battery NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2282 of 3171

GENERAL MAINTENANCE

MA-7

C

D

E

F

G

H

I

J

K

MA

B

MA

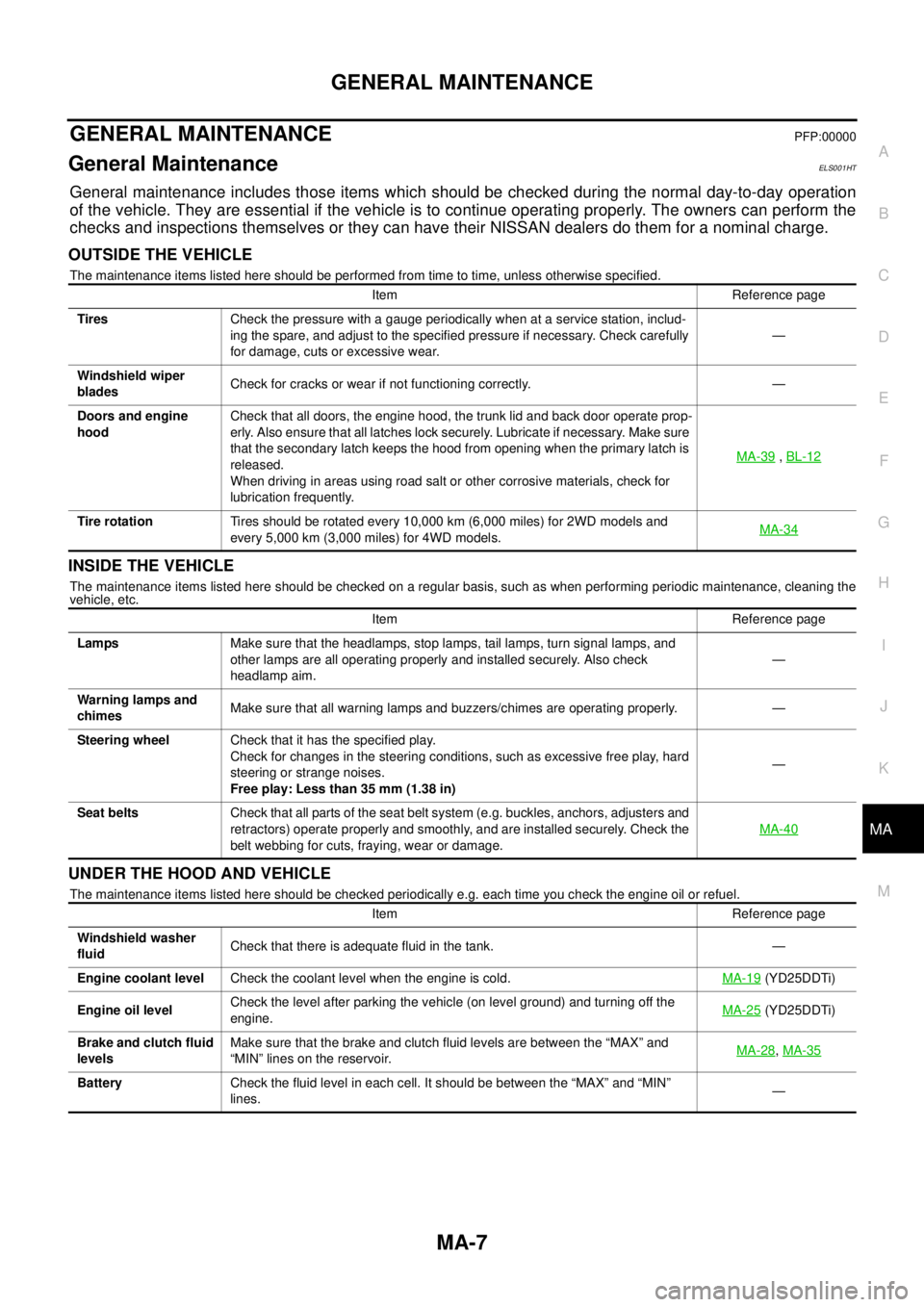

GENERAL MAINTENANCEPFP:00000

General MaintenanceELS001HT

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them for a nominal charge.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the engine oil or refuel.Item Reference page

TiresCheck the pressure with a gauge periodically when at a service station, includ-

ing the spare, and adjust to the specified pressure if necessary. Check carefully

for damage, cuts or excessive wear.—

Windshield wiper

bladesCheck for cracks or wear if not functioning correctly. —

Doors and engine

hoodCheck that all doors, the engine hood, the trunk lid and back door operate prop-

erly. Also ensure that all latches lock securely. Lubricate if necessary. Make sure

that the secondary latch keeps the hood from opening when the primary latch is

released.

When driving in areas using road salt or other corrosive materials, check for

lubrication frequently.MA-39

,BL-12

Tire rotationTires should be rotated every 10,000 km (6,000 miles) for 2WD models and

every 5,000 km (3,000 miles) for 4WD models.MA-34

Item Reference page

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check

headlamp aim.—

Warning lamps and

chimesMake sure that all warning lamps and buzzers/chimes are operating properly. —

Steering wheelCheck that it has the specified play.

Check for changes in the steering conditions, such as excessive free play, hard

steering or strange noises.

Free play: Less than 35 mm (1.38 in)—

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage.MA-40

Item Reference page

Windshield washer

fluidCheck that there is adequate fluid in the tank. —

Engine coolant levelCheck the coolant level when the engine is cold.MA-19

(YD25DDTi)

Engine oil levelCheck the level after parking the vehicle (on level ground) and turning off the

engine.MA-25

(YD25DDTi)

Brake and clutch fluid

levelsMake sure that the brake and clutch fluid levels are between the “MAX” and

“MIN” lines on the reservoir.MA-28

,MA-35

BatteryCheck the fluid level in each cell. It should be between the “MAX” and “MIN”

lines.—

Page 2334 of 3171

TRANSMISSION ASSEMBLY

MT-17

D

E

F

G

H

I

J

K

L

MA

B

MT

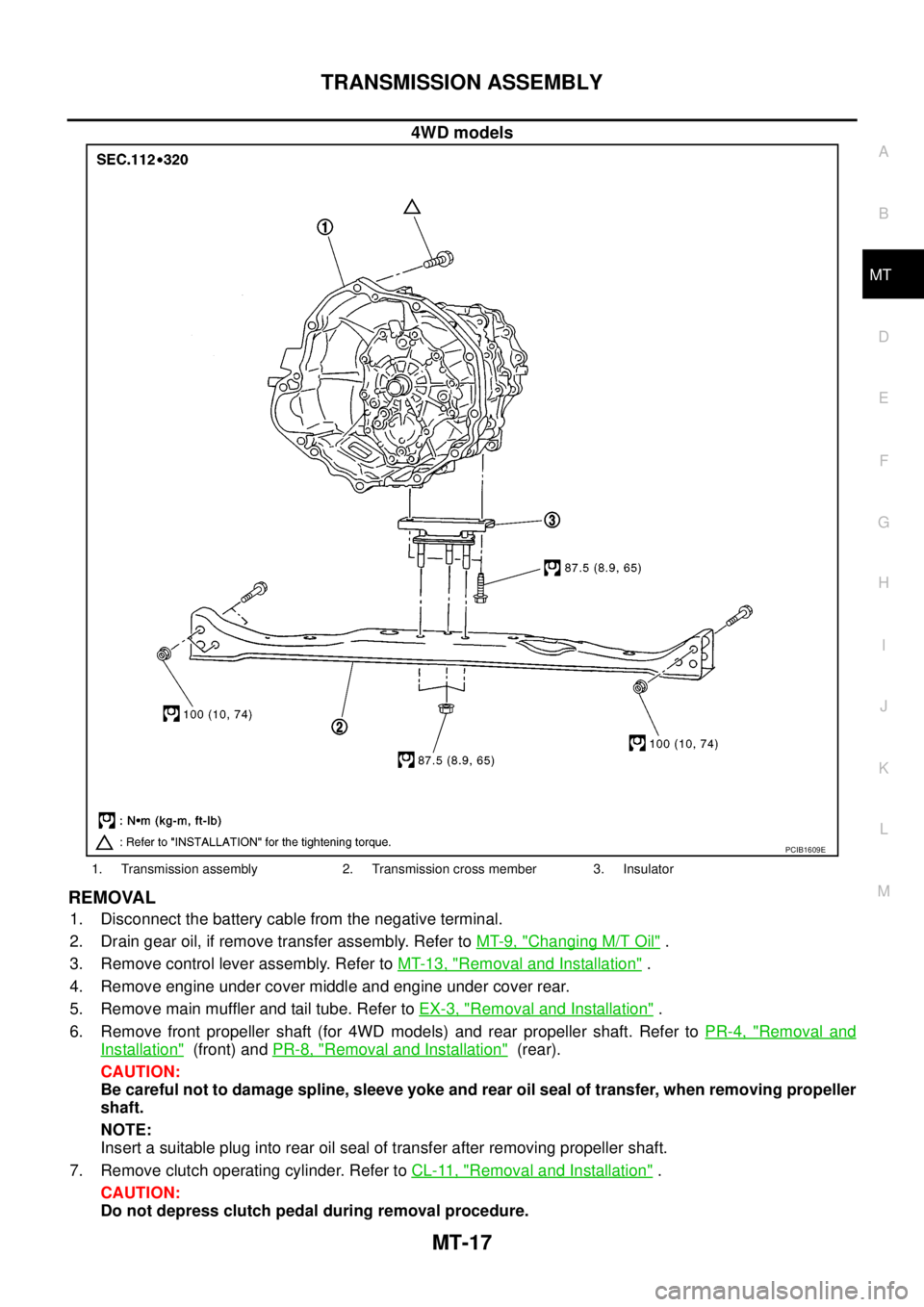

4WD models

REMOVAL

1. Disconnect the battery cable from the negative terminal.

2. Drain gear oil, if remove transfer assembly. Refer toMT-9, "

Changing M/T Oil".

3. Remove control lever assembly. Refer toMT-13, "

Removal and Installation".

4. Remove engine under cover middle and engine under cover rear.

5. Remove main muffler and tail tube. Refer toEX-3, "

Removal and Installation".

6. Remove front propeller shaft (for 4WD models) and rear propeller shaft. Refer toPR-4, "

Removal and

Installation"(front) andPR-8, "Removal and Installation"(rear).

CAUTION:

Be careful not to damage spline, sleeve yoke and rear oil seal of transfer, when removing propeller

shaft.

NOTE:

Insert a suitable plug into rear oil seal of transfer after removing propeller shaft.

7. Remove clutch operating cylinder. Refer toCL-11, "

Removal and Installation".

CAUTION:

Do not depress clutch pedal during removal procedure.

PCIB1609E

1. Transmission assembly 2. Transmission cross member 3. Insulator

Page 2404 of 3171

PREPARATION

MTC-17

C

D

E

F

G

H

I

K

L

MA

B

MTC

Recovery/Recycling/

Recharging equipment (ACR4)Function: Refrigerant recovery and

recycling and recharging

Electrical leak detectorPower supply:

DC 12V (Cigarette lighter)

(J-43926)

Refrigerant dye leak detection kit

Kit includes:

(J-42220)

UV lamp and UV safety goggles

(J-41459)

HFC-134a (R-134a) dye injector

Use with J-41447, 1/4 ounce

bottle

(J-41447)

HFC-134a (R-134a) fluorescent

leak detection dye

(Box of 24, 1/4 ounce bottles)

(J-43872)

Refrigerant dye cleanerPower supply:

DC 12V (Battery terminal)

(J-42220)

UV lamp and UV safety gogglesPower supply:

DC 12V (Battery terminal)

For checking refrigerant leak when

fluorescent dye is installed in A/C

system

Includes:

UV lamp and UV safety goggles

(J-41447)

HFC-134a (R-134a) fluorescent

leak detection dye

(Box of 24, 1/4 ounce bottles)Application: For HFC-134a (R-134a)

PA G o i l

Container: 1/4 ounce (7.4 cc) bottle

(Includes self-adhesive dye

identification labels for affixing to

vehicle after charging system with

dye.) Tool number

Tool nameDescription

RJIA0195E

SHA705EB

ZHA200H

SHA438F

SHA439F

Page 2436 of 3171

TROUBLE DIAGNOSIS

MTC-49

C

D

E

F

G

H

I

K

L

MA

B

MTC

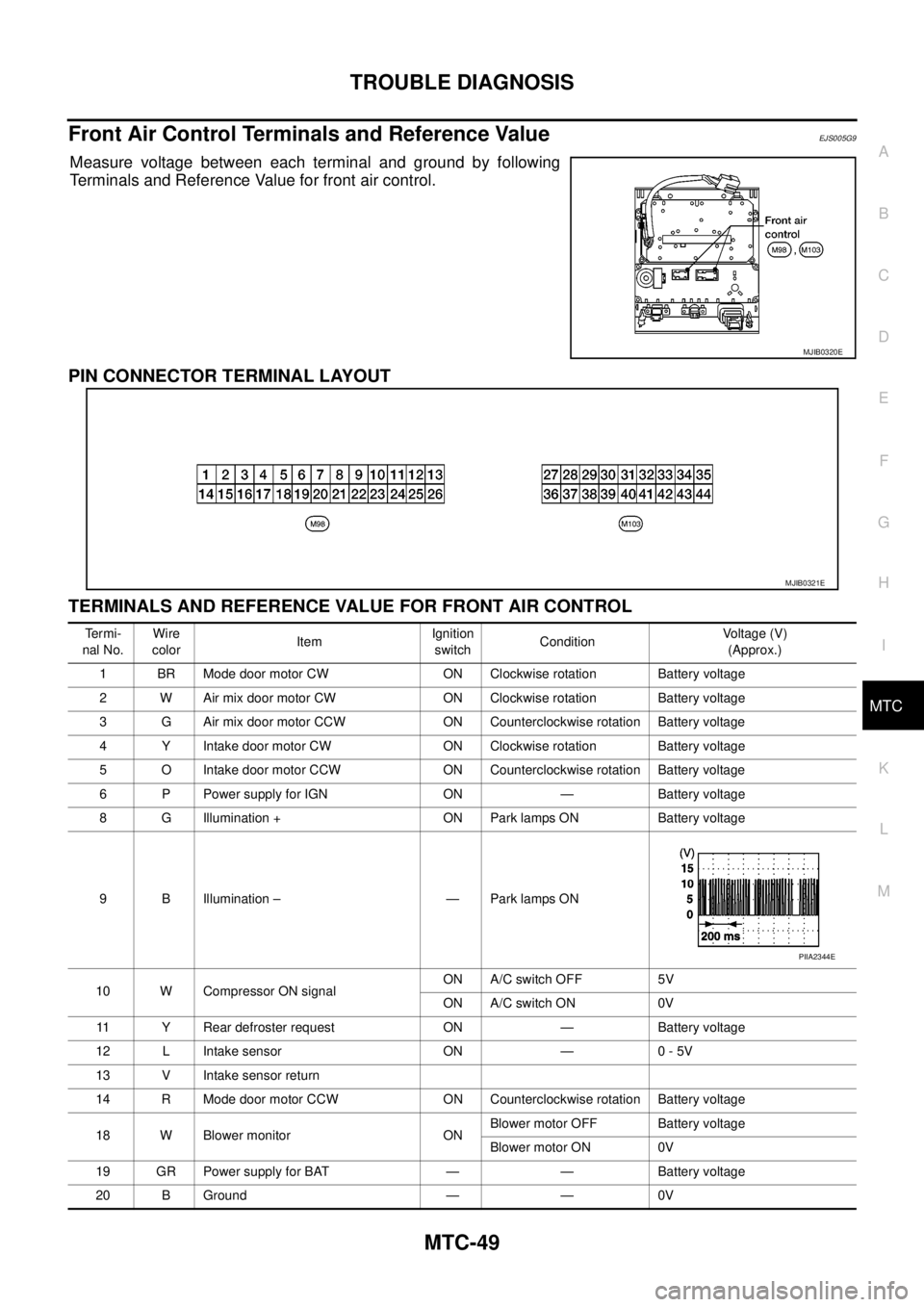

Front Air Control Terminals and Reference ValueEJS005G9

Measure voltage between each terminal and ground by following

Terminals and Reference Value for front air control.

PIN CONNECTOR TERMINAL LAYOUT

TERMINALS AND REFERENCE VALUE FOR FRONT AIR CONTROL

MJIB0320E

MJIB0321E

Te r m i -

nal No.Wire

colorItemIgnition

switchConditionVoltage (V)

(Approx.)

1 BR Mode door motor CW ON Clockwise rotation Battery voltage

2 W Air mix door motor CW ON Clockwise rotation Battery voltage

3 G Air mix door motor CCW ON Counterclockwise rotation Battery voltage

4 Y Intake door motor CW ON Clockwise rotation Battery voltage

5 O Intake door motor CCW ON Counterclockwise rotation Battery voltage

6 P Power supply for IGN ON — Battery voltage

8 G Illumination + ON Park lamps ON Battery voltage

9 B Illumination – — Park lamps ON

10 W Compressor ON signalON A/C switch OFF 5V

ON A/C switch ON 0V

11 Y Rear defroster request ON — Battery voltage

12 L Intake sensor ON — 0 - 5V

13 V Intake sensor return

14 R Mode door motor CCW ON Counterclockwise rotation Battery voltage

18 W Blower monitor ONBlower motor OFF Battery voltage

Blower motor ON 0V

19 GR Power supply for BAT — — Battery voltage

20 B Ground — — 0V

PIIA2344E

Page 2437 of 3171

MTC-50

TROUBLE DIAGNOSIS

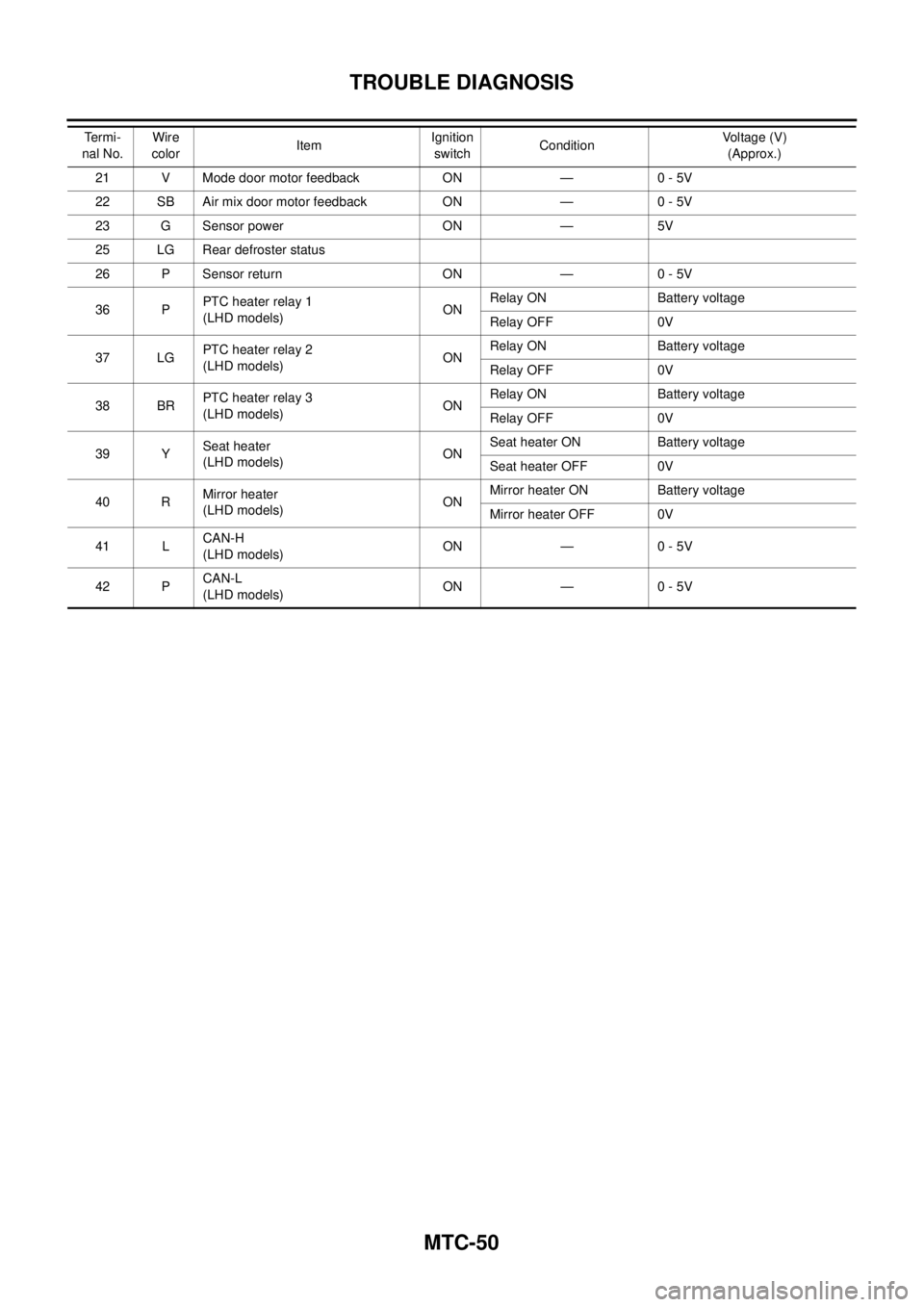

21 V Mode door motor feedback ON — 0 - 5V

22 SB Air mix door motor feedback ON — 0 - 5V

23 G Sensor power ON — 5V

25 LG Rear defroster status

26 P Sensor return ON — 0 - 5V

36 PPTC heater relay 1

(LHD models)ONRelay ON Battery voltage

Relay OFF 0V

37 LGPTC heater relay 2

(LHD models)ONRelay ON Battery voltage

Relay OFF 0V

38 BRPTC heater relay 3

(LHD models)ONRelay ON Battery voltage

Relay OFF 0V

39 YSeat heater

(LHD models)ONSeat heater ON Battery voltage

Seat heater OFF 0V

40 RMirror heater

(LHD models)ONMirror heater ON Battery voltage

Mirror heater OFF 0V

41 LCAN-H

(LHD models)ON — 0 - 5V

42 PCAN-L

(LHD models)ON — 0 - 5V Te r m i -

nal No.Wire

colorItemIgnition

switchConditionVoltage (V)

(Approx.)

Page 2444 of 3171

TROUBLE DIAGNOSIS

MTC-57

C

D

E

F

G

H

I

K

L

MA

B

MTC

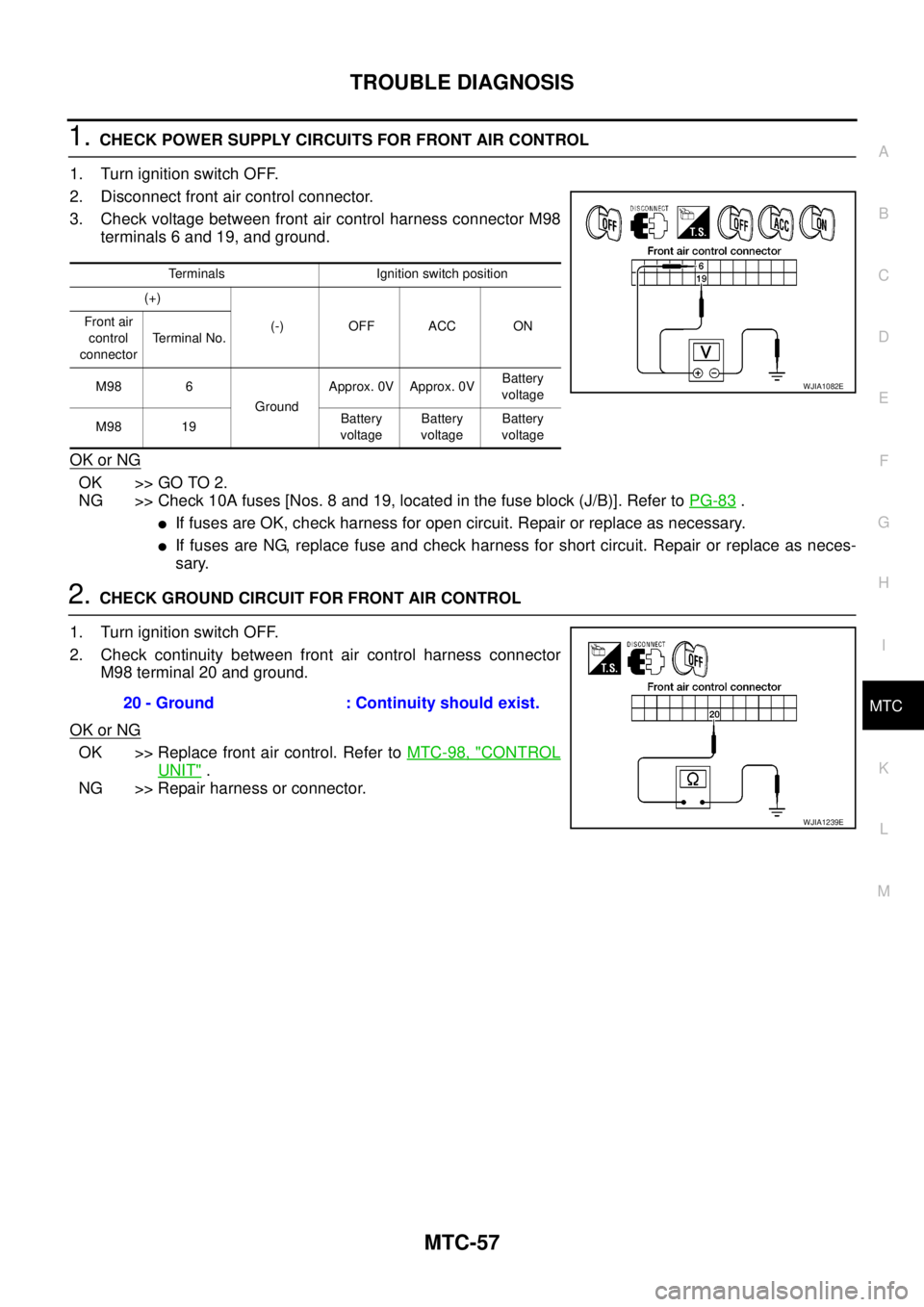

1.CHECK POWER SUPPLY CIRCUITS FOR FRONT AIR CONTROL

1. Turn ignition switch OFF.

2. Disconnect front air control connector.

3. Check voltage between front air control harness connector M98

terminals 6 and 19, and ground.

OK or NG

OK >> GO TO 2.

NG >> Check 10A fuses [Nos. 8 and 19, located in the fuse block (J/B)]. Refer toPG-83

.

lIf fuses are OK, check harness for open circuit. Repair or replace as necessary.

lIf fuses are NG, replace fuse and check harness for short circuit. Repair or replace as neces-

sary.

2.CHECK GROUND CIRCUIT FOR FRONT AIR CONTROL

1. Turn ignition switch OFF.

2. Check continuity between front air control harness connector

M98 terminal 20 and ground.

OK or NG

OK >> Replace front air control. Refer toMTC-98, "CONTROL

UNIT".

NG >> Repair harness or connector.

Terminals Ignition switch position

(+)

(-) OFF ACC ON Front air

control

connectorTerminal No.

M98 6

GroundApprox. 0V Approx. 0VBattery

voltage

M98 19Battery

voltageBattery

voltageBattery

voltage

WJIA1082E

20 - Ground : Continuity should exist.

WJIA1239E

Page 2460 of 3171

TROUBLE DIAGNOSIS

MTC-73

C

D

E

F

G

H

I

K

L

MA

B

MTC

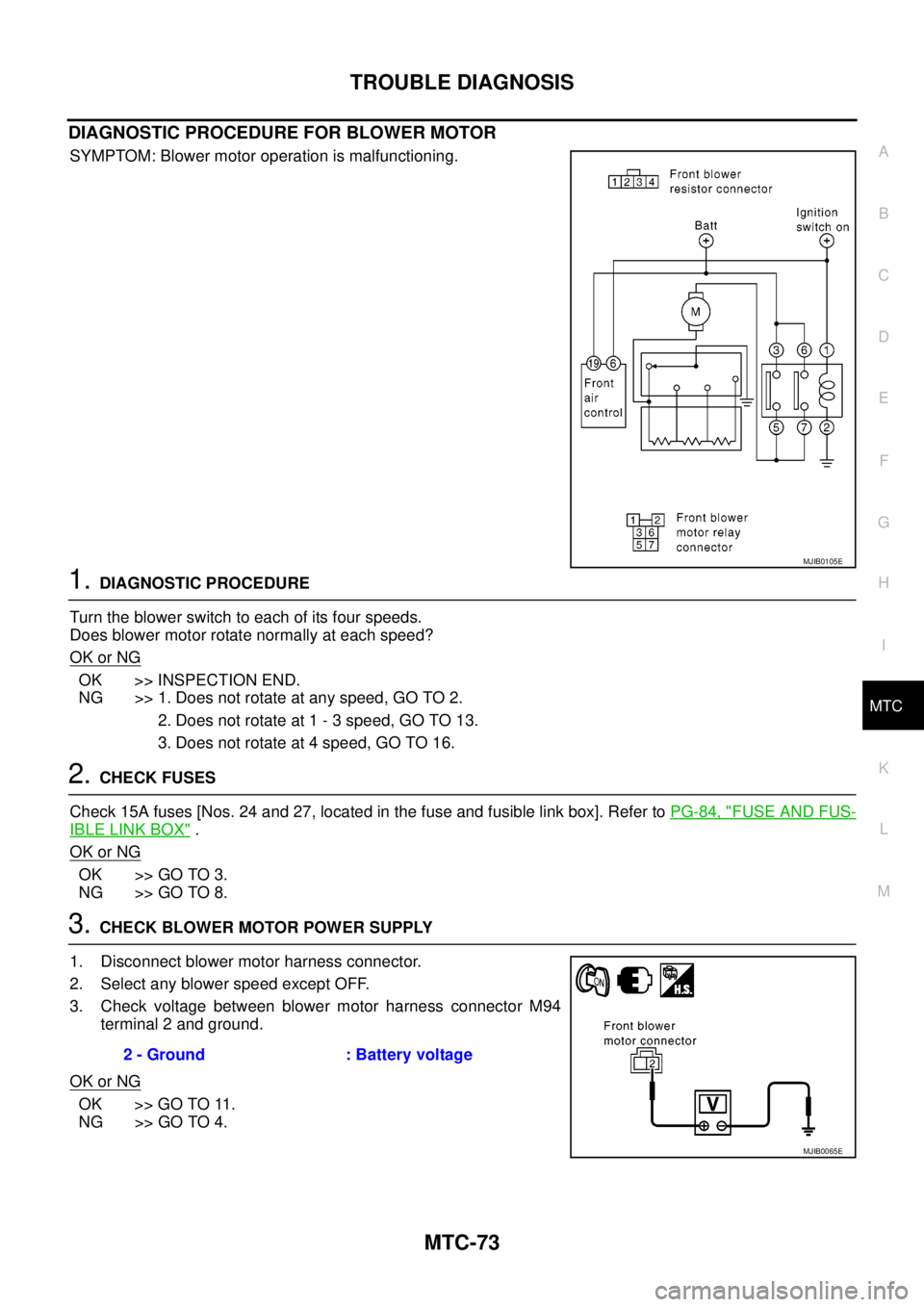

DIAGNOSTIC PROCEDURE FOR BLOWER MOTOR

SYMPTOM: Blower motor operation is malfunctioning.

1.DIAGNOSTIC PROCEDURE

Turntheblowerswitchtoeachofitsfourspeeds.

Does blower motor rotate normally at each speed?

OK or NG

OK >> INSPECTION END.

NG >> 1. Does not rotate at any speed, GO TO 2.

2. Does not rotate at 1 - 3 speed, GO TO 13.

3. Does not rotate at 4 speed, GO TO 16.

2.CHECK FUSES

Check 15A fuses [Nos. 24 and 27, located in the fuse and fusible link box]. Refer toPG-84, "

FUSE AND FUS-

IBLE LINK BOX".

OK or NG

OK >> GO TO 3.

NG >> GO TO 8.

3.CHECK BLOWER MOTOR POWER SUPPLY

1. Disconnect blower motor harness connector.

2. Select any blower speed except OFF.

3. Check voltage between blower motor harness connector M94

terminal 2 and ground.

OK or NG

OK >> GO TO 11.

NG >> GO TO 4.

MJIB0105E

2 - Ground : Battery voltage

MJIB0065E

Page 2461 of 3171

MTC-74

TROUBLE DIAGNOSIS

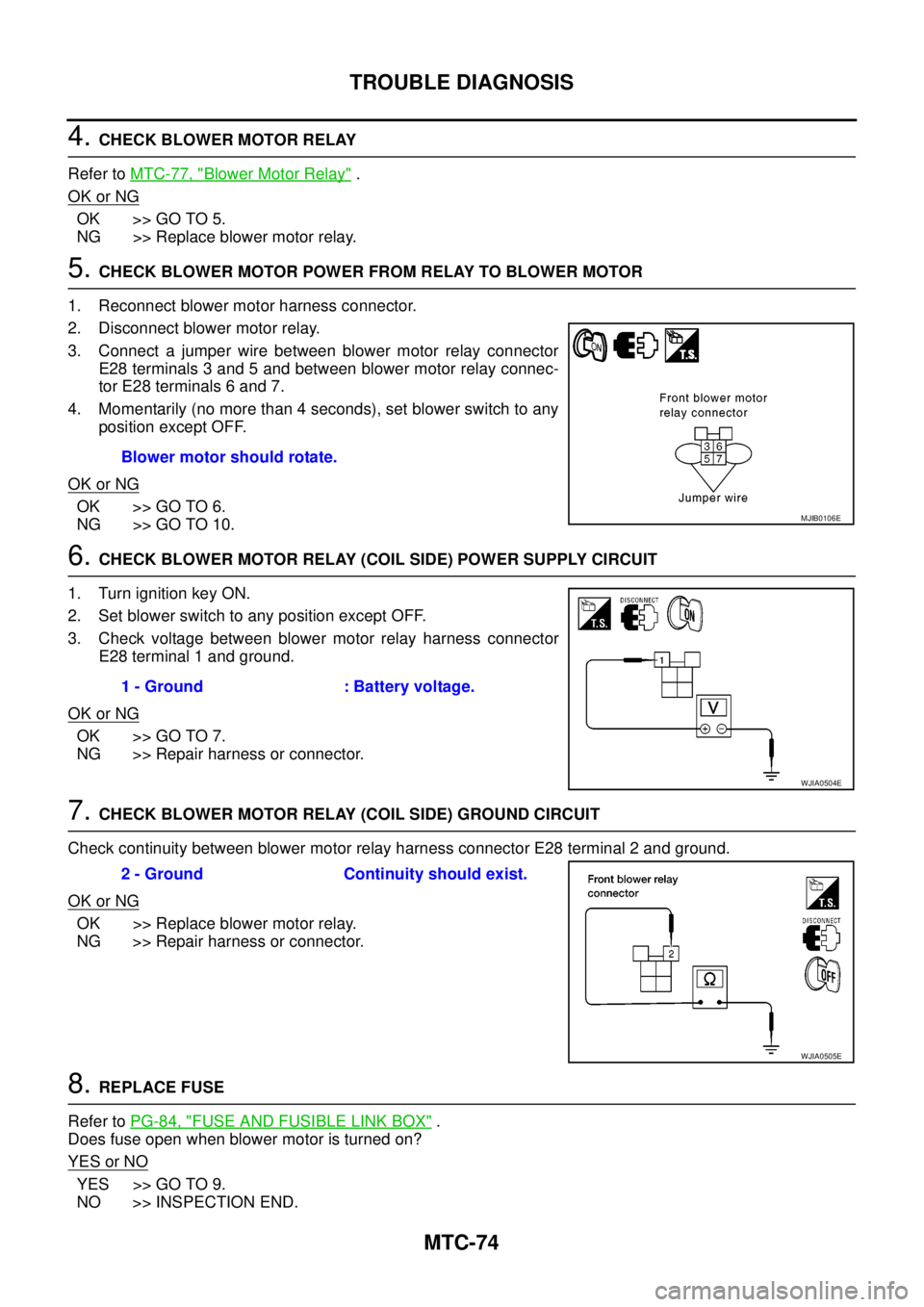

4.CHECK BLOWER MOTOR RELAY

Refer toMTC-77, "

Blower Motor Relay".

OK or NG

OK >> GO TO 5.

NG >> Replace blower motor relay.

5.CHECK BLOWER MOTOR POWER FROM RELAY TO BLOWER MOTOR

1. Reconnect blower motor harness connector.

2. Disconnect blower motor relay.

3. Connect a jumper wire between blower motor relay connector

E28 terminals 3 and 5 and between blower motor relay connec-

tor E28 terminals 6 and 7.

4. Momentarily (no more than 4 seconds), set blower switch to any

position except OFF.

OK or NG

OK >> GO TO 6.

NG >> GO TO 10.

6.CHECK BLOWER MOTOR RELAY (COIL SIDE) POWER SUPPLY CIRCUIT

1. Turn ignition key ON.

2. Set blower switch to any position except OFF.

3. Check voltage between blower motor relay harness connector

E28 terminal 1 and ground.

OK or NG

OK >> GO TO 7.

NG >> Repair harness or connector.

7.CHECK BLOWER MOTOR RELAY (COIL SIDE) GROUND CIRCUIT

Check continuity between blower motor relay harness connector E28 terminal 2 and ground.

OK or NG

OK >> Replace blower motor relay.

NG >> Repair harness or connector.

8.REPLACE FUSE

Refer toPG-84, "

FUSE AND FUSIBLE LINK BOX".

Does fuse open when blower motor is turned on?

YESorNO

YES >> GO TO 9.

NO >> INSPECTION END.Blower motor should rotate.

MJIB0106E

1 - Ground : Battery voltage.

WJIA0504E

2 - Ground Continuity should exist.

WJIA0505E

Page 2468 of 3171

TROUBLE DIAGNOSIS

MTC-81

C

D

E

F

G

H

I

K

L

MA

B

MTC

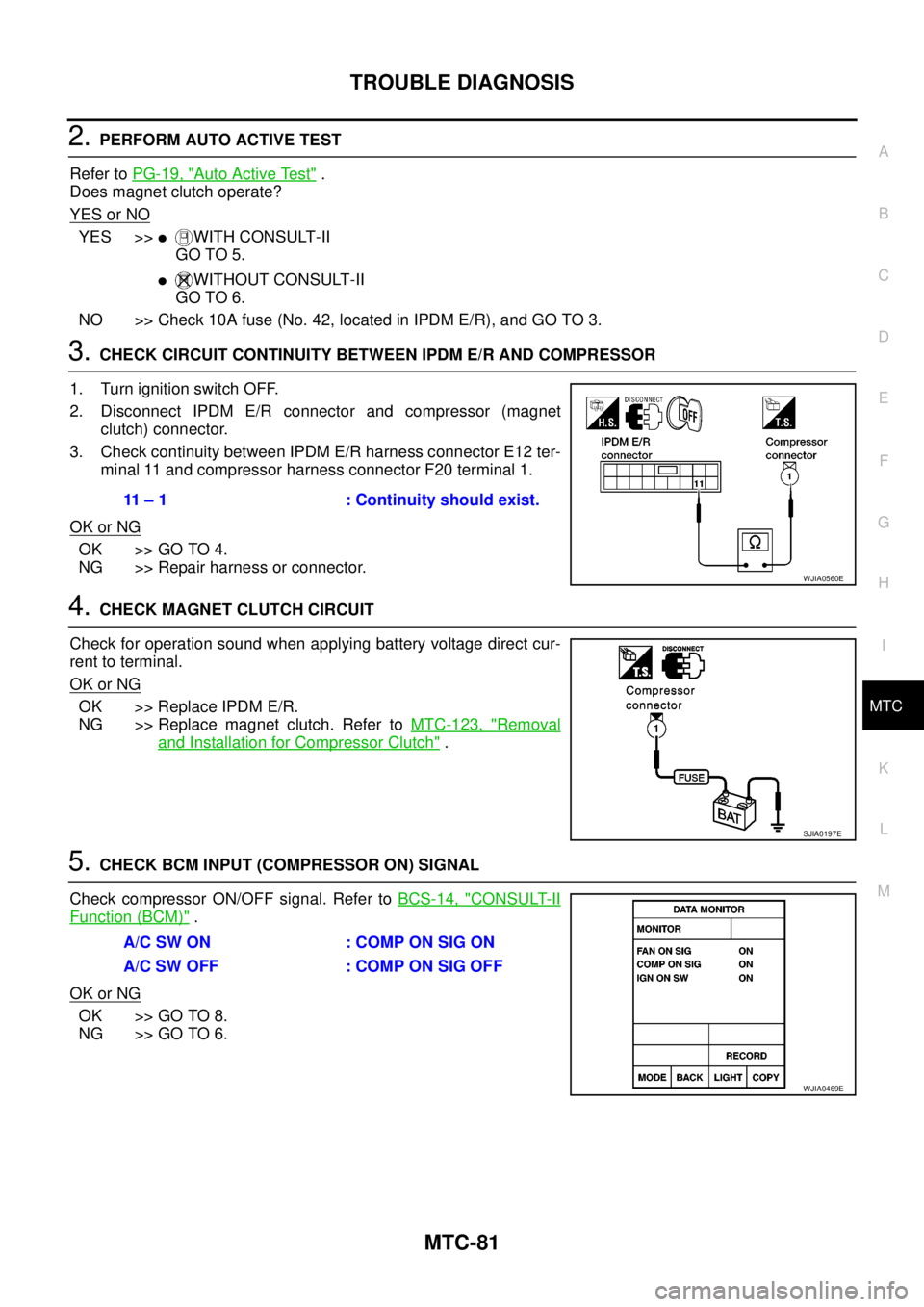

2.PERFORM AUTO ACTIVE TEST

Refer toPG-19, "

Auto Active Test".

Does magnet clutch operate?

YES or NO

YES >>lWITH CONSULT-II

GO TO 5.

lWITHOUT CONSULT-II

GO TO 6.

NO >> Check 10A fuse (No. 42, located in IPDM E/R), and GO TO 3.

3.CHECK CIRCUIT CONTINUITY BETWEEN IPDM E/R AND COMPRESSOR

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector and compressor (magnet

clutch) connector.

3. Check continuity between IPDM E/R harness connector E12 ter-

minal 11 and compressor harness connector F20 terminal 1.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4.CHECK MAGNET CLUTCH CIRCUIT

Check for operation sound when applying battery voltage direct cur-

rent to terminal.

OK or NG

OK >> Replace IPDM E/R.

NG >> Replace magnet clutch. Refer toMTC-123, "

Removal

and Installation for Compressor Clutch".

5.CHECK BCM INPUT (COMPRESSOR ON) SIGNAL

Check compressor ON/OFF signal. Refer toBCS-14, "

CONSULT-II

Function (BCM)".

OK or NG

OK >> GO TO 8.

NG >> GO TO 6.

11 – 1 : Continuity should exist.

WJIA0560E

SJIA0197E

A/C SW ON : COMP ON SIG ON

A/CSWOFF :COMPONSIGOFF

WJIA0469E

Page 2513 of 3171

MTC-126

REFRIGERANT LINES

BREAK-IN OPERATION

When replacing compressor clutch assembly, always conduct the break-in operation. This is done by engag-

ing and disengaging the clutch about 30 times. Break-in operation raises the level of transmitted torque.

Removal and Installation for Low-pressure Flexible HoseEJS005HE

REMOVAL

1. Remove the engine room cover using power tools.

2. Remove the engine air cleaner and air ducts. Refer toEM-15, "

AIR CLEANER AND AIR DUCT".

3. Remove the cowl top extension. Refer toEI-20, "

COWL TOP".

4. Discharge the refrigerant. Refer toMTC-118, "

HFC-134a (R-134a) Service Procedure".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

5. Remove the low-pressure flexible hose. Refer toMTC-120, "

Components".

INSTALLATION

Installation is in the reverse order of removal.

Refer toMTC-120, "

Components".

CAUTION:

lReplace the O-ring of the low-pressure flexible hose with a new one, then apply compressor oil to

it when installing it.

lAfter charging refrigerant, check for leaks.

Removal and Installation for High-pressure Flexible HoseEJS005HF

REMOVAL

1. Remove the engine under cover.

2. Remove the engine air cleaner and air ducts. Refer toEM-15, "

AIR CLEANER AND AIR DUCT"

3. Discharge the refrigerant. Refer toMTC-118, "HFC-134a (R-134a) Service Procedure".

4. Remove the high-pressure flexible hose. Refer toMTC-120, "

Components".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer toMTC-120, "

Components".

CAUTION:

lReplace the O-ring of the high-pressure flexible hose with a new one, then apply compressor oil to

it when installing it.

lAfter charging refrigerant, check for leaks.

Removal and Installation for High-pressure PipeEJS005HG

REMOVAL

1. Remove the cowl top extension. Refer toEI-20, "COWL TOP".

2. Disconnect the battery negative cable.

3. Reposition the IPDM E/R aside.

4. Remove the front right wheel and tire assembly. Refer toWT-5, "

Rotation".

5. Position aside the front floor insulator.

6. Discharge the refrigerant. Refer toMTC-118, "

HFC-134a (R-134a) Service Procedure".

7. Remove the low pressure pipe. Refer toMTC-127, "

Removal and Installation for Low-pressure Pipe".

8. Remove the high-pressure pipe. Refer toMTC-120, "

Components".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer toMTC-120, "

Components".