fuses NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2219 of 3171

LT-136

PARKING, LICENSE PLATE AND TAIL LAMPS

How to Proceed With Trouble Diagnosis

EKS00P9M

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer toLT- 1 2 5 , "

System Description".

3. Carry out the Preliminary Check. Refer toLT- 1 3 6 , "

Preliminary Check".

4. Check symptom and repair or replace the cause of malfunction.

5. Do the clarence, license plate and tail lamps operate normally? If YES, GO TO 6. If NO, GO TO 4.

6. INSPECTION END

Preliminary CheckEKS00P9N

CHECK POWER SUPPLY AND GROUND CIRCUIT

1.CHECK FUSES OR FUSIBLE LINK

Check for blown fuses or fusible link.

Refer toLT-128, "Wiring Diagram—TAIL/L—".

OK or NG

OK >> GO TO 2.

NG >> If fuse or fusible link is blown, be sure to eliminate cause of malfunction before installing new fuse

or fusible link. Refer toPG-4, "

POWER SUPPLY ROUTING CIRCUIT".

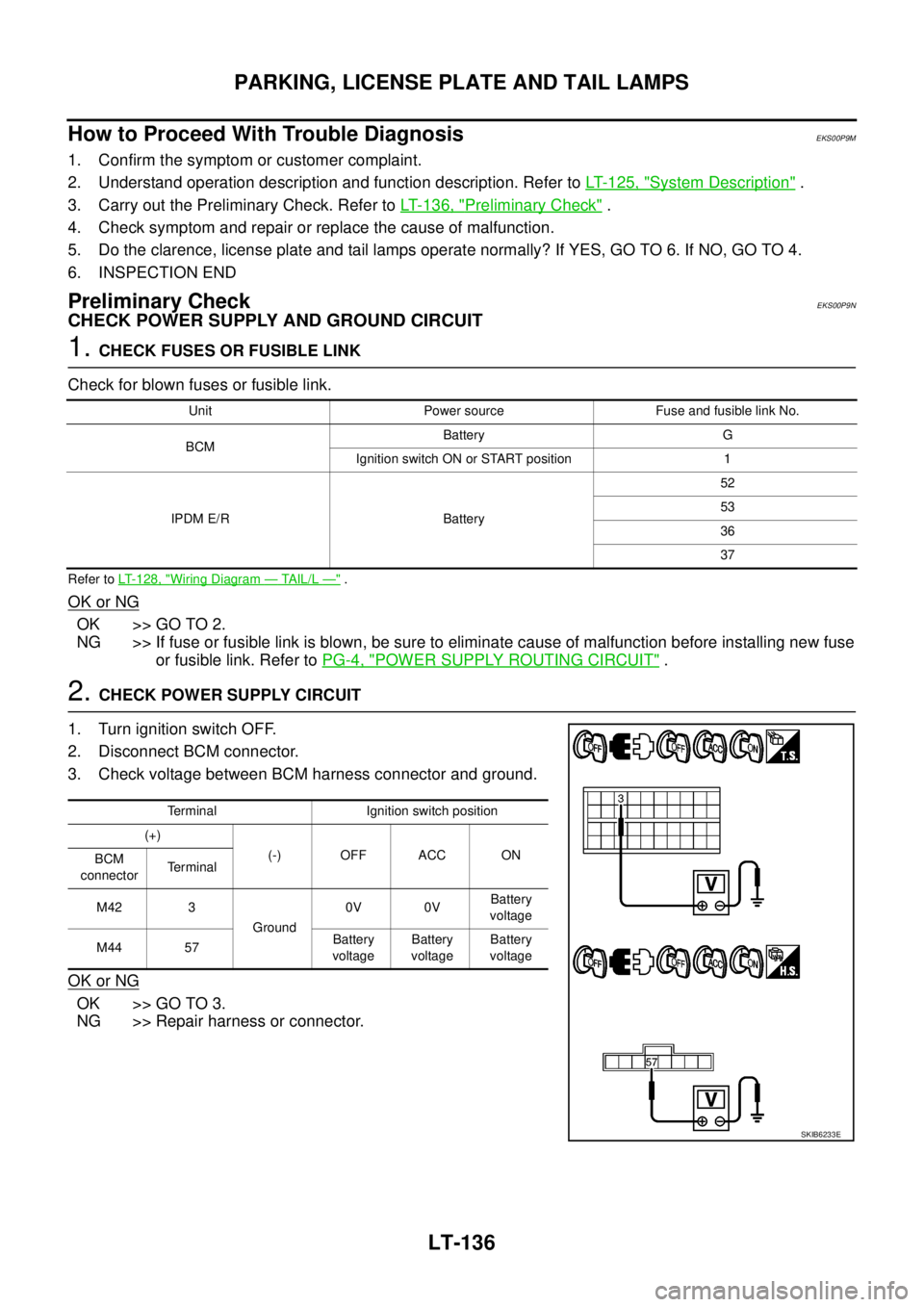

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check voltage between BCM harness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

Unit Power source Fuse and fusible link No.

BCMBattery G

Ignition switch ON or START position 1

IPDM E/R Battery52

53

36

37

Terminal Ignition switch position

(+)

(-) OFF ACC ON

BCM

connectorTerminal

M42 3

Ground0V 0VBattery

voltage

M44 57Battery

voltageBattery

voltageBattery

voltage

SKIB6233E

Page 2238 of 3171

INTERIOR ROOM LAMP

LT-155

C

D

E

F

G

H

I

J

L

MA

B

LT

*1: Double cab, *2: King cab

How to Proceed With Trouble DiagnosisEKS00P97

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer toLT- 1 4 5 , "

System Description".

3. Carry out the Preliminary Check. Refer toLT- 1 5 5 , "

Preliminary Check".

4. Check symptom and repair or replace the cause of malfunction.

5. Does the interior room lamp operate normally? If YES: GO TO 6. If NO: GO TO 4.

6. INSPECTION END

Preliminary CheckEKS00P98

INSPECTION FOR POWER SUPPLY AND GROUND CIRCUIT

1.CHECK FUSES OR FUSIBLE LINK

Check for blown fuses or fusible link.

Refer toLT-149, "Wiring Diagram—INT/L—".

OK or NG

OK >> GO TO 2.

NG >> If fuse or fusible link is blown, be sure to eliminate cause of malfunction before installing new fuse

or fusible link. Refer toPG-4, "

POWER SUPPLY ROUTING CIRCUIT".

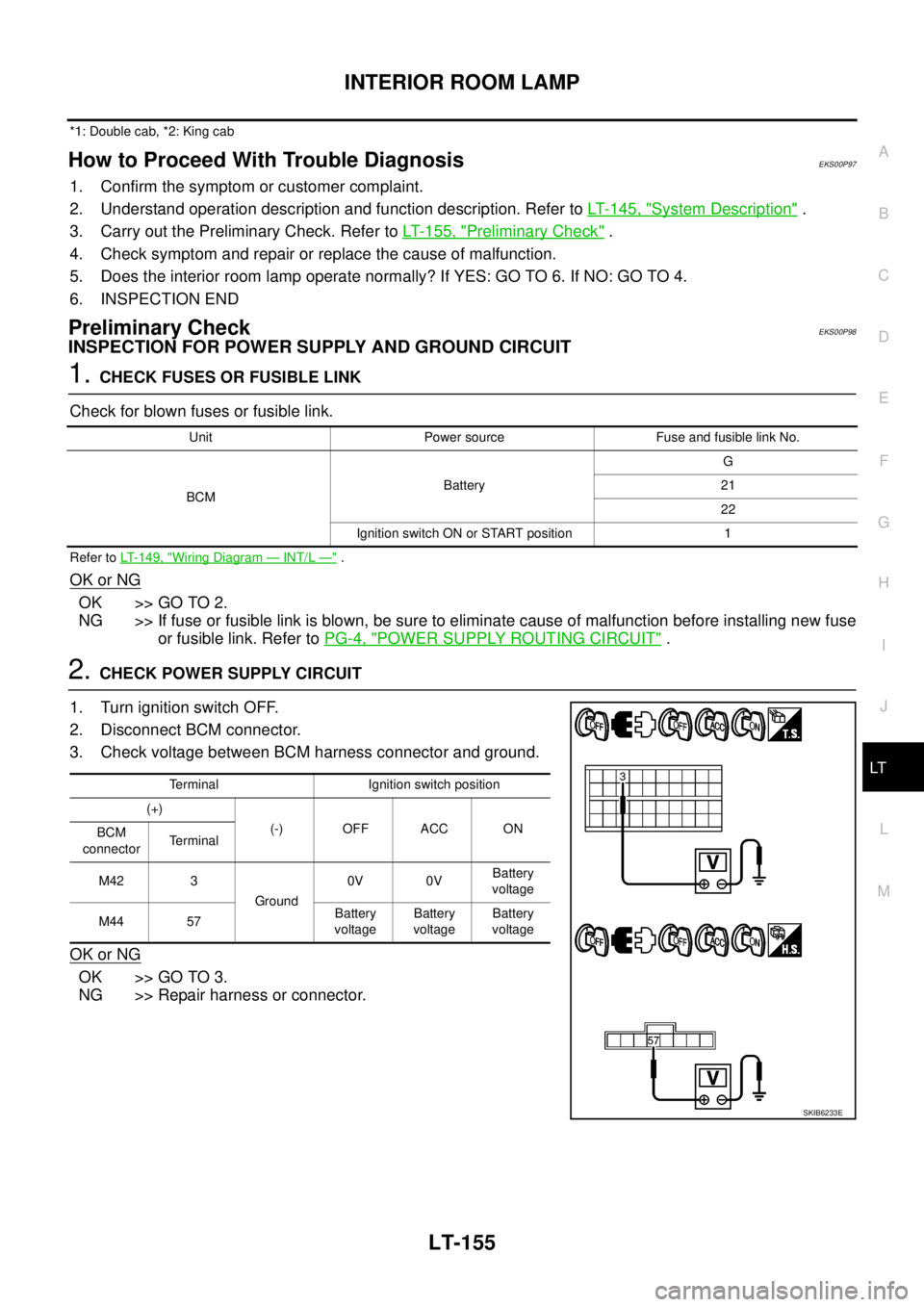

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check voltage between BCM harness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

Unit Power source Fuse and fusible link No.

BCMBatteryG

21

22

Ignition switch ON or START position 1

Terminal Ignition switch position

(+)

(-) OFF ACC ON

BCM

connectorTerminal

M42 3

Ground0V 0VBattery

voltage

M44 57Battery

voltageBattery

voltageBattery

voltage

SKIB6233E

Page 2444 of 3171

TROUBLE DIAGNOSIS

MTC-57

C

D

E

F

G

H

I

K

L

MA

B

MTC

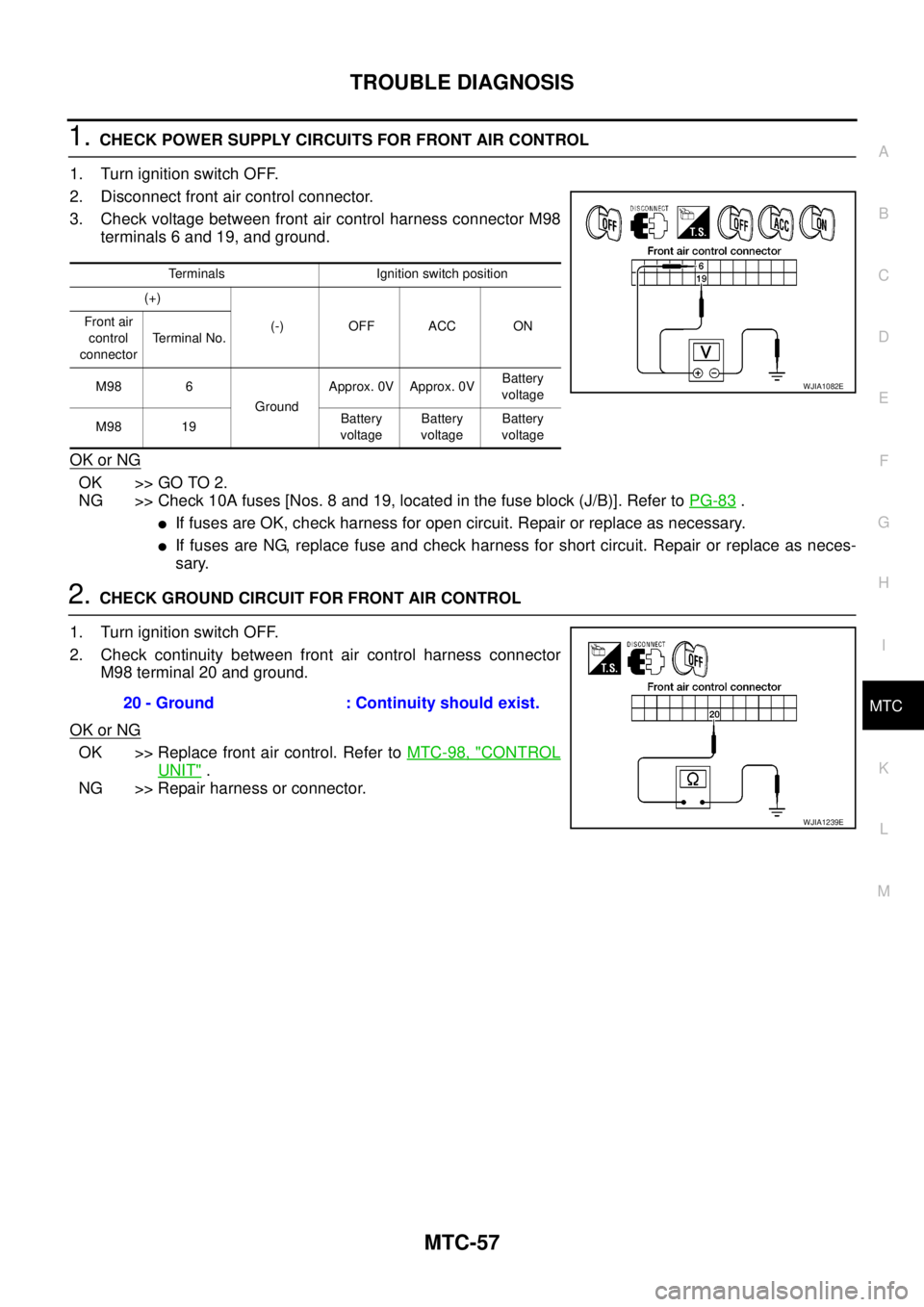

1.CHECK POWER SUPPLY CIRCUITS FOR FRONT AIR CONTROL

1. Turn ignition switch OFF.

2. Disconnect front air control connector.

3. Check voltage between front air control harness connector M98

terminals 6 and 19, and ground.

OK or NG

OK >> GO TO 2.

NG >> Check 10A fuses [Nos. 8 and 19, located in the fuse block (J/B)]. Refer toPG-83

.

lIf fuses are OK, check harness for open circuit. Repair or replace as necessary.

lIf fuses are NG, replace fuse and check harness for short circuit. Repair or replace as neces-

sary.

2.CHECK GROUND CIRCUIT FOR FRONT AIR CONTROL

1. Turn ignition switch OFF.

2. Check continuity between front air control harness connector

M98 terminal 20 and ground.

OK or NG

OK >> Replace front air control. Refer toMTC-98, "CONTROL

UNIT".

NG >> Repair harness or connector.

Terminals Ignition switch position

(+)

(-) OFF ACC ON Front air

control

connectorTerminal No.

M98 6

GroundApprox. 0V Approx. 0VBattery

voltage

M98 19Battery

voltageBattery

voltageBattery

voltage

WJIA1082E

20 - Ground : Continuity should exist.

WJIA1239E

Page 2460 of 3171

TROUBLE DIAGNOSIS

MTC-73

C

D

E

F

G

H

I

K

L

MA

B

MTC

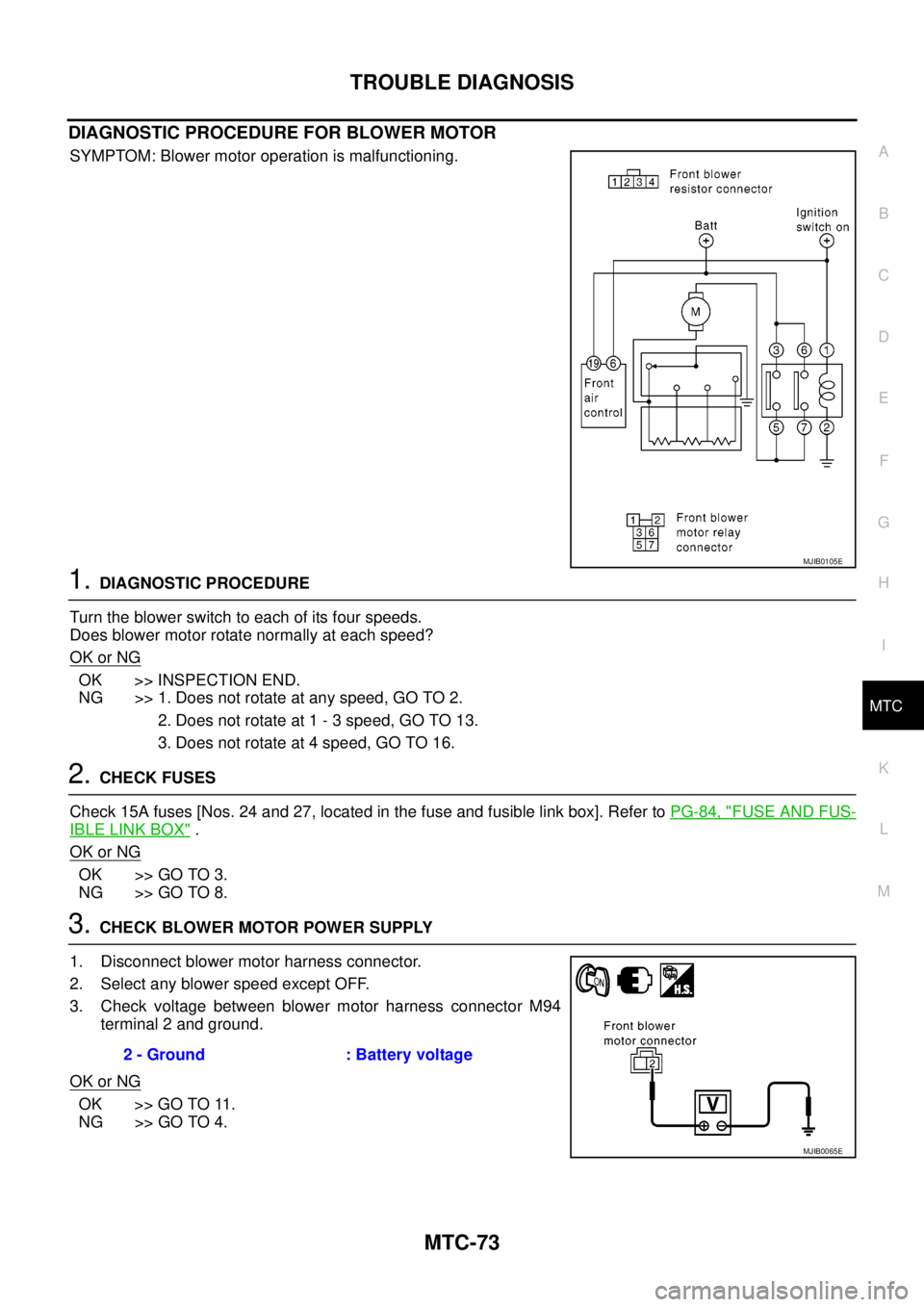

DIAGNOSTIC PROCEDURE FOR BLOWER MOTOR

SYMPTOM: Blower motor operation is malfunctioning.

1.DIAGNOSTIC PROCEDURE

Turntheblowerswitchtoeachofitsfourspeeds.

Does blower motor rotate normally at each speed?

OK or NG

OK >> INSPECTION END.

NG >> 1. Does not rotate at any speed, GO TO 2.

2. Does not rotate at 1 - 3 speed, GO TO 13.

3. Does not rotate at 4 speed, GO TO 16.

2.CHECK FUSES

Check 15A fuses [Nos. 24 and 27, located in the fuse and fusible link box]. Refer toPG-84, "

FUSE AND FUS-

IBLE LINK BOX".

OK or NG

OK >> GO TO 3.

NG >> GO TO 8.

3.CHECK BLOWER MOTOR POWER SUPPLY

1. Disconnect blower motor harness connector.

2. Select any blower speed except OFF.

3. Check voltage between blower motor harness connector M94

terminal 2 and ground.

OK or NG

OK >> GO TO 11.

NG >> GO TO 4.

MJIB0105E

2 - Ground : Battery voltage

MJIB0065E

Page 2462 of 3171

TROUBLE DIAGNOSIS

MTC-75

C

D

E

F

G

H

I

K

L

MA

B

MTC

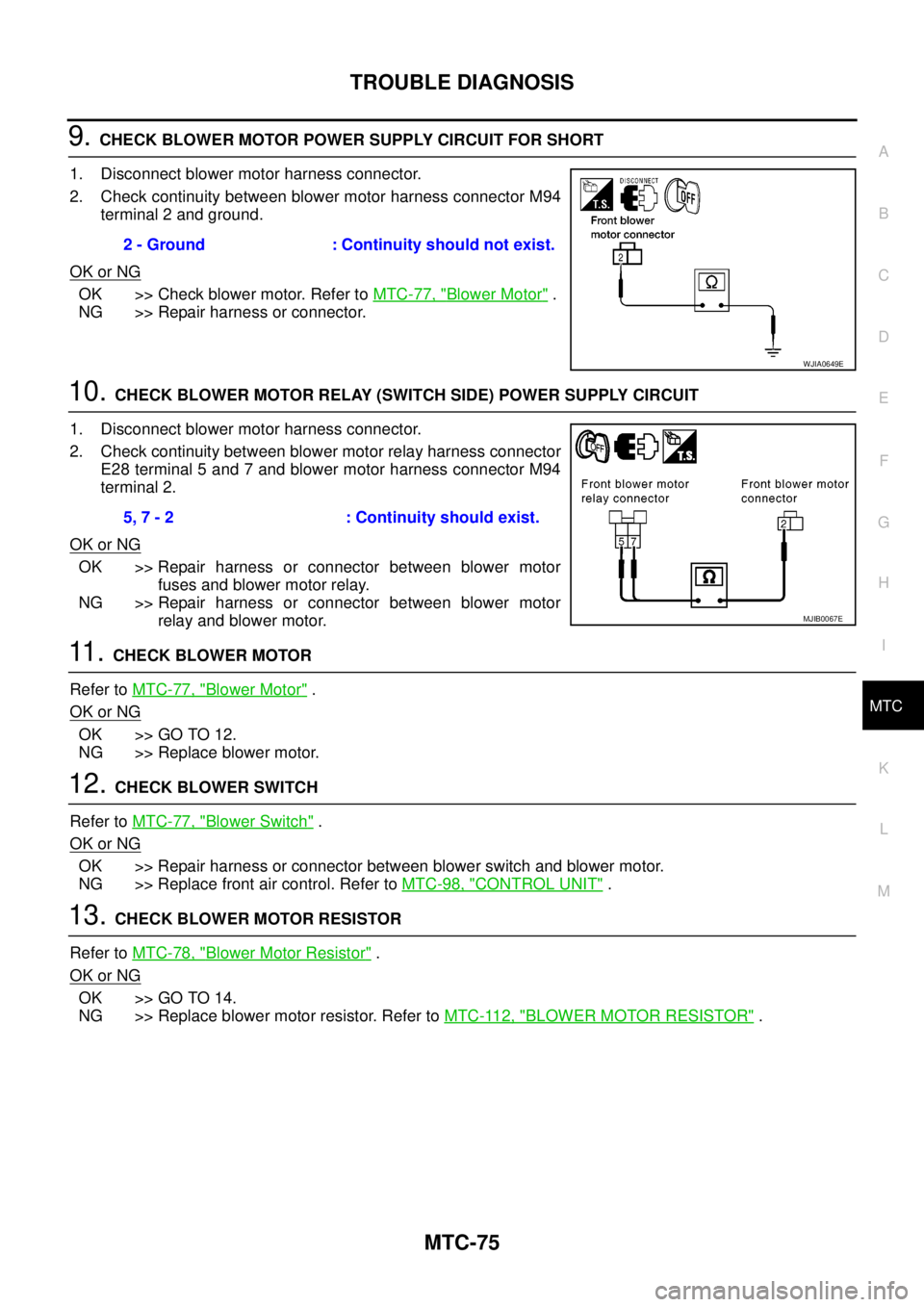

9.CHECK BLOWER MOTOR POWER SUPPLY CIRCUIT FOR SHORT

1. Disconnect blower motor harness connector.

2. Check continuity between blower motor harness connector M94

terminal 2 and ground.

OK or NG

OK >> Check blower motor. Refer toMTC-77, "Blower Motor".

NG >> Repair harness or connector.

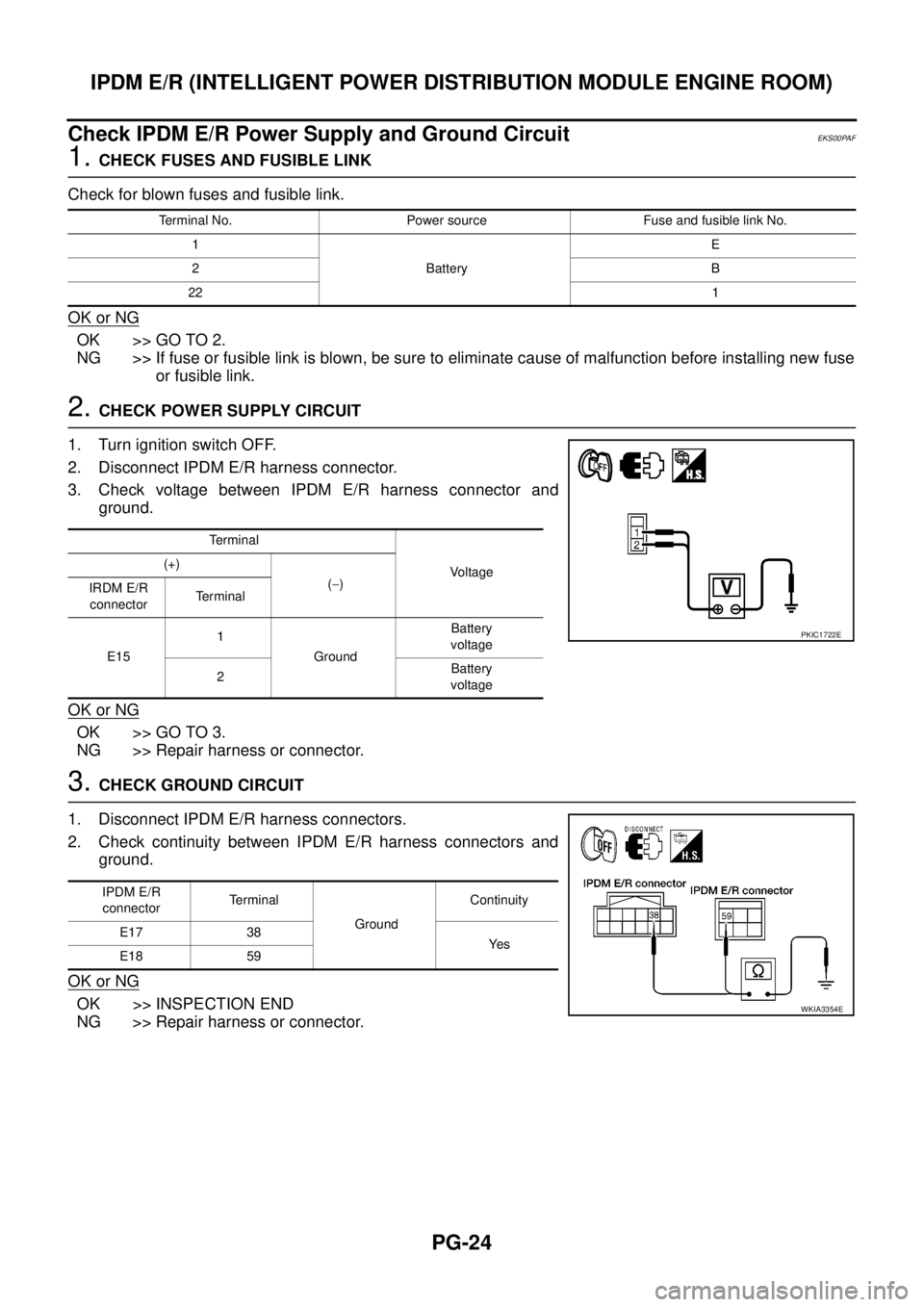

10.CHECK BLOWER MOTOR RELAY (SWITCH SIDE) POWER SUPPLY CIRCUIT

1. Disconnect blower motor harness connector.

2. Check continuity between blower motor relay harness connector

E28 terminal 5 and 7 and blower motor harness connector M94

terminal 2.

OK or NG

OK >> Repair harness or connector between blower motor

fuses and blower motor relay.

NG >> Repair harness or connector between blower motor

relay and blower motor.

11 .CHECK BLOWER MOTOR

Refer toMTC-77, "

Blower Motor".

OK or NG

OK >> GO TO 12.

NG >> Replace blower motor.

12.CHECK BLOWER SWITCH

Refer toMTC-77, "

Blower Switch".

OK or NG

OK >> Repair harness or connector between blower switch and blower motor.

NG >> Replace front air control. Refer toMTC-98, "

CONTROL UNIT".

13.CHECK BLOWER MOTOR RESISTOR

Refer toMTC-78, "

Blower Motor Resistor".

OK or NG

OK >> GO TO 14.

NG >> Replace blower motor resistor. Refer toMTC-112, "

BLOWER MOTOR RESISTOR". 2 - Ground : Continuity should not exist.

WJIA0649E

5, 7 - 2 : Continuity should exist.

MJIB0067E

Page 2553 of 3171

PG-24

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Check IPDM E/R Power Supply and Ground Circuit

EKS00PAF

1.CHECK FUSES AND FUSIBLE LINK

Check for blown fuses and fusible link.

OK or NG

OK >> GO TO 2.

NG >> If fuse or fusible link is blown, be sure to eliminate cause of malfunction before installing new fuse

or fusible link.

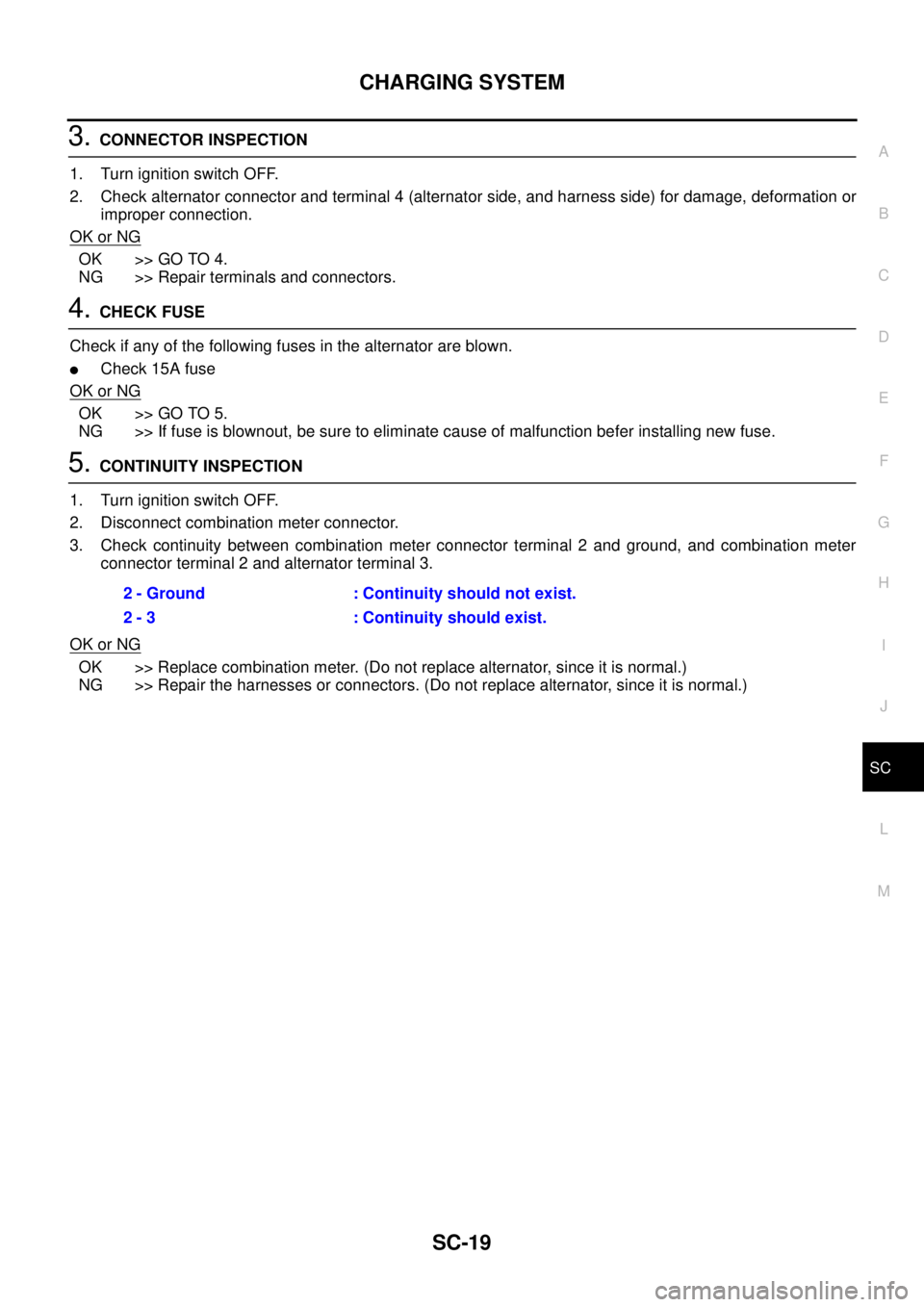

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector.

3. Check voltage between IPDM E/R harness connector and

ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

1. Disconnect IPDM E/R harness connectors.

2. Check continuity between IPDM E/R harness connectors and

ground.

OK or NG

OK >> INSPECTION END

NG >> Repair harness or connector.

Terminal No. Power source Fuse and fusible link No.

1

BatteryE

2B

221

Te r m i n a l

Vo l ta g e (+)

(-)

IRDM E/R

connectorTerminal

E151

GroundBattery

voltage

2Battery

voltage

PKIC1722E

IPDM E/R

connectorTerminal

GroundContinuity

E17 38

Ye s

E18 59

WKIA3354E

Page 2852 of 3171

CHARGING SYSTEM

SC-19

C

D

E

F

G

H

I

J

L

MA

B

SC

3.CONNECTOR INSPECTION

1. Turn ignition switch OFF.

2. Check alternator connector and terminal 4 (alternator side, and harness side) for damage, deformation or

improper connection.

OK or NG

OK >> GO TO 4.

NG >> Repair terminals and connectors.

4.CHECK FUSE

Check if any of the following fuses in the alternator are blown.

lCheck 15A fuse

OK or NG

OK >> GO TO 5.

NG >> If fuse is blownout, be sure to eliminate cause of malfunction befer installing new fuse.

5.CONTINUITY INSPECTION

1. Turn ignition switch OFF.

2. Disconnect combination meter connector.

3. Check continuity between combination meter connector terminal 2 and ground, and combination meter

connector terminal 2 and alternator terminal 3.

OK or NG

OK >> Replace combination meter. (Do not replace alternator, since it is normal.)

NG >> Repair the harnesses or connectors. (Do not replace alternator, since it is normal.)2 - Ground : Continuity should not exist.

2 - 3 : Continuity should exist.

Page 2854 of 3171

CHARGING SYSTEM

SC-21

C

D

E

F

G

H

I

J

L

MA

B

SC

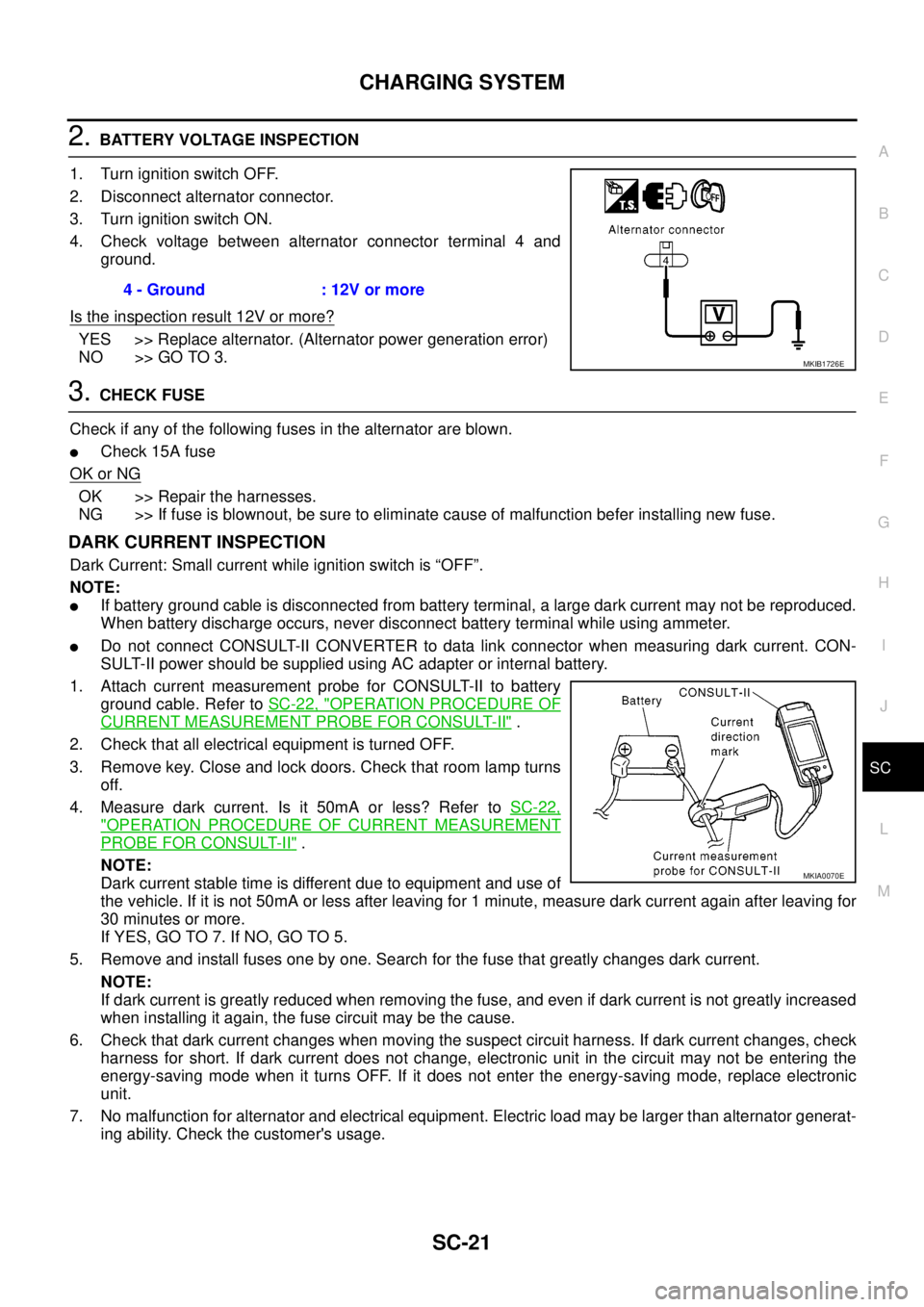

2.BATTERY VOLTAGE INSPECTION

1. Turn ignition switch OFF.

2. Disconnect alternator connector.

3. Turn ignition switch ON.

4. Check voltage between alternator connector terminal 4 and

ground.

Is the inspection result 12V or more?

YES >> Replace alternator. (Alternator power generation error)

NO >> GO TO 3.

3.CHECK FUSE

Check if any of the following fuses in the alternator are blown.

lCheck 15A fuse

OK or NG

OK >> Repair the harnesses.

NG >> If fuse is blownout, be sure to eliminate cause of malfunction befer installing new fuse.

DARK CURRENT INSPECTION

Dark Current: Small current while ignition switch is “OFF”.

NOTE:

lIf battery ground cable is disconnected from battery terminal, a large dark current may not be reproduced.

When battery discharge occurs, never disconnect battery terminal while using ammeter.

lDo not connect CONSULT-II CONVERTER to data link connector when measuring dark current. CON-

SULT-II power should be supplied using AC adapter or internal battery.

1. Attach current measurement probe for CONSULT-II to battery

ground cable. Refer toSC-22, "

OPERATION PROCEDURE OF

CURRENT MEASUREMENT PROBE FOR CONSULT-II".

2. Check that all electrical equipment is turned OFF.

3. Remove key. Close and lock doors. Check that room lamp turns

off.

4. Measure dark current. Is it 50mA or less? Refer toSC-22,

"OPERATION PROCEDURE OF CURRENT MEASUREMENT

PROBE FOR CONSULT-II".

NOTE:

Dark current stable time is different due to equipment and use of

the vehicle. If it is not 50mA or less after leaving for 1 minute, measure dark current again after leaving for

30 minutes or more.

If YES, GO TO 7. If NO, GO TO 5.

5. Remove and install fuses one by one. Search for the fuse that greatly changes dark current.

NOTE:

If dark current is greatly reduced when removing the fuse, and even if dark current is not greatly increased

when installing it again, the fuse circuit may be the cause.

6. Check that dark current changes when moving the suspect circuit harness. If dark current changes, check

harness for short. If dark current does not change, electronic unit in the circuit may not be entering the

energy-saving mode when it turns OFF. If it does not enter the energy-saving mode, replace electronic

unit.

7. No malfunction for alternator and electrical equipment. Electric load may be larger than alternator generat-

ing ability. Check the customer's usage.4 - Ground : 12V or more

MKIB1726E

MKIA0070E

Page 3020 of 3171

TROUBLE DIAGNOSIS FOR SYSTEM

TF-53

C

E

F

G

H

I

J

K

L

MA

B

TF

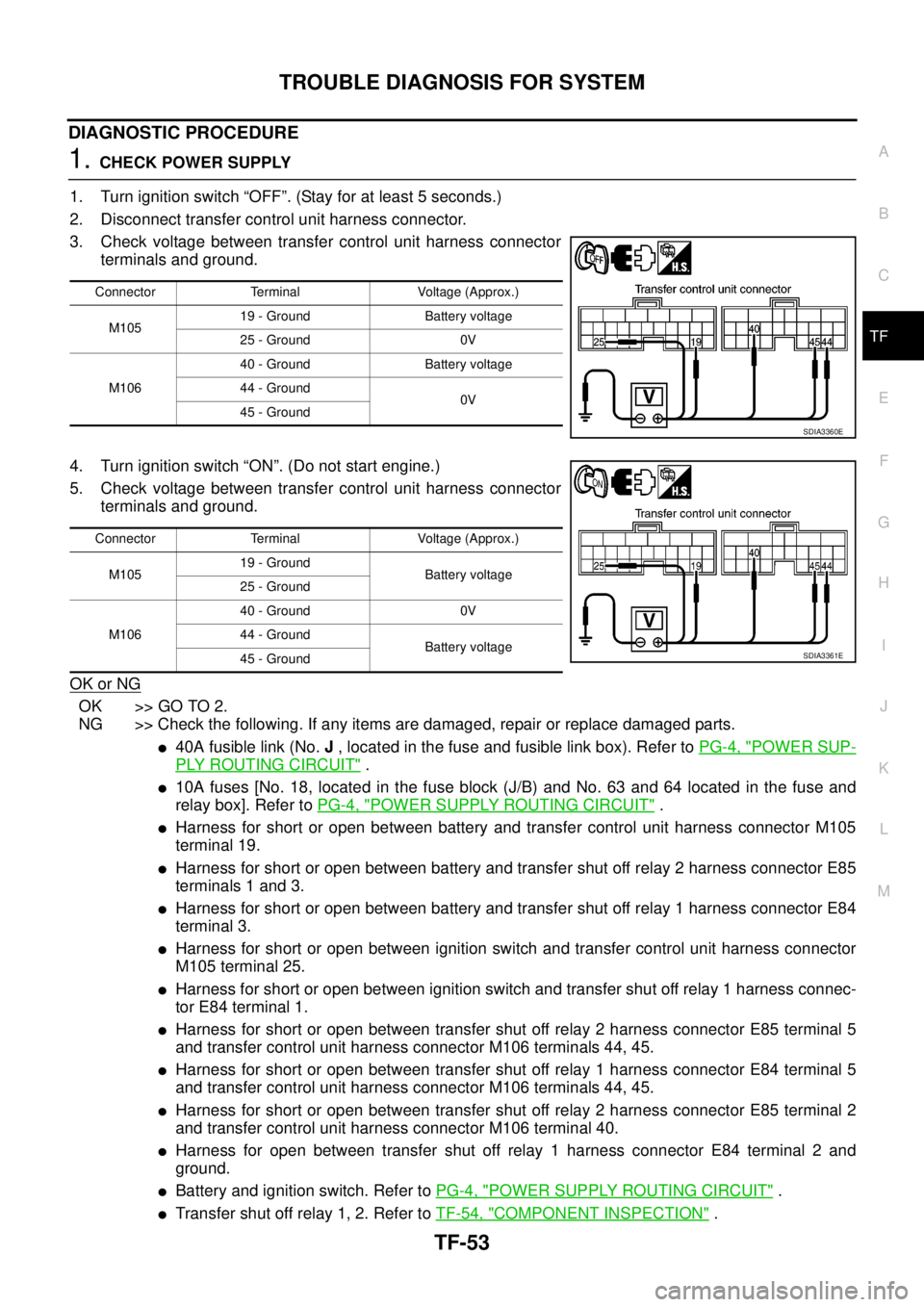

DIAGNOSTIC PROCEDURE

1.CHECK POWER SUPPLY

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector.

3. Check voltage between transfer control unit harness connector

terminals and ground.

4. Turn ignition switch “ON”. (Do not start engine.)

5. Check voltage between transfer control unit harness connector

terminals and ground.

OK or NG

OK >> GO TO 2.

NG >> Check the following. If any items are damaged, repair or replace damaged parts.

l40A fusible link (No.J, located in the fuse and fusible link box). Refer toPG-4, "POWER SUP-

PLY ROUTING CIRCUIT".

l10A fuses [No. 18, located in the fuse block (J/B) and No. 63 and 64 located in the fuse and

relay box]. Refer toPG-4, "

POWER SUPPLY ROUTING CIRCUIT".

lHarness for short or open between battery and transfer control unit harness connector M105

terminal 19.

lHarness for short or open between battery and transfer shut off relay 2 harness connector E85

terminals 1 and 3.

lHarness for short or open between battery and transfer shut off relay 1 harness connector E84

terminal 3.

lHarness for short or open between ignition switch and transfer control unit harness connector

M105 terminal 25.

lHarness for short or open between ignition switch and transfer shut off relay 1 harness connec-

tor E84 terminal 1.

lHarness for short or open between transfer shut off relay 2 harness connector E85 terminal 5

and transfer control unit harness connector M106 terminals 44, 45.

lHarness for short or open between transfer shut off relay 1 harness connector E84 terminal 5

and transfer control unit harness connector M106 terminals 44, 45.

lHarness for short or open between transfer shut off relay 2 harness connector E85 terminal 2

and transfer control unit harness connector M106 terminal 40.

lHarness for open between transfer shut off relay 1 harness connector E84 terminal 2 and

ground.

lBattery and ignition switch. Refer toPG-4, "POWER SUPPLY ROUTING CIRCUIT".

lTransfer shut off relay 1, 2. Refer toTF-54, "COMPONENT INSPECTION".

Connector Terminal Voltage (Approx.)

M10519 - Ground Battery voltage

25 - Ground 0V

M10640 - Ground Battery voltage

44 - Ground

0V

45 - Ground

SDIA3360E

Connector Terminal Voltage (Approx.)

M10519 - Ground

Battery voltage

25 - Ground

M10640 - Ground 0V

44 - Ground

Battery voltage

45 - Ground

SDIA3361E

Page 3056 of 3171

TROUBLE DIAGNOSIS FOR SYMPTOMS

TF-89

C

E

F

G

H

I

J

K

L

MA

B

TF

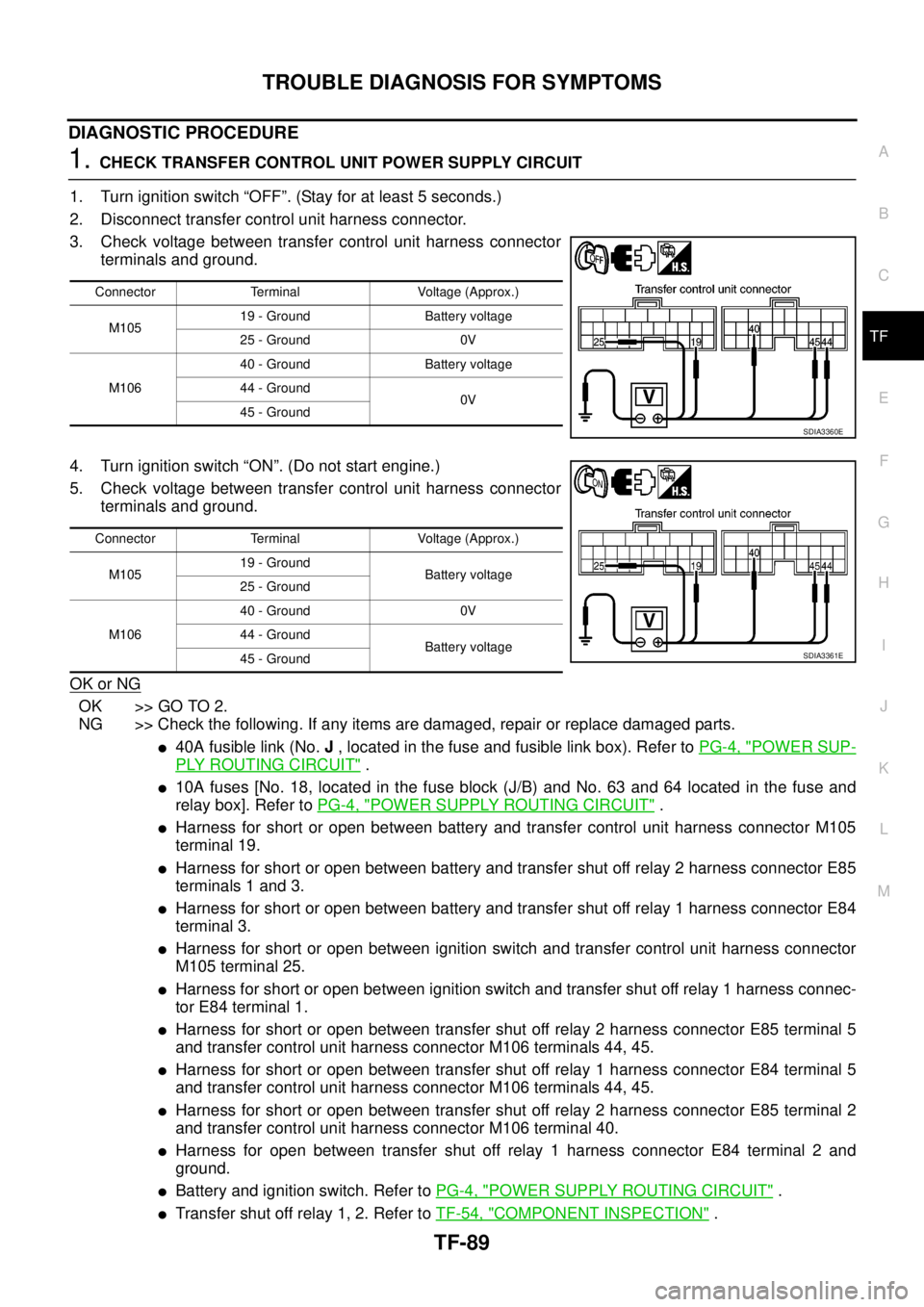

DIAGNOSTIC PROCEDURE

1.CHECK TRANSFER CONTROL UNIT POWER SUPPLY CIRCUIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector.

3. Check voltage between transfer control unit harness connector

terminals and ground.

4. Turn ignition switch “ON”. (Do not start engine.)

5. Check voltage between transfer control unit harness connector

terminals and ground.

OK or NG

OK >> GO TO 2.

NG >> Check the following. If any items are damaged, repair or replace damaged parts.

l40A fusible link (No.J, located in the fuse and fusible link box). Refer toPG-4, "POWER SUP-

PLY ROUTING CIRCUIT".

l10A fuses [No. 18, located in the fuse block (J/B) and No. 63 and 64 located in the fuse and

relay box]. Refer toPG-4, "

POWER SUPPLY ROUTING CIRCUIT".

lHarness for short or open between battery and transfer control unit harness connector M105

terminal 19.

lHarness for short or open between battery and transfer shut off relay 2 harness connector E85

terminals 1 and 3.

lHarness for short or open between battery and transfer shut off relay 1 harness connector E84

terminal 3.

lHarness for short or open between ignition switch and transfer control unit harness connector

M105 terminal 25.

lHarness for short or open between ignition switch and transfer shut off relay 1 harness connec-

tor E84 terminal 1.

lHarness for short or open between transfer shut off relay 2 harness connector E85 terminal 5

and transfer control unit harness connector M106 terminals 44, 45.

lHarness for short or open between transfer shut off relay 1 harness connector E84 terminal 5

and transfer control unit harness connector M106 terminals 44, 45.

lHarness for short or open between transfer shut off relay 2 harness connector E85 terminal 2

and transfer control unit harness connector M106 terminal 40.

lHarness for open between transfer shut off relay 1 harness connector E84 terminal 2 and

ground.

lBattery and ignition switch. Refer toPG-4, "POWER SUPPLY ROUTING CIRCUIT".

lTransfer shut off relay 1, 2. Refer toTF-54, "COMPONENT INSPECTION".

Connector Terminal Voltage (Approx.)

M10519 - Ground Battery voltage

25 - Ground 0V

M10640 - Ground Battery voltage

44 - Ground

0V

45 - Ground

SDIA3360E

Connector Terminal Voltage (Approx.)

M10519 - Ground

Battery voltage

25 - Ground

M10640 - Ground 0V

44 - Ground

Battery voltage

45 - Ground

SDIA3361E