display NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1256 of 3171

EC-276

DTC P2135 APP SENSOR

On Board Diagnosis Logic

EBS01KKW

The MI will not light up for this self-diagnosis.

NOTE:

lIf DTC P2135 is displayed with DTC P0642 or P0643, first perform the trouble diagnosis for DTC

P0642 or P0643. Refer toEC-222, "

DTC P0642, P0643 SENSOR POWER SUPPLY".

lIf DTC P2135 is displayed with DTC P0652 or P0653, first perform the trouble diagnosis for DTC

P0652 or P0653. Refer toEC-227, "

DTC P0652, P0653 SENSOR POWER SUPPLY".

DTC Confirmation ProcedureEBS01KKX

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

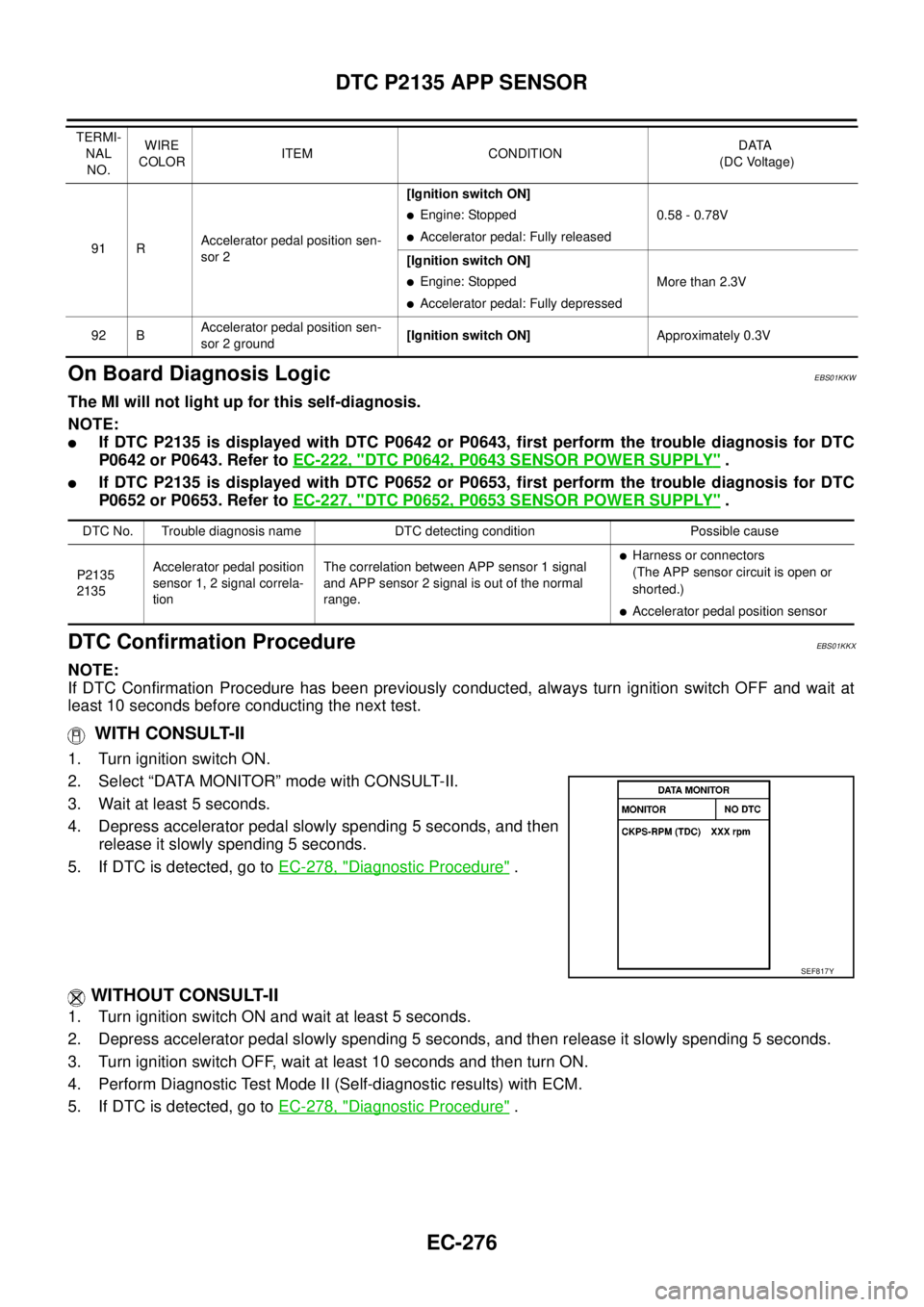

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. Depress accelerator pedal slowly spending 5 seconds, and then

release it slowly spending 5 seconds.

5. If DTC is detected, go toEC-278, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Turn ignition switch ON and wait at least 5 seconds.

2. Depress accelerator pedal slowly spending 5 seconds, and then release it slowly spending 5 seconds.

3. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

4. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

5. If DTC is detected, go toEC-278, "

Diagnostic Procedure".

91 RAccelerator pedal position sen-

sor 2[Ignition switch ON]

lEngine: Stopped

lAccelerator pedal: Fully released0.58 - 0.78V

[Ignition switch ON]

lEngine: Stopped

lAccelerator pedal: Fully depressedMore than 2.3V

92 BAccelerator pedal position sen-

sor 2 ground[Ignition switch ON]Approximately 0.3V TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage)

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P2135

2135Accelerator pedal position

sensor 1, 2 signal correla-

tionThe correlation between APP sensor 1 signal

and APP sensor 2 signal is out of the normal

range.

lHarness or connectors

(The APP sensor circuit is open or

shorted.)

lAccelerator pedal position sensor

SEF817Y

Page 1274 of 3171

EC-294

DTC P2228, P2229 BARO SENSOR

Diagnostic Procedure

EBS01KLL

1.INSPECTION START

With CONSULT-II

1. Turn ignition switch ON.

2. Select “SELF DIAG RESULTS” mode with CONSULT-II.

3. Touch “ERASE”.

4. PerformEC-293, "

DTC Confirmation Procedure",again.

5. Is DTC P2228 or P2229 displayed again?

Without CONSULT-II

1. Turn ignition switch ON.

2. Erase the Diagnostic Test Mode II (Self-diagnostic results) memory. Refer toEC-27

.

3. PerformEC-293, "

DTC Confirmation Procedure",again.

4. Is DTC 2228 or 2229 displayed again?

Ye s o r N o

Yes >>GOTO2.

No >>INSPECTION END

2.REPLACE ECM

1. Replace ECM.

2. Perform initialization of NATS system and registration of all NATS ignition key IDs. Refer toBL-172, "

ECM

Re-communicating Function".

3. Perform Fuel Pump Learning Valve Clearing. Refer toEC-24, "

Fuel Pump Learning Value Clearing".

4. Perform Injector Adjustment Value Registration. Refer toEC-25, "

Injector Adjustment Value Registration".

>>INSPECTION END

Page 1279 of 3171

GLOW CONTROL SYSTEM

EC-299

C

D

E

F

G

H

I

J

K

L

MA

EC

5.CHECK DTC

Check that DTC U1000 is not displayed.

Ye s o r N o

Yes >> Perform trouble diagnoses for DTC U1000, refer toEC-79, "DTC U1000 CAN COMMUNICATION

LINE".

No >> GO TO 6.

6.CHECK COMBINATON METER OPERATION

Does combination meter operate normally?

Ye s o r N o

Ye s > > G O T O 1 4 .

No >> Check combination meter circuit. Refer toDI-4, "

COMBINATION METERS".

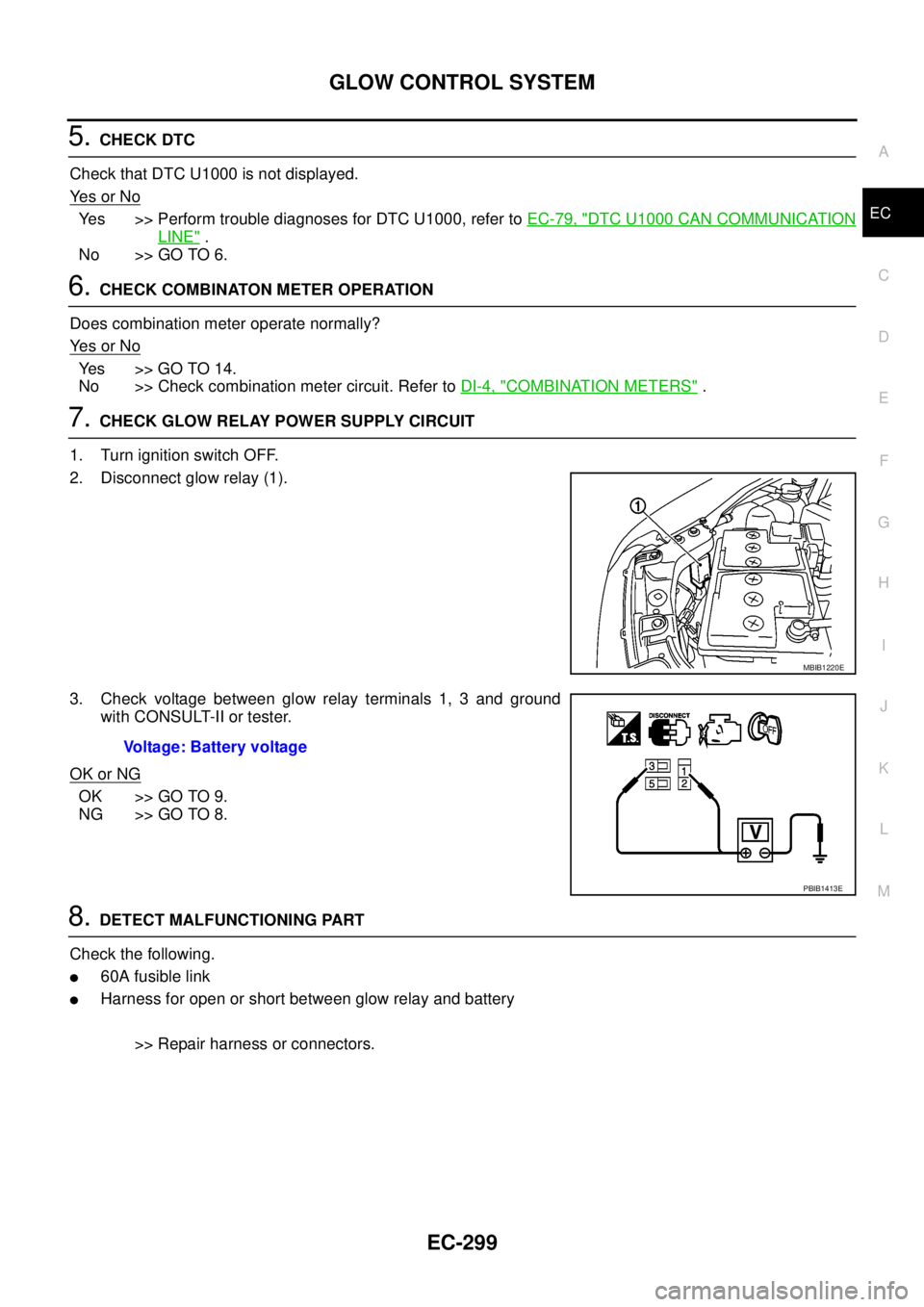

7.CHECK GLOW RELAY POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect glow relay (1).

3. Check voltage between glow relay terminals 1, 3 and ground

with CONSULT-II or tester.

OK or NG

OK >> GO TO 9.

NG >> GO TO 8.

8.DETECT MALFUNCTIONING PART

Check the following.

l60A fusible link

lHarness for open or short between glow relay and battery

>> Repair harness or connectors.

MBIB1220E

Voltage: Battery voltage

PBIB1413E

Page 1333 of 3171

ASCD INDICATOR

EC-353

C

D

E

F

G

H

I

J

K

L

MA

EC

Diagnostic ProcedureEBS01KN0

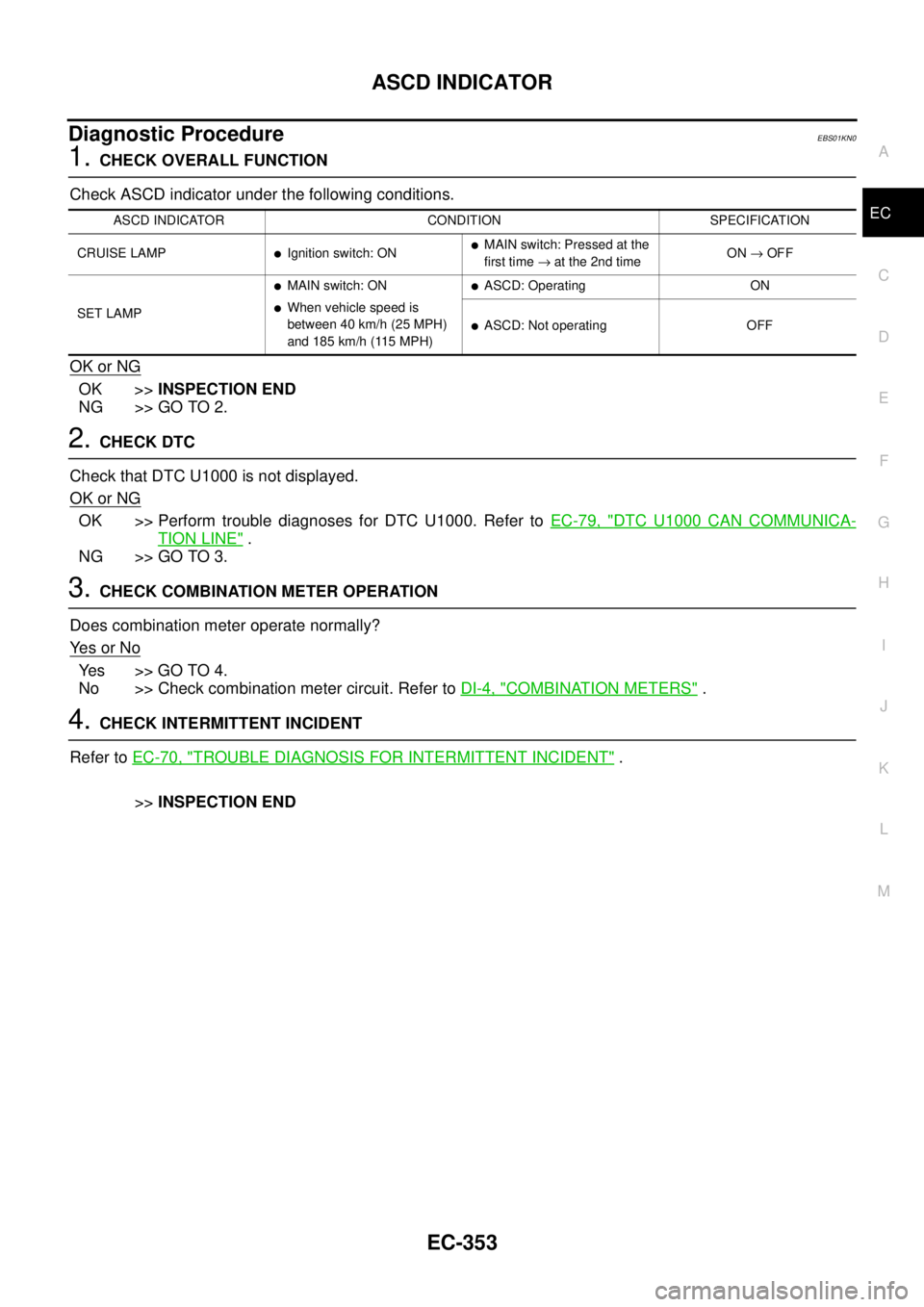

1.CHECK OVERALL FUNCTION

Check ASCD indicator under the following conditions.

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

2.CHECK DTC

Check that DTC U1000 is not displayed.

OK or NG

OK >> Perform trouble diagnoses for DTC U1000. Refer toEC-79, "DTC U1000 CAN COMMUNICA-

TION LINE".

NG >> GO TO 3.

3.CHECK COMBINATION METER OPERATION

Does combination meter operate normally?

Ye s o r N o

Ye s > > G O T O 4 .

No >> Check combination meter circuit. Refer toDI-4, "

COMBINATION METERS".

4.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

ASCD INDICATOR CONDITION SPECIFICATION

CRUISE LAMP

lIgnition switch: ONlMAIN switch: Pressed at the

first time®at the 2nd timeON®OFF

SET LAMP

lMAIN switch: ON

lWhen vehicle speed is

between 40 km/h (25 MPH)

and185km/h(115MPH)

lASCD: Operating ON

lASCD: Not operating OFF

Page 1660 of 3171

GI-38

CONTROL UNIT CONFIGURATION PROCEDURE

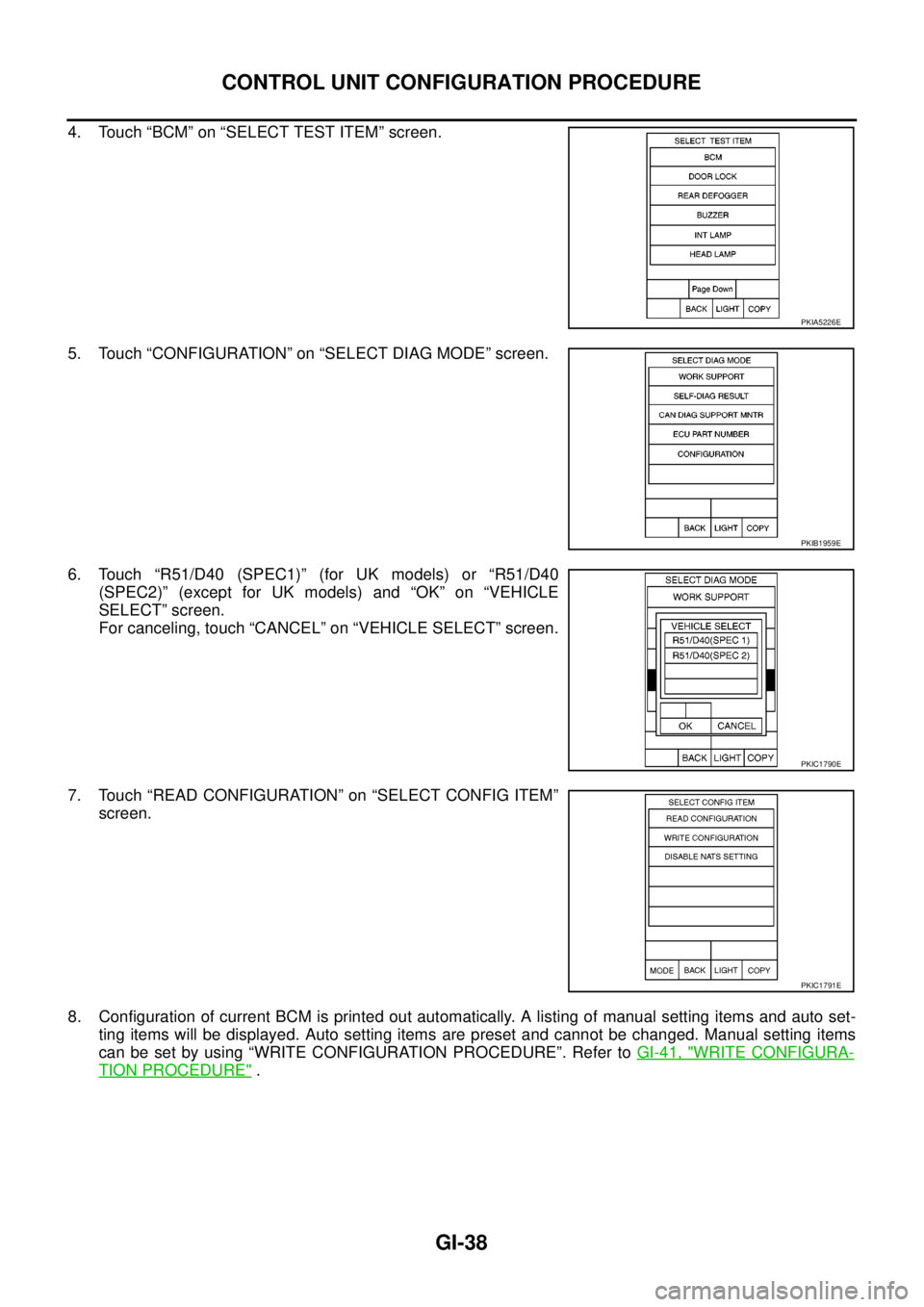

4. Touch “BCM” on “SELECT TEST ITEM” screen.

5. Touch “CONFIGURATION” on “SELECT DIAG MODE” screen.

6. Touch “R51/D40 (SPEC1)” (for UK models) or “R51/D40

(SPEC2)” (except for UK models) and “OK” on “VEHICLE

SELECT” screen.

For canceling, touch “CANCEL” on “VEHICLE SELECT” screen.

7. Touch “READ CONFIGURATION” on “SELECT CONFIG ITEM”

screen.

8. Configuration of current BCM is printed out automatically. A listing of manual setting items and auto set-

ting items will be displayed. Auto setting items are preset and cannot be changed. Manual setting items

can be set by using “WRITE CONFIGURATION PROCEDURE”. Refer toGI-41, "

WRITE CONFIGURA-

TION PROCEDURE".

PKIA5226E

PKIB1959E

PKIC1790E

PKIC1791E

Page 1734 of 3171

GW-48

REAR WINDOW DEFOGGER

Ground is supplied

lto BCM terminal 55

lto front air control terminal 20

lthrough body grounds M21, M80 and M83

lto IPDM E/R terminals 38 and 59

lthrough body grounds E21, E41 and E61.

When front air control (rear window defogger switch) is turned to ON,

Ground is supplied

lto BCM terminal 20

lthrough front air control terminal 11

lthrough front air control terminal 20

lthrough body grounds M21, M80 and M83.

Then rear window defogger switch is illuminated.

Then BCM recognizes that rear window defogger switch is turned to ON.

Then it sends rear window defogger switch signals to IPDM E/R via DATA LINE (CAN H, CAN L).

When display panel receives rear window defogger switch signals it illuminates on the screen.

When IPDM E/R receives rear window defogger switch signals,

Ground is supplied

lto rear window defogger relay (located in the IPDM E/R)

lthrough IPDM E/R terminals 38 and 59

lthrough body grounds E21, E41 and E61

and then rear window defogger relay and heated mirror is energized.

Power is supplied

lthrough IPDM E/R terminal 60

lto rear window defogger terminal 1.

Ground is supplied

lto rear window window defogger terminal 2

lthrough body ground D152.

With power and ground supplied, rear window defogger filaments heat and defog the rear window.

CAN Communication System DescriptionEIS00B8G

Refer toLAN-23, "CAN COMMUNICATION".

Page 1740 of 3171

GW-54

REAR WINDOW DEFOGGER

CONSULT-II Function (BCM)

EIS00B8M

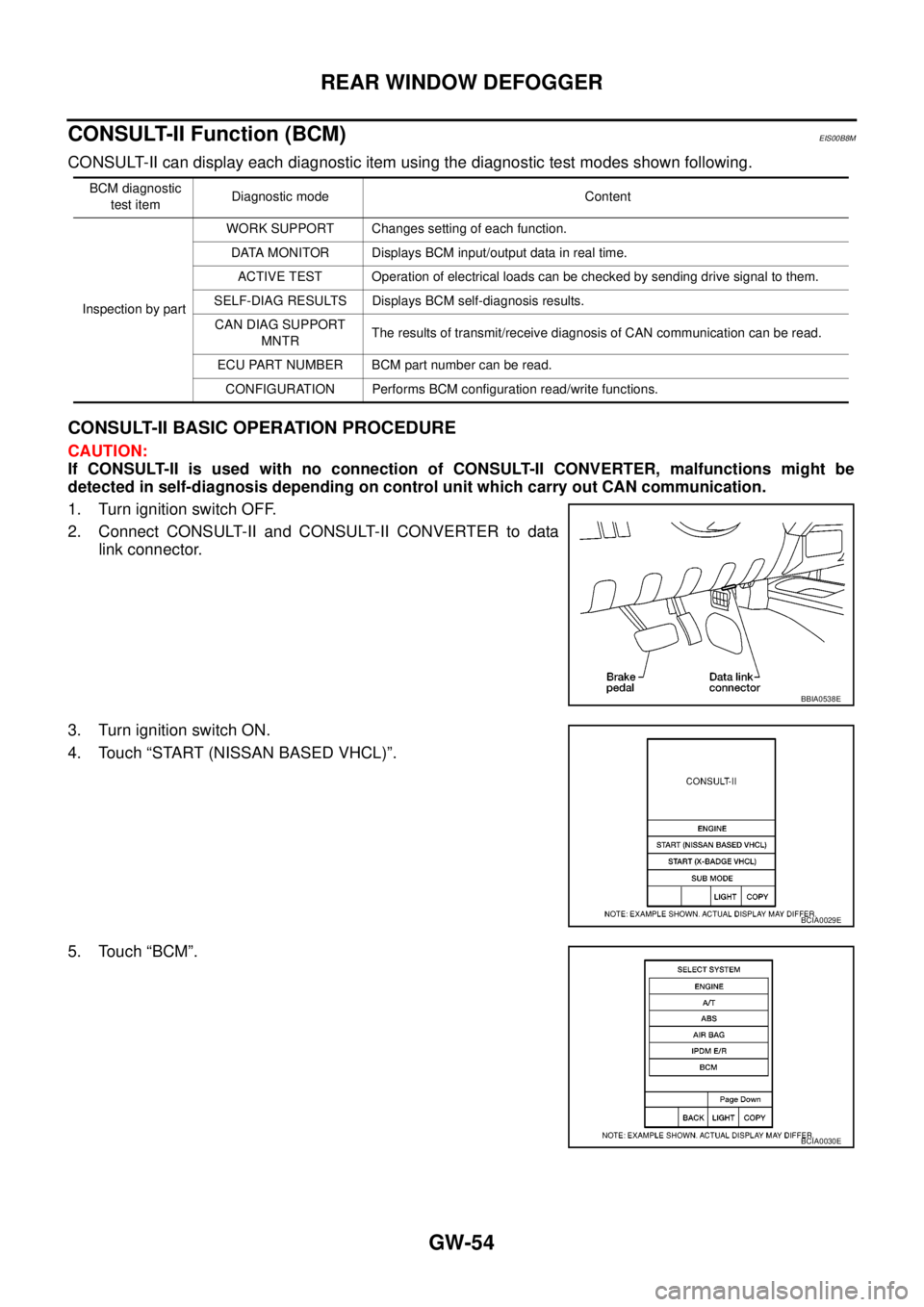

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II BASIC OPERATION PROCEDURE

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. Turn ignition switch OFF.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data

link connector.

3. Turn ignition switch ON.

4. Touch “START (NISSAN BASED VHCL)”.

5. Touch “BCM”.

BCM diagnostic

test itemDiagnostic mode Content

Inspection by partWORK SUPPORT Changes setting of each function.

DATA MONITOR Displays BCM input/output data in real time.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results.

CAN DIAG SUPPORT

MNTRThe results of transmit/receive diagnosis of CAN communication can be read.

ECU PART NUMBER BCM part number can be read.

CONFIGURATION Performs BCM configuration read/write functions.

BBIA0538E

BCIA0029E

BCIA0030E

Page 1741 of 3171

REAR WINDOW DEFOGGER

GW-55

C

D

E

F

G

H

J

K

L

MA

B

GW

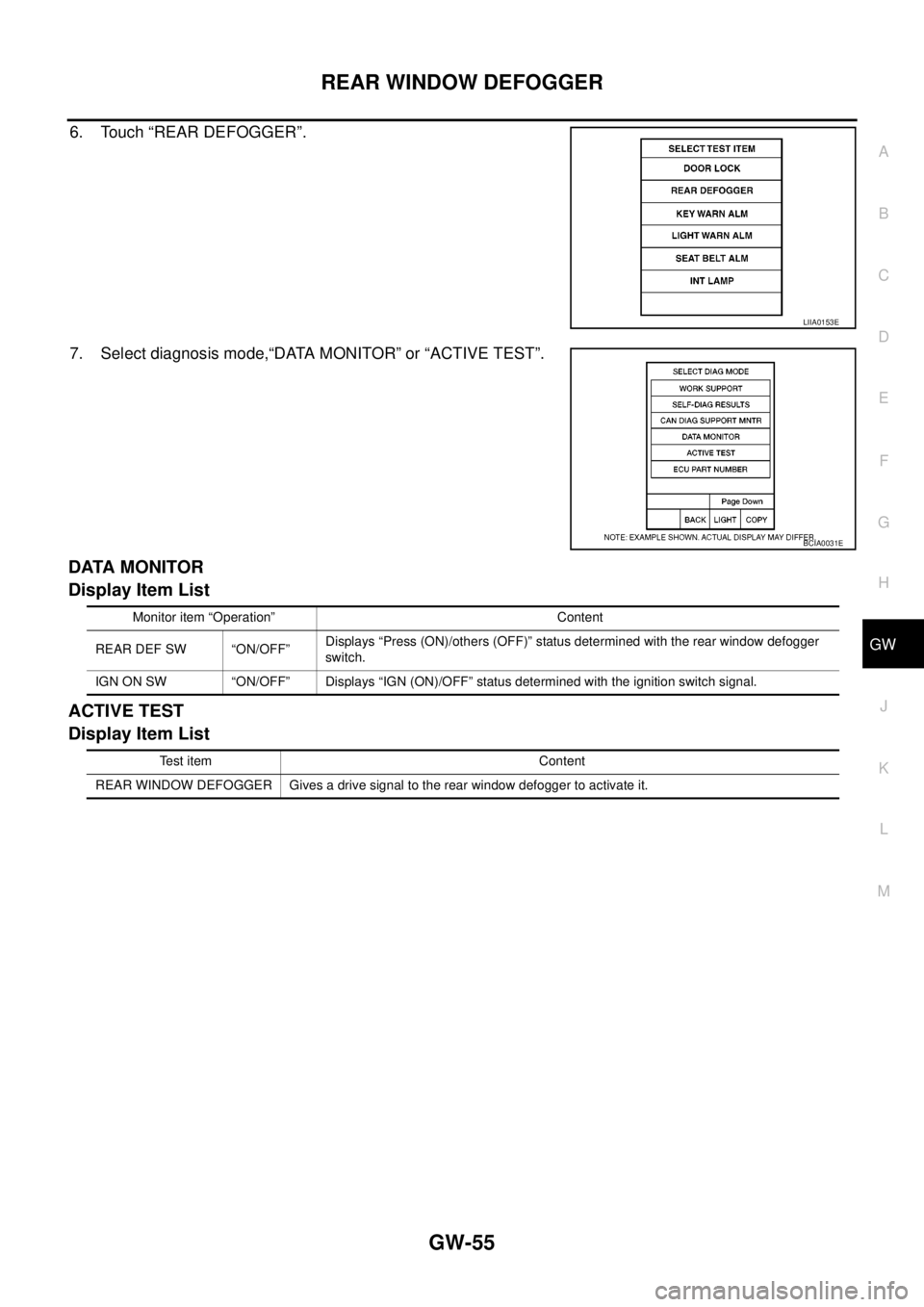

6. Touch “REAR DEFOGGER”.

7. Select diagnosis mode,“DATA MONITOR” or “ACTIVE TEST”.

DATA MONITOR

Display Item List

ACTIVE TEST

Display Item List

LIIA0153E

BCIA0031E

Monitor item “Operation” Content

REAR DEF SW “ON/OFF”Displays “Press (ON)/others (OFF)” status determined with the rear window defogger

switch.

IGN ON SW “ON/OFF” Displays “IGN (ON)/OFF” status determined with the ignition switch signal.

Test item Content

REAR WINDOW DEFOGGER Gives a drive signal to the rear window defogger to activate it.

Page 1742 of 3171

GW-56

REAR WINDOW DEFOGGER

Trouble Diagnoses Symptom Chart

EIS00B8N

lMake sure other systems using the signal of the following systems operate normally.

BCM Power Supply and Ground Circuit CheckEIS00B8O

First perform the “SELF-DIAG RESULTS” in “BCM” with CONSULT-II, when perform the each trouble

diagnosis. Refer toBCS-16, "

CAN Communication Inspection Using CONSULT-II (Self-Diagnosis)".

1.CHECK FUSE

lCheck 10A fuse [No. 1, located in the fuse block (J/B)]

lCheck 50A fusible link (letterGlocated in the fuse and fusible link box)

NOTE:

Refer toGW-47, "

Component Parts and Harness Connector Location".

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse. Refer toPG-

4, "POWER SUPPLY ROUTING CIRCUIT".

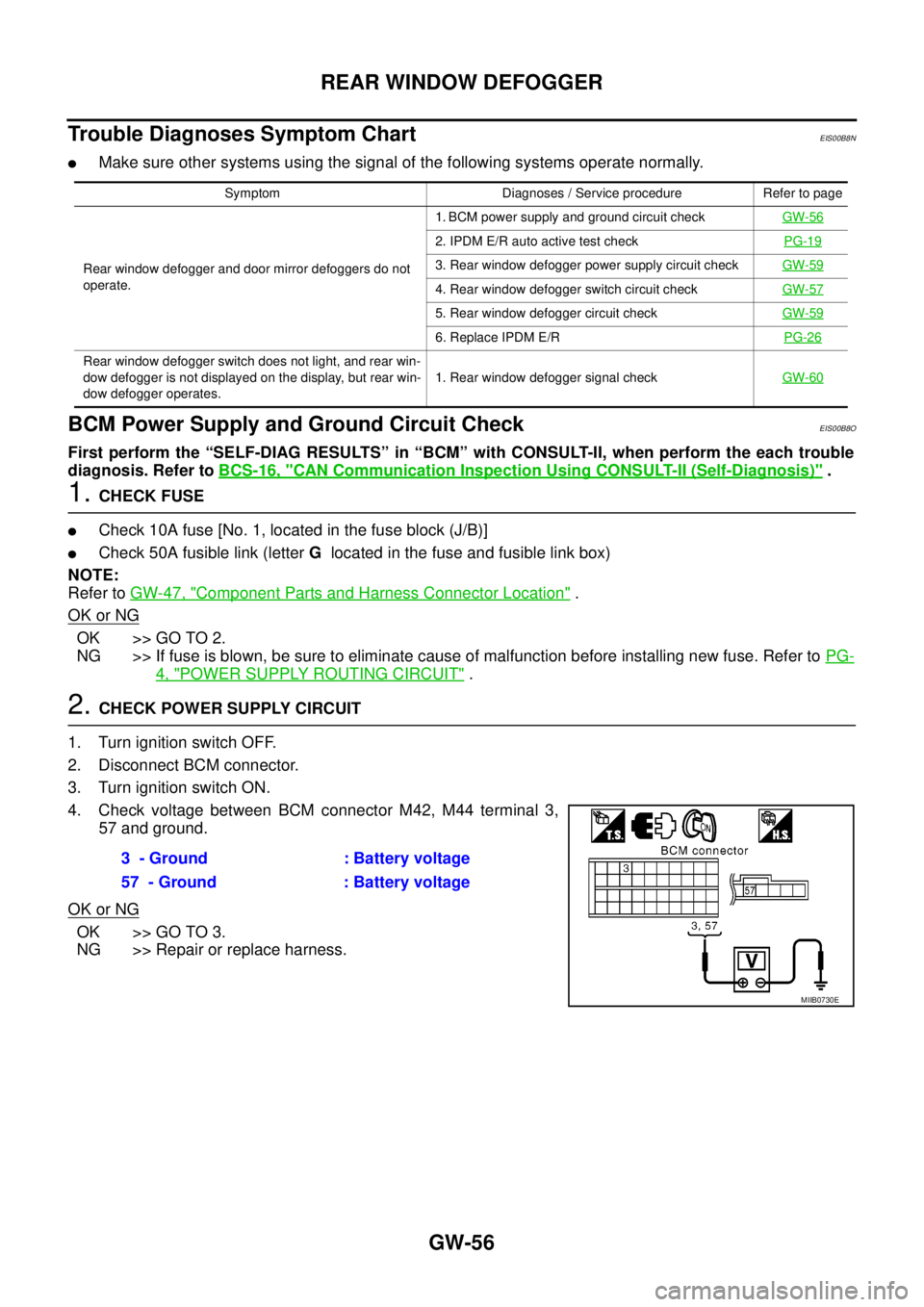

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Turn ignition switch ON.

4. Check voltage between BCM connector M42, M44 terminal 3,

57 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

Symptom Diagnoses / Service procedure Refer to page

Rear window defogger and door mirror defoggers do not

operate.1. BCM power supply and ground circuit checkGW-56

2. IPDM E/R auto active test checkPG-19

3. Rear window defogger power supply circuit checkGW-59

4. Rear window defogger switch circuit checkGW-57

5. Rear window defogger circuit checkGW-59

6. Replace IPDM E/RPG-26

Rear window defogger switch does not light, and rear win-

dow defogger is not displayed on the display, but rear win-

dow defogger operates.1. Rear window defogger signal checkGW-60

3 - Ground : Battery voltage

57 - Ground : Battery voltage

MIIB0730E

Page 1746 of 3171

GW-60

REAR WINDOW DEFOGGER

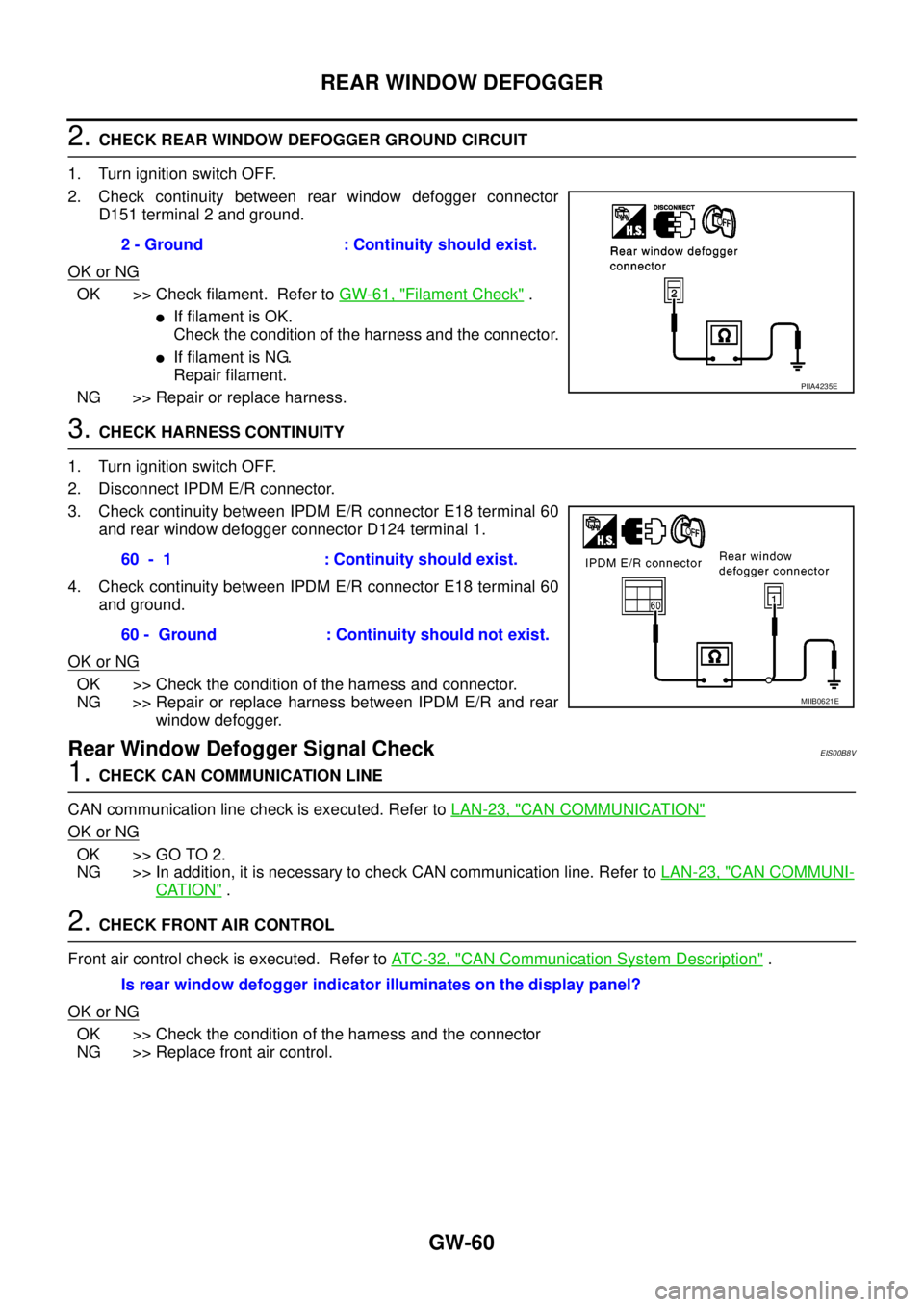

2.CHECK REAR WINDOW DEFOGGER GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between rear window defogger connector

D151 terminal 2 and ground.

OK or NG

OK >> Check filament. Refer toGW-61, "Filament Check".

lIf filament is OK.

Check the condition of the harness and the connector.

lIf filament is NG.

Repair filament.

NG >> Repair or replace harness.

3.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R connector E18 terminal 60

and rear window defogger connector D124 terminal 1.

4. Check continuity between IPDM E/R connector E18 terminal 60

and ground.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Repair or replace harness between IPDM E/R and rear

window defogger.

Rear Window Defogger Signal CheckEIS00B8V

1.CHECK CAN COMMUNICATION LINE

CAN communication line check is executed. Refer toLAN-23, "

CAN COMMUNICATION"

OK or NG

OK >> GO TO 2.

NG >> In addition, it is necessary to check CAN communication line. Refer toLAN-23, "

CAN COMMUNI-

CATION".

2.CHECK FRONT AIR CONTROL

Front air control check is executed. Refer toAT C - 3 2 , "

CAN Communication System Description".

OK or NG

OK >> Check the condition of the harness and the connector

NG >> Replace front air control.2 - Ground : Continuity should exist.

PIIA4235E

60 - 1 : Continuity should exist.

60 - Ground : Continuity should not exist.

MIIB0621E

Is rear window defogger indicator illuminates on the display panel?