display NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1068 of 3171

EC-88

DTC P0093 FUEL SYSTEM

DTC P0093 FUEL SYSTEM

PFP:17520

On Board Diagnosis LogicEBS01KDQ

NOTE:

If DTC P0093 is displayed with DTC P0652 or P0653, first perform the trouble diagnosis for DTC P0652

or P0653. Refer toEC-227, "

DTC P0652, P0653 SENSOR POWER SUPPLY".

DTC Confirmation ProcedureEBS01KDR

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Start engine and keep engine speed more than 4,000 rpm for at

least 5 seconds.

4. If DTC is detected, go toEC-89, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Start engine and keep engine speed more than 4,000 rpm for at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-89, "

Diagnostic Procedure".

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0093

0093Fuel system leakECM detects a fuel system leak.

(The relation between the output voltage to the

fuel pump and input voltage from the fuel rail

pressure sensor is out of the normal range.)

lFuel pump

lFuel rail

lFuel pipe

lFuel rail pressure relief valve

lAir mixed with fuel

lLack of fuel

SEF817Y

Page 1089 of 3171

DTC P0122, P0123 APP SENSOR

EC-109

C

D

E

F

G

H

I

J

K

L

MA

EC

On Board Diagnosis LogicEBS01KEL

The MI will not light up for these self-diagnoses.

NOTE:

If DTC P0122 or P0123 is displayed with DTC P0642 or P0643, first perform the trouble diagnosis for

DTC P0642 or P0643. Refer toEC-222, "

DTC P0642, P0643 SENSOR POWER SUPPLY".

DTC Confirmation ProcedureEBS01KEM

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go toE C - 111 , "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Turn ignition switch ON and wait at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toE C - 111 , "

Diagnostic Procedure".

91 RAccelerator pedal position

sensor 2[Ignition switch ON]

lEngine stopped

lAccelerator pedal: Fully released0.58 - 0.78V

[Ignition switch ON]

lEngine stopped

lAccelerator pedal: Fully depressedMore than 2.3V

92 BAccelerator pedal position

sensor 2 ground[Ignition switch ON]Approximately 0.3V TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage)

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0122

0122Accelerator pedal position

sensor 1 circuit low inputAn excessively low voltage from the APP sensor

1 is sent to ECM.

lHarness or connectors

(The APP sensor 1 circuit is open or

shorted.)

lAccelerator pedal position sensor

(Accelerator pedal position sensor 1) P0123

0123Accelerator pedal position

sensor 1 circuit high inputAn excessively high voltage from the APP sensor

1 is sent to ECM.

SEF817Y

Page 1098 of 3171

EC-118

DTC P0192, P0193 FRP SENSOR

DTC P0192, P0193 FRP SENSOR

PFP:16638

DescriptionEBS01KEZ

The fuel rail pressure (FRP) sensor is placed to the fuel rail. It measures the fuel pressure in the fuel rail. The

sensor sends voltage signal to the ECM. As the pressure increases, the voltage rises.

The ECM controls the fuel pressure in the fuel rail by the inlet throttling device. The ECM uses the signal from

fuel rail pressure sensor as a feedback signal.

CONSULT-II Reference Value in Data Monitor ModeEBS01KF0

Specification data are reference values.

ECM Terminals and Reference ValueEBS01KF1

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

On Board Diagnosis LogicEBS01KF2

The MI will not light up for these self-diagnoses.

NOTE:

If DTC P0192 or P0193 is displayed with DTC P0652 or P0653, first perform the trouble diagnosis for

DTC P0652 or P0653. Refer toEC-227, "

DTC P0652, P0653 SENSOR POWER SUPPLY".

MONITOR CONDITION SPECIFICATOIN

ACT CR PRESS

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever: P or N (A/T), Neutral (M/T)

lNo loadIdle 25 - 35 MPa

2,000 rpm 40 - 50 MPa

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage)

48

49L

BFuel rail pressure sensor[Engine is running]

lWarm-up condition

lIdle speed1.7 - 2.0V

[Engine is running]

lWarm-up condition

lEngine speed: 2,000 rpm2.0 - 2.3V

63 RFuel rail pressure sensor power

supply[Ignition switch ON]Approximately 5.3V

67 —Sensor ground

(Sensor shield circuit)[Ignition switch ON]Approximately 0.3V

68 W Fuel rail pressure sensor ground[Ignition switch ON]Approximately 0.3V

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0192

0192Fuel rail pressure sensor

circuit low inputAn excessively low voltage from the sensor is

sent to ECM.

lHarness or connectors

(The sensor circuit is open or

shorted.)

lFuel rail temperature sensor P0193

0193Fuel rail pressure sensor

circuit high inputAn excessively high voltage from the sensor is

sent to ECM.

Page 1103 of 3171

DTC P0200 FUEL INJECTOR

EC-123

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0200 FUEL INJECTORPFP:16600

On Board Diagnosis LogicEBS01KF8

DTC Confirmation ProcedureEBS01KF9

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Start engine and let it idle for at least 5 seconds.

4. If DTC is detected, go toEC-123, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Start engine and let it idle for at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-123, "

Diagnostic Procedure".

Diagnostic ProcedureEBS01KFA

1.INSPECTION START

With CONSULT-II

1. Turn ignition switch ON.

2. Select “SELF DIAG RESULTS” mode with CONSULT-II.

3. Touch “ERASE”.

4. PerformEC-123, "

DTC Confirmation Procedure", again.

5. Is DTC P0200 displayed again?

Without CONSULT-II

1. Turn ignition switch ON.

2. Erase the Diagnostic Test Mode II (Self-diagnostic results) memory. Refer toEC-27

.

3. PerformEC-123, "

DTC Confirmation Procedure", again.

4. Is DTC 0200 displayed again?

Ye s o r N o

Ye s > > G O T O 2 .

No >>INSPECTION END

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0200

0200Fuel injector power supply

circuitECM detects a voltage of power source for the

fuel injector is excessively high or low.

lECM

SEF817Y

Page 1110 of 3171

EC-130

DTC P0201 - P0204 FUEL INJECTOR

4.CHECK FUEL INJECTOR-II

With CONSULT-II

1. Remove two fuel injectors.

NOTE:

One is from malfunctioning cylinder and the other is from any cylinder other than the malfunctioning cylin-

der.

2. Swap the two fuel injectors to the other cylinder.

3. Reconnect ECM harness connector and fuel injector harness connectors.

4. Turn ignition switch ON.

5. Perform Injector Adjustment Value Registration. Refer toEC-25, "

Injector Adjustment Value Registration".

6. Select “SELF DIAG RESULTS” mode with CONSULT-II.

7. Touch “ERASE”.

8. PerformEC-127, "

DTC Confirmation Procedure".

9. Is DTC displayed for the other cylinder?

Without CONSULT-II

1. Remove two fuel injectors.

NOTE:

One is from malfunctioning cylinder and the other is from any cylinder other than the malfunctioning cylin-

der.

2. Swap the two fuel injectors to the other cylinder.

3. Reconnect ECM harness connector and fuel injector harness connectors.

4. Turn ignition switch ON.

5. Perform Injector Adjustment Value Registration. Refer toEC-25, "

Injector Adjustment Value Registration".

6. Erase the Diagnostic Test Mode II (Self-diagnostic results) memory. Refer toEC-27

.

7. Perform DTC Confirmation Procedure,EC-127, "

DTC Confirmation Procedure".

8. Is DTC displayed for the other cylinder?

Ye s o r N o

Yes >>GOTO5.

No >> GO TO 6.

5.REPLACE FUEL INJECOR

1. Replace fuel injector of malfunctioning cylinder.

2. Perform Injector Adjustment Value Registration. Refer toEC-25, "

Injector Adjustment Value Registration".

>>INSPECTION END

6.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

Component InspectionEBS01KFI

FUEL INJECTOR

1. Disconnect fuel injector harness connector.

Page 1112 of 3171

EC-132

DTC P0217 ENGINE OVER TEMPERATURE

DTC P0217 ENGINE OVER TEMPERATURE

PFP:21481

DescriptionEBS01KFK

SYSTEM DESCRIPTION

NOTE:

If DTC P0217 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to

EC-79, "

DTC U1000 CAN COMMUNICATION LINE".

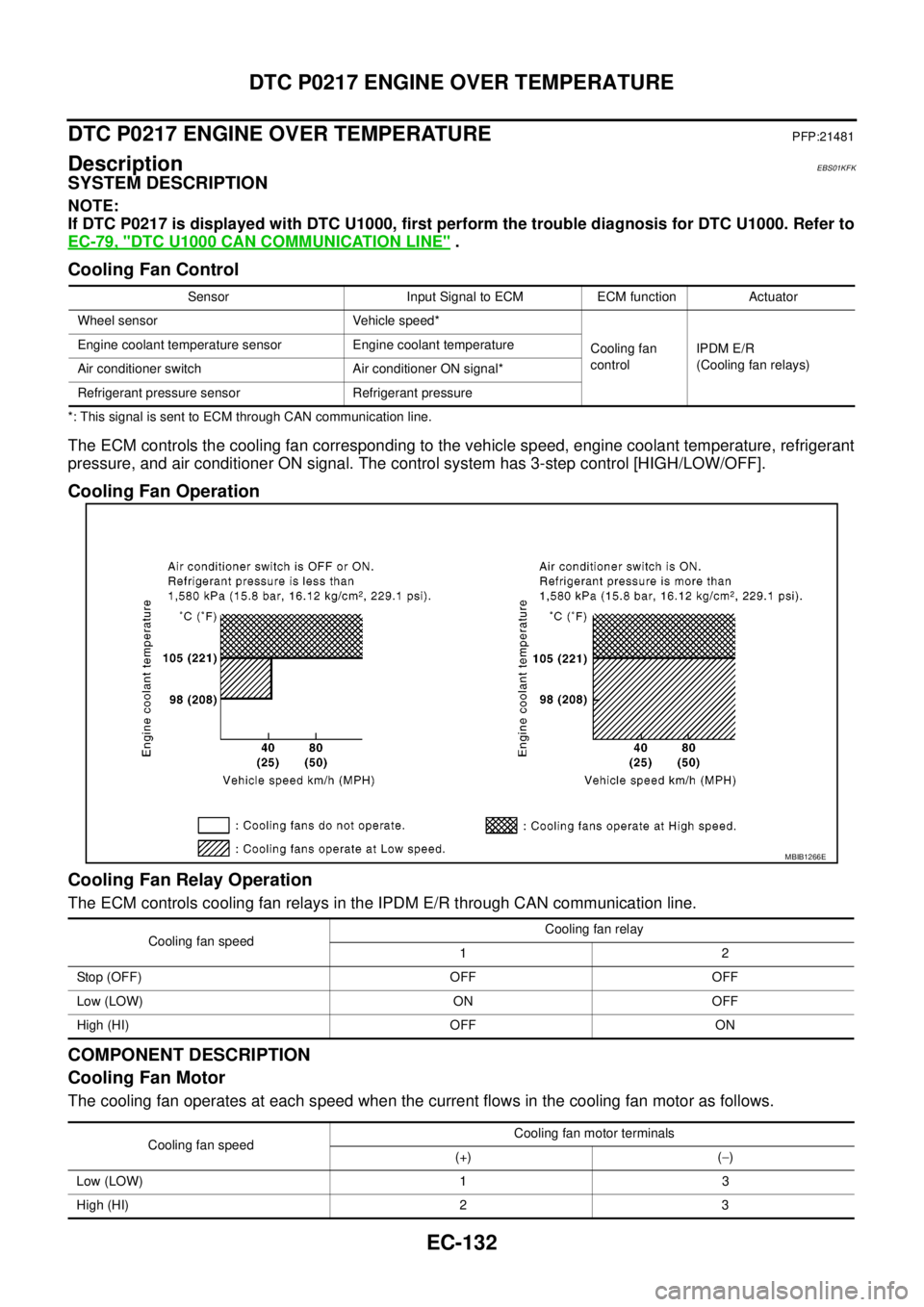

Cooling Fan Control

*: This signal is sent to ECM through CAN communication line.

The ECM controls the cooling fan corresponding to the vehicle speed, engine coolant temperature, refrigerant

pressure, and air conditioner ON signal. The control system has 3-step control [HIGH/LOW/OFF].

Cooling Fan Operation

Cooling Fan Relay Operation

The ECM controls cooling fan relays in the IPDM E/R through CAN communication line.

COMPONENT DESCRIPTION

Cooling Fan Motor

The cooling fan operates at each speed when the current flows in the cooling fan motor as follows.

Sensor Input Signal to ECM ECM function Actuator

Wheel sensor Vehicle speed*

Cooling fan

controlIPDM E/R

(Cooling fan relays) Engine coolant temperature sensor Engine coolant temperature

Air conditioner switch Air conditioner ON signal*

Refrigerant pressure sensor Refrigerant pressure

MBIB1266E

Cooling fan speedCooling fan relay

12

Stop (OFF) OFF OFF

Low (LOW) ON OFF

High (HI) OFF ON

Cooling fan speedCooling fan motor terminals

(+) (-)

Low (LOW) 1 3

High (HI) 2 3

Page 1123 of 3171

DTC P0222, P0223 APP SENSOR

EC-143

C

D

E

F

G

H

I

J

K

L

MA

EC

On Board Diagnosis LogicEBS01KFV

The MI will not light up for these self-diagnoses.

NOTE:

If DTC P0222 or P0223 is displayed with DTC P0652 or P0653, first perform the trouble diagnosis for

DTC P0652 or P0653. Refer toEC-227, "

DTC P0652, P0653 SENSOR POWER SUPPLY".

DTC Confirmation ProcedureEBS01KFW

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go toEC-145, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Turn ignition switch ON and wait at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-145, "

Diagnostic Procedure".

91 RAccelerator pedal position

sensor 2[Ignition switch ON]

lEngine: Stopped

lAccelerator pedal: Fully released0.58 - 0.78V

[Ignition switch ON]

lEngine: Stopped

lAccelerator pedal: Fully depressedMore than 2.3V

92 BAccelerator pedal position

sensor 2 ground[Ignition switch ON]Approximately 0.3V TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage)

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0222

0222Accelerator pedal position

sensor 2 circuit low inputAn excessively low voltage from the APP sensor

2 is sent to ECM.

lHarness or connectors

(The APP sensor 2 circuit is open or

shorted.)

lAccelerator pedal position sensor

(Accelerator pedal position sensor 2) P0223

0223Accelerator pedal position

sensor 2 circuit high inputAn excessively high voltage from the APP sen-

sor 2 is sent to ECM.

SEF817Y

Page 1128 of 3171

EC-148

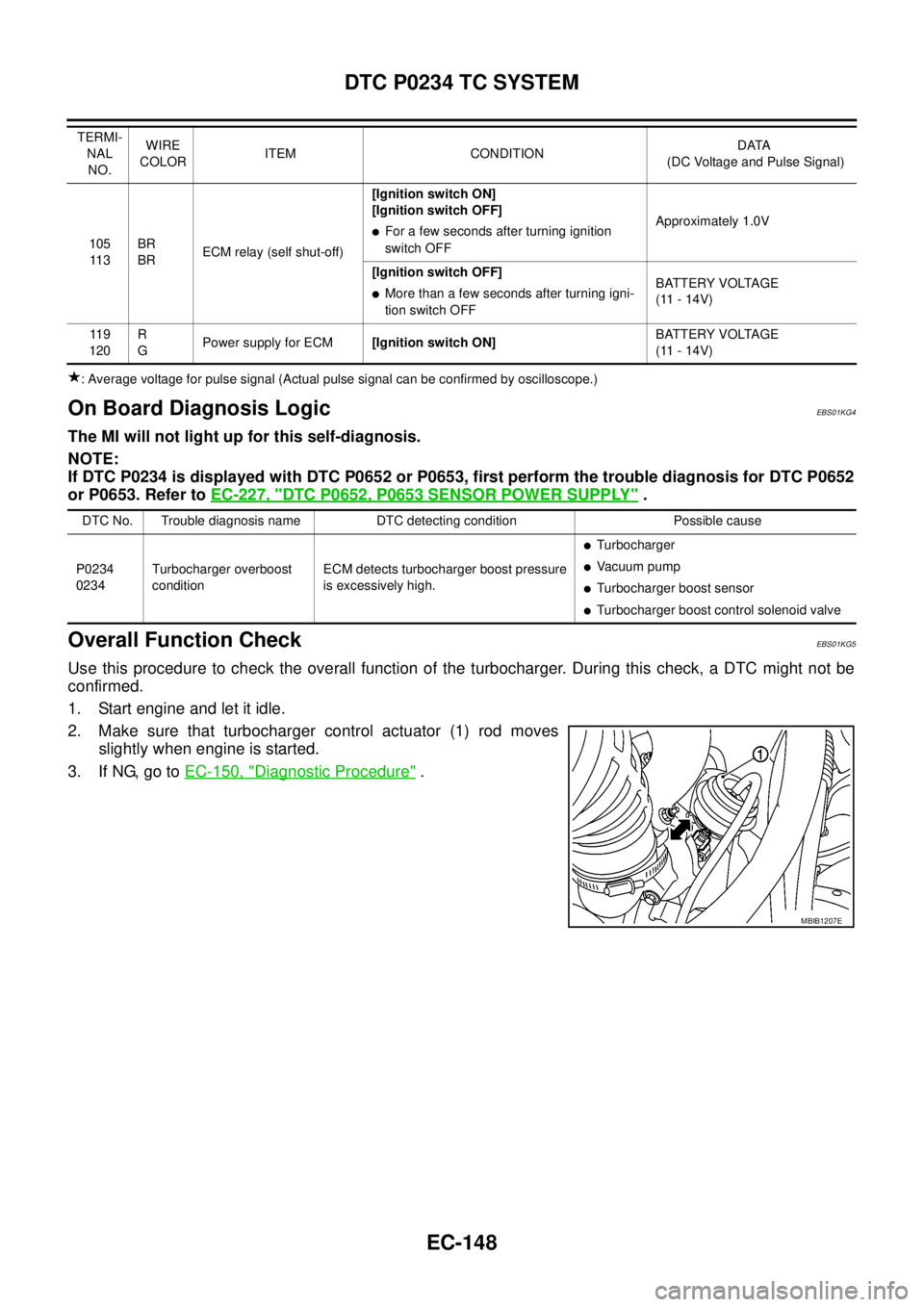

DTC P0234 TC SYSTEM

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

On Board Diagnosis LogicEBS01KG4

The MI will not light up for this self-diagnosis.

NOTE:

If DTC P0234 is displayed with DTC P0652 or P0653, first perform the trouble diagnosis for DTC P0652

or P0653. Refer toEC-227, "

DTC P0652, P0653 SENSOR POWER SUPPLY".

Overall Function CheckEBS01KG5

Use this procedure to check the overall function of the turbocharger. During this check, a DTC might not be

confirmed.

1. Start engine and let it idle.

2. Make sure that turbocharger control actuator (1) rod moves

slightly when engine is started.

3. If NG, go toEC-150, "

Diagnostic Procedure".

105

11 3BR

BRECM relay (self shut-off)[Ignition switch ON]

[Ignition switch OFF]lFor a few seconds after turning ignition

switch OFFApproximately 1.0V

[Ignition switch OFF]

lMore than a few seconds after turning igni-

tion switch OFFBATTERY VOLTAGE

(11 - 14V)

11 9

120R

GPower supply for ECM[Ignition switch ON]BATTERY VOLTAGE

(11 - 14V) TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse Signal)

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0234

0234Turbocharger overboost

conditionECM detects turbocharger boost pressure

is excessively high.

lTurbocharger

lVa c u u m p u m p

lTurbocharger boost sensor

lTurbocharger boost control solenoid valve

MBIB1207E

Page 1134 of 3171

EC-154

DTC P0237, P0238 TC BOOST SENSOR

On Board Diagnosis Logic

EBS01KGD

The MI will not light up for these self-diagnoses.

NOTE:

If DTC P0237 or P0238 is displayed with DTC P0652 or P0653, first perform the trouble diagnosis for

DTC P0652 or P0653. Refer toEC-227, "

DTC P0652, P0653 SENSOR POWER SUPPLY".

DTC Confirmation ProcedureEBS01KGE

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go toEC-156, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Turn ignition switch ON and wait at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-156, "

Diagnostic Procedure".

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0237

0237Turbocharger boost sensor

circuit low inputAn excessively low voltage from the sensor is

sent to ECM.

lHarness or connectors

(The sensor circuit is open or

shorted.)

lTurbocharger boost sensor P0238

0238Turbocharger boost sensor

circuit high inputAn excessively high voltage from the sensor is

sent to ECM.

SEF817Y

Page 1140 of 3171

EC-160

DTC P0335 CKP SENSOR

On Board Diagnosis Logic

EBS01KGM

NOTE:

If DTC P0335 is displayed with DTC P0652 or P0653, first perform the trouble diagnosis for DTC P0652

or P0653. Refer toEC-227, "

DTC P0652, P0653 SENSOR POWER SUPPLY".

DTC Confirmation ProcedureEBS01KGN

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Start engine and let it idle for at least 5 seconds.

If engine can not start, keep ignition switch at START position for

5 seconds.

4. If DTC is detected, go toEC-162, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Start engine and let it idle for at least 5 seconds.

If engine can not start, keep ignition switch at START position for 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-162, "

Diagnostic Procedure".

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0335

0335Crankshaft position sen-

sor circuitCrankshaft position sensor signal is not detect

by the ECM when engine is running.

lHarness or connectors

(The sensor circuit is open or

shorted.)

lCrankshaft position sensor

SEF817Y