items are

monitored. In “MAIN SIGNALS”, predetermined items are monitored.

4. Touch “START”.

BCIA0031E

WKIA1264E

Display itemsCONSULT-II

display codeMalfunction detectionTIME

Possible causes

CRNT PAST

NO DTC IS DETECTED.

FURTHER TESTING

MAYBEREQUIRED.—————

CAN COMM CIRC U1000

lIf CAN communication reception/transmission

data has a malfunction, or if any of the control

units fail, data reception/transmission cannot be

confirmed.

lWhen the data in CAN communication is not

received before the specified time.XXAny of items listed

below have

errors:

lTRANSMIT

DIAG

lECM

lBCM/SEC

ALL SIGNALS All signals will be monitored.

MAIN SIGNALS Monitors the predetermined item(s).

SELECTION FROM MENU Selects and monitors individual signal(s).

Page 2547 of 3171

PG-18

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

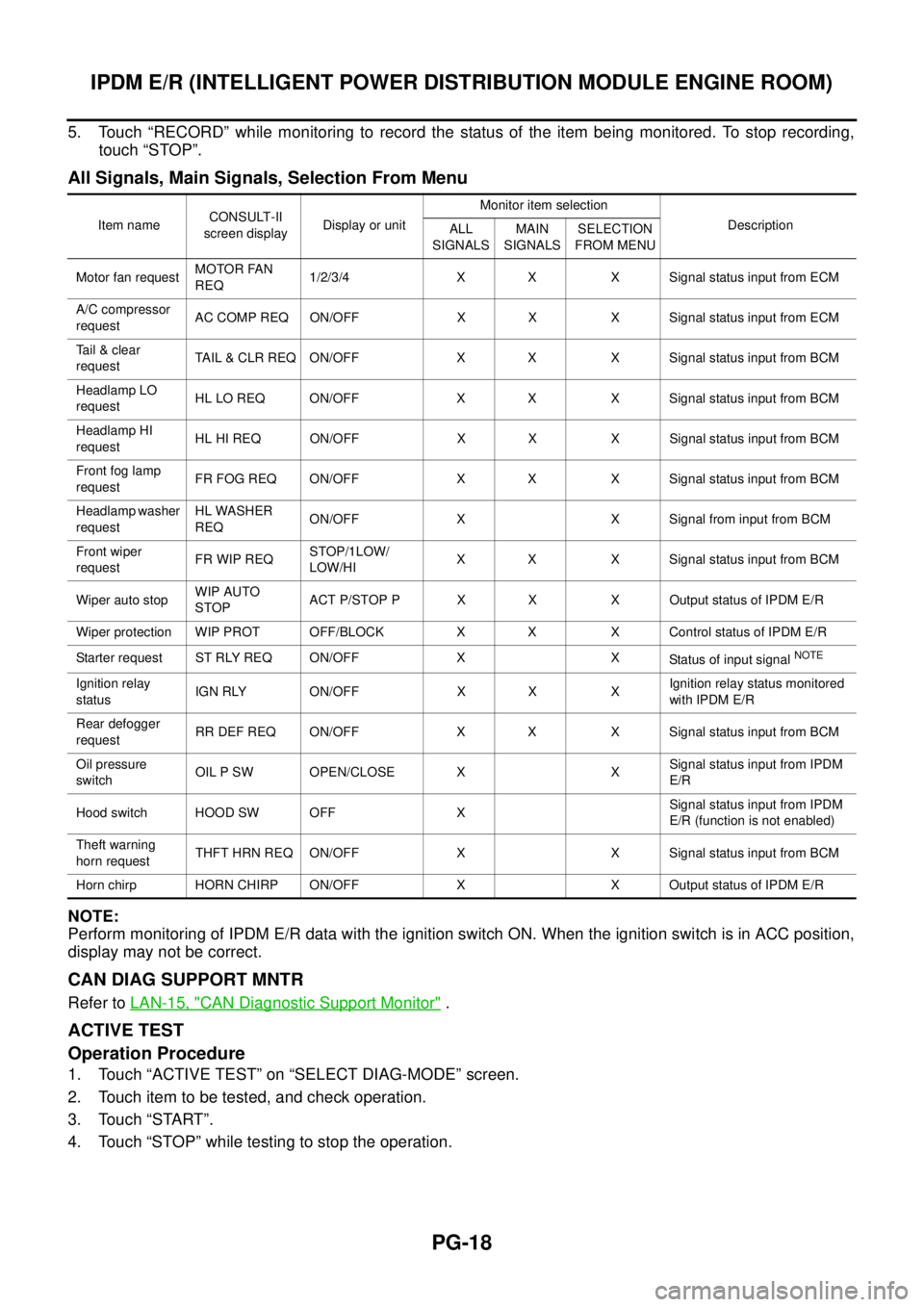

5. Touch “RECORD” while monitoring to record the status of the item being monitored. To stop recording,

touch “STOP”.

All Signals, Main Signals, Selection From Menu

NOTE:

Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is in ACC position,

display may not be correct.

CAN DIAG SUPPORT MNTR

Refer toLAN-15, "CAN Diagnostic Support Monitor".

ACTIVE TEST

Operation Procedure

1. Touch “ACTIVE TEST” on “SELECT DIAG-MODE” screen.

2. Touch item to be tested, and check operation.

3. Touch “START”.

4. Touch “STOP” while testing to stop the operation.

Item nameCONSULT-II

screen displayDisplay or unitMonitor item selection

Description

ALL

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

Motor fan requestMOTOR FAN

REQ1/2/3/4 X X X Signal status input from ECM

A/C compressor

requestAC COMP REQ ON/OFF X X X Signal status input from ECM

Tail & clear

requestTAIL & CLR REQ ON/OFF X X X Signal status input from BCM

Headlamp LO

requestHL LO REQ ON/OFF X X X Signal status input from BCM

Headlamp HI

requestHL HI REQ ON/OFF X X X Signal status input from BCM

Front fog lamp

requestFR FOG REQ ON/OFF X X X Signal status input from BCM

Headlamp washer

requestHL WASHER

REQON/OFF X X Signal from input from BCM

Front wiper

requestFR WIP REQSTOP/1LOW/

LOW/HIX X X Signal status input from BCM

Wiper auto stopWIP AUTO

STOPACT P/STOP P X X X Output status of IPDM E/R

Wiper protection WIP PROT OFF/BLOCK X X X Control status of IPDM E/R

Starter request ST RLY REQ ON/OFF X X

Status of input signal

NOTE

Ignition relay

statusIGN RLY ON/OFF X X XIgnition relay status monitored

with IPDM E/R

Rear defogger

requestRR DEF REQ ON/OFF X X X Signal status input from BCM

Oil pressure

switchOIL P SW OPEN/CLOSE X XSignal status input from IPDM

E/R

Hood switch HOOD SW OFF XSignal status input from IPDM

E/R (function is not enabled)

Theft warning

horn requestTHFT HRN REQ ON/OFF X X Signal status input from BCM

Horn chirp HORN CHIRP ON/OFF X X Output status of IPDM E/R